Layup Configuration Effect on Notch Residual Strength in Composite Laminates

Abstract

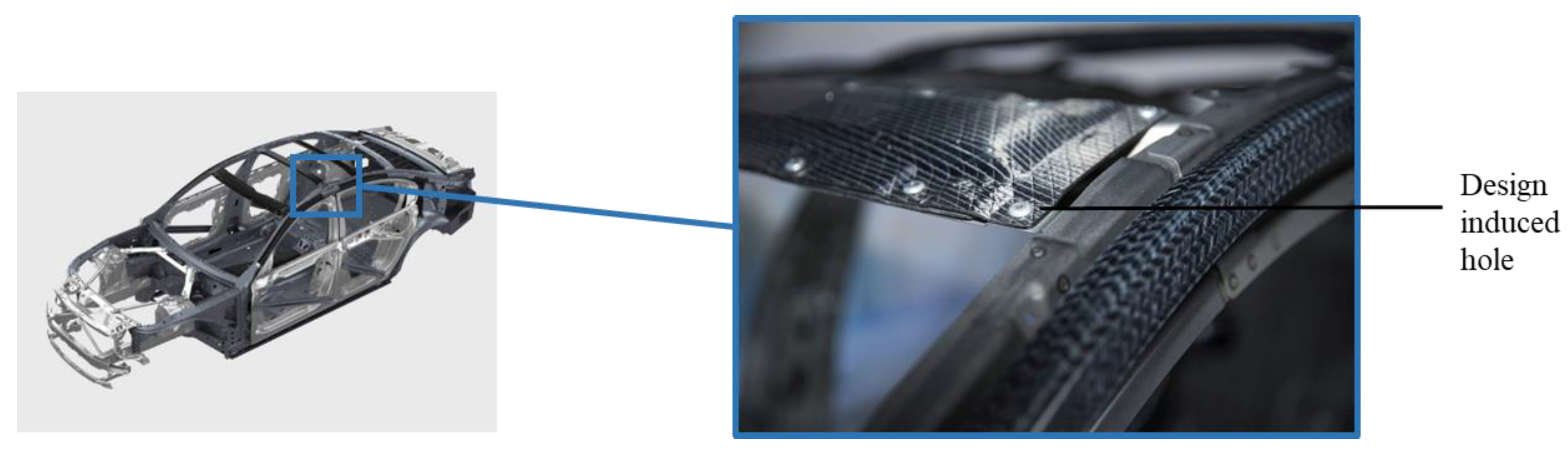

:1. Introduction

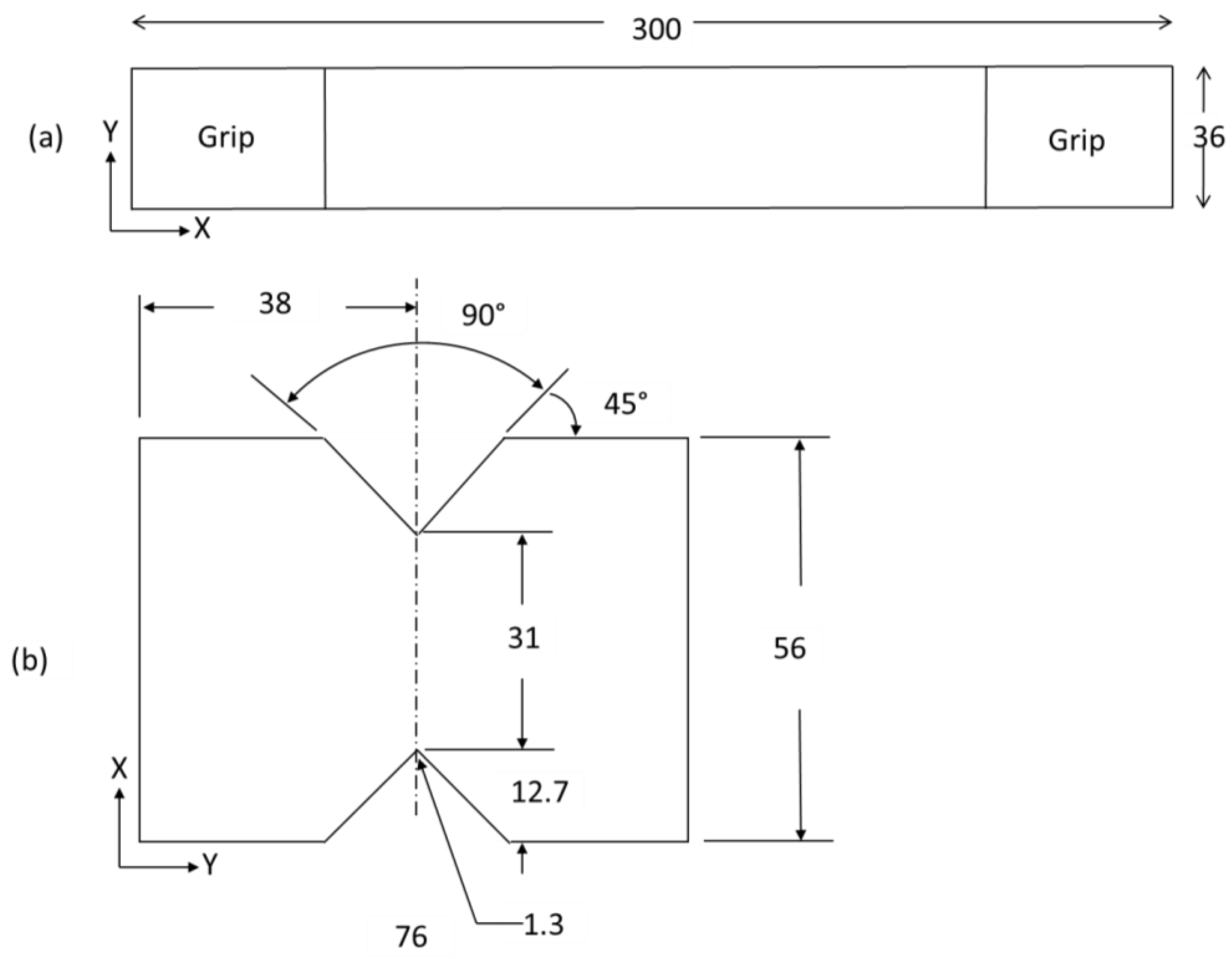

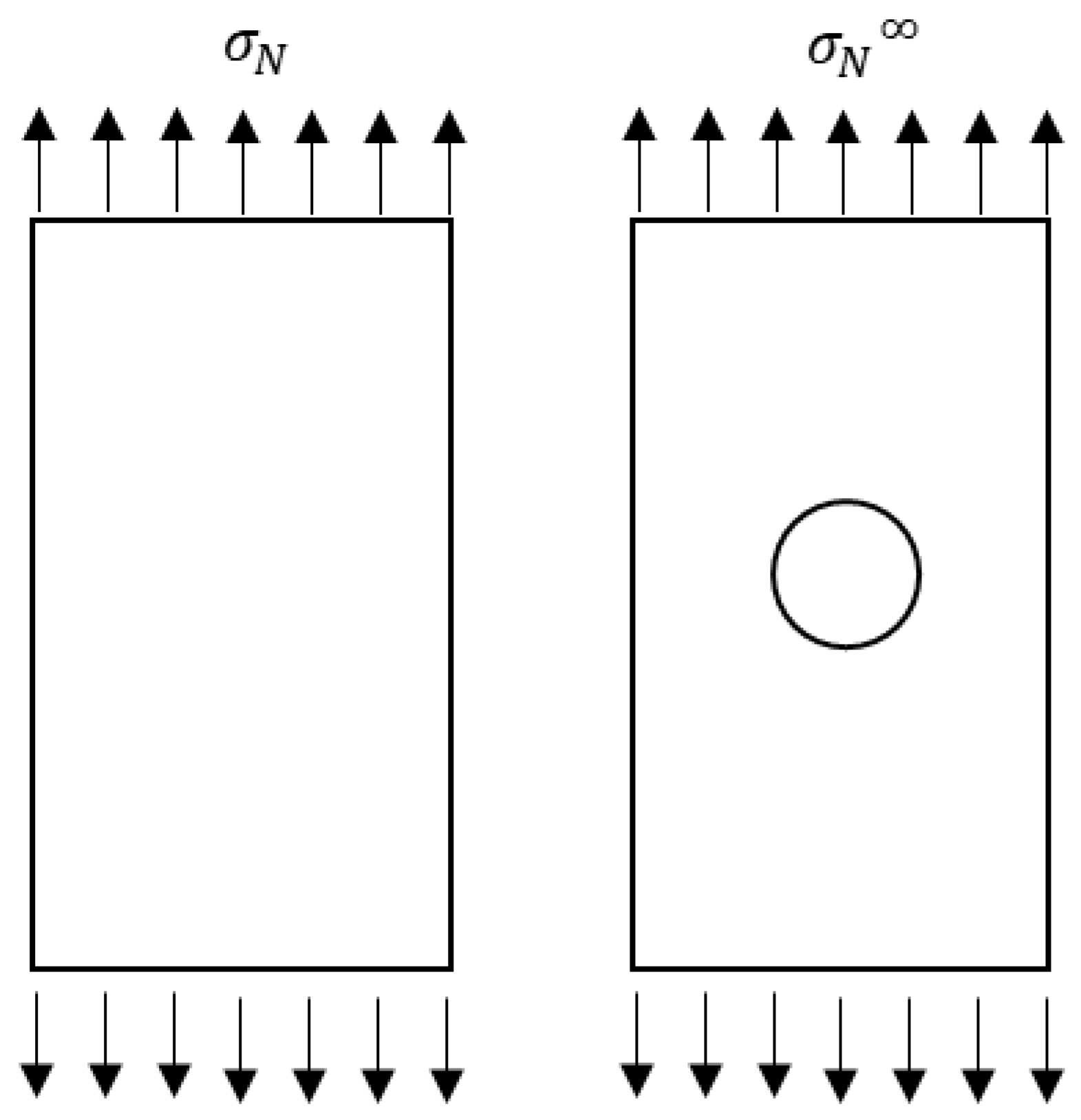

2. Material

3 Methods

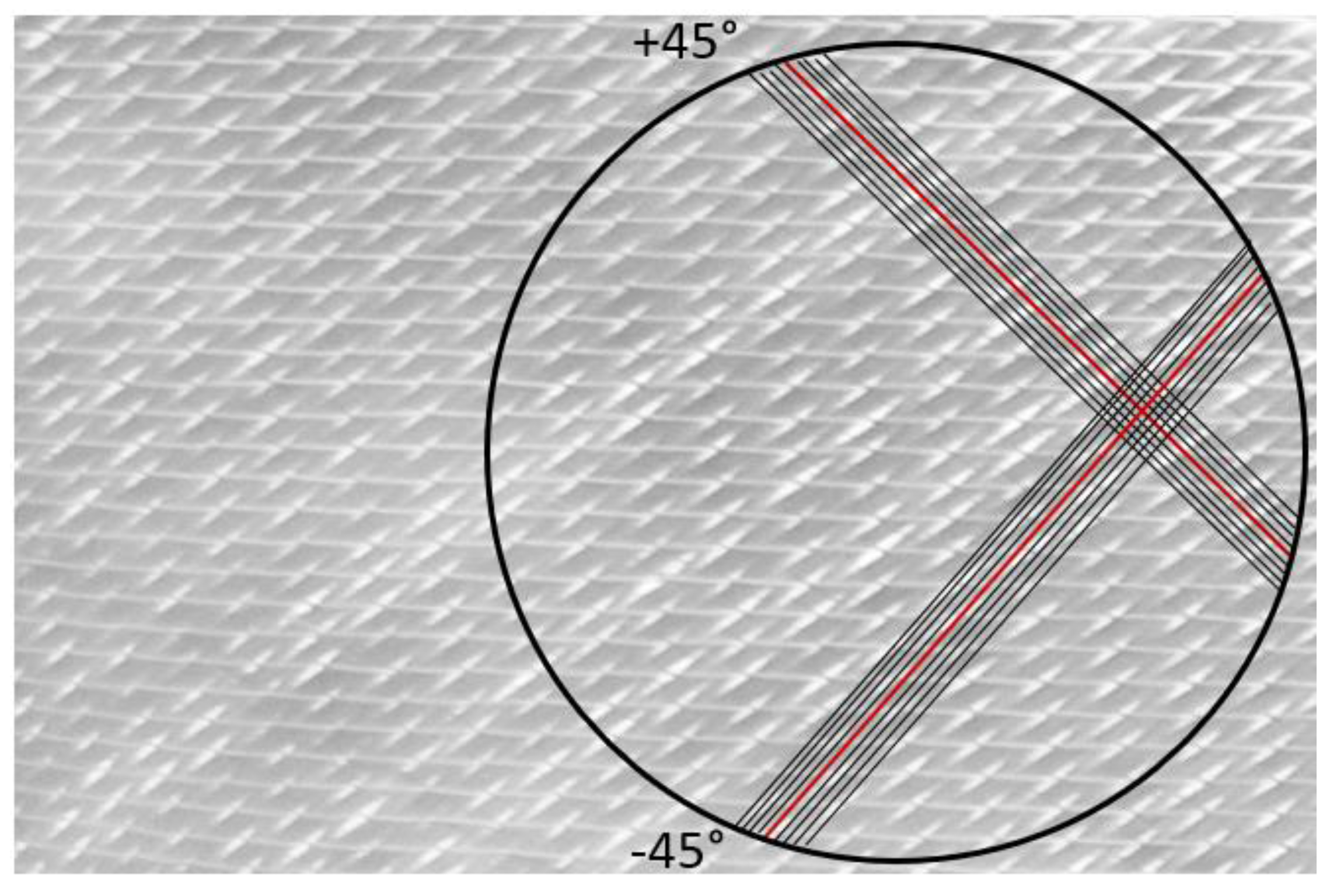

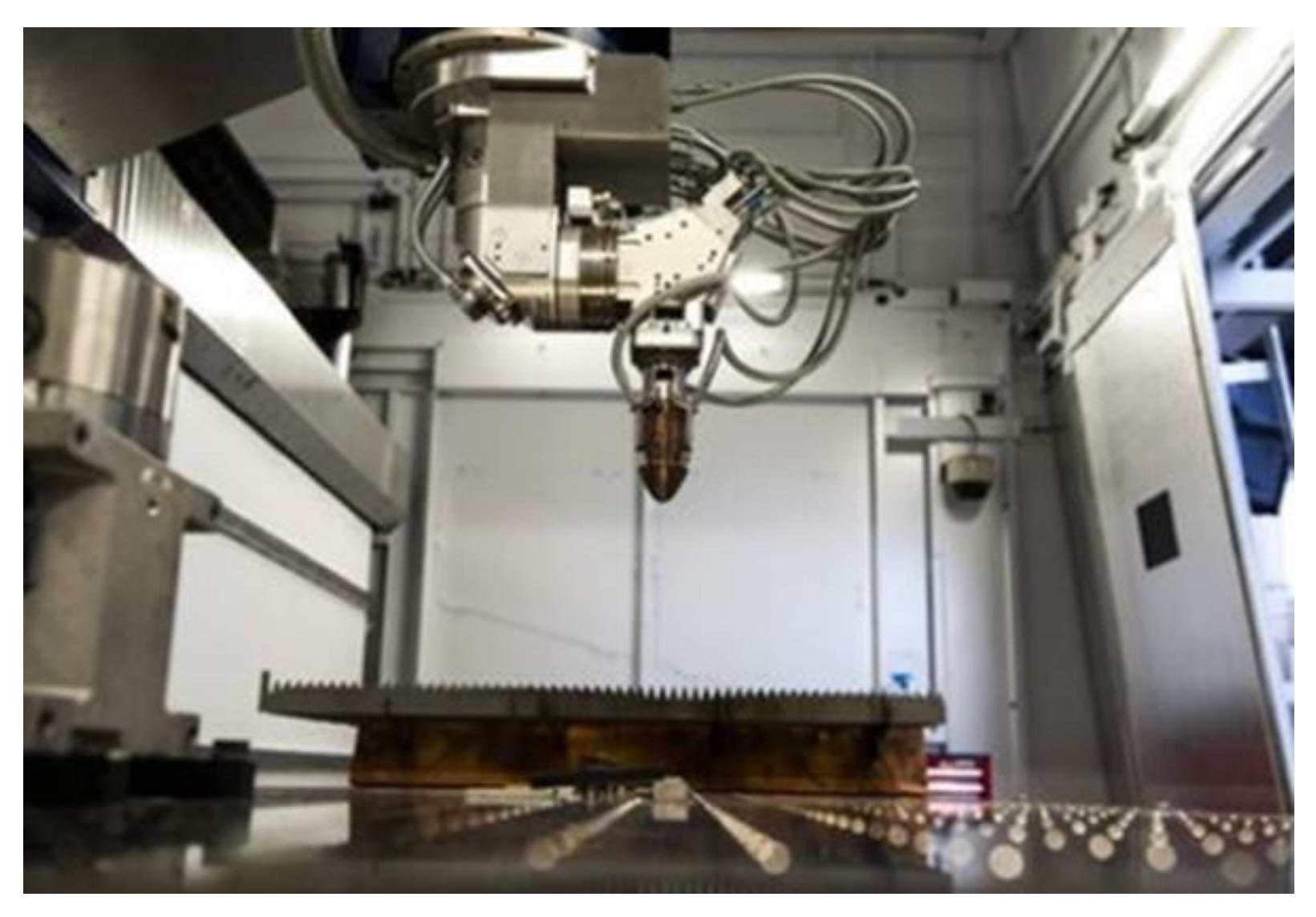

3.1. Preliminary Study on the Quality of Circular Holes

3.2. Lekhnitskii’s Equation

3.3. Finite Element Analysis (FEA)

3.4. Digital Image Correlation (DIC)

4. Results and Discussion

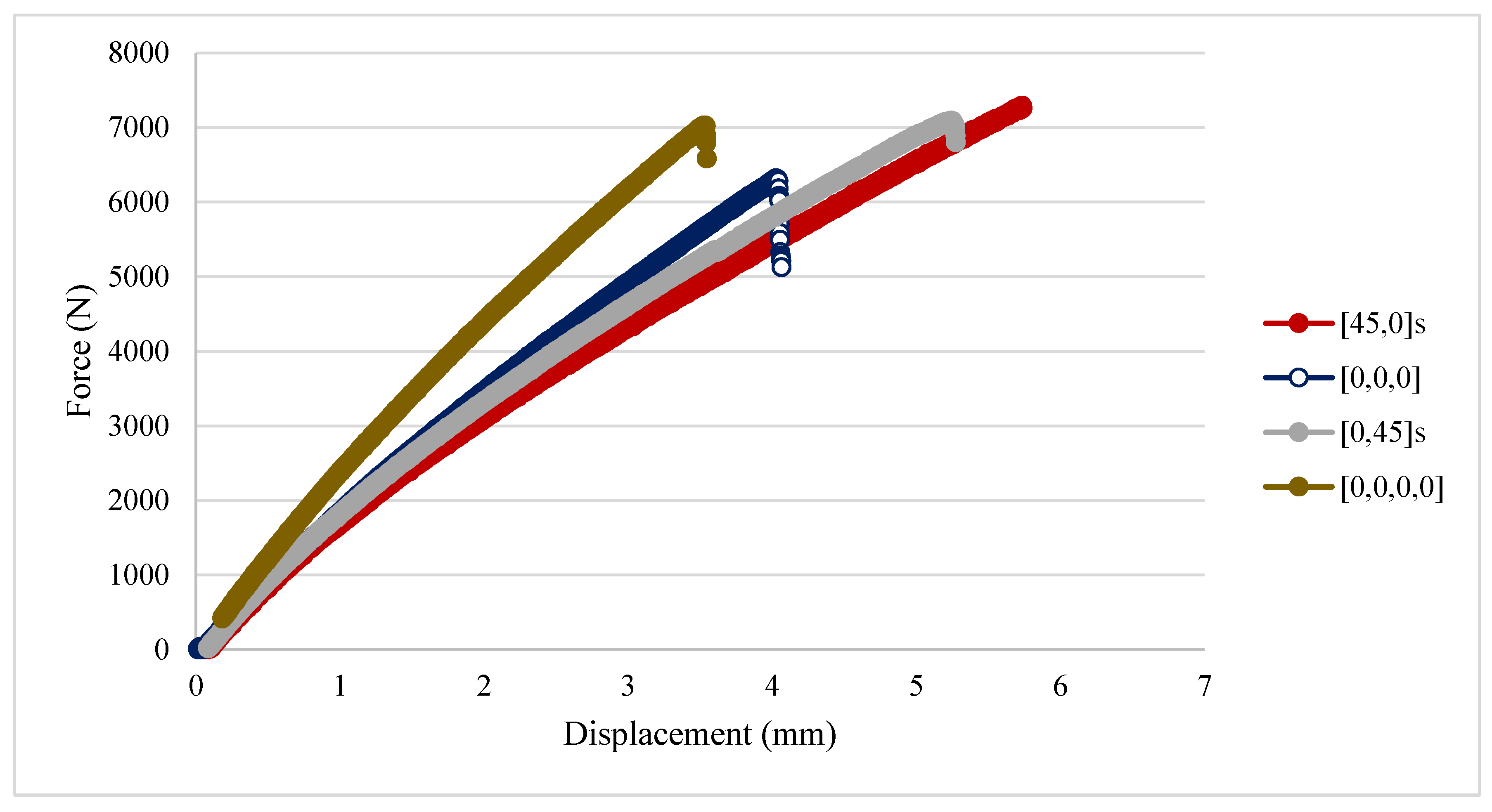

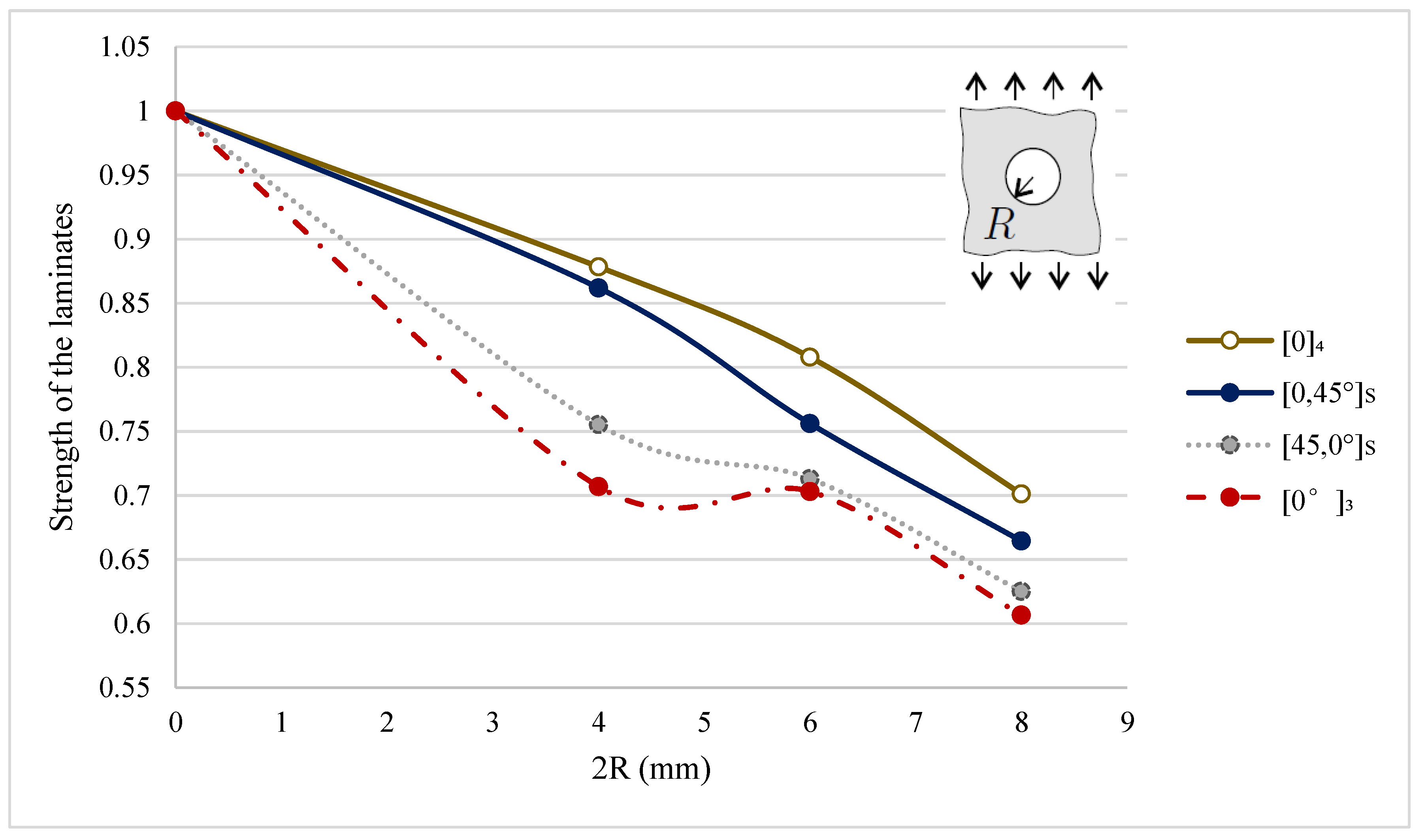

4.1. Strength of the Laminates

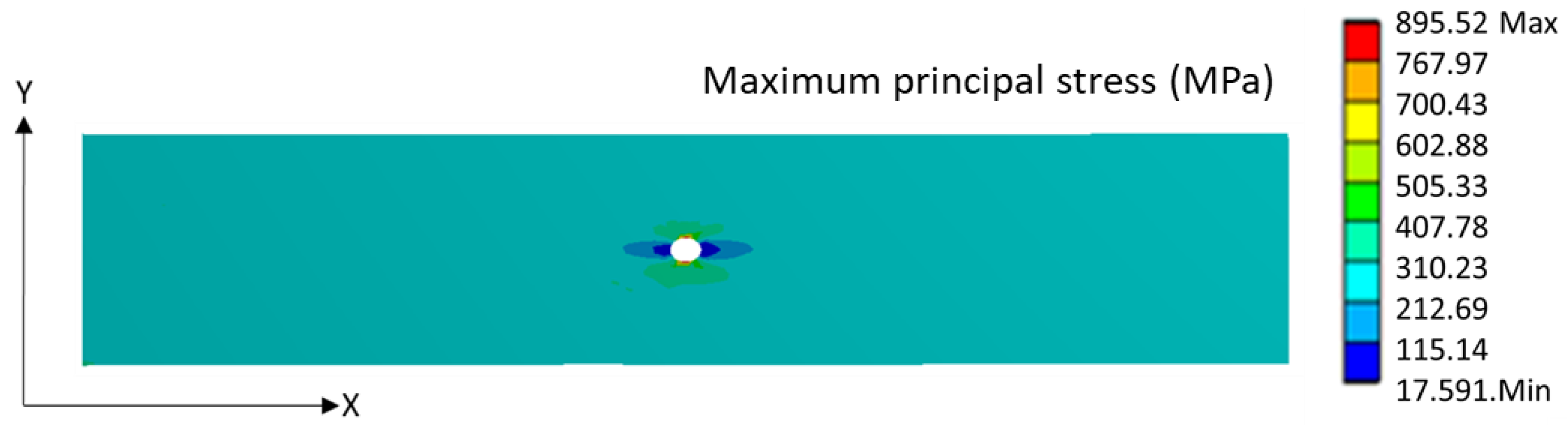

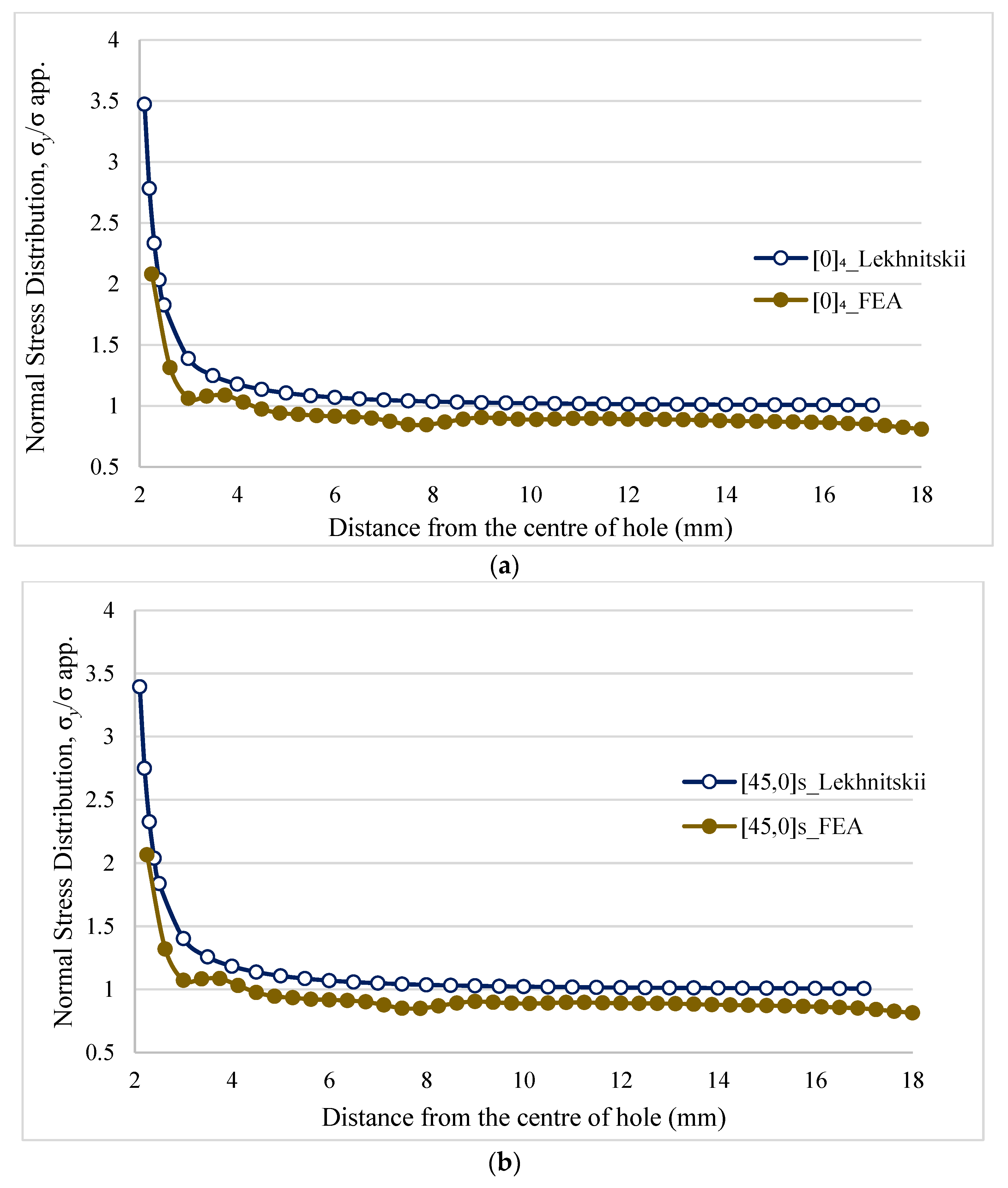

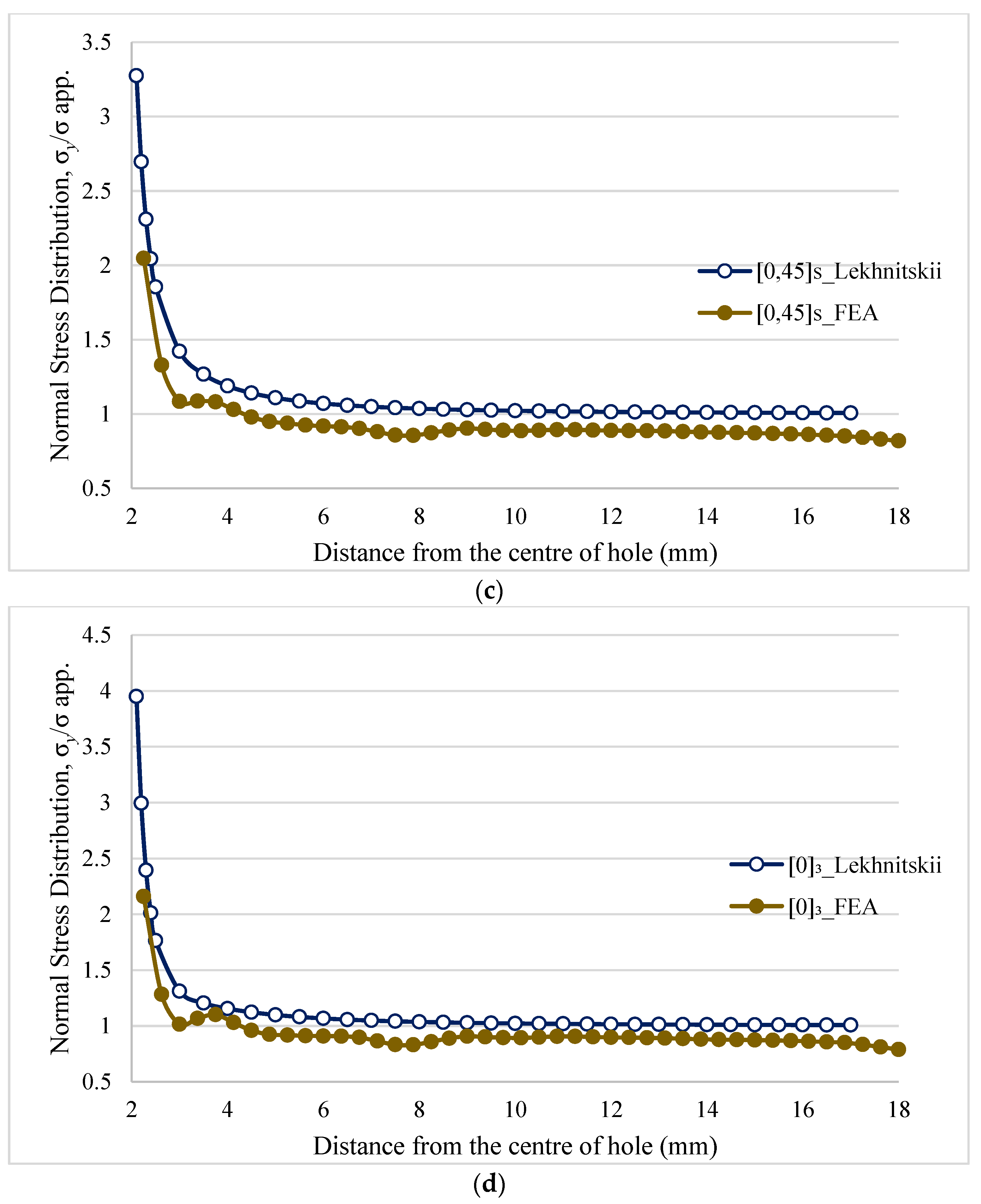

4.2. Normal Stress Distribution

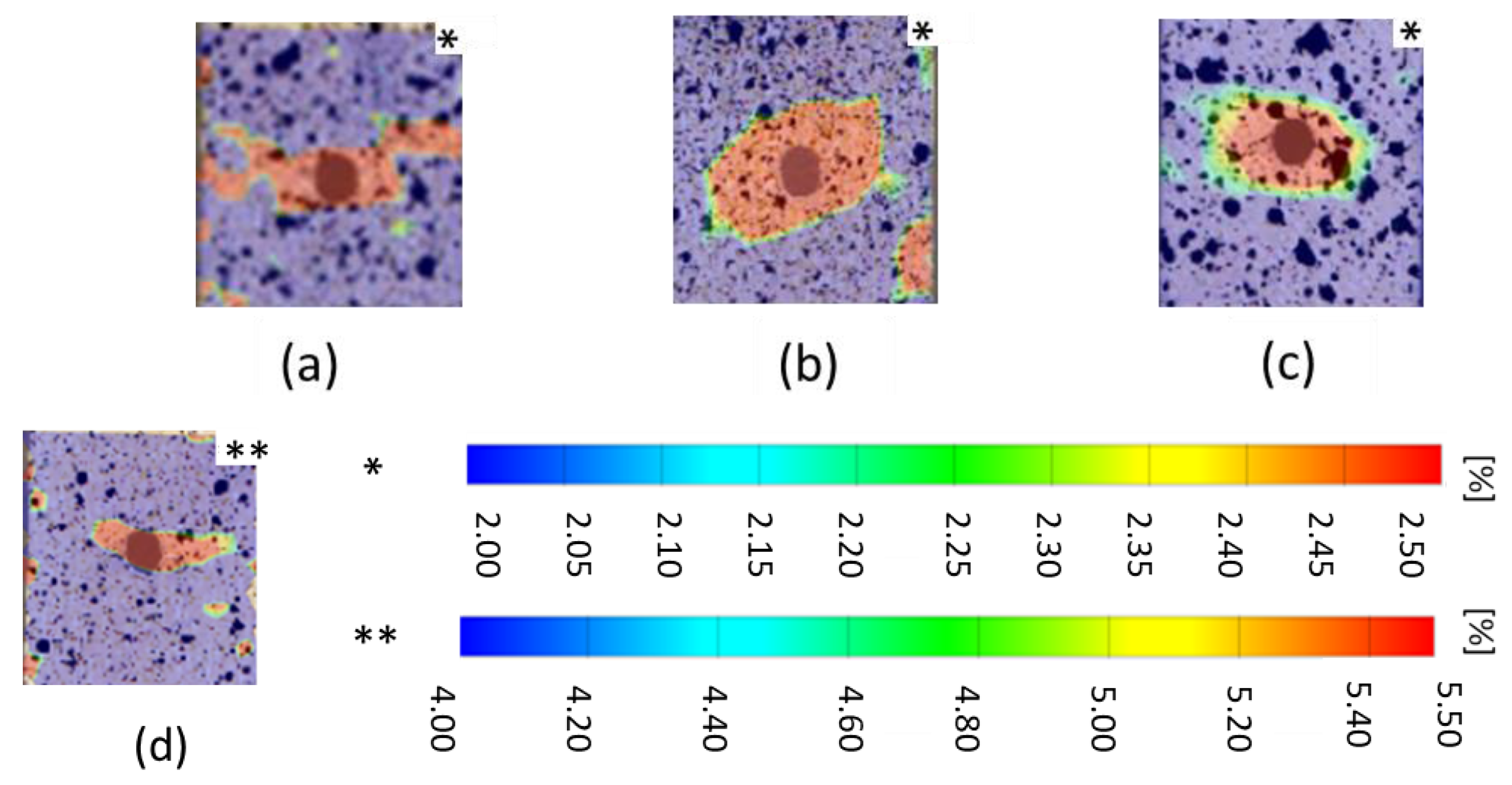

4.3. Strain Evolution

5. Conclusions

- Tensile test on notched and unnotched [45,0]S and [0,45]S laminates revealed, even though they have similar unnotched strength ([45,0]S: 7270N and [0,45]S: 7055N), when they are subjected to circular hole, strength was reduced by 25% for [45,0]S but only 14% for [0,45]S.

- In full-field strain measurement, [45,0]S shows a high longitudinal strain (4%–5.5%) around the notch compared to [0,45]S laminate with 2%–2.5%.

- Unsymmetric laminate shows high stress distribution at the edge of the hole compared to symmetric laminates.

- All laminates show very high stress concentration near the edge of hole. Stress distribution is linear after 2 mm from the edge of hole. Until 2 mm, normal stress distribution increases exponentially towards the edge of the hole.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kroll, L.; Kostka, P.; Lepper, M.; Hufenbach, W. Extended proof of fibre-reinforced laminates with holes. J. Achiev. Mater. Manuf. Eng. 2009, 33, 41–46. [Google Scholar]

- Lotfi, T.; Moussa, K.; Bernard, L. Stress concentration in a circular hole in composite plate. Compos. Struct. 2005, 68, 31–36. [Google Scholar]

- Venkateswaran, B.S.; Holger, S.; Marcello, A.; Tilo, S. Study on the Quality of Quasi-Isotropic Composite Laminates Containing a Circular Hole. JMSR 2017, 6, 67. [Google Scholar]

- Ko, W.L. Stress concentration around a small circular hole in the HiMAT composite plate. NASA Tech. Memo. 1985, 86038. [Google Scholar]

- Sudarsono, S.; Keiji, O. Fatigue Behavior of Open-Holed CFRP Laminates with Initially Cut Fibers. Open J. Compos. Mater. 2017, 7, 49–62. [Google Scholar] [CrossRef]

- Holger, S.; Colin, G.; Tomasz, O.; Sylvio, S.; Lothar, K. High-performance lightweight structures with Fiber Reinforced Thermoplastics and Structured Metal Thin Sheets. JMSR 2014, 4, 28–35. [Google Scholar]

- Razavian, I.; Ghasemi, A.R. Measurement of Variation in Fracture Strength and Calculation of Stress Concentration Factor in Composite Laminates with Circular Hole. J. Solid Mech. 2012, 4, 226–236. [Google Scholar]

- Waddoups, M.E.; Eisenmann, J.R.; Kaminski, B.E. Macroscopic Fracture Mechanics of Advanced Composite Materials. J. Compos. Mater. 1971, 5, 446–454. [Google Scholar] [CrossRef]

- Belmonte, H.M.S.; Ogin, S.L.; Smith, P.A.; Lewin, R. A physical-based model for the notched strength of woven quasi-isotropic CFRP laminate. Compos. A 2004, 35, 763–778. [Google Scholar] [CrossRef]

- Belingardi, G.; Koricho, E.G.; Beyene, A.T. Characterization and damage analysis of notched cross-ply and angle-ply fabric GFRP composite material. Compos. Struct. 2013, 102, 237–249. [Google Scholar] [CrossRef]

- ASTM D3039/D3039M-17. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM D7078/D7078M-12. Standard Test Method for Shear Properties of Composite Materials by V-Notched Rail Shear Method; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Springer, G.S.; Kollár, L.P. Mechanics of Composite Structures; Cambridge University Press: New York, NY, USA, 2003; p. 477. [Google Scholar]

- Guocai, V.; Yi, T.; Jenn-Ming, Y. Evaluation of residual strength of notched fiber metal laminates. Mater. Sci. Eng. A 2007, 457, 338–349. [Google Scholar]

- Lekhnistskii, S.G. Anisotropic Plates; Gordon and Breach Science Publishers: New York, NY, USA, 1968. [Google Scholar]

- Kim, J.K.; Kim, D.S.; Takeda, N. Notched strength and fracture criterion in fabric composite plates containing a circular hole. Compos. Mater. 1995, 29, 982–998. [Google Scholar] [CrossRef]

- Caminero, M.A.; Lopez-Pedrosa, M.; Pinna, C.; Soutis, C. Damage Assessment of Composite Structures Using Digital Image Correlation. Appl. Compos. Mater. 2014, 21, 91–106. [Google Scholar] [CrossRef]

- Pandita, S.D.; Nishiyabu, K.; Verpoest, I. Strain concentrations in woven fabric composites with holes. Compos. Struct. 2003, 59, 361–368. [Google Scholar] [CrossRef]

- Kolanu, N.R.; Prakash, S.S.; Ramji, M. Experimental study on compressive behavior of GFRP stiffened panels using digital image correlation. Ocean Eng. 2016, 114, 290–302. [Google Scholar] [CrossRef]

- Bataxi; Chen, X.; Yu, Z.; Wang, H.; Bil, C. Strain Monitoring on Damaged Composite Laminates Using Digital Image Correlation. Proced. Eng. 2015, 99, 353–360. [Google Scholar]

- Sun, Y.; Pang, J.H.L. Study of optimal subset size in digital image correlation of speckle pattern images. Opt. Lasers Eng. 2007, 45, 967–974. [Google Scholar]

- ASTM D5766/D5766M–02a. Standard Test Method for Open Hole Tensile Strength of Polymer Matrix Composite Laminates; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

| Layup | E11 = E22 (All Sample) (GPa) | E11 = E22 (Average) (GPa) | SD (E11) (GPa) | ʋ12 | G22 (GPa) | Thickness (mm) |

|---|---|---|---|---|---|---|

| f[0°]4 | 17,783.2 17,394.4 17,508.0 17,433.7 17,360.7 | 17.495 | 0.1696 | 0.139 | 1.597 | 0.66 |

| f[0,45°]S | 12,015.8 12,247.5 11,655.5 12,203.5 11,834.6 | 11.992 | 0.2492 | 0.306 | 1.388 | 0.66 |

| f[45,0°]S | 10,656.8 10,007.8 11,574.2 10,154.1 10,300.4 | 10.538 | 0.6270 | 0.169 | 1.062 | 0.66 |

| f[0°]3 | 16,196.5 16,478.4 16,763.9 15,900.4 16,787.5 | 16.425 | 0.3797 | 0.05 | 0.892 | 0.54 |

| Layup | 2R (mm) | 2R/W | (MPa) | (MPa) | |

|---|---|---|---|---|---|

| f[0]4 | 4 | 0.111 | 342.13 | 346.69 | 0.8784 |

| f[0]4 | 6 | 0.167 | 313.78 | 318.87 | 0.8079 |

| f[0]4 | 8 | 0.222 | 261.58 | 276.75 | 0.7012 |

| f[0,45°]S | 4 | 0.111 | 293.30 | 297.21 | 0.8619 |

| f[0,45°]S | 6 | 0.167 | 255.62 | 260.74 | 0.7561 |

| f[0,45°]S | 8 | 0.222 | 216.52 | 229.11 | 0.6644 |

| f[45,0°]S | 4 | 0.111 | 264.90 | 268.43 | 0.7553 |

| f[45,0°]S | 6 | 0.167 | 249.02 | 253.43 | 0.7131 |

| f[45,0°]S | 8 | 0.222 | 209.97 | 222.16 | 0.6251 |

| f[0]3 | 4 | 0.111 | 262.84 | 266.34 | 0.7069 |

| f[0]3 | 6 | 0.167 | 263.02 | 264.91 | 0.7031 |

| f[0]3 | 8 | 0.222 | 216.18 | 228.61 | 0.6067 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santhanakrishnan Balakrishnan, V.; Seidlitz, H.; Weiß, S. Layup Configuration Effect on Notch Residual Strength in Composite Laminates. Materials 2018, 11, 308. https://doi.org/10.3390/ma11020308

Santhanakrishnan Balakrishnan V, Seidlitz H, Weiß S. Layup Configuration Effect on Notch Residual Strength in Composite Laminates. Materials. 2018; 11(2):308. https://doi.org/10.3390/ma11020308

Chicago/Turabian StyleSanthanakrishnan Balakrishnan, Venkateswaran, Holger Seidlitz, and Sabine Weiß. 2018. "Layup Configuration Effect on Notch Residual Strength in Composite Laminates" Materials 11, no. 2: 308. https://doi.org/10.3390/ma11020308

APA StyleSanthanakrishnan Balakrishnan, V., Seidlitz, H., & Weiß, S. (2018). Layup Configuration Effect on Notch Residual Strength in Composite Laminates. Materials, 11(2), 308. https://doi.org/10.3390/ma11020308