Gleeble-Simulated and Semi-Industrial Studies on the Microstructure Evolution of Fe-Co-Cr-Mo-W-V-C Alloy during Hot Deformation

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.2. Compression Simulation Test

2.3. Microstructure Characterization

2.4. Calculation of Mechanical Properties of Carbides

3. Results

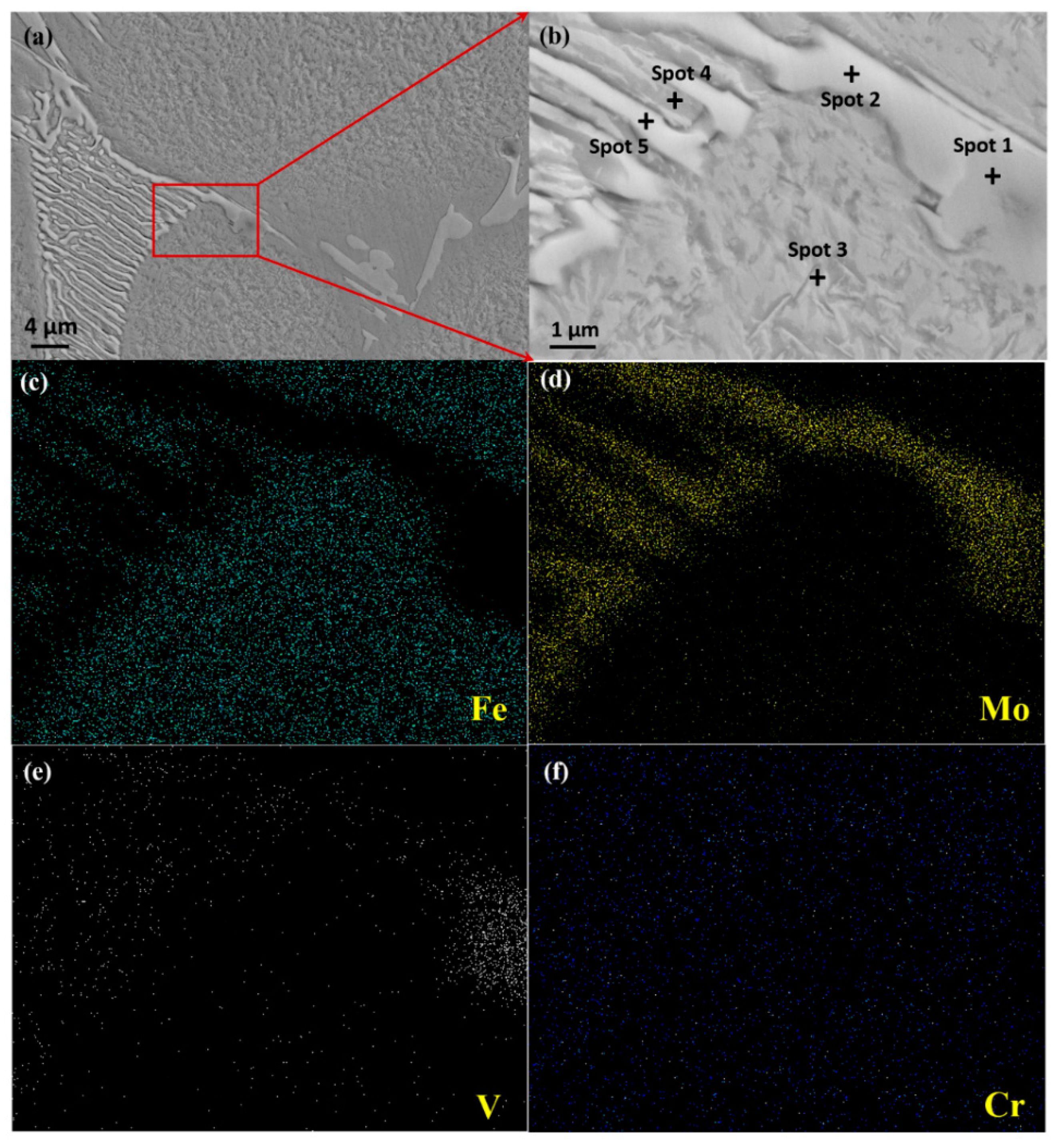

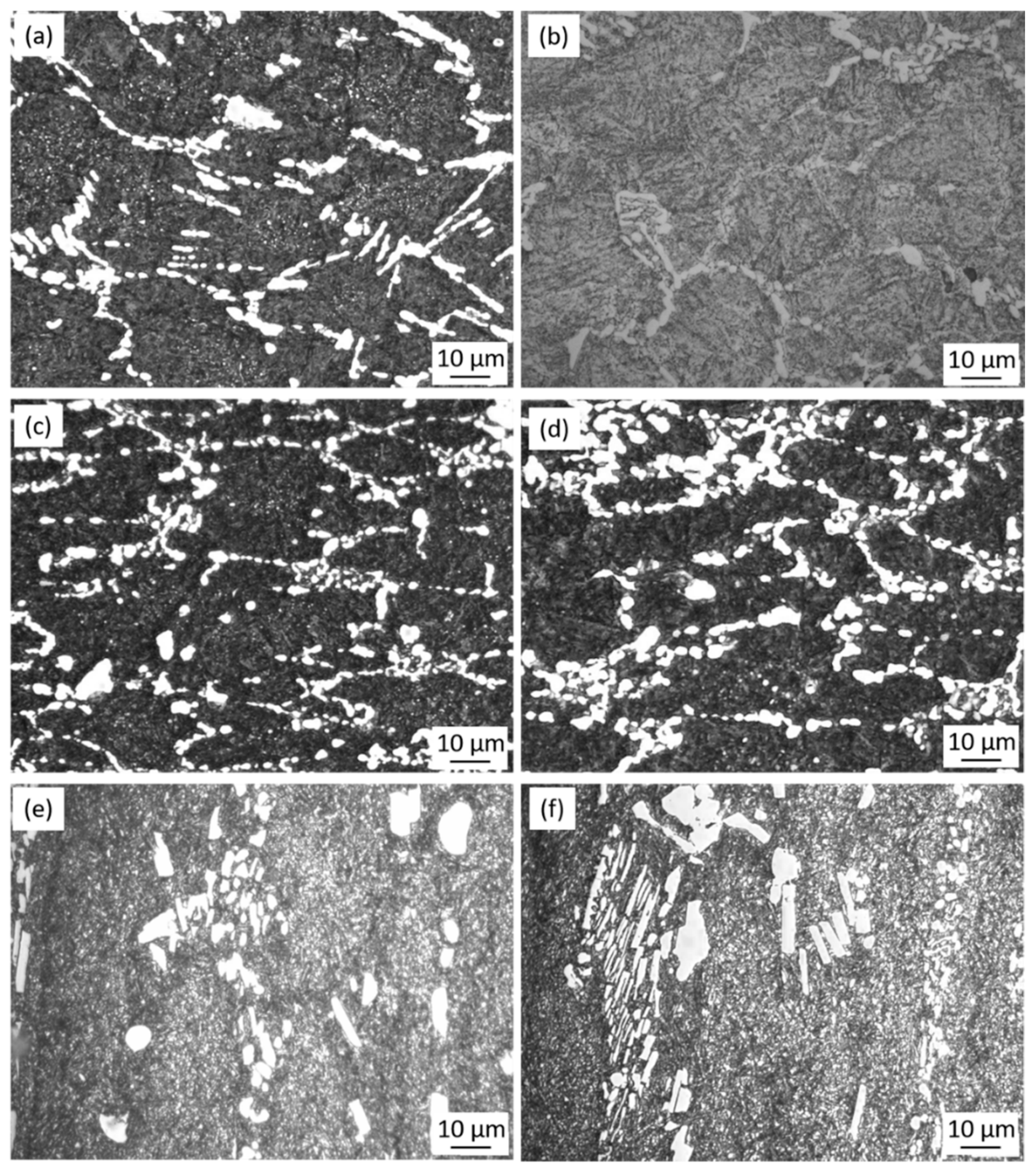

3.1. As-Cast and Wrought Microstructures

3.2. Mechanical Properties of the Carbides

3.3. Stress-Strain Curves and Microstructure Evolution

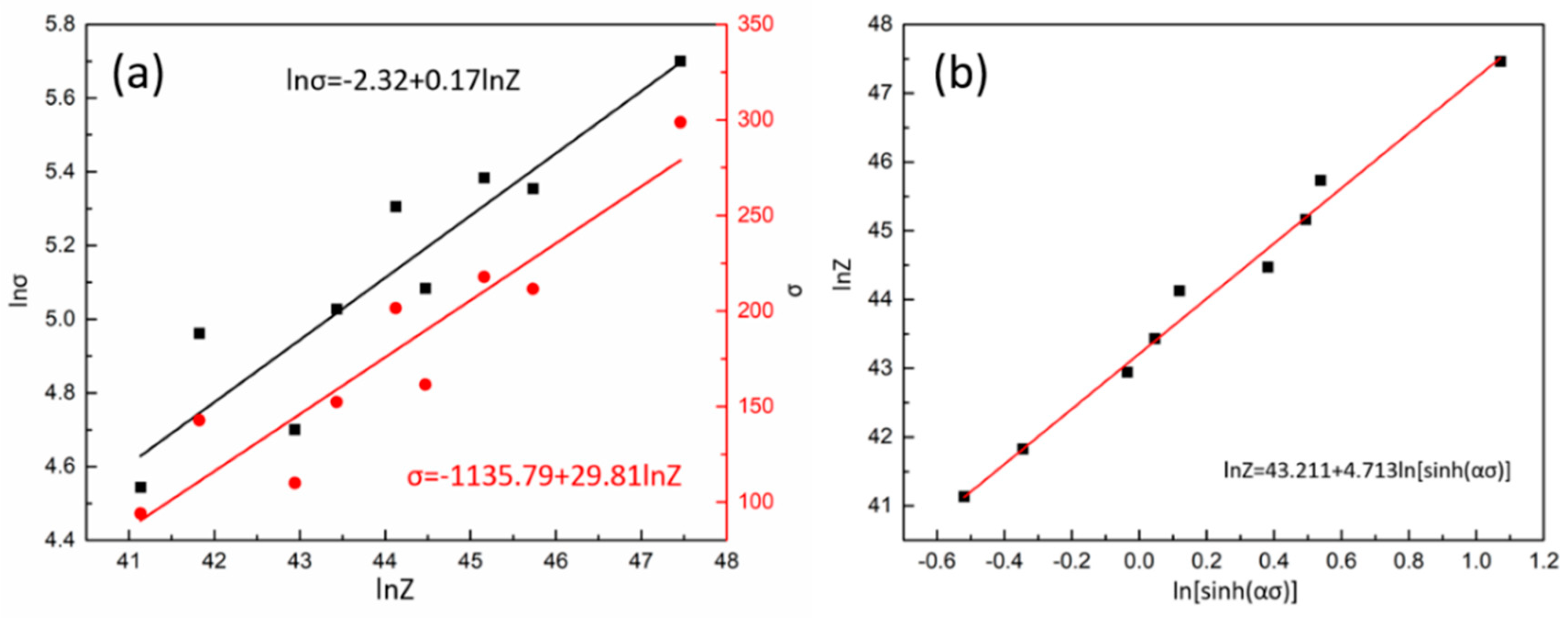

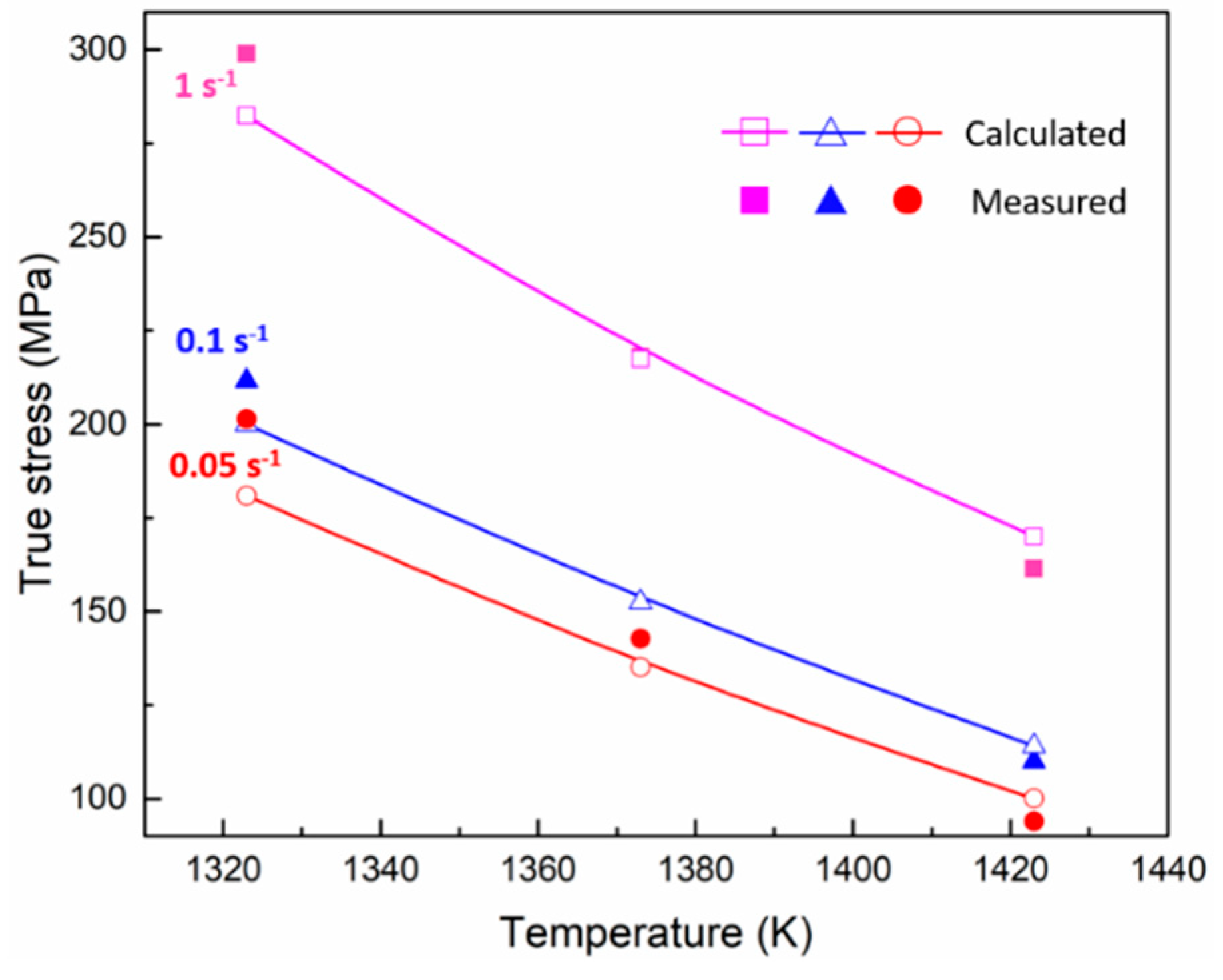

3.3.1. Stress-Strain Curves

3.3.2. Microstructure Evolution

4. Conclusions

- The carbides in as-cast Fe-Co-Cr-Mo-W-V-C alloy are principally Mo-rich M2C (Mo2C), with a certain amount of V-rich MC (VC) and Cr-rich Cr7C3 and Cr23C6 carbides. The carbides in wrought Fe-Co-Cr-Mo-W-V-C alloy consist of Mo-rich M6C (Fe2Mo4C), VC, Cr7C3, and a small amount of retained Mo2C.

- Of the five carbides, Cr7C3 had the maximum bulk modulus and B/G values of 316.6 GPa and 2.48, indicating that Cr7C3 has the strongest ability to resist external force and crack initiation. VC had the maximum shear modulus and Yong’s modulus values of 187.3 GPa and 465.3 GPa, which implies VC can be considered as a potential hard material. However, its obvious brittleness can also deteriorate the mechanical properties of the alloy.

- True stress-strain curves are sensitive to the deformation temperature and strain rate. At a given temperature, the flow stress increases with increasing strain rate. At a given strain rate, the flow stress increases with a decrease in temperature.

- A constitutive equation to describe the relationship of peak true stress, strain rate, and deformation temperature for Fe-Co-Cr-Mo-W-V-C alloy was established and expressed as:The use of this equation allows one to predict the true stress under different hot working conditions.

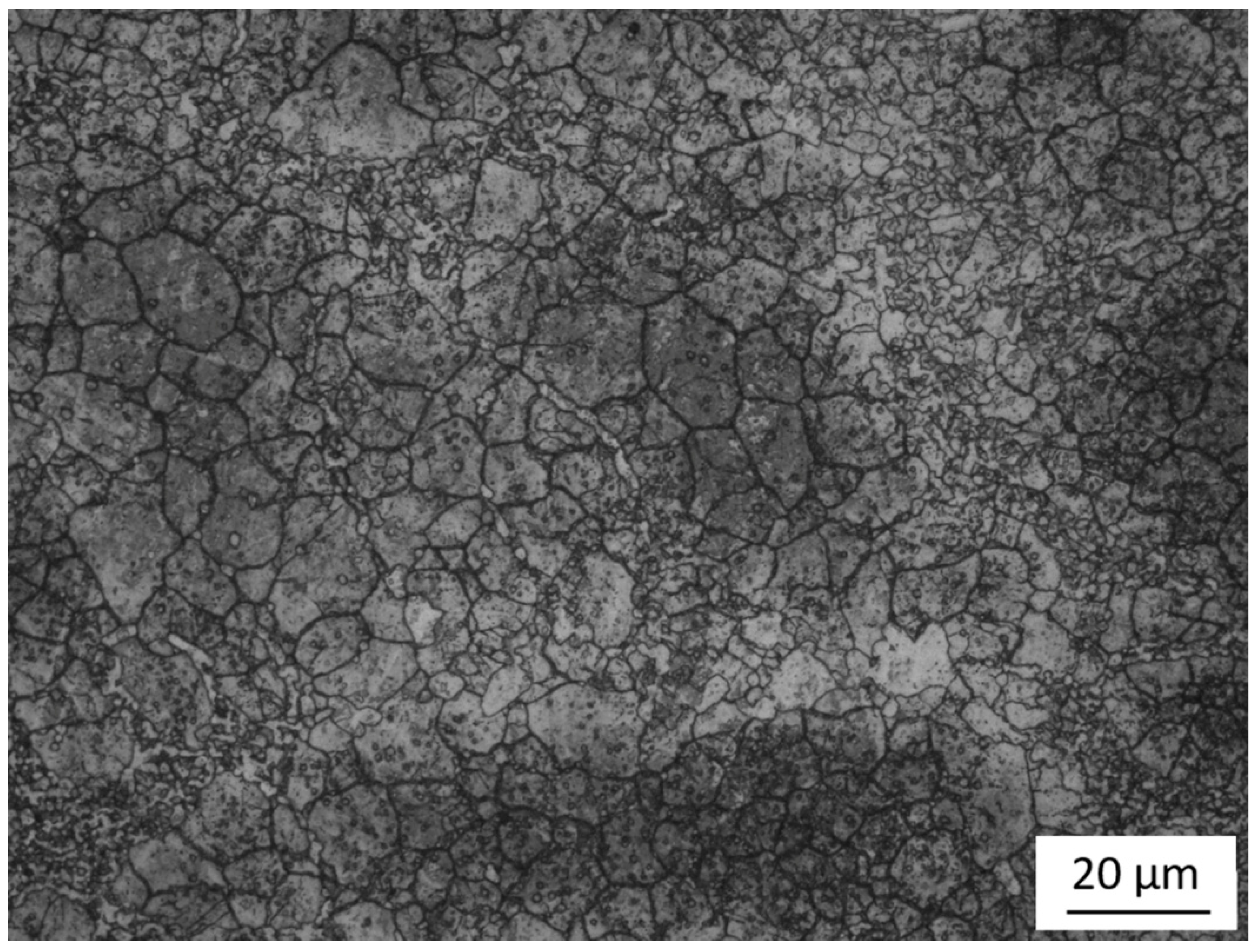

- Under the same strain rate, with an increase of deformation temperature, the network of carbides are broken more completely and better dissolved into the matrix. Because the diffusion rate increases with increasing temperature, which impedes the disruption of grain boundaries in the process of hot deformation and also enhances the grain boundary migration, the average grain size can increase from 11 μm (1373 K) to 18 μm (1423 K).

- Employing the laboratorial optimal temperature (1373 K) in forging an industrial square billet resulted in uniform grains, with the largest size of 17 µm, surrounded by homogenous spherical carbides.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wieczerzak, K.; Bala, P.; Stepien, M.; Cios, G.; Koziel, T. Formation of eutectic carbides in Fe–Cr–Mo–C alloy during non-equilibrium crystallization. Mater. Des. 2016, 94, 61–68. [Google Scholar] [CrossRef]

- Peng, H.; Hu, L.; Li, L.; Zhang, L.; Zhang, X. Evolution of the microstructure and mechanical properties of powder metallurgical high-speed steel S390 after heat treatment. J. Alloys Compd. 2018, 740, 766–773. [Google Scholar] [CrossRef]

- Guo, J.; Liu, L.; Liu, S.; Zhou, Y.; Qi, X.; Ren, X.; Yang, Q. Stability of eutectic carbide in Fe-Cr-Mo-WVC alloy by first-principles calculation. Mater. Des. 2016, 106, 355–362. [Google Scholar] [CrossRef]

- Moon, H.K.; Lee, K.B.; Kwon, H. Influences of Co addition and austenitizing temperature on secondary hardening and impact fracture behavior in P/M high speed steels of W–Mo–Cr–V (–Co) system. Mater. Sci. Eng. A 2008, 474, 328–334. [Google Scholar] [CrossRef]

- Chandhok, V.K.; Hirth, J.P.; Dulis, E.J. Effect of cobalt on tempering tool and alloy steels. Trans. ASM 1963, 56, 677–693. [Google Scholar]

- Decaudin, B.; Djega-Mariadassou, C.; Cizeron, G. Structural study of M50 steel carbides. J. Alloys Compd. 1995, 226, 208–212. [Google Scholar] [CrossRef]

- Lee, E.S.; Park, W.J.; Jung, J.Y.; Ahn, S. Solidification microstructure and M2C carbide decomposition in a spray-formed high-speed steel. Metall. Mater. Trans. A 1998, 29, 1395–1404. [Google Scholar] [CrossRef]

- Zhou, X.; Fang, F.; Li, G.; Jiang, J. Morphology and properties of M2C eutectic carbides in AISI M2 steel. ISIJ Int. 2010, 50, 1151–1157. [Google Scholar] [CrossRef]

- Luo, Y.; Guo, H.; Sun, X.; Mao, M.; Guo, J. Effects of austenitizing conditions on the microstructure of AISI M42 high-speed steel. Metals 2017, 7, 27. [Google Scholar] [CrossRef]

- Nogueira, R.A.; Ribeiro, O.C.; das Neves, M.D.; de Lima, L.F.C.; Ambrozio, F.; Friedrich, D.; Boehs, L. Influence of the heat treatment on the microstructure of AISI T15 high speed steel. Mater. Sci. Forum. 2003, 416, 89–94. [Google Scholar] [CrossRef]

- Bin, Z.; Yu, S.; Jun, C.; Cui, Z.S. Breakdown behavior of eutectic carbide in high speed steel during hot compression. J. Iron Steel Res. Int. 2011, 18, 41–48. [Google Scholar]

- Deng, Y.K.; Chen, J.R.; Wang, S.Z. High Speed Tool Steel; Metallurgical Industry Press: Beijing, China, 2002. [Google Scholar]

- Nkhoma, R.K.; Siyasiya, C.W.; Stumpf, W.E. Hot workability of AISI 321 and AISI 304 austenitic stainless steels. J. Alloys Compd. 2014, 595, 103–112. [Google Scholar] [CrossRef]

- Rastegari, H.; Kermanpur, A.; Najafizadeh, A.; Porter, D.; Somani, M. Warm deformation processing maps for the plain eutectoid steels. J. Alloys Compd. 2015, 626, 136–144. [Google Scholar] [CrossRef]

- Saadatkia, S.; Mirzadeh, H.; Cabrera, J.M. Hot deformation behavior, dynamic recrystallization, and physically-based constitutive modeling of plain carbon steels. Mater. Sci. Eng. A 2015, 636, 196–202. [Google Scholar] [CrossRef]

- Liang, H.Q.; Nan, Y.; Ning, Y.Q.; Li, H.; Zhang, J.L.; Shi, Z.F.; Guo, H.Z. Correlation between strain-rate sensitivity and dynamic softening behavior during hot processing. J. Alloys Compd. 2015, 632, 478–485. [Google Scholar] [CrossRef]

- Zhao, J.; Ding, H.; Zhao, W.; Huang, M.; Wei, D.; Jiang, Z. Modelling of the hot deformation behaviour of a titanium alloy using constitutive equations and artificial neural network. Comp. Mater. Sci. 2014, 92, 47–56. [Google Scholar] [CrossRef]

- Wang, L.X.; Fang, G.; Leeflang, M.A.; Duszczyk, J.; Zhou, J. Constitutive behavior and microstructure evolution of the as-extruded AE21 magnesium alloy during hot compression testing. J. Alloys Compd. 2015, 622, 121–129. [Google Scholar] [CrossRef]

- Guo, J.; Zhao, S.; Murakami, R.I.; Ding, R.; Fan, S. Modeling the hot deformation behavior of Al alloy 3003. J. Alloys Compd. 2013, 566, 62–67. [Google Scholar] [CrossRef]

- Tan, J.Q.; Zhan, M.; Liu, S.; Huang, T.; Guo, J.; Yang, H. A modified Johnson–Cook model for tensile flow behaviors of 7050-T7451 aluminum alloy at high strain rates. Mater. Sci. Eng. A 2015, 631, 214–219. [Google Scholar] [CrossRef]

- Ning, Y.; Yao, Z.; Guo, H.; Fu, M.W. Hot deformation behavior and hot working characteristic of Nickel-base electron beam weldments. J. Alloys Compd. 2014, 584, 494–502. [Google Scholar] [CrossRef]

- Kar, S.K.; Sondhi, S.K. Microstructure based and temperature dependent model of flow behavior of a polycrystalline nickel based superalloy. Mater. Sci. Eng. A 2014, 601, 97–105. [Google Scholar] [CrossRef]

- Kang, M.; Park, G.; Jung, J.G.; Kim, B.H.; Lee, Y.K. The effects of annealing temperature and cooling rate on carbide precipitation behavior in H13 hot-work tool steel. J. Alloys Compd. 2015, 627, 359–366. [Google Scholar] [CrossRef]

- Hou, Z.; Hedström, P.; Chen, Q.; Xu, Y.; Wu, D.; Odqvist, J. Quantitative modeling and experimental verification of carbide precipitation in a martensitic Fe–0.16 wt.% C–4.0 wt.% Cr alloy. J. Odqvist. Calphad 2016, 53, 39–48. [Google Scholar] [CrossRef]

- Cabrol, E.; Bellot, C.; Lamesle, P.; Delagnes, D.; Povoden-Karadeniz, E. Experimental investigation and thermodynamic modeling of molybdenum and vanadium-containing carbide hardened iron-based alloys. J. Alloys Compd. 2013, 556, 203–209. [Google Scholar] [CrossRef]

- Godec, M.; Pritovsek, T.V.; Batic, B.S.; McGuiness, P.; Burja, J.; Podgornik, B. Surface and bulk carbide transformations in high-speed steel. Sci. Rep. 2015, 5, 16202–16213. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.W.; Guo, H.J.; Sun, X.L.; Guo, J.; Wang, F. Effects of Nitrogen on the Morphology and Evolution of M 2 C Eutectic Carbides in Fe-Mo-W-Co-Cr-VC Alloy. JOM 2018. [Google Scholar] [CrossRef]

- Lee, K.B.; Kwon, H.; Yang, H.R. Effects of alloying additions and austenitizing treatments on secondary hardening and fracture behavior for martensitic steels containing both Mo and W. Mater. Trans. A 2001, 32, 1659–1670. [Google Scholar] [CrossRef]

- Wang, M.J.; Wang, Y.; Xing, Y.C.; Chen, L. Effect of nitrogen on the austenite cooling transformation kinetics of a high-speed steel. Mater. Sci. Eng. A 2006, 438, 1143–1145. [Google Scholar] [CrossRef]

- Guo, J.; Ai, L.; Wang, T.; Feng, Y.; Wan, D.; Yang, Q. Microstructure evolution and micro-mechanical behavior of secondary carbides at grain boundary in a Fe–Cr–W–Mo–V–C alloy. Mater. Sci. Eng. A 2018, 715, 359–369. [Google Scholar] [CrossRef]

- Luo, Y.W.; Guo, H.J.; Sun, X.L.; Guo, J.; Wang, F. Influnence of the nitrogen content on carbide transformation of AISI M42 high-speed steels during annealing. Sci. Rep. 2018, 8, 4328–4337. [Google Scholar] [CrossRef]

- Kang, M.W.; Lee, Y.K. The effects of austenitizing conditions on the microstructure and wear resistance of a centrifugally cast high-speed steel roll. Metall. Mater. Trans. A 2016, 47, 3365–3374. [Google Scholar] [CrossRef]

- Boccalini, M.; Goldenstein, H. Solidification of high speed steels. Int. Mater. Rev. 2001, 46, 92–115. [Google Scholar] [CrossRef]

- Zhou, X.F.; Fang, F.; Li, F.; Jiang, J.Q. Morphology and microstructure of M2C carbide formed at different cooling rates in AISI M2 high speed steel. J. Mater. Sci. 2011, 46, 1196–1202. [Google Scholar] [CrossRef]

- Suetin, D.V.; Shein, I.R.; Ivanovskii, A.L. Structural, electronic properties and stability of tungsten mono-and semi-carbides: A first principles investigation. J. Phys. Chem. Solids 2009, 70, 64–71. [Google Scholar] [CrossRef]

- Zhou, W.; Liu, L.; Li, B.; Wu, P.; Song, Q. Structural, elastic and electronic properties of intermetallics in the Pt–Sn system: A density functional investigation. Comp. Mater. Sci. 2009, 46, 921–931. [Google Scholar] [CrossRef]

- Sin’ko, G.V. Ab initio calculations of the second-order elastic constants of crystals under arbitrary isotropic pressure. Phys. Rev. B 2008, 77, 104118. [Google Scholar] [CrossRef]

- Li, Y.; Gao, Y.; Xiao, B.; Min, T.; Yang, Y.; Ma, S.; Yi, D. The electronic, mechanical properties and theoretical hardness of chromium carbides by first-principles calculations. Alloys Compd. 2011, 509, 5242–5249. [Google Scholar] [CrossRef]

- Liu, H.; Zhu, J.; Liu, Y.; Lai, Z. First-principles study on the mechanical properties of vanadium carbides VC and V4C3. Mater. Lett. 2008, 62, 3084–3086. [Google Scholar] [CrossRef]

- Jiang, C. First-principles study of structural, elastic, and electronic properties of chromium carbides. Appl. Phys. Lett. 2008, 92, 041909. [Google Scholar] [CrossRef]

- Lv, Z.Q.; Dong, F.; Zhou, Z.A.; Jin, G.F.; Sun, S.H.; Fu, W.T. Structural properties, phase stability and theoretical hardness of Cr23−xMxC6 (M= Mo, W; x= 0 − 3). J. Alloys Compd. 2014, 607, 207–214. [Google Scholar] [CrossRef]

- Music, D.; Kreissig, U.; Mertens, R.; Schneider, J.M. Electronic structure and mechanical properties of Cr7C3. Phys. Lett. A 2004, 326, 473–476. [Google Scholar] [CrossRef]

- Henriksson, K.O.; Sandberg, N.; Wallenius, J. Carbides in stainless steels: Results from ab initio investigations. Appl. Phys. Lett. 2008, 93, 191912. [Google Scholar] [CrossRef]

- Yang, X.; Li, W.; Ma, J.; Hu, S.; He, Y.; Li, L.; Xiao, B. Thermo-physical simulation of the compression testing for constitutive modeling of GH4169 superalloy during linear friction welding. J. Alloys Compd. 2016, 656, 395–407. [Google Scholar] [CrossRef]

- Peng, X.; Su, W.; Xiao, D.; Xu, G. Investigation on Hot Workability of Homogenized Al-Zn-Mg-Cu Alloy Based on Activation Energy and Processing Map. JOM 2018, 70, 993–999. [Google Scholar] [CrossRef]

- Lin, Y.C.; Wu, X.Y.; Chen, X.M.; Chen, J.; Wen, D.X.; Zhang, J.L.; Li, L.T. EBSD study of a hot deformed nickel-based superalloy. J. Alloys Compd. 2015, 640, 101–113. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, K.; Jiang, S.; Zhou, H.; Zhao, C.; Yang, X. Dynamic recrystallization behavior of a γ′-hardened nickel-based superalloy during hot deformation. J. Alloys Compd. 2015, 623, 374–385. [Google Scholar] [CrossRef]

- Frost, H.J.; Ashby, M.F. Deformation—Mechanism Maps. In The Plasticity and Creep of Metals and Ceramics; Pergamon Press: Oxford, UK, 1982. [Google Scholar]

- Sellars, C.M.; McTegart, W.J. On the mechanism of hot deformation. Acta Metall. 1966, 14, 1136–1138. [Google Scholar] [CrossRef]

- Jonas, J.J.; Sellars, C.M.; Tegart, W.M. Strength and structure under hot-working conditions. Metall. Rev. 1969, 14, 1–24. [Google Scholar]

- Thomas, A.; El-Wahabi, M.; Cabrera, J.M.; Prado, J.M. High temperature deformation of Inconel 718. J. Mater. Process. Tech. 2006, 177, 469–472. [Google Scholar] [CrossRef]

| Spot | C | Fe | Mo | W | Co | Cr | V |

|---|---|---|---|---|---|---|---|

| 1 | 13.27 ± 1.80 | 16.70 ± 6.70 | 24.28 ± 1.16 | 2.39 ± 0.39 | - | 6.19 ± 0.19 | 37.17 ± 7.17 |

| 2 | 12.59 ± 2.34 | 8.68 ± 0.64 | 53.41 ± 1.49 | 7.66 ± 0.66 | - | 9.38 ± 0.38 | 8.28 ± 1.28 |

| 3 | 7.22 ± 1.22 | 74.69 ± 0.17 | 6.07 ± 0.79 | - | 7.67 ± 0.16 | 3.89 ± 0.89 | 0.46 ± 0.46 |

| 4 | 6.03 ± 0.39 | 67.53 ± 0.55 | 11.64 ± 1.64 | 2.37 ± 0.37 | 6.85 ± 0.85 | 4.57 ± 0.57 | 1.01 ± 0.14 |

| 5 | 15.02 ± 5.02 | 16.05 ± 6.05 | 46.66 ± 6.66 | 8.34 ± 0.34 | 0.31 ± 0.31 | 6.16 ± 0.16 | 7.46 ± 0.66 |

| Spot | C | Fe | Mo | W | Co | Cr | V |

|---|---|---|---|---|---|---|---|

| 1 | 13.24 ± 3.24 | 10.97 ± 0.81 | 21.87 ± 1.47 | 2.34 ± 0.43 | - | 5.78 ± 0.78 | 45.80 ± 5.90 |

| 2 | 5.47 ± 0.47 | 75.19 ± 5.19 | 5.48 ± 0.48 | 1.87 ± 0.19 | 7.58 ± 0.58 | 3.78 ± 0.78 | 0.63 ± 0.63 |

| 3 | 7.43 ± 1.73 | 34.09 ± 4.09 | 39.40 ± 1.40 | 8.96 ± 0.96 | 1.66 ± 0.24 | 5.05 ± 0.53 | 3.41 ± 0.41 |

| 4 | 11.18 ± 1.18 | 11.76 ± 1.76 | 51.73 ± 1.73 | 8.90 ± 0.90 | - | 6.93 ± 0.93 | 9.50 ± 0.15 |

| Carbides | Space Group | a | b | c | C11 | C12 | C13 | C33 | C44 | C66 |

|---|---|---|---|---|---|---|---|---|---|---|

| Mo2C | P63/mmc | 3.060 | 3.060 | 4.655 | 506.2 | 138.1 | 193.3 | 474.3 | 184.0 | 132.1 |

| Fe2Mo4C | Fdm | 11.422 | 11.422 | 11.422 | 391.4 | 148.9 | - | - | 106.1 | - |

| VC | Fmm | 4.175 | 4.175 | 4.175 | 611.5 | 145.3 | - | - | 156.8 | - |

| Cr7C3 | P63/mmc | 6.957 | 6.957 | 4.451 | 504.2 | 211.7 | 254.0 | 402.0 | 146.2 | 130.6 |

| Cr23C6 | Fmm | 10.754 | 10.7546 | 10.754 | 485.2 | 200.0 | - | - | 139.6 | - |

| Carbides | B | G | B/G | E |

|---|---|---|---|---|

| Mo2C | 281.8(336.0 g) | 153.8(181.6 g) | 1.83 | 390.4(461.6 g) |

| Fe2Mo4C | 229.7 | 112.2 | 2.05 | 289.4 |

| VC | 300.7(293.1 g,290.9 b) | 187.3(176.9 g,215.5 b) | 1.61 | 465.3(441.7 g,518.5 b) |

| Cr7C3 | 316.6(300.6 a,311.7 e) | 127.5(118 a) | 2.48 | 337.2(313 a) |

| Cr23C6 | 295.1(282.3 a,300 c,294 f) | 140.8(145.4 a,136 d,137 c) | 2.09 | 364.5(357 c,372.3 a) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, Y.; Guo, H.; Guo, J.; Yang, W. Gleeble-Simulated and Semi-Industrial Studies on the Microstructure Evolution of Fe-Co-Cr-Mo-W-V-C Alloy during Hot Deformation. Materials 2018, 11, 2577. https://doi.org/10.3390/ma11122577

Luo Y, Guo H, Guo J, Yang W. Gleeble-Simulated and Semi-Industrial Studies on the Microstructure Evolution of Fe-Co-Cr-Mo-W-V-C Alloy during Hot Deformation. Materials. 2018; 11(12):2577. https://doi.org/10.3390/ma11122577

Chicago/Turabian StyleLuo, Yiwa, Hanjie Guo, Jing Guo, and Wensheng Yang. 2018. "Gleeble-Simulated and Semi-Industrial Studies on the Microstructure Evolution of Fe-Co-Cr-Mo-W-V-C Alloy during Hot Deformation" Materials 11, no. 12: 2577. https://doi.org/10.3390/ma11122577

APA StyleLuo, Y., Guo, H., Guo, J., & Yang, W. (2018). Gleeble-Simulated and Semi-Industrial Studies on the Microstructure Evolution of Fe-Co-Cr-Mo-W-V-C Alloy during Hot Deformation. Materials, 11(12), 2577. https://doi.org/10.3390/ma11122577