1. Introduction

The research on the reuse of waste substances carried out to date has brought many positive results, which have been successfully implemented for industrial activities. An example is fly ash being used as a pozzolanic material in concrete [

1] or as a component of geopolymers [

2]. Another industrial waste is sludge produced in sewage treatment plants. Suchorab et al. [

3] used a sewage sludge to obtain lightweight aggregates for use in concrete. Also, agricultural waste is used for the production of building materials, for example, from industrial hemp cultivations. Brzyski et al. [

4,

5] used pieces of the wooden core of hemp stalks (hemp shives) together with lime binder to obtain a thermal insulating composite for use as wall material. The issue increasingly being considered in scientific communities is the rational management of the construction waste. This issue also concerns ceramic materials. The use of ceramic waste as a modifier and its addition to concrete dates back to ancient times. In ancient Rome, sometimes, crushed tiles and bricks in the form of powder were used as mortar components [

6]. In the modern era, the aggregates from crushed building elements began to be re-used in concrete production after World War II. This was due to the large amount of debris remaining after war. The addition of ceramic bricks to concrete has even been regulated by the German standard DIN 4163: “Concrete with contrite bricks—specification of production and use” in 1951 [

7]. The current research on the use of red ceramics in concrete is mainly focused on the ecological effect and also on the physical and mechanical properties of this ceramic waste concrete [

6,

8,

9,

10,

11,

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25].

Gonzalez et al. [

8] manufactured structural concrete using recycled brick aggregates and stated that it was possible to produce concrete characterized by medium strength using a high percentage of aggregates obtained from recycled brick. Gonzales et al. [

9] investigated the effect of ceramic aggregates on the properties of high-performance concrete and showed that concrete produced with up to 30% fine red ceramic aggregates achieved similar or improved mechanical and durability properties to those of conventional concrete with natural aggregates. Utilization of waste ceramics as coarse aggregate in standard-strength structural concrete was also investigated by Anderson et al. [

10]. Torkittikul et al. [

11] used ceramic waste in the form of fine aggregate to produce Portland cement and fly ash concrete. He noticed that the compressive strength of the ceramic waste concrete increased with the ceramic waste content and was optimal at 50% for the control concrete. Improving the 28-day strength of concrete containing 75% of the ceramic waste aggregate as a substitute for natural aggregate was also noted by Awoyera et al. [

12]. In turn, Cabrera-Covarrubias et al. [

13] used fine ceramic aggregates as a partial replacement for natural sand in mortars and proved that the compressive and flexural strengths of the recycled mortars decrease proportionally to the amount of natural sand replacement used. The influence of replacing the sand with fine red ceramic aggregate was also studied by Silva et al. [

14]. The results showed that the maximum proportion of ceramic aggregate that has a positive effect on mortar properties is 20%. A similar observation was described in [

15], where replacing the traditional aggregate with ceramic aggregate (crushed roof tiles) in amounts above 30% resulted in a decrease in the compressive strength of the mortar. Vieria et al. [

16] proved that as the content of fine red ceramic aggregate in the concrete increases, the concrete’s resistance to shrinkage decreases.

Other research results present the work carried out on the concretes made from precious white ceramic [

25,

26,

27,

28,

29,

30,

31,

32]. This type of material, obtained from the waste elements of sanitary or technical (e.g., electrical insulators) ceramic is important because of the beneficial effect on the concrete features [

25,

26,

27,

28,

29,

30,

31,

32]. The results show that the greater the addition of the ceramic aggregate, the higher the strength parameters of the concrete [

29]. Interesting features of the concrete formed with the use of cullet sanitary aggregates, the composition of which is similar to the one of ceramic electrical insulators, are shown in paper [

30]. To provide economic justification of the work, the authors look for special applications of this type of concrete. The results show that it can be successfully used under the conditions in which the concrete is exposed to high temperatures or in the places where a high abrasion resistance is required. Despite the fact that there has been no comprehensive experimental research conducted on elements made of concrete prepared with recycled precious ceramic aggregates, it is expected that this trend can be implemented in industry. Sanitary ceramic aggregates have also been used in the production of innovative mineral-asphalt mixtures [

32].

Ceramic waste is also used in powder form. Kannan et al. [

33] used it as a partial replacement of Portland cement, and stated that producing high-performance concrete could be an excellent source for recycling large quantities of ceramic waste powder. In turn, El-Dieb et al. [

34] proved that the use of a 10% ceramic waste powder replacement (of Portland cement) level was adequate for strength improvement, and replacement levels between 10% and 20% could be used to improve the workability retention of concrete. Kulovana et al. [

35] proved that the optimal amount of ceramic powder in the mix is 20% of the cement mass in the case of compressive strength, liquid water transport parameters and resistance to de-icing salts.

An important issue related to the durability of concretes is its resistance to aggressive chemical environments. Under the influence of external factors, concrete is often exposed to the destruction associated with the impact of harmful chemical compounds. Harmful environments may be related to the presence of gaseous pollutants (e.g., carbon dioxide, sulfur dioxide), mineral acids (e.g., sulfuric acid, hydrochloric acid) or organic acids (e.g., lactic or acetic acid) [

36,

37,

38]. The chemical attack may vary depending on the environment to which the concrete is exposed. Aggressive environments could be, for example, acid rain, or pollution from chemical plants. The degree of building material deterioration is dependent on the acid concentration in the surrounding environment [

39]. Municipal sewage also constitutes an aggressive environment. Among others, prefabricated concrete pipes are used for the discharge of sewage. Repairing corroded sewer pipes is a serious problem. The main source of deterioration is the effect of sulfides and hydrogen sulfide. The most dangerous compound in municipal sewage is H

2S. After oxidation of this compound by aerobic bacteria, sulfuric acid is formed, which destroys concrete surfaces. [

40]. There are certain techniques to improve the durability of concrete pipes, such as lowering the concentration of sulfide in wastewater by adding iron [

41], making protective coatings on the concrete surface [

42], or increasing the pH of the concrete surface by spraying with magnesium hydroxide [

43]. Li et al. [

44] proved that the resistance of concrete to the attack of sulfuric acid depends mainly on the amount of Ca(OH)

2 produced during the hydration of the cement; therefore, it was proved [

45] that the addition of pozzolanic components increases the resistance of the concrete to the sulfuric acid attack. Recycled aggregate is increasingly frequently used in concrete production (e.g., ceramic aggregates mentioned earlier). Therefore, there is a need to examine such concretes for chemical attack resistance, whether their presence will improve or degrade the durability of concretes. Higashiyama et al. [

17] investigated the resistance of mortars with ceramic waste to chloride penetration and stated that the ceramic waste mortar significantly resists the chloride ingress in comparison with the river sand mortar. Gonzales et al. [

9] proved that after 180 days of curing, the concretes produced with up to 50% content of coarse mixed aggregates (including waste from brick masonry and concrete) achieved low chloride corrosion risk. In turn, Medina [

26] showed that chloride penetration was slightly deeper in recycled concretes based on sanitary ceramic aggregates in relation to concrete based on traditional aggregates. Vieira et al. [

16] proved that in mixes with fine sanitary ceramic aggregates, chloride ion penetration is higher than in the case of concretes based on red ceramic aggregates, because of the more porous microstructure of sanitary ceramics. The resistance to an aggressive environment of the concrete with the addition of other aggregates from recycling was investigated by Thomas et al. [

46]. These studies showed that the high-strength rubberized concrete is highly resistant to the aggressive sulfuric acid environments. Araghi et al. [

47], on the other hand, tested the recycled concrete based on poly(ethylene terephthalate) (PET) particles and showed that its weight loss after immersion in 5% sulfuric acid solution decreases as the content of PET particles increases. Sofi [

48] tested the durability of recycled concrete based on waste tyre rubber, and proved that the reduction in its weight and compressive strength after acid attack decreases as the content of waste tyre rubber increases. Yang et al. [

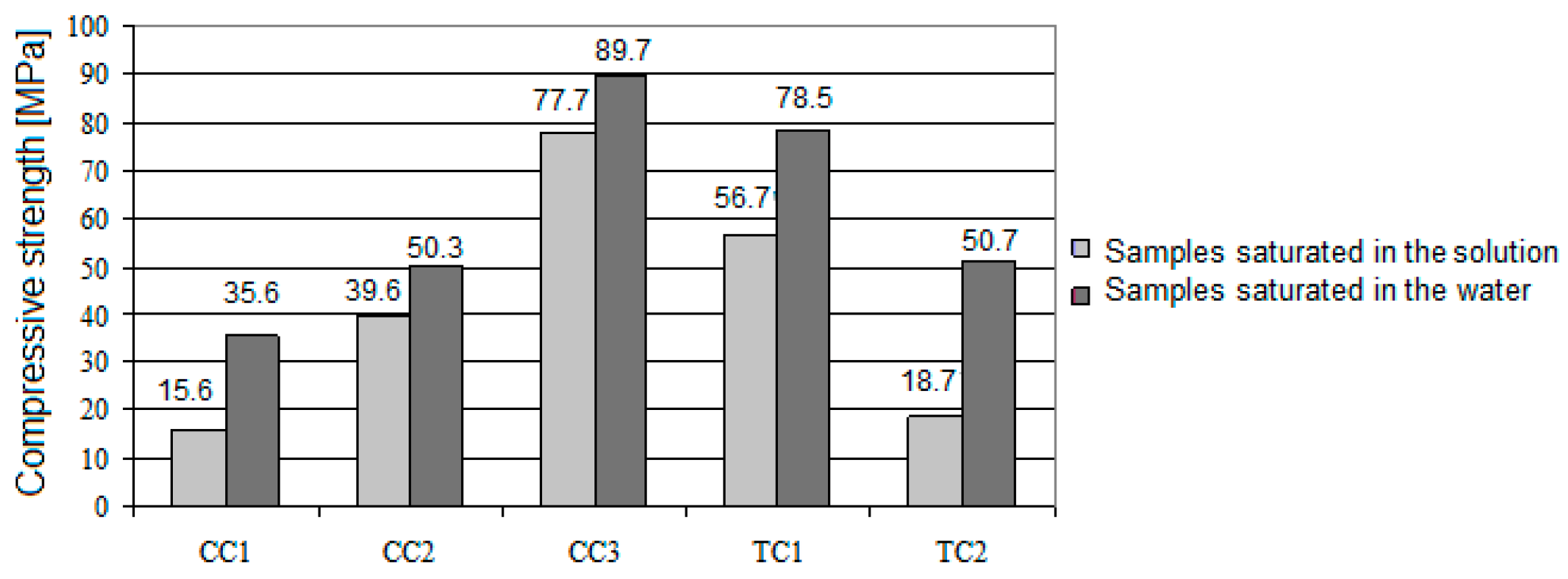

49] proved that replacing the river sand with sea sand and fresh water with sea water results in the increase of the concrete’s resistance to sulfuric acid.

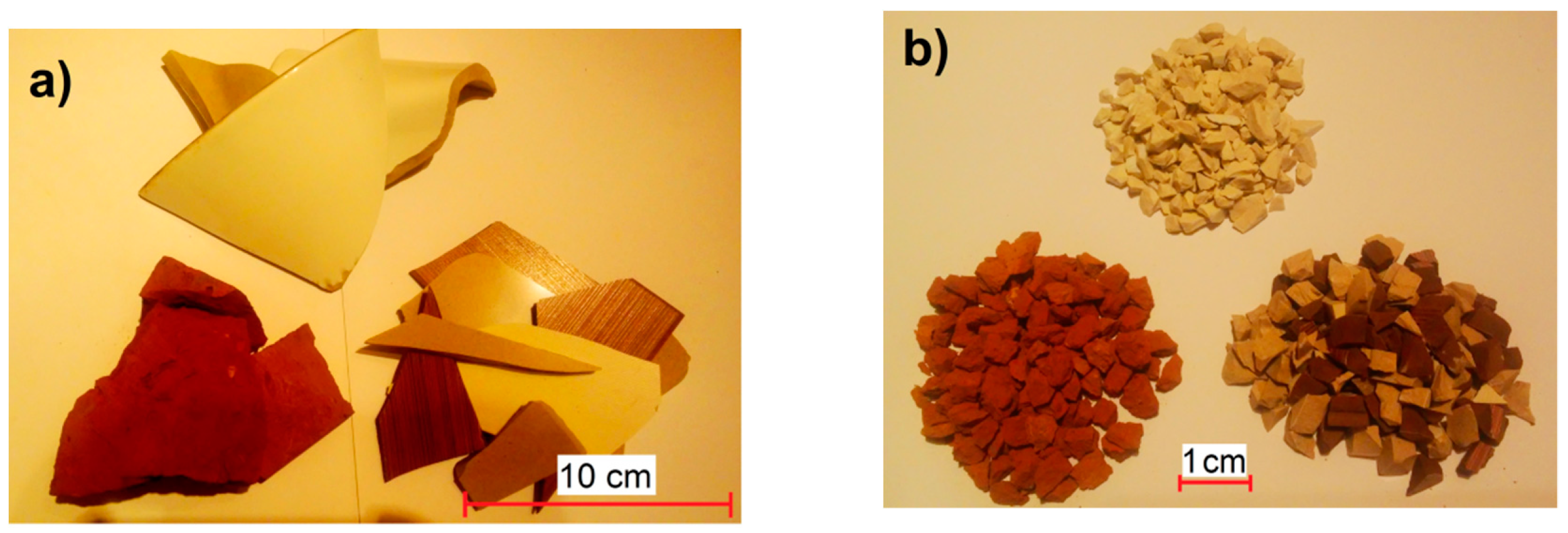

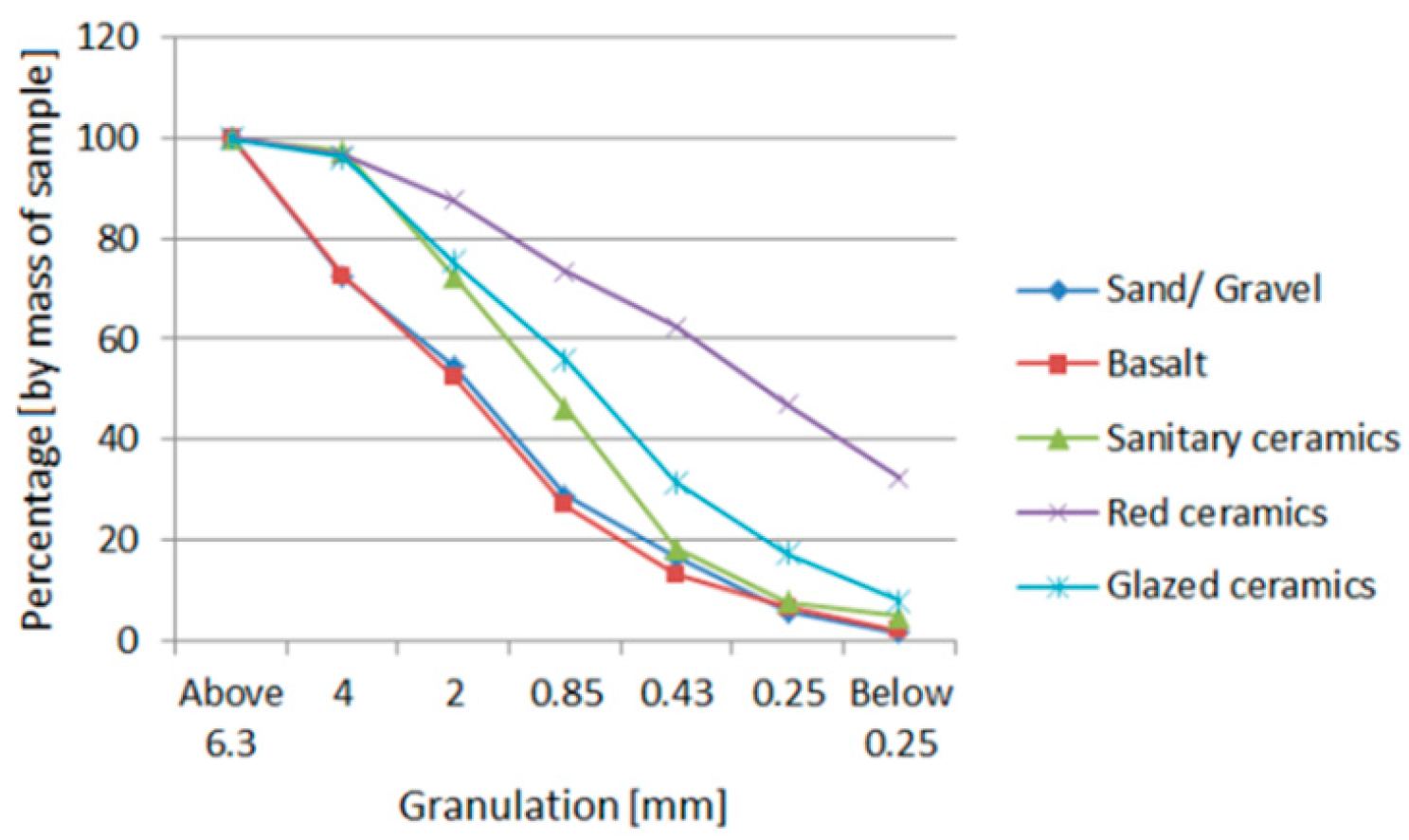

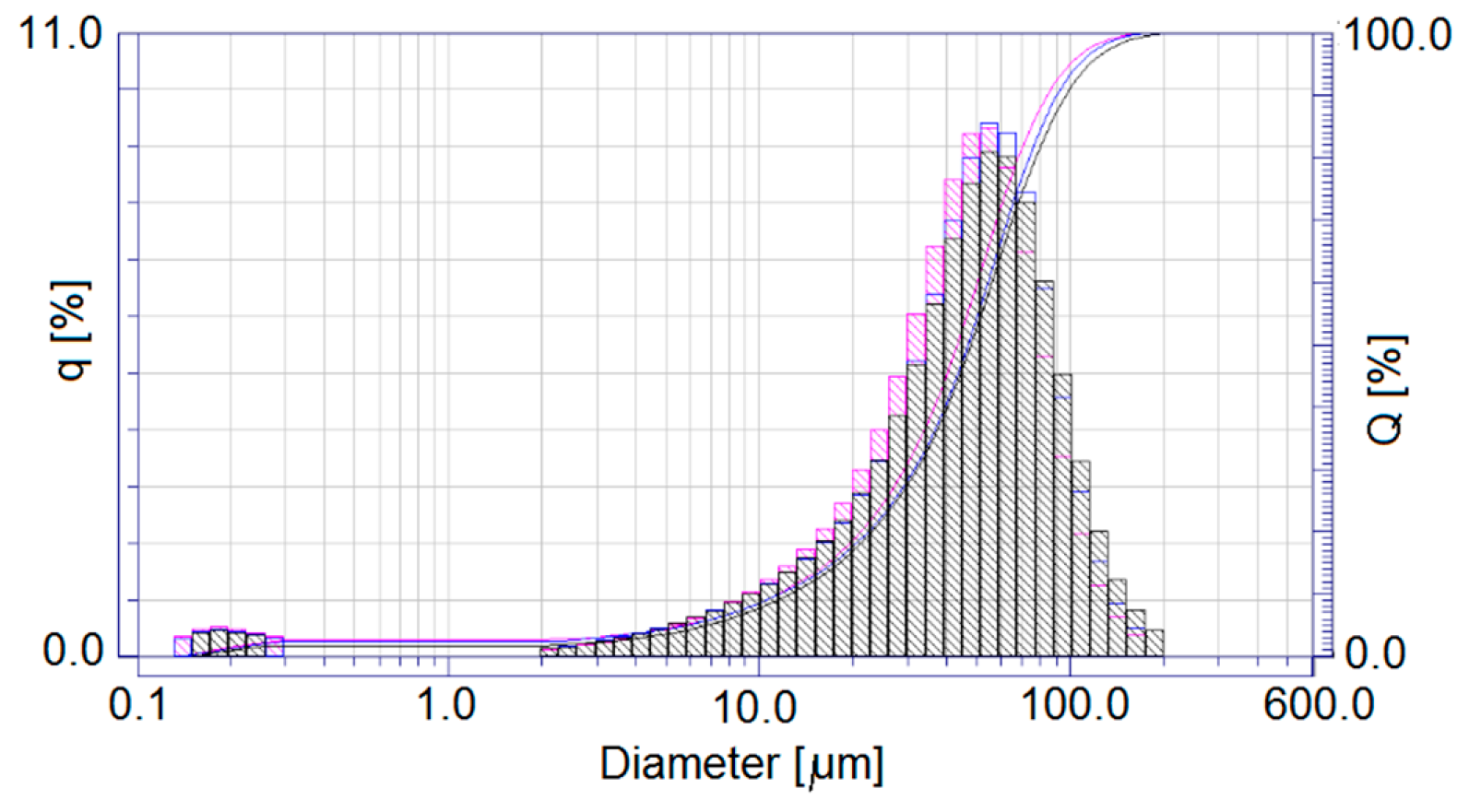

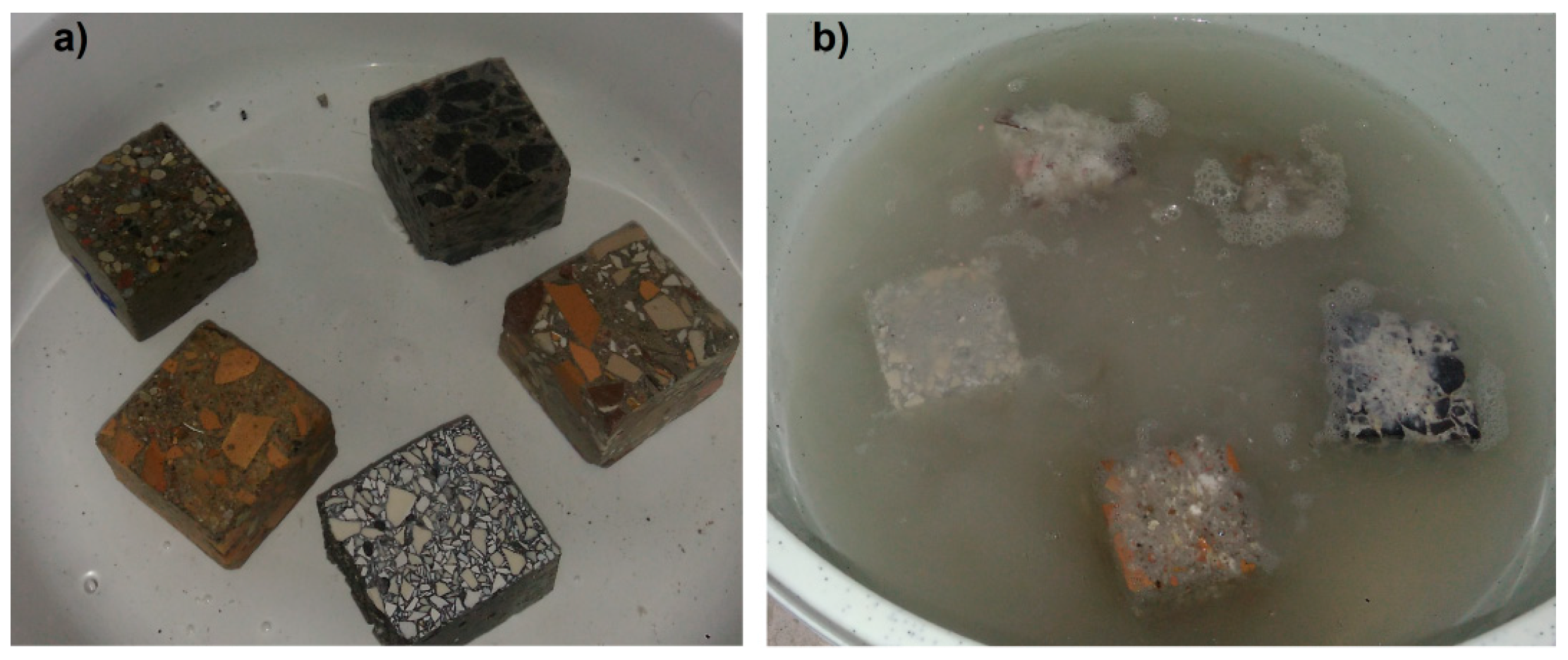

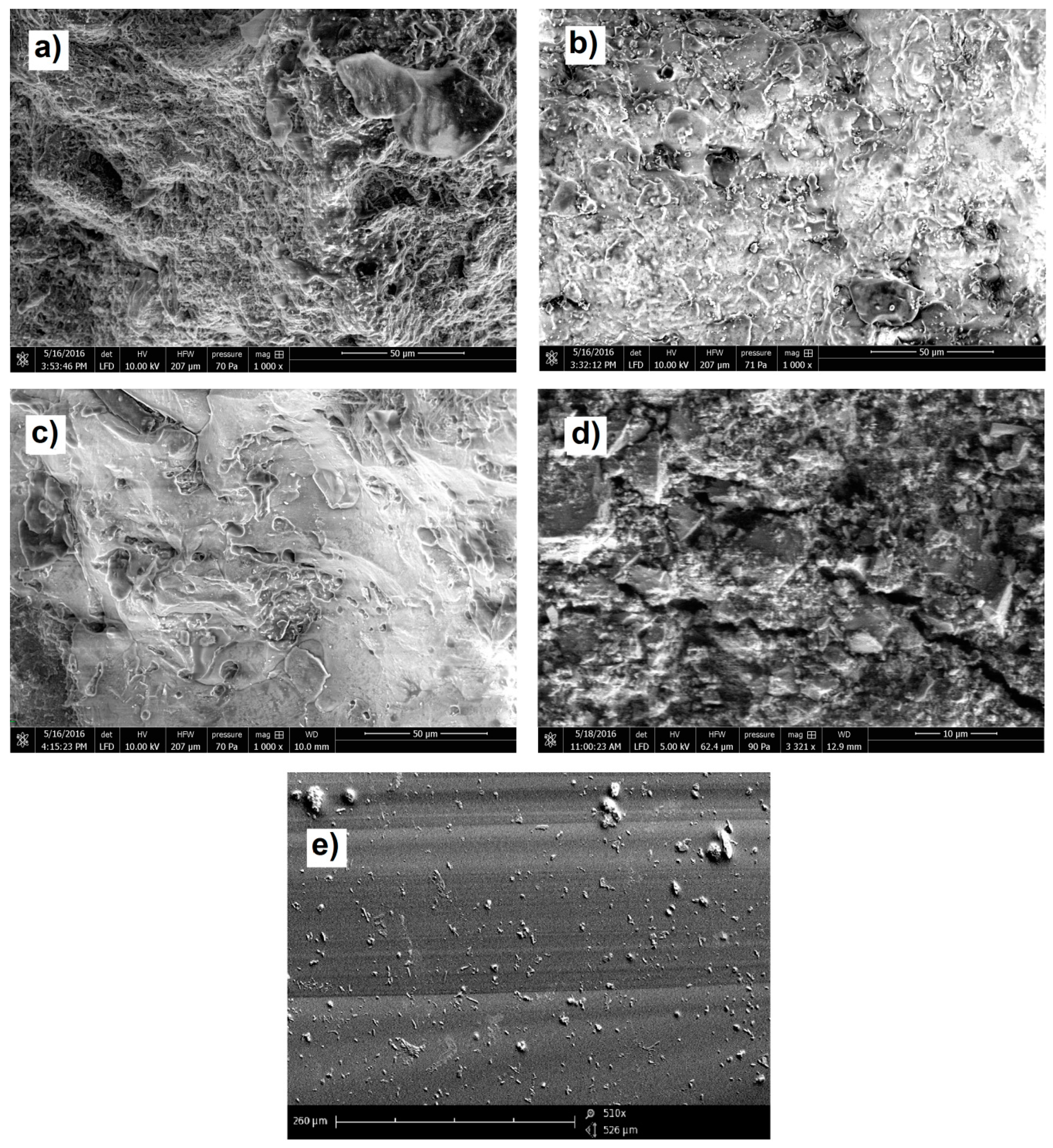

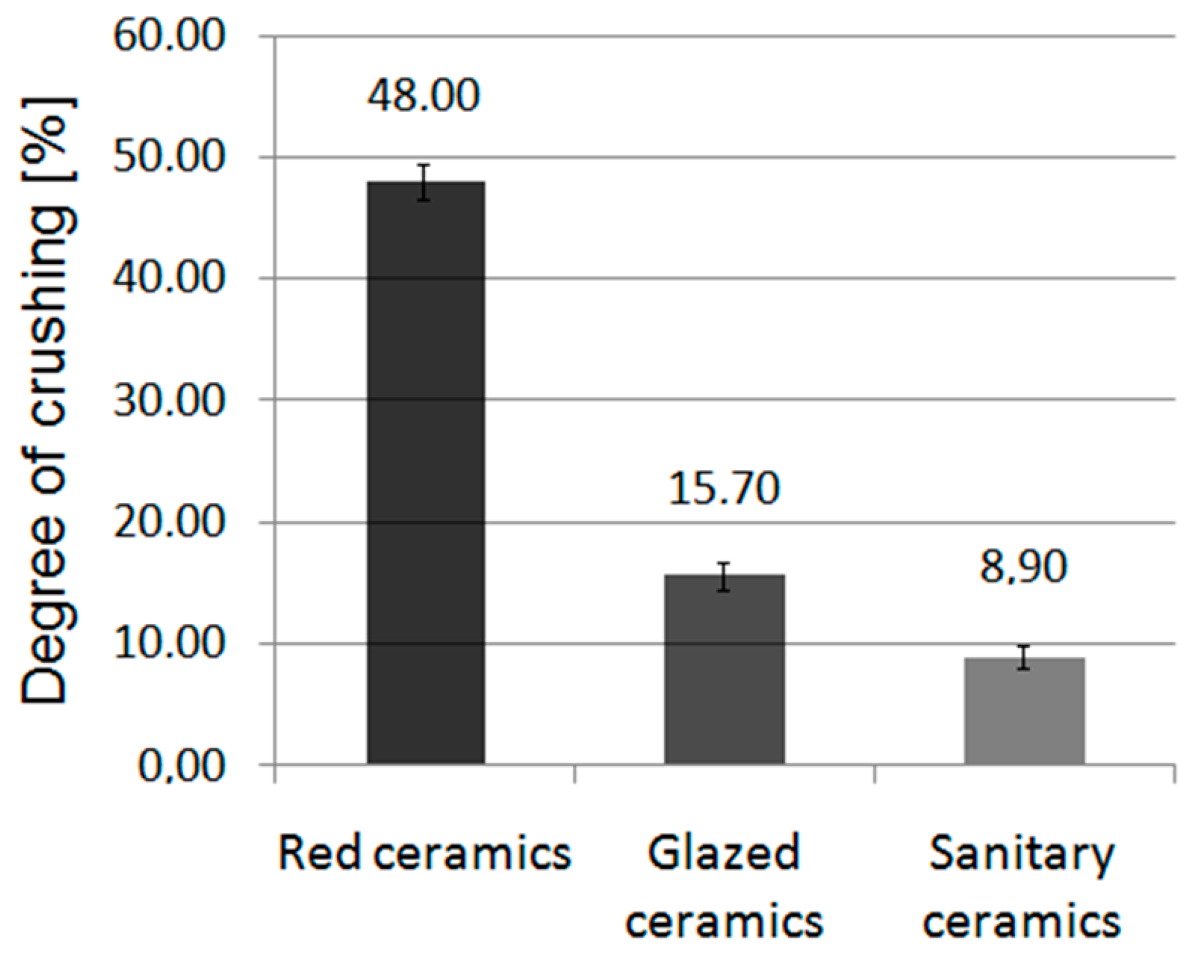

This work is a continuation of the previously conducted research, in which attention was focused on the waste ceramic matter obtained from sanitary ware products [

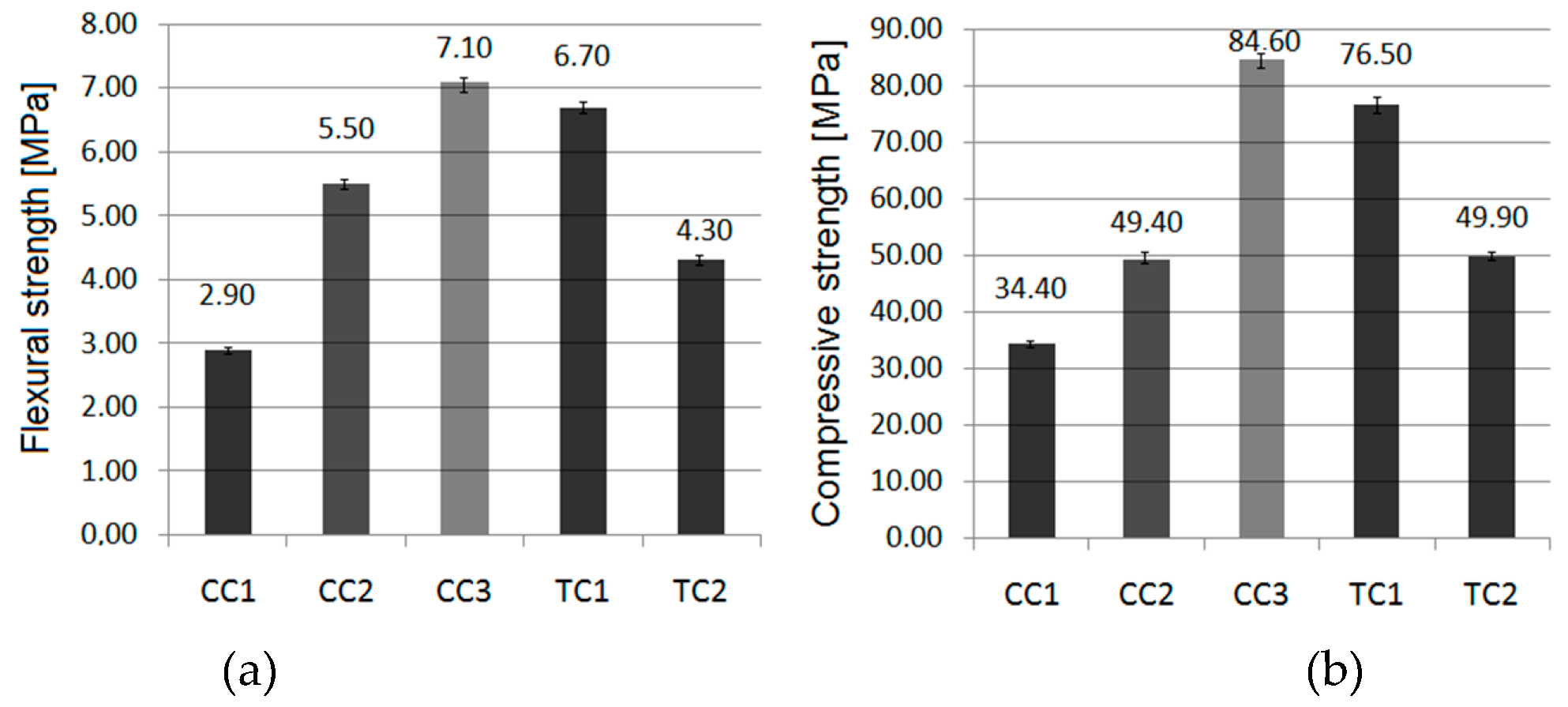

26]. The article presents the waste ceramic products that have been proposed as a substrate for the industrial production of concrete for use in the production of sewer pipes for the discharge of municipal sewage. The suitable ratio of coarse to fine aggregates was selected, their density, absorptivity and crushing strength were examined. The aim of the research was to select specific types of ceramic construction waste (from three different kinds of ceramic products), determine their basic parameters, attempt to produce aggregate concrete, evaluate the basic parameters of the obtained concretes (consistency of fresh mix, apparent density, absorptivity, flexural and compressive strength) and evaluate the effect of modification of aggregate composition on the concretes resistance to aggressive environment.

The analysis of the results allowed the authors to identify the technical and environmental aspects of recycling ceramic waste material.