Modification of a Defect-Based Fatigue Assessment Model for Al-Si-Cu Cast Alloys

Abstract

1. Introduction

- Experimental investigation of the impact of local defect population on the fatigue behaviour of Al-Si-Cu cast alloys.

- Estimation of crack initiation lifetime based on experimental analysis using in situ XCT scans.

- Extension of the fatigue lifetime model by Tiryakioglu [12] to additionally assess the fatigue strength in the long-life region.

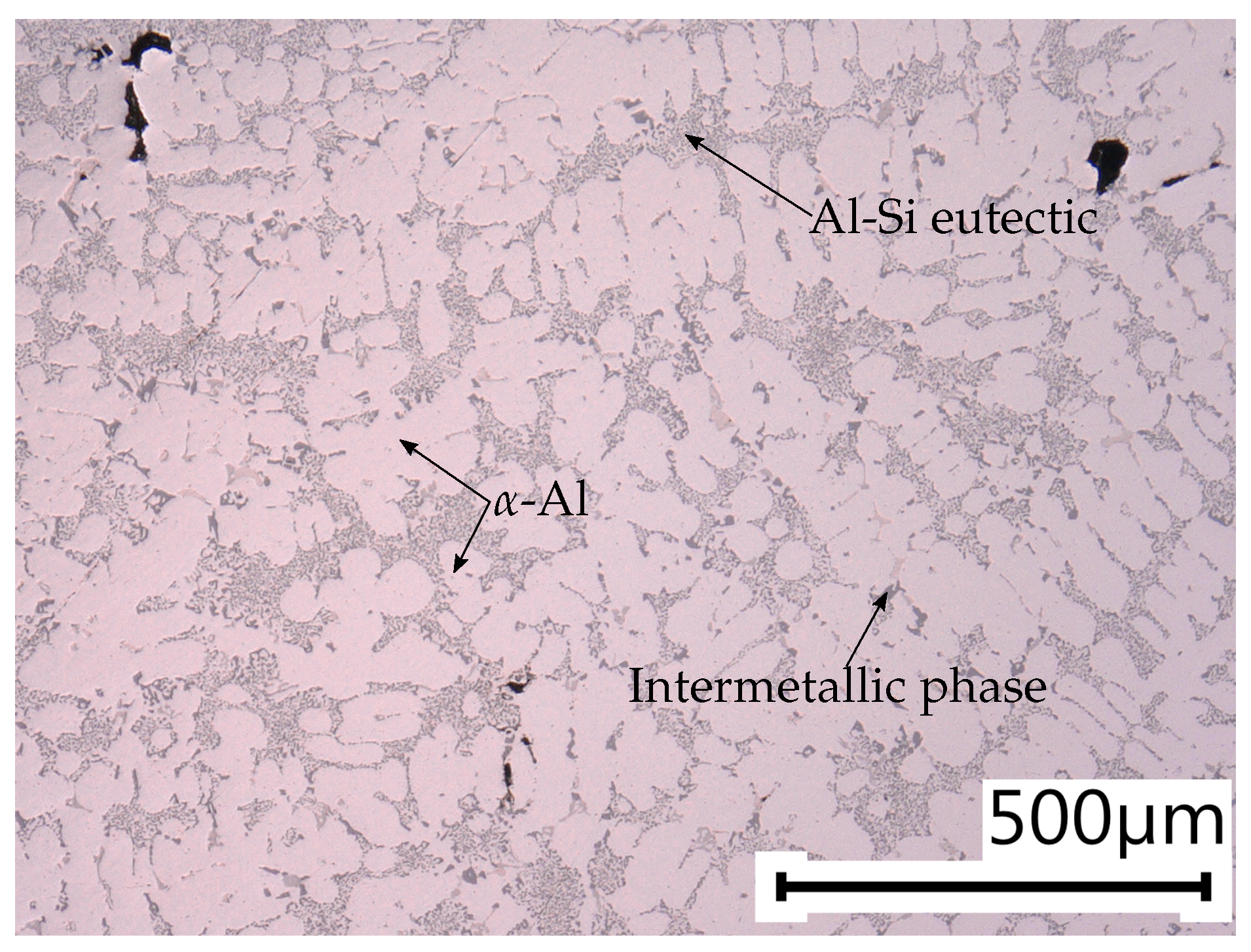

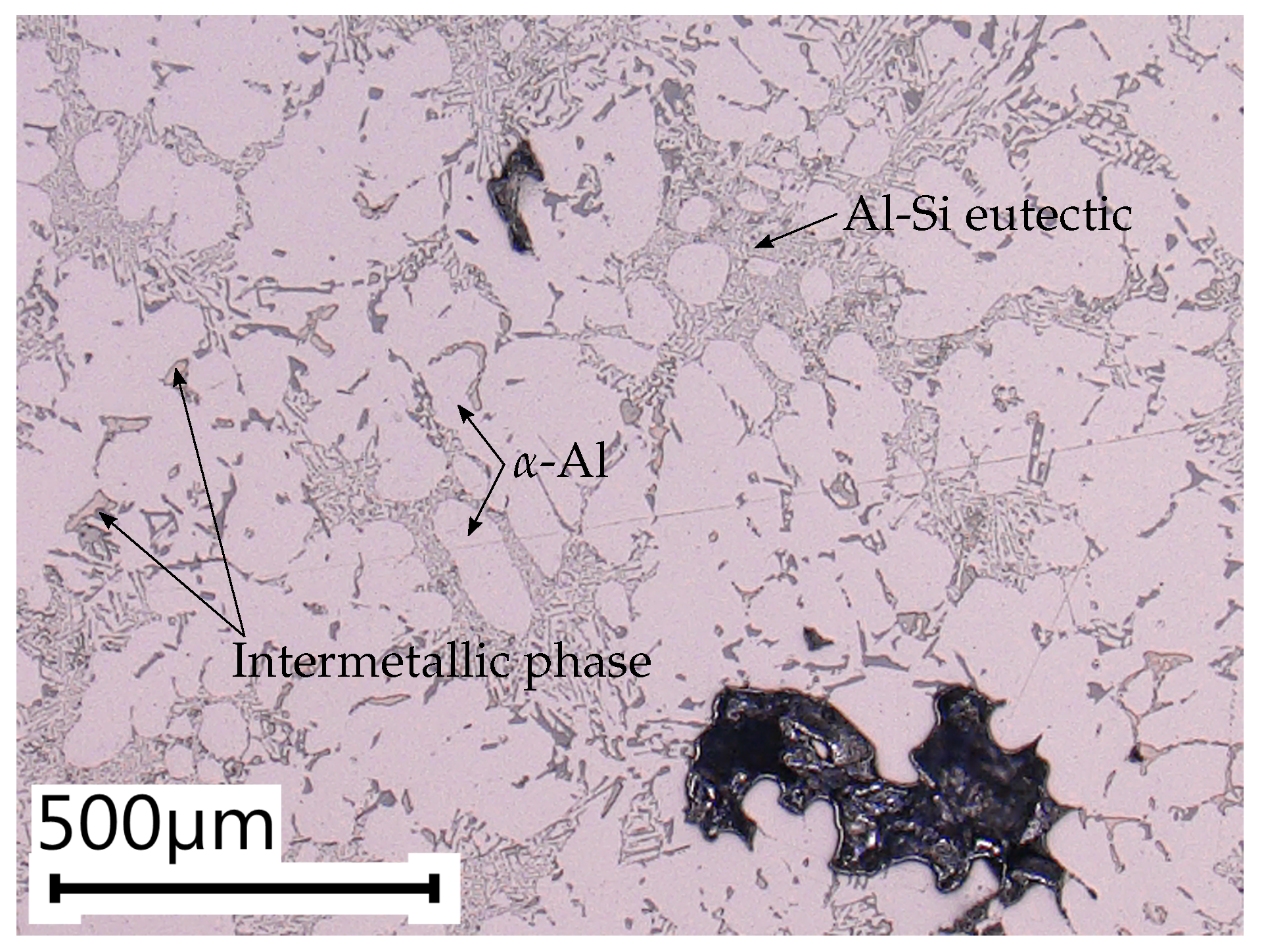

2. Materials and Methods

3. Results

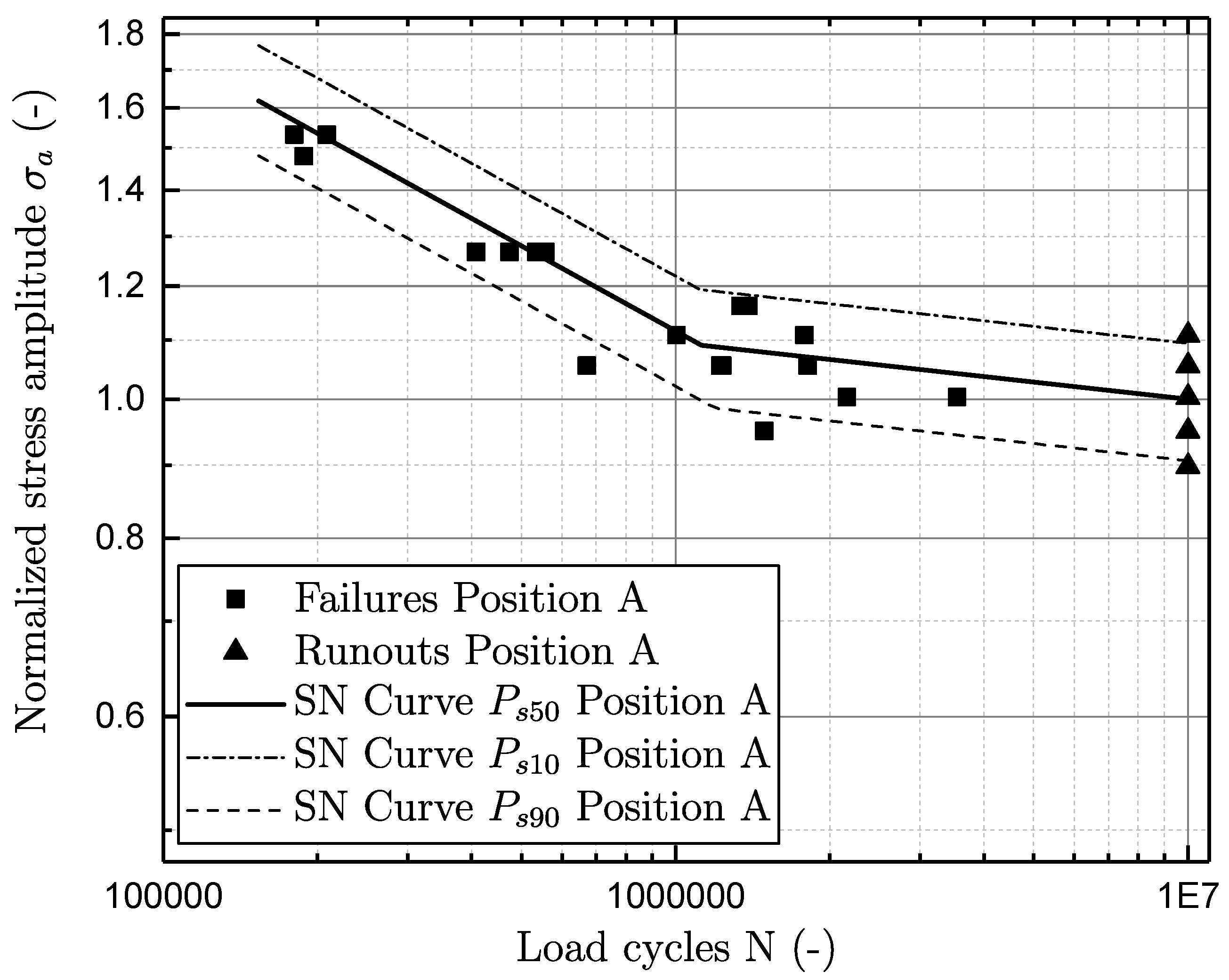

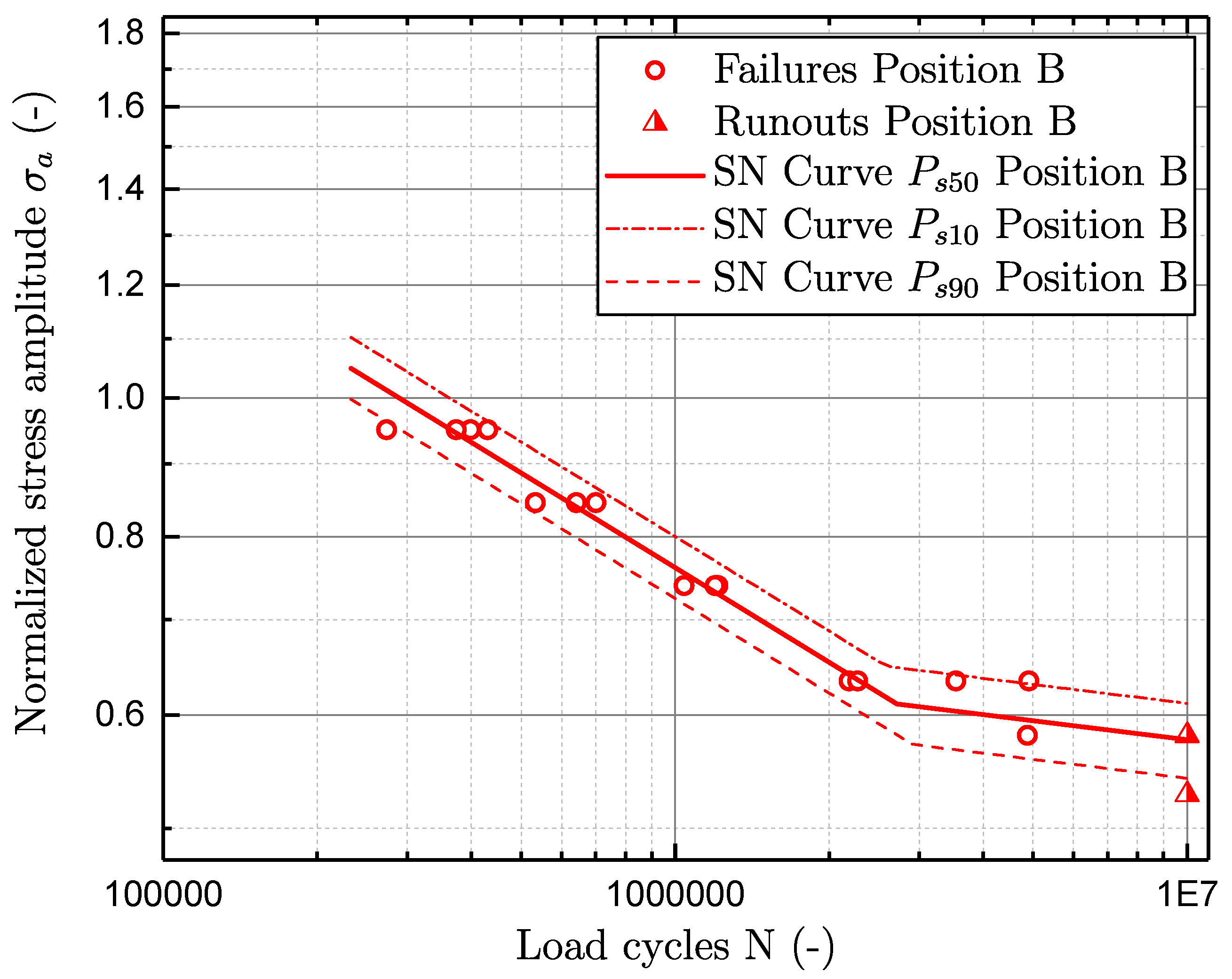

3.1. Fatigue and Quasi-Static Testing

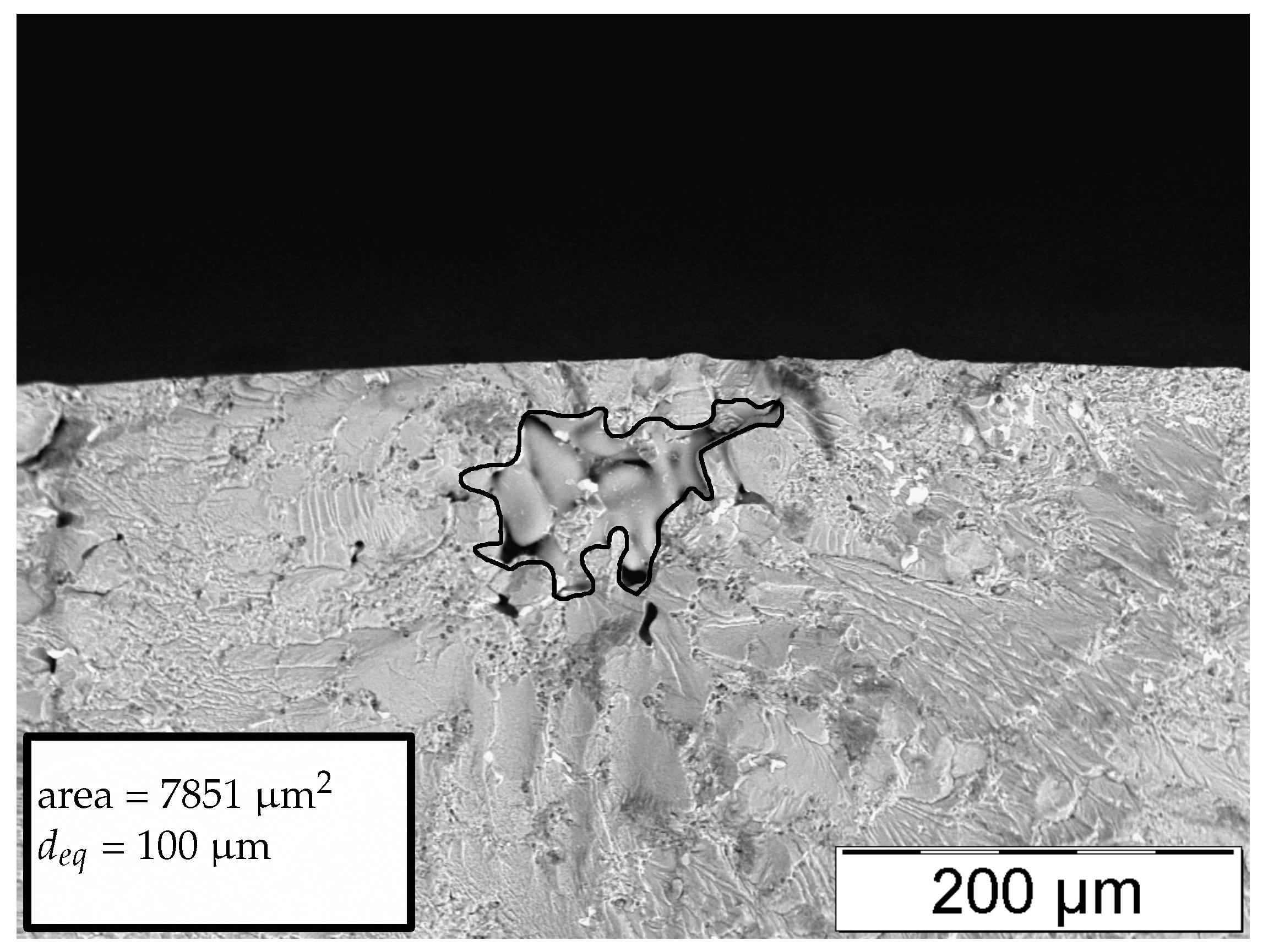

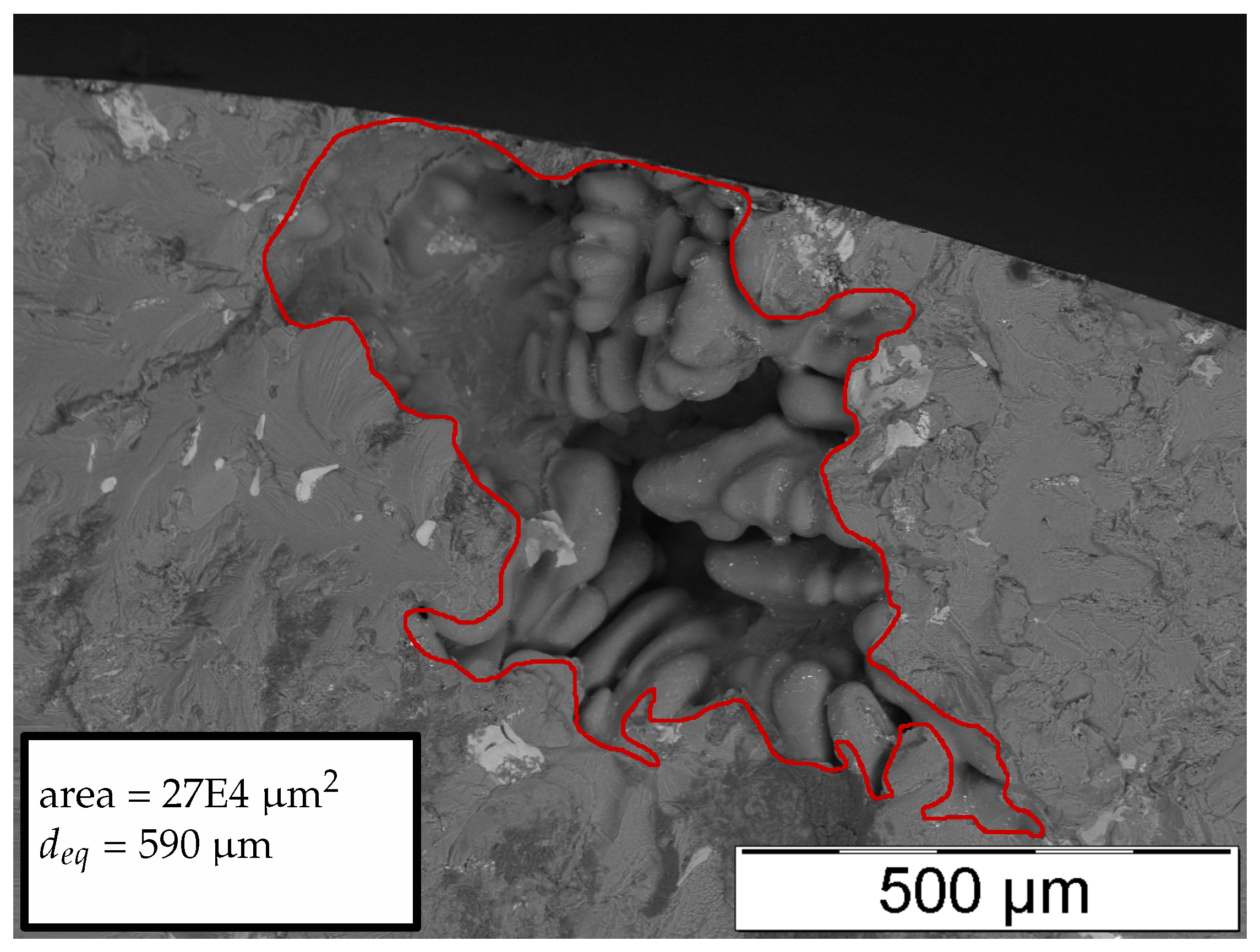

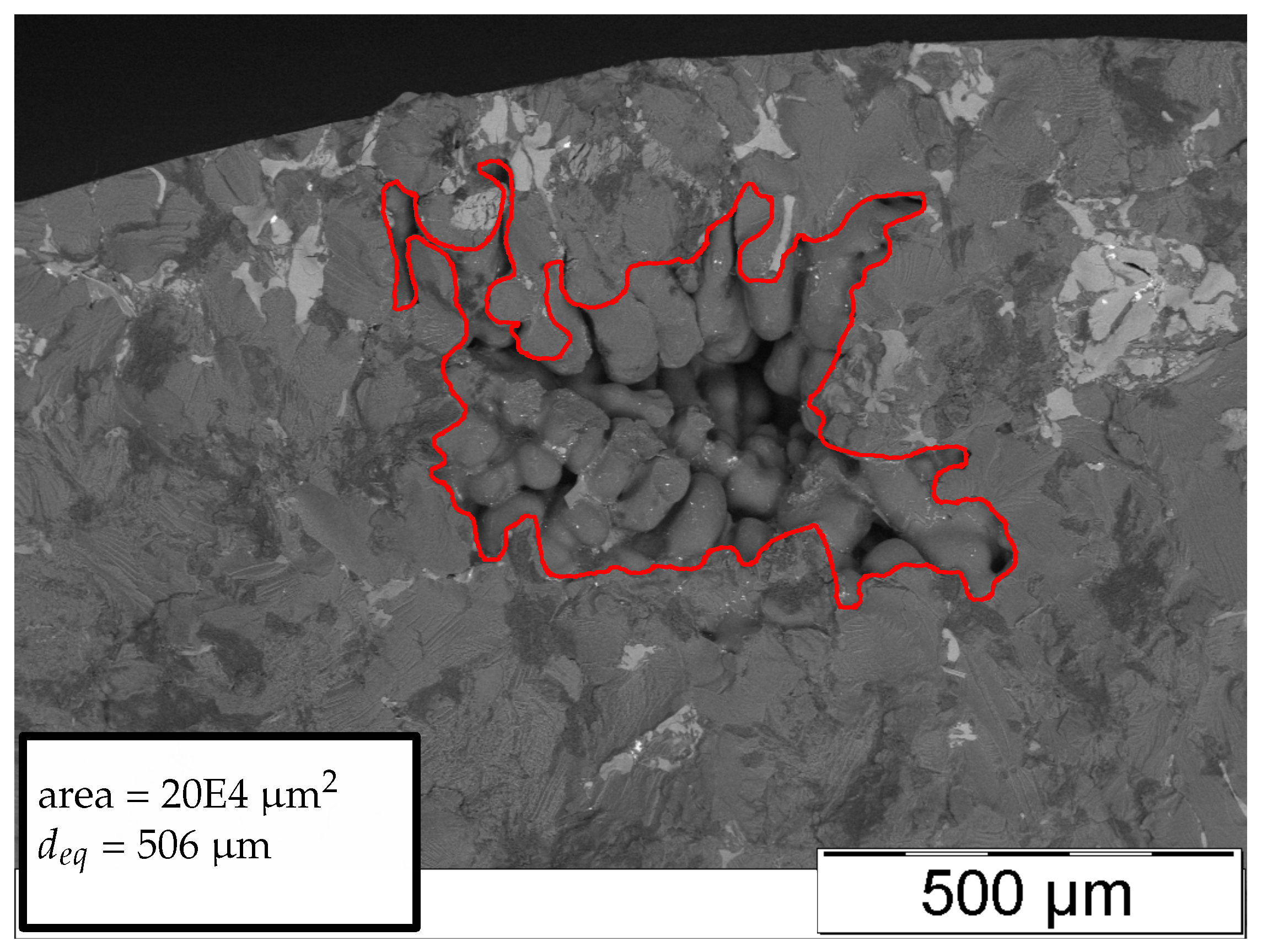

3.2. Fractography

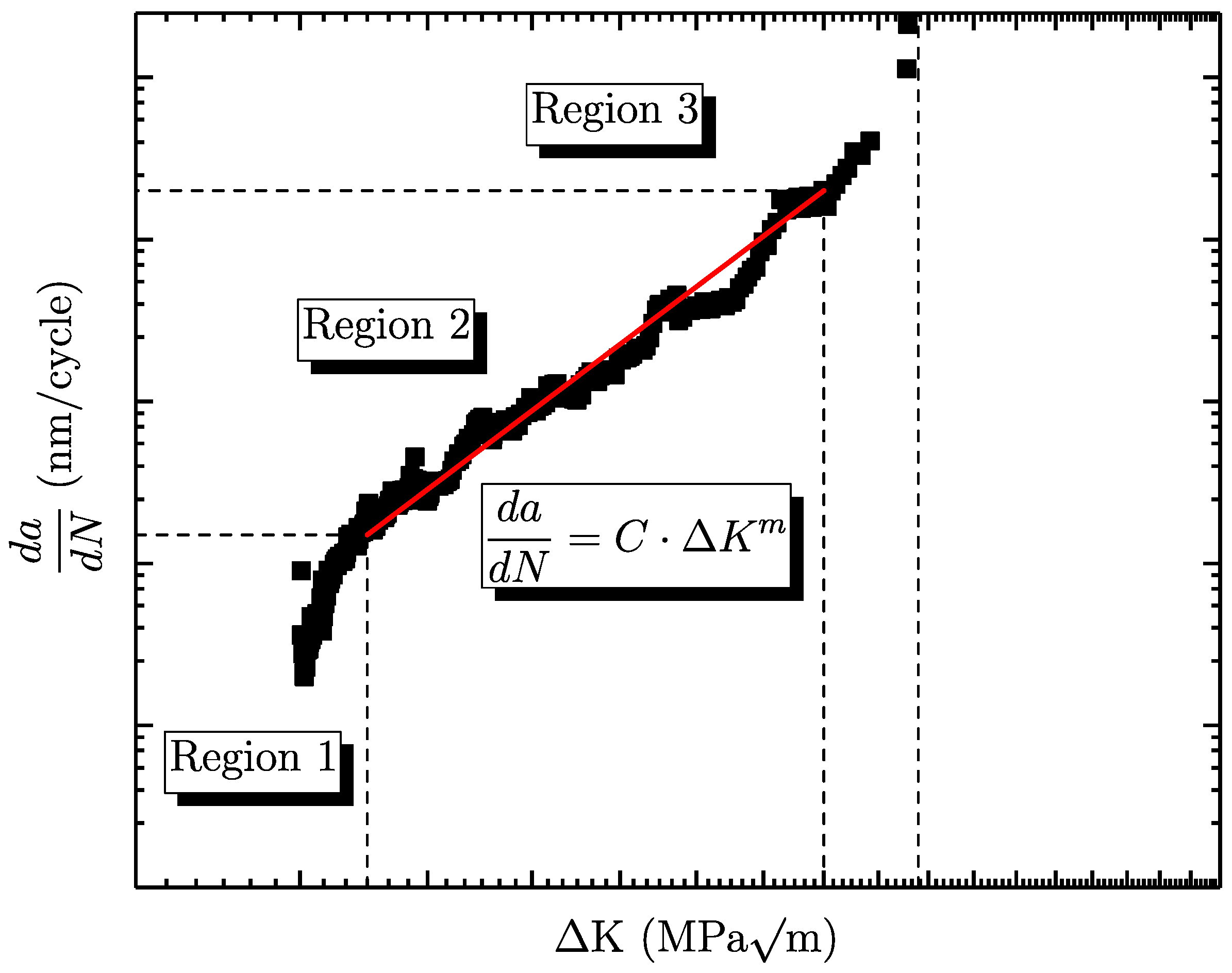

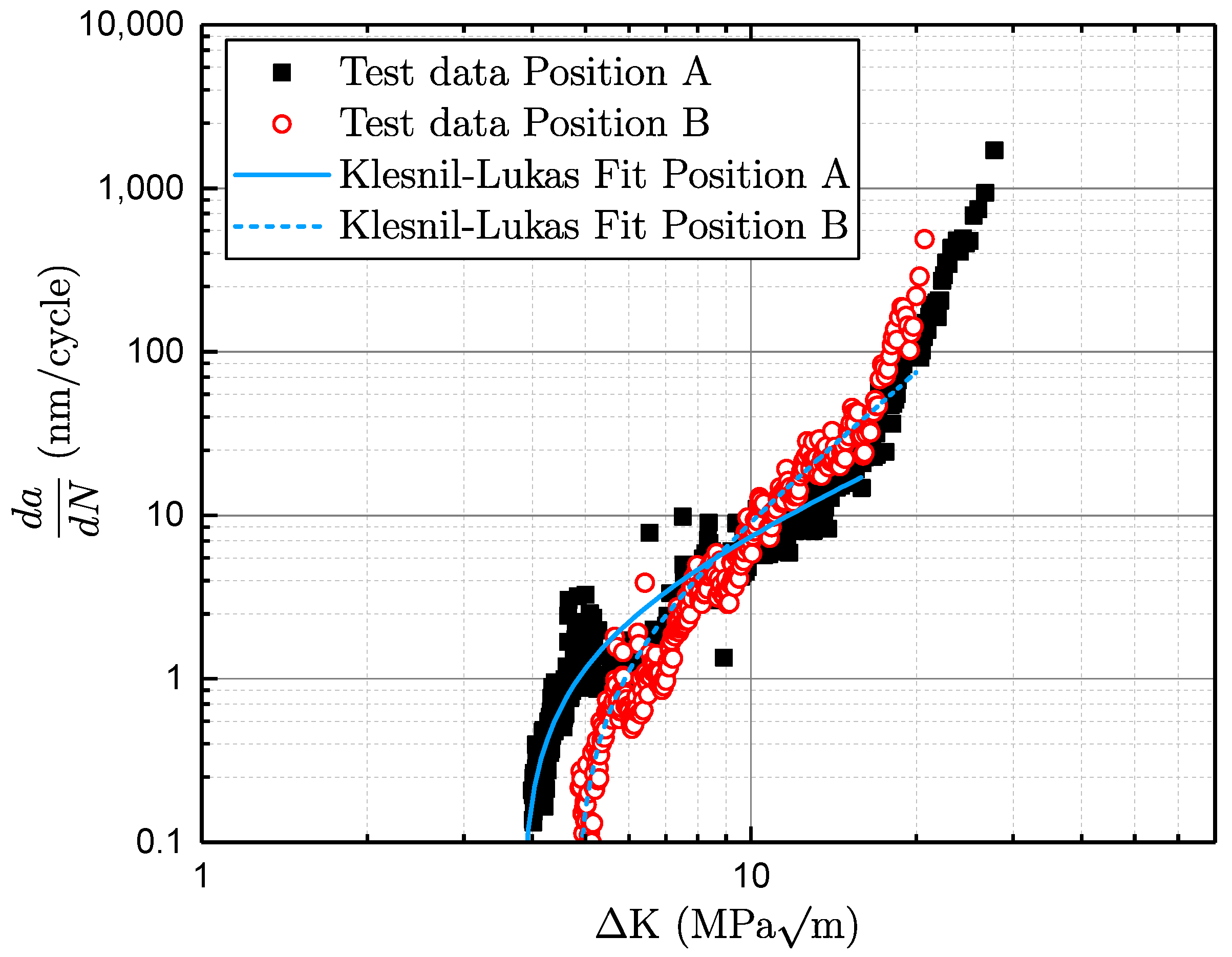

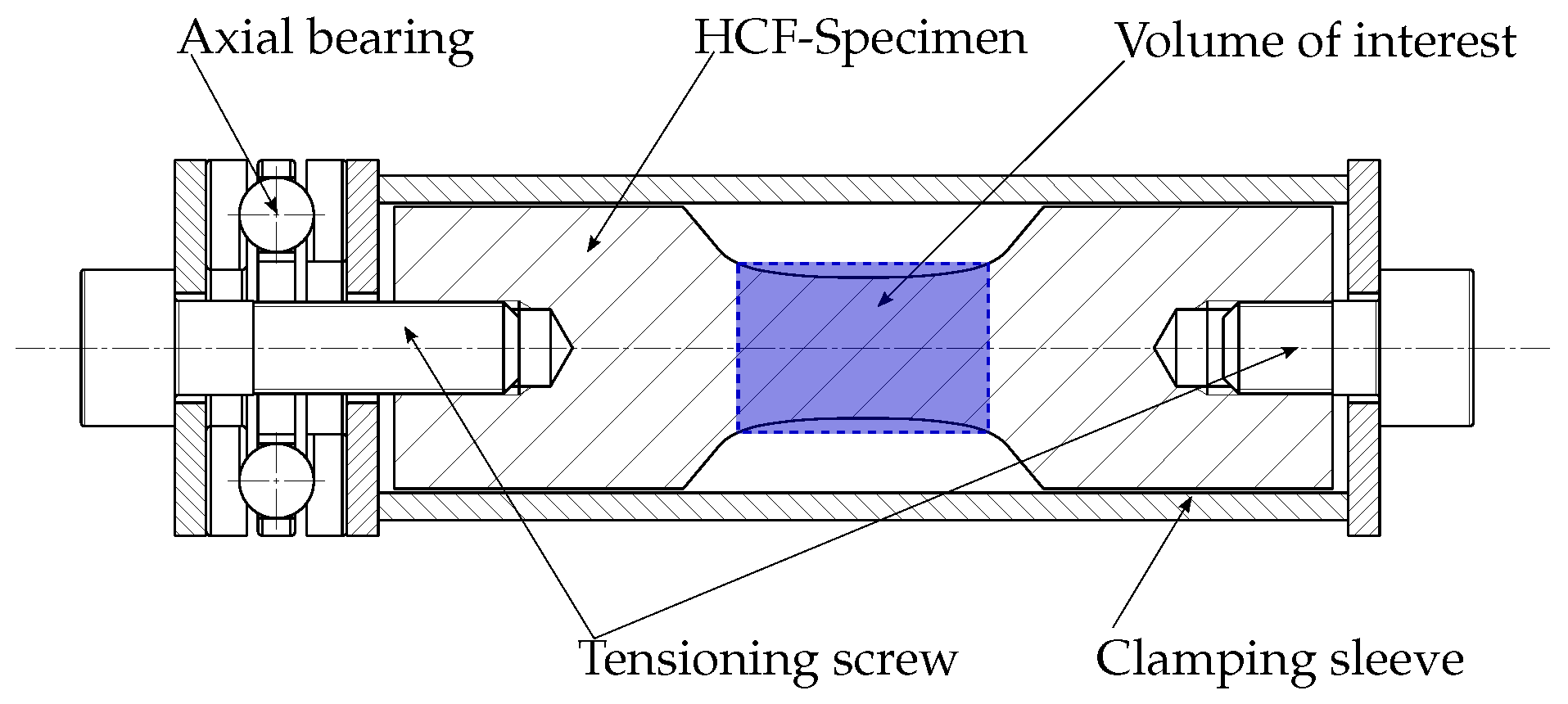

3.3. Fracture Mechanical Tests

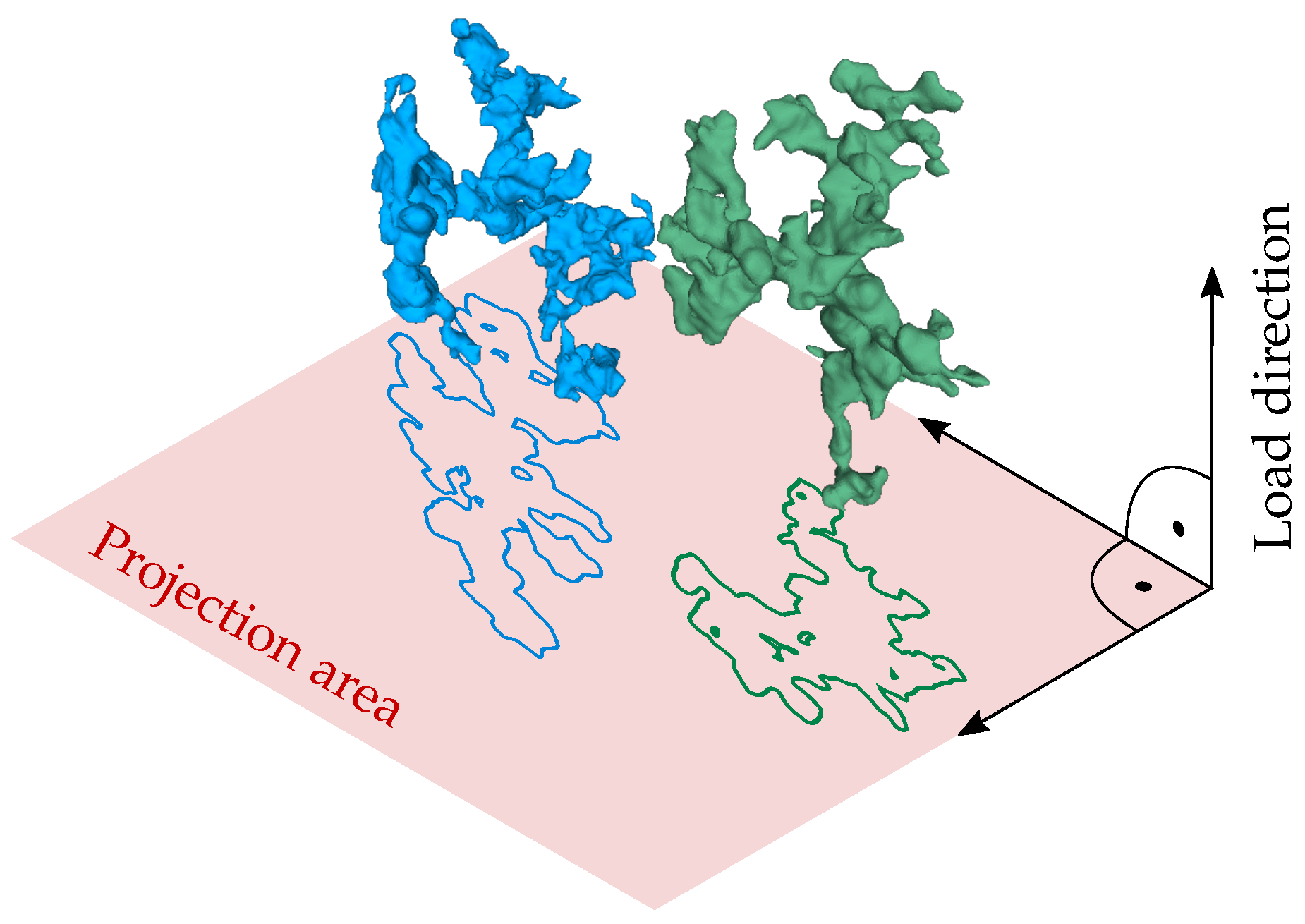

3.4. X-Ray Computed Tomography

3.5. Fatigue Assessment Model

4. Discussion

5. Conclusions

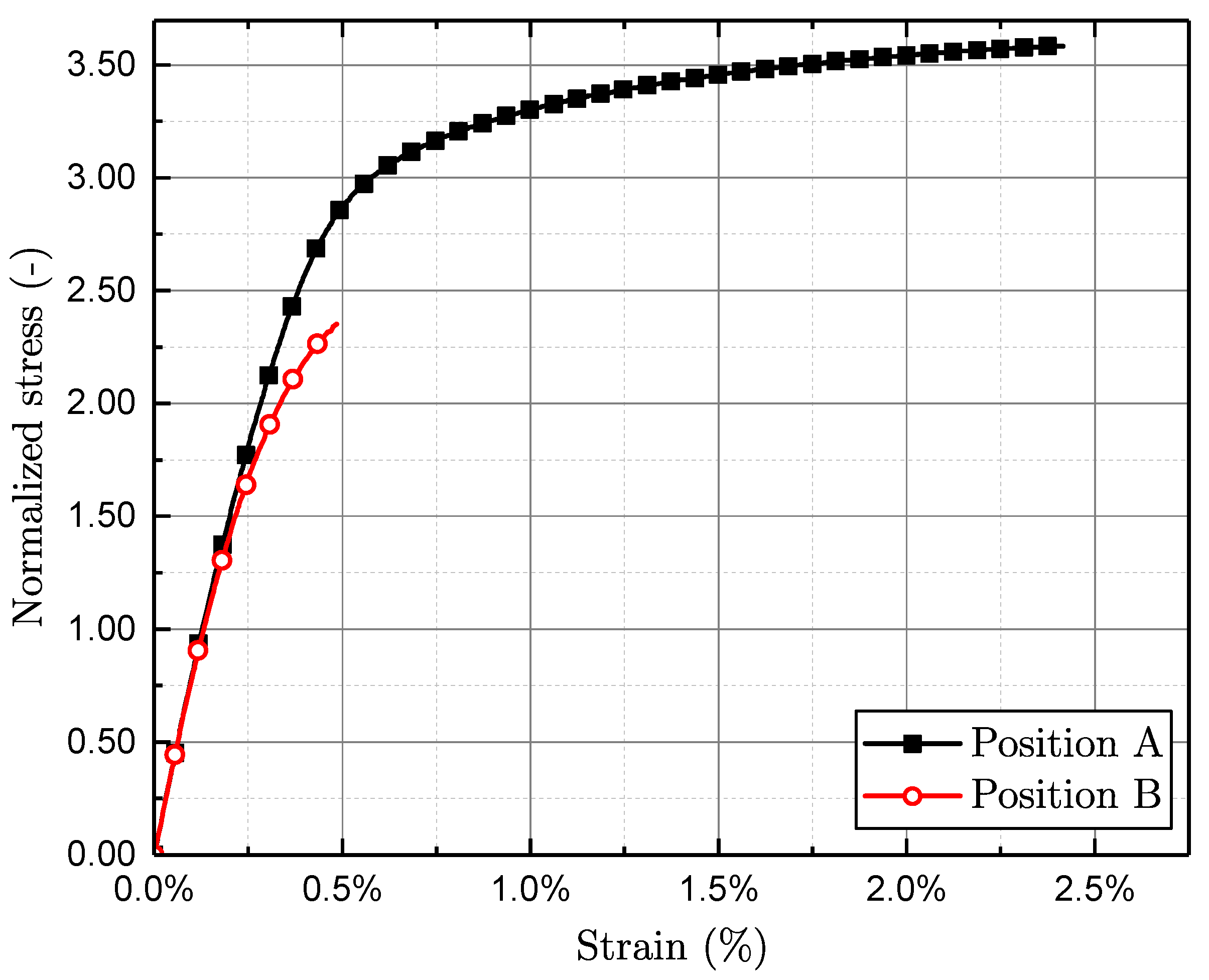

- Two sampling positions with varying local cooling conditions are investigated. Therefore, the local dendrite arm spacing as well as the defect population differ significantly and broadens the application field for the developed methodology. These changes reflect in the investigated quasi-static properties, revealing that position B possesses a relatively brittle material behaviour with a fracture elongation of just 0.15% compared to other sample positions.

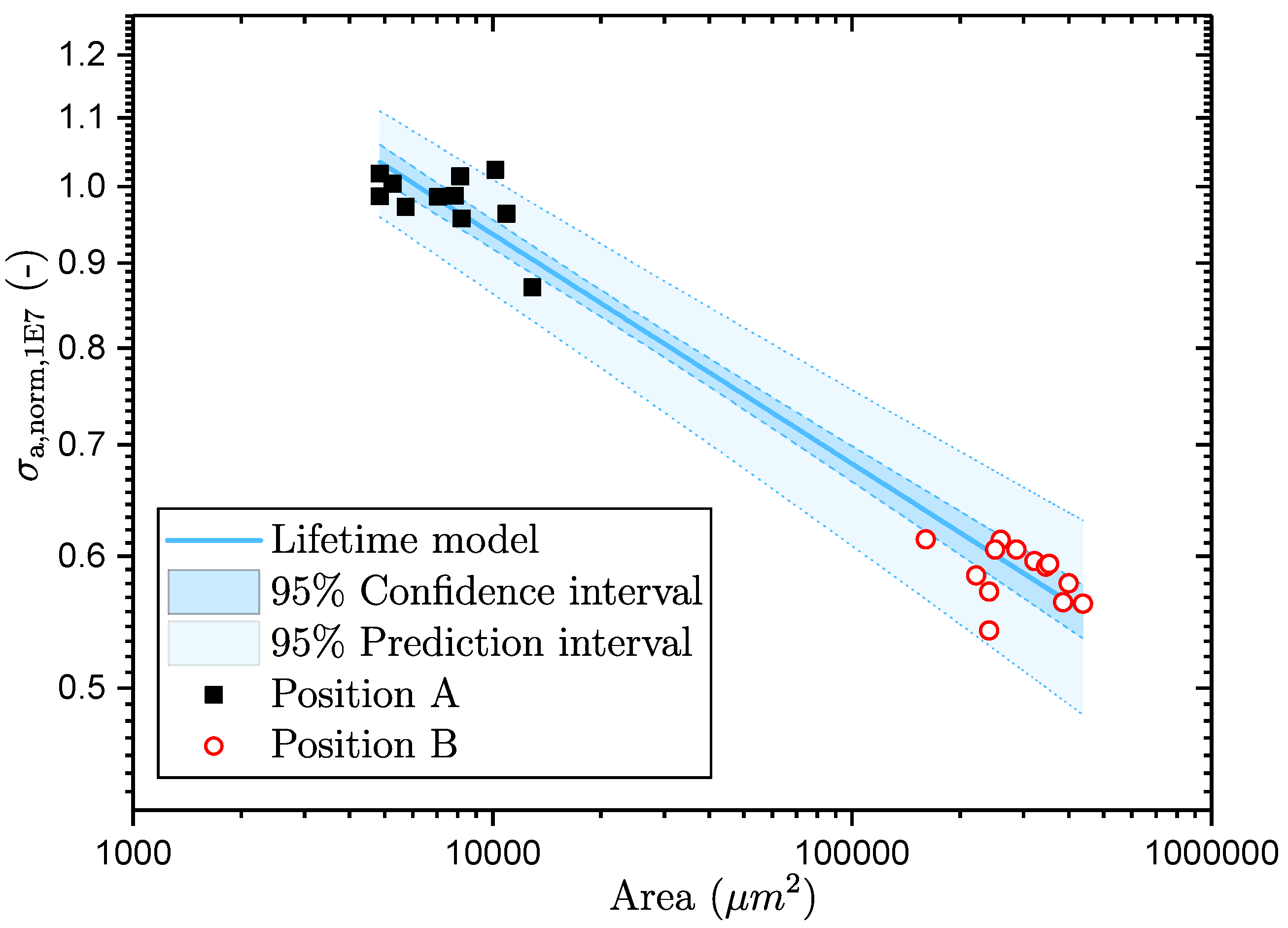

- Extensive fatigue tests are conducted in the high-cycle regime. The fatigue data is statistically evaluated. Hence, the normalised fatigue strength of position A is set as unified reference value with a mean defect size of 100 m. Furthermore, the evaluated normalised fatigue strength of position B is about 0.58 with an average defect size of 500 m.

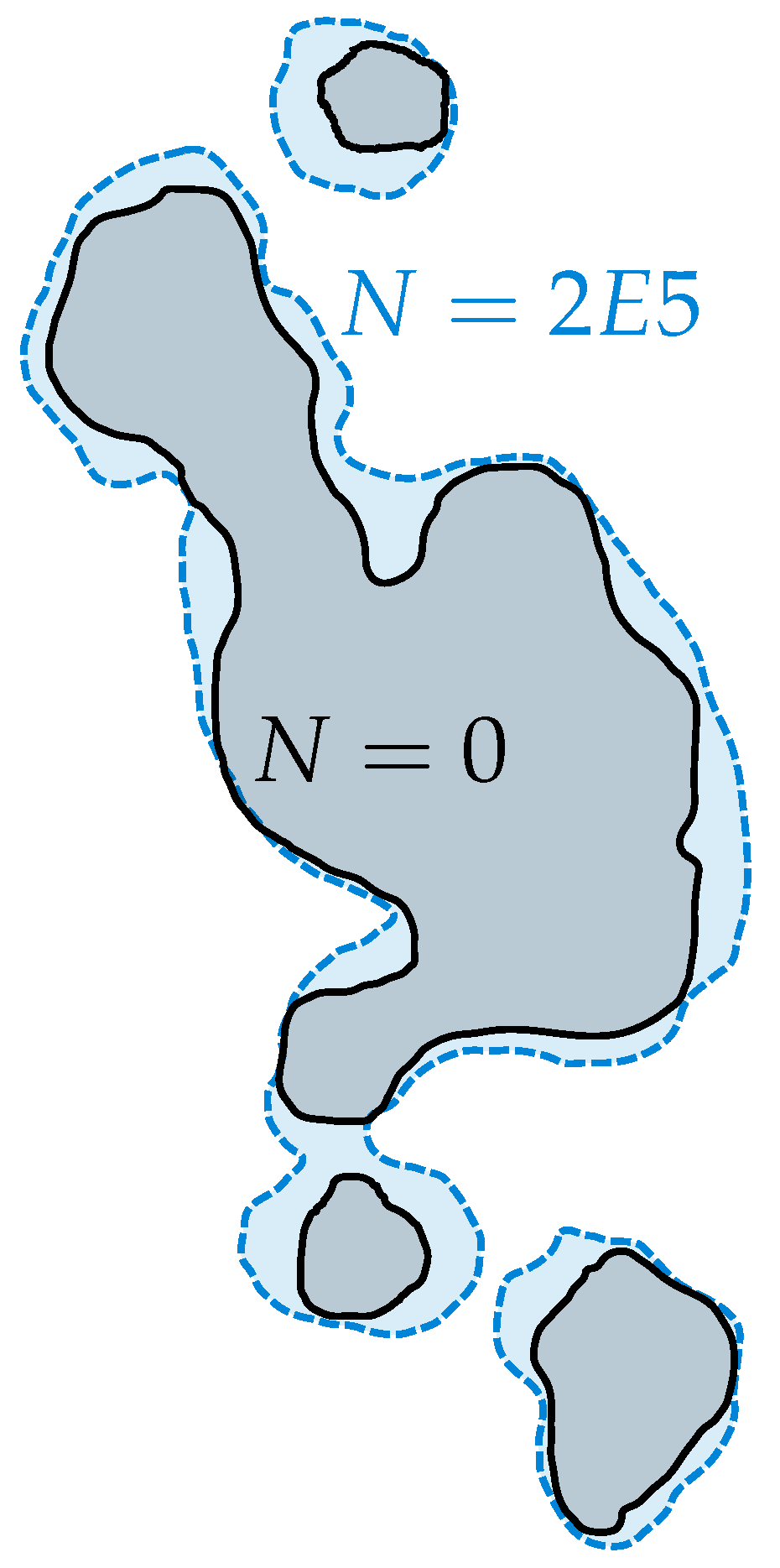

- X-ray computed tomography scans during intermittent fatigue testing revealed that the crack initiation lifetime is below 10% of the number of load cycles until burst failure for Al-Si-Cu cast alloys. This is in agreement with preliminary findings [35].

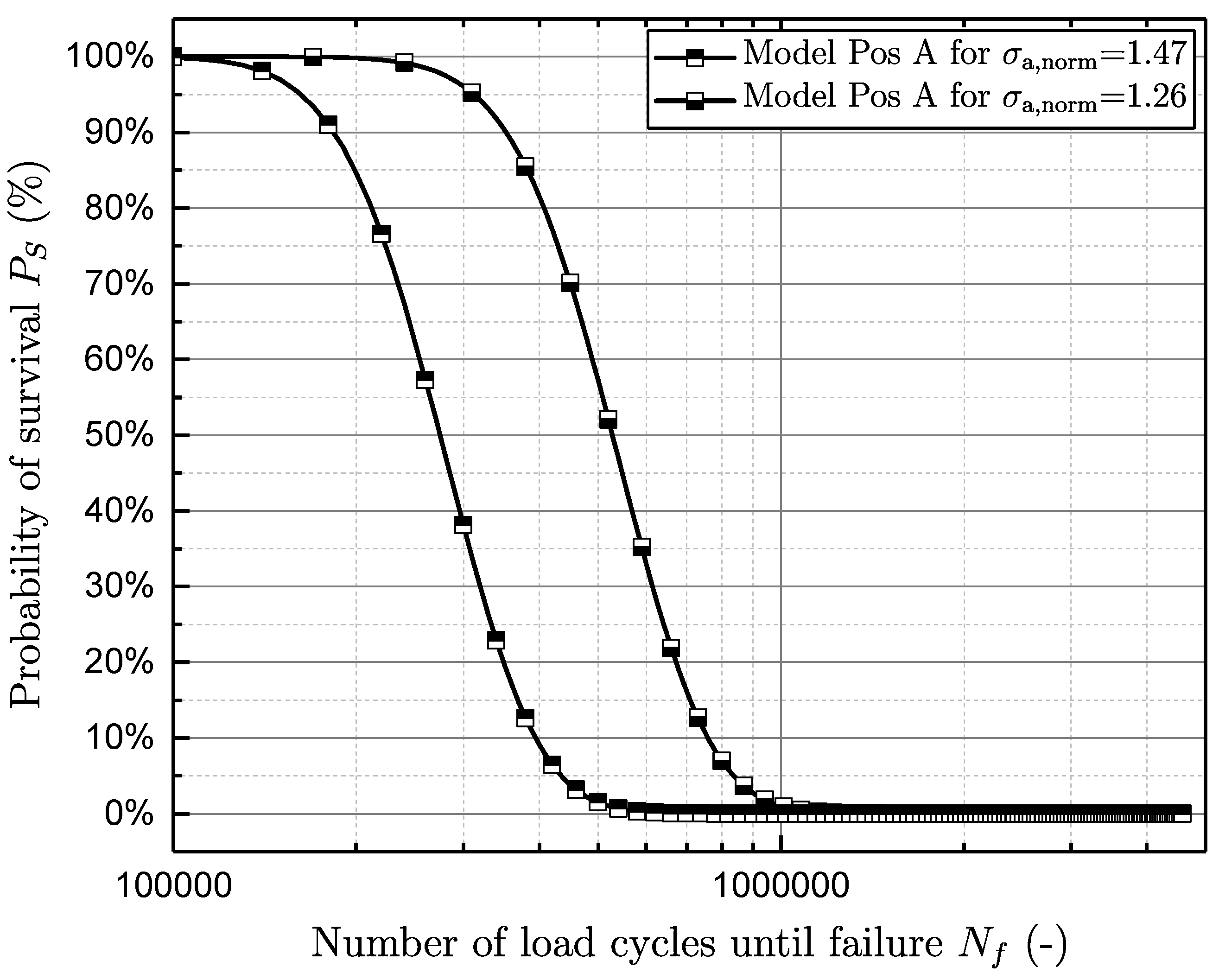

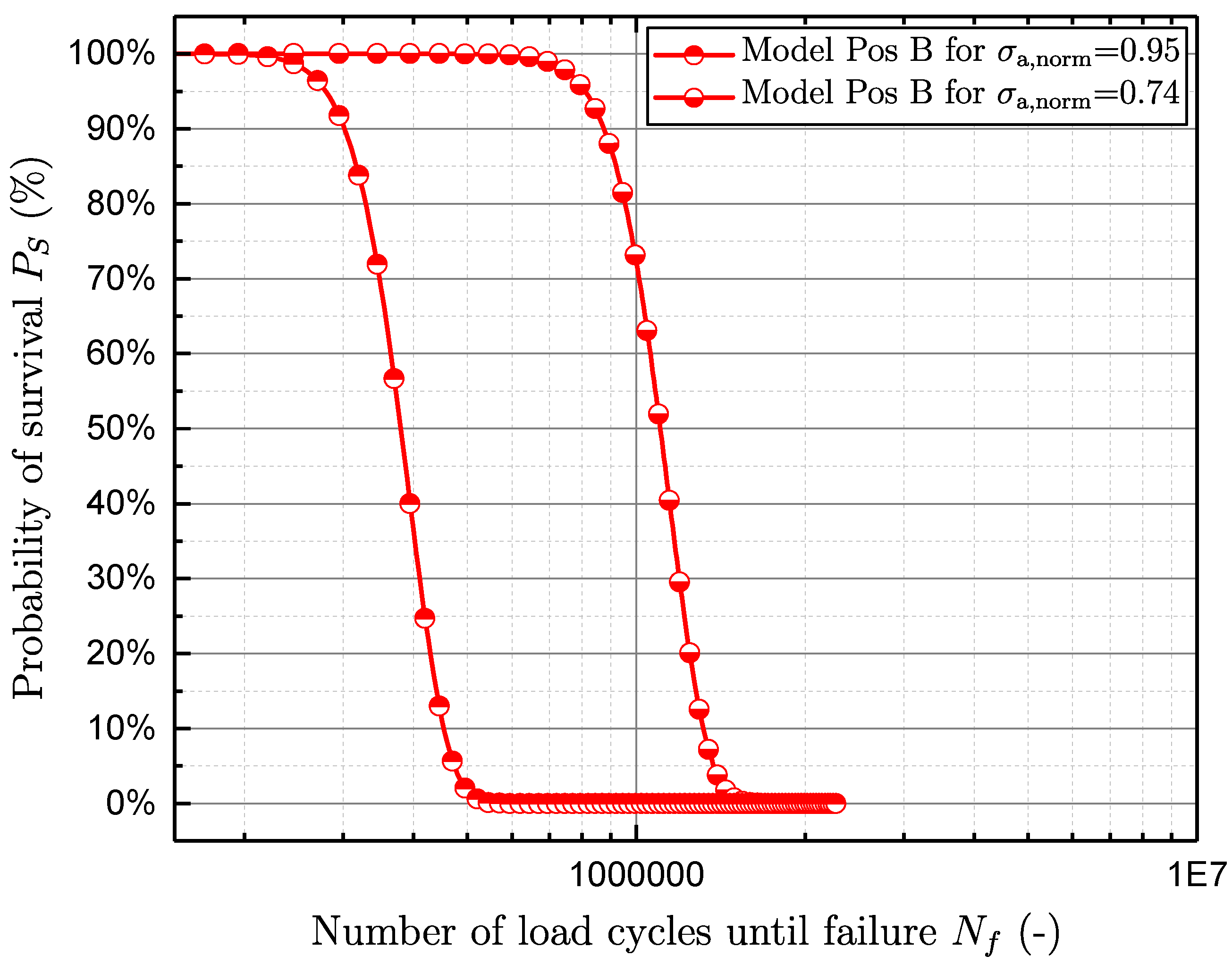

- Tiryakioglu’s fatigue lifetime model by [12] is modified in order to extend its area of validity towards the long-life region, utilising the crack propagation approach of Klesnil–Lukas [25]. The presented model highlights a proper correlation to the examined fatigue tests resulting in a deviation of the mean long-life fatigue strength of up to 5% and up to 9% in the finite-life region.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| GEV | Generalized extreme value distribution |

| Location and scale parameter of extreme value distribution type 1 | |

| Probability of failure | |

| Number of cycles until failure | |

| Number of cycles of crack initiation | |

| B | Offset parameter |

| m | Slope parameter |

| Stress amplitude | |

| Nominal stress amplitude | |

| Long-life fatigue strength amplitude | |

| Equivalent circle diameter | |

| SEM | Scanning electron microscopy |

| XCT | X-ray computed tomography |

| Stress concentration factor | |

| Constants for number of cycles until crack initiation | |

| DAS | Dendrite arm spacing |

| C | Crack propagation parameter |

| Stress intensity factor range | |

| Long crack threshold range | |

| n | Coefficient for crack propagation |

| f | Crack opening function |

| R | Load stress ratio |

| p,q | Exponents of Forman–Mettu NASGRO equation |

| SENB | Single edge notched bending specimen |

| HCF | High-cycle fatigue |

| HV | Vickers hardness |

| , | Coefficients of √area approach |

| R | Load stress ratio |

| Slope of S–N curve in the finite-life region | |

| Slope of S–N curve in the long-life region | |

| Number of load-cycles until specimen burst failure | |

| Number of load-cycles at transition knee point of S–N curve | |

| Scatter band of S–N curve in the long-life regime | |

| Scatter band of S–N curve in the finite-life regime | |

| Normalised ultimate tensile strength | |

| Normalised yield stress | |

| A | Elongation at fracture |

| Sphericity | |

| Volume of a defect | |

| Surface of a defect | |

| Crack propagation coefficient | |

| Initial defect area | |

| a | Crack length |

| Coefficient of determination | |

| P | Cumulative density function of the Gumbel distribution |

| Probability of survival | |

| HIP | Hot isostatic pressed |

References

- Canales, A.A.; Carrera, E.; Silva, J.T.; Valtierra, S.; Colás, R. Mechanical properties in as-cast and heat treated Al-Si-Cu alloys. Int. J. Microstruct. Mater. Prop. 2012, 7, 281. [Google Scholar] [CrossRef]

- Di Sabatino, M.; Arnberg, L. Castability of aluminium alloys. Trans. Indian Inst. Met. 2009, 62, 321–325. [Google Scholar] [CrossRef]

- Zhang, L.Y.; Jiang, Y.H.; Ma, Z.; Shan, S.F.; Jia, Y.Z.; Fan, C.Z.; Wang, W.K. Effect of cooling rate on solidified microstructure and mechanical properties of aluminium-A356 alloy. J. Mater. Process. Technol. 2008, 207, 107–111. [Google Scholar] [CrossRef]

- Stroppe, H. Berechnung der Wöhler-Linie für Aluminium-Gusslegierungen aus dem statischen Zugversuch und dem Dendritenarmabstand. Mater. Werkst. 2009, 40, 738–742. [Google Scholar] [CrossRef]

- Yi, J.Z.; Gao, Y.X.; Lee, P.D.; Lindley, T.C. Microstructure-based fatigue life prediction for cast A356-T6 aluminum-silicon alloys. Metall. Mater. Trans. B 2006, 37, 301–311. [Google Scholar] [CrossRef]

- Iben Houria, M.; Nadot, Y.; Fathallah, R.; Roy, M.; Maijer, D.M. Influence of casting defect and SDAS on the multiaxial fatigue behaviour of A356-T6 alloy including mean stress effect. Int. J. Fatigue 2015, 80, 90–102. [Google Scholar] [CrossRef]

- Brueckner-Foit, A.; Luetje, M.; Bacaicoa, I.; Geisert, A.; Fehlbier, M. On the role of internal defects in the fatigue damage process of a cast Al-Si-Cu alloy. Procedia Struct. Integr. 2017, 7, 36–43. [Google Scholar] [CrossRef]

- Brueckner-Foit, A.; Luetje, M.; Wicke, M.; Bacaicoa, I.; Geisert, A.; Fehlbier, M. On the role of internal defects in the fatigue damage process of a cast Al-Si-Cu alloy. Int. J. Fatigue 2018, 116, 562–571. [Google Scholar] [CrossRef]

- Atxaga, G.; Pelayo, A.; Irisarri, A.M. Effect of microstructure on fatigue behaviour of cast Al–7Si–Mg alloy. Mater. Sci. Technol. 2013, 17, 446–450. [Google Scholar] [CrossRef]

- Melo, M.L.N.M.; Rizzo, E.M.S.; Santos, R.G. Predicting dendrite arm spacing and their effect on microporosity formation in directionally solidified Al-Cu alloy. J. Mater. Sci. 2005, 40, 1599–1609. [Google Scholar] [CrossRef]

- Tiryakioğlu, M. On the size distribution of fracture-initiating defects in Al- and Mg-alloy castings. Mater. Sci. Eng. A 2008, 476, 174–177. [Google Scholar] [CrossRef]

- Tiryakioğlu, M. Statistical distributions for the size of fatigue-initiating defects in Al–7%Si–0.3%Mg alloy castings: A comparative study. Mater. Sci. Eng. A 2008, 497, 119–125. [Google Scholar] [CrossRef]

- Gnedenko, B. Sur la distribution limite du terme maximum d’une serie aleatoire. Ann. Math. 1943, 44, 423–453. [Google Scholar] [CrossRef]

- Anderson, K.V.; Daniewicz, S.R. Statistical analysis of the influence of defects on fatigue life using a Gumbel distribution. Int. J. Fatigue 2018, 112, 78–83. [Google Scholar] [CrossRef]

- Gumbel, E.J. Statistics of Extremes; Columbia University Press: New York, NY, USA, 1958. [Google Scholar]

- Tiryakioğlu, M. Relationship between Defect Size and Fatigue Life Distributions in Al-7 Pct Si-Mg Alloy Castings. Metall. Mater. Trans. A 2009, 40, 1623–1630. [Google Scholar] [CrossRef]

- Tiryakioğlu, M. On the relationship between statistical distributions of defect size and fatigue life in 7050-T7451 thick plate and A356-T6 castings. Mater. Sci. Eng. A 2009, 520, 114–120. [Google Scholar] [CrossRef]

- Paris, P.; Erdogan, F. A critical analysis of crack propagation laws. J. Basic Eng. 1963, 85, 528–533. [Google Scholar] [CrossRef]

- Leitner, M.; Garb, C.; Remes, H.; Stoschka, M. Microporosity and statistical size effect on the fatigue strength of cast aluminium alloys EN AC-45500 and 46200. Mater. Sci. Eng. A 2017, 707, 567–575. [Google Scholar] [CrossRef]

- Nicoletto, G.; Konečná, R.; Fintova, S. Characterization of microshrinkage casting defects of Al–Si alloys by X-ray computed tomography and metallography. Int. J. Fatigue 2012, 41, 39–46. [Google Scholar] [CrossRef]

- Shiozawa, K.; Tohda, Y.; Sun, S.M. Crack initiation and small fatigue crack growth behaviour of squeeze-cast Al-Si aluminium alloys. Fatigue Fract. Eng. Mater. Struct. 1997, 20, 237–247. [Google Scholar] [CrossRef]

- Gao, Y.X.; Yi, J.Z.; Lee, P.D.; Lindley, T.C. A micro-cell model of the effect of microstructure and defects on fatigue resistance in cast aluminum alloys. Acta Mater. 2004, 52, 5435–5449. [Google Scholar] [CrossRef]

- Gao, Y.X.; Yi, J.Z.; Lee, P.D.; Lindley, T.C. The effect of porosity on the fatigue life of cast aluminium-silicon alloys. Fatigue Fract. Eng. Mater. Struct. 2004, 27, 559–570. [Google Scholar] [CrossRef]

- Jones, R.; Singh Raman, R.K.; McMillan, A.J. Crack growth: Does microstructure play a role? Eng. Fract. Mech. 2018, 187, 190–210. [Google Scholar] [CrossRef]

- Klesnil, M.; Lukáš, P. Influence of strength and stress history on growth and stabilisation of fatigue cracks. Eng. Fract. Mech. 1972, 4, 77–92. [Google Scholar] [CrossRef]

- Forman, R.G.; Mettu, S.R. Behavior of Surface and Corner Cracks Subjected to Tensile And Bending Loads in Ti-6Al-4V Alloy; NASA Technical Memorandum 102165; NASA Johnson Space Center: Houston, TX, USA, 1990.

- Maierhofer, J.; Pippan, R.; Gänser, H.P. Modified NASGRO equation for physically short cracks. Int. J. Fatigue 2014, 59, 200–207. [Google Scholar] [CrossRef]

- Murakami, Y.; Endo, M. Effects of defects, inclusions and inhomogeneities on fatigue strength. Int. J. Fatigue 1994, 16, 163–182. [Google Scholar] [CrossRef]

- Murakami, Y. Metal fatigue: Effects of Small Defects and Nonmetallic Inclusions; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- El Haddad, M.H.; Topper, T.H.; Smith, K.N. Prediction of non propagating cracks. Eng. Fract. Mech. 1979, 11, 573–584. [Google Scholar] [CrossRef]

- El Haddad, M.H.; Smith, K.N.; Topper, T.H. Fatigue Crack Propagation of Short Cracks. J. Eng. Mater. Technol. 1979, 101, 42. [Google Scholar] [CrossRef]

- Chapetti, M.D. Fatigue propagation threshold of short cracks under constant amplitude loading. Int. J. Fatigue 2003, 25, 1319–1326. [Google Scholar] [CrossRef]

- Murakami, Y. Material defects as the basis of fatigue design. Int. J. Fatigue 2012, 41, 2–10. [Google Scholar] [CrossRef]

- Aigner, R.; Leitner, M.; Stoschka, M. Fatigue strength characterization of Al-Si cast material incorporating statistical size effect. MATEC Web Conf. 2018, 165, 14002. [Google Scholar] [CrossRef]

- Serrano-Munoz, I.; Buffiere, J.Y.; Mokso, R.; Verdu, C.; Nadot, Y. Location, location &size: Defects close to surfaces dominate fatigue crack initiation. Sci. Rep. 2017, 7, 45239. [Google Scholar] [CrossRef] [PubMed]

- Tiryakioğlu, M.; Robinson, J.S.; Salazar-Guapuriche, M.A.; Zhao, Y.Y.; Eason, P.D. Hardness–strength relationships in the aluminum alloy 7010. Mater. Sci. Eng. A 2015, 631, 196–200. [Google Scholar] [CrossRef]

- Zhang, P.; Li, S.X.; Zhang, Z.F. General relationship between strength and hardness. Mater. Sci. Eng. A 2011, 529, 62–73. [Google Scholar] [CrossRef]

- Garb, C.; Leitner, M.; Grün, F. Application of √area-concept to assess fatigue strength of AlSi7Cu0.5Mg casted components. Eng. Fract. Mech. 2017, 185, 61–71. [Google Scholar] [CrossRef]

- Garb, C.; Leitner, M.; Tauscher, M.; Weidt, M.; Brunner, R. Statistical analysis of micropore size distributions in Al-Si castings evaluated by X-ray computed tomography. Int. J. Mater. Res. 2018. [Google Scholar] [CrossRef]

- Limodin, N.; El Bartali, A.; Wang, L.; Lachambre, J.; Buffière, J.Y.; Charkaluk, E. Application of X-ray microtomography to study the influence of the casting microstructure upon the tensile behaviour of an Al–Si alloy. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2014, 324, 57–62. [Google Scholar] [CrossRef]

- Linder, J.; Axelsson, M.; Nilsson, H. The influence of porosity on the fatigue life for sand and permanent mould cast aluminium. Int. J. Fatigue 2006, 28, 1752–1758. [Google Scholar] [CrossRef]

- Hilbinger, R.M.; Gerth, S.; Randelzhofer, P. Erzeugung und Charakterisierung porenbehafteter Prüfkörper für Schwingprüfung und Gießsimulation: Creation and characterization of specimen with pores for fatigue tests and casting process simulation. Mater. Werkst. 2017, 48, 77–87. [Google Scholar] [CrossRef]

- Kuwazuru, O.; Murata, Y.; Hangai, Y.; Utsunomiya, T.; Kithara, S.; Yoshikawa, N. X-Ray CT Inspection for Porosities and Its Effect on Fatigue of Die Cast Aluminium Alloy. J. Solid Mech. Mater. Eng. 2008, 2, 1220–1231. [Google Scholar] [CrossRef]

- Rotella, A.; Nadot, Y.; Piellard, M.; Augustin, R.; Fleuriot, M. Fatigue limit of a cast Al-Si-Mg alloy (A357-T6) with natural casting shrinkages using ASTM standard X-ray inspection. Int. J. Fatigue 2018, 114, 177–188. [Google Scholar] [CrossRef]

- González, R.; Martínez, D.I.; González, J.A.; Talamantes, J.; Valtierra, S.; Colás, R. Experimental investigation for fatigue strength of a cast aluminium alloy. Int. J. Fatigue 2011, 33, 273–278. [Google Scholar] [CrossRef]

- Groza, M.; Nadot, Y.; Varadi, K. Defect size map for nodular cast iron components with ellipsoidal surface defects based on the defect stress gradient approach. Int. J. Fatigue 2018, 112, 206–215. [Google Scholar] [CrossRef]

- Hosokawa, A.; Toda, H.; Batres, R.; Li, H.; Kuwazuru, O.; Kobayashi, M.; Yakita, H. Ductile fracture via hydrogen pore mechanism in an aluminum alloy; quantitative microstructural analysis and image-based finite element analysis. Mater. Sci. Eng. A 2016, 671, 96–106. [Google Scholar] [CrossRef]

- Tenkamp, J.; Koch, A.; Knorre, S.; Krupp, U.; Michels, W.; Walther, F. Defect-correlated fatigue assessment of A356-T6 aluminum cast alloy using computed tomography based Kitagawa-Takahashi diagrams. Int. J. Fatigue 2018, 108, 25–34. [Google Scholar] [CrossRef]

- Kitagawa, H. Applicability of fracture mechanics to very small cracks or the cracks in the early stage. In Proceedings of the Second International Conference on Mechanical Behavior of Materials, Boston, MA, USA, 16–20 August 1976; pp. 627–631. [Google Scholar]

- Sjölander, E.; Seifeddine, S. The heat treatment of Al–Si–Cu–Mg casting alloys. J. Mater. Process. Technol. 2010, 210, 1249–1259. [Google Scholar] [CrossRef]

- Yang, H.; Ji, S.; Fan, Z. Effect of heat treatment and Fe content on the microstructure and mechanical properties of die-cast Al–Si–Cu alloys. Mater. Des. 2015, 85, 823–832. [Google Scholar] [CrossRef]

- Zolotorevsky, V.S.; Belov, N.A.; Glazoff, M.V. Casting Aluminum Alloys; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Do Lee, C. Effect of T6 heat treatment on the defect susceptibility of fatigue properties to microporosity variations in a low-pressure die-cast A356 alloy. Mater. Sci. Eng. A 2013, 559, 496–505. [Google Scholar] [CrossRef]

- Zhu, M.; Jian, Z.; Yang, G.; Zhou, Y. Effects of T6 heat treatment on the microstructure, tensile properties, and fracture behavior of the modified A356 alloys. Mater. Des. 2012, 36, 243–249. [Google Scholar] [CrossRef]

- González, R.; González, A.; Talamantes-Silva, J.; Valtierra, S.; Mercado-Solís, R.D.; Garza-Montes-de Oca, N.F.; Colás, R. Fatigue of an aluminium cast alloy used in the manufacture of automotive engine blocks. Int. J. Fatigue 2013, 54, 118–126. [Google Scholar] [CrossRef]

- Murakami, Y.; Takahashi, K.; Yamashita, T. Quantitative Evaluation of the Effect of Surface Roughness on Fatigue Strength. Effect of Depth and Pitch of Roughness. Trans. Jpn. Soc. Mech. Eng. Ser. A 1997, 63, 1612–1619. [Google Scholar] [CrossRef]

- DIN 50100:2016-12. Load Controlled Fatigue Testing—Execution and Evaluation of Cyclic Tests at Constant Load Amplitudes on Metallic Specimens and Components; Beuth Verlag: Berlin, Germany, 2016. [Google Scholar]

- Leitner, H. Simulation des Ermüdungsverhaltens von Aluminiumguslegierungen. Ph.D. Thesis, Montanuniversität Leoben, Leoben, Austria, 2001. [Google Scholar]

- ASTM International E 739. Standard Practice for Statistical Analysis of Linear or Linearized Stress-Life (S–N) and Strain Life (E-N) Fatigue Data; ASTM International: West Conshohocken, PA, USA, 1998. [Google Scholar]

- Dengel, D.; Harig, H. Estimation of the fatigue limit by progressively-increasing load tests. Fatigue Fract. Eng. Mater. Struct. 1980, 3, 113–128. [Google Scholar] [CrossRef]

- DIN EN ISO 6892-1. Metallic Materials-Tensile Testing-Part 1: Method of Test at Room Temperature; Beuth Verlag: Berlin, Germany, 2016. [Google Scholar]

- Mahdi, S.; Cenac, M. Estimating Parameters of Gumbel Distribution using the Methods of Moments, probability weighted moments and maximum likelihood. Revista de Matemática Teoría y Aplicaciones 2005, 12, 151–156. [Google Scholar] [CrossRef]

- Beretta, S.; Murakami, Y. Statistical analysis of defects for fatigue strength prediction and quality control of materials. Fatigue Fract. Eng. Mater. Struct. 1998, 21, 1049–1065. [Google Scholar] [CrossRef]

- Newman, J.C., Jr.; Yamada, Y. Compression precracking methods to generate near-threshold fatigue-crack-growth-rate data. Int. J. Fatigue 2010, 32, 879–885. [Google Scholar] [CrossRef]

- Newman, J., Jr.; Schneider, J.; Daniel, A.; McKnight, D. Compression pre-cracking to generate near threshold fatigue-crack-growth rates in two aluminum alloys. Int. J. Fatigue 2005, 27, 1432–1440. [Google Scholar] [CrossRef]

- Pippan, R.; Plöchl, L.; Klanner, F.; Stüwe, H. The Use of Fatigue Specimens Precracked in Compression for Measuring Threshold Values and Crack Growth. J. Test. Eval. 1994, 22, 98–103. [Google Scholar] [CrossRef]

- Maierhofer, J.; Kolitsch, S.; Pippan, R.; Gänser, H.P.; Madia, M.; Zerbst, U. The cyclic R-curve—Determination, problems, limitations and application. Eng. Fract. Mech. 2018, 198, 45–64. [Google Scholar] [CrossRef]

- ASTM International E 399-90. Standard Test Method for Plane-Strain Fracture Toughness of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 1997. [Google Scholar]

- ASTM International E 647-00. Standard test Method for Measurement of Fatigue Crack Growth Rates; ASTM International: West Conshohocken, PA, 2000. [Google Scholar]

- Garb, C.; Leitner, M.; Stauder, B.; Schnubel, D.; Grün, F. Application of modified Kitagawa-Takahashi diagram for fatigue strength assessment of cast Al–Si–Cu alloys. Int. J. Fatigue 2018, 111, 256–268. [Google Scholar] [CrossRef]

- Baruchel, J. X-Ray Tomography in Material Science; Hermes Science Publ: Paris, France, 2000. [Google Scholar]

- Hsieh, J. Computed Tomography, 3rd ed.; Society of Photo-Optical Instrumentation Engineers (SPIE): Bellingham, WA, USA, 2015. [Google Scholar]

- Serrano-Munoz, I.; Buffiere, J.Y.; Verdu, C. Casting defects in structural components: Are they all dangerous? A 3D study. Int. J. Fatigue 2018, 117, 471–484. [Google Scholar] [CrossRef]

- Marquardt, D.W. An Algorithm for Least-Squares Estimation of Nonlinear Parameters. J. Soc. Ind. Appl. Math. 1963, 11, 431–441. [Google Scholar] [CrossRef]

| Si [%] | Cu [%] | Fe [%] | Mn [%] | Mg [%] | Ti [%] |

|---|---|---|---|---|---|

| 7.5–8.5 | 2.0–3.5 | 0.8 | 0.15–0.65 | 0.05–0.55 | 0.25 |

| Position | [-] | [-] | [-] | [-] | [-] | [-] |

|---|---|---|---|---|---|---|

| A | 1.00 | 5.06 | 25 | 1.1E6 | 1.21 | 2.46 |

| B | 0.58 | 4.55 | 23 | 2.7E6 | 1.13 | 1.5 |

| Position | [-] | [-] | A [%] |

|---|---|---|---|

| A | 3.52 ± 0.07 | 1.63 ± 0.04 | 1.62 ± 0.4 |

| B | 2.28 ± 0.10 | 1.38 ± 0.03 | 0.15 ± 0.04 |

| Position | [-] | [-] | |

| Experiment | A | 1.00 | 1.21 |

| Model | A | 0.96 | 1.23 |

| Deviation | A | −4.6% | +1.4% |

| Position | [-] | [-] | |

| Experiment | B | 0.58 | 1.13 |

| Model | B | 0.59 | 1.10 |

| Deviation | B | +1.8% | −2.9% |

| Position | [-] | [-] | [-] | |

| Experiment | A | 2.5E5 | 5.5E5 | 2.46 |

| Model | A | 2.8E5 | 5.3E5 | 2.14 |

| Deviation | A | +9.1% | -3.8% | −14.9% |

| Position | [-] | [-] | [-] | |

| Experiment | B | 3.8E5 | 1.2E6 | 1.57 |

| Model | B | 3.8E5 | 1.1E6 | 1.50 |

| Deviation | B | 0.0% | −8.6% | −4.7% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aigner, R.; Leitner, M.; Stoschka, M.; Hannesschläger, C.; Wabro, T.; Ehart, R. Modification of a Defect-Based Fatigue Assessment Model for Al-Si-Cu Cast Alloys. Materials 2018, 11, 2546. https://doi.org/10.3390/ma11122546

Aigner R, Leitner M, Stoschka M, Hannesschläger C, Wabro T, Ehart R. Modification of a Defect-Based Fatigue Assessment Model for Al-Si-Cu Cast Alloys. Materials. 2018; 11(12):2546. https://doi.org/10.3390/ma11122546

Chicago/Turabian StyleAigner, Roman, Martin Leitner, Michael Stoschka, Christian Hannesschläger, Thomas Wabro, and Robert Ehart. 2018. "Modification of a Defect-Based Fatigue Assessment Model for Al-Si-Cu Cast Alloys" Materials 11, no. 12: 2546. https://doi.org/10.3390/ma11122546

APA StyleAigner, R., Leitner, M., Stoschka, M., Hannesschläger, C., Wabro, T., & Ehart, R. (2018). Modification of a Defect-Based Fatigue Assessment Model for Al-Si-Cu Cast Alloys. Materials, 11(12), 2546. https://doi.org/10.3390/ma11122546