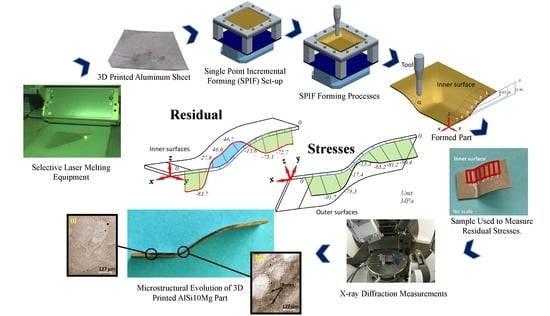

Experimental Determination of Residual Stresses Generated by Single Point Incremental Forming of AlSi10Mg Sheets Produced Using SLM Additive Manufacturing Process

Abstract

Share and Cite

López, C.; Elías-Zúñiga, A.; Jiménez, I.; Martínez-Romero, O.; R. Siller, H.; Diabb, J.M. Experimental Determination of Residual Stresses Generated by Single Point Incremental Forming of AlSi10Mg Sheets Produced Using SLM Additive Manufacturing Process. Materials 2018, 11, 2542. https://doi.org/10.3390/ma11122542

López C, Elías-Zúñiga A, Jiménez I, Martínez-Romero O, R. Siller H, Diabb JM. Experimental Determination of Residual Stresses Generated by Single Point Incremental Forming of AlSi10Mg Sheets Produced Using SLM Additive Manufacturing Process. Materials. 2018; 11(12):2542. https://doi.org/10.3390/ma11122542

Chicago/Turabian StyleLópez, Cecilio, Alex Elías-Zúñiga, Isaac Jiménez, Oscar Martínez-Romero, Héctor R. Siller, and José M. Diabb. 2018. "Experimental Determination of Residual Stresses Generated by Single Point Incremental Forming of AlSi10Mg Sheets Produced Using SLM Additive Manufacturing Process" Materials 11, no. 12: 2542. https://doi.org/10.3390/ma11122542

APA StyleLópez, C., Elías-Zúñiga, A., Jiménez, I., Martínez-Romero, O., R. Siller, H., & Diabb, J. M. (2018). Experimental Determination of Residual Stresses Generated by Single Point Incremental Forming of AlSi10Mg Sheets Produced Using SLM Additive Manufacturing Process. Materials, 11(12), 2542. https://doi.org/10.3390/ma11122542