Synergistic Benefits of Using Expansive and Shrinkage Reducing Admixture on High-Performance Concrete

Abstract

1. Introduction

2. Experimental Program

2.1. Mixture Proportions and Materials

2.2. Details of the Experimental Test Setup and Specimen Preparation

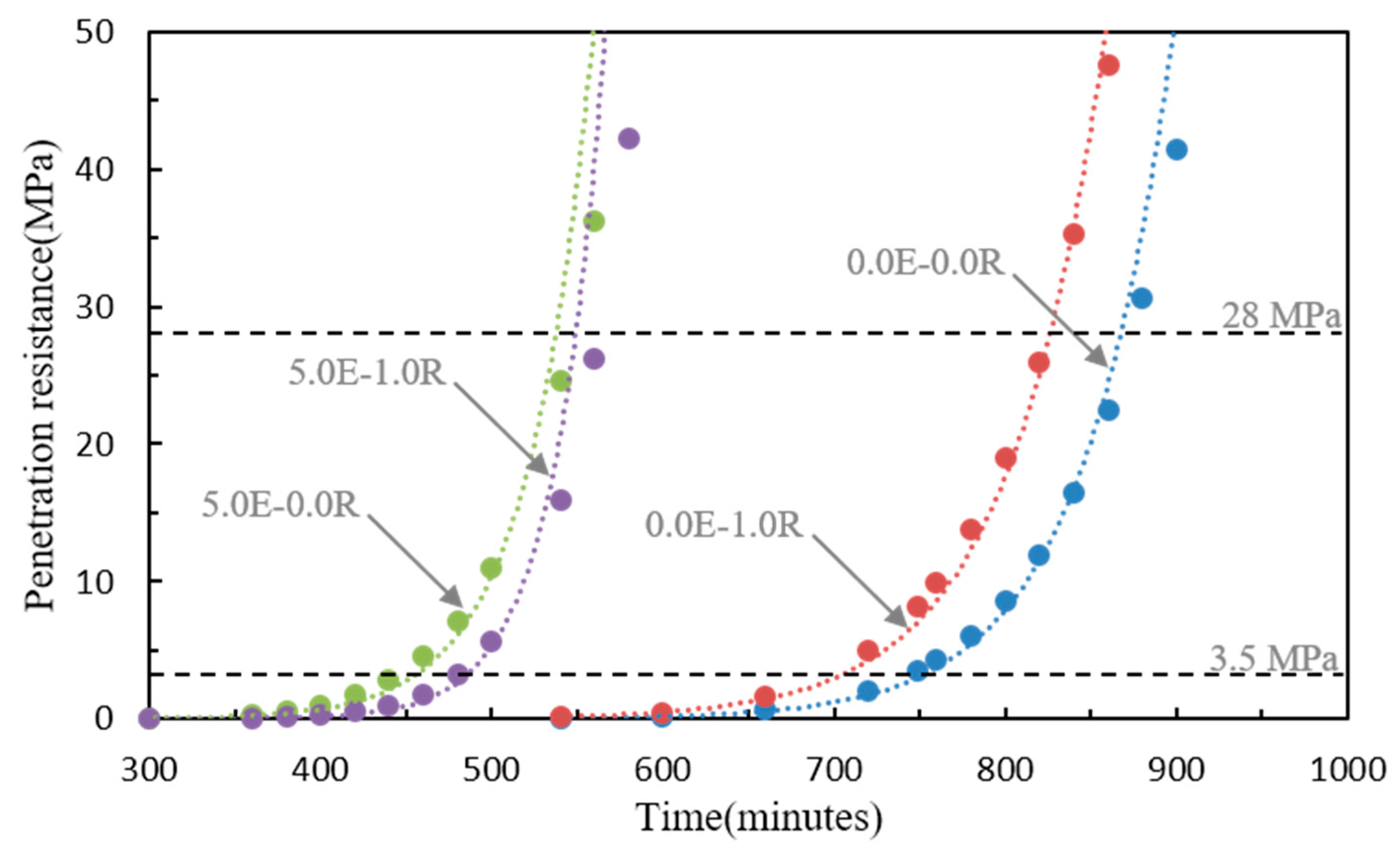

2.2.1. Flow and Setting Properties

2.2.2. Compressive and Tensile Strength

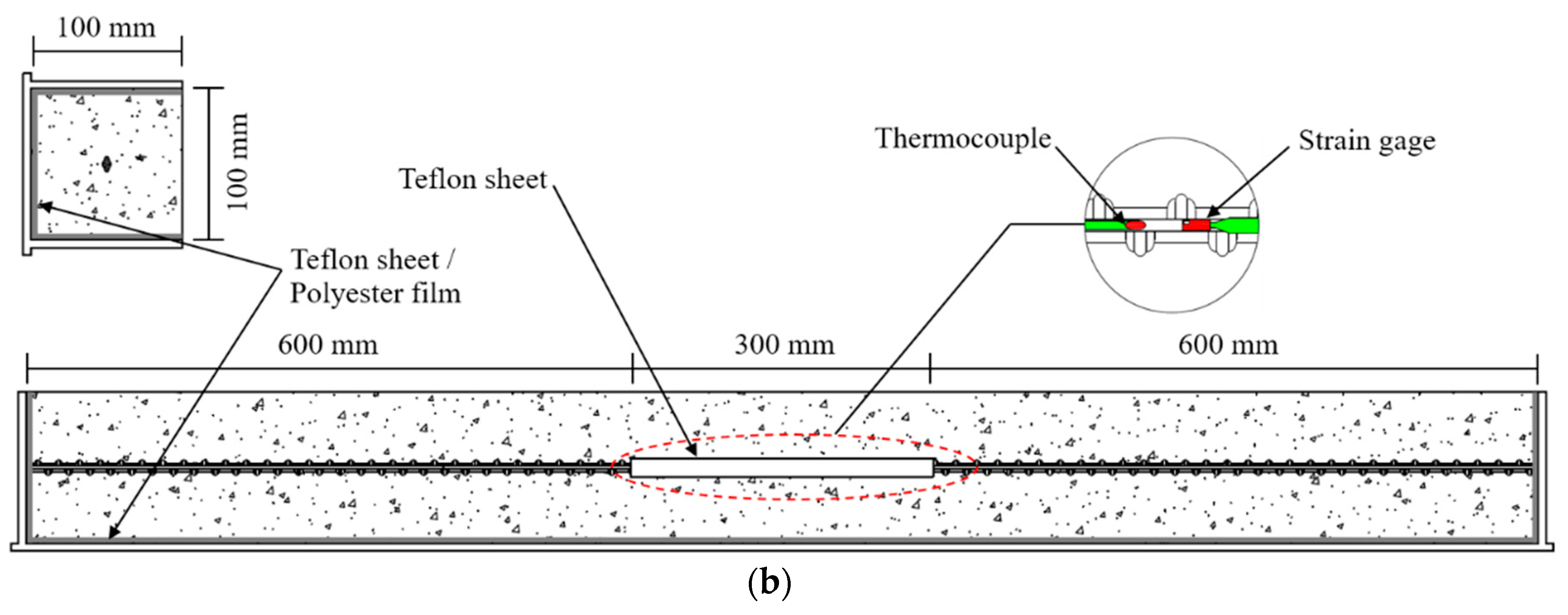

2.2.3. Autogenous Shrinkage Tests

3. Test Results and Discussion

3.1. Properties of Fresh HPC

3.2. Properties of Hardened HPC

3.2.1. Compressive Strength

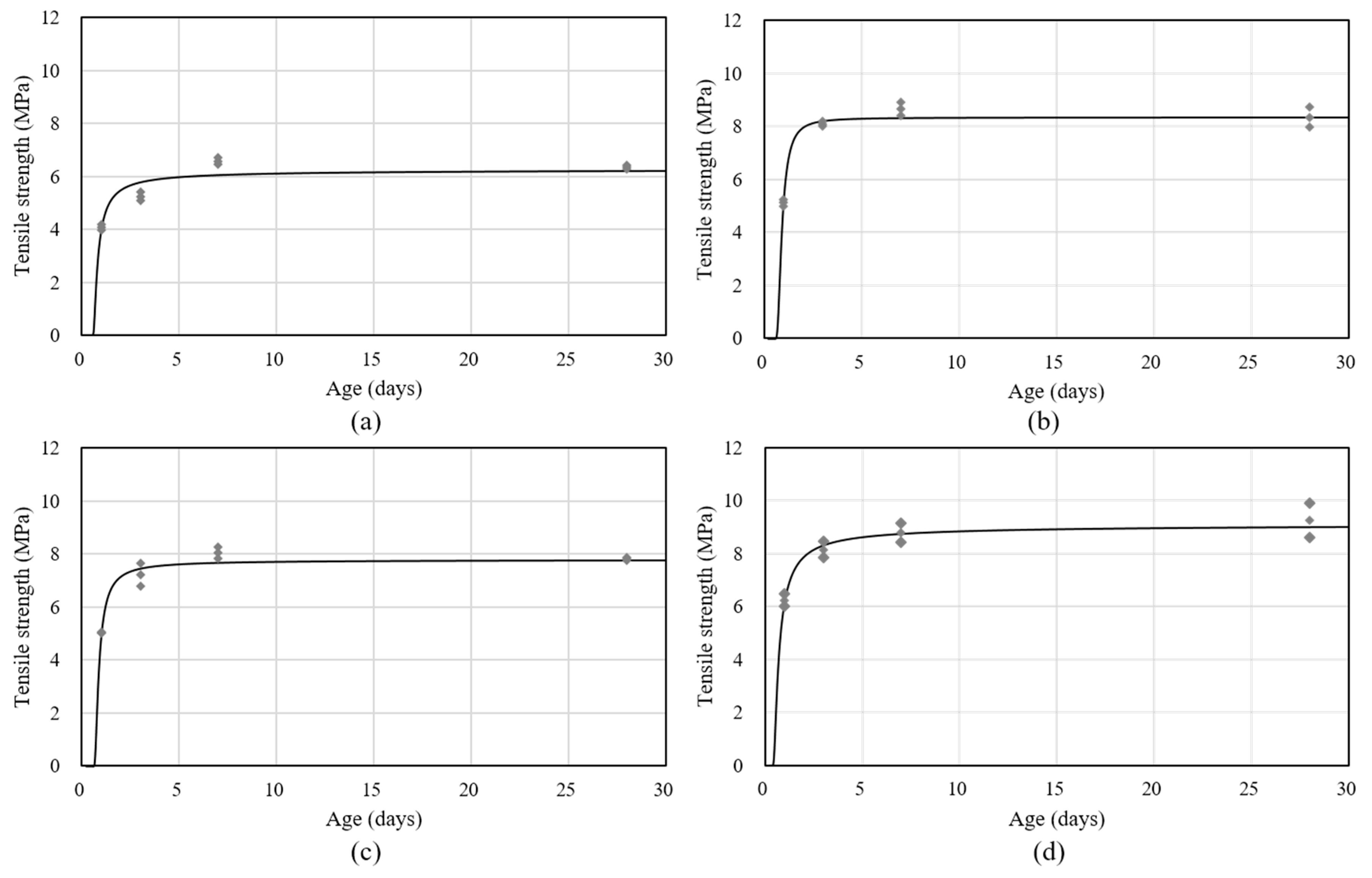

3.2.2. Tensile Strength

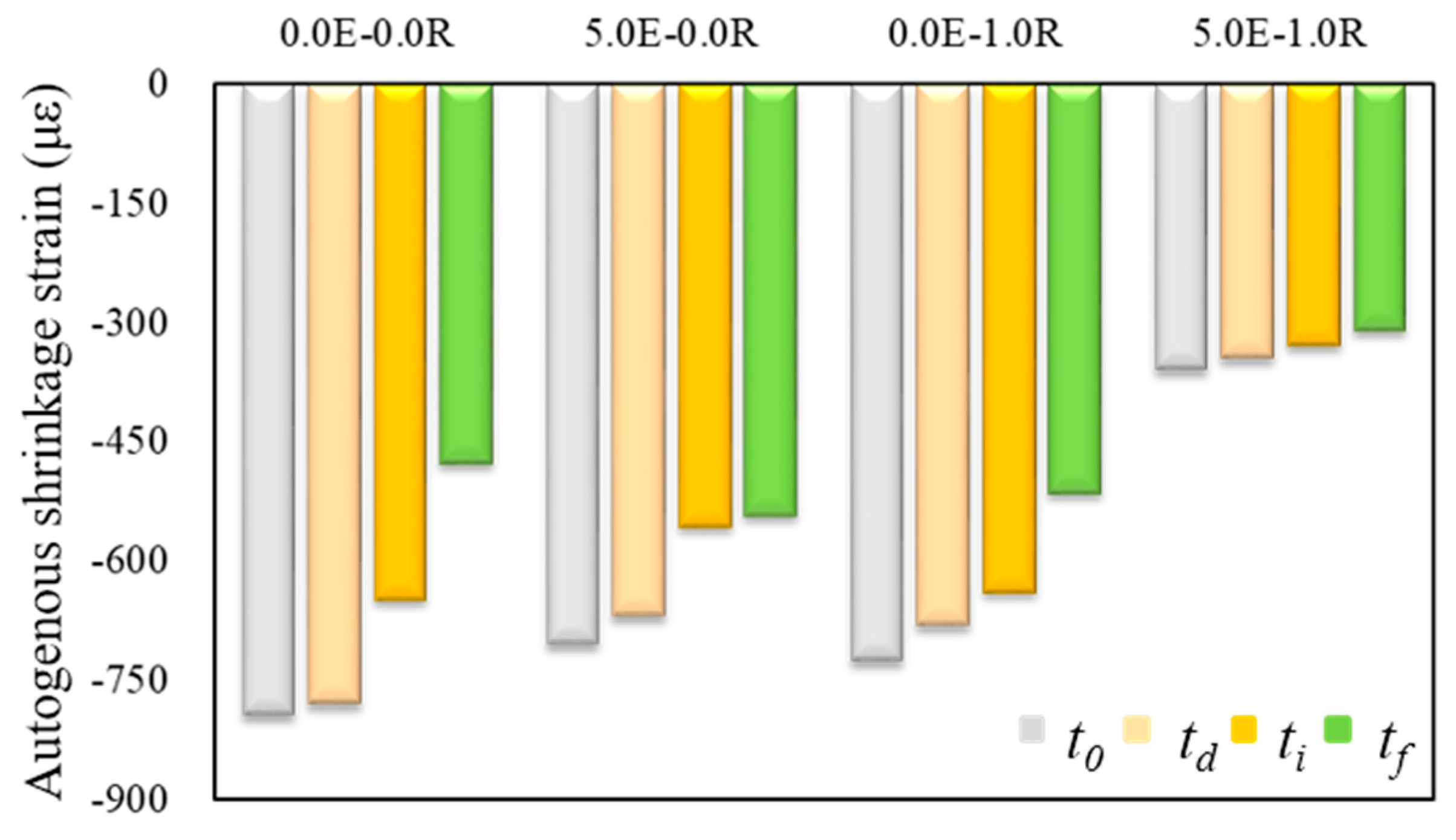

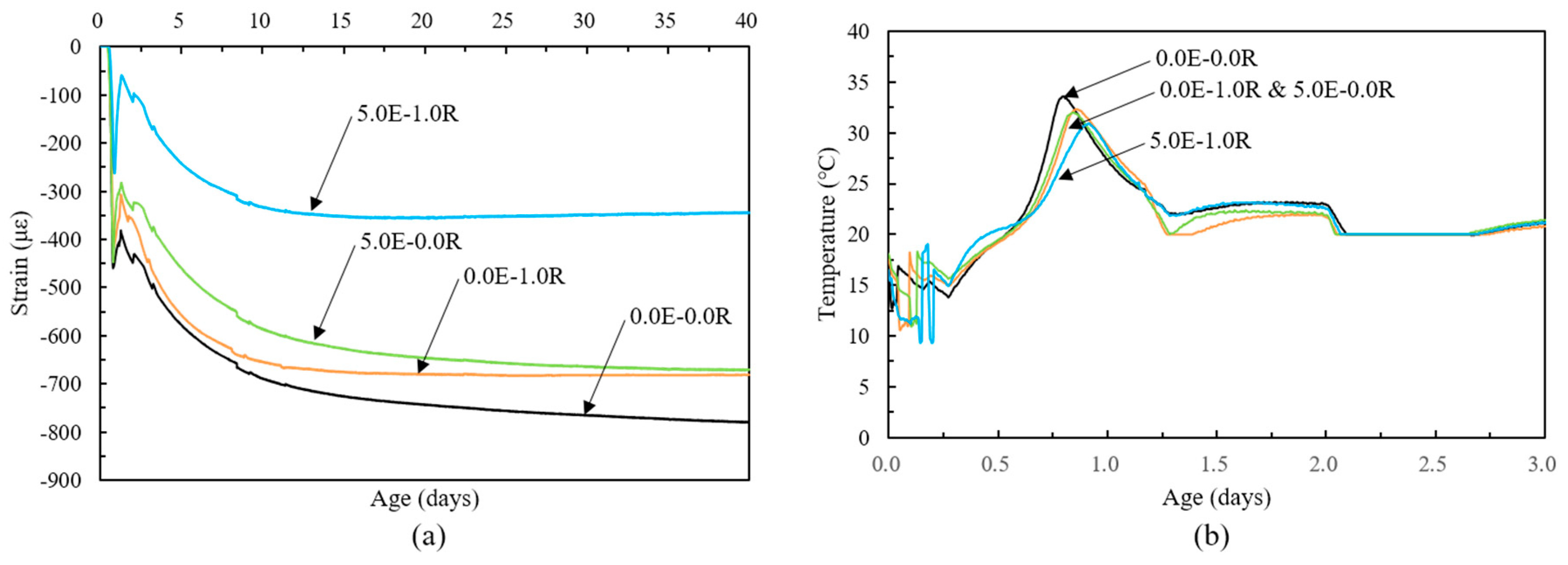

3.3. Autogenous Shrinkage Behavior under Free Conditions

3.3.1. Comparison of the Shrinkage Behavior under Different Time-Zero Conditions

3.3.2. Comparison of the Shrinkage Behavior of the HPC to Different Admixture Contents

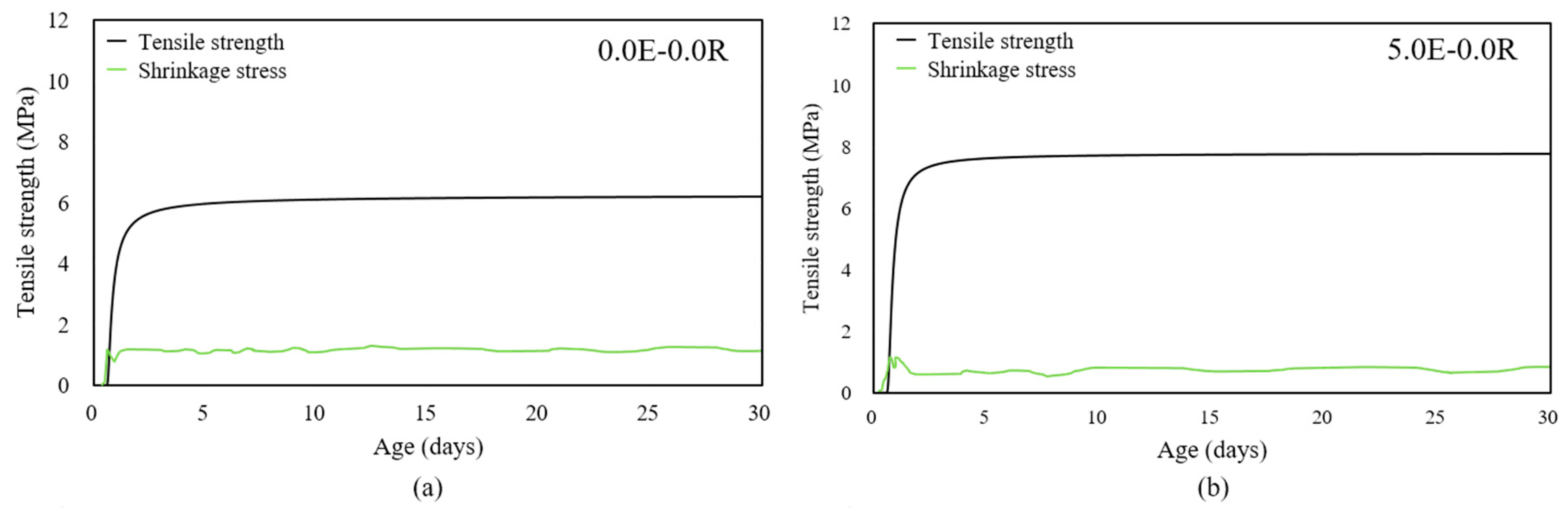

3.4. Autogenous Shrinkage Behavior under Restrained Conditions

4. Conclusions

- (1)

- The HPC mixture including SA showed slightly earlier setting times, and when using EA were approximately 22.6–37.9% earlier than those of the other specimens without EA. For the compressive strength mixture including admixture contents provided 4.8–12% higher compressive strength than those of specimen 0.0E-0.0R. This is because of the micro-cracks in the matrix are decreased by reducing the shrinkage, and the capillary pores are filled, basically resulting in a denser matrix according to the secondary ettringite when using EA and/or SA;

- (2)

- The specimen with 1.0% SA, improved test age tensile strength approximately 1.2–23.2%, and specimen with 5.0% EA, improved the tensile strength approximately 2.8–31.5% compared to the 0.0E-0.0R specimen. Due to the synergistic effect of the EA and SA, the 5.0E-1.0R specimens showed the greatest strength for test ages;

- (3)

- A comparison of 40 day shrinkage behavior under different time-zero conditions, using initial and final set as time-zeros were respectively 8.3–21.0% and 13.7–40.0% decreased than those evaluated from the start point of the shrinkage strain development. Therefore, the start point of shrinkage strain development was assumed to be time-zero for the free autogenous shrinkage measurements in this study;

- (4)

- The specimens using 1.0% SA or 5.0% EA resulted in a 12.6% or 14.0% reduction in autogenous shrinkage after 40 days compared to the 0.0E-0.0R specimen, respectively. The combined effect of the EA and SA resulted in a 55.7% reduction in autogenous shrinkage. Therefore, just combining the EA and SA, restrained autogenous shrinkage cracks do not occur.

Author Contributions

Funding

Conflicts of Interest

References

- Meddah, M.S.; Suzuki, M.; Sato, R. Influence of a combination of expansive and shrinkage-reducing admixture on autogenous deformation and self-stress of silica fume high-performance concrete. Constr. Buil. Mater. 2011, 25, 239–250. [Google Scholar] [CrossRef]

- Triandafilou, L.N. Implementation of high-performance materials: When Will They Become Standard? J. Transport. Res. Board. 2005, 11, 22–48. [Google Scholar] [CrossRef]

- Bentz, D.P.; Jensen, O.M. Mitigation strategies for autogenous shrinkage cracking. Cem. Concr. Compos. 2004, 26, 677–685. [Google Scholar] [CrossRef]

- Miguel, J.O.; Antόnio, B.T.; Fernando, G.B. Combined effect of expansive and shrinkage reducing admixtures to control autogenous shrinkage in self-compacting concrete. Cons. Buil. Mater. 2014, 52, 267–275. [Google Scholar]

- Yoo, D.Y.; Banthia, N.; Yoon, Y.S. Effectiveness of shrinkage reducing admixture in reducing autogenous shrinkage stress of ultra-high-performance fiber-reinforced concrete. Cem. Concr. Comps. 2015, 64, 27–36. [Google Scholar] [CrossRef]

- Park, J.J.; Yoo, D.Y.; Kim, S.W.; Yoon, Y.S. Benefits of using expansive and shrinkage reducing agents in ultra-high-performance concrete for volume stability. Mag. Concr. Res. 2014, 66, 745–750. [Google Scholar] [CrossRef]

- Jiang, Z.; Sun, Z.; Wang, P. Autogenous relative humidity change and autogenous shrinkage of high performance cement pastes. Cem. Concr. Res. 2005, 35, 1539–1545. [Google Scholar] [CrossRef]

- Meddah, M.S.; Suzuki, M.; Sato, R. Combined effect of shrinkage reducing and expansive agents on autogenous deformation of high-performance concrete, Sustainable concrete technology and structures in local climate and development conditions. In Proceedings of the 3rd ACF international conference—ACF/VCA-2008, HoChiMinh City, Vietnam, 11–13 November 2008; pp. 339–346. [Google Scholar]

- Bentz, D.P.; Geiker, M.R.; Hansen, K.K. Shrinkage-reducing admixtures and early age desiccation in cement pastes and mortars. Cem. Concr. Res. 2001, 31, 1075–1085. [Google Scholar] [CrossRef]

- Malteses, C.; Pistolesi, C.; Lolli, A.; Bravo, A.; Ceruli, T.; Salvioni, D. Combined effect of expansive and shrinkage reducing admixtures to obtain stable and durable mortars. Cem. Concr. Res. 2005, 35, 2244–2251. [Google Scholar]

- Brooks, J.J.; Johari, M.A.M.; Mazloom, M. Effect of admixtures on the setting times of high-strength concrete. Cem. Concr. Comps. 2000, 22, 293–301. [Google Scholar] [CrossRef]

- Konik, Z.; Malolepszy, J.; Roszczynialsky, W.; Stok, A. Production of expansive additive to Portland cement. J. Euro. Ceram. Socie. 2007, 27, 605–609. [Google Scholar] [CrossRef]

- Han, C.G.; Han, M.C.; Song, S.H.; Yoon, S. Drying shrinkage of concrete combining expansive additives and shrinkage reducing agent. J. Korea Concr. Insti. 2006, 18, 397–404. [Google Scholar]

- Weiss, J.; Berke, N.S. Shrinkage reducing admixtures. In Early Age Cracking in Cementitious Systems; Bentur, A., Ed.; RILEM State-of-the-Art Report; International Union of Testing and Research Laboratories for Materials and Structures: Paris, France, 2002. [Google Scholar]

- Shah, S.P.; Karaguler, M.E.; Sarigaphuti, M. Effect of shrinkage reducing admixtures on restrained shrinkage cracking of concrete. ACI Mater. J. 1992, 89, 289–295. [Google Scholar]

- Balogh, A. New admixture combats concrete shrinkage. Concr. Construct. 1996, 41, 546–551. [Google Scholar]

- Folliard, K.J.; Berke, N.S. Properties of high performance concrete containing shrinkage reducing admixture. Cement Concr. Res. 1997, 27, 1357–1364. [Google Scholar] [CrossRef]

- Tanimura, M.; Hiramatsu, Y.; Hyodo, H.; Sato, R. Flexural performance of RC members made of low shrinkage high performance concrete. In Proceedings of the 6th international symposium on utilization of high strength/high performance concrete; Leipzig, Germany. 2002, 2, 1437–1452. [Google Scholar]

- Meddah, M.S.; Suzuki, M.; Sato, R. Self-induced stress in high-performance concrete treated with a combination of shrinkage-reducing and expansive admixtures. In Proceedings of the 21st Century Superhero, Session C6. In The 11th annual international FIB symposium; Proceeding papers on CD-ROM, London, UK, 22–24 June 2009. [Google Scholar]

- Yoo, D.Y.; Min, K.H.; Lee, J.H.; Yoon, Y.S. Shrinkage and cracking of restrained ultra-high-performance fiber-reinforced concrete slabs at early age. Const. Buil. Mater. 2014, 73, 357–365. [Google Scholar] [CrossRef]

- Tazawa, E. (Ed.) Autogenous Shrinkage of Concrete; Japan Concrete Institute (JCI), E&FN Spon: London, UK, 1999. [Google Scholar]

- Kang, S.T.; Choi, J.I.; Koh, K.T.; Lee, K.S.; Lee, B.Y. Hybrid effect of steel fiber and microfiber on the tensile behavior of ultra-high performance concrete. Comps. Struct. 2016, 245, 37–42. [Google Scholar] [CrossRef]

- Standard Test Method for Slump of Hydraulic Cement Concrete; ASTM C143/C143M-15; ASTM International: West Conshohocken, PA, USA, 2015; pp. 1–4.

- Standard Test Method for Time of Setting of Concrete Mixture by Penetration Resistance; ASTM C403-08; ASTM International: West Conshohocken, PA, USA, 2008; pp. 1–7.

- Yoo, D.Y.; Park, J.J.; Kim, S.W.; Yoon, Y.S. Early age setting, shrinkage and tensile characteristics of ultra high performance fiber reinforced concrete. Const. Buil. Mater. 2013, 41, 427–438. [Google Scholar] [CrossRef]

- Standard Test Method for Time of Compressive Strength of Cylindrical Concrete Specimens; ASTM C39-14; ASTM International: West Conshohocken, PA, USA, 2014; pp. 1–7.

- Dao, V.T.N.; Dux, P.F. Tensile properties of early-age concrete. ACI Mater. J. 2009, 106, 483–492. [Google Scholar]

- Kang, S.T.; Kim, J.K. The relation between fiber orientation and tensile behavior in an ultra high performance fiber reinforced cementitious composites (UHPFRCC). Cem. Concr. Compos. 2011, 41, 1001–1014. [Google Scholar] [CrossRef]

- Saliba, J.; Rozière, E.; Grondin, F.; Loukili, A. Influence of shrinkage-Reducing admixtures on plastic and long-term shrinkage. Cem. Concr. Comps. 2011, 33, 209–217. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Kang, S.T.; Lee, J.H.; Yoon, Y.S. Effect of shrinkage reducing admixture on tensile and flexural behaviors of UHPCFRC considering fiber distribution characteristics. Cem. Concr. Res. 2013, 54, 180–190. [Google Scholar] [CrossRef]

- Wang, J.Y.; Banthia, N.; Zhang, M.H. Effect of shrinkage reducing admixture on flexural behaviors of fiber reinforced cementitious composites. Cem. Concr. Comps. 2012, 34, 443–450. [Google Scholar] [CrossRef]

- Jonasson, J.E. Slipform Construction-Calculations for Assessing Protection against Early Freezing, Fo 4: 84; Swedish Cement and Concrete Institute: Stockholm, Sweden, 1985; pp. 1–13. [Google Scholar]

- Graybeal, B.A. Compressive behavior of ultra-high-performance fiber-reinforced concrete. ACI Mater. J. 2007, 104, 146–152. [Google Scholar]

- Yoo, D.Y.; Park, J.J.; Kim, S.W.; Yoon, Y.S. Influence of reinforcing bar type on autogenous shrinkage stress and bond behavior of ultra high performance fiber reinforced concrete. Cem. Concr. Compos. 2014, 48, 150–161. [Google Scholar] [CrossRef]

- Standard Test Method for Autogenous Strain of Cement Paste and Mortar; ASTM C1698; ASTM International: West Conshohocken, PA, USA, 2009.

- Darquennes, A.; Staquet, S.; Espion, B. Determination of time-zero and its effect on autogenous deformation evolution. Eur. J. Environ. Civil. Eng. 2011, 15, 1017–1029. [Google Scholar] [CrossRef]

- Kazemi-Kamyab, H.; Denarie, E.; Bruhwiler, E. Very early age stiffness development of UHPFRC matrices in low temperatures. In Proceedings of the 8th fib PhD symposium in Kgs, Lyngby, Denmark, 2010. [Google Scholar]

- Bjøntegaard, ø.; Sellevold, E.J. Interaction between thermal dilation and autogenous deformation in high performance concrete. Mater. Struct. 2001, 34, 266–272. [Google Scholar] [CrossRef]

- Bernard, F. (Ed.) Ultra high performance fibre-reinforced concretes. In Interim Recommendations; Association Française de G_enie Civil (AFGC/SETRA): Bagneux, France, 2002. [Google Scholar]

- Hwang, S.D.; Khayat, K.H. Effect of mixture composition on restrained shrinkage cracking of self-consolidating concrete used in repair. ACI Mater. J. 2008, 105, 499–509. [Google Scholar]

- Rajabipour, F.; Sant, G.; Weiss, J. Interactions between shrinkage reducing admixtures (SRA) and cement paste’spore solution. Cem. Concr. Res. 2008, 38, 606–615. [Google Scholar] [CrossRef]

- Abdalla, A. Concrete cover requirements for FRP reinforced members in hot climates. Compos. Struct. 2006, 73, 61–69. [Google Scholar] [CrossRef]

| w/b (%) | C | W | BS | Zr | Silica Sand | Silica Flour | SF (vf, %) | SP | EA (%) | SA (%) | Flow (mm) | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 19.5 | 16.3 | ||||||||||||

| 0.0E-0.0R | 21.7 | 1.00 | 0.27 | 0.18 | 0.08 | 1.10 | 0.30 | 1.0 | 0.5 | 0.02 | - | - | 820 |

| 5.0E-0.0R | 0.02 | 5.0 | - | 765 | |||||||||

| 0.0E-1.0R | 0.01 | - | 1.0 | 750 | |||||||||

| 5.0E-1.0R | 0.02 | 5.0 | 1.0 | 750 | |||||||||

| Surface Area (cm2/g) | Density (g/cm3) | Chemical Composition (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | ZrO2 | Na2O | K2O | |||

| C | 3413 | 3.15 | 21.25 | 5.28 | 3.02 | 61.00 | 3.71 | 1.24 | - | - | - |

| BS | 4250 | 2.90 | 21.01 | 6.40 | 0.09 | 43.32 | 5.90 | 2.78 | - | - | - |

| Zr | 80,000 | 2.50 | 94.00 | 0.23 | 0.10 | - | - | 3.00 | - | - | |

| Silica flour | 2.65 | 0.75 | 99.60 | 0.31 | 0.025 | 0.010 | 0.006 | - | - | 0.009 | 0.004 |

| Diameter df (mm) | Length, lf (mm) | Aspect Ratio (df/lf) | Density (g/cm3) | Tensile Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|---|

| 0.2 | 16.3 | 81.5 | 7.9 | 2650 | 200 |

| 19.5 | 97.5 |

| Types | a | b | R2 | Initial Set (Hours) | Final Set (Hours) | fck (MPa) | |

|---|---|---|---|---|---|---|---|

| Mean | S.D. | ||||||

| 0.0E-0.0R | 12.72 | 35.65 | 0.973 | 11.77 | 13.96 | 103.65 | 1.44 |

| 5.0E-0.0R | 10.57 | 27.49 | 0.993 | 7.49 | 9.09 | 110.36 | 0.32 |

| 0.0E-1.0R | 13.40 | 37.97 | 0.934 | 12.06 | 14.08 | 108.44 | 1.82 |

| 5.0E-1.0R | 13.59 | 35.93 | 0.938 | 8.02 | 9.34 | 116.12 | 1.81 |

| Types | Tensile Strength (MPa) | Non-Linear Regression Coefficients | |||||

|---|---|---|---|---|---|---|---|

| 1-day | 3-day | 7-day | 28-day | β | k | R2 | |

| 0.0E-0.0R | 4.98 | 5.30 | 6.57 | 6.35 | 0.130 | 1.402 | 0.965 |

| 5.0E-0.0R | 5.12 | 8.10 | 8.68 | 8.35 | 0.046 | 3.665 | 0.982 |

| 0.0E-1.0R | 5.04 | 7.23 | 8.05 | 7.82 | 0.074 | 1.980 | 0.966 |

| 5.0E-1.0R | 6.24 | 8.15 | 8.79 | 9.25 | 0.156 | 1.449 | 0.983 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, T.-F.; Kim, S.-K.; Koh, K.-T.; Yoon, Y.-S. Synergistic Benefits of Using Expansive and Shrinkage Reducing Admixture on High-Performance Concrete. Materials 2018, 11, 2514. https://doi.org/10.3390/ma11122514

Yuan T-F, Kim S-K, Koh K-T, Yoon Y-S. Synergistic Benefits of Using Expansive and Shrinkage Reducing Admixture on High-Performance Concrete. Materials. 2018; 11(12):2514. https://doi.org/10.3390/ma11122514

Chicago/Turabian StyleYuan, Tian-Feng, Seong-Kyum Kim, Kyung-Teak Koh, and Young-Soo Yoon. 2018. "Synergistic Benefits of Using Expansive and Shrinkage Reducing Admixture on High-Performance Concrete" Materials 11, no. 12: 2514. https://doi.org/10.3390/ma11122514

APA StyleYuan, T.-F., Kim, S.-K., Koh, K.-T., & Yoon, Y.-S. (2018). Synergistic Benefits of Using Expansive and Shrinkage Reducing Admixture on High-Performance Concrete. Materials, 11(12), 2514. https://doi.org/10.3390/ma11122514