Development of Compact High-Voltage Power Supply for Stimulation to Promote Fruiting Body Formation in Mushroom Cultivation

Abstract

:1. Introduction

2. Experimental Setup

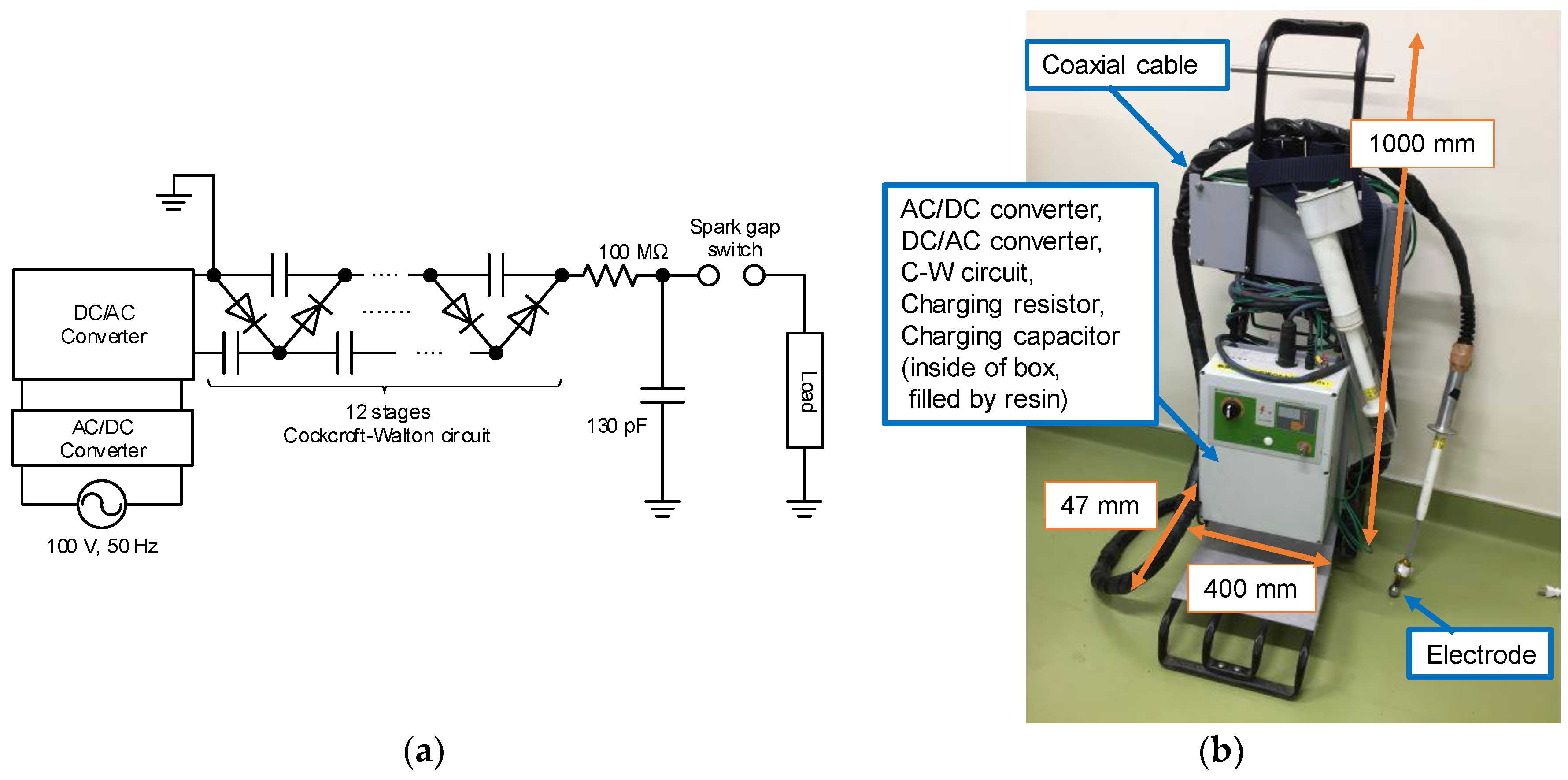

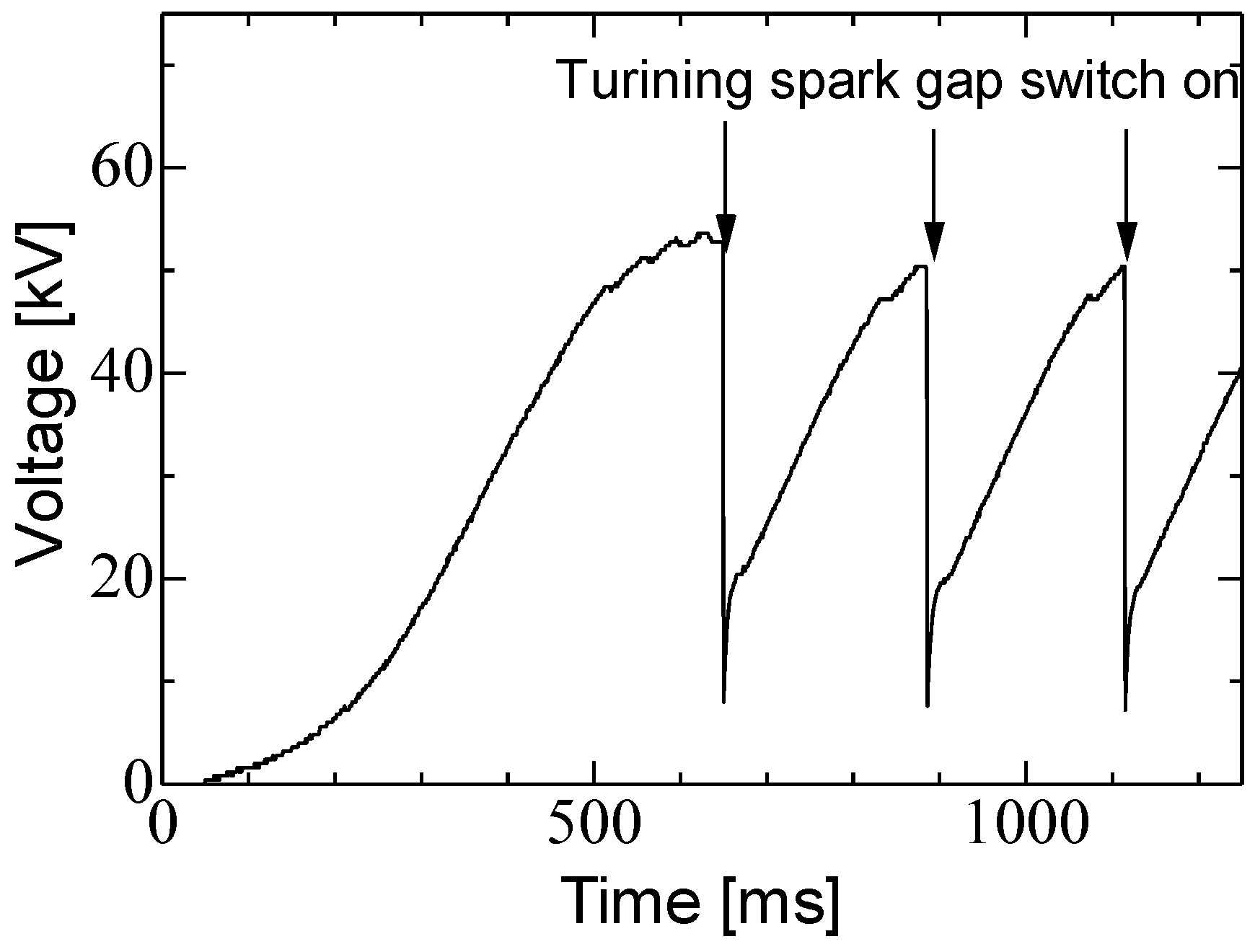

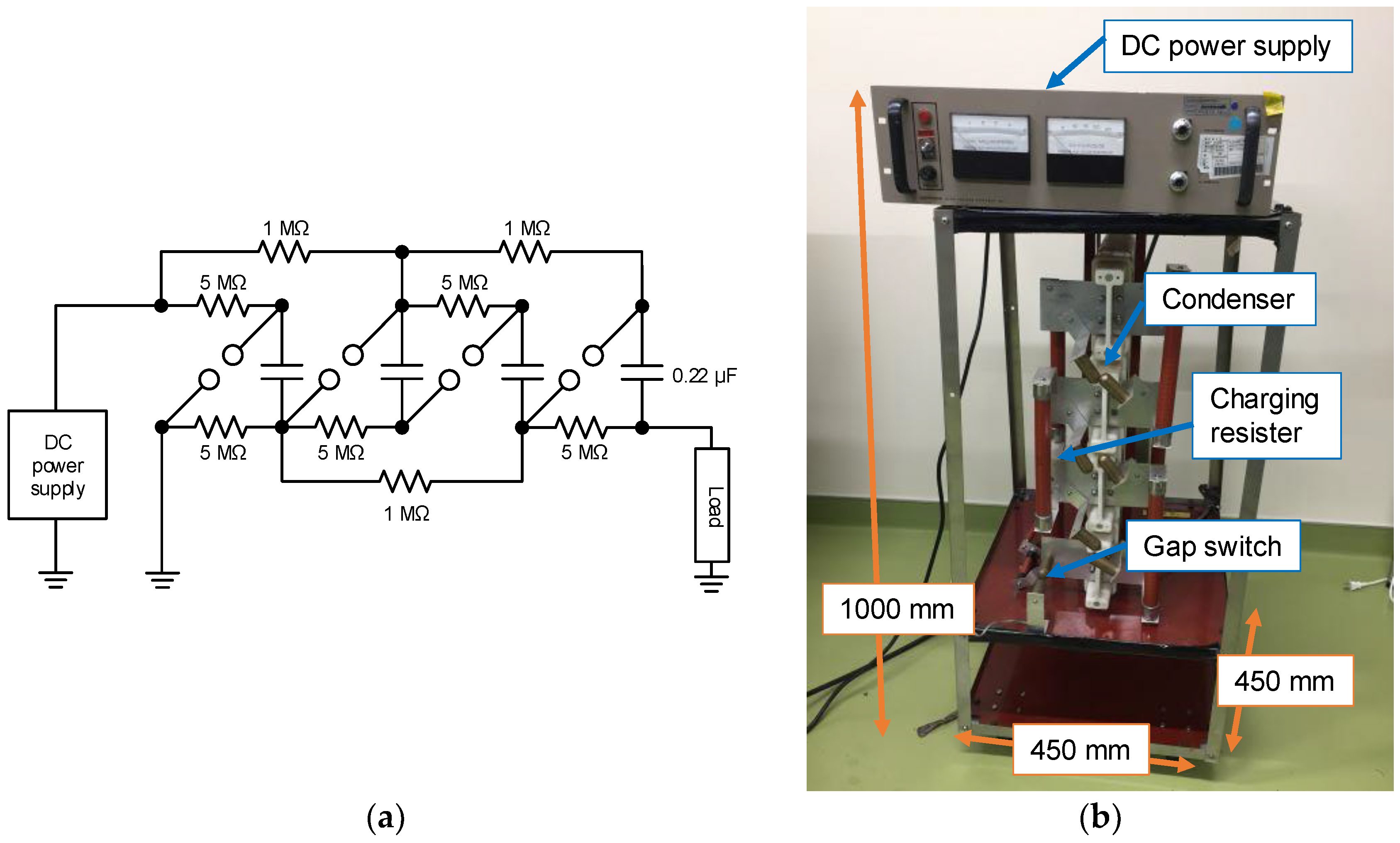

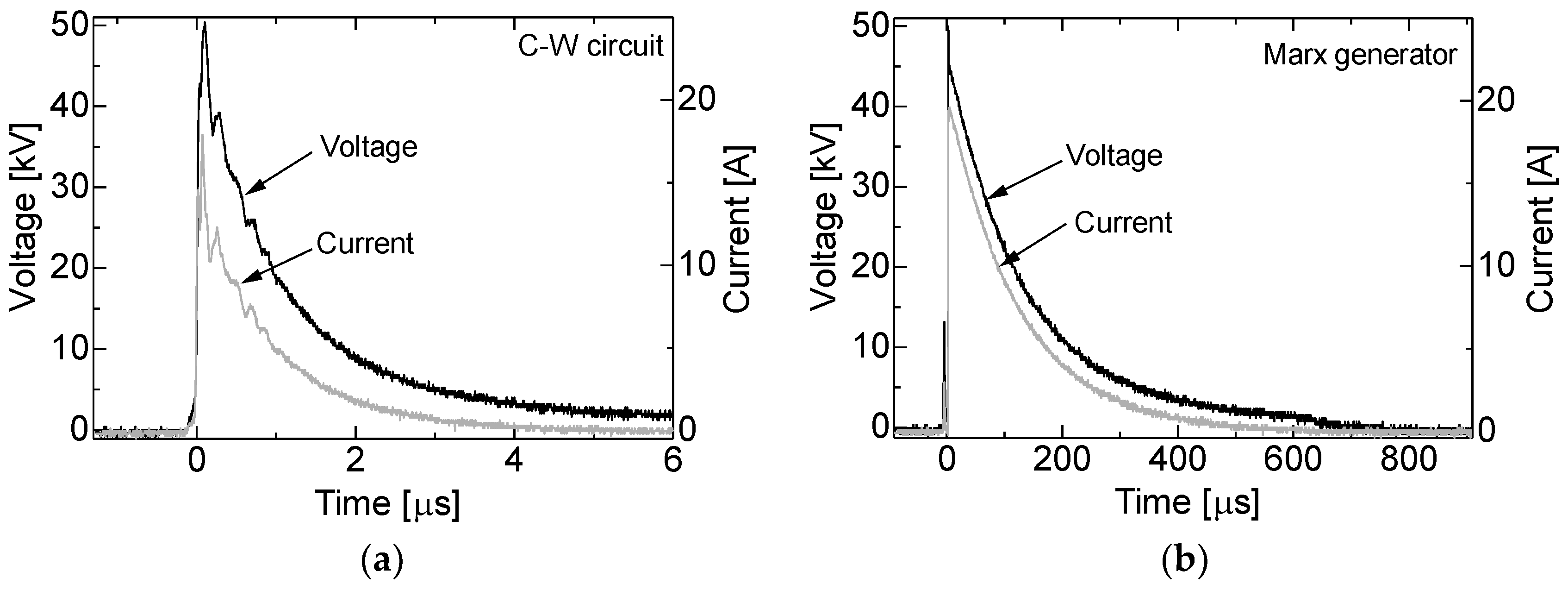

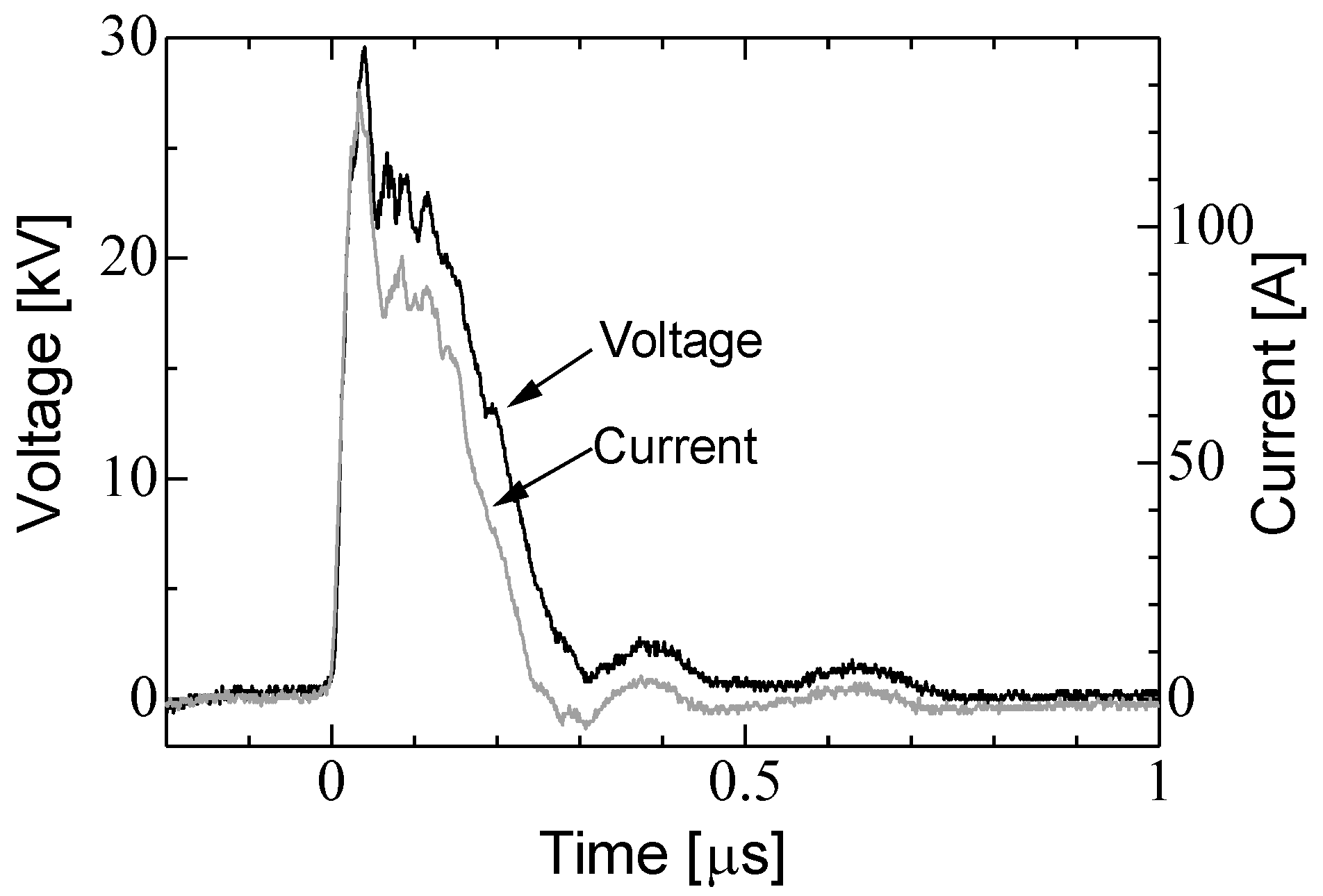

2.1. Pulsed Power Generators

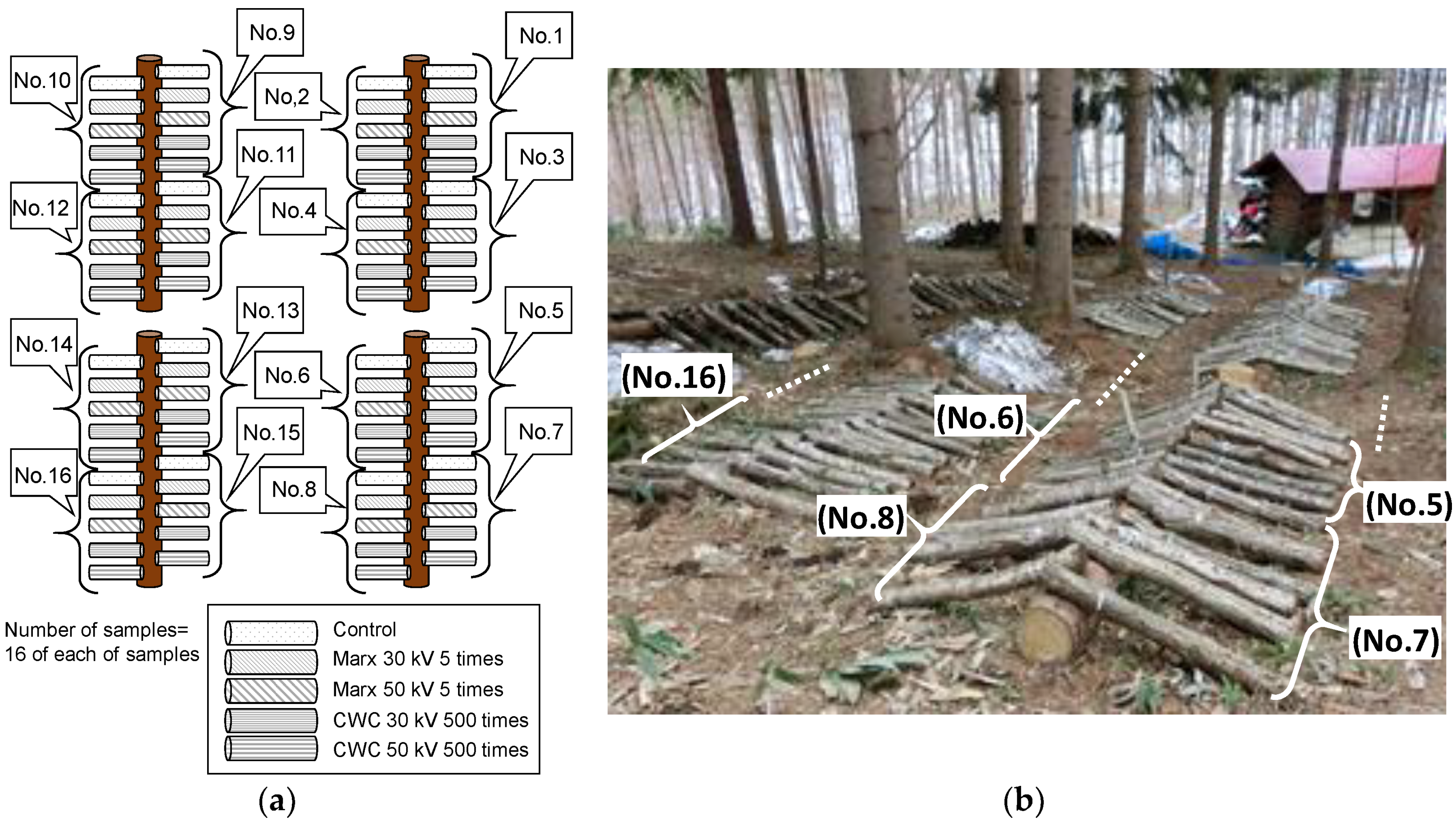

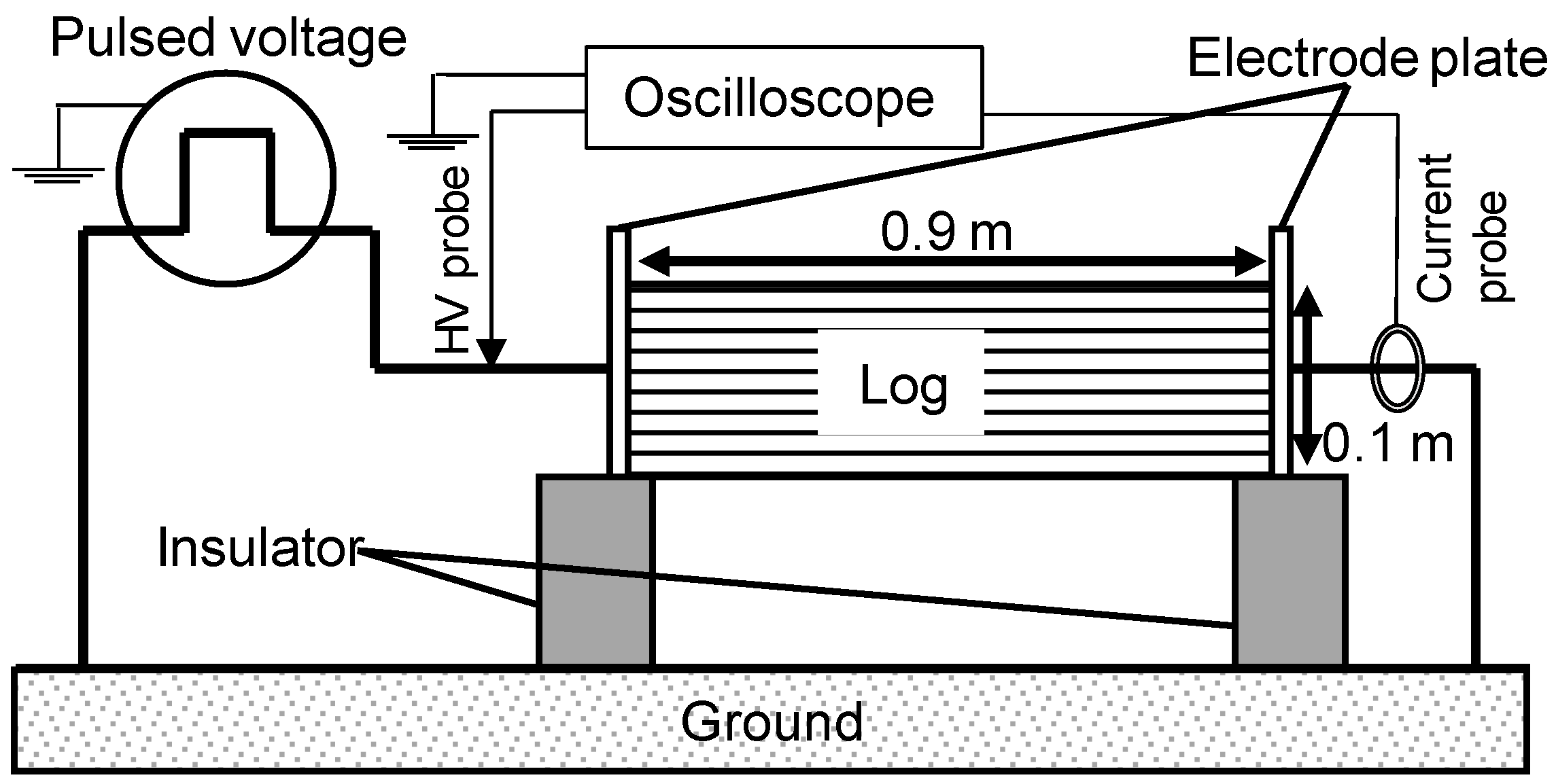

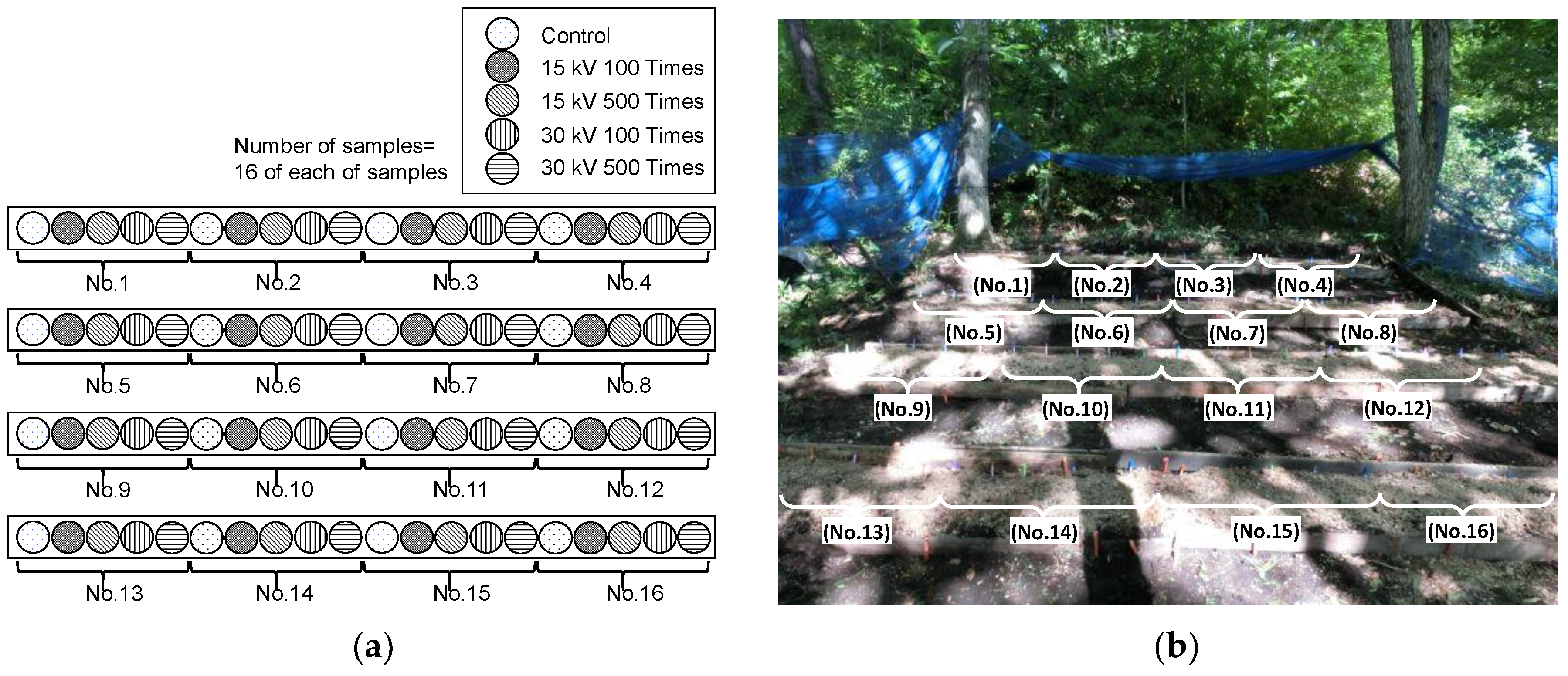

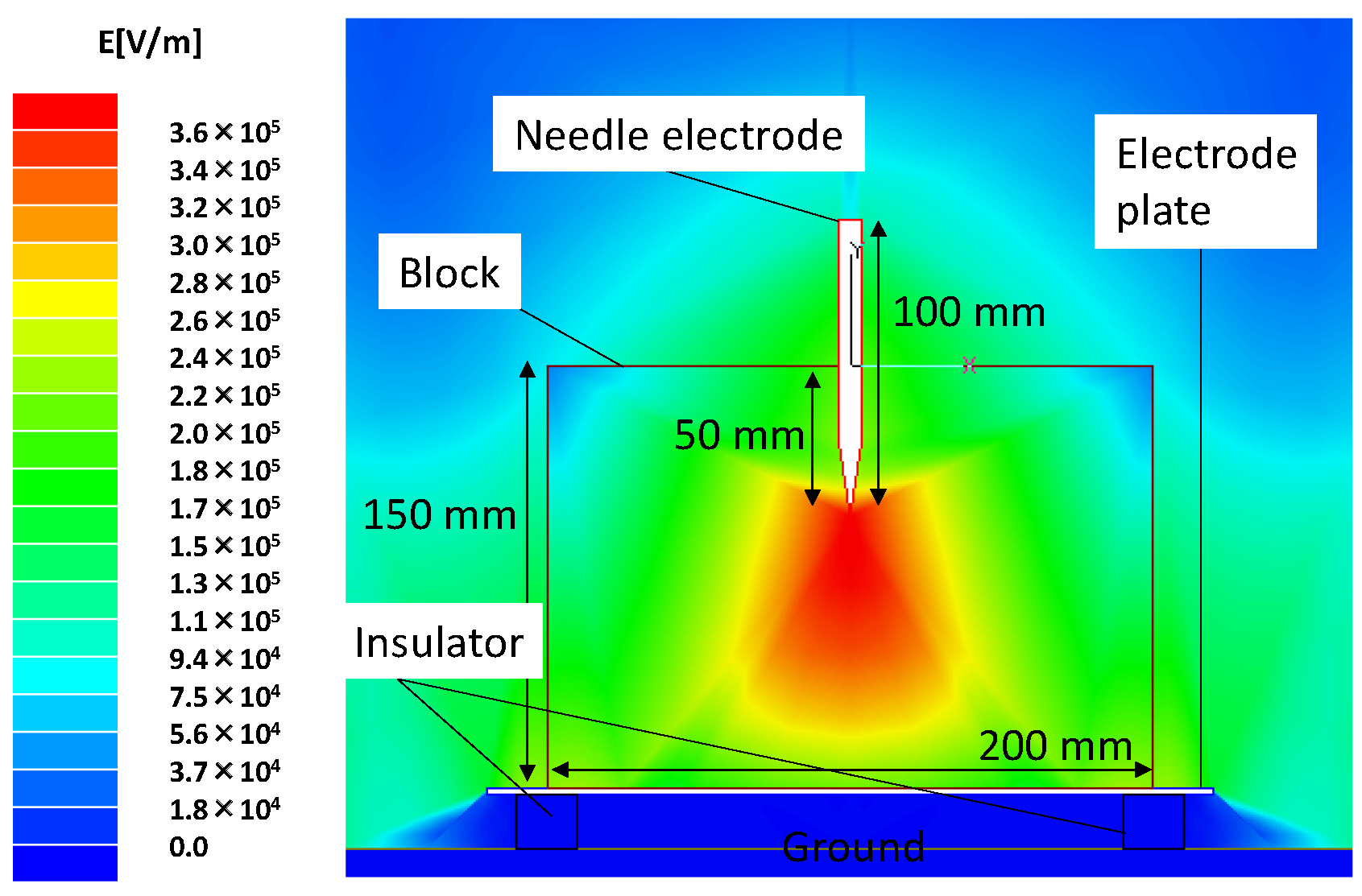

2.2. Electrical Stimulation to L. edodes

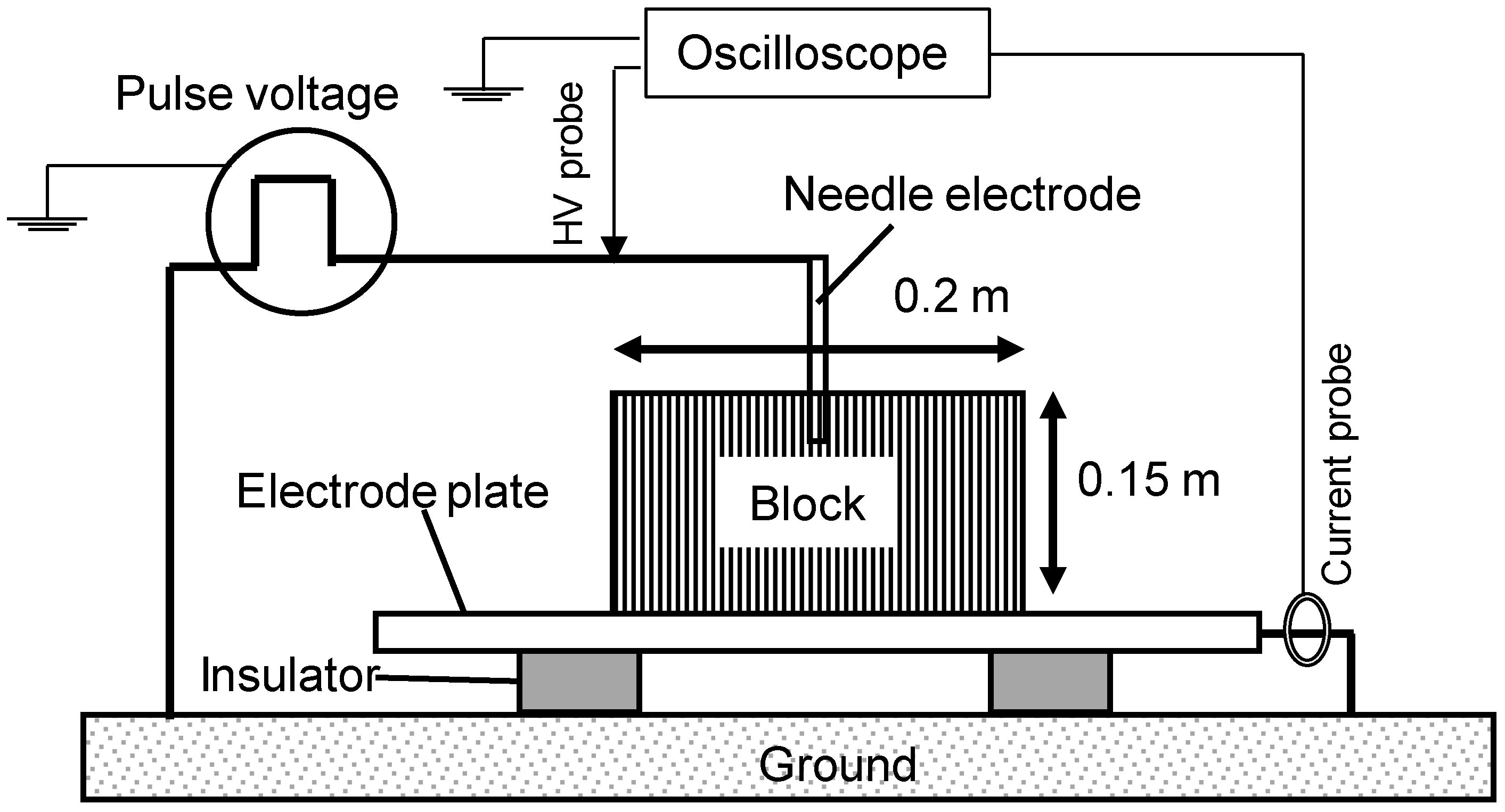

2.3. Electrical Stimulation to Lyophyllum deeastes Sing

3. Results

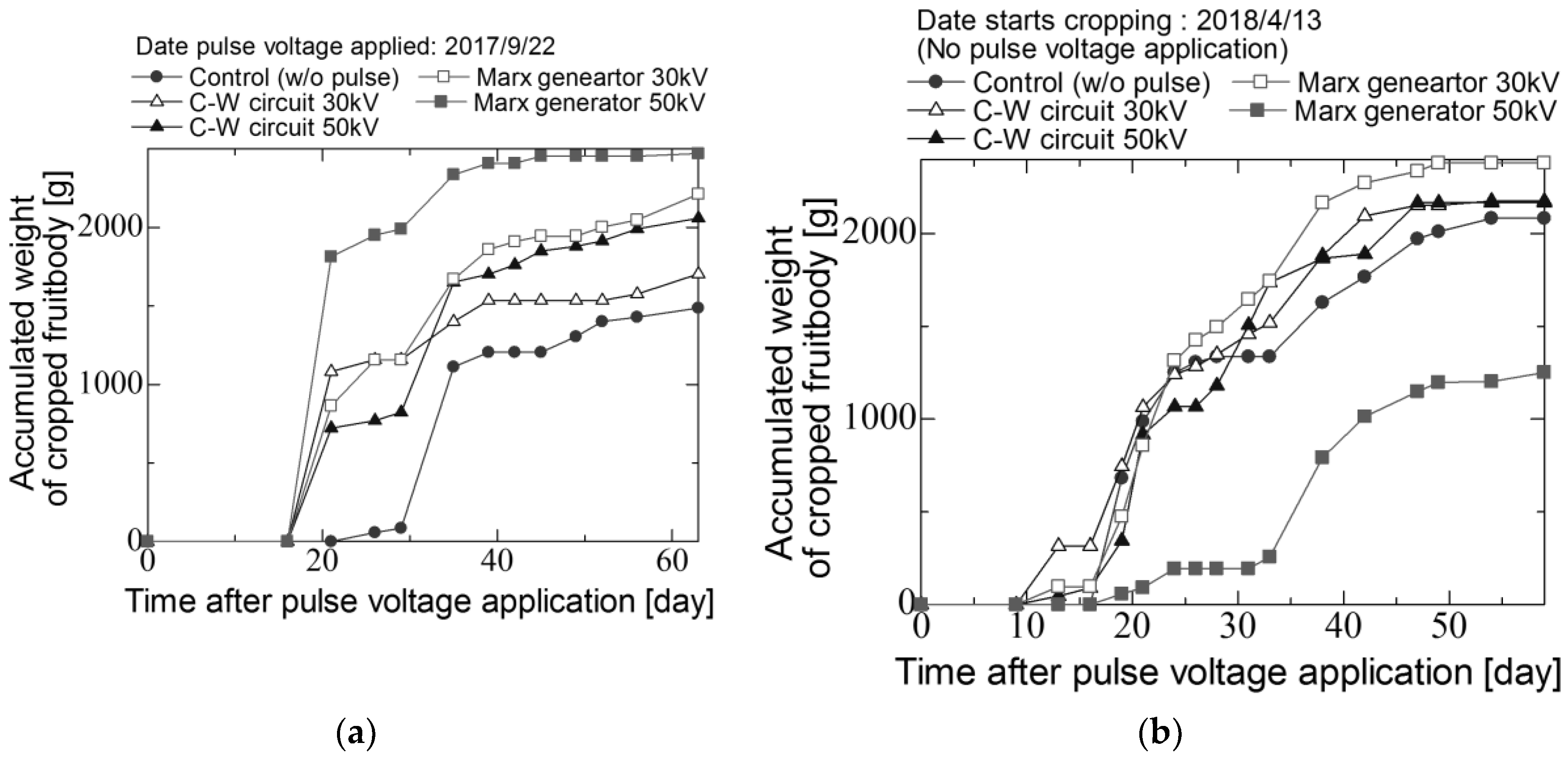

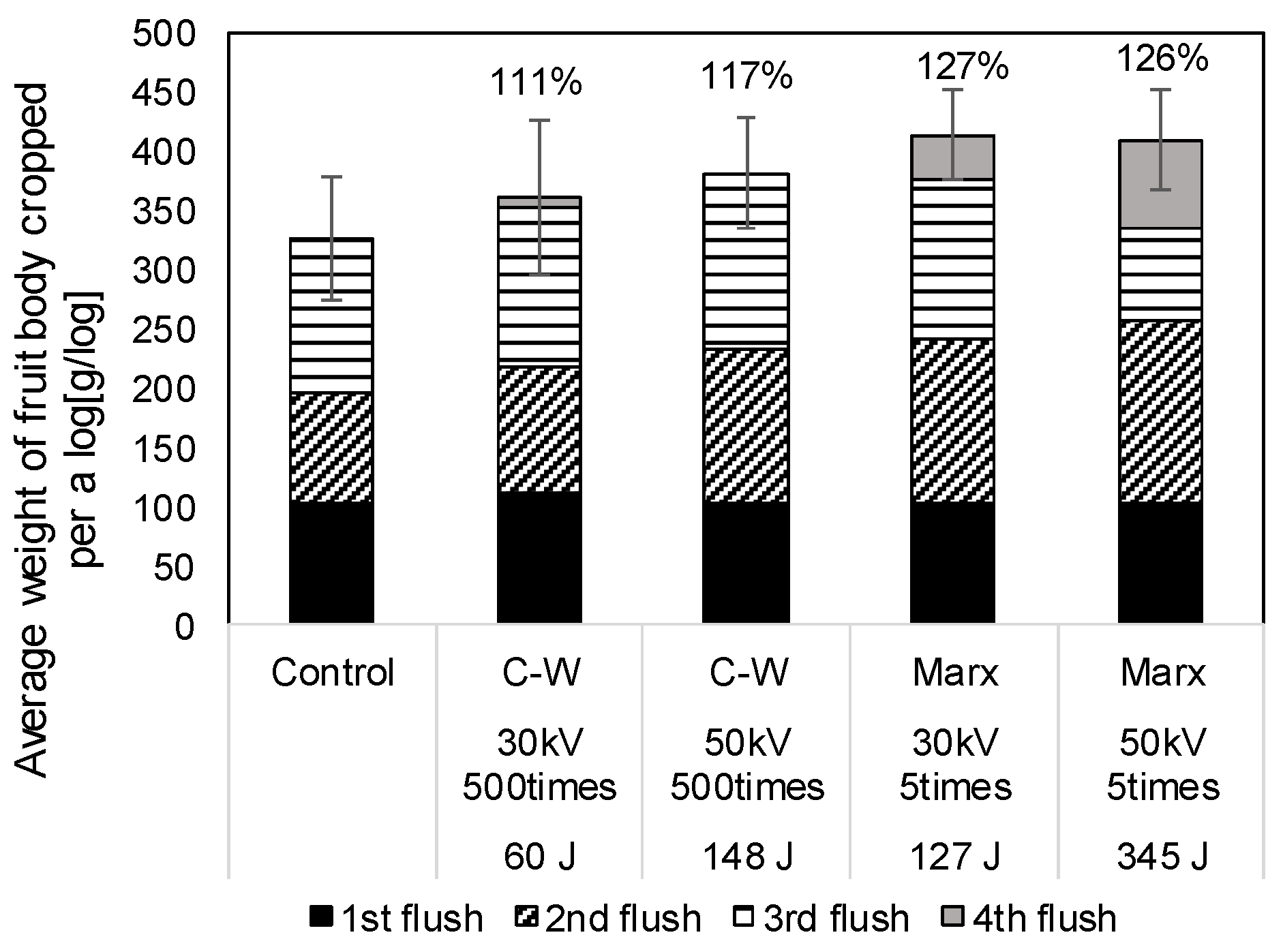

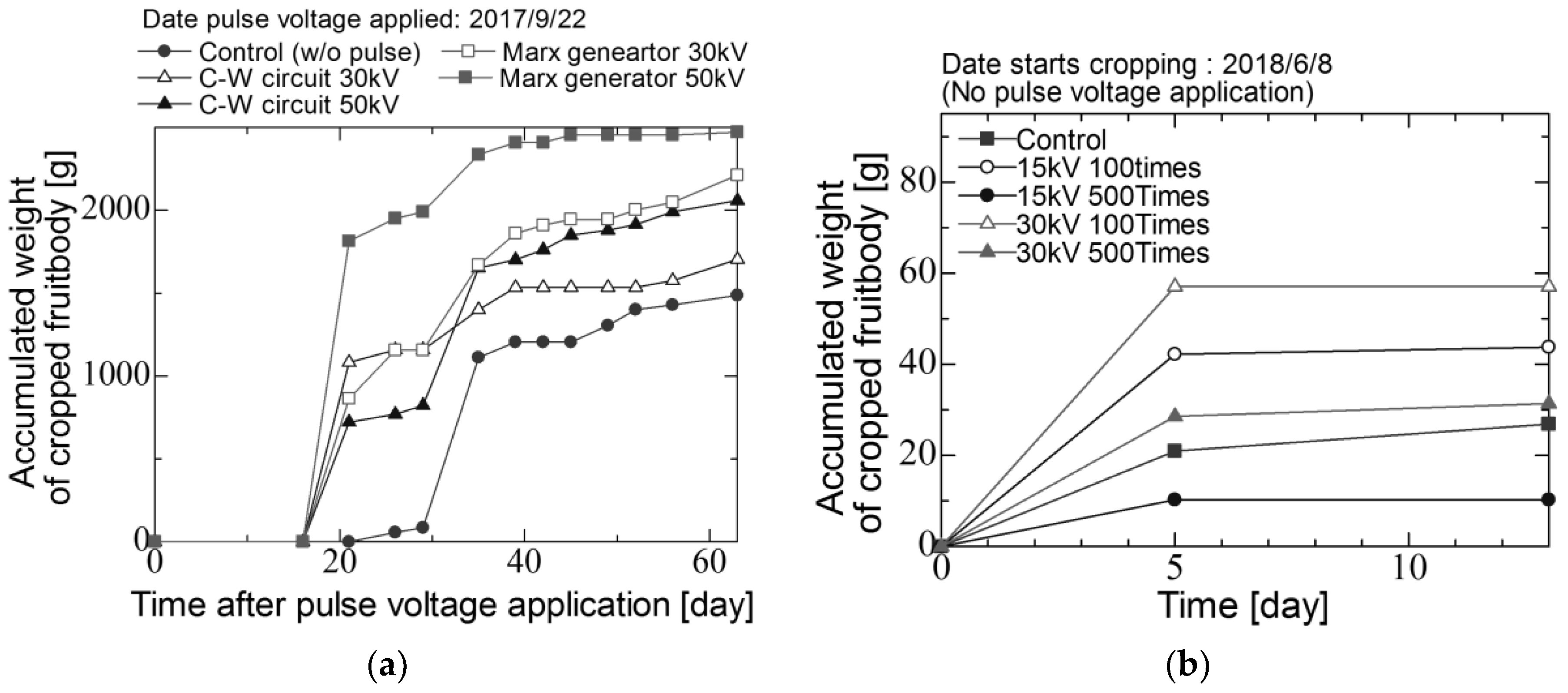

3.1. Electrical Stimulation to Logs and Cropping Fruits Body of L. edodes

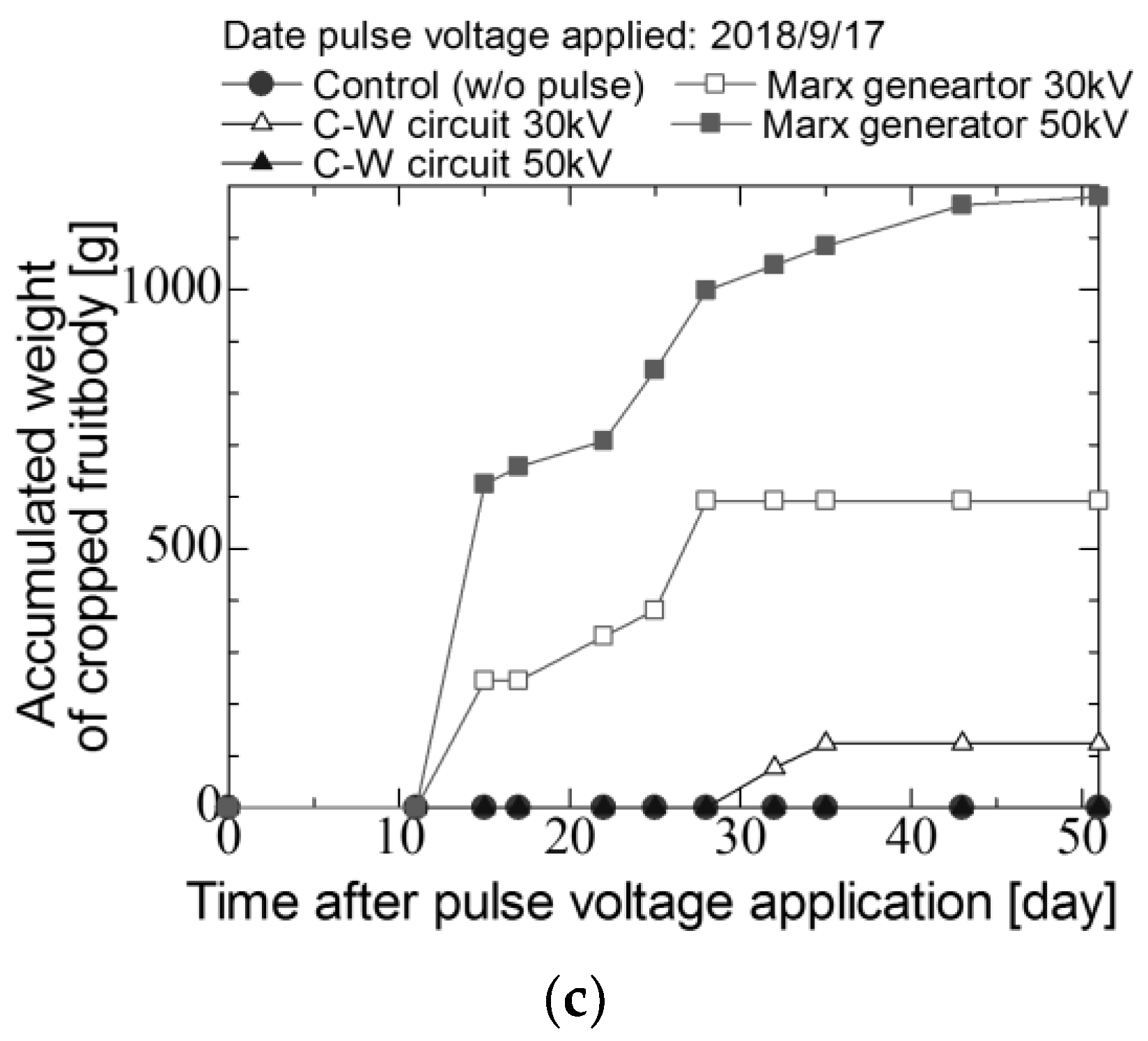

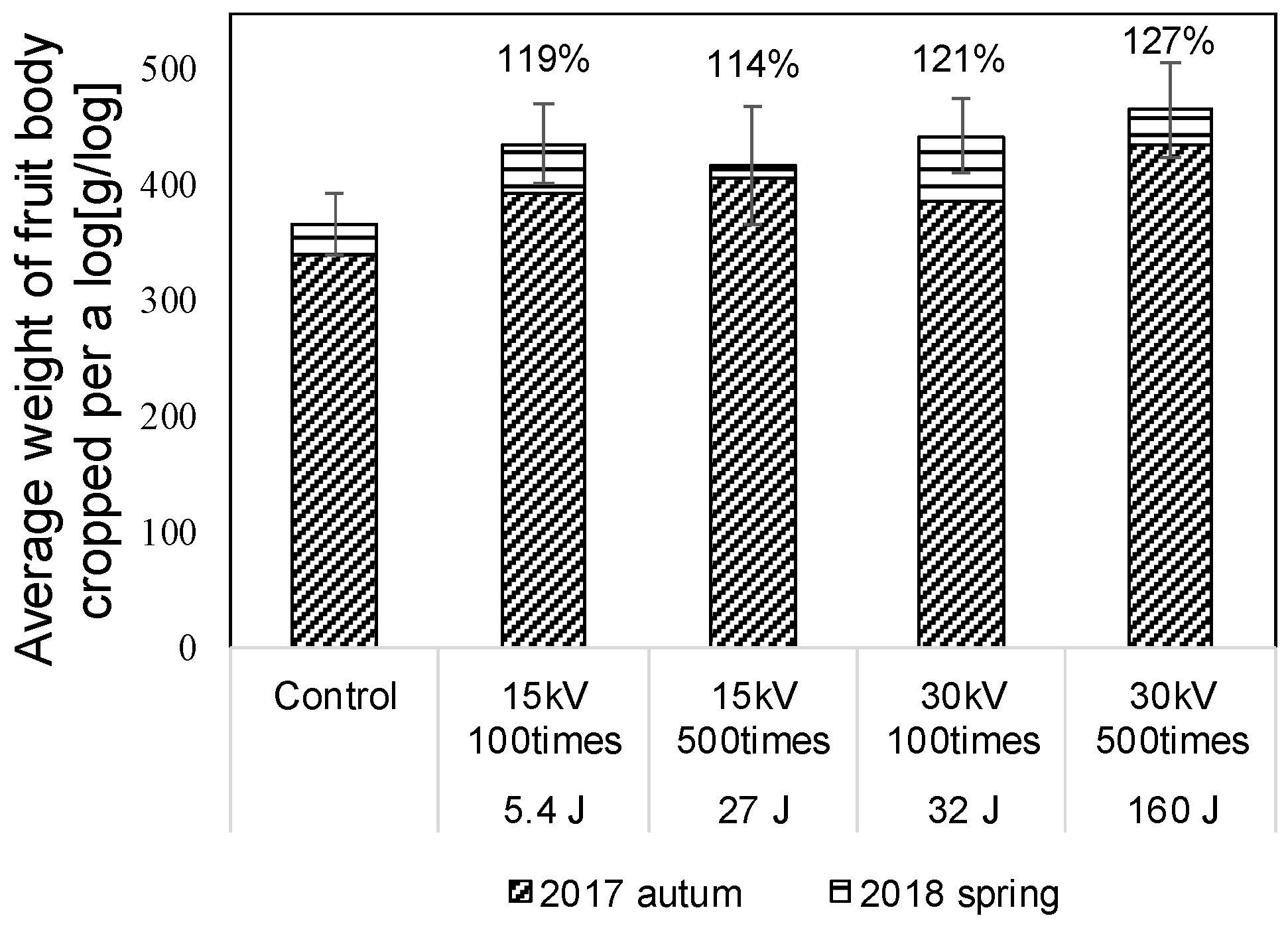

3.2. Electrical Stimulation to Blocks and Cropping Fruits Body of Lyophyllum deeastes

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jitsufuchi, Y.; Jitsufuchi, Y.; Yamamoto, M. Research for Improvement of Lentinula edodes Cultivation: Application of Electric Stimulation for Mushroom Cultivation; Kyushu Electrical Co.: Fukuoka, Japan, 1987. (In Japanese) [Google Scholar]

- Tsukamoto, S.; Maeda, T.; Ikeda, M.; Akiyama, H. Application of pulsed power to mushroom culturing. In Proceedings of the 14th IEEE International Pulsed Power Conference, Dallas, TX, USA, 15–18 June 2003; Volume 2, pp. 1116–1119. [Google Scholar]

- Takaki, K.; Yamazaki, N.; Mukaigawa, S.; Fujiwara, T.; Kofujita, H.; Takahashi, K.; Narimatsu, M.; Nagane, K. Fruit body formation of basidiomycete by pulse voltage stimulations. Front. Appl. Plasma Technol. 2009, 2, 61–64. [Google Scholar]

- Kudo, S.; Mitobe, S.; Yoshimura, Y. Electric stimulation multiplication of Lentinulus edodes. J. Inst. Electrost. Jpn. 1999, 23, 186–190. [Google Scholar]

- Ohga, S.; Iida, S.; Koo, C.-D.; Cho, N.-S. Effect of electric impulse on fruit body production on Lentinula edodes in the sawdust-based substrate. Mushroom Sci. Biotechnol. 2001, 9, 7–12. [Google Scholar]

- Ohga, S.; Cho, N.S.; Li, Y.; Royse, D.J. Utilization of pulsed power to stimulate fructification of edible mushroom. Mushroom Sci. 2004, 16, 343–352. [Google Scholar]

- Takaki, K.; Kanesawa, K.; Yamazaki, N.; Mukaigawa, S.; Fujiwara, T.; Takahasi, K.; Yamasita, K.; Nagane, K. Effect of pulsed high-voltage stimulation on Pholiota nameko mushroom yield. Acta Phys. Pol. Ser. A 2009, 115, 953–956. [Google Scholar] [CrossRef]

- Takaki, K.; Kanesawa, K.; Yamazaki, N.; Mukaigawa, S.; Fujiwara, T.; Takahasi, K.; Yamasita, K.; Nagane, K. Improvement of edible mushroom yield by electric stimulations. J. Plasma Fusion Res. Ser. 2009, 8, 556–559. [Google Scholar]

- Ohga, S.; Iida, S. Effect of Electric Impulse on sporocarp formation of ectomycorrhizal fungus Laccaria laccata in Japanese red pine plantation. J. For. Res. 2001, 6, 37–41. [Google Scholar] [CrossRef]

- Islam, F.; Ohga, S. The response of fruit body formation on Tricholoma matsutake in situ condition by applying electric pulse stimulator. ISRN Agron. 2012, 2012, 462724:1–462724:6. [Google Scholar] [CrossRef]

- Mankowski, J.; Kristiansen, M. A review of short pulse generator technology. IEEE Trans. Plasma Sci. 2000, 28, 102–108. [Google Scholar] [CrossRef]

- Takaki, K.; Takahashi, K.; Ueno, T.; Akiyama, M.; Sakugawa, T. Design and practice of pulsed power circuit. J. Plasma Fusion Res. 2011, 87, 202–215. [Google Scholar]

- Kobougias, I.C.; Tatakis, E.C. Optimal design of a half-wave Cockcroft-walton voltage multiplier with minimum total capacitance. IEEE Trans. Power Electron. 2010, 25, 2460–2468. [Google Scholar] [CrossRef]

- Rossi, J.O.; Tan, I.H.; Ueda, M. Plasma implantation using high-eneryg ions an short high voltage pulses. Nucl. Instrum. Method Phys. Res. B 2006, 242, 328–331. [Google Scholar] [CrossRef]

- Buescher, E.S.; Schoenbach, K.H. Effects of submicrosecond, high intensity pulsed electric fields on living cells—Intracellular electromanip- ulation. IEEE Trans. Dielectr. Electr. Insul. 2003, 10, 788–794. [Google Scholar] [CrossRef]

- Takaki, K.; Takahashi, K.; Sakamoto, Y.; Plant and Mushroom Development. Chap. 7 High-voltage methods for mushroom fruit-body developments. In Physical Methods for Stimulation of Plant and Mushroom Development; El-Esawai, M.A., Ed.; IntechOpen Ltd.: London, UK, 2018; pp. 95–113. [Google Scholar]

- Miyazaki, Y.; Sakuragi, Y.; Yamazaki, T.; Shishido, K. Target Genes of the Developmental Regulator PRIB of the Mushroom Lentinula edodes Target Genes of the Developmental Regulator PRIB of the Mushroom Lentinula edodes. Biosci. Biotechnol. Biochem. 2004, 68, 1898–1905. [Google Scholar] [CrossRef] [PubMed]

- Muraguchi, H.; Fujita, T.; Kishibe, Y.; Konno, K.; Ueda, N.; Nakahori, K.; Kamada, T. The exp1 gene essential for pileus expansion and autolysis of the inky cap mushroom Coprinopsis cinerea (Coprinus cinereus) encodes an HMG protein. Fungal Genet. Biol. 2008, 45, 890–896. [Google Scholar] [CrossRef] [PubMed]

- Nakade, K.; Watanabe, H.; Sakamoto, Y.; Sato, T. Gene silencing of the Lentinula edodes lcc1 gene by expression of a homologous inverted repeat sequence. Microbiol. Res. 2001, 166, 484–493. [Google Scholar] [CrossRef] [PubMed]

- Takaki, K.; Yoshida, K.; Saito, T.; Kusaka, T.; Yamaguchi, R.; Takahashi, K.; Sakamoto, Y. Effect of electrical stimulation on fruit body formation in cultivating mushrooms. Microoganisms 2014, 2, 58–72. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Takahashi, K.; Miyamoto, K.; Takaki, K.; Takahashi, K. Development of Compact High-Voltage Power Supply for Stimulation to Promote Fruiting Body Formation in Mushroom Cultivation. Materials 2018, 11, 2471. https://doi.org/10.3390/ma11122471

Takahashi K, Miyamoto K, Takaki K, Takahashi K. Development of Compact High-Voltage Power Supply for Stimulation to Promote Fruiting Body Formation in Mushroom Cultivation. Materials. 2018; 11(12):2471. https://doi.org/10.3390/ma11122471

Chicago/Turabian StyleTakahashi, Katsuyuki, Kai Miyamoto, Koichi Takaki, and Kyusuke Takahashi. 2018. "Development of Compact High-Voltage Power Supply for Stimulation to Promote Fruiting Body Formation in Mushroom Cultivation" Materials 11, no. 12: 2471. https://doi.org/10.3390/ma11122471

APA StyleTakahashi, K., Miyamoto, K., Takaki, K., & Takahashi, K. (2018). Development of Compact High-Voltage Power Supply for Stimulation to Promote Fruiting Body Formation in Mushroom Cultivation. Materials, 11(12), 2471. https://doi.org/10.3390/ma11122471