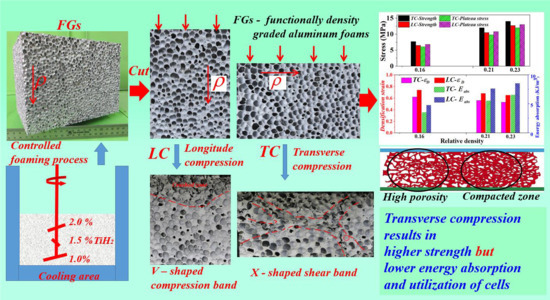

Anisotropic Compressive Behavior of Functionally Density Graded Aluminum Foam Prepared by Controlled Melt Foaming Process

Abstract

:1. Introduction

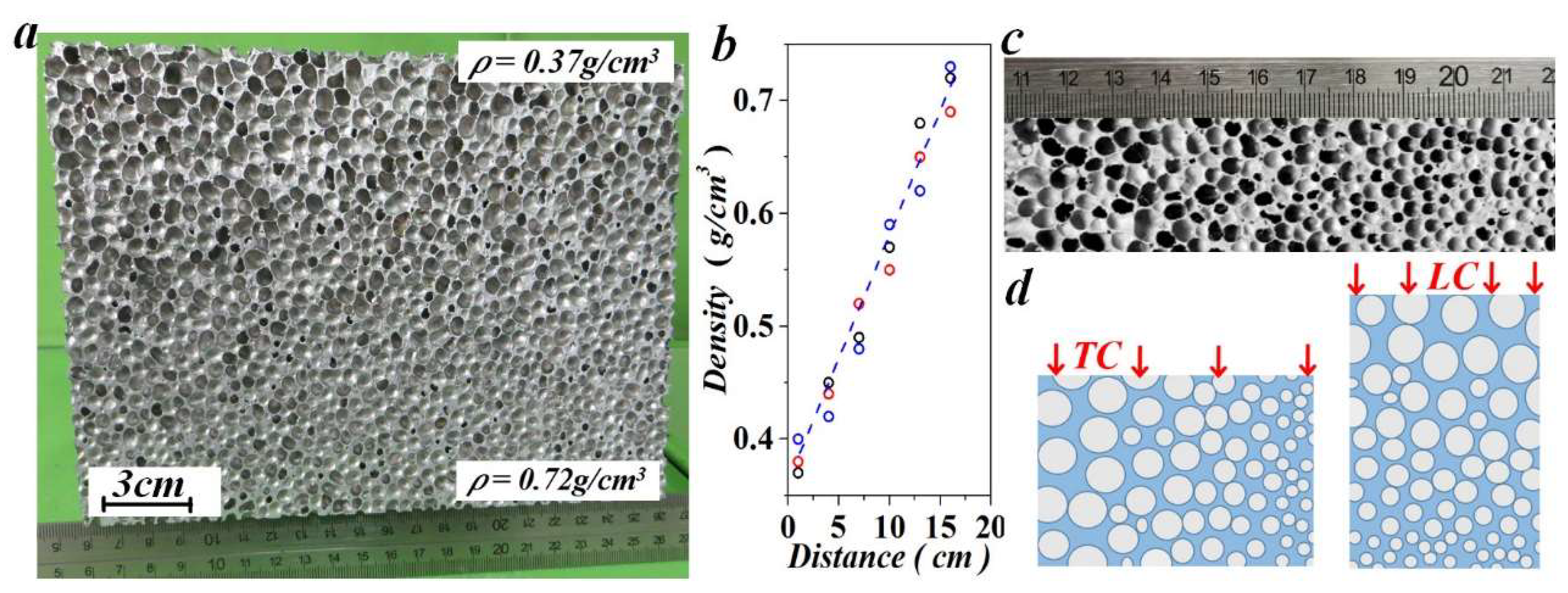

2. Materials and Methods

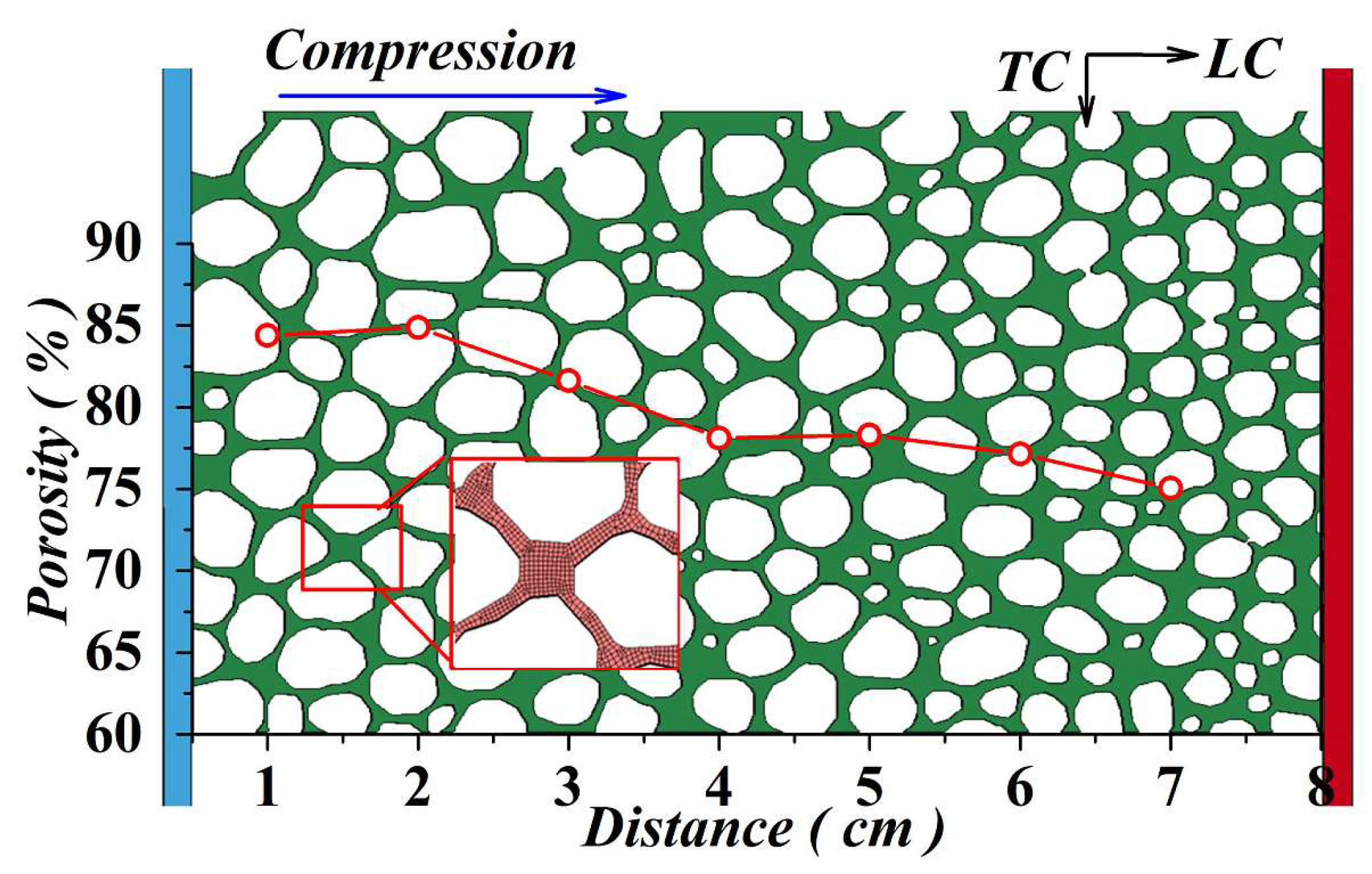

3. Results

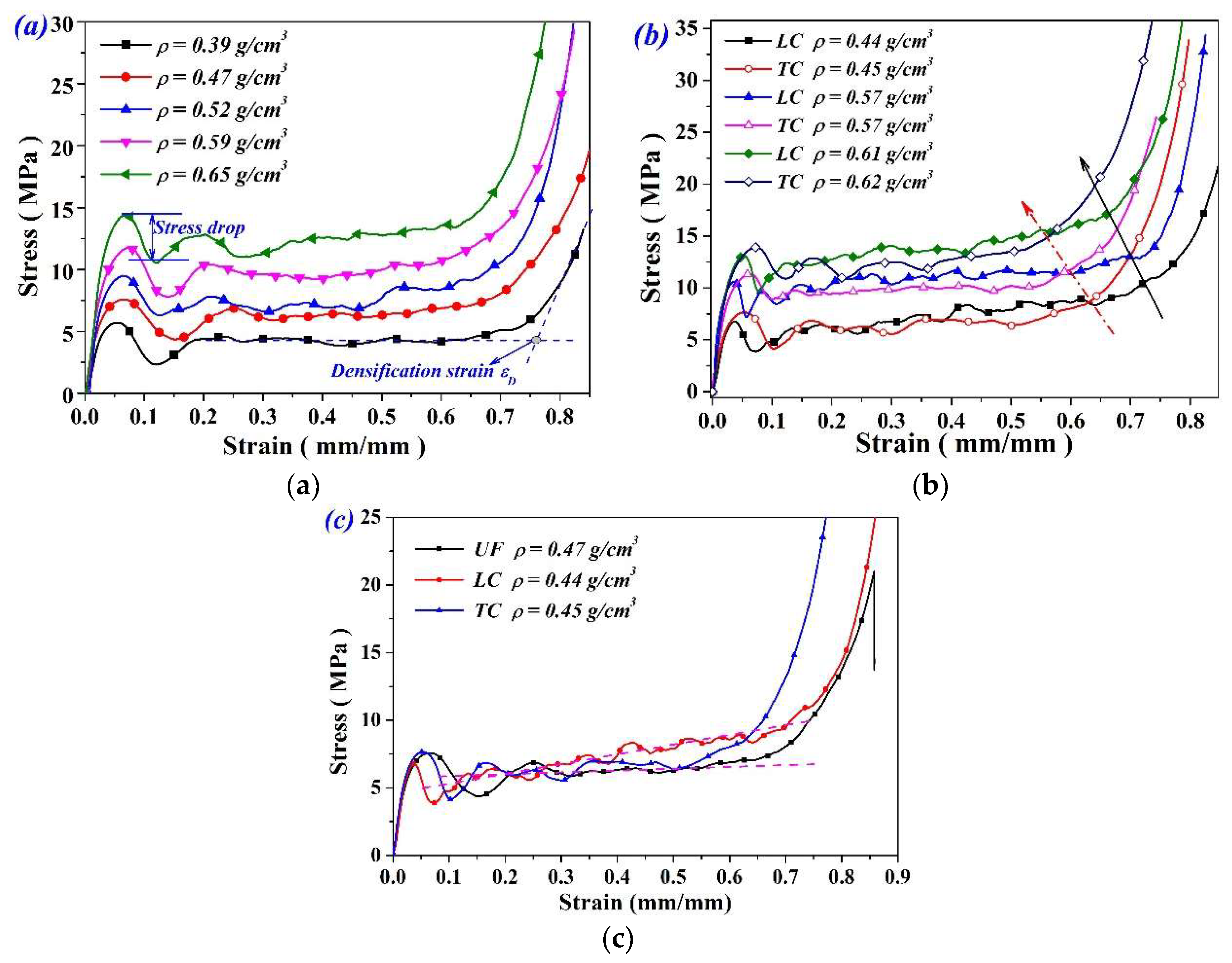

3.1. Quasi-Static Compression Behavior

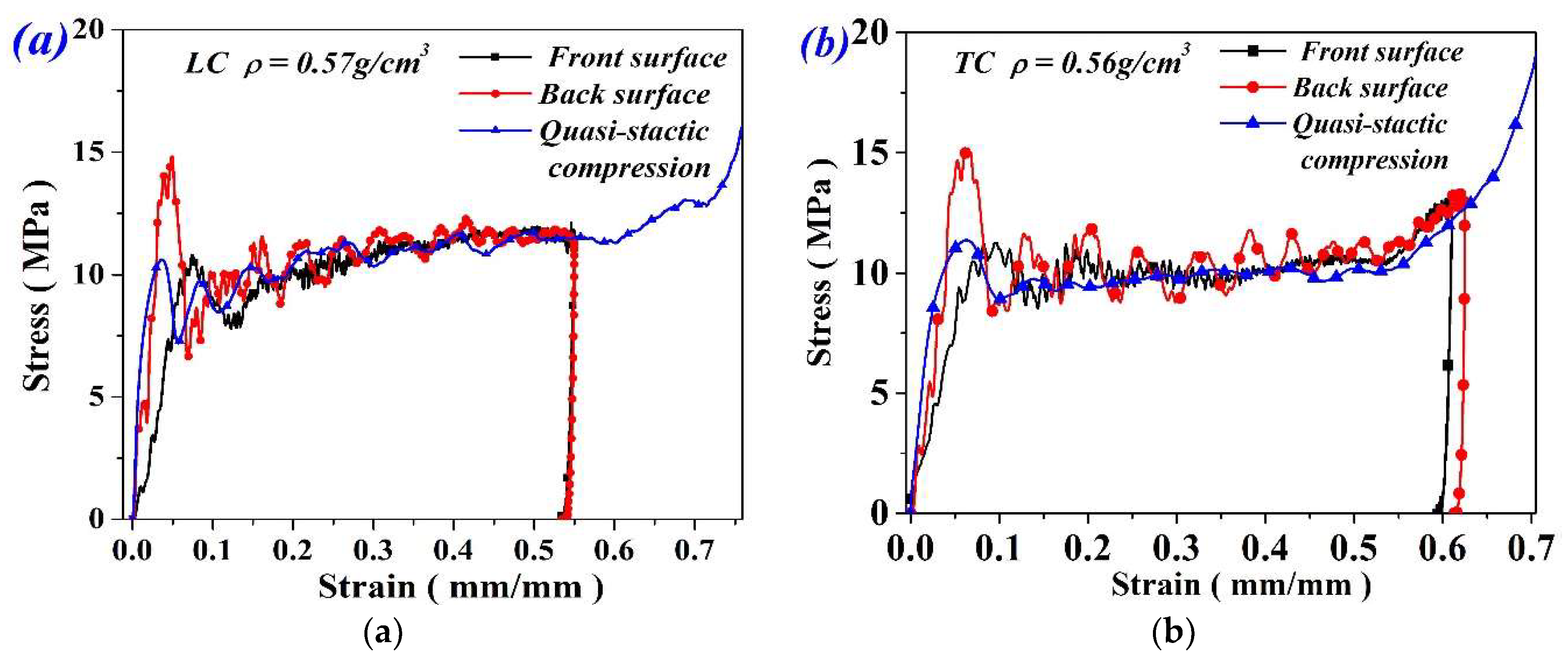

3.2. Drop-Weight Impact Tests

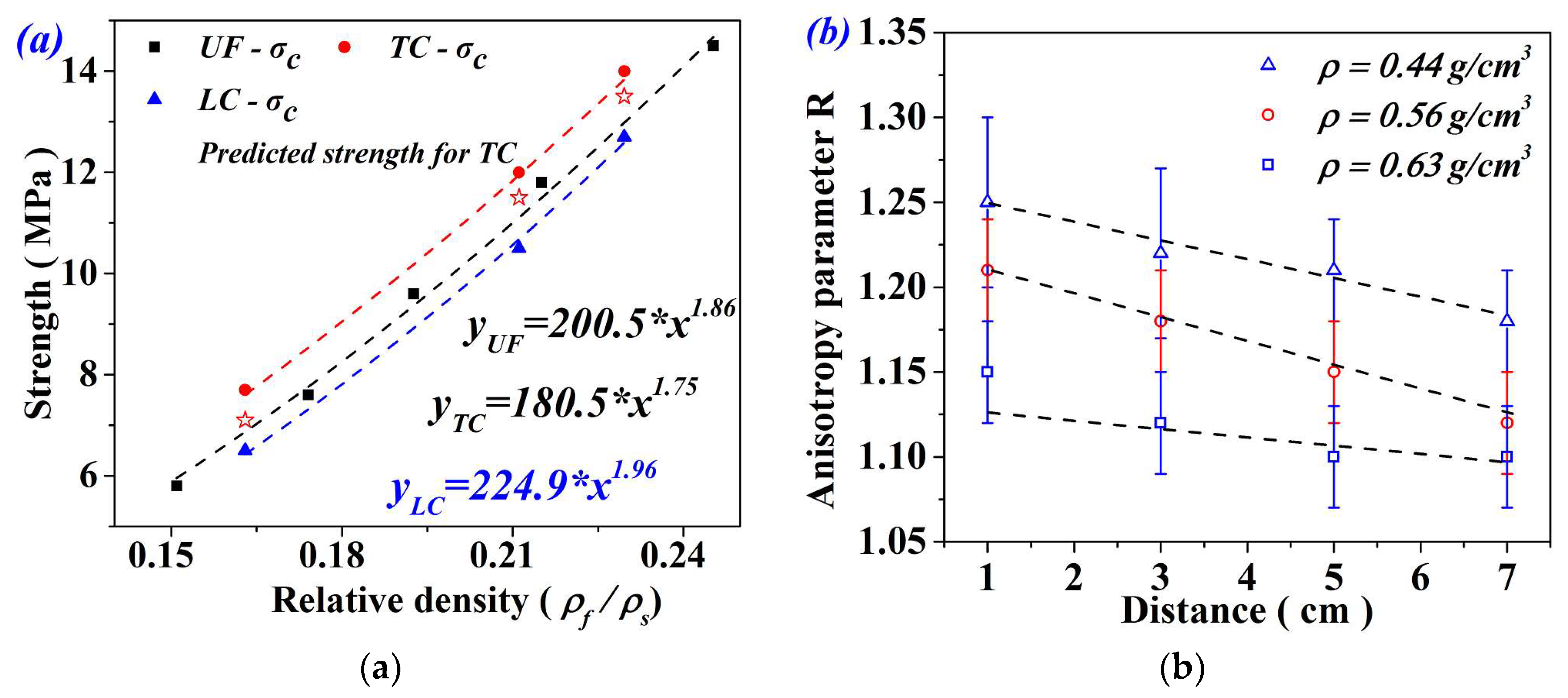

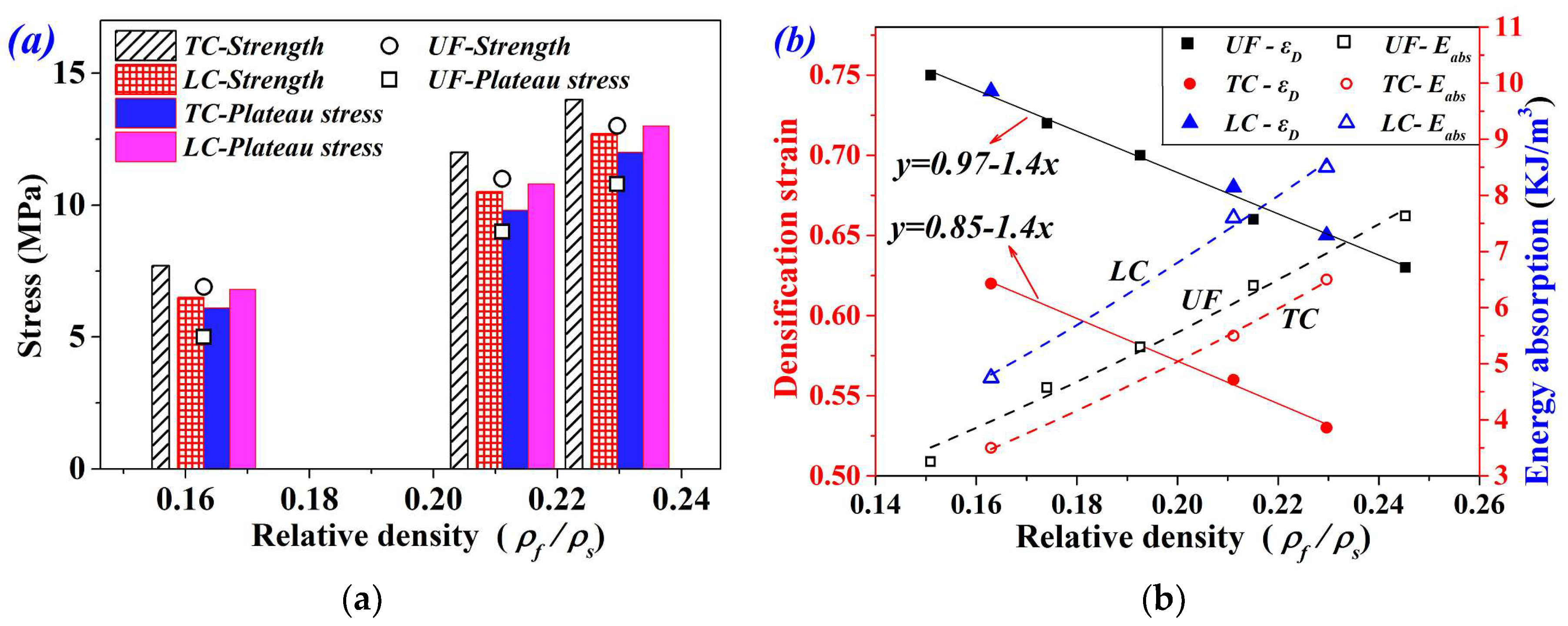

3.3. Mechanical Properties and Energy Absorption

4. Discussion

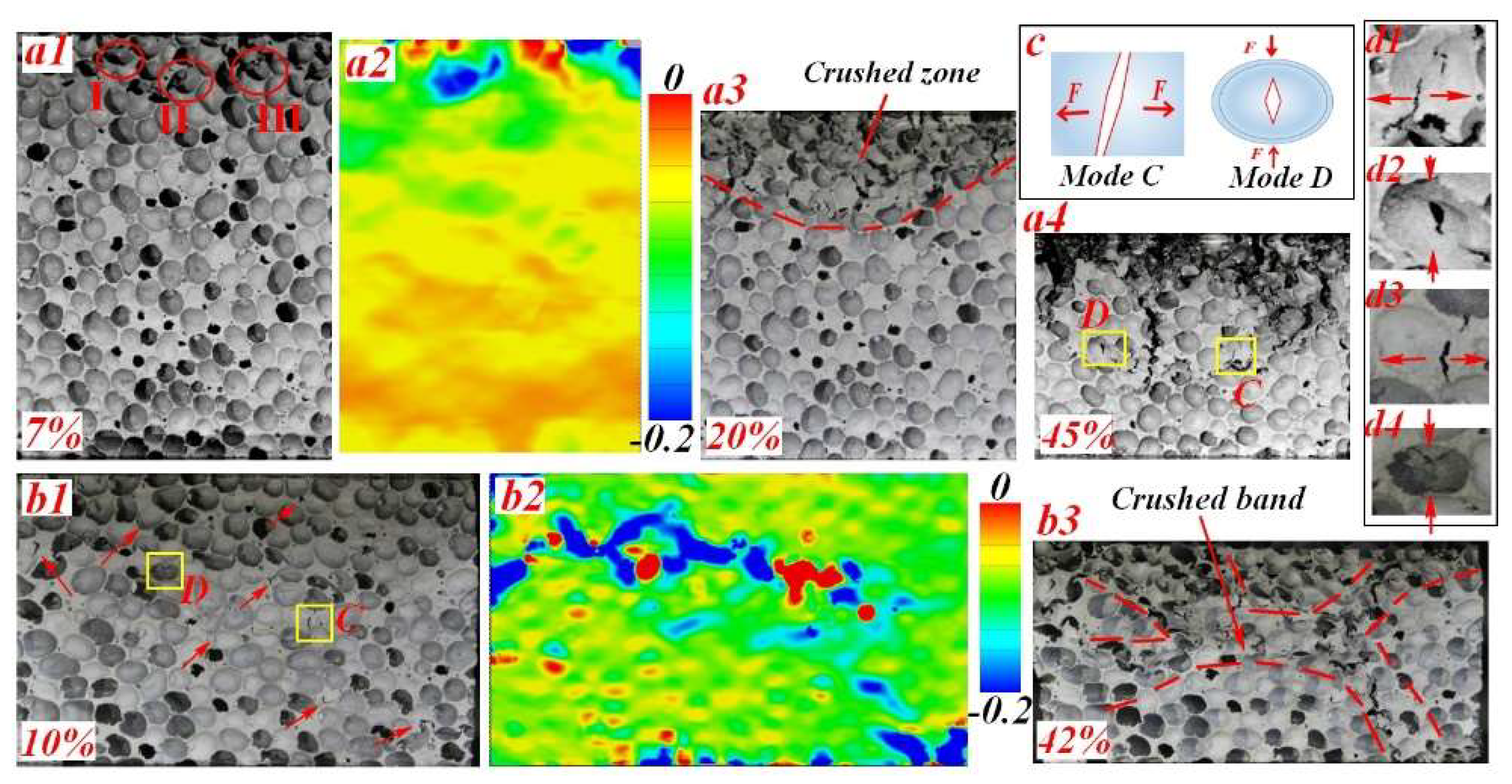

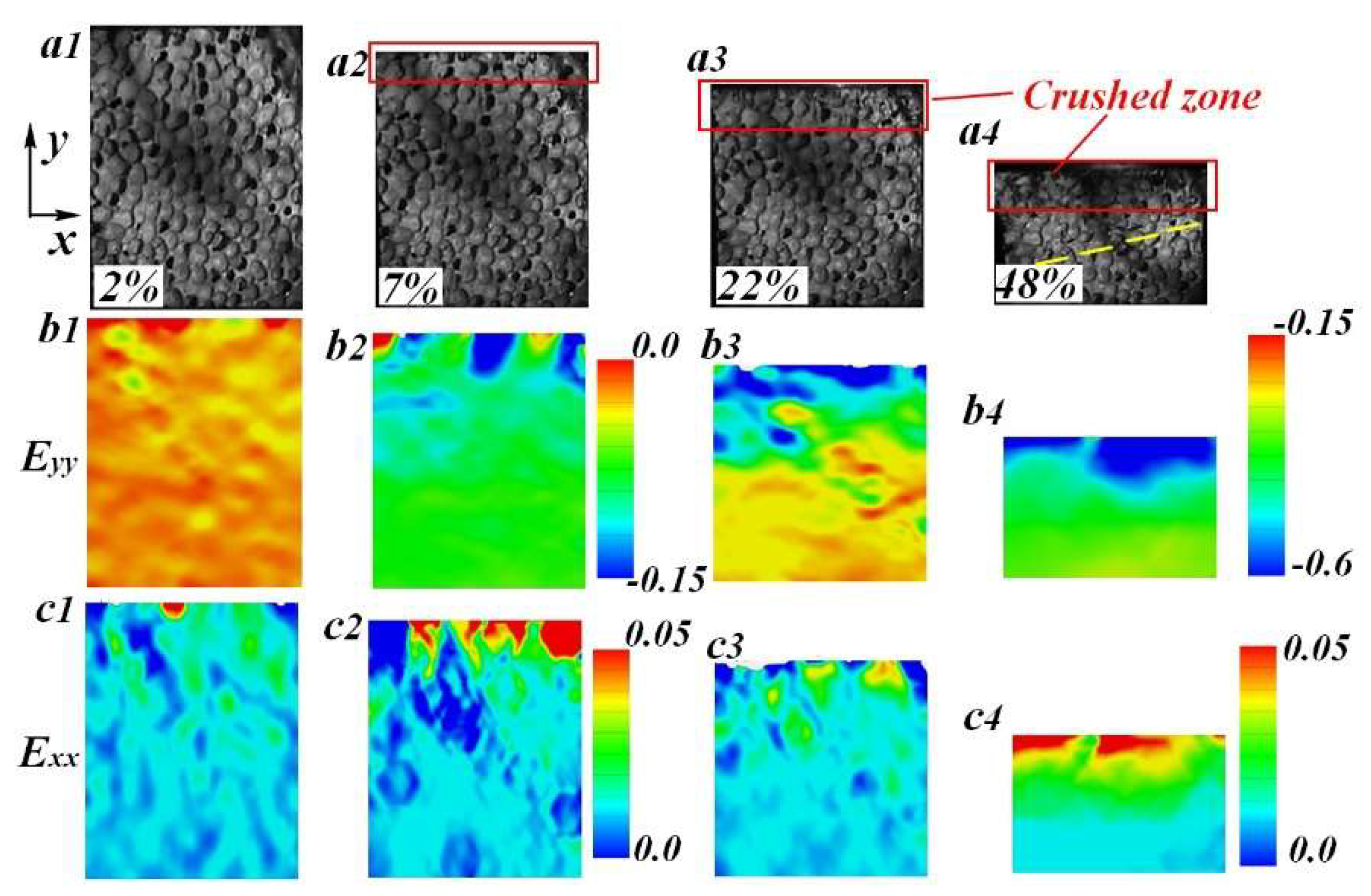

4.1. Quasi-Static Deformation Mechanisms

4.2. Axial Deformation Under Drop-Weight Impact

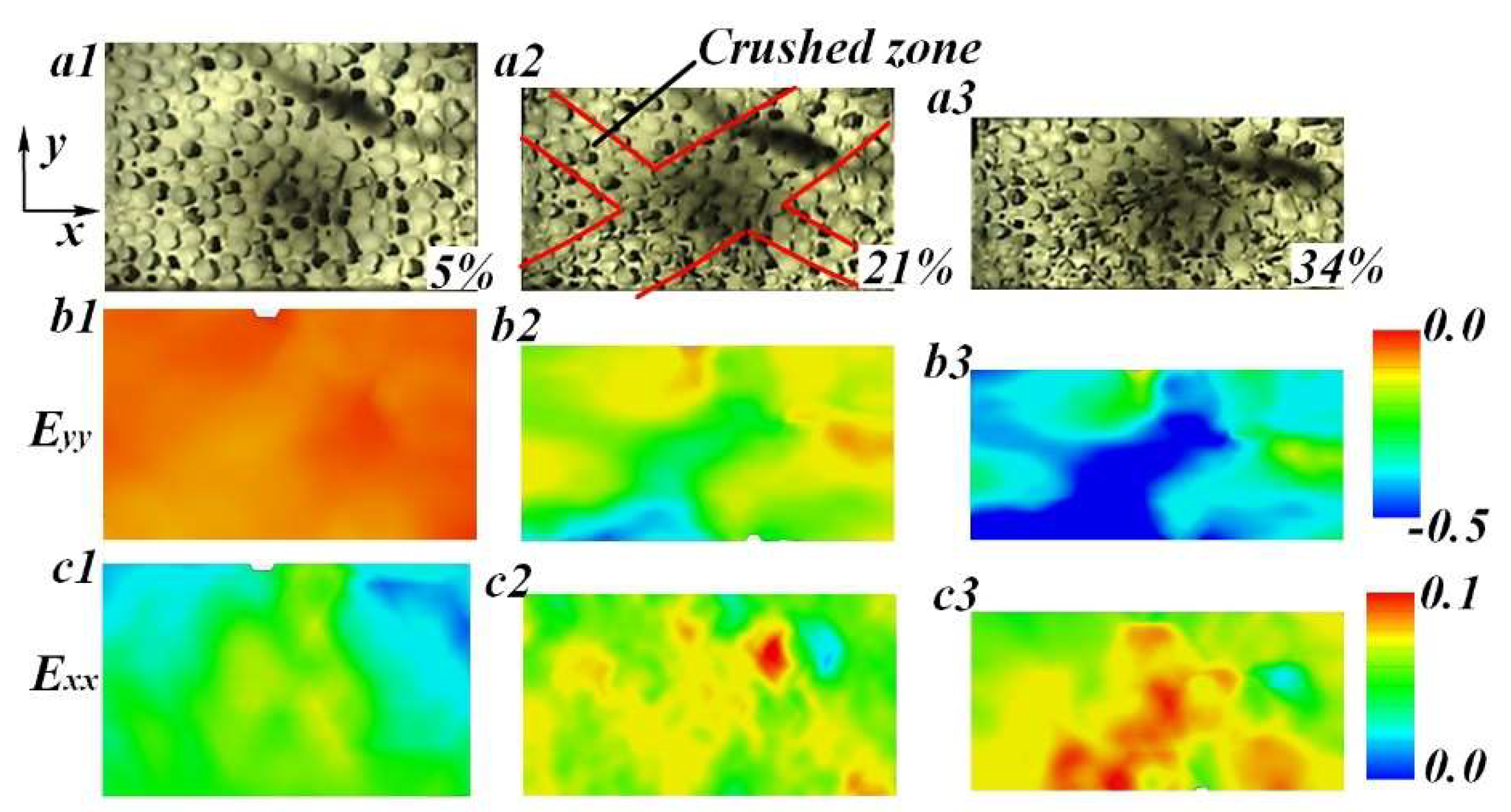

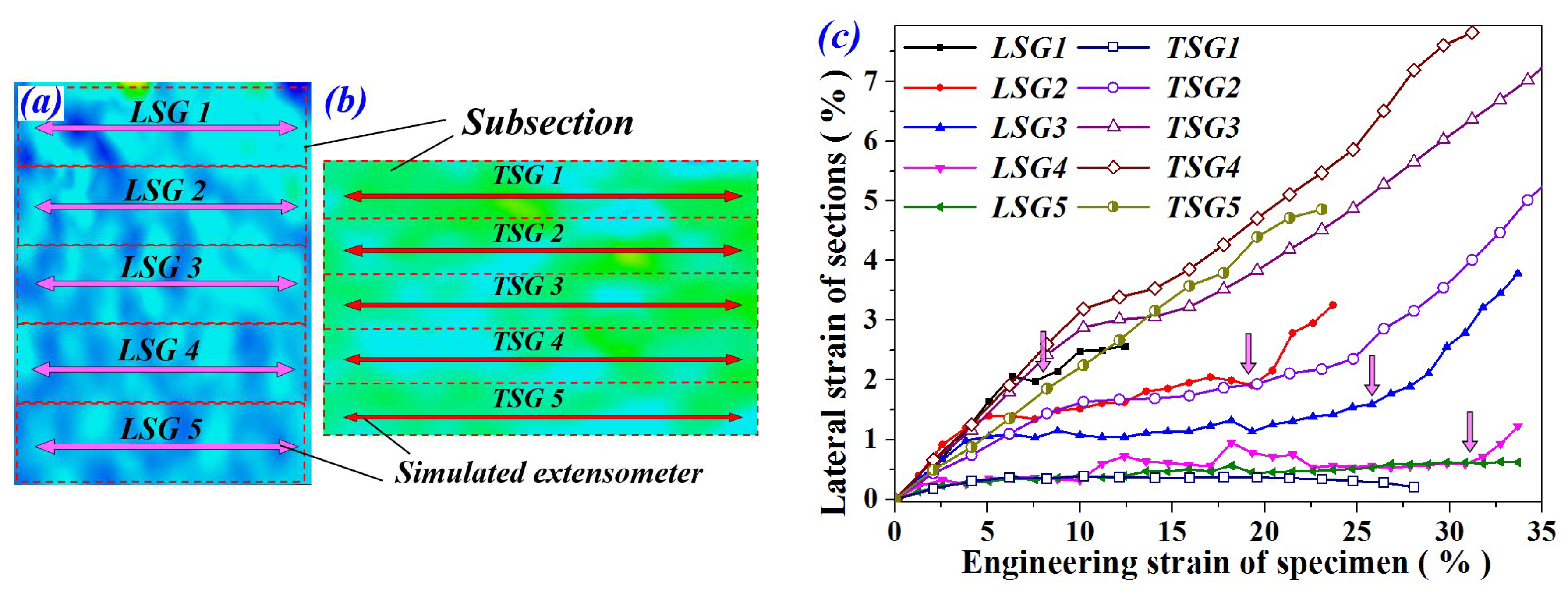

4.3. Lateral Deformation Under Drop-Weight Impact

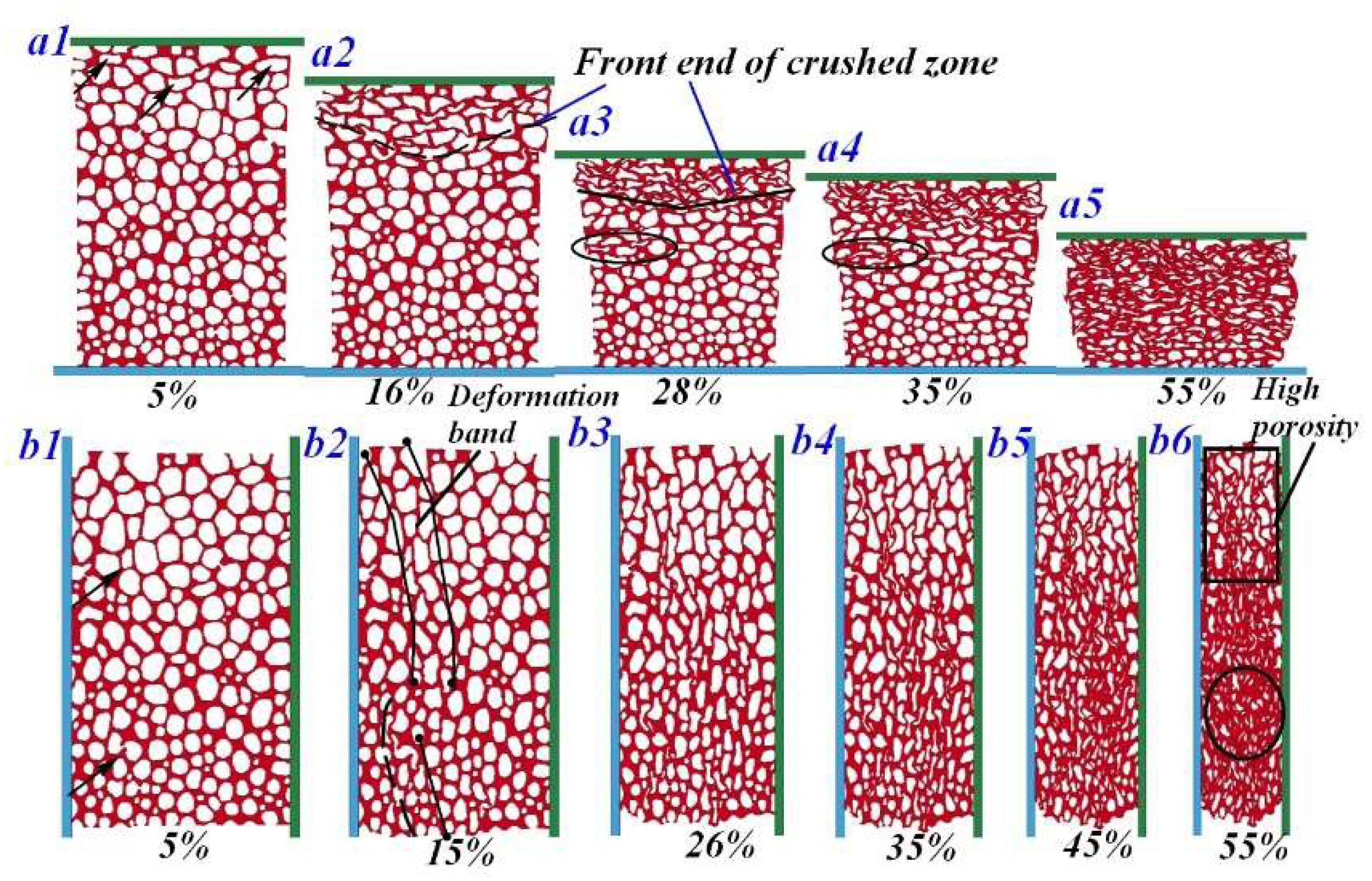

4.4. Anisotropic Compression Behavior in Numerical Simulation

5. Conclusions

- The transverse compression of FGs lead to higher collapse strength but significantly reduced energy absorption, which was attributed to the decrease in plateau stress and densification strain.

- The deformation behavior of FGs under longitudinal and transverse compression was respectively dominated by the progressively extended and randomly distributed deformation bands.

- The high strength of transverse compressed specimen was primarily due to the density anisotropy and transition in deformation mechanisms at both macro and cell levels.

- The decrease in densification strain of FGs under transverse compression was caused by lower utilization of cells in the high porosity zone.

- Transverse compression caused more tearing and lateral stretching deformation on cells because of the high lateral strain level in the specimens.

Author Contributions

Funding

Conflicts of Interest

References

- Matsumoto, Y.; Brothers, A.H.; Stock, S.R.; Dunand, D.C. Uniform and graded chemical milling of aluminum foams. Mater. Sci. Eng. A 2007, 447, 150–157. [Google Scholar] [CrossRef]

- Hangai, Y.; Takahashi, K.; Utsunomiya, T.; Kitahara, S.; Kuwazuru, O.; Yoshikawa, N. Fabrication of functionally graded aluminum foam using aluminum alloy die castings by friction stir processing. Mater. Sci. Eng. A 2012, 534, 716–719. [Google Scholar] [CrossRef]

- Hassani, A.; Habibolahzadeh, A.; Bafti, H. Production of graded aluminum foams via powder space holder technique. Mater. Des. 2012, 40, 510–515. [Google Scholar] [CrossRef]

- Jung, A.; Beex, L.A.A.; Diebels, S.; Bordas, S.P.A. Open-cell aluminum foams with graded coatings as passively controllable energy absorbers. Mater. Des. 2015, 87, 36–41. [Google Scholar] [CrossRef]

- Xia, Y.; Wu, C.; Liu, Z.X.; Yuan, Y. Protective effect of graded density aluminum foam on RC slab under blast loading—An experimental study. Constr. Build. Mater. 2018, 111, 209–222. [Google Scholar] [CrossRef]

- Hangai, Y.; Utsunomiya, T.; Kuwazuru, O.; Kitahara, S.; Yoshikawa, N. Deformation and plateau region of functionally graded aluminum foam by amount combinations of added blowing agent. Materials 2015, 8, 7161–7168. [Google Scholar] [CrossRef] [PubMed]

- Hangai, Y.; Morita, T.; Utsunomiya, T. Functionally graded aluminum foam consisting of dissimilar aluminum alloys fabricated by sintering and dissolution process. Mater. Sci. Eng. A 2017, 696, 544–551. [Google Scholar] [CrossRef]

- He, S.; Zhang, Y.; Dai, G.; Jiang, J. Preparation of density-graded aluminum foam. Mater. Sci. Eng. A 2014, 618, 496–499. [Google Scholar] [CrossRef]

- García-Moreno, F. Commercial Applications of Metal Foams: Their Properties and Production. Materials 2016, 9, 85. [Google Scholar] [CrossRef] [PubMed]

- Ajdari, A.; Nayeb-Hashemi, H.; Vaziri, A. Dynamic crushing and energy absorption of regular, irregular and functionally graded cellular structures. Int. J. Solids Struct. 2011, 48, 506–516. [Google Scholar] [CrossRef]

- Shunmugasamy, V.C.; Mansoor, B. Aluminum foam sandwich with density-graded open-cell core: Compressive and flexural response. Mater. Sci. Eng. A 2018, 731, 220–230. [Google Scholar] [CrossRef]

- Zheng, J.; Qin, Q.; Wang, T.J. Impact plastic crushing and design of density-graded cellular materials. Mech. Mater. 2016, 94, 66–78. [Google Scholar] [CrossRef]

- Liu, X.R.; Tian, X.G.; Lu, T.J.; Liang, B. Sandwich plates with functionally graded metallic foam cores subjected to air blast loading. Int. J. Mech. Sci. 2014, 84, 61–72. [Google Scholar] [CrossRef]

- Yang, J.; Wang, S.; Ding, Y.; Zheng, Z.; Yu, J. Crashworthiness of graded cellular materials: A design strategy based on a nonlinear plastic shock model. Mater. Sci. Eng. A 2016, 680, 411–420. [Google Scholar] [CrossRef]

- Kitazono, K.; Kikuchi, Y.; Sato, E.; Kuribayashi, K. Anisotropic compressive behavior of Al–Mg alloy foams manufactured through accumulative roll-bonding process. Mater. Lett. 2007, 61, 1771–1774. [Google Scholar] [CrossRef]

- Mu, Y.; Yao, G.; Luo, H. Effect of cell shape anisotropy on the compressive behavior of closed-cell aluminum foams. Mater. Des. 2010, 31, 1567–1569. [Google Scholar] [CrossRef]

- Mu, Y.; Yao, G. Anisotropic compressive behavior of closed-cell Al–Si alloy foams. Mater. Sci. Eng. A 2010, 527, 1117–1119. [Google Scholar] [CrossRef]

- Kováčik, J.; Marsavina, L.; Linul, E. Poisson’s ratio of closed-cell aluminum foams. Materials 2018, 11, 1904. [Google Scholar] [CrossRef] [PubMed]

- Amsterdam, E.; Hoorn, H.V.; De Hosson, J.T.M.; Onck, P.R. The Influence of cell shape anisotropy on the tensile behavior of open cell aluminum foam. Adv. Eng. Mater. 2008, 10, 877–881. [Google Scholar] [CrossRef]

- Linul, E.; Movahedi, N.; Marsavina, L. The temperature and anisotropy effect on compressive behavior of cylindrical closed-cell aluminum-alloy foams. J. Alloy Compd. 2018, 740, 1172–1179. [Google Scholar] [CrossRef]

- Amsterdam, E.; De Hosson, J.T.M.; Onck, P.R. On the plastic collapse stress of open-cell aluminum foam. Scr. Mater. 2008, 59, 653–656. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure and Properties, 2nd ed.; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Matsumoto, R.; Kanatani, S. Filling of surface pores of aluminum foam with polyamide by selective laser melting for improvement in mechanical properties. J. Mater. Process. Tech. 2016, 237, 402–408. [Google Scholar] [CrossRef]

- Fan, Z.; Zhang, B.; Gao, Y.; Guan, X.; Xu, P. Deformation mechanisms of spherical cell porous aluminum under quasi-static compression. Scr. Mater. 2018, 142, 32–35. [Google Scholar] [CrossRef]

- Bastawros, A.F.; Smith, H.B.; Evans, A.G. Experimental analysis of deformation mechanisms in a closed-cell aluminum alloy foam. J. Mech. Phys. Solids 2000, 48, 301–322. [Google Scholar] [CrossRef]

- Bart-Smith, H.; Bastawros, A.F.; Mumm, D.R.; Evans, A.G.; Sypeck, D.J.; Wadley, H.N.G. Compressive deformation and yielding mechanisms in cellular Al alloys determined using X-ray tomography and surface strain mapping. Acta Mater. 1998, 46, 3583–3592. [Google Scholar] [CrossRef]

- Zheng, Z.; Yu, J.; Wang, C.; Liao, S.; Liu, Y. Dynamic crushing of cellular materials: A unified framework of plastic shock wave models. Int. J. Impact Eng. 2013, 53, 29–43. [Google Scholar] [CrossRef]

- Amsterdam, E.; Onck, P.R.; De Hosson, J.T.M. Fracture and microstructure of open cell aluminum foam. J. Mater. Sci. 2005, 40, 5813–5819. [Google Scholar] [CrossRef]

- Onck, P.R.; Van Merkerk, R.; Raaijmakers, A.; De Hosson, J.T.M. Fracture of open- and closed-cell metal foams. J. Mater. Sci. 2005, 40, 5821–5828. [Google Scholar] [CrossRef] [Green Version]

- Song, H.; He, Q.; Xie, J.; Tobota, A. Fracture mechanisms and size effects of brittle metallic foams: In-situ compression tests inside SEM. Compos. Sci. Technol. 2008, 68, 2441–2450. [Google Scholar] [CrossRef]

- Amsterdam, E.; De Hosson, J.T.M.; Onck, P.R. Failure mechanisms of closed-cell aluminum foam under monotonic and cyclic loading. Acta Mater. 2006, 54, 4465–4472. [Google Scholar] [CrossRef]

- Onck, P.R.; Van, M.R.; De Hosson, J.T.M. Fracture of metal foams: In-situ testing and numerical modeling. Adv. Eng. Mater. 2004, 6, 429–431. [Google Scholar] [CrossRef]

- Kadkhodapour, J.; Raeisi, S. Micro-macro investigation of deformation and failure in closed-cell aluminum foams. Comp. Mater. Sci. 2014, 83, 137–148. [Google Scholar] [CrossRef]

- Mu, Y.L.; Yao, G.C.; Liang, L.S.; Luo, H.J.; Zu, G.Y. Deformation mechanisms of closed-cell aluminum foam in compression. Scr. Mater. 2010, 63, 629–632. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Hu, S.; Fan, Z. Anisotropic Compressive Behavior of Functionally Density Graded Aluminum Foam Prepared by Controlled Melt Foaming Process. Materials 2018, 11, 2470. https://doi.org/10.3390/ma11122470

Zhang B, Hu S, Fan Z. Anisotropic Compressive Behavior of Functionally Density Graded Aluminum Foam Prepared by Controlled Melt Foaming Process. Materials. 2018; 11(12):2470. https://doi.org/10.3390/ma11122470

Chicago/Turabian StyleZhang, Bingbing, Shuangqi Hu, and Zhiqiang Fan. 2018. "Anisotropic Compressive Behavior of Functionally Density Graded Aluminum Foam Prepared by Controlled Melt Foaming Process" Materials 11, no. 12: 2470. https://doi.org/10.3390/ma11122470

APA StyleZhang, B., Hu, S., & Fan, Z. (2018). Anisotropic Compressive Behavior of Functionally Density Graded Aluminum Foam Prepared by Controlled Melt Foaming Process. Materials, 11(12), 2470. https://doi.org/10.3390/ma11122470