Low-Stress Mechanical Property Study of Various Functional Fabrics for Tactile Property Evaluation

Abstract

1. Introduction

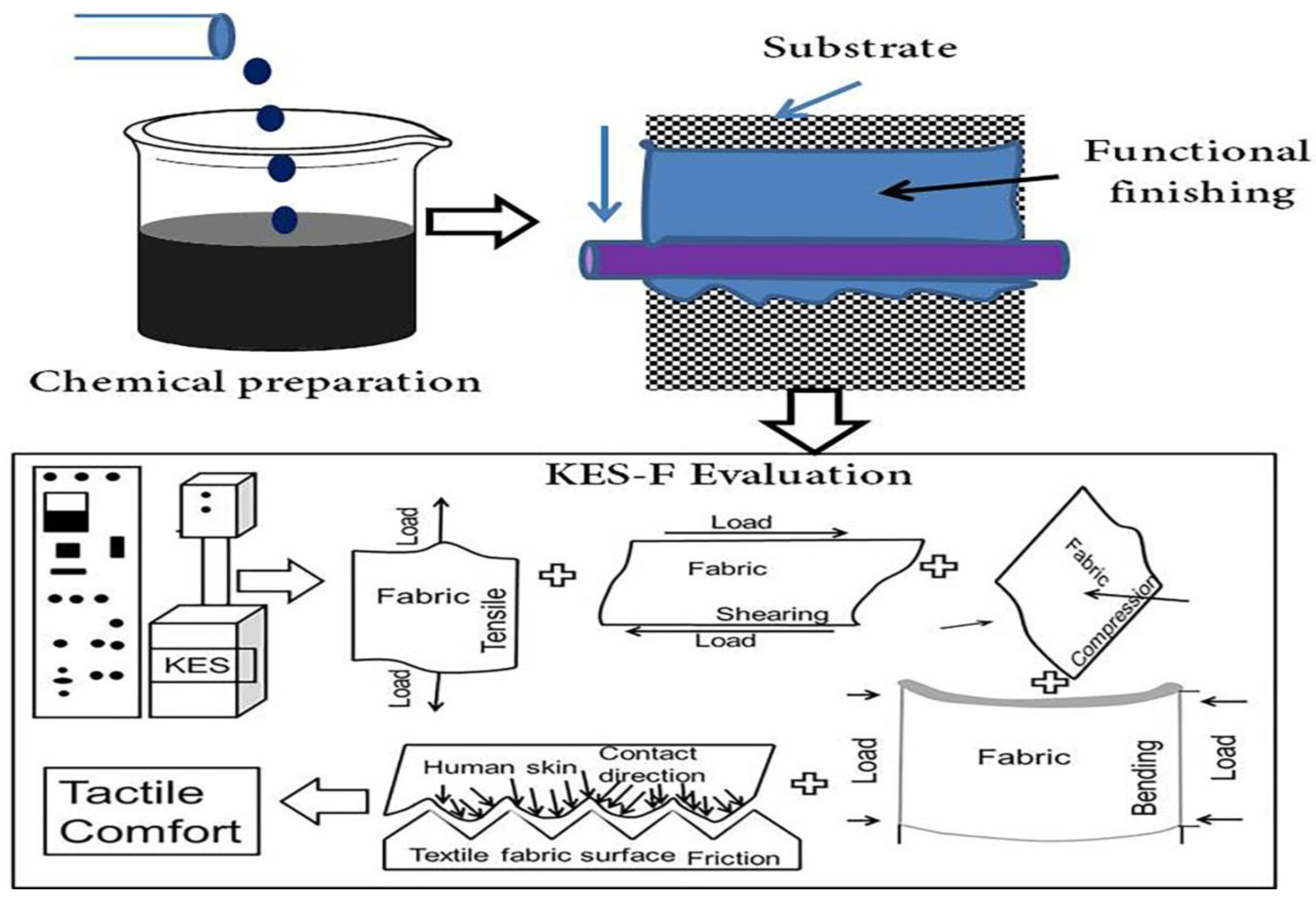

2. Materials and Methods

2.1. Material Preparation

2.2. Methods

3. Results and Discussion

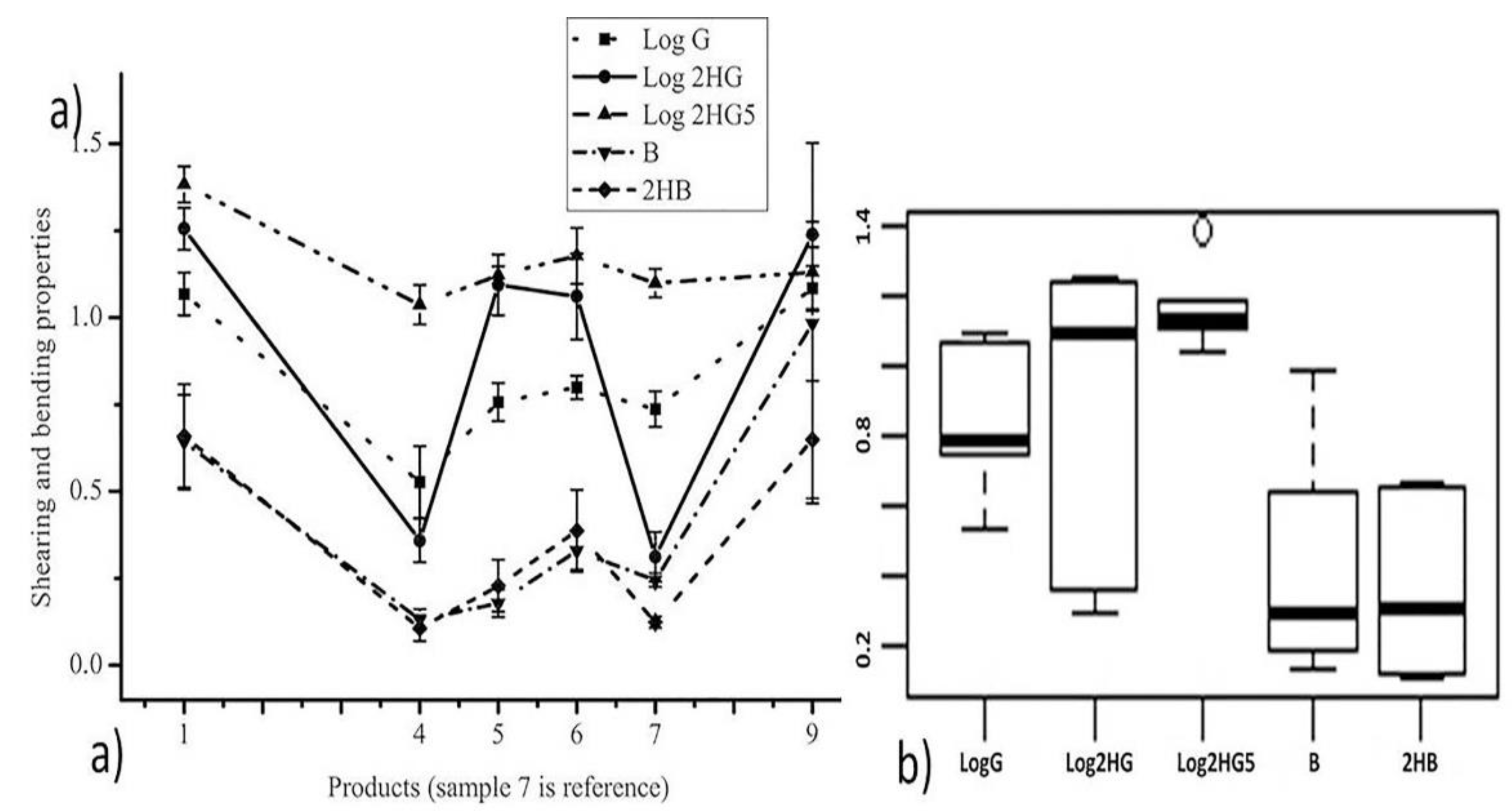

3.1. Correlations between Mechanical Properties

3.2. Effect of Functional Finishing on Low-Stress Mechanical Properties

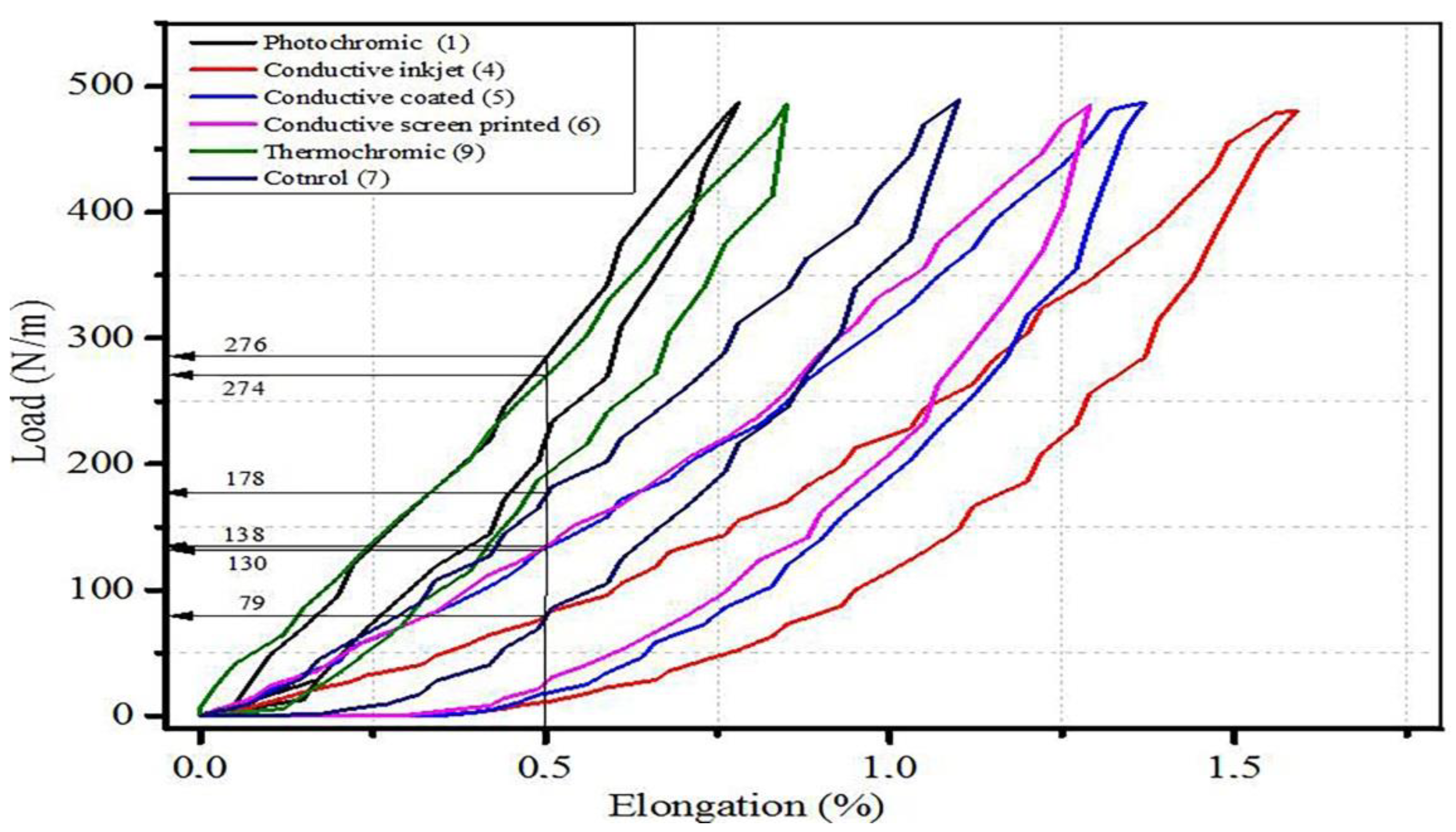

3.2.1. Tensile Properties

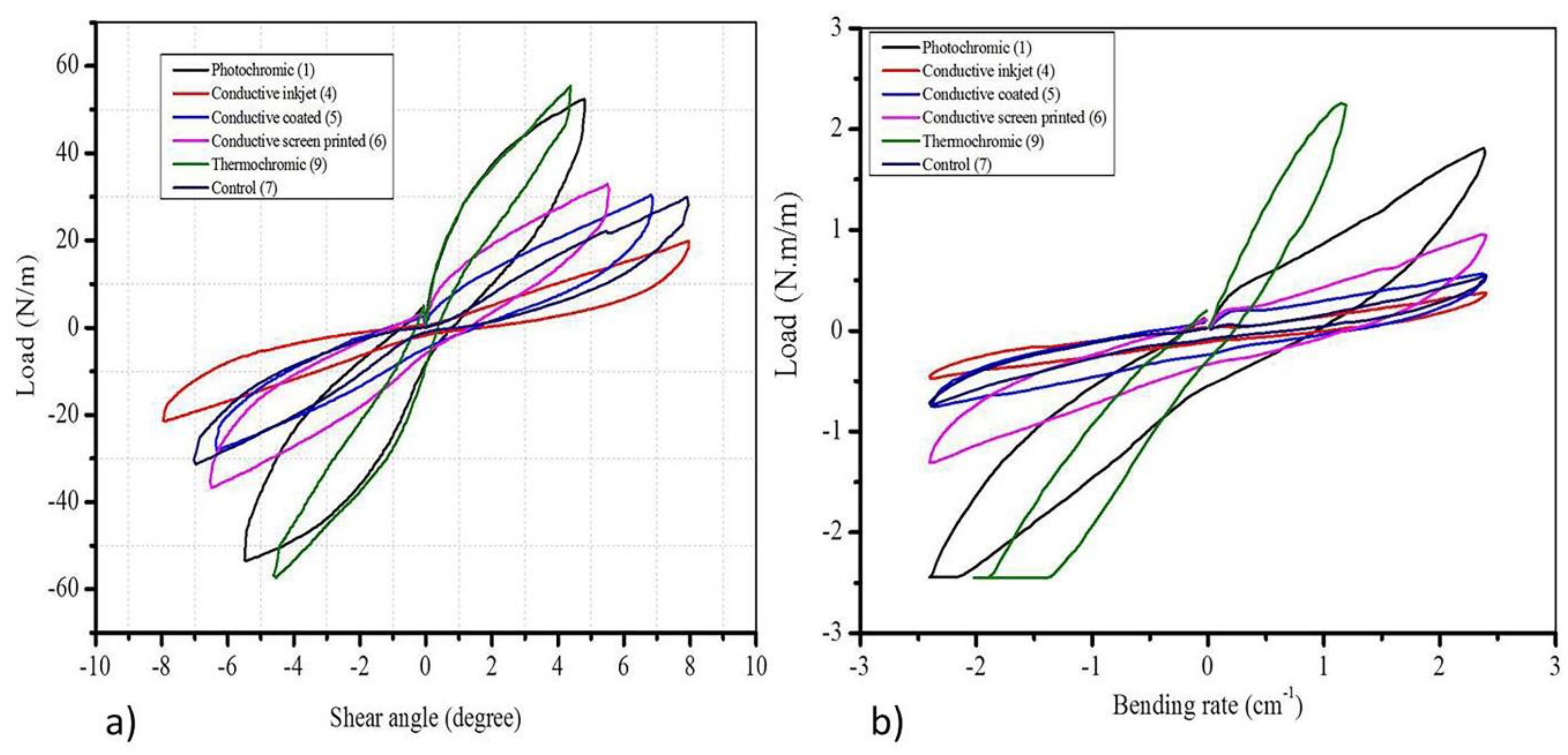

3.2.2. Change in Shearing and Bending Properties

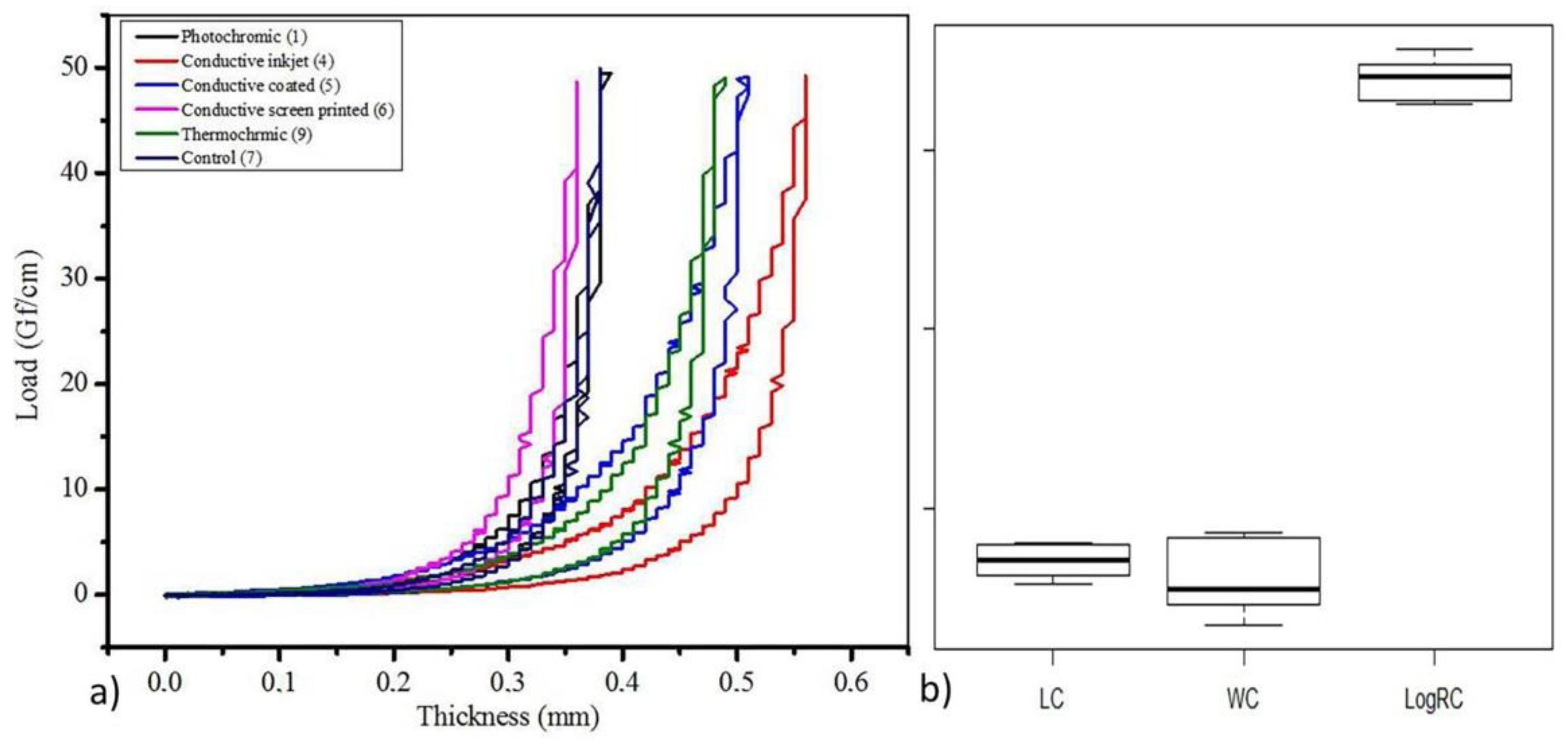

3.2.3. Change in the Compressional Properties

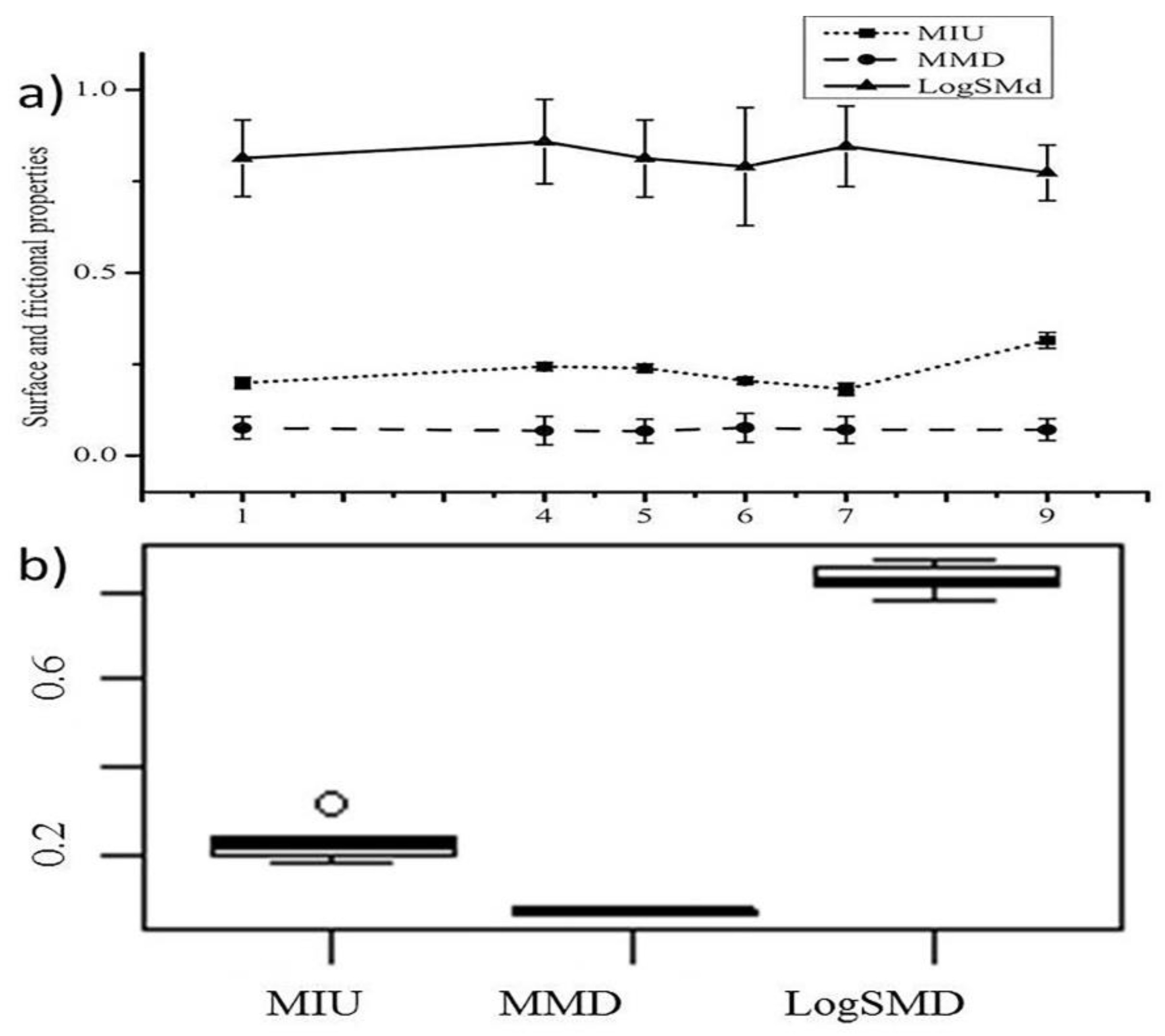

3.2.4. Change in the Surface Frictional Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nayak, R.K.; Punj, S.K.; Chatterjeé, K.N.; Behera, B.K. Comfort properties of suiting fabrics. Indian J. Fiber Text. Res. 2009, 34, 122–128. [Google Scholar]

- Behera, B.K. Comfort and handle behavior of linen-blended fabrics. Autex Res. J. 2007, 7, 32–47. [Google Scholar]

- Raj, S.; Sreenivasan, S. Total Wear Comfort Index as an Objective Parameter for Characterization of Overall Wearability of Cotton Fabrics. J. Eng. Fiber. Fabr. 2009, 4, 29–41. [Google Scholar] [CrossRef]

- Hollies, N.R.S. Textile Visual and Tactile Perceptions of Textile Quality. J. Text. Inst. 2008, 80, 37–41. [Google Scholar] [CrossRef]

- Hu, J.Y.; Li, Y.; Yeung, K.W. Mechanical tactile properties. In Clothing Biosensory Engineering; Li, Y., Wong, A.S.W., Eds.; Woodhead publishing: Boca Raton, FL, USA, 2006; pp. 261–284. [Google Scholar]

- Peirce, F.T. The handle of cloth as a measurable quantity. J. Text. Inst. Trans. 1930, 21, T377–T416. [Google Scholar] [CrossRef]

- Chen, Y.; Collier, B.; Hu, P.; Objective, D. Evaluation of Fabric Softness. Text. Res. J. 2000, 70, 443–448. [Google Scholar] [CrossRef]

- Kang, T.J.; Cho, D.H.; Kim, S.M. New Objective Evaluation of Fabric Smoothness Appearance. Text. Res. J. 2001, 71, 446–453. [Google Scholar] [CrossRef]

- Kim, J.O.; Slaten, B.L. Objective Evaluation of Fabric Hand: Part I: Relationships of Fabric Hand by the Extraction Method and Related Physical and Surface. Text. Res. J. 1999, 69, 59–67. [Google Scholar] [CrossRef]

- Kawabata, S.; Niwa, M. Objective Measurement of Fabric Mechanical Property and Quality. Int. J. Cloth. Sci. Technol. 1991, 3, 7–18. [Google Scholar] [CrossRef]

- Minazio, P.G. FAST–Fabric Assurance by Simple Testing. Int. J. Cloth. Sci. Technol. 1995, 7, 43–48. [Google Scholar] [CrossRef]

- Hu, J.Y.; Hes, L.; Li, Y.; Yeung, K.W.; Yao, B.G. Fabric Touch Tester: Integrated evaluation of thermal-mechanical sensory properties of polymeric materials. Polym. Test. 2006, 25, 1081–1090. [Google Scholar] [CrossRef]

- Kawabata, S. The Standardization and Analysis of Hand Evaluation. In Effect of Mechanical and Physical Properties on Fabric Hand; Behery, H.M., Ed.; Woodhead publishing: Boca Raton, FL, USA, 2005; pp. 389–443. [Google Scholar]

- Gong, R.H.; Mukhopadhyay, S.K. Fabric objective measurement: A comparative study of fabric characteristics. J. Text. Inst. 1993, 84, 192–198. [Google Scholar] [CrossRef]

- Ly, N.G.; Tester, D.H.; Buckenham, P.; Roczniok, A.F.; Adriaansen, A.L.; Scaysbrook, F.; de Jong, S. Simple Instruments for Quality Control by Finishers and Tailors. Text. Res. J. 1991, 61, 402–406. [Google Scholar] [CrossRef]

- Pan, N.; Zeronian, S.H.; Ryu, H.S. An Alternative Approach to the Objective Measurement of Fabrics. Text. Res. J. 1993, 63, 33–43. [Google Scholar]

- Alamdar-Yazdi, A. An improved method of fabric objective measurement. J. Text. Inst. 2004, 95, 19–29. [Google Scholar] [CrossRef]

- Lam, Y.L.; Kan, C.W.; Yuen, C.W.M. Objective measurement of hand properties of plasma pre-treated cotton fabrics subjected to flame-retardant finishing catalyzed by zinc oxide. Fibers Polym. 2014, 15, 1880–1886. [Google Scholar] [CrossRef]

- Mahar, T.J.; Postle, R. Measuring and Interpreting Low-Stress Fabric Mechanical and Surface Properties: Part II: Applications to Finishing, Drycleaning, and Photodegredation of Wool Fabrics. Text. Res. J. 1989, 59, 357–368. [Google Scholar] [CrossRef]

- Tadesse, M.G.; Harpa, R.; Chen, Y.; Wang, L.; Nierstrasz, V.; Loghin, C. Assessing the comfort of functional fabrics for smart clothing using subjective evaluation. J. Ind. Text. 2018, 1–17. [Google Scholar] [CrossRef]

- Yadav, A.; Prasad, V.; Kathe, A.A.; Raj, S.; Yadav, D.; Sundaramoorthy, C.; Vigneshwaran, N. Functional finishing in cotton fabrics using zinc oxide nanoparticles. Bull. Mater. Sci. 2006, 29, 641–645. [Google Scholar] [CrossRef]

| Code | W (gsm); T (mm) | Function | Materials and Chemical Agents | Methods |

|---|---|---|---|---|

| 1 | 181.8 ± 0.03; 0.62 ± 0.02 | Photochromic (K/S; 1.30 ± 0.21) | Reversal Ruby Red dye (Vivimed Labs, Hyderabad, India; 2.5 g L−1), dipropylene glycol diacrylate monomer varnish, Ebecryl 81 oligomer (Allnex, Frankfurt am Main, Germany), photo-initiator (Genocure TPO-L; Rahn AG, Zurich, Switzerland) | Inkjet printing 300 dpi |

| 4 | 186.7 ± 0.15; 0.75 ± 0.02 | Conductive (SR; 0.168 ± 0.013 kΩ/square) | PEDOT-PSS (1.3 wt %; Heraeus GmbH, Hanau, Germany), glycerol with water (6:4 w/w) and Triton surfactant (Sigma Aldrich, St. Louis, MO, USA) | Inkjet printing 300 dpi |

| 5 | 176 ± 0.2; 0.73 ± 0.01 | Conductive (SR; 7.98 ± 0.969 Ω/square) | PEDOT-PSS, DMSO (5%; Sigma Aldrich), U2101 binder (Alberdingk B., Krefeld, Germany), Gel L75N rheology modifier (48 wt %; Borchers, West Lake, OH, USA) | Coating; 200 μm heighst |

| 6 | 186.8 ± 0.05; 0.56 ± 0.01 | Conductive (SR; 4.41 ± 0.396 Ω/square) | PEDOT-PSS, DMSO, U2101, Gel L75N, PET 70 mesh size | Screen printing |

| 9 | 244.5 ± 0.06; 0.70 ± 0.02 | Thermochromic (K/S; 4.63 ± 0.32) | Variotherm AQ ink (5%), ChromaZone extender (95%; Zenit, Stockholm, Sweden), PET 70 mesh size | Screen printing |

| Mechanical Properties | Property | Definitions | Unit |

|---|---|---|---|

| Tensile [KES-1] | EMT | Elongation | % |

| LT | Linearity of the curve | - | |

| WT | Tensile energy | gf.cm/cm2 | |

| RT | Tensile resilience | % | |

| Bending [KES-2] | B | Bending rigidity | gf.cm2/cm |

| 2HB | Bending hysteresis | gf.cm2/cm | |

| Shear [KES-1] | G | Shear rigidity | gf/cm.degree |

| 2HG | Shear hysteresis at 0.5° | gf/cm | |

| 2HG5 | Shear hysteresis at 5° | gf/cm | |

| Compression [KES-3] | LC | Linearity of Compression | - |

| WC | Compressional energy | gf.cm/cm2 | |

| RC | Compressional resilience | % | |

| Surface friction [KES-4] | MIU | Coefficient of friction | - |

| MMD | Mean deviation of MIU | - | |

| SMD | Geometrical roughness | μm |

| MP | LT | WT | RT | EMT | G | 2HG | 2HG5 | B | 2HB | LC | WC | RC | MIU | MMD |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WT | −0.87 | |||||||||||||

| RT | 0.88 | −0.98 | ||||||||||||

| EMT | −0.87 | 1.00 | −0.97 | |||||||||||

| G | 0.86 | −0.58 | 0.70 | −0.58 | ||||||||||

| 2HG | 0.90 | −0.58 | 0.62 | −0.58 | 0.93 | |||||||||

| 2HG5 | 0.83 | −0.70 | 0.72 | −0.70 | 0.77 | 0.79 | ||||||||

| B | 0.03 | 0.37 | −0.19 | 0.37 | 0.50 | 0.37 | 0.00 | |||||||

| 2HB | 0.59 | −0.18 | 0.32 | −0.18 | 0.89 | 0.83 | 0.61 | 0.77 | ||||||

| LC | 0.61 | −0.89 | 0.81 | −0.89 | 0.19 | 0.23 | 0.35 | −0.67 | −0.26 | |||||

| WC | −0.74 | 0.53 | −0.53 | 0.53 | −0.71 | −0.74 | −0.81 | −0.19 | −0.71 | −0.17 | ||||

| RC | −0.47 | 0.81 | −0.72 | 0.81 | −0.04 | −0.07 | −0.25 | 0.76 | 0.41 | −0.98 | 0.01 | |||

| MIU | 0.12 | −0.08 | 0.20 | −0.08 | 0.29 | 0.13 | −0.33 | 0.45 | 0.17 | 0.10 | 0.29 | −0.07 | ||

| MMD | 0.64 | −0.49 | 0.48 | −0.49 | 0.60 | 0.62 | 0.79 | 0.11 | 0.62 | 0.15 | −0.98 | −0.01 | −0.41 | |

| SMD | −0.91 | 0.99 | −0.97 | 0.99 | −0.63 | −0.64 | −0.69 | 0.30 | −0.25 | −0.87 | 0.56 | 0.77 | −0.14 | −0.50 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tadesse, M.G.; Nagy, L.; Nierstrasz, V.; Loghin, C.; Chen, Y.; Wang, L. Low-Stress Mechanical Property Study of Various Functional Fabrics for Tactile Property Evaluation. Materials 2018, 11, 2466. https://doi.org/10.3390/ma11122466

Tadesse MG, Nagy L, Nierstrasz V, Loghin C, Chen Y, Wang L. Low-Stress Mechanical Property Study of Various Functional Fabrics for Tactile Property Evaluation. Materials. 2018; 11(12):2466. https://doi.org/10.3390/ma11122466

Chicago/Turabian StyleTadesse, Melkie Getnet, Ladislav Nagy, Vincent Nierstrasz, Carmen Loghin, Yan Chen, and Lichuan Wang. 2018. "Low-Stress Mechanical Property Study of Various Functional Fabrics for Tactile Property Evaluation" Materials 11, no. 12: 2466. https://doi.org/10.3390/ma11122466

APA StyleTadesse, M. G., Nagy, L., Nierstrasz, V., Loghin, C., Chen, Y., & Wang, L. (2018). Low-Stress Mechanical Property Study of Various Functional Fabrics for Tactile Property Evaluation. Materials, 11(12), 2466. https://doi.org/10.3390/ma11122466