3.1. Changes in Mechanical Properties

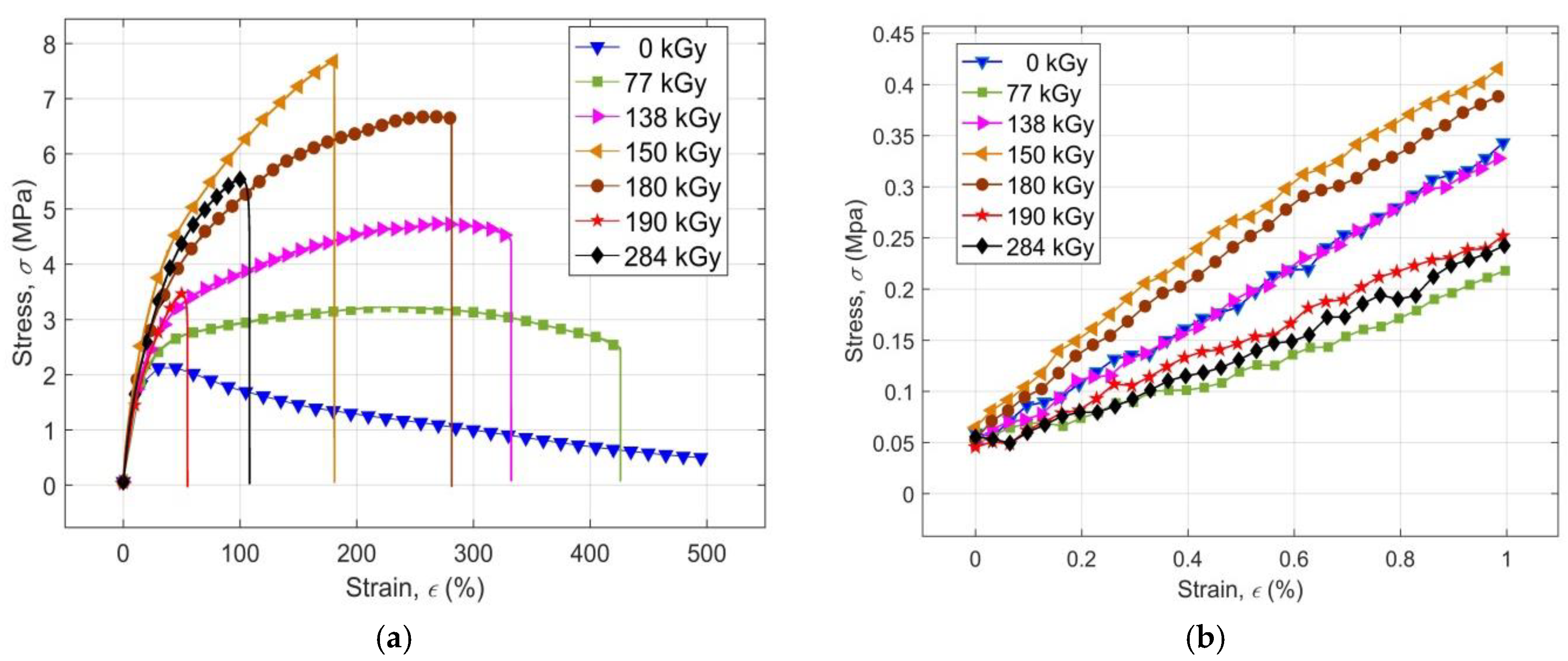

The results of the uniaxial tensile tests for samples of the non-irradiated PS PMX3 and PS PMX3 irradiated with high energy EB radiation by doses ranging from 77 kGy to 284 kGy, in the form of average engineering stress-strain curves, are presented in

Figure 1a. As expected, the effect of EB irradiation on the shape of the stress-strain curves, obtained under the given conditions of tensile tests, is evident. It is apparent already at a first glance that all curves exhibit a relatively short linear elastic region with a low proportionality ratio, a relatively short linear visco-elastic region with low value of limit of elasticity, a relatively low value of tensile modulus and ultimate strength, as well as tear stress, but that their strain at break achieves an extremely wide range of values. A detailed view of the linear region of the stress-strain curves is shown in

Figure 1b.

The shape of the stress-strain curve of the virgin sample resembles the stress-strain curve of the linear amorphous reactoplastics (non-cross-linked resins) with low strength, without an ultimate strength, but with ductility of non-cross-linked, non-crystallizing elastomers in a rubbery state near viscous flow temperature [

22]. Once the strength limit has been reached, the stress decreases with the increasing strain in a non-linear manner, albeit continuously. The material ductility at the same time was so big that its sample during the performed tensile tests could not be ruptured even at a strain above 500%. The stress-strain curves after irradiation of material with radiation doses of 77 kGy and 138 kGy show the characteristics of partially cross-linked non-crystallising elastomers in a rubbery state high above the temperature of their glass transition

Tg [

23], with much higher strength and lower ductility than in the non-irradiated sample.

As a result of irradiation of the sample with a radiation dose of 150 kGy, its stress-strain curve showed a shape corresponding to the tensile response of a brittle, three-dimensional (already cured) amorphous resin in a glassy state, well below the

Tg temperature [

24], with ductility smaller than in the case of application of lower radiation doses. The strength of the irradiated material at a dose of 150 kGy achieves the maximum value at the same time. The shape of the stress-strain curve at higher radiation doses corresponds to curves of the amorphous cured resins in a glassy state, at a temperature just below

Tg [

22], with strength substantially lower than at a dose of 150 kGy, and with a corresponding ductility.

It is evident from the above that the tensile response of the virgin sample reflects the mechanical properties of the polymeric blend of non-cross-linked resins and rubber forming PS PMX3. After irradiation with radiation doses below 150 kGy, the mechanical properties of the partially cross-linked rubber predominate. At a dose of 150 kGy, the properties of the cured resins are dominant, whereas, at higher radiation doses, the effects of radiation-induced degradation of a polymeric network of irradiated material are manifested with predominant mechanical properties of the cured resins. During EB irradiation with radiation doses within the given range of values, the irradiated material progressively enters various physical states undergoing various relaxation transitions events initiated by the absorbed ionizing radiation, resulting in observed non-linear changes in its mechanical properties. A more detailed analysis of the stress-strain curves makes it possible to quantify the effect of the magnitude of radiation dose on the basic mechanical characteristics of the investigated PS PMX3, such as stress and strain at break, ultimate limit, and the tensile modulus

M 40. The tensile modulus at 40% strain was selected for assessing the stiffness of the irradiated material in the initial stages of deformation mainly because of the possibility of its identification for all applied radiation doses to the break of the sample and a good information capability on the elasticity of tested material [

23].

The values of strain at break

εb and of the tensile stress at break

σb of the investigated PS PMX3 for different radiation doses, in the form of stress-strain curves to the break of the sample, are presented in

Figure 2a, while their changes with the increasing dose of irradiation are shown in

Figure 2b. Vertical abscissas show the error intervals of experimental data with the corresponding standard deviation. It is evident from

Figure 2a,b that up to a dose of 150 kGy,

εb decreases in a non-linear manner, but continuously, with a corresponding increase of

σb. Changes in values

εb and

σb after irradiation of the samples of PS PMX3 by radiation doses of 77 kGy, 138 kGy, and 150 kGy thus show the expected opposite trend. The value

εb = 180.9% at 150 kGy versus the value

εb = 332.4% at a dose of 138 kGy is approximately 1.84 times lower, and compared to the value

εb = 426% at 77 kGy, it is approximately 2.36 times lower. The value

σb = 7.681 MPa at 150 kGy is versus the value

σb = 4.441 MPa at 138 kGy more than 1.73 times higher, and compared to the value

σb = 2.466 MPa at 77 kGy, it is approximately 3.12 times higher. The identified changes of values

εb and

σb demonstrate the changes in the mechanical properties of the irradiated PS PMX3 in this interval of radiation doses in terms of a significant reduction in its total ductility (

εb), while at the same time, its tensile strength (

σb) significantly increases due to the prevalence of cross-linking reactions over the intensity of the reactions of polymer chain scission and degradation of intermolecular cross-links initiated by the absorbed high-energy EB radiation [

25]. Higher radiation doses produce more cross-links between macromolecular chains of irradiated material, resulting in an increase in resistance to the release of intermolecular forces by mechanical loading, or in an increase in its stiffness. At higher radiation doses, the polymeric network becomes tighter, and it restricts the internal mobility of the chains, thereby increasing the resistance of the irradiated material to its mechanical damage, or its strength [

26]. Higher density of 3D structures of polymeric network and limited mobility of polymeric chains, i.e., higher stiffness, as well as strength of material due to irradiation by higher radiation doses, also prevent the structural reorganization of polymeric chains during its tensile stress, which significantly reduces the ability of PS PMX3 to be plastically deformed by drawing, or its ductility [

27]. At radiation doses above 150 kGy, the dependence of both

εb and

σb on the magnitude of the dose of the absorbed EB radiation is non-monotonic. At 180 kGy

σb, it drops to the value of 6.637 MPa, while

εb rises to 281.2%; at 190 kGy,

σb and

εb simultaneously drop to 3.172 MPa and 54.39%, while at a dose of 284 kGy,

σb and

εb simultaneously increase to the values of 5.041 MPa and 107.5%, respectively. At a dose of 180 kGy, due to the dominance of the degradation processes over the radiation, cross-linking prevails over the degradation of transverse inter-molecular bonds between the chains of the polymeric network over their production, which makes the network less tight. The lower density of bonds reduces the size of intermolecular interactions and releases limited mobility of chains, which is accompanied by observed decreases in strength (

σb) and increased ductility (

εb) of the irradiated material. During further increases of the radiation dose, the changes of

εb and

σb show the same trend with an analogous course, so it is possible to assume that further degradation of the radiation-induced polymeric network of the irradiated material will occur. The

εb and

σb values for the non-irradiated sample could not be determined, as it was not ruptured under the given conditions of the tensile tests.

The values of the strength limit

σm and the modulus

M 40 of the investigated PS PMX3 for the virgin sample and the samples irradiated with different doses of EB radiation are presented in

Figure 3a, and their changes with the increasing dose of absorbed radiation are shown in

Figure 3b. For clarity,

Figure 3a shows the entire stress-strain curves till completion of the tensile tests, not only after they have been torn apart, as in

Figure 2a. It is evident from

Figure 3a,b that up to a dose of 150 kGy both

σm and

M 40 are non-linear, but they grow monotonously. The values

σm = 3.23 MPa at 77 kGy,

σm = 4.734 MPa at 138 kGy and

σm = 7.674 MPa at 150 kGy, compared to the non-irradiated sample

σm = 2.143 MPa, are approximately 1.5, 2.1, and 3.6 times higher, respectively. Values of the modulus

M 40 = 2.598 MPa at 77 kGy,

M 40 = 3.059 MPa at 138 kGy and

M 40 = 4.3110 MPa at 150 kGy, compared to

M 40 = 2.13 MPa for a non-irradiated sample, are approximately 1.2, 1.4, and 2 times higher, respectively. The recorded changes in the values of

σm and

M 40 after application of radiation doses of 77 kGy, 138 kGy, and 150 kGy demonstrate the expected increase in tensile strength of the irradiated PS PMX3 with a simultaneous increase in stiffness at the initial stages of deformation, which can also be attributed to the prevailing radiation-induced cross-linking reactions over the degradation processes in the irradiated material, with the mechanism described above. At radiation doses above 150 kGy, as with at

εb and

σb, the dependencies of both

σm and

M 40 on the magnitude of the dose of the absorbed radiation are non-monotonic, but they exhibit the same trend with an analogous course. At 180 kGy, the value

σm drops to 6.682 MPa and

M 40 drops to 3.67 MPa; at 190 kGy, the value

σm drops to 3.476 and

M 40 drops to 3.21 MPa, due to the induction-induced reduction of strength and an increase of the ductility of the sample due to the predominance of the degradation processes over the forming processes of the polymer network with the mechanism described above. At a dose of 284 kGy, the values of

σm and

M 40 simultaneously increase to 5.551 MPa and 3.931 MPa, respectively. However, this increase in

σm and

M 40, as well as the increase of

εb and

σb at the radiation dose of 284 kGy, is due to the continued degradation of the sample material, and not to the subsequent process of formation of the polymeric network or by the radiation-induced change of crystallinity of PS PMX3 [

28]. Due to the chemical composition of the irradiated material, it can be assumed that at high radiation doses, the cross-linked nitrile rubber therein becomes completely disintegrated, and it thereby transforms to a filler dispersed in the polymeric matrix of the blend of melamine and phenol-formaldehyde resin of the composite created by the high-energy EB irradiation with mechanical properties quite different from those of the original polymer system. However, this assumption will need to be verified in ongoing research using the DSC, DMTA, TGA, and FT-IR techniques, or other diagnostic techniques.

The ultimate strength after irradiation of the investigated material with a radiation dose of 150 kGy is equal to the stress at break of

σb, which is typical for brittle amorphous polymers, such as cross-linked reactoplasts, including the cured resins [

24]. During all other applied radiation doses, the tensile response of the irradiated PS exhibits signs of the tensile response of more ductile materials with significantly lower stiffness and strength [

23]. From the point of view of enhancement of mechanical properties of the investigated PS PMX3 with its irradiation by high-energy EB radiation, it is possible to consider the radiation dose of 150 kGy as optimal.

The experimental values of the monitored mechanical characteristics for the virgin sample, as well as for the PS PMX3 samples irradiated with the individual radiation doses, are summarized in

Table 1.

3.2. Regression Analysis

The effect of EB irradiation on the change of mechanical properties of PS PMX3 by radiation doses up to 150 kGy, at which it is possible to observe a significant improvement, is demonstrated by results of the regression analysis at the confidence level of 95% shown in

Figure 4a,b (for

εb and

σb), and in

Figure 5a,b (for

σm and

M 40).

The realized regression analysis of the experimental data has shown that all the analyzed functional dependencies at a given interval of radiation dose can be described with a relatively high degree of reliability by a single regression model, in the form

where

y(

x) is the corresponding mechanical characteristic of the irradiated material,

x is the radiation dose absorbed, and Δ

yi,

θi,

mi, and

δ represent unknown but the correct coefficients of the model that have been reliably estimated in the process of parametric fitting of experimental data using the Trust Region algorithm of non-linear least squares method [

29] in the device ‘CF Tool’ of the Matlab

® software package. The following is then valid for the model coefficients Δ

yi:

where

y(0) is the initial value of the corresponding mechanical characteristic as it follows from the relation (1) for

x = 0. The subscript

i pertains to critical points of the curve

y = y (

x) where a significant change in the velocity of its trend takes place, and

N is the number of these critical points. The negative value of the quotient in the model exponent then represents a decreasing trend, while its positive value represents the increasing trend of

y(

x). The coefficient

δ represents a non-constant error parameter of the model, which will be discussed later.

The dashed lines in

Figure 4 and

Figure 5 represent the 95% prediction intervals of the estimated coefficients of the model representing the 5% probability that the results of future measurements of the mechanical characteristics of the irradiated PS PMX3 under the same experimental conditions will not lie between their lower and upper boundaries [

30].

The regression model (1) describes changes in the observed mechanical characteristics of the irradiated polymeric material due to the prevalence of formation of transverse intermolecular bonds between macromolecular chains and their simultaneous breaking accompanied by degradation of the formed polymer network. Due to the different nature of intermolecular bonds present in the polymer (hydrogen, dipole, Van der Waals, or ionic interactions with different values of dissociation energy), as well as due to the different spatial arrangement of macromolecules, a specific distribution of intermolecular bond strengths is observed between macromolecules of polymeric materials, which match the Boltzmann distribution. However, radiation-induced (similarly as temperature-induced) breaking of intermolecular bonds is not a random process subject to Boltzmann’s distribution [

24]. Since the failure of each bond leads to a redistribution of stresses in all other bonds, each previous failure event has a notable effect on the failure of all remaining bonds. The interaction of these failures is therefore subject to Weibull’s statistics [

31]. Given the above, the regression model (1) can be interpreted in a good approximation by the function of probability density of the Weibull’s distribution of EB radiation-induced breaking of transverse intermolecular bonds of the irradiated polymer in the presence of simultaneous formation of a polymeric 3D network with new cross-links (quantified by an error

δ of the model) in the following form [

32]:

where the pre-exponential factor or hazard function

bkxk−1 of the Weibull’s distribution approximates the constants Δ

yi, the scale parameter

b = ±1/

θi and the shape parameter, or the Weibull modulus

k =

mi. Since the sum (ΣΔ

yi +

δ) approximates the initial values of the respective mechanical characteristics

y(0) and

θi of the radiation dose at the critical points of the curve

y =

y(

x), the values Δ

yi and

θi depend on the initial physical state of the irradiated sample of material, its properties and conditions of irradiation, while the Weibull’s moduli

mi reflect the statistics of transverse intermolecular bonds breaking due to EB irradiation with different radiation doses. Since the breaking of bonds is conditioned by overcoming the energy barrier of intermolecular forces, the values of the coefficients

mi depend on the magnitude of the activation energy of the individual relaxation events observed at the applied radiation doses due to the release of the polymeric chains with respect to the relevant type of motion corresponding to the given primary as well as secondary relaxation event [

33]. At the same time, the degree of chains mobility is determined by the actual physical state of the polymer. In the glassy state, it is limited only to local movements of individual molecules, vibrations, bending and stretching of bonds, rotation of lateral molecular groups, and movement of only a few main chains. In the area of the glass transition, significant movement of lateral groups is possible, as well as gradual movement and reptation of the main chains, which transforms to a large-scale movement of segments and whole chains in a rubbery state. The state of viscous flow allows for the sliding of whole macromolecular chains and global translations of entire polymer molecules between entanglements with subsequent decay of the polymeric material as a whole [

34]. Since the critical condition for radiation-induced polymer cross-linking is, in addition to the formation of secondary radicals in its amorphous regions, also the sufficiently high mobility of the chains which are carried by these secondary radicals, the radiation cross-linking by ionizing radiation is an optimal rubbery, or visco-elastic state with high mobility of entire chains [

28]. Since the sensitivity of the individual tensile characteristics

εb,

σb,

σm, and

M 40 to the magnitude of the absorbed radiation dose is different, it can be naturally expected that values of the parameters

mi for their description with the use of the model (1) will also be different.

The radiation cross-linking is an excessively-complicated process due to the complexity of the polymerization reactions running in the irradiated three-component material, the analytical description of which requires a solution of the system of non-linear differential equations. This solution can be obtained only with the use of numerical methods with an approximate result [

34]. In order to simplify this problem, the influence of the radiation-induced formation of the polymeric network on the mechanical properties of the irradiated PS PMX3 in the model (1) is approximated only by an unknown, non-constant error parameter

δ. The value of the error parameter at the same time depends on the magnitude of the radiation dose

x, as well as on the values of other coefficients of the model Δ

yi,

θi, and

mi, i.e., on the initial physical state of the irradiated material sample, its properties and conditions of irradiation, as well as on the activation energies of the relaxation events initiated by individual radiation doses of the absorbed radiation that together determine the intensity of radiation-induced generation of cross-links and formation of polymer network.

The coefficients Δ

yi,

mi and

δ, estimated in the process of parametric fitting of the experimental data, coefficients

θi and percentage deviations of the coefficients Δ

y(0) from their experimental values, as well as the statistical parameters ‘goodness of fit’ SSE, RMSE, R

2 and Adj-R

2 [

35], are listed in

Table 2 (for

εb and

σb) and

Table 3 (for

σm and

M 40). Due to the aforementioned low number of available experimental data, it was impossible to identify the coefficients

θi by parametric fitting of the experimental data; therefore, they were estimated directly from the graphical interpretation of the functional dependencies of the monitored mechanical characteristics of the irradiated material.

Relatively low values of SSE and RMSE, the close proximity of the parameters R2 and Adj-R2 to one (or their equality at the value of one), and low values of deviations Δy(0) show the relatively high performance of the found model. However, due to the low amount of available experimental data, more detailed statistical analysis of the descriptive and predictive capabilities of the model was not possible, and it will be necessary to realize this within the framework of ongoing research.