Evolution of Dislocation Loops Induced by Different Hydrogen Irradiation Conditions in Reduced-Activation Martensitic Steel

Abstract

1. Introduction

2. Materials and Methods

3. Results

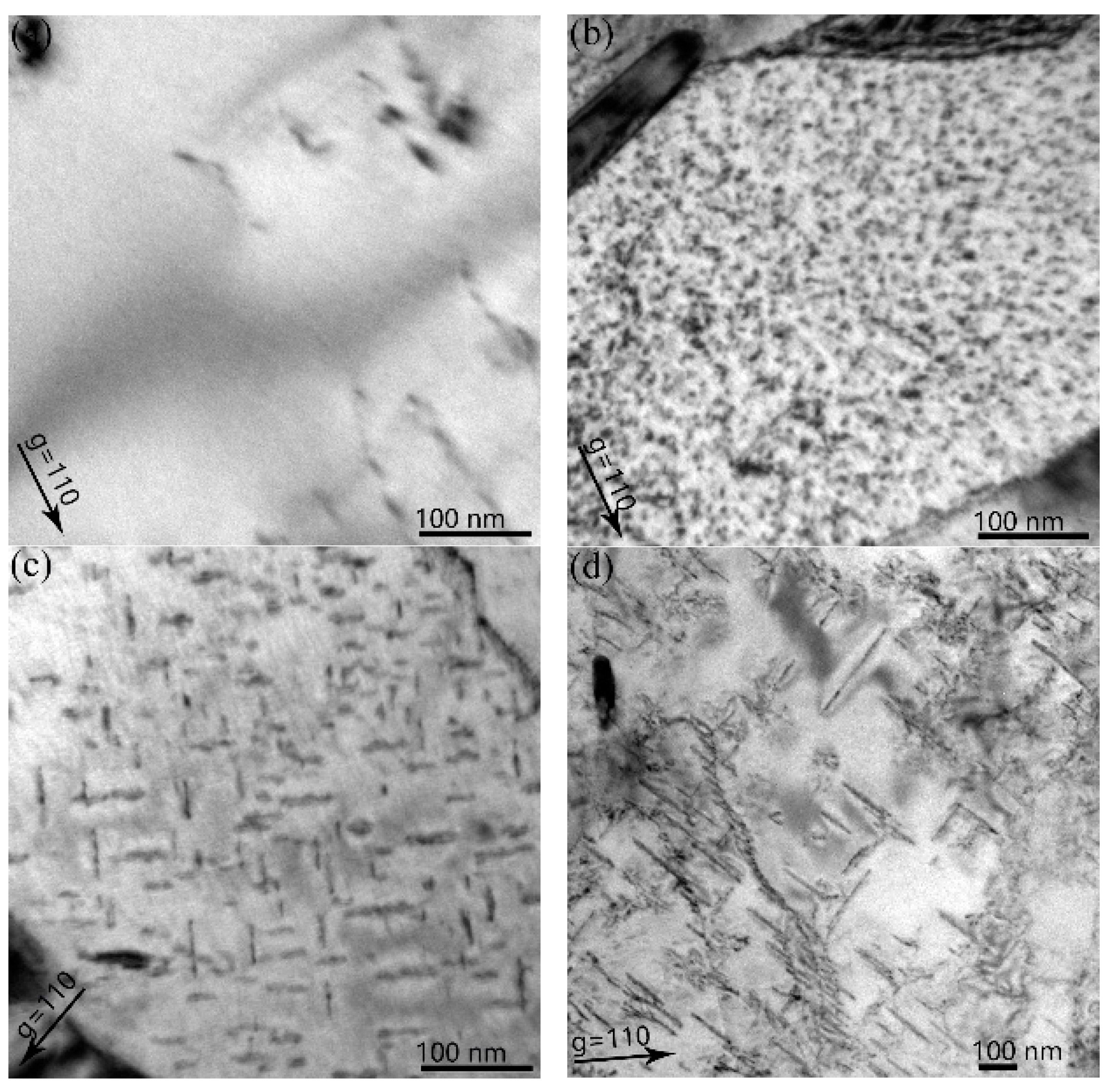

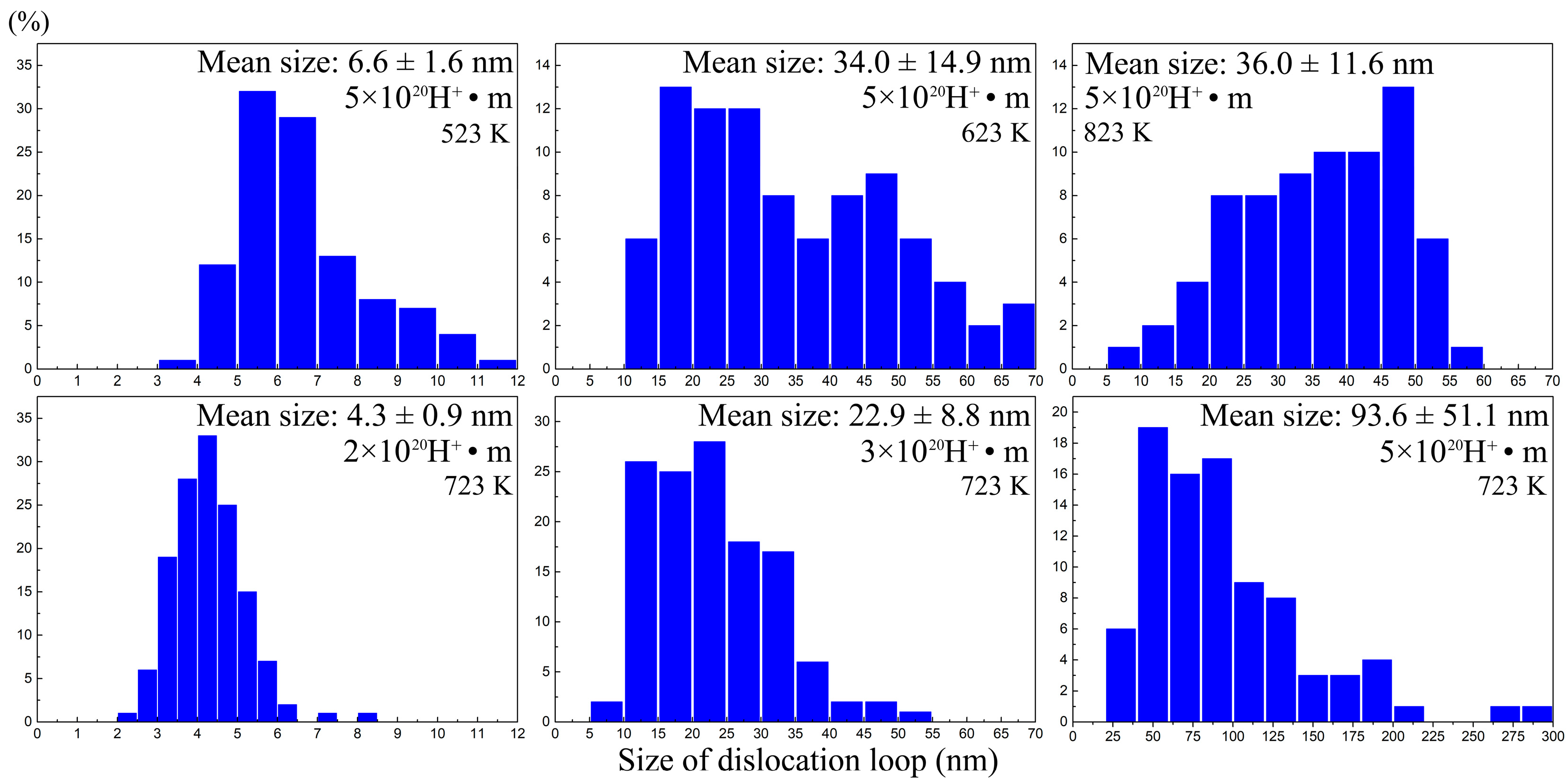

3.1. Dislocation Loop Evolution in RAFM Steel with Increasing Temperature

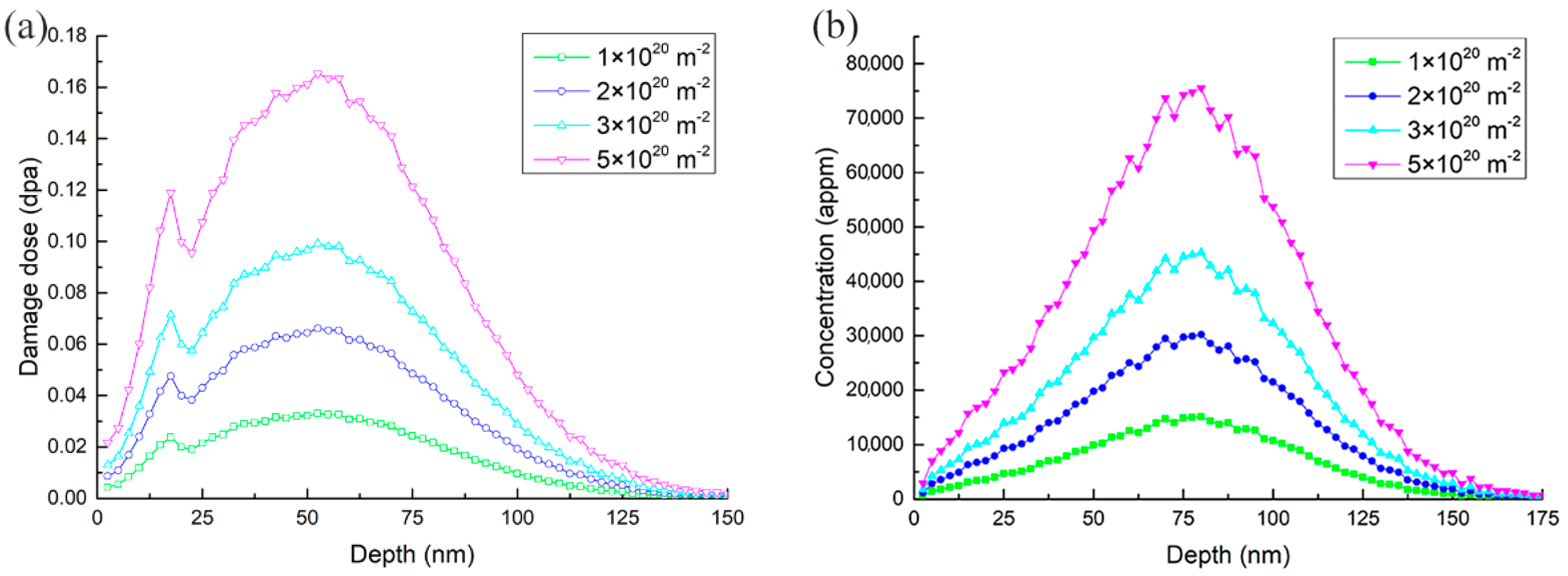

3.2. Dislocation Loop Evolution in RAFM Steel with Increasing Hydrogen Fluence

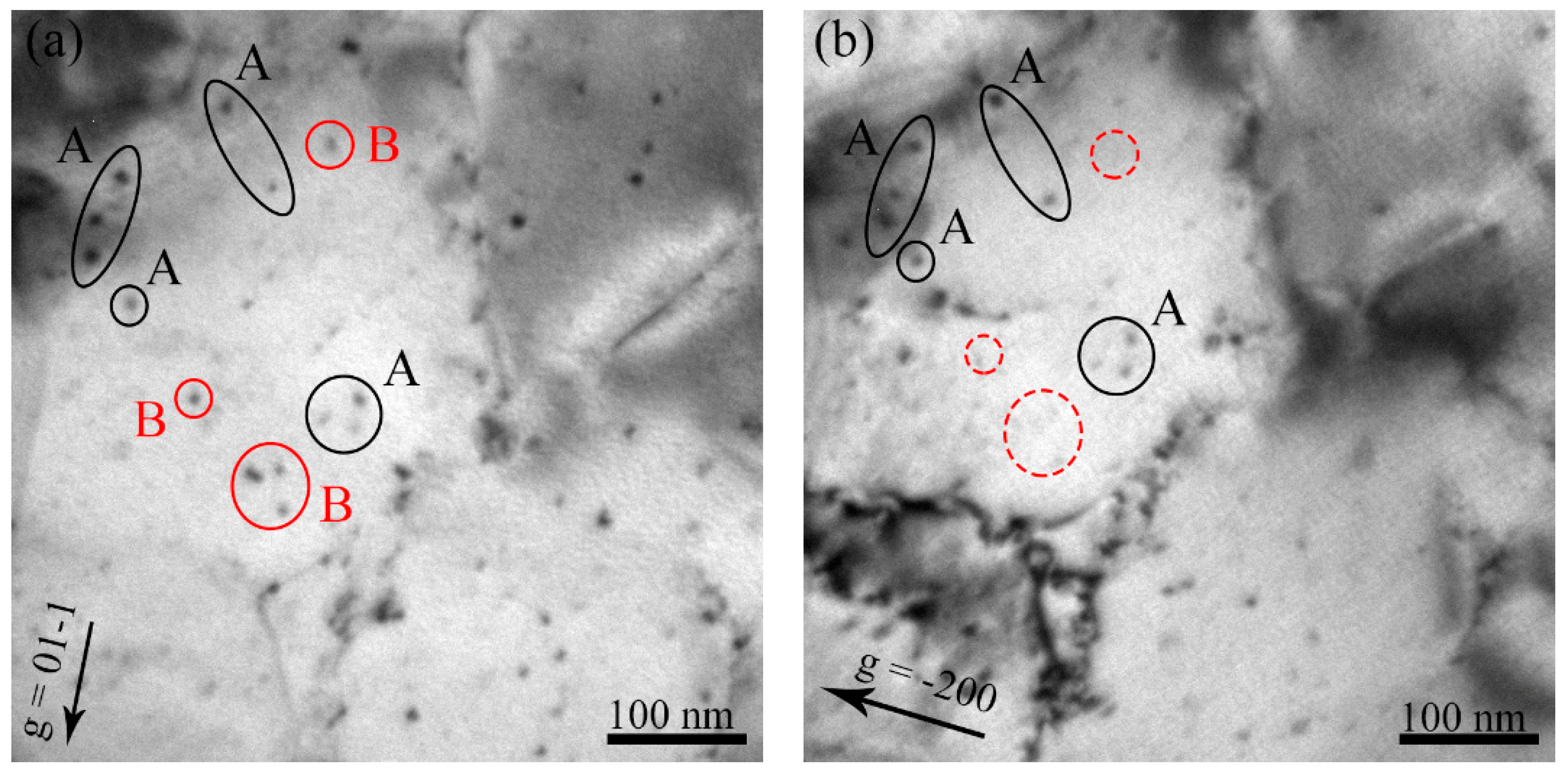

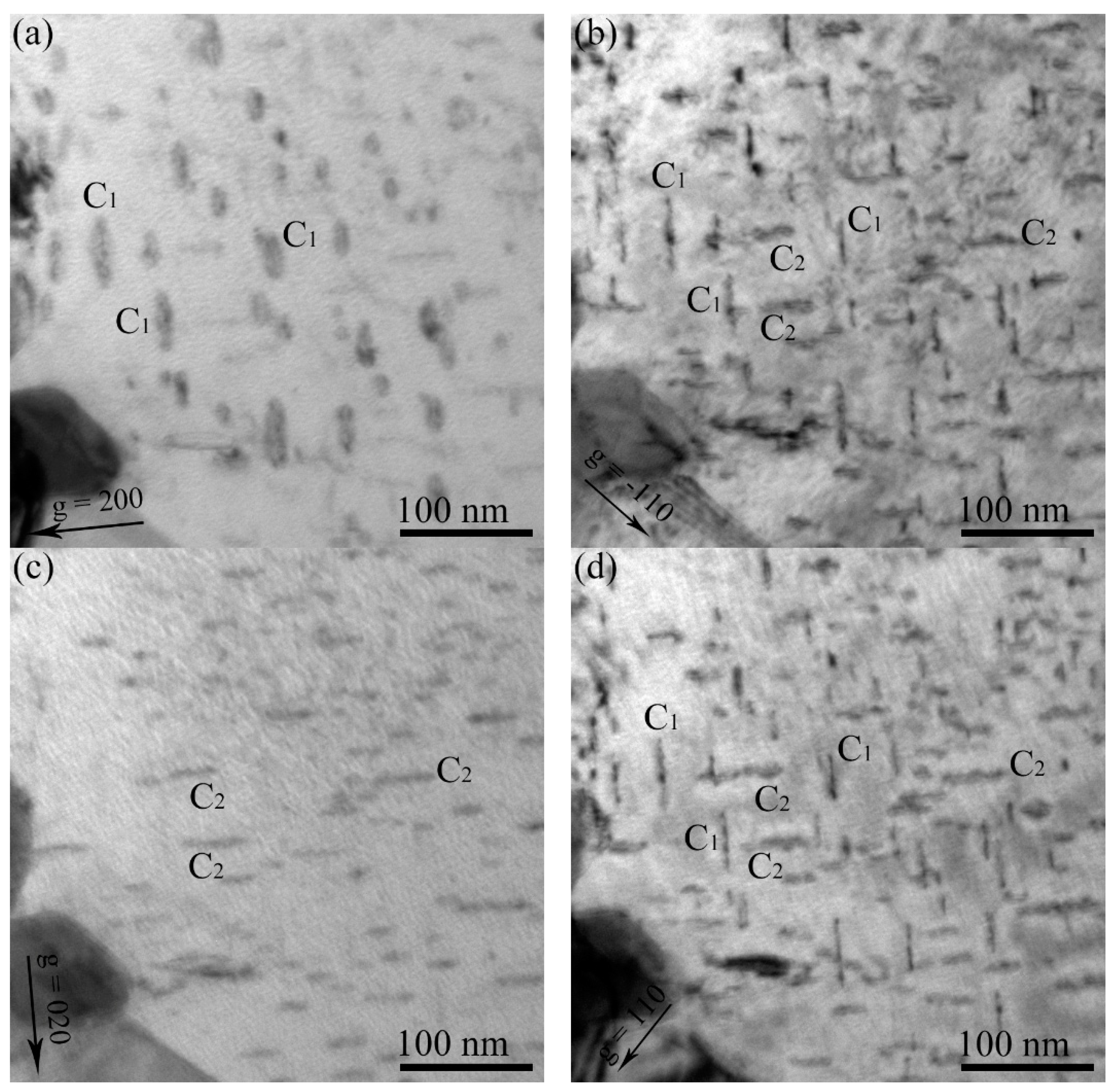

3.3. Burgers Vectors Analysis of Dislocation Loops

4. Discussion

4.1. Evolution of Dislocation Loops Dependent on Irradiation Temperature

4.2. Evolution of Dislocation Loop Dependent on Irradiation Fluence

4.3. Burgers Vector Evolution of Dislocation Loop

5. Conclusions

- The results of the elevated temperature irradiations indicate that there is an optimum temperature for dislocation loop growth and nucleation, which, in this work, is 723 K. This is because of the differentiation of activation energy for migration between the self-interstitial and vacancy induced by hydrogen and the different chemical components of steels. The presence of hydrogen shifts the peak position of the size distribution of loops with temperature to the higher temperature.

- Compared with the neutron and heavy ion irradiations at the same damage level, larger dislocation loops were observed in the hydrogen ion irradiation. A potential mechanism was given as follows: the probability of the recombination of self-interstitials with vacancies that are produced by hydrogen irradiation can be effectively reduced through the formation of H–V complexes.

- At an irradiation temperature of 523 K, 47.3% a0 <111> and 52.7% a0 <100> loops were observed, but only a0 <100> loops were observed above 623 K, when irradiated to 0.16 dpa. This can be explained by the mechanism where an elevated temperature favors the transformation of a0 <111> to a0 <100> loops, and the irradiation ions of hydrogen and solute atoms, such as Cr, might further promote the transformation. The presence of hydrogen promotes the formation of a0 <100> loops.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zinkle, S.J.; Was, G.S. Materials challenges in nuclear energy. Acta Mater. 2013, 61, 735–758. [Google Scholar] [CrossRef]

- Kawai, M.; Kokawa, H.; Michiuchi, M.; Kurisihita, H.; Goto, T.; Futakawa, M.; Yoshiie, T.; Hasegawa, A.; Watanabe, S.; Yamamura, T.; et al. Present status of study on development of materials resistant to radiation and beam impact. J. Nucl. Mater. 2008, 377, 21–27. [Google Scholar] [CrossRef]

- Ohshima, H.; Kubo, S. 5-sodium-cooled fast reactor. In Handbook of Generation IV Nuclear Reactors; Elsevier: New York, NY, USA, 2016; pp. 119–155. [Google Scholar]

- Marian, J.; Hoang, T.; Fluss, M.; Hsiung, L.L. A review of helium-hydrogen synergistic effects in radiation damage observed in fusion energy steels and an interaction model to guide future understanding. J. Nucl. Mater. 2015, 462, 409–421. [Google Scholar] [CrossRef]

- Klueh, R.L.; Gelles, D.S.; Jitsukawa, S.; Kimura, A.; Odette, G.R.; Van der Schaaf, B.; Victoria, M. Ferritic/martensitic steels—Overview of recent results. J. Nucl. Mater. 2002, 307–311, 455–465. [Google Scholar] [CrossRef]

- Baluc, N.; Schäublin, R.; Spätig, P.; Victoria, M. On the potentiality of using ferritic/martensitic steels as structural materials for fusion reactors. Nucl. Fusion 2004, 44, 56–61. [Google Scholar] [CrossRef]

- Kupriiyanova, Y.E.; Bryk, V.V.; Borodin, O.V.; Kalchenko, A.S.; Voyevodin, V.N.; Tolstolutskaya, G.D.; Garner, F.A. Use of double and triple-ion irradiation to study the influence of high levels of helium and hydrogen on void swelling of 8-12% Cr ferritic-martensitic steels. J. Nucl. Mater. 2016, 468, 264–273. [Google Scholar] [CrossRef]

- Zinkle, S.J. Challenges in developing materials for fusion technology-past, present and future. Fusion Sci. Technol. 2013, 64, 65–75. [Google Scholar] [CrossRef]

- Wakai, E.; Kikuchi, K.; Yamamoto, S.; Aruga, T.; Ando, M.; Tanigawa, H.; Taguchi, T.; Sawai, T.; Oka, K.; Ohnuki, S. Swelling behavior of F82H steel irradiated by triple/dual ion beams. J. Nucl. Mater. 2003, 318, 267–273. [Google Scholar] [CrossRef]

- Liu, C.; Klein, H.; Jung, P. Embrittlement of RAFM EUROFER97 by implanted hydrogen. J. Nucl. Mater. 2004, 335, 77–82. [Google Scholar] [CrossRef]

- Farrell, K. Experimental effects of helium on cavity formation during irradiation—A review. Radiat. Eff. 1980, 53, 175–194. [Google Scholar] [CrossRef]

- Heinisch, H.L.; Gao, F.; Kurtz, R.J. Atomic-scale modeling of interactions of helium, vacancies and helium-vacancy clusters with screw dislocations in alpha-iron. Philos. Mag. 2010, 90, 885–895. [Google Scholar] [CrossRef]

- Brimbal, D.; Décamps, B.; Henry, J.; Meslin, E.; Barbu, A. Single- and dual-beam in situ irradiations of high-purity iron in a transmission electron microscope: Effects of heavy ion irradiation and helium injection. Acta Mater. 2014, 64, 391–401. [Google Scholar] [CrossRef]

- Prokhodtseva, A.; Décamps, B.; Ramar, A.; Schäublin, R. Impact of He and Cr on defect accumulation in ion-irradiated ultrahigh-purity Fe(Cr) alloys. Acta Mater. 2013, 61, 6958–6971. [Google Scholar] [CrossRef]

- Tanaka, T.; Oka, K.; Ohnuki, S.; Yamashita, S.; Suda, T.; Watanabe, S.; Wakai, E. Synergistic effect of helium and hydrogen for defect evolution under multi-ion irradiation of Fe-Cr ferritic alloys. J. Nucl. Mater. 2004, 329–333, 294–298. [Google Scholar] [CrossRef]

- Ando, M.; Tanigawa, H.; Jitsukawa, S.; Sawai, T.; Katoh, Y.; Kohyama, A.; Nakamura, K.; Takeuchi, H. Evaluation of hardening behaviour of ion irradiated reduced activation ferritic/martensitic steels by an ultra-micro-indentation technique. J. Nucl. Mater. 2002, 307–311, 260–265. [Google Scholar] [CrossRef]

- Xiong, X.; Yang, F.; Zou, X.; Suo, J. Effect of twice quenching and tempering on the mechanical properties and microstructures of SCRAM steel for fusion application. J. Nucl. Mater. 2012, 430, 114–118. [Google Scholar] [CrossRef]

- Standard Practice for Neutron Radiation Damage Simulation by Charged-Particle Irradiation, ASTM Designation E 521-89, Annual Book of ASTM Standards, vol. 12.02; American Society for Testing and Materials: Philadelphia, PA, USA, 1989; p. D-9.

- Ehrhart, P.; Averback, R.S. Diffuse X-ray scattering studies of neutron- and electron-irradiated Ni, Cu and dilute alloys. Philos. Mag. A 1989, 60, 283–306. [Google Scholar] [CrossRef]

- Klimenkov, M.; Materna-Morris, E.; Möslang, A. Characterization of radiation induced defects in EUROFER 97 after neutron irradiation. J. Nucl. Mater. 2011, 417, 124–126. [Google Scholar] [CrossRef]

- Li, S.; Li, Y.; Lo, Y.C.; Neeraj, T.; Srinivasan, R.; Ding, X.; Sun, J.; Qi, L.; Gumbsch, P.; Li, J. The interaction of dislocations and hydrogen-vacancy complexes and its importance for deformation-induced proto nano-voids formation in α-Fe. Int. J. Plast. 2015, 74, 175–191. [Google Scholar] [CrossRef]

- Hashimoto, N.; Sakuraya, S.; Tanimoto, J.; Ohnuki, S. Effect of impurities on vacancy migration energy in Fe-based alloys. J. Nucl. Mater. 2014, 445, 224–226. [Google Scholar] [CrossRef]

- Xu, S.; Yao, Z.; Jenkins, M.L. TEM characterisation of heavy-ion irradiation damage in FeCr alloys. J. Nucl. Mater. 2009, 386–388, 161–164. [Google Scholar] [CrossRef]

- Yao, Z.; Jenkins, M.L.; Hernández-Mayoral, M.; Kirk, M.A. The temperature dependence of heavy-ion damage in iron: A microstructural transition at elevated temperatures. Philos. Mag. 2010, 90, 4623–4634. [Google Scholar] [CrossRef]

- Jenkins, M.L.; Yao, Z.; Hernández-Mayoral, M.; Kirk, M.A. Dynamic observations of heavy-ion damage in Fe and Fe-Cr alloys. J. Nucl. Mater. 2009, 389, 197–202. [Google Scholar] [CrossRef]

- Masters, B.C. Dislocation loops in irradiated iron. Philos. Mag. 1965, 11, 881–893. [Google Scholar] [CrossRef]

- Huang, X.; Shen, Y.; Li, Q.; Xu, Z.; Zhu, J. Microstructural evolution of CLAM steel under 3.5MeV Fe13+ ion irradiation. Fusion Eng. Des. 2016, 109–111, 1058–1066. [Google Scholar] [CrossRef]

- Schäublin, R.; Victoria, M. Differences in the microstructure of the F82H ferritic / martensitic steel after proton and neutron irradiation. J. Nucl. Mater. 2000, 287, 339–343. [Google Scholar]

- Wakai, E.; Miwa, Y.; Hashimoto, N.; Robertson, J.P.; Klueh, R.L.; Shiba, K.; Abiko, K.; Furuno, S.; Jitsukawa, S. Microstructural study of irradiated isotopically tailored F82H steel. J. Nucl. Mater. 2002, 307–311, 203–211. [Google Scholar] [CrossRef]

- Schaeublin, R.; Gelles, D.; Victoria, M. Microstructure of irradiated ferritic/martensitic steels in relation to mechanical properties. J. Nucl. Mater. 2002, 307–311, 197–202. [Google Scholar] [CrossRef]

- Dethloff, C.; Gaganidze, E.; Aktaa, J. Microstructural defects in EUROFER 97 after different neutron irradiation conditions. Nucl. Mater. Energy 2016, 9, 471–475. [Google Scholar] [CrossRef]

- Jia, X.; Dai, Y. Microstructure in martensitic steels T91 and F82H after irradiation in SINQ Target-3. J. Nucl. Mater. 2003, 318, 207–214. [Google Scholar] [CrossRef]

- Little, E.A.; Bullough, R.; Wood, M.H. On the Swelling Resistance of Ferritic Steel. Proc. R. Soc. A Math. Phys. Eng. Sci. 1980, 372, 565–579. [Google Scholar] [CrossRef]

- Kirsanov, V.V.; Musina, M.V.; Rybin, V.V. The influence of hydrogen on the formation of helium vacancy voids in metal. J. Nucl. Mater. 1992, 191–194, 1318–1322. [Google Scholar] [CrossRef]

- Krom, A.H.M.; Bakker, A.D. Hydrogen trapping models in steel. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2000, 31, 1475–1482. [Google Scholar] [CrossRef]

- Hayward, E.; Deo, C. Synergistic effects in hydrogen–helium bubbles. J. Phys. Condens. Matter 2012, 24, 265402. [Google Scholar] [CrossRef] [PubMed]

- Bacon, D.J.; Gao, F.; Osetsky, Y.N. Primary damage state in fcc, bcc and hcp metals as seen in molecular dynamics simulations. J. Nucl. Mater. 2000, 276, 1–12. [Google Scholar] [CrossRef]

- Stoller, R.E.; Odette, G.R.; Wirth, B.D. Primary damage formation in bcc iron. J. Nucl. Mater. 1997, 251, 49–60. [Google Scholar] [CrossRef]

- Terentyev, D.A.; Malerba, L.; Hou, M. Dimensionality of interstitial cluster motion in bcc-Fe. Phys. Rev. B Condens. Matter Mater. Phys. 2007, 75, 1–13. [Google Scholar] [CrossRef]

- Masters, B.C. Dislocation loops in irradiated iron. Nature 1963, 200, 254. [Google Scholar] [CrossRef]

- Marian, J.; Wirth, B.D.; Perlado, J.M. Mechanism of Formation and Growth of <100> Interstitial Loops in Ferritic Materials. Phys. Rev. Lett. 2002, 88, 4. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Stoller, R.E.; Osetsky, Y.N.; Terentyev, D. Solving the puzzle of 100 Interstitial Loop Formation in bcc Iron. Phys. Rev. Lett. 2013, 110, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Gao, N.; Jung, P.; Sauvage, T. A new mechanism of loop formation and transformation in bcc iron without dislocation reaction. J. Nucl. Mater. 2013, 441, 216–221. [Google Scholar] [CrossRef]

- Schäublin, R.; Décamps, B.; Prokhodtseva, A.; Löffler, J.F. On the origin of the primary ½ a0 <111> and a0 <100> loops in irradiated Fe(Cr) alloys. Acta Mater. 2017, 133, 427–439. [Google Scholar] [CrossRef]

| g\b | 111 | 11-1 | 1-11 | −111 | 100 | 010 | 001 |

|---|---|---|---|---|---|---|---|

| 0–11 | × | √ | √ | × | × | √ | √ |

| −200 | √ | √ | √ | √ | √ | × | × |

| −110 | × | × | √ | √ | √ | √ | × |

| 020 | √ | √ | √ | √ | × | √ | × |

| 110 | √ | √ | × | × | √ | √ | × |

| Materials | Irradiation Type | Tirr (K) | Tirr (°C) | Dose (dpa) | Loop Size (nm) | Density (m−3) | Burgers Vectors of Loop | Ref. | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Max | Mean | 1/2 a0 <111> | a0 <100> | |||||||

| Pure Fe | Ion (Fe+) | 573 | 300 | 1 | - | 5–20 | - | 92% | 8% | [23] |

| 673 | 400 | 1.3 | 68 | 30–50 | - | √ | √ | [24] | ||

| 723 | 450 | 2 | 225 | - | - | √ | √ | [24] | ||

| 773 | 500 | 2 | 50 | - | - | × | √ | [24] | ||

| 2.5 | 85 | - | - | × | √ | [25] | ||||

| 823 | 550 | 74.2 | - | 100–150 | - | × | √ | [26] | ||

| CLAM | Ion (Fe+) | 573 | 300 | 0.46 | 8.5 | - | 1.9 × 1022 | - | - | [27] |

| 2.79 | 13 | - | 2.8 × 1022 | - | - | [27] | ||||

| 823 | 550 | 0.38 | 18 | - | 9.4 × 1021 | - | - | [27] | ||

| 2.75 | 32 | - | 1.5 × 1022 | - | - | [27] | ||||

| F82H | Neutron | 523 | 250 | 0.7 | - | 2.2 | 3 × 1021 | - | - | [28] |

| 2.8 | - | 7.9 | 1.4 × 1022 | √ | × | [29] | ||||

| 573 | 300 | 51 | - | 11 | 4 × 1022 | √ | × | [29] | ||

| 575 | 302 | 8.8 | - | 5.4 | - | √ | √ | [30] | ||

| 583 | 310 | 6.9 | - | 6.9 | 2.8 × 1022 | - | - | [28] | ||

| 673 | 400 | 7.4 | - | 33 | 6 × 1021 | - | - | [29] | ||

| Eurofer-97 | Neutron | 573 | 300 | 15 | - | 2.8–4.2 | 2.1–5.8 × 1021 | √ | √ | [31] |

| T91 | Neutron | 403 | 130 | 4.6 | - | 3.8 | 2.5 × 1022 | - | - | [32] |

| 523 | 250 | 8.3 | - | 4.5 | 3.6 × 1022 | - | - | [32] | ||

| 633 | 360 | 11.8 | - | 8.9 | 1.3 × 1022 | - | - | [32] | ||

| FV448 | Neutron | 653 | 380 | 30 | 110 | 50 | 7 × 1021 | - | >98% | [33] |

| 733 | 460 | 30 | >300 | 300 | 1 × 1018 | - | >98% | [33] | ||

| Fe-9.24Cr | Ion (H+) | 523 | 250 | 0.16 | 11.7 | 6.6 | 2.5 × 1021 | 47.3% | 52.7% | Present study |

| 623 | 350 | 0.16 | 68.9 | 34.0 | 1.1 × 1021 | × | √ | |||

| 723 | 450 | 0.06 | 8.1 | 4.3 | 6.6 × 1022 | × | √ | |||

| 0.1 | 52.7 | 22.9 | 8.1 × 1021 | × | √ | |||||

| 0.16 | 285.7 | 93.6 | 1.7 × 1021 | × | √ | |||||

| 823 | 550 | 0.16 | 58.1 | 36.0 | 7.9 × 1020 | × | √ | |||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Guo, L.; Shen, Z.; Xin, J.; Huang, Q.; Wei, Y.; Long, Y.; Zhou, X.; Chen, C. Evolution of Dislocation Loops Induced by Different Hydrogen Irradiation Conditions in Reduced-Activation Martensitic Steel. Materials 2018, 11, 2276. https://doi.org/10.3390/ma11112276

Zhang W, Guo L, Shen Z, Xin J, Huang Q, Wei Y, Long Y, Zhou X, Chen C. Evolution of Dislocation Loops Induced by Different Hydrogen Irradiation Conditions in Reduced-Activation Martensitic Steel. Materials. 2018; 11(11):2276. https://doi.org/10.3390/ma11112276

Chicago/Turabian StyleZhang, Weiping, Liping Guo, Zhenyu Shen, Jingping Xin, Qunying Huang, Yaxia Wei, Yunxiang Long, Xiong Zhou, and Cheng Chen. 2018. "Evolution of Dislocation Loops Induced by Different Hydrogen Irradiation Conditions in Reduced-Activation Martensitic Steel" Materials 11, no. 11: 2276. https://doi.org/10.3390/ma11112276

APA StyleZhang, W., Guo, L., Shen, Z., Xin, J., Huang, Q., Wei, Y., Long, Y., Zhou, X., & Chen, C. (2018). Evolution of Dislocation Loops Induced by Different Hydrogen Irradiation Conditions in Reduced-Activation Martensitic Steel. Materials, 11(11), 2276. https://doi.org/10.3390/ma11112276