Promising Tensile and Fatigue Properties of Commercially Pure Titanium Processed by Rotary Swaging and Annealing Treatment

Abstract

:1. Introduction

2. Experimental Procedures

3. Results and Discussion

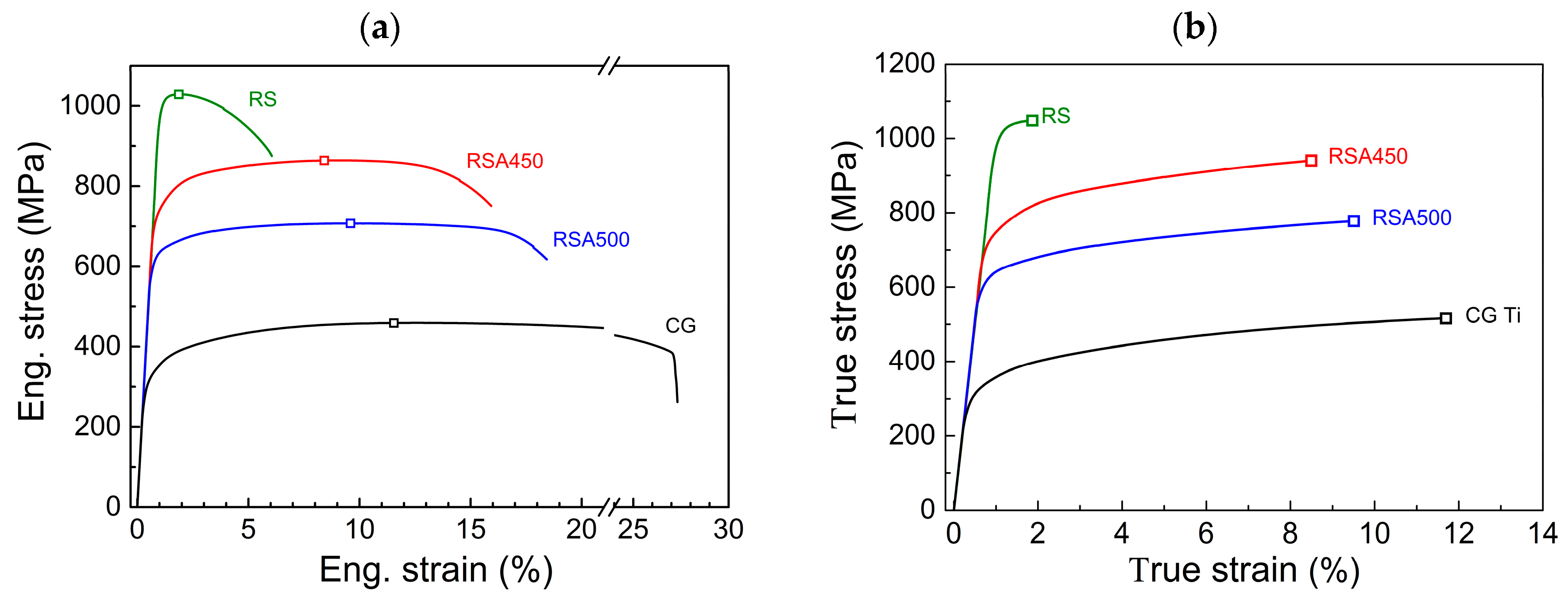

3.1. Tensile Properties

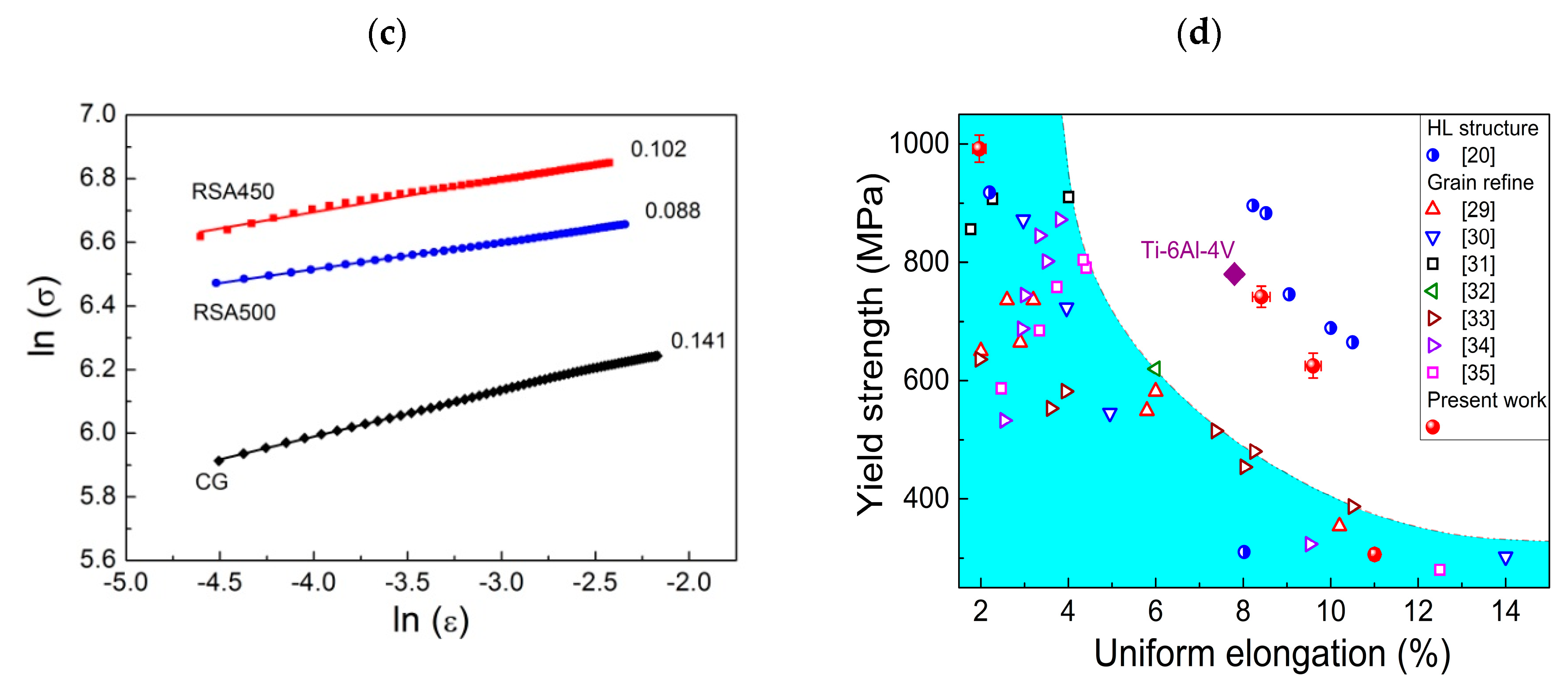

3.2. Fatigue Limit

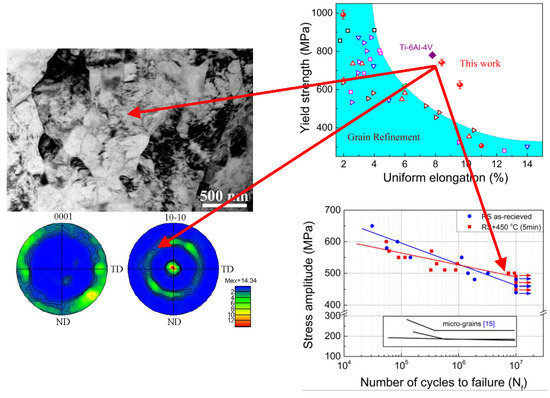

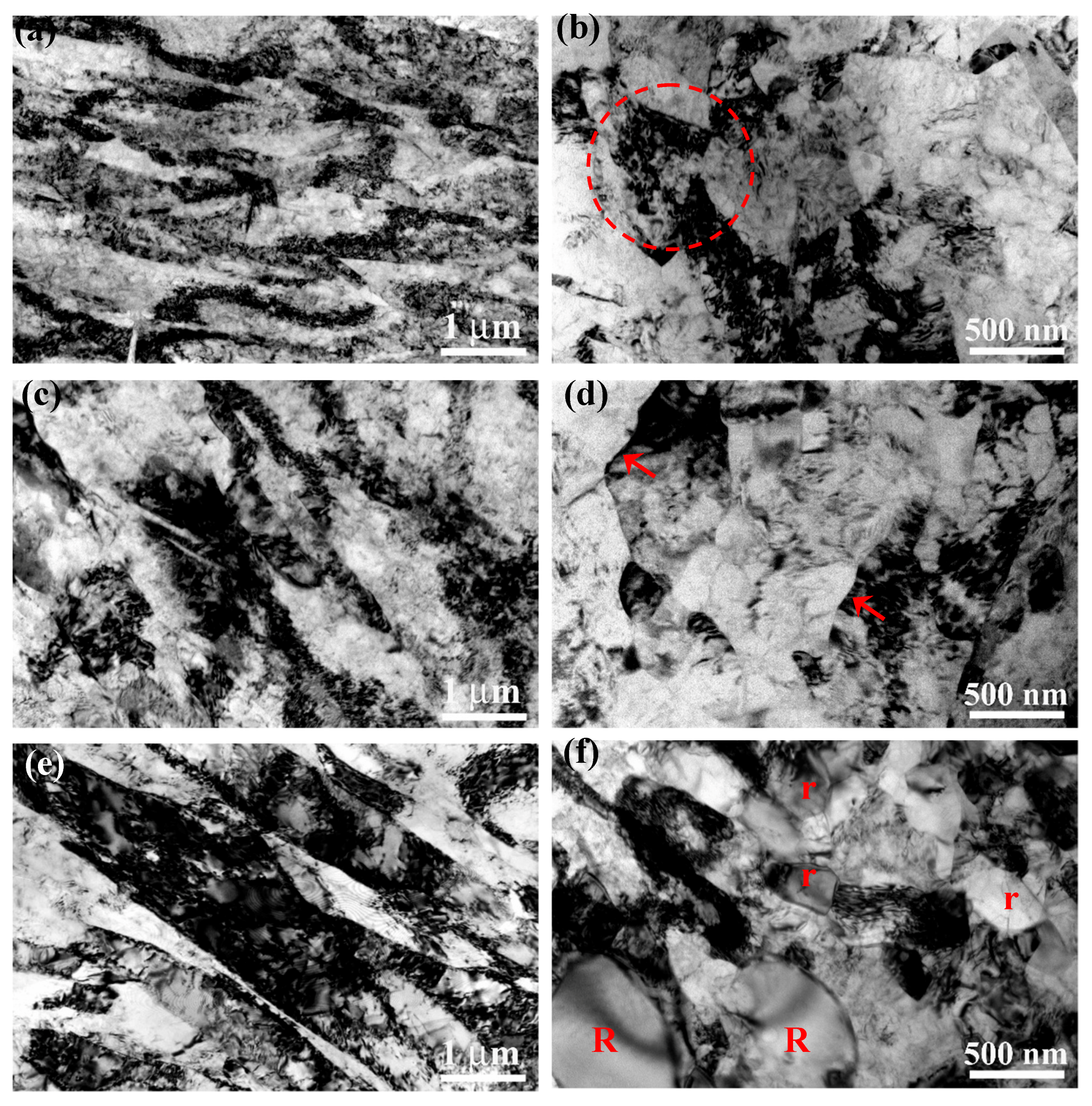

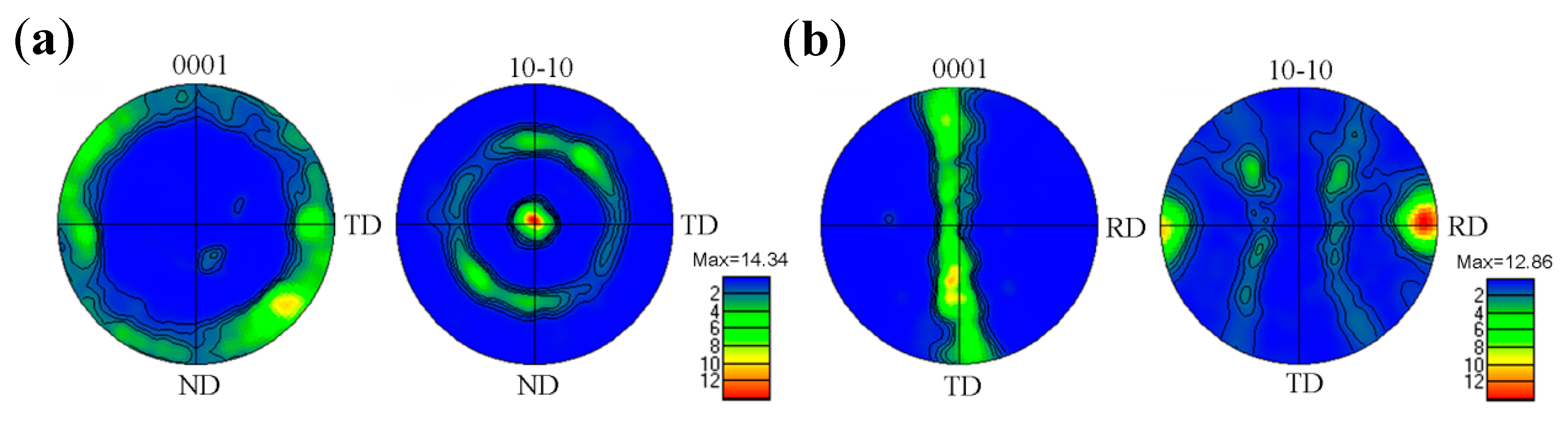

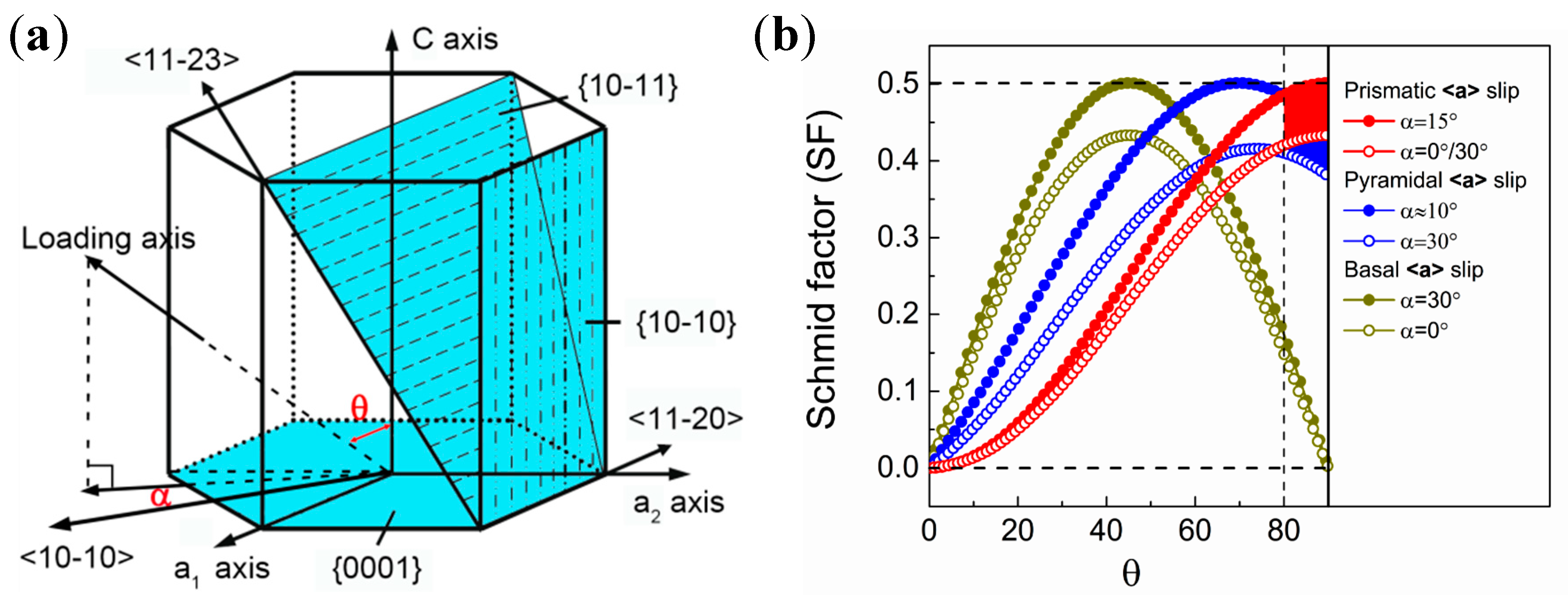

3.3. Microstructures with Preferential Crystallographic Texture

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ehtemam-Haghighi, S.; Cao, G.; Zhang, L.C. Nanoindentation study of mechanical properties of Ti based alloys with Fe and Ta additions. J. Alloys Compd. 2017, 692, 892–897. [Google Scholar] [CrossRef]

- Haghighi, S.E.; Lu, H.B.; Jian, G.Y.; Cao, G.H.; Habibi, D.; Zhang, L.C. Effect of α″ martensite on the microstructure and mechanical properties of beta-type Ti–Fe–Ta alloys. Mater. Des. 2015, 76, 47–54. [Google Scholar] [CrossRef]

- Okulov, I.V.; Bönisch, M.; Okulov, A.V.; Volegov, A.S.; Attar, H.; Ehtemam-Haghighi, S.; Calin, M.; Wang, Z.; Hohenwarter, A.; Kaban, I.; et al. Phase formation, microstructure and deformation behavior of heavily alloyed TiNb- and TiV-based titanium alloys. Mater. Sci. Eng. A 2018, 733, 80–86. [Google Scholar] [CrossRef]

- Attar, H.; Ehtemam-Haghighi, S.; Kent, D.; Dargusch, M.S. Recent developments and opportunities in additive manufacturing of titanium-based matrix composites: A review. Int. J. Mach. Tools Manuf. 2018, 133, 85–102. [Google Scholar] [CrossRef]

- Ehtemam-Haghighi, S.; Prashanth, K.G.; Attar, H.; Chaubey, A.K.; Cao, G.H.; Zhang, L.C. Evaluation of mechanical and wear properties of Ti-xNb-7Fe alloys designed for biomedical applications. Mater. Des. 2016, 111, 592–599. [Google Scholar] [CrossRef]

- Okulov, I.V.; Wendrock, H.; Volegov, A.S.; Attar, H.; Kühn, U.; Skrotzki, W.; Eckert, J. High strength beta titanium alloys: New design approach. Mater. Sci. Eng. A 2015, 628, 297–302. [Google Scholar] [CrossRef]

- Elias, C.N.; Meyers, M.A.; Valiev, R.Z.; Monteiro, S.N. Ultrafine grained titanium for biomedical applications: An overview of performance. J. Mater. Res. Technol. 2013, 2, 340–350. [Google Scholar] [CrossRef]

- Rack, H.J.; Qazi, J.I. Titanium alloys for biomedical applications. Mater. Sci. Eng. C 2006, 26, 1269–1277. [Google Scholar] [CrossRef]

- Mora-Sanchez, H.; Sabirov, I.; Monclus, M.A.; Matykina, E.; Molina-Aldareguia, J.M. Ultra-fine grained pure Titanium for biomedical applications. Mater. Technol. 2016, 31, 756–771. [Google Scholar] [CrossRef]

- Stolyarov, V.V.; Zhu, Y.T.; Alexandrov, I.V.; Lowe, T.C.; Valiev, R.Z. Influence of ECAP routes on the microstructure and properties of pure Ti. Mater. Sci. Eng. A 2001, 299, 59–67. [Google Scholar] [CrossRef]

- Huang, Z.; Cao, Y.; Nie, J.; Zhou, H.; Li, Y. Microstructures and mechanical properties of commercially pure Ti processed by rotationally accelerated shot peening. Materials 2018, 11, 366. [Google Scholar] [CrossRef] [PubMed]

- Sergueeva, A.V.; Stolyarov, V.V.; Valiev, R.Z.; Mukherjee, A.K. Advanced mechanical properties of pure titanium with ultrafine grained structure. Scr. Mater. 2001, 45, 747–752. [Google Scholar] [CrossRef]

- Stolyarov, V.V.; Zhu, Y.T.; Lowe, T.C.; Islamgaliev, R.K.; Valiev, R.Z. A two step SPD processing of ultrafine-grained titanium. Nanostruct. Mater. 1999, 11, 947–954. [Google Scholar] [CrossRef]

- Pachla, W.; Kulczyk, M.; Sus-Ryszkowska, M.; Mazur, A.; Kurzydlowski, K.J. Nanocrystalline titanium produced by hydrostatic extrusion. J. Mater. Process. Technol. 2008, 205, 173–182. [Google Scholar] [CrossRef]

- Ma, X.; Huang, C.; Moering, J.; Ruppert, M.; Höppel, H.W.; Göken, M.; Narayan, J.; Zhu, Y. Mechanical properties of copper/bronze laminates: Role of interfaces. Acta Mater. 2016, 116, 43–52. [Google Scholar] [CrossRef]

- Huang, C.X.; Wang, Y.F.; Ma, X.L.; Yin, S.; Höppel, H.W.; Göken, M.; Wu, X.L.; Gao, H.J.; Zhu, Y.T. Interface affected zone for optimal strength and ductility in heterogeneous laminate. Mater. Today 2018, 21, 713–719. [Google Scholar] [CrossRef]

- Stolyarov, V.V.; Zhu, Y.T.; Alexandrov, I.V.; Lowe, T.C.; Valiev, R.Z. Grain refinement and properties of pure Ti processed by warm ECAP and cold rolling. Mater. Sci. Eng. A 2003, 343, 43–50. [Google Scholar] [CrossRef]

- Stolyarov, V.V.; Zhu, Y.T.; Lowe, T.C.; Valiev, R.Z. Microstructure and properties of pure Ti processed by ECAP and cold extrusion. Mater. Sci. Eng. A 2001, 303, 82–89. [Google Scholar] [CrossRef]

- Yang, D.K.; Hodgson, P.D.; Wen, C.E. Simultaneously enhanced strength and ductility of titanium via multimodal grain structure. Scr. Mater. 2010, 63, 941–944. [Google Scholar] [CrossRef]

- Wu, X.; Yang, M.; Yuan, F.; Wu, G.; Wei, Y.; Huang, X.; Zhu, Y. Heterogeneous lamella structure unites ultrafine-grain strength with coarse-grain ductility. Proc. Natl. Acad. Sci. USA 2015, 112, 14501–14505. [Google Scholar] [CrossRef] [PubMed]

- Attar, H.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Manufacture by selective laser melting and mechanical behavior of commercially pure titanium. Mater. Sci. Eng. A 2014, 593, 170–177. [Google Scholar] [CrossRef]

- Vinogradov, A.Y.; Stolyarov, V.V.; Hashimoto, S.; Valiev, R.Z. Cyclic behavior of ultrafine-grain titanium produced by severe plastic deformation. Mater. Sci. Eng. A 2001, 318, 163–173. [Google Scholar] [CrossRef]

- Zhernakov, V.S.; Latysh, V.V.; Stolyarov, V.V.; Zharikov, A.I.; Valiev, R.Z. The developing of nanostructured SPD Ti for structural use. Scr. Mater. 2001, 44, 1771–1774. [Google Scholar] [CrossRef]

- Kim, W.J.; Hyun, C.Y.; Kim, H.K. Fatigue strength of ultrafine-grained pure Ti after severe plastic deformation. Scr. Mater. 2006, 54, 1745–1750. [Google Scholar] [CrossRef]

- Kitahara, H.; Matsushita, S.; Tsushida, M.; Ando, S.; Tsuji, N. Fatigue properties of ARB-processed Ti sheets with crystallographic texture. Int. J. Fatigue 2016, 92, 18–24. [Google Scholar] [CrossRef]

- Kitahara, H.; Uchikado, K.; Jun-Ichi, M.; Iida, N.; Tsushida, M.; Tsuji, N.; Ando, S.; Tonda, H. Fatigue crack propagation behavior in commercial purity Ti severely deformed by accumulative roll bonding process. Mater. Trans. 2008, 49, 64–68. [Google Scholar] [CrossRef]

- Kitahara, H.; Matsushita, S.; Tsushida, M. Effect of ARB Processing on Fatigue Crack Closure in Commercially Pure Titanium. Mater. Trans. 2013, 54, 528–531. [Google Scholar] [CrossRef] [Green Version]

- Pachla, W.; Kulczyk, M.; Przybysz, S.; Skiba, J.; Wojciechowski, K.; Przybysz, M.; Topolski, K.; Sobolewski, A.; Charkiewicz, M. Effect of severe plastic deformation realized by hydrostatic extrusion and rotary swaging on the properties of CP Ti grade 2. J. Mater. Process. Technol. 2015, 221, 255–268. [Google Scholar] [CrossRef]

- Stolyarov, V.V.; Zeipper, L.; Mingler, B.; Zehetbauer, M. Influence of post-deformation on CP-Ti processed by equal channel angular pressing. Mater. Sci. Eng. A 2008, 476, 98–105. [Google Scholar] [CrossRef]

- Mendes, A.; Kliauga, A.M.; Ferrante, M.; Sordi, V.L. How severe plastic deformation at cryogenic temperature affects strength, fatigue, and impact behaviour of grade 2 titanium. IOP Conf. Ser. Mater. Sci. Eng. 2014, 63, 012161. [Google Scholar] [CrossRef] [Green Version]

- Kim, W.J.; Yoo, S.J.; Lee, J.B. Microstructure and mechanical properties of pure Ti processed by high-ratio differential speed rolling at room temperature. Scr. Mater. 2010, 62, 451–454. [Google Scholar] [CrossRef]

- Purcek, G.; Yapici, G.G.; Karaman, I.; Maier, H.J. Effect of commercial purity levels on the mechanical properties of ultrafine-grained titanium. Mater. Sci. Eng. A 2011, 528, 2303–2308. [Google Scholar] [CrossRef]

- Zherebtsov, S.V.; Dyakonov, G.S.; Salem, A.A.; Sokolenko, V.I.; Salishchev, G.A.; Semiatin, S.L. Formation of nanostructures in commercial-purity titanium via cryorolling. Acta Mater. 2013, 61, 1167–1178. [Google Scholar] [CrossRef]

- Milner, J.L.; Abu-Farha, F.; Bunget, C.; Kurfess, T.; Hammond, V.H. Grain refinement and mechanical properties of CP-Ti processed by warm accumulative roll bonding. Mater. Sci. Eng. A 2013, 561, 109–117. [Google Scholar] [CrossRef]

- Li, Z.; Fu, L.; Fu, B.; Shan, A. Effects of annealing on microstructure and mechanical properties of nano-grained titanium produced by combination of asymmetric and symmetric rolling. Mater. Sci. Eng. A 2012, 558, 309–318. [Google Scholar] [CrossRef]

- Mughrabi, H.; Höppel, H.W.; Kautz, M. Fatigue and microstructure of ultrafine-grained metals produced by severe plastic deformation. Scr. Mater. 2004, 51, 807–812. [Google Scholar] [CrossRef]

- Hanlon, T.; Kwon, Y.N.; Suresh, S. Grain size effects on the fatigue response of nanocrystalline metals. Scr. Mater. 2003, 49, 675–680. [Google Scholar] [CrossRef]

- Huang, H.W.; Wang, Z.B.; Lu, J.; Lu, K. Fatigue behaviors of AISI 316L stainless steel with a gradient nanostructured surface layer. Acta Mater. 2015, 87, 150–160. [Google Scholar] [CrossRef]

- Medvedev, A.E.; Ng, H.P.; Lapovok, R.; Estrin, Y.; Lowe, T.C.; Anumalasetty, V.N. Effect of bulk microstructure of commercially pure titanium on surface characteristics and fatigue properties after surface modification by sand blasting and acid-etching. J. Mech. Behav. Biomed. Mater. 2016, 57, 55–68. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.X.; Hu, W.P.; Wang, Q.Y.; Wang, C.; Yang, G.; Zhu, Y.T. An ideal ultrafine-grained structure for high strength and high ductility. Mater. Res. Lett. 2015, 3, 88–94. [Google Scholar] [CrossRef]

- Sabirov, I.; Perez-Prado, M.T.; Molina-Aldareguia, J.M.; Semenova, I.P.; Salimgareeva, G.K.; Valiev, R.Z. Anisotropy of mechanical properties in high-strength ultra-fine-grained pure Ti processed via a complex severe plastic deformation route. Scr. Mater. 2011, 64, 69–72. [Google Scholar] [CrossRef]

- Wagner, F.; Ouarem, A.; Richeton, T.; Toth, L.S. Improving Mechanical Properties of cp Titanium by Heat Treatment Optimization. Adv. Eng. Mater. 2018, 20, 1700237. [Google Scholar] [CrossRef]

- Vinogradov, A.; Serebryany, V.N.; Dobatkin, S.V. Tailoring Microstructure and Properties of Fine Grained Magnesium Alloys by Severe Plastic Deformation. Adv. Eng. Mater. 2018, 20, 1700785. [Google Scholar] [CrossRef]

- Richeton, T.; Wagner, F.; Chen, C.; Tóth, L. Combined effects of texture and grain size distribution on the tensile behavior of α-titanium. Materials 2018, 11, 1088. [Google Scholar] [CrossRef] [PubMed]

- Song, B.; Wang, C.; Guo, N.; Pan, H.; Xin, R. Improving tensile and compressive properties of an extruded AZ91 rod by the combined use of torsion deformation and aging treatment. Materials 2018, 10, 280. [Google Scholar] [CrossRef] [PubMed]

- Gong, J.; Wilkinson, A.J. Anisotropy in the plastic flow properties of single-crystal α titanium determined from micro-cantilever beams. Acta Mater. 2009, 57, 5693–5705. [Google Scholar] [CrossRef]

- Won, J.W.; Park, K.T.; Hong, S.G.; Lee, C.S. Anisotropic yielding behavior of rolling textured high purity titanium. Mater. Sci. Eng. A 2015, 637, 215–221. [Google Scholar] [CrossRef]

| Materials | Samples | Yield Strength (MPa) | UTS (MPa) | Uniform Elongation (%) | Total Elongation (%) |

|---|---|---|---|---|---|

| CP-Ti (grade 2) | CG | 318 | 440 | 11.5 | 28 |

| RS | 998 | 1040 | 1.6 | 6 | |

| RSA450 | 740 | 870 | 8.5 | 17 | |

| RSA500 | 620 | 710 | 9.5 | 19 | |

| Ti-6Al-4V [a] | ASTM F 67 | 795 | 860 | 10 |

| Materials | Samples | YS (MPa) | UTS (MPa) | σf (MPa) | σf/σUTS | σ′f | b | Reference |

|---|---|---|---|---|---|---|---|---|

| CP-Ti (Grade 2) | RS | 989 | 1040 | 460 | 0.44 | 920 | −0.053 | |

| RSA450 | 740 | 870 | 490 | 0.56 | 831 | −0.034 | ||

| CG | 248 | 418 | 210 | 0.50 | 311 | −0.023 | [24] | |

| ECAP | 635 | 669 | 350 | 0.52 | 654 | −0.041 | [24] | |

| 970 | 1050 | 420 | 0.40 | [22] | ||||

| 800 | 816 | 403 | 0.49 | [22] | ||||

| ARB | 870 | 895 | 425 | 0.47 | [24] | |||

| 810 | 850 | 400 | 0.47 | [24] | ||||

| Ti-6Al-4V | CG | 875 | 965 | 515 | 0.53 | [22] |

| Loading Direction | Θ | Prismatic <a> Slip {10-10} <11-20> | Basal <a> Slip {0001} <11-20> | Pyramidal <a> Slip {10-11} <11-20> |

|---|---|---|---|---|

| //RD | 80° | 0.42–0.49 | 0.15–0.17 | 0.41–0.49 |

| 90° | 0.43–0.5 | 0 | 0.38–0.44 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.; Wang, Y.; Huang, A.; Gao, L.; Li, Y.; Huang, C. Promising Tensile and Fatigue Properties of Commercially Pure Titanium Processed by Rotary Swaging and Annealing Treatment. Materials 2018, 11, 2261. https://doi.org/10.3390/ma11112261

Wang M, Wang Y, Huang A, Gao L, Li Y, Huang C. Promising Tensile and Fatigue Properties of Commercially Pure Titanium Processed by Rotary Swaging and Annealing Treatment. Materials. 2018; 11(11):2261. https://doi.org/10.3390/ma11112261

Chicago/Turabian StyleWang, Mingsai, Yanfei Wang, Aihui Huang, Lei Gao, Yusheng Li, and Chongxiang Huang. 2018. "Promising Tensile and Fatigue Properties of Commercially Pure Titanium Processed by Rotary Swaging and Annealing Treatment" Materials 11, no. 11: 2261. https://doi.org/10.3390/ma11112261

APA StyleWang, M., Wang, Y., Huang, A., Gao, L., Li, Y., & Huang, C. (2018). Promising Tensile and Fatigue Properties of Commercially Pure Titanium Processed by Rotary Swaging and Annealing Treatment. Materials, 11(11), 2261. https://doi.org/10.3390/ma11112261