Experimental Study on Mechanical and Sensing Properties of Smart Composite Prestressed Tendon

Abstract

:1. Introduction

2. Smart Composite Prestressed Tendon Solution

2.1. Carbon Fiber-Based Smart Bar

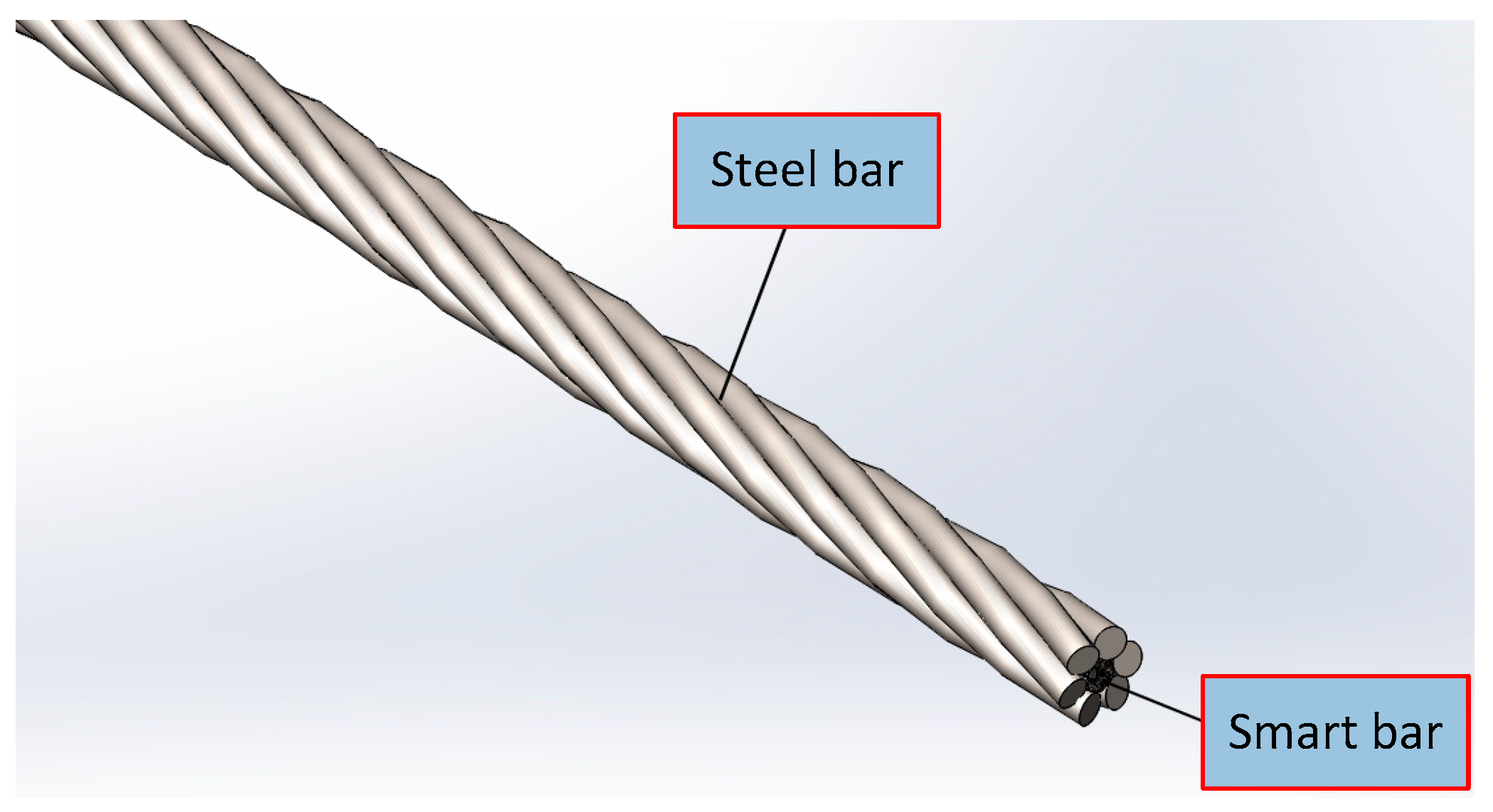

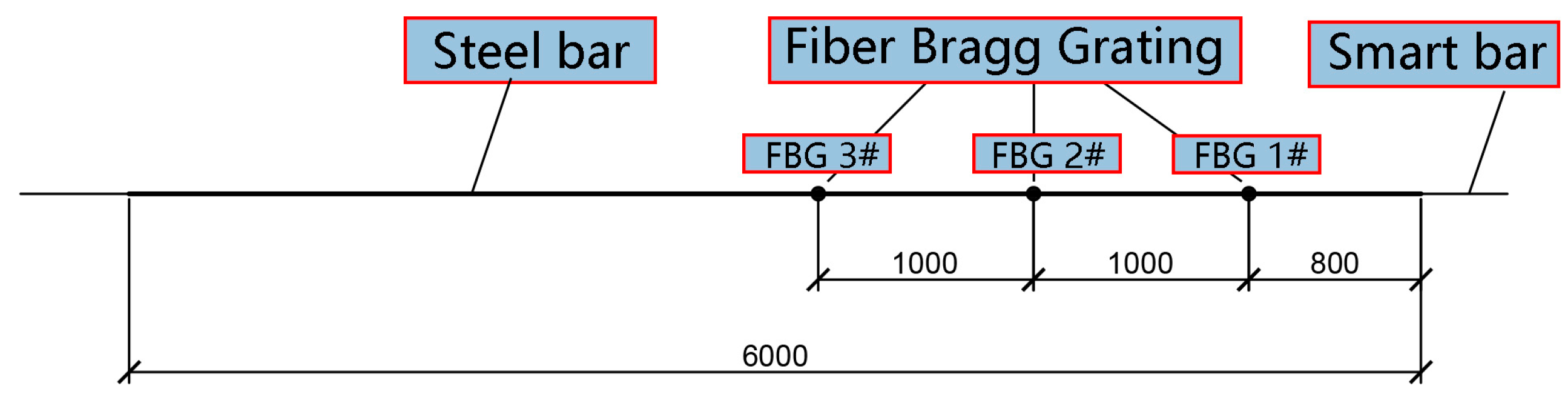

2.2. Smart Composite Prestressed Tendon

3. Experiment Design

4. Test Results and Analysis

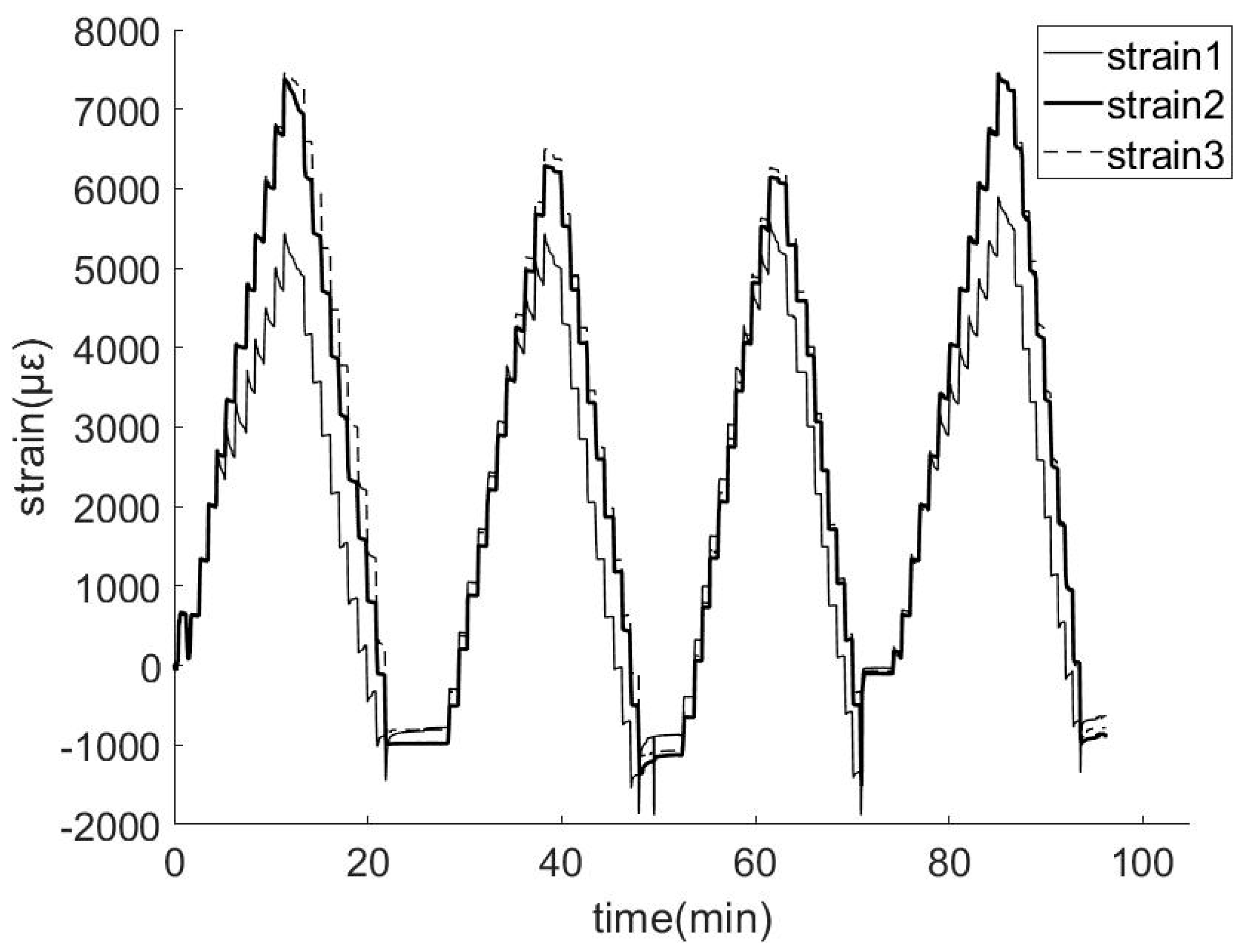

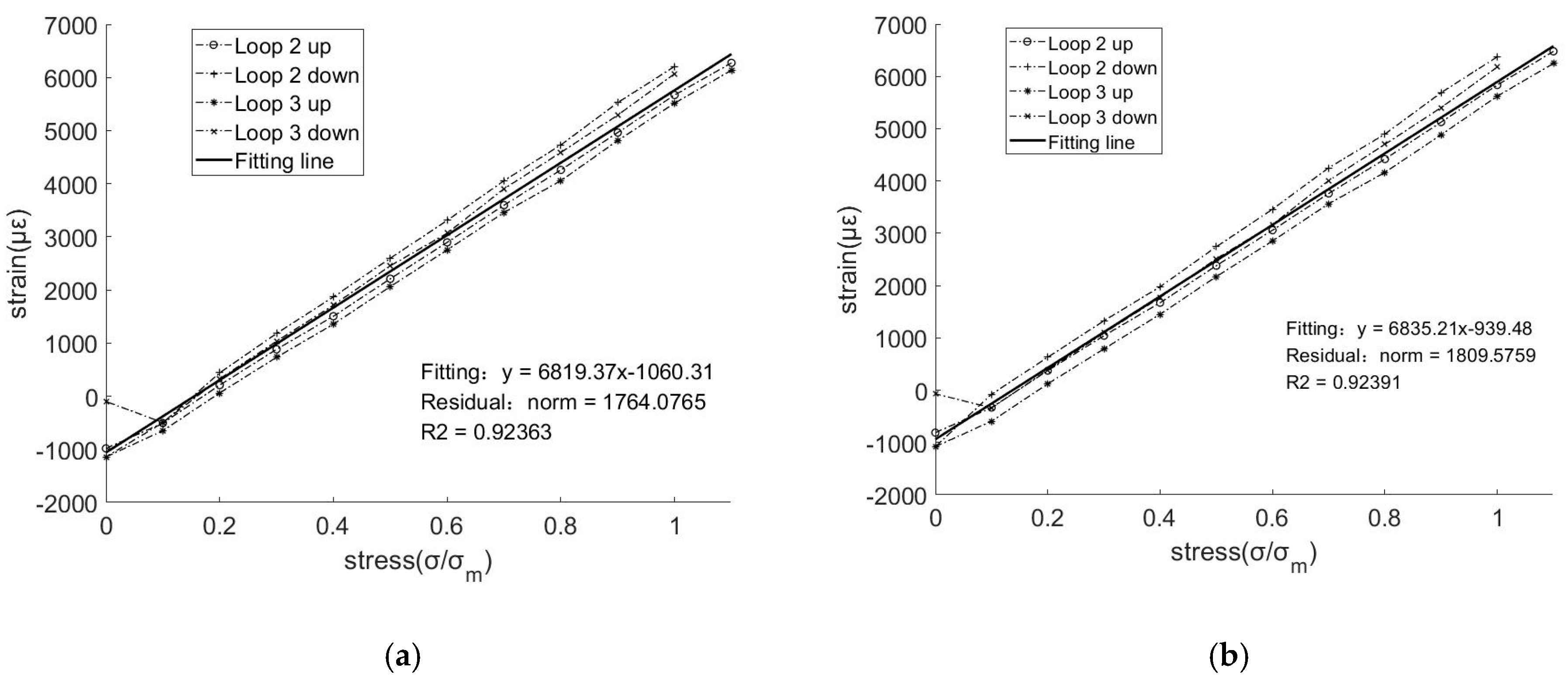

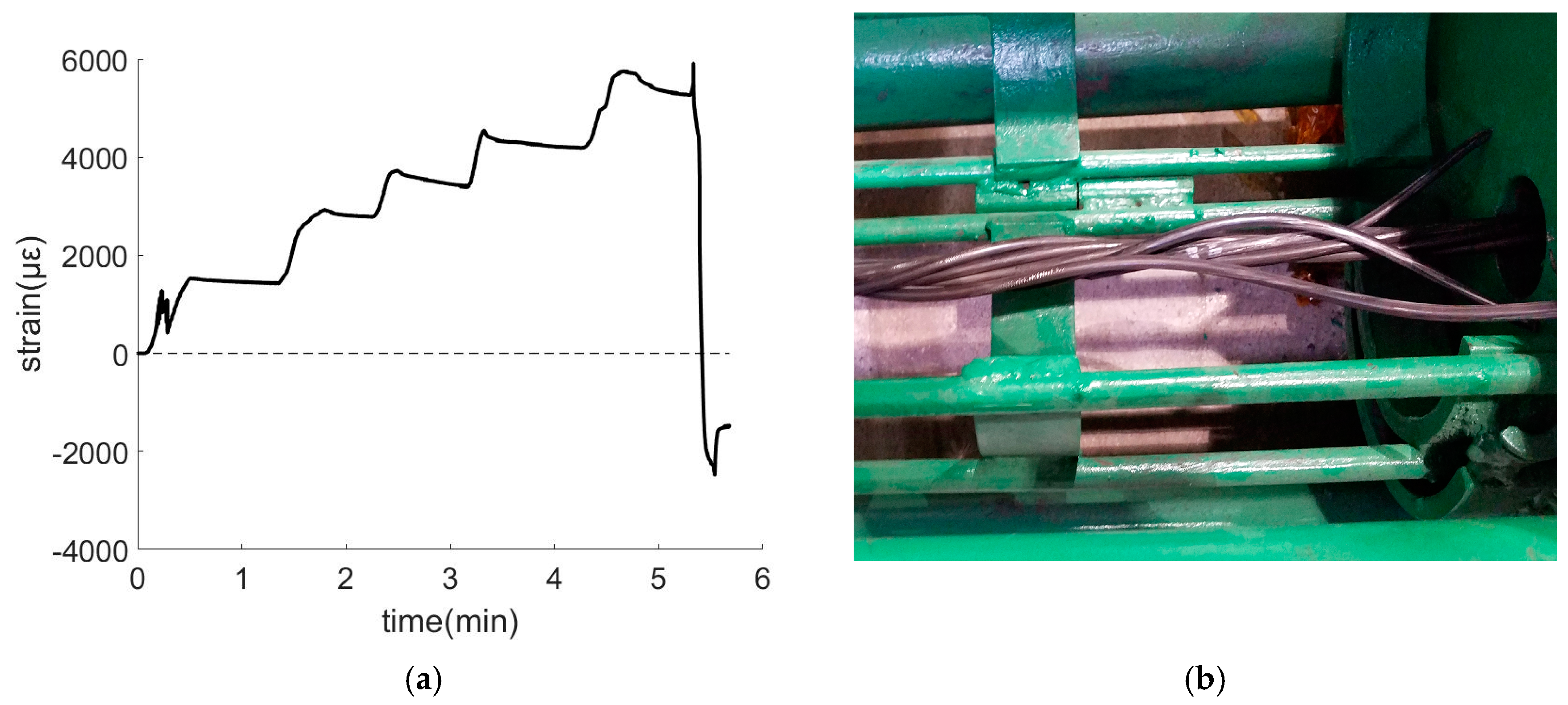

4.1. Tensile Test

4.2. Holding Force Test

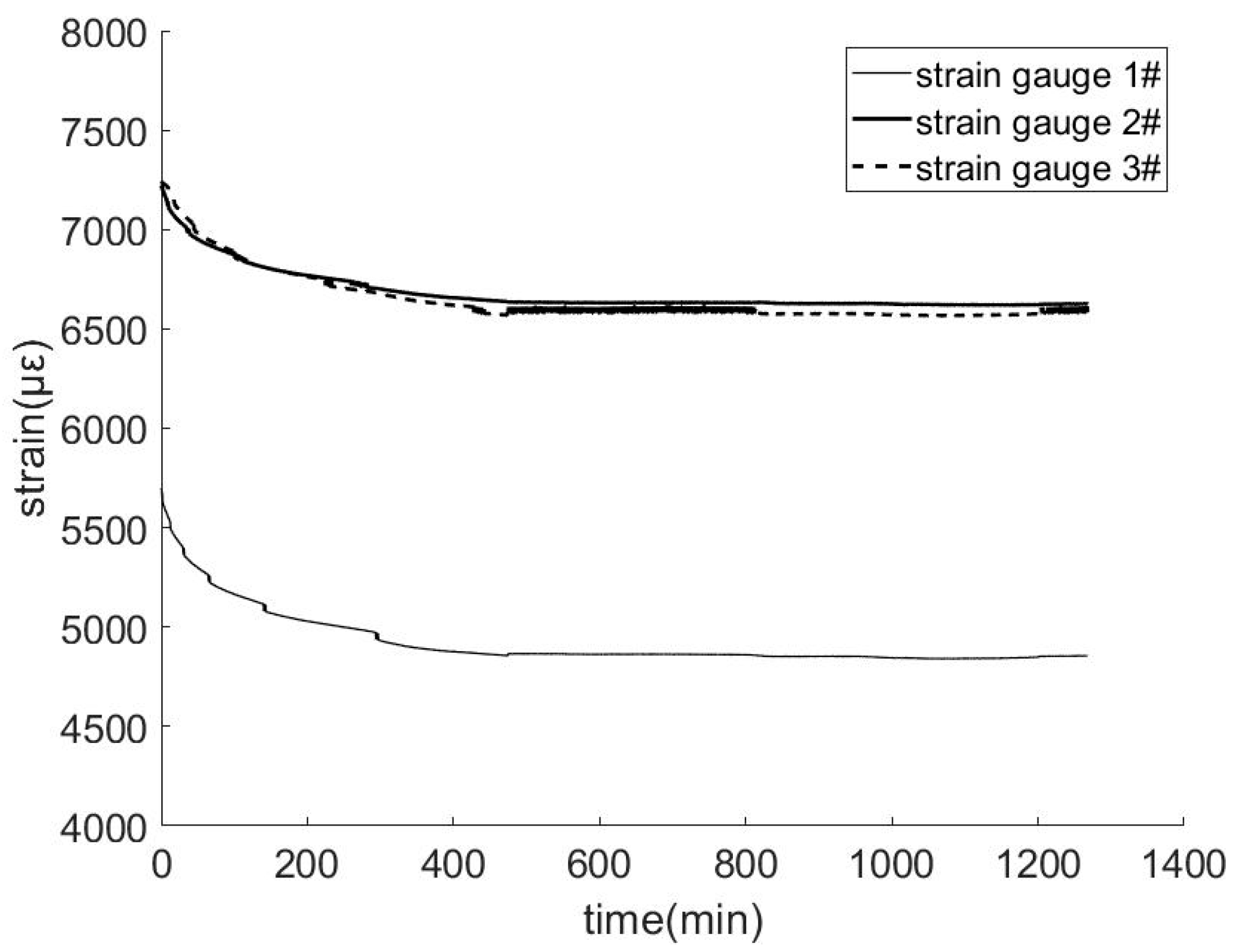

4.3. Fracture Test

5. Conclusions

- The smart composite cable withstood an operating load with high strain. It worked stably under the tensioning process and relative long-term loading conditions of the construction stage. The cable was used as a prestressed tendon for prestressed concrete components, and it exhibited reliable work performance.

- By embedding an FBG strain gauge on the inner carbon fiber-based bar of the smart cable, the self-sensing function of the stress state of the complete composite cable was effectively realized. The composite cable exhibited good linearity and repeatability, and it can be used to high pre-stress levels during normal operation. Additionally, it exhibited high long-term stability and displayed reliable sensing performance after failure.

- The tension transmission of the composite cable requires a specific distance. Thus, consistent strain data was obtained when the FBG strain gauges were arranged in the area of deformation conformability beyond a certain distance from the end, and the measurement accuracy and reliability of the sensor simultaneously improved by arranging multiple FBG strain gages.

- While using smart composite prestressed tendon as reinforcements, the slip phenomenon can occur during the first tensioning due to the non-uniform longitudinal connection between the inner carbon fiber based smart bar and outer steel wires. Recommendations include performing several pre-tensioning stages prior to construction, such that the slip occurs to the maximum possible extent in the pre-tensioning stage. Furthermore, the contact and engagement forces between the steel wires and smart bar during production should be increased to further improve the mechanical properties and sensing performance of prestressed smart composite cables.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Brownjohn, J.M.; De Stefano, A.; Xu, Y.L.; Wenzel, H.; Aktan, A.E. Vibration-based monitoring of civil infrastructure: challenges and successes. J. Civ. Struct. Health Monit. 2011, 1, 79–95. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.L.; Satpathi, D.; Koontz, S.; Jarosevic, A.; Chandoga, M. Monitoring of cable forces using magneto-elastic sensors. In Computational Mechanics in Structural Engineering; Elsevier: Amsterdam, The Netherlands, 1999; pp. 337–347. [Google Scholar]

- Yim, J.; Wang, M.L.; Shin, S.W.; Yun, C.B.; Jung, H.J.; Kim, J.T.; Eem, S.H. Field application of elasto-magnetic stress sensors for monitoring of cable tension force in cable-stayed bridges. Smart Struct. Syst. 2013, 12, 465–482. [Google Scholar] [CrossRef]

- Nair, A.; Cai, C.S. Acoustic emission monitoring of bridges: Review and case studies. Eng. Struct. 2010, 32, 1704–1714. [Google Scholar] [CrossRef]

- Hill, K.O.; Meltz, G. Fiber bragg grating technology fundamentals and overview. J. Lightwave Technol. 1997, 15, 1263–1276. [Google Scholar] [CrossRef]

- Alavie, A.T.; Maaskant, R.; Ohn, M.; Karr, S.; Huang, S. A structurally integrated Bragg grating laser sensing system for a carbon fiber prestressed concrete highway bridge. Smart Mater. Struct. 1995, 4, 20. [Google Scholar]

- Chan, P.K.; Jin, W.; Lau, A.K.T.; Zhou, L. Strain monitoring of composite-boned concrete specimen measurements by use of FMCW multiplexed fiber Bragg grating sensor array. In Proceedings of the International Conference on Sensors and Control Techniques (ICSC 2000), Wuhan, China, 19–21 June 2000; pp. 56–60. [Google Scholar]

- Zhang, X.F.; Zhu, Z.R.; Teng, J.; Xiao, Y.Q.; Zhu, Y.H.; Li, C.T. Smart Fiber Bragg Grating Cable and Its Application in Shenzhen Vanke Center. Earthq. Resistant Eng. Retrofit. 2011, 1, 23. [Google Scholar]

- Zhao, X.; Liu, L.; Ji, J.; Li, S.; Zhang, E.; Jin, A. Reliability Research on Smart Bridge Cable with Built-in Fiber Bragg Grating Sensors. Piezoelectr. Acoustoopt. 2013, 1, 011. [Google Scholar]

- Zhou, Z.; Ou, J.P.; Wang, B. Smart FRP-OFGB bars and their application in reinforced concrete beams. In Proceedings of the First International Conference on Structural Health Monitoring and Intelligent Structure, Tokyo, Japan, 13–15 November 2003; pp. 13–15. [Google Scholar]

- Zhou, Z.; Zhang, Z.; Deng, N.; Zhao, X.; Li, D.; Wang, C.; Ou, J. Applications of FRP-OFBG sensors on bridge cables. In Proceedings of the Smart Structures and Materials 2005: Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems, SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, San Diego, CA, USA, 17 May 2005; pp. 668–678. [Google Scholar]

- Li, D.; Zhou, Z.; Ou, J. Development and sensing properties study of FRP–FBG smart stay cable for bridge health monitoring applications. Measurement 2011, 44, 722–729. [Google Scholar] [CrossRef]

- Yang, J.; Yuan, L. Package and installation of embeddable fiber optic sensors. Opt. Laser Eng. 2009, 47, 1085–1090. [Google Scholar] [CrossRef]

- Hui, L.I.; Jinping, O.U. Structural health monitoring: From sensing technology stepping to health diagnosis. Procedia Eng. 2011, 14, 753–760. [Google Scholar] [CrossRef]

- Kim, S.T.; Park, Y.; Park, S.Y.; Cho, K.; Cho, J.R. A sensor-type PC strand with an embedded FBG sensor for monitoring prestress forces. Sensors 2015, 15, 1060–1070. [Google Scholar] [CrossRef] [PubMed]

- Cho, K.; Kim, S.T.; Cho, J.R.; Park, Y.H. Analytical model of nonlinear stress-strain relation for a strand made of two materials. Materials 2017, 10, 1003. [Google Scholar]

- Cho, K.; Kim, S.T.; Cho, J.R.; Park, Y.H. Estimation of Tendon Force Distribution in Prestressed Concrete Girders Using Smart Strand. Appl. Sci. 2017, 7, 1319. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dan, D.; Jia, P.; Li, G.; Niu, P. Experimental Study on Mechanical and Sensing Properties of Smart Composite Prestressed Tendon. Materials 2018, 11, 2087. https://doi.org/10.3390/ma11112087

Dan D, Jia P, Li G, Niu P. Experimental Study on Mechanical and Sensing Properties of Smart Composite Prestressed Tendon. Materials. 2018; 11(11):2087. https://doi.org/10.3390/ma11112087

Chicago/Turabian StyleDan, Danhui, Pengfei Jia, Guoqiang Li, and Po Niu. 2018. "Experimental Study on Mechanical and Sensing Properties of Smart Composite Prestressed Tendon" Materials 11, no. 11: 2087. https://doi.org/10.3390/ma11112087

APA StyleDan, D., Jia, P., Li, G., & Niu, P. (2018). Experimental Study on Mechanical and Sensing Properties of Smart Composite Prestressed Tendon. Materials, 11(11), 2087. https://doi.org/10.3390/ma11112087