On Multi-Objective Based Constitutive Modelling Methodology and Numerical Validation in Small-Hole Drilling of Al6063/SiCp Composites

Abstract

:1. Introduction

- ⇀

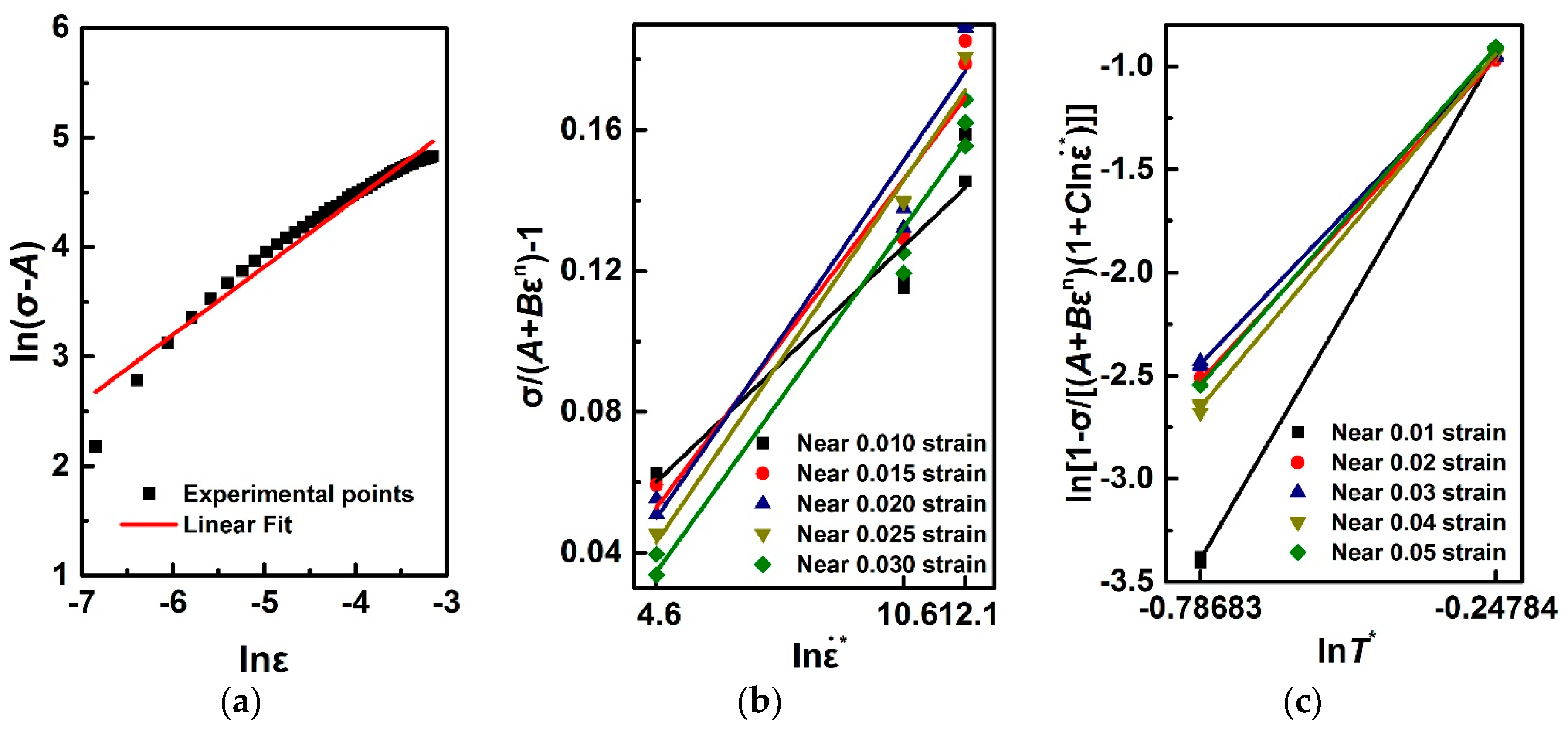

- Identify and fix the initial yield stress from the quasi-static test at the reference strain rate and room temperature ;

- ⇀

- Fit the quasi-static flow stress-strain curve to determine the coefficients and based on linear regression in Equation (3) transformed logarithmically through the elasto-plastic term in Equation (1):

- ⇀

- Identify the strain rate hardening coefficient by fitting linearly the data of against under the same strain at room/reference temperature for SHPB data from:

- ⇀

- Obtain a set of values under the different strains according to the aforementioned strategy for solving , and average it to find a final evaluation of ;

- ⇀

- Identify a slope value for through the linear regression of against under the same strain or rate of strain;

- ⇀

- Average a set of values calculated under different strains or rates of strain, and find an estimation of .

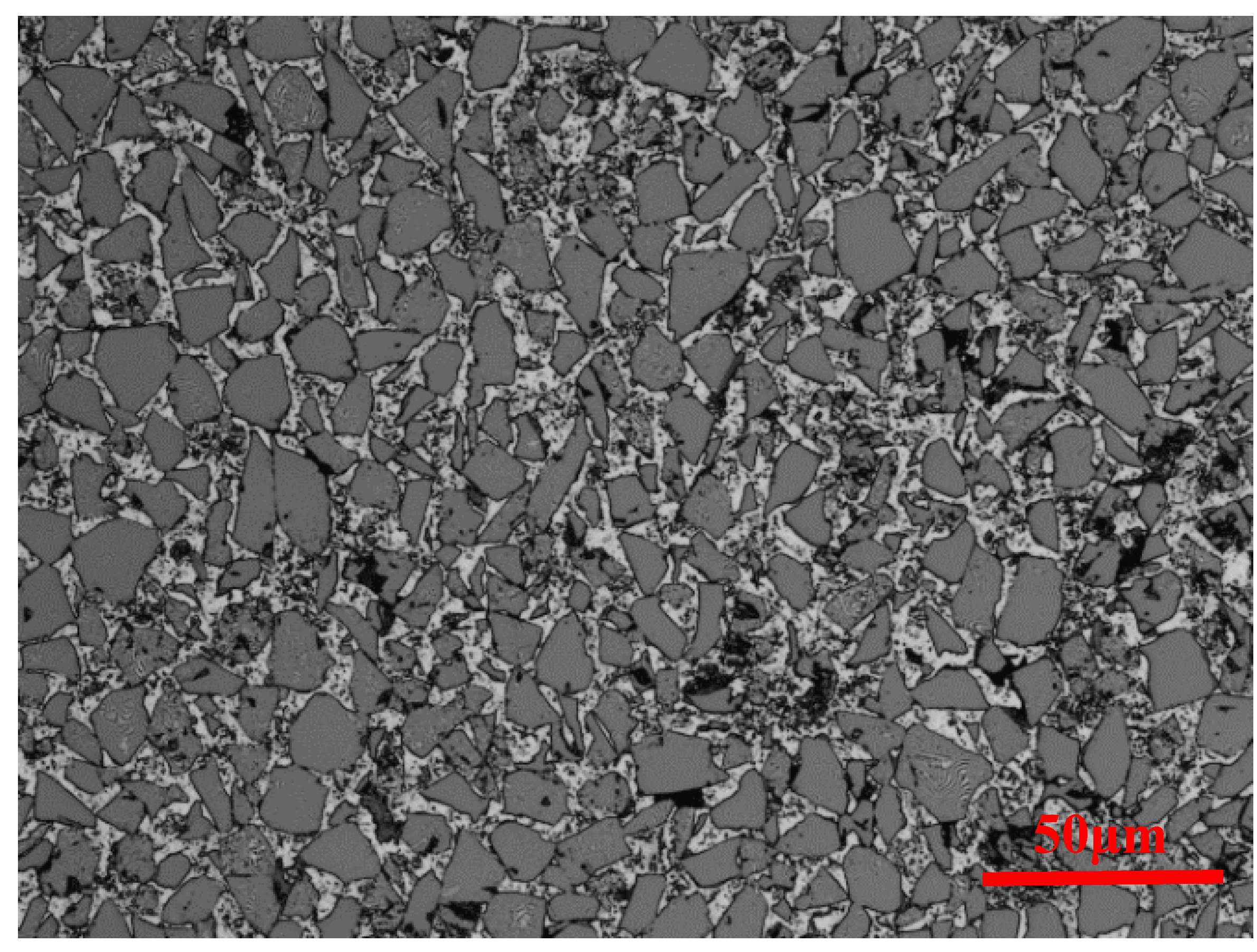

2. Experimental Materials, Test Procedure and Results

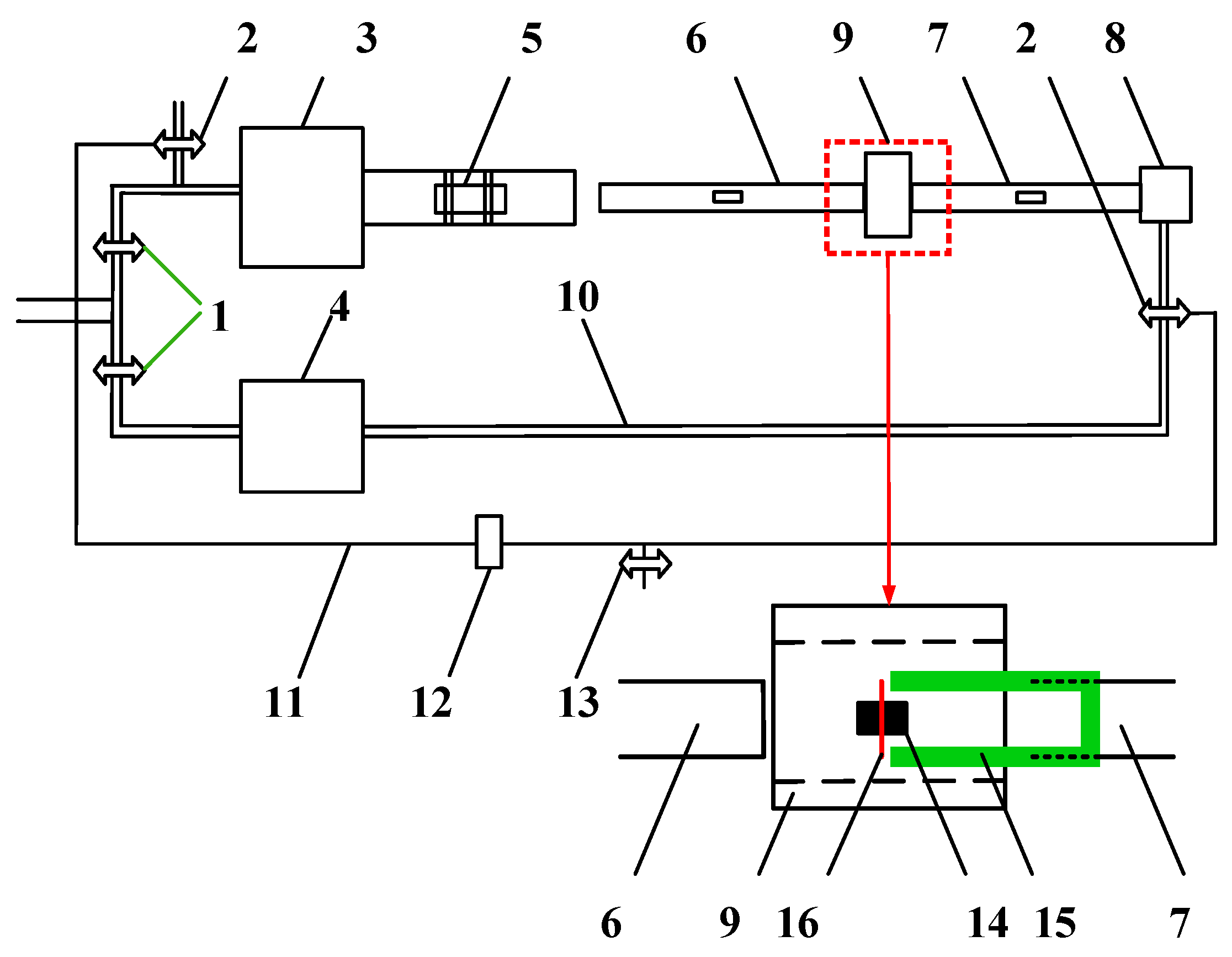

2.1. Test Procedure

2.2. Test Results

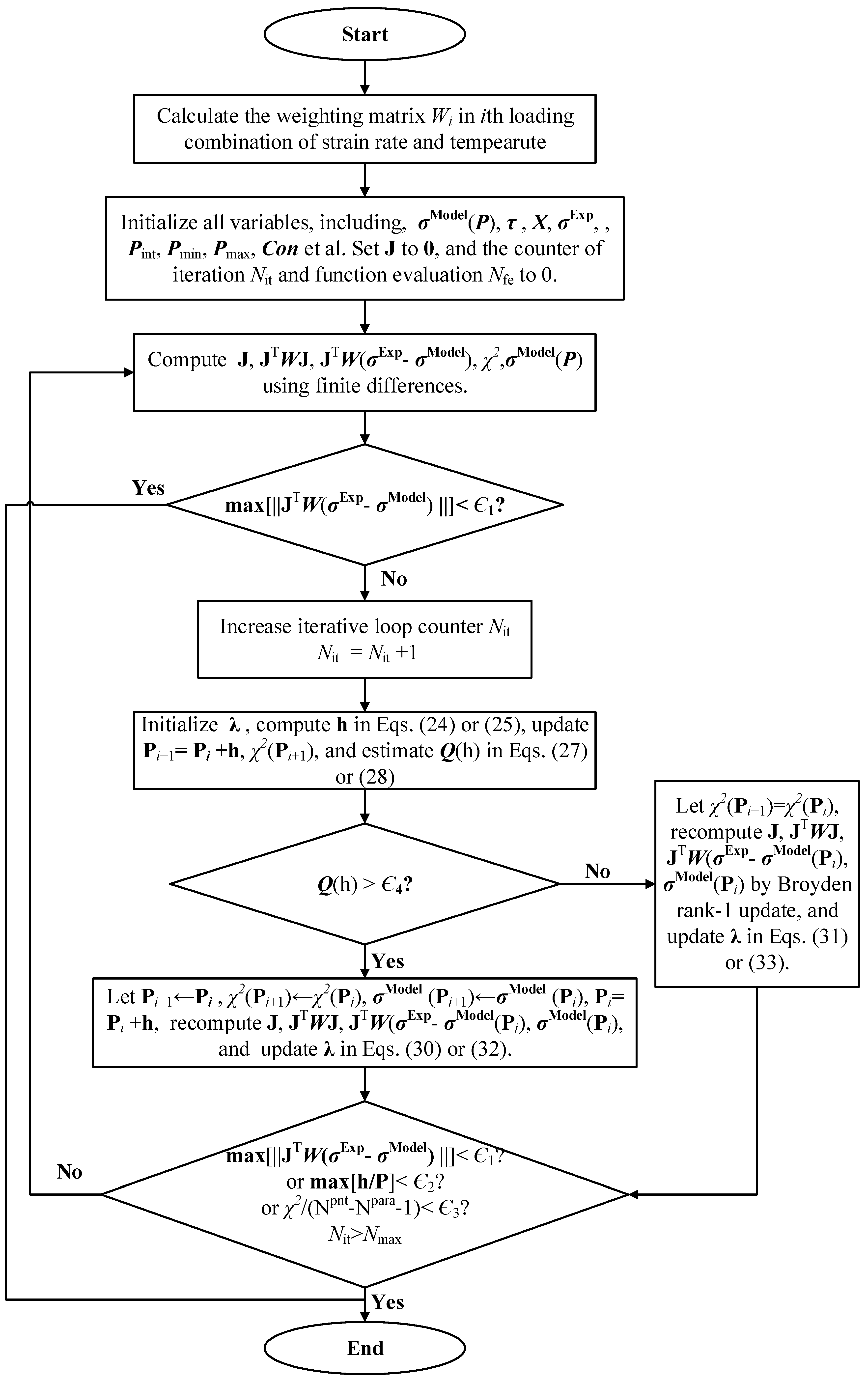

3. Parametric Identification

3.1. Multi-Objective Strategy Considering Weighted Measurement Errors

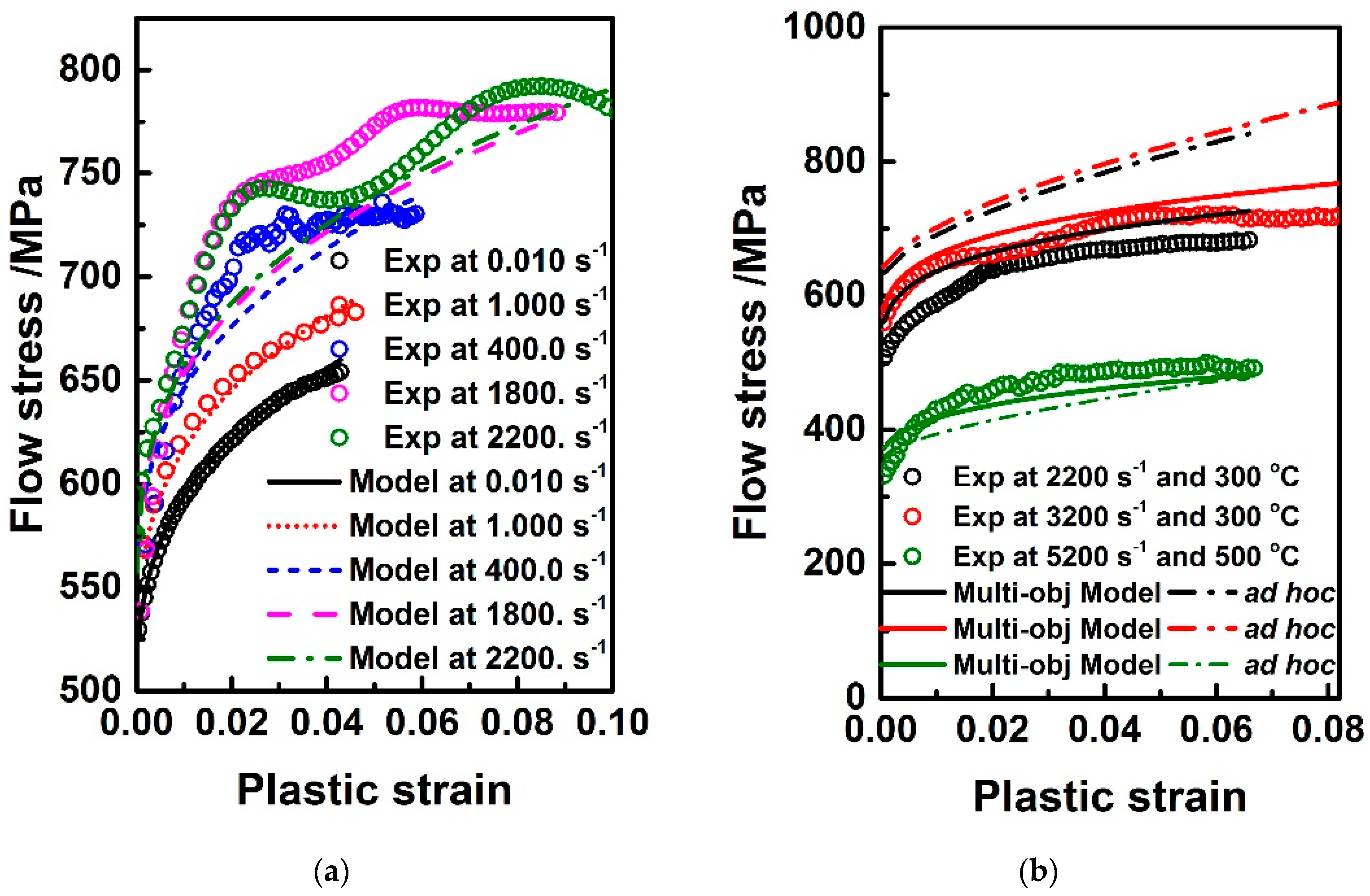

3.2. Identification Results and Discussion

4. Materials and Methods

4.1. Materials

4.2. Methods

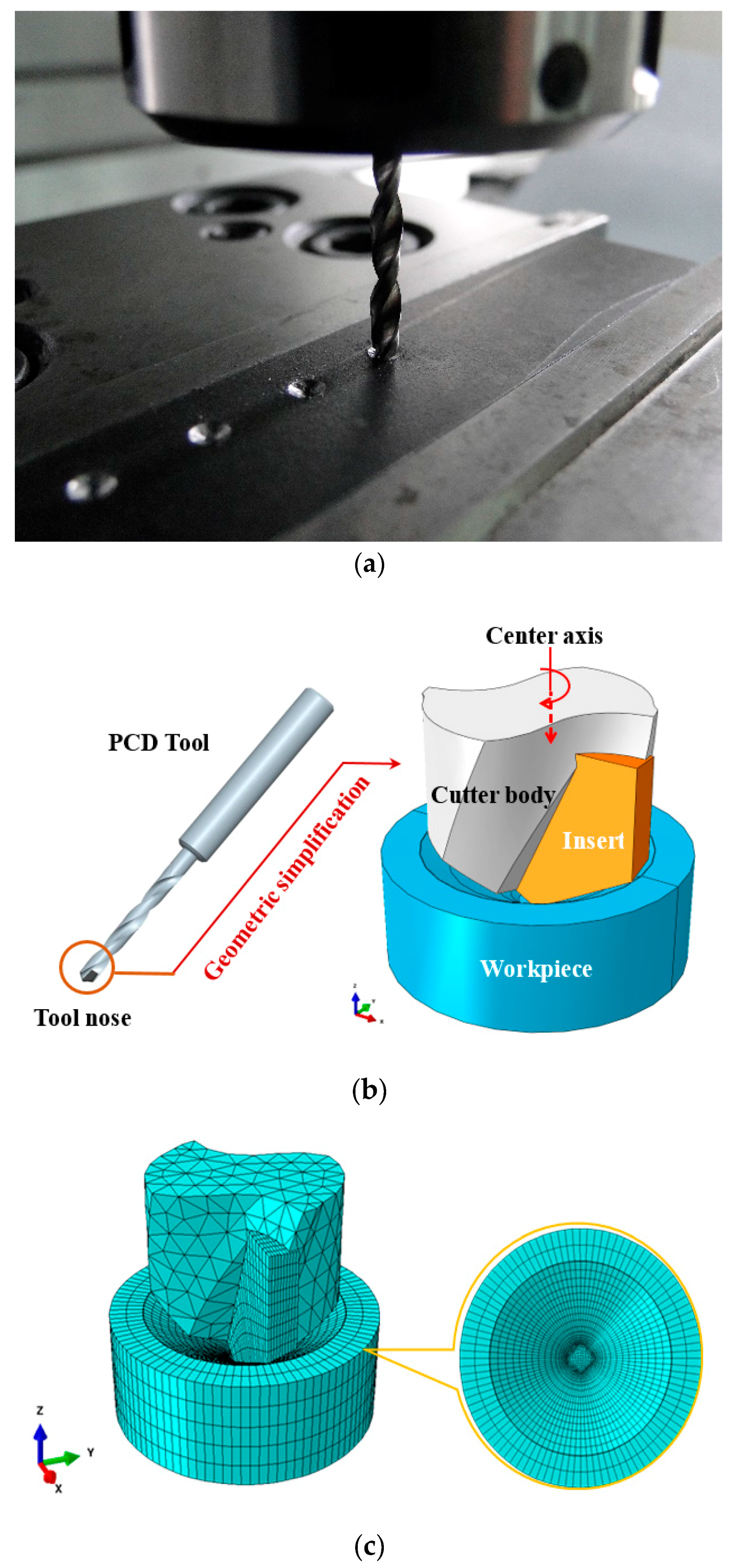

4.2.1. Finite Element Modelling of Drilling

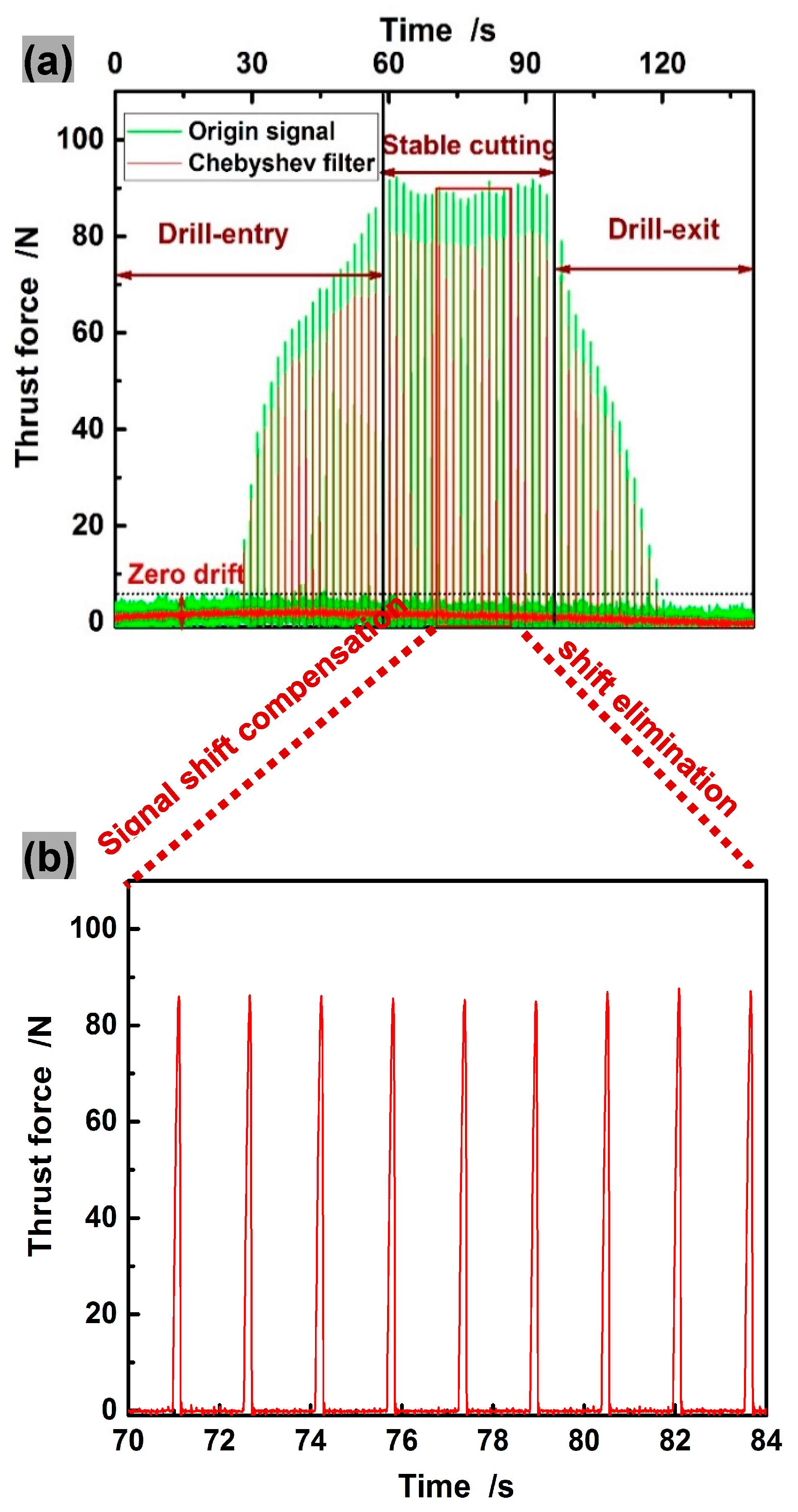

4.2.2. Experimental Set-Up and Signal Processing

4.3. Results and Discussion

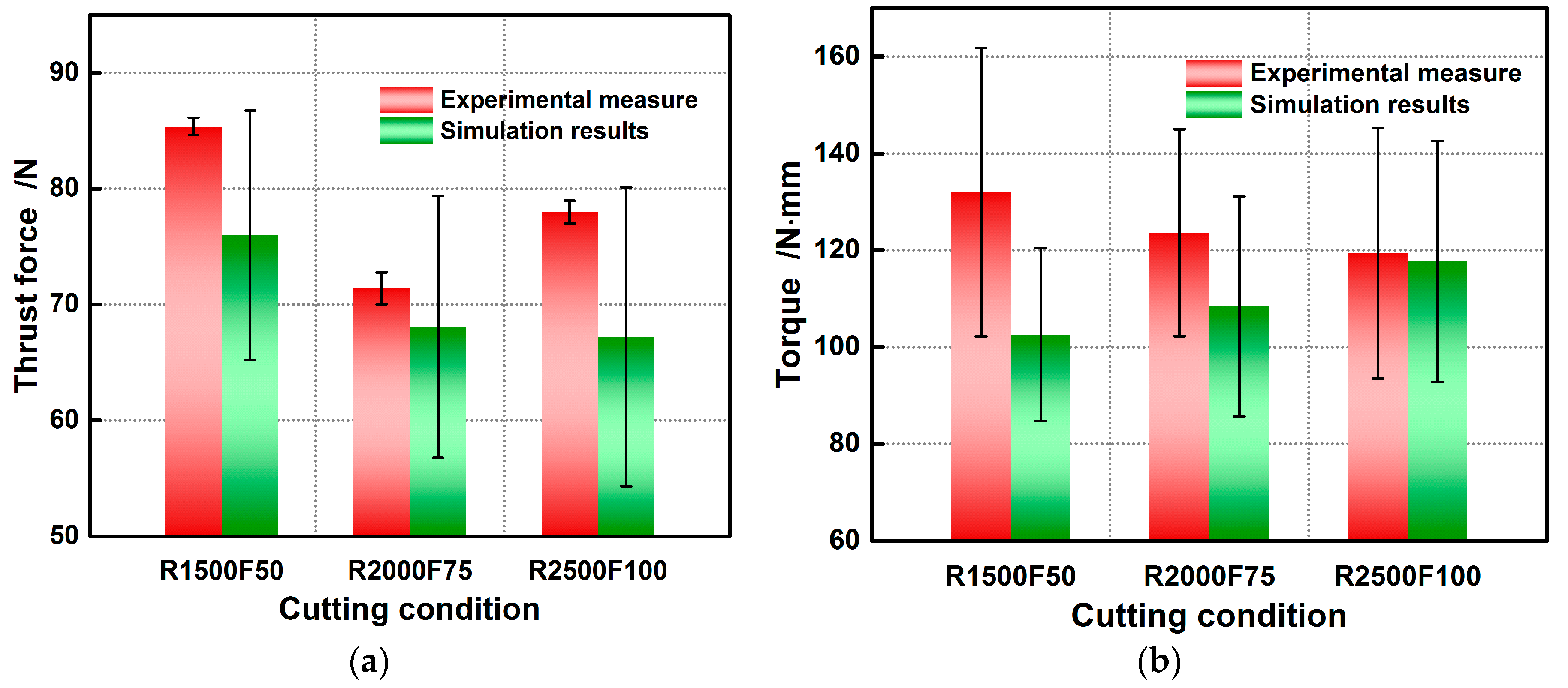

4.3.1. Validation of Thrust Force and Torque

4.3.2. Validation of Chip Morphology

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A. Algorithm Implementation

A.1. Initialization and Update of Damping Factor

A.2. Update of Jacobian Matrix

A.3. Update of Step Length

A.4. Convergence Criteria

- ①

- Gradient criterion

- ②

- Step length increment criterionwhere and are the specified thresholds for iterative termination.

A.5. Error Criteria

References

- Kadivar, M.A.; Akbari, J.; Yousefi, R.; Rahi, A.; Nick, M.G. Investigating the effects of vibration method on ultrasonic-assisted drilling of Al/SiCp metal matrix composites. Robot. Comput.-Integr. Manuf. 2014, 30, 344–350. [Google Scholar] [CrossRef]

- Ekici, E.; Motorcu, A.R. Evaluation of drilling Al/SiC composites with cryogenically treated HSS drills. Int. J. Adv. Manuf. Technol. 2014, 74, 1495–1505. [Google Scholar] [CrossRef]

- Sener, K.; Gökmen, U.; Cinici, H. Study on the mechanical and drilling properties of AA7039 composites reinforced with Al2O3/B4C/SiC particles. Compos. Part B-Eng. 2016, 93, 43–55. [Google Scholar] [CrossRef]

- Sima, M.; Özel, T. Modified material constitutive models for serrated chip formation simulations and experimental validation in machining of titanium alloy Ti-6Al-4V. Int. J. Mach. Tools Manuf. 2010, 50, 943–960. [Google Scholar] [CrossRef]

- Dabboussi, W.; Nemes, J.A. Modeling of ductile fracture using the dynamic punch test. Int. J. Mech. Sci. 2005, 47, 1282–1299. [Google Scholar] [CrossRef]

- Liu, Z.S.; Swaddiwudhipong, S.; Islam, M.J. Perforation of steel and aluminum targets using a modified Johnson-Cook material model. Nucl. Eng. Des. 2012, 250, 108–115. [Google Scholar] [CrossRef]

- Tan, J.Q.; Zhan, M.; Liu, S.; Huang, T.; Guo, J.; Yang, H. A modified Johnson–Cook model for tensile flow behaviors of 7050-T7451 aluminum alloy at high strain rates. Mater. Sci. Eng. A-Struct. 2015, 631, 214–219. [Google Scholar] [CrossRef]

- Zhang, D.N.; Shangguan, Q.Q.; Xie, C.J.; Liu, F. A modified Johnson–Cook model of dynamic tensile behaviors for 7075-T6 aluminum alloy. J. Alloys Compd. 2015, 619, 186–194. [Google Scholar] [CrossRef]

- Langrand, B.; Geoffroy, P.; Petitniot, J.L.; Fabis, J.; Markiewicz, E.; Drazetic, P. Identification technique of constitutive model parameters for crashworthiness modelling. Aerosp. Sci. Technol. 1999, 3, 215–227. [Google Scholar] [CrossRef]

- Dandekar, C.R.; Shin, Y.C. Modeling of machining of composite materials: A review. Int. J. Mach. Tools Manuf. 2012, 57, 102–121. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A constitutive model and data for metals subjected to large strains high strain rates and high temperatures. In Proceedings of the 7th International Symposium on Ballistics, The Hague, The Netherlands, 19–21 April 1983. [Google Scholar]

- Peirs, J.; Verleysen, P.; Paepegem, W.V.; Degrieck, J. Determining the stress-strain behaviour at large strains from high strain rate tensile and shear experiments. Int. J. Impact Eng. 2011, 38, 406–415. [Google Scholar] [CrossRef]

- Shrot, A.; Bäker, M. Determination of Johnson–Cook parameters from machining simulations. Comput. Mater. Sci. 2012, 52, 298–304. [Google Scholar] [CrossRef]

- Song, W.; Ning, J.; Mao, X.; Tang, H. A modified Johnson–Cook model for titanium matrix composites reinforced with titanium carbide particles at elevated temperatures. Mater. Sci. Eng. A-Struct. 2013, 576, 280–289. [Google Scholar] [CrossRef]

- Trimble, D.; Shipley, H.; Lea, L.; Jardine, A.; O’Donnell, G.E. Constitutive analysis of biomedical grade Co-27Cr-5Mo alloy at high strain rates. Mater. Sci. Eng. A-Struct. 2017, 682, 466–474. [Google Scholar] [CrossRef]

- Milani, A.S.; Dabboussi, W.; Nemes, J.A.; Abeyaratne, R.C. An improved multi-objective identification of Johnson–Cook material parameter. Int. J. Impact Eng. 2009, 36, 294–302. [Google Scholar] [CrossRef]

- Chen, Y.; Ghosh, S. Micromechanical analysis of strain rate-dependent deformation and failure in composite microstructures under dynamic loading conditions. Int. J. Plast. 2012, 32, 218–247. [Google Scholar] [CrossRef]

- Roth, C.C.; Mohr, D. Effect of strain rate on ductile fracture initiation in advanced high strength steel sheets: Experiments and modeling. Int. J. Plast. 2014, 56, 19–44. [Google Scholar] [CrossRef]

- Nemat-Nasser, S.; Isaacs, J.B. Direct measurement of isothermal flow stress of metals at elevated temperatures and high strain rates with application to Ta and TaW alloys. Acta Mater. 1997, 45, 907–919. [Google Scholar] [CrossRef]

- Suo, T.; Fan, X.; Hu, G.; Li, Y.; Tang, Z.; Xuea, P. Compressive behavior of C/SiC composites over a wide range of strain rates and temperatures. Carbon 2013, 62, 481–492. [Google Scholar] [CrossRef]

- Li, Y.; Guo, Y.; Hu, H.; Wei, Q. A critical assessment of high-temperature dynamic mechanical testing of metals. Int. J. Impact Eng. 2009, 36, 177–184. [Google Scholar] [CrossRef]

- Ye, T.; Li, L.; Guo, P.; Xiao, G.; Chen, Z. Effect of aging treatment on the microstructure and flow behavior of 6063 aluminum alloy compressed over a wide range of strain rate. Int. J. Impact Eng. 2016, 90, 72–80. [Google Scholar] [CrossRef]

- Li, Y.; Ramesh, K.T.; Chin, E. Viscoplastic deformations and compressive damage in an A359/SiCp metal–matrix composite. Acta Mater. 2000, 48, 1563–1573. [Google Scholar] [CrossRef]

- Li, Y.; Ramesh, K.T.; Chin, E. The compressive viscoplastic response of an A359/SiCp metal–matrix composite and of the A359 aluminum alloy matrix. Int. J. Solids Struct. 2000, 37, 7547–7562. [Google Scholar] [CrossRef]

- Zhu, D.; Wu, G.; Chen, G.; Zhang, Q. Dynamic deformation behavior of a high reinforcement content TiB2/Al composite at high strain rates. Mater. Sci. Eng. A-Struct. 2008, 487, 536–540. [Google Scholar] [CrossRef]

- Marquardt, D.W. An Algorithm for Least Squares Estimation of Nonlinear Parameters. J. Soc. Ind. Appl. Math. 1963, 11, 431–441. [Google Scholar] [CrossRef]

- Rey, P.A.; Ledref, J.; Senatore, J.; Landon, Y. Modelling of cutting forces in orbital drilling of titanium alloy Ti-6Al-4V. Int. J. Mach. Tools Manuf. 2016, 106, 75–88. [Google Scholar] [CrossRef]

- Ay, M.; Altunpak, Y.; Hartomacıoğlu, S. The Grey-Based Taguchi Method: Optimisation of Drilling of Hybrid Aluminum Matrix Composites. Acta Phys. Pol. A 2017, 131, 551–555. [Google Scholar] [CrossRef]

- Nan, X.; Xie, L.; Zhao, W. On the application of 3D finite element modeling for small-diameter hole drilling of AISI 1045 steel. Int. J. Adv. Manuf. Technol. 2016, 84, 1927–1939. [Google Scholar] [CrossRef]

- Ghandehariun, A.; Kishawy, H.; Balazinski, M. On machining modeling of metal matrix composites: A novel comprehensive constitutive equation. Int. J. Mech. Sci. 2016, 107, 235–241. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 1985, 12, 31–48. [Google Scholar] [CrossRef]

- Tan, H.; Huang, Y.; Liu, C.; Geubelle, P.H. The Mori–Tanaka method for composite materials with nonlinear interface debonding. Int. J. Plast. 2005, 21, 1890–1918. [Google Scholar] [CrossRef]

- Seidt, J.D.; Gilat, A.; Klein, J.A.; Leach, J.R. High strain rate, high temperature constitutive and failure models for EOD impact scenarios. In Proceedings of the SEM Annual Conference & Exposition on Experimental and Applied Mechanics, Springfield, MA, USA, 4–6 June 2007. [Google Scholar]

- Hooputra, H.; Gese, H.; Dell, H.; Werner, H. A comprehensive failure model for crashworthiness simulation of aluminum extrusions. Int. J. Crashworth. 2004, 9, 449–464. [Google Scholar] [CrossRef]

- Xu, J.; Mansori, M.E. Cutting Modeling of Hybrid CFRP/Ti Composite with Induced Damage Analysis. Materials 2016, 9, 22. [Google Scholar] [CrossRef] [PubMed]

- Zorev, N.N. Inter-relationship between shear processes occurring along tool face and shear plane in metal cutting. Int. Res. Prod. Eng. 1963, 49, 143–152. [Google Scholar]

- Wojciechowski, S. The estimation of cutting forces and specific force coefficients during finishing ball end milling of inclined surfaces. Int. J. Mach. Tools Manuf. 2015, 89, 110–123. [Google Scholar] [CrossRef]

- Broyden, C.G. A class of methods for solving nonlinear simultaneous equations. Math. Comput. 1965, 19, 577–593. [Google Scholar] [CrossRef]

- Griewank, A. Broyden Updating, the Good and the Bad! Doc. Math. 2012, ISMP (2012), 301–315. [Google Scholar]

- Gavin, H.P. The Levenberg-Marquardt Method for Nonlinear Least Squares Curve-Fitting Problems; Department of Civil and Environmental Engineering, Duke University: Durham, UK, 2013. [Google Scholar]

- Ma, C.; Jiang, L. Some research on Levenberg-Marquardt method for the nonlinear equations. Appl. Math. Comput. 2007, 184, 1032–1040. [Google Scholar] [CrossRef]

- Pujol, J. The solution of nonlinear inverse problems and the Levenberg-Marquardt method. Geophysics 2007, 72, W1–W16. [Google Scholar] [CrossRef]

| Strategy | Algorithm | Parameters (A, B, n, C, m) | R2 | OFSE |

|---|---|---|---|---|

| Multi-objective | Improved L-M | (453.0, 470.6, 0.2558, 0.009522, 3.954) | 0.9556 | 21.88 MPa |

| ad hoc | Linear regression | (528.7, 1004.; 0.6185, 0.015400, 3.290) | 0.9146 | 34.17 MPa |

| 0.09212 | 0.3647 | −2.312 | 0.04424 | 2.6 |

| Notation | Material Properties | Value |

|---|---|---|

| Density (kg/m3) | 2960 | |

| Specific heat capacity (J/kg·°C−1) | 750 | |

| α | Coefficient of thermal expansion (10−6 °C−1) | 7.7 |

| κ | Thermal conductivity (W/m·°C−1) | 175 |

| Volume fraction of SiC (vol %) | 65 | |

| Elastic modulus (GPa) | 221 | |

| υ | Poisson’s ratio | 0.21 |

| Room/reference temperature (°C) | 20 | |

| Melting point | 635 | |

| Reference strain rate | 0.01 | |

| η | Inelastic heat fraction | 0.9 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiang, J.; Xie, L.; Gao, F.; Zhang, Y.; Yi, J.; Wang, T.; Pang, S.; Wang, X. On Multi-Objective Based Constitutive Modelling Methodology and Numerical Validation in Small-Hole Drilling of Al6063/SiCp Composites. Materials 2018, 11, 97. https://doi.org/10.3390/ma11010097

Xiang J, Xie L, Gao F, Zhang Y, Yi J, Wang T, Pang S, Wang X. On Multi-Objective Based Constitutive Modelling Methodology and Numerical Validation in Small-Hole Drilling of Al6063/SiCp Composites. Materials. 2018; 11(1):97. https://doi.org/10.3390/ma11010097

Chicago/Turabian StyleXiang, Junfeng, Lijing Xie, Feinong Gao, Yu Zhang, Jie Yi, Tao Wang, Siqin Pang, and Xibin Wang. 2018. "On Multi-Objective Based Constitutive Modelling Methodology and Numerical Validation in Small-Hole Drilling of Al6063/SiCp Composites" Materials 11, no. 1: 97. https://doi.org/10.3390/ma11010097

APA StyleXiang, J., Xie, L., Gao, F., Zhang, Y., Yi, J., Wang, T., Pang, S., & Wang, X. (2018). On Multi-Objective Based Constitutive Modelling Methodology and Numerical Validation in Small-Hole Drilling of Al6063/SiCp Composites. Materials, 11(1), 97. https://doi.org/10.3390/ma11010097