Effect of CeO2 on Microstructure and Wear Resistance of TiC Bioinert Coatings on Ti6Al4V Alloy by Laser Cladding

Abstract

:1. Introduction

2. Experimental Procedures

2.1. Materials Used

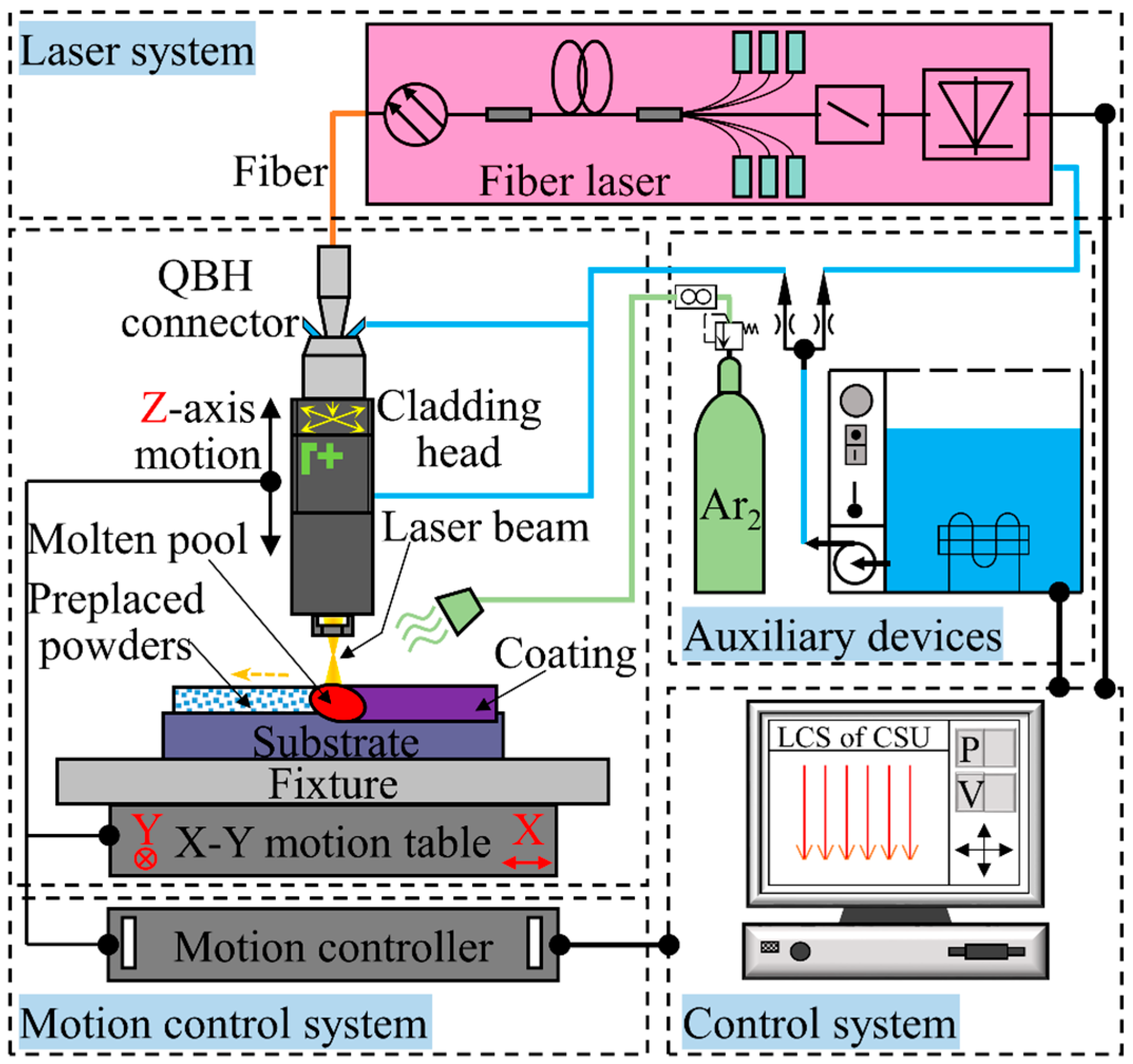

2.2. Laser-Cladding Process

2.3. Microanalysis of the Coatings

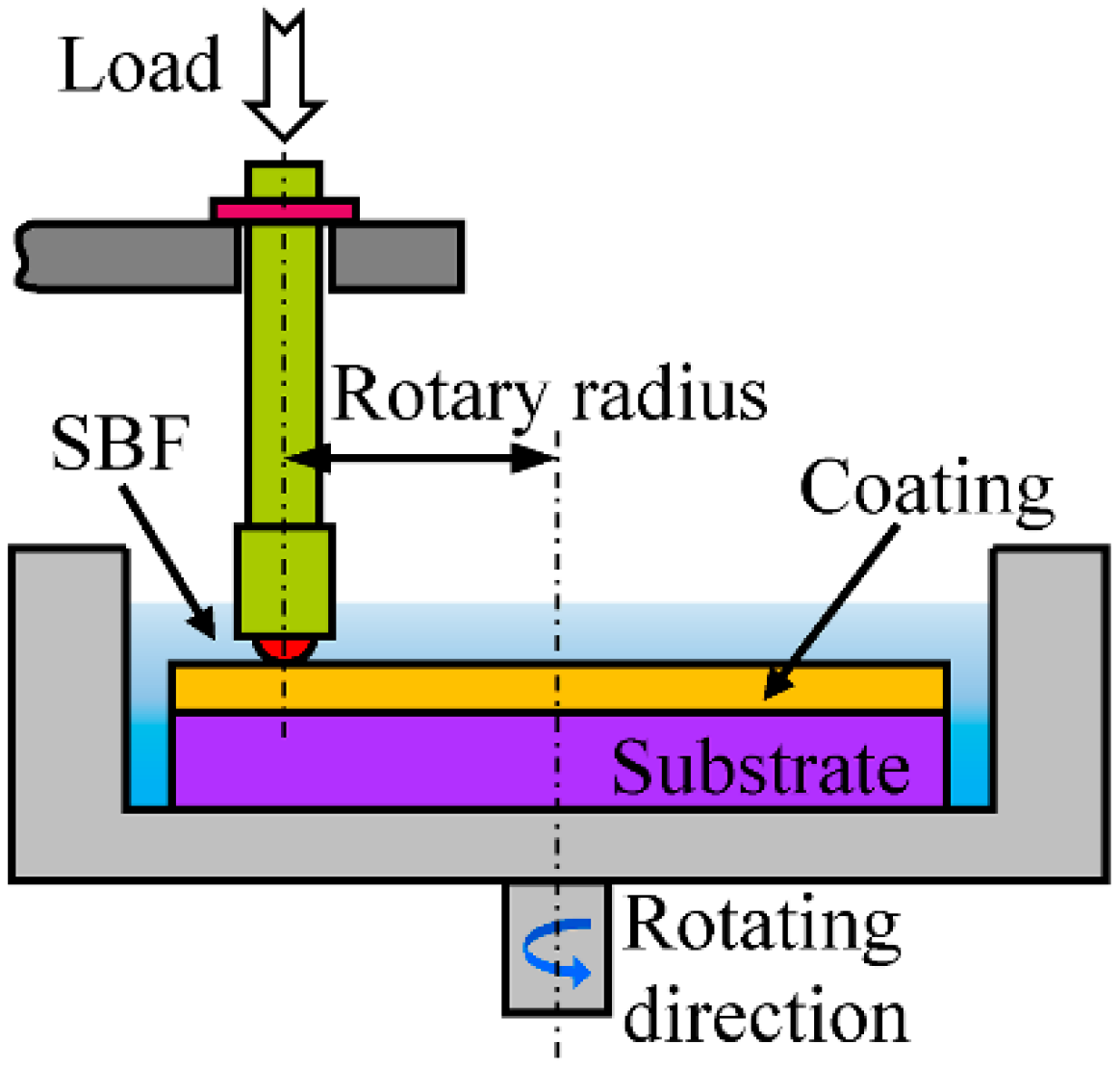

2.4. Micro-Hardness and Wear Resistance

3. Results and Discussion

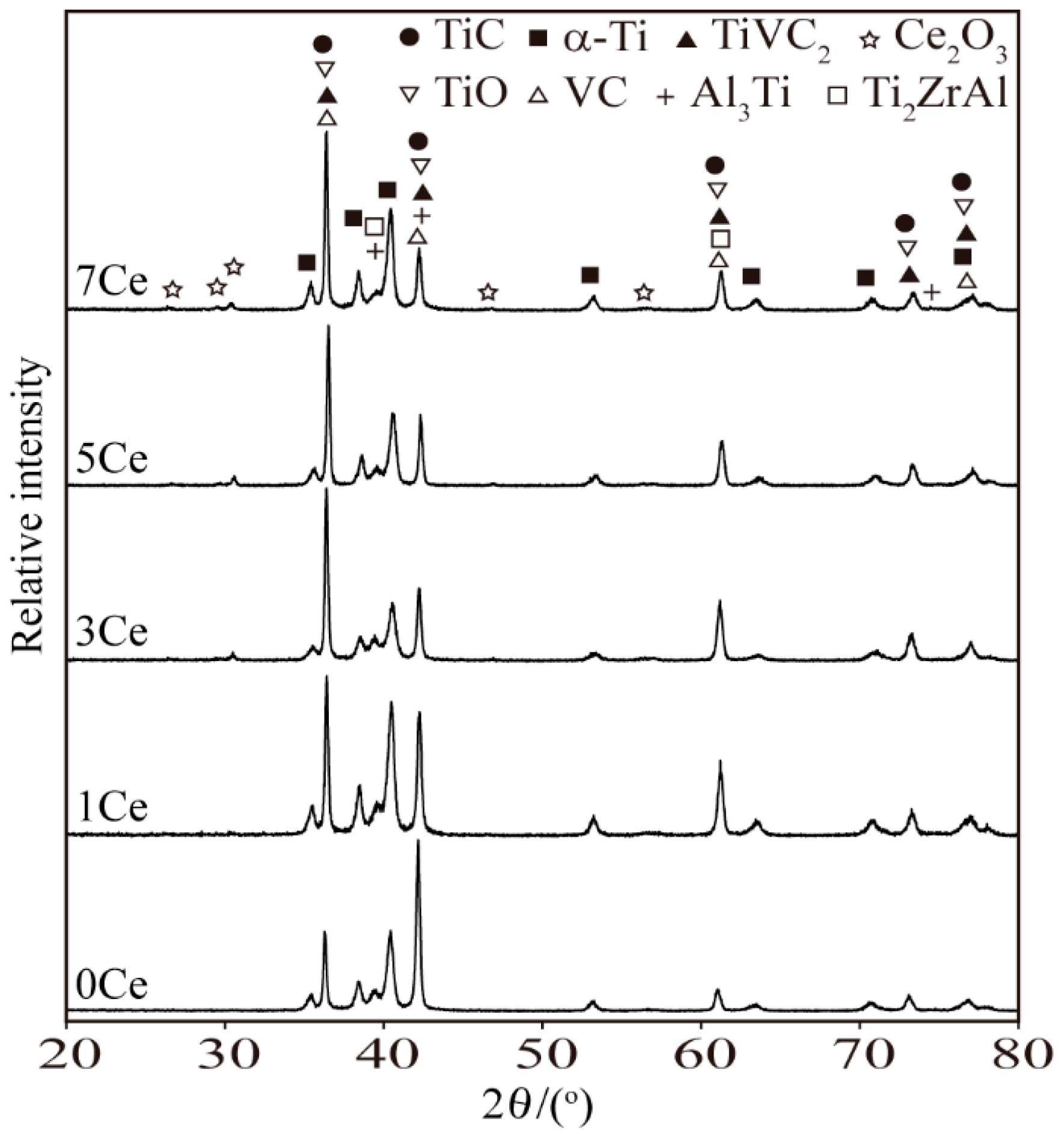

3.1. Phases of the Coatings Fabricated by Laser Cladding

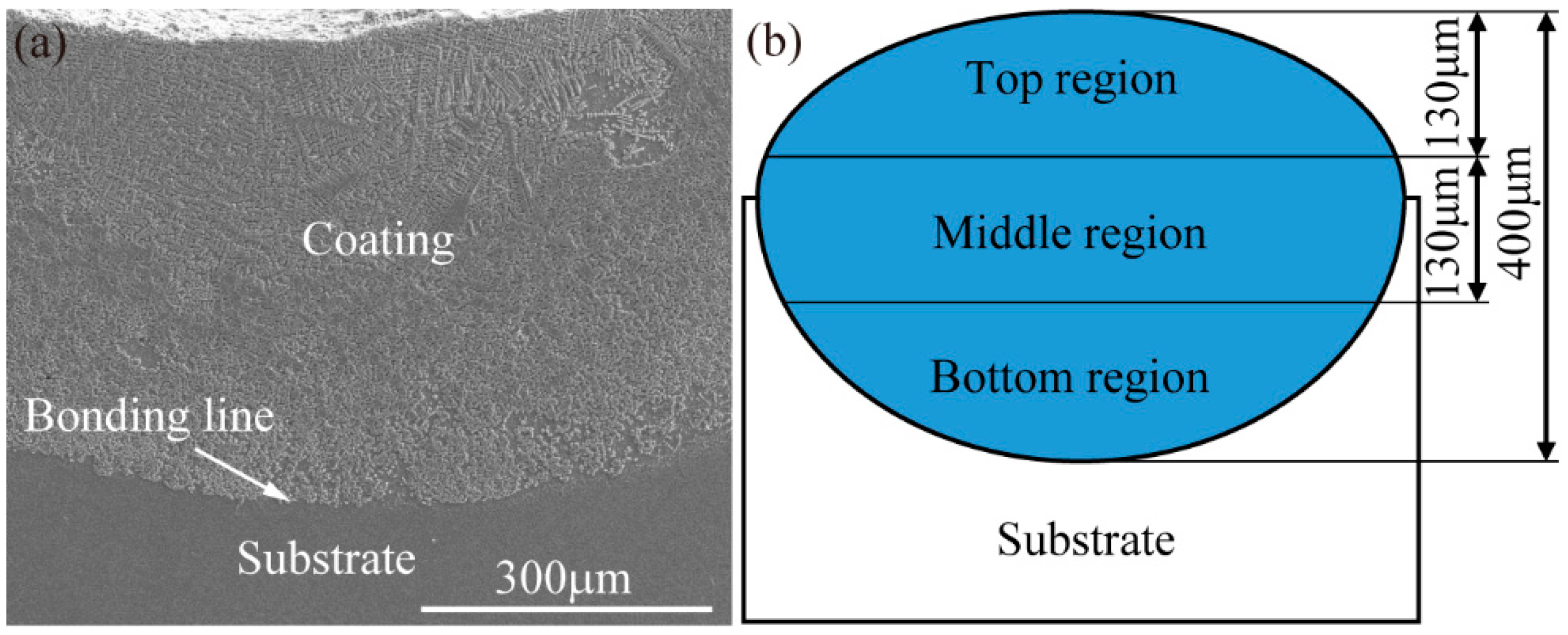

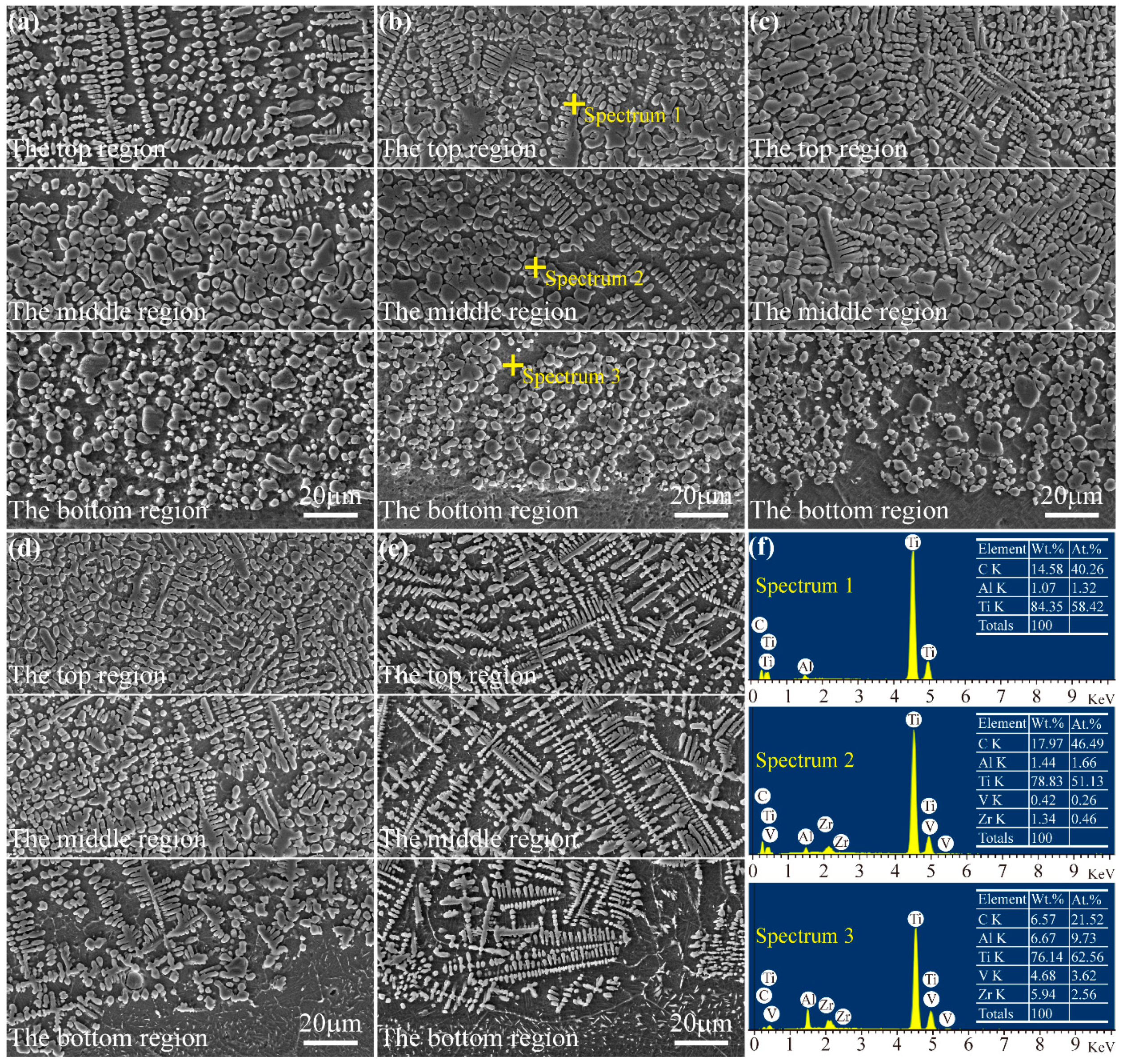

3.2. Microstructures of the Coatings

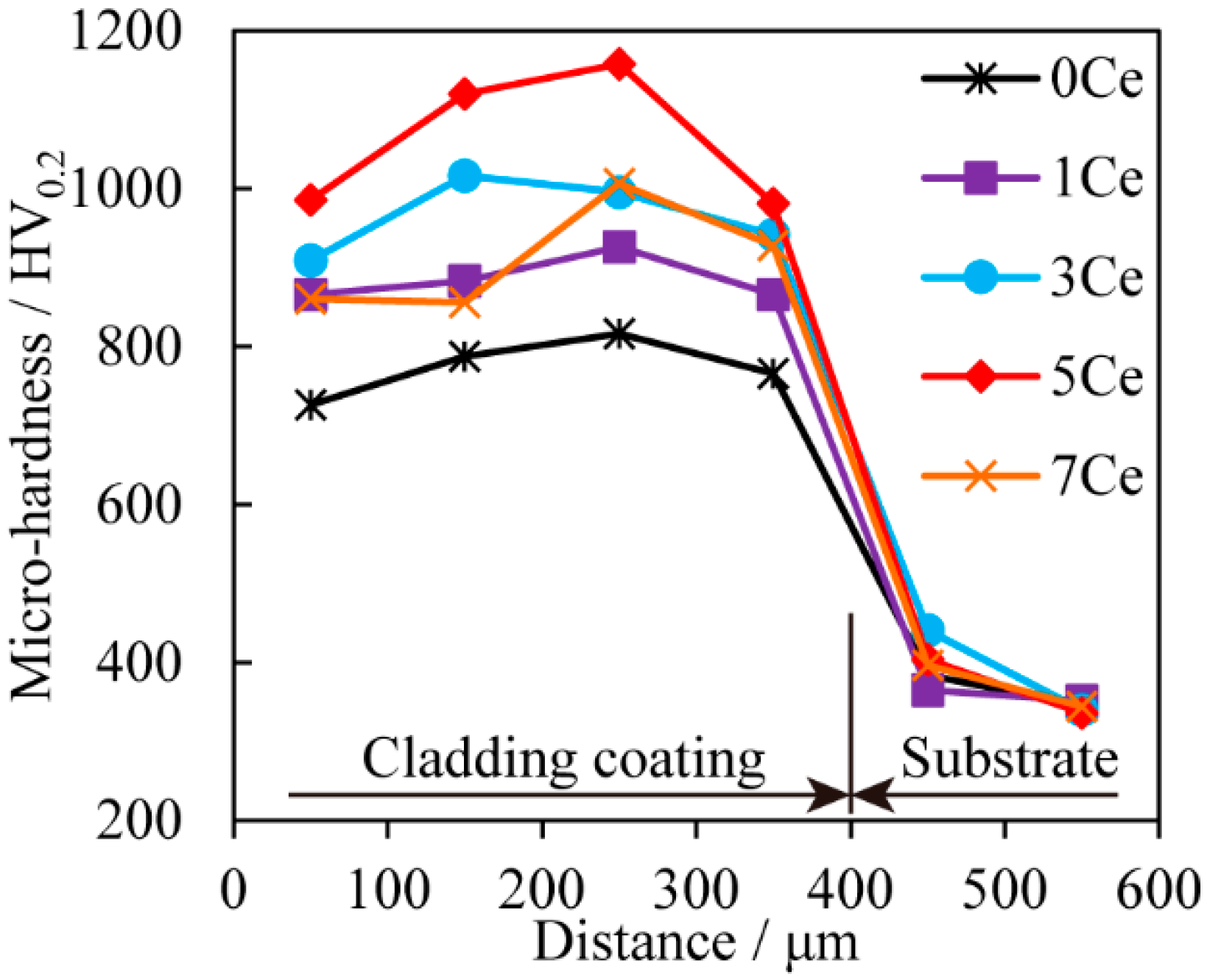

3.3. Micro-Hardness of the Coatings

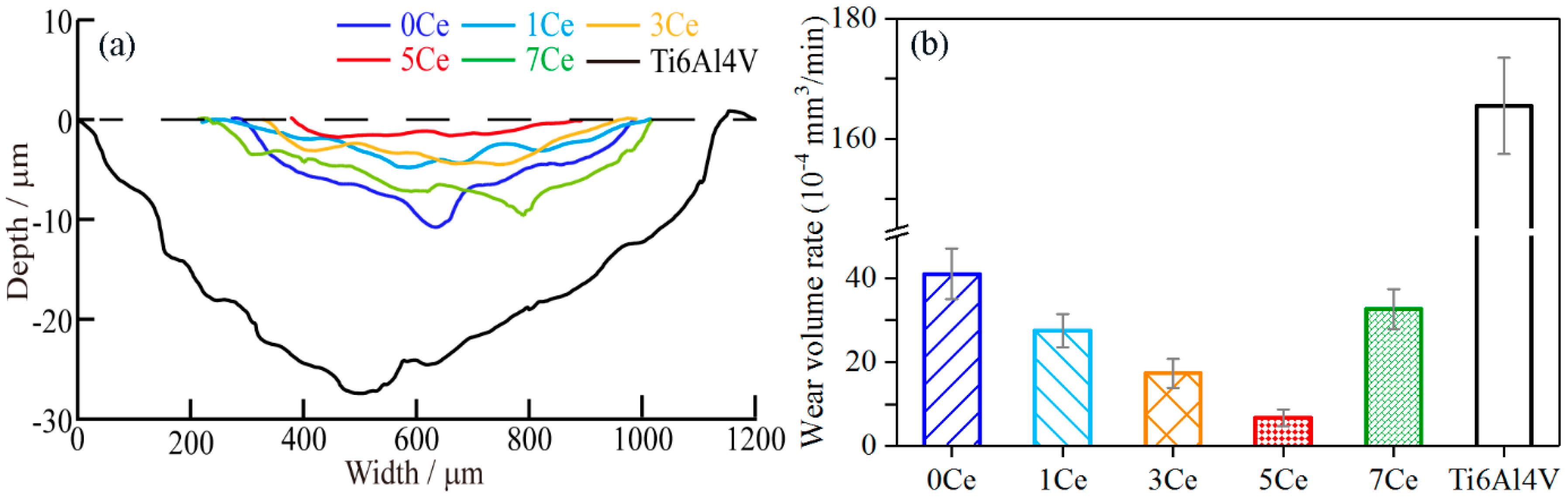

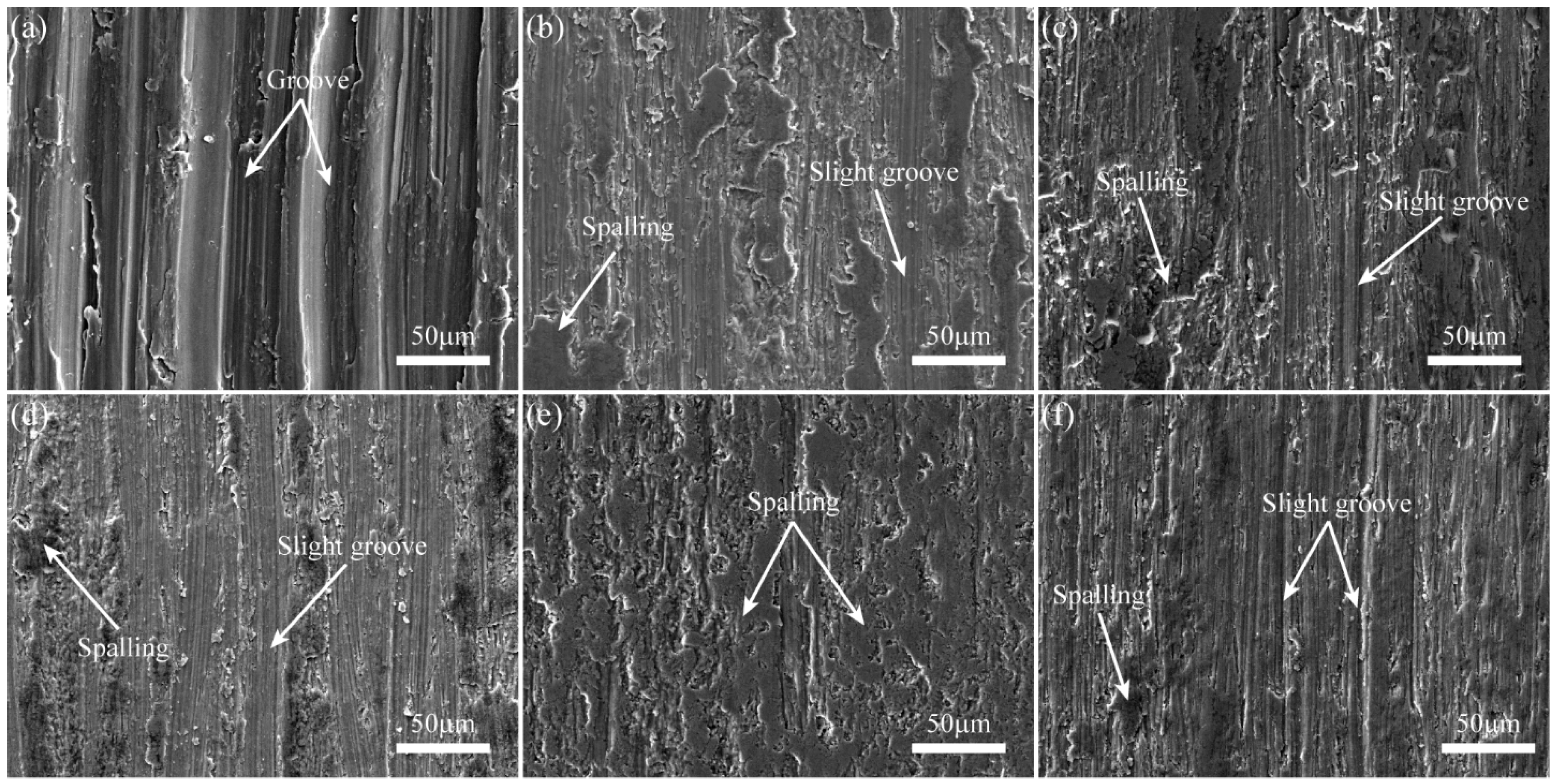

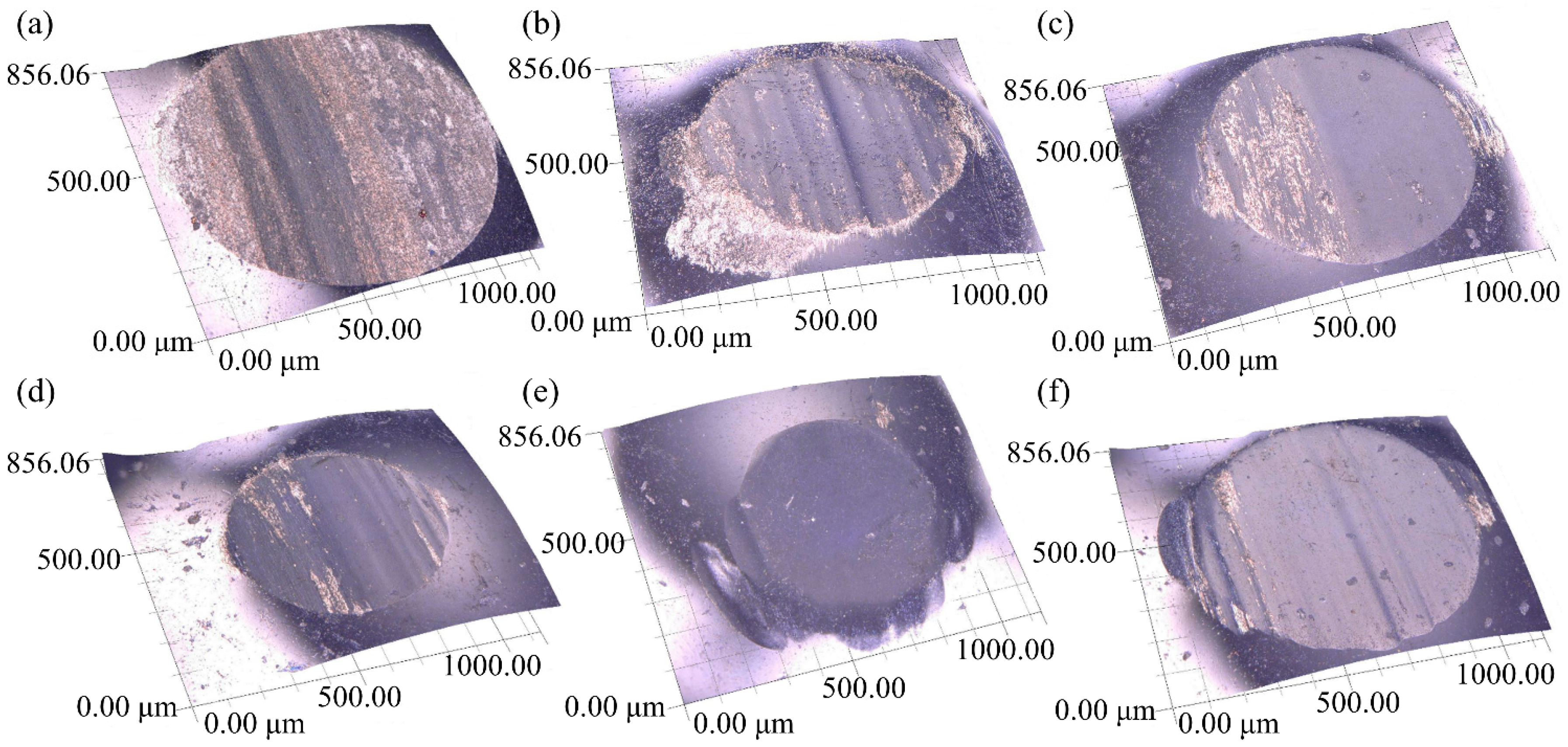

3.4. Wear Resistance of the Coatings

4. Conclusions

- 1

- TiC coatings on Ti6Al4V alloy substrates were fabricated by the laser-cladding process with TiC–ZrO2–CeO2 mixed powders. The coatings were mainly composed of TiC, α-Ti, TiO, VC, TiVC2, Al3Ti and Ti2ZrAl phases.

- 2

- The cross-sectional microstructures of the coatings from the top surface to the inside gradually changed from dendrites to granular crystals. With the increase of CeO2 additive content in the pre-placed powders, the microstructures of the coatings became more compact and finer. Excessive CeO2 additive in the preplaced powders led to a reduction in the function of refinement, as in the 7Ce coating.

- 3

- The effect of CeO2 additive in the pre-placed powders on the mechanical properties of the coatings was obvious. The micro-hardness and wear resistance of the coatings increased with the increase of CeO2 additive content, but excessive CeO2 additive reduced the strengthening effect. Compared with the substrate, the micro-hardness and wear resistance of the 5Ce coating were improved by 3.2 and 24.59 times, respectively.

Acknowledgements

Author Contributions

Conflicts of Interest

References

- Liu, X.Y.; Chu, P.K.; Ding, C.X. Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Mater. Sci. Eng. R. 2004, 47, 49–121. [Google Scholar] [CrossRef]

- Hanawa, T. Recent Development of New Alloys for Biomedical Use. Mater. Sci. Forum. 2006, 512, 243–248. [Google Scholar] [CrossRef]

- Hacisalihoglu, I.; Samancioglu, A.; Yildiz, F.; Purcek, G.; Alsaran, A. Tribocorrosion properties of different type titanium alloys in simulated body fluid. Wear 2015, 332–333, 679–686. [Google Scholar] [CrossRef]

- Vieira, A.C.; Ribeiro, A.R.; Rocha, L.A.; Celis, J.P. Influence of pH and corrosion inhibitors on the tribocorrosion of titanium in artificial saliva. Wear 2006, 261, 994–1001. [Google Scholar] [CrossRef]

- Zhang, C.; Xu, H.F.; Geng, X.; Wang, J.J.; Xiao, J.K.; Zhu, P.Z. Effect of Spray Distance on Microstructure and Tribological Performance of Suspension Plasma-Sprayed Hydroxyapatite-Titania Composite Coatings. J. Therm. Spray Technol. 2016, 25, 1255–1263. [Google Scholar] [CrossRef]

- Perumal, G.; Geetha, M.; Asokamani, R.; Alagumurthi, N. Wear studies on plasma sprayed Al2O3–40wt% 8YSZ composite ceramic coating on Ti-6Al-4V alloy used for biomedical applications. Wear 2014, 311, 101–113. [Google Scholar] [CrossRef]

- Nie, X.; Leyland, A.; Matthews, A. Deposition of layered bioceramic hydroxyapatite/TiO2 coatings on titanium alloys using a hybrid technique of micro-arc oxidation and electrophoresis. Surf. Coat. Technol. 2000, 125, 407–414. [Google Scholar] [CrossRef]

- Sarraf, M.; Razak, B.A.; Nasiri-Tabrizi, B.; Dabbagh, A.; Kasim, N.H.A.; Basirun, W.J.; Bin Sulaiman, E. Nanomechanical properties, wear resistance and in-vitro characterization of Ta2O5 nanotubes coating on biomedical grade Ti-6Al-4V. J. Mech. Behav. Biomed. 2017, 66, 159–171. [Google Scholar] [CrossRef] [PubMed]

- Souza, M.R.; Reyes, K.M.; Oliveira, N.T.C.; Kuromoto, N.K.; Marino, C.E.B. Bioactivity of self-organized TiO2 nanotubes used as surface treatment on Ti biomaterials. Mater. Res. Express 2016, 3. [Google Scholar] [CrossRef]

- Xu, X.; Han, J.G.; Wang, C.M.; Huang, A.G. Laser Cladding of Composite Bioceramic Coatings on Titanium Alloy. J. Mater. Eng. Perform. 2016, 25, 656–667. [Google Scholar] [CrossRef]

- Chien, C.; Liu, C.; Kuo, T. Effects of Laser Power Level on Microstructural Properties and Phase Composition of Laser-Clad Fluorapatite/Zirconia Composite Coatings on Ti6Al4V Substrates. Materials 2016, 9. [Google Scholar] [CrossRef] [PubMed]

- Khanna, R.; Kokubo, T.; Matsushita, T.; Takadama, H. Fabrication of dense α-alumina layer on Ti-6Al-4V alloy hybrid for bearing surfaces of artificial hip joint. Mater. Sci. Eng. C 2016, 69, 1229–1239. [Google Scholar] [CrossRef] [PubMed]

- Shtansky, D.V.; Levashov, E.A.; Glushankova, N.A.; D’Yakonova, N.B.; Kulinich, S.A.; Petrzhik, M.I.; Kiryukhantsev-Korneev, F.V.; Rossi, F. Structure and properties of CaO- and ZrO2-doped TiCxNy coatings for biomedical applications. Surf. Coat. Technol. 2004, 182, 101–111. [Google Scholar] [CrossRef]

- Kayali, Y. The Corrosion and Wear Behavior of TiN and TiAlN Coated AISI 316 L Stainless Steel1. Prot. Met. Phys. Chem. 2014, 50, 412–419. [Google Scholar] [CrossRef]

- Mohseni, E.; Zalnezhad, E.; Bushroa, A.R. Comparative investigation on the adhesion of hydroxyapatite coating on Ti-6Al-4V implant: A review paper. Int. J. Adhes. Adhes. 2014, 48, 238–257. [Google Scholar] [CrossRef]

- Wang, S.A.; Lacefield, W.R.; Lemons, J.E. Interfacial shear strength and histology of plasma sprayed and sintered hydroxyapatite implants in Tivo. Biomaterials 1996, 17, 1965–1970. [Google Scholar] [CrossRef]

- Vilar, R. Laser cladding. J. Laser Appl. 1999, 11, 64–79. [Google Scholar] [CrossRef]

- Smolina, I.; Szymczyk, P.; Chlebus, E.; Ivashchenko, I.; Kurzynowski, T. Composite Laser-Clad Coating on Titanium Substrate Using Pure Hydroxyapatite Powder. Powder Metall. Met. Ceram. 2015, 54, 318–323. [Google Scholar] [CrossRef]

- Chien, C.S.; Hong, T.F.; Han, T.J.; Kuo, T.Y.; Liao, T.Y. Effects of different binders on microstructure and phase composition of hydroxyapatite Nd-YAG laser clad coatings. Appl. Surf. Sci. 2011, 257, 2387–2393. [Google Scholar] [CrossRef]

- Zhu, Y.Z.; Liu, Q.B.; Xu, P.; Li, L.; Jiang, H.B.; Bai, Y. Bioactivity of calcium phosphate bioceramic coating fabricated by laser cladding. Laser Phys. Lett. 2016, 13. [Google Scholar] [CrossRef]

- Zheng, M.; Fan, D.; Li, X.K.; Li, W.F.; Liu, Q.B.; Zhang, J.B. Microstructure and osteoblast response of gradient bioceramic coating on titanium alloy fabricated by laser cladding. Appl. Surf. Sci. 2008, 255, 426–428. [Google Scholar] [CrossRef]

- Li, H.C.; Wang, D.G.; Chen, C.Z.; Weng, F. Effect of CeO2 and Y2O3 on microstructure, bioactivity and degradability of laser cladding CaO-SiO2 coating on titanium alloy. Colloid. Surf. B 2015, 127, 15–21. [Google Scholar] [CrossRef] [PubMed]

- Chien, C.S.; Liu, C.W.; Kuo, T.Y.; Wu, C.C.; Hong, T.F. Bioactivity of fluorapatite/alumina composite coatings deposited on Ti6Al4V substrates by laser cladding. Appl. Phys. A 2016, 122, 1–10. [Google Scholar] [CrossRef]

- Koch, C.F.; Johnson, S.; Kumar, D.; Jelinek, M.; Chrisey, D.B.; Doraiswamy, A.; Jin, C.; Narayan, R.J.; Mihailescu, I.N. Pulsed laser deposition of hydroxyapatite thin films. Mater. Sci. Eng. C 2007, 27, 484–494. [Google Scholar] [CrossRef]

- Silva, P.L.; Santos, J.D.; Monteiro, F.J.; Knowles, J.C. Adhesion and microstructural characterization of plasma-sprayed hydroxyapatite/glass ceramic coatings onto Ti-6A1-4V substrates. Surf. Coat. Technol. 1998, 102, 191–196. [Google Scholar] [CrossRef]

- Thomas, M.B.; Doremus, R.H.; Jarcho, M.; Salsbury, R.L. Dense hydroxylapatite: Fatigue and fracture strength after various treatments, from diametral tests. J. Mater. Sci. 1980, 15, 891–894. [Google Scholar] [CrossRef]

- De With, G.; Van Dijk, H.J.A.; Hattu, N.; Prijs, K. Preparation, microstructure and mechanical properties of dense polycrystalline hydroxy apatite. J. Mater. Sci. 1981, 16, 1592–1598. [Google Scholar] [CrossRef]

- Van Raay, J.J.A.M.; Rozing, P.M.; Van Blitterswijk, C.A.; Van Haastert, R.M.; Koerten, H.K. Biocompatibility of wear-resistant coatings in orthopaedic surgery in vitro testing with human fibroblast cell cultures. J. Mater. Sci. 1995, 6, 80–84. [Google Scholar] [CrossRef]

- Soon, G.; Pingguan-Murphy, B.; Lai, K.W.; Akbar, S.A. Review of zirconia-based bioceramic Surface modification and cellular response. Ceram. Int. 2016, 42, 12543–12555. [Google Scholar] [CrossRef]

- Lei, Y.W.; Sun, R.L.; Tang, Y.; Niu, W. Experimental and Thermodynamic Analysis of Laser Clad Cr3C2/Ni Coatings on a Ti6Al4V Substrate Produced with Different Incident Laser Powers. Laser Eng. 2015, 32, 207–220. [Google Scholar]

- Li, Q.T.; Lei, Y.P.; Fu, H.G. Growth mechanism, distribution characteristics and reinforcing behavior of (Ti, Nb)C particle in laser cladded Fe-based composite coating. Appl. Surf. Sci. 2014, 316, 610–616. [Google Scholar] [CrossRef]

- Chien, C.S.; Liao, T.Y.; Hong, T.F.; Kuo, T.Y.; Wu, J.L.; Lee, T.M. Investigation into microstructural properties of fluorapatite Nd-YAG laser clad coatings with PVA and WG binders. Surf. Coat. Technol. 2011, 205, 3141–3146. [Google Scholar] [CrossRef]

- Zhang, H.; Zou, Y.; Zou, Z.D.; Shi, C.W. Effects of CeO2 on microstructure and corrosion resistance of TiC-VC reinforced Fe-based laser cladding layers. J. Rare Earth. 2014, 32, 1095–1100. [Google Scholar] [CrossRef]

- Weng, F.; Chen, C.Z.; Yu, H.J. Research status of laser cladding on titanium and its alloys: A review. Mater. Des. 2014, 58, 412–425. [Google Scholar] [CrossRef]

- Qiao, H.; Li, Q.T.; Fu, H.G.; Lei, Y.P. Microstructure and micro-hardness of in situ synthesized TiC particles reinforced Fe-based alloy composite coating by laser cladding. Mater. Werkst. 2014, 45, 85–90. [Google Scholar] [CrossRef]

- Liu, Y.H.; Qu, W.C.; Su, Y. TiC Reinforcement Composite Coating Produced Using Graphite of the Cast Iron by Laser Cladding. Materials 2016, 9. [Google Scholar] [CrossRef] [PubMed]

- Gropyanov, V.M.; Yudin, B.F.; Avgustinik, A.I. Study of high temperature interaction in the system TiC-ZrO2. Refract. Ind. Ceram. 1966, 7, 599–603. [Google Scholar] [CrossRef]

- Gropyanov, V.M. Some properties and structure of compounds of variable composition in the TiC-ZrO2 system. Refract. Ind. Ceram. 1968, 9, 388–390. [Google Scholar] [CrossRef]

- Graciani, J.; Márquez, A.M.; Plata, J.J.; Ortega, Y.; Hernández, N.C.; Meyer, A.; Zicovich-Wilson, C.M.; Sanz, J.F. Comparative Study on the Performance of Hybrid DFT Functionals in Highly Correlated Oxides: The Case of CeO2 and Ce2O3. J. Chem. Theory Comput. 2011, 7, 56–65. [Google Scholar] [CrossRef] [PubMed]

- Stetsovych, V.; Pagliuca, F.; Dvořák, F.; Duchoň, T.; Vorokhta, M.; Aulická, M.; Lachnitt, J.; Schernich, S.; Matolínová, I.; Veltruská, K.; et al. Epitaxial Cubic Ce2O3 Films via Ce-CeO2 Interfacial Reaction. J. Phys. Chem. Lett. 2013, 4, 866–871. [Google Scholar] [CrossRef] [PubMed]

- Li, J.N.; Gong, S.I.; Wang, X.C.; Suo, H.B. Physical and Suface performance of Laser Clad Ni Based Coating on a TA15-2 Alloy. Chin. J. Laser 2013, 40, 128–133. [Google Scholar] [CrossRef]

- Zhang, H.; Zou, Y.; Da, Z.Z.; Hao, Y.L. Effect of Graphite Addition on Microstructure and Wear Resistance of Fe-Ti-V-C Cladding Layers. Tribology 2014, 34, 319–324. [Google Scholar] [CrossRef]

- Kurz, W. Fundamentals of Solidification; Enfield Publishing & Distribution Company: Enfield, NH, USA, 1998. [Google Scholar]

- Schwendner, K.I.; Banerjee, R.; Collins, P.C.; Brice, C.A.; Fraser, H.L. Direct laser deposition of alloys from elemental powder blends. Scr. Mater. 2001, 45, 1123–1129. [Google Scholar] [CrossRef]

- Cheng, X.Y.; Feng, Y.S.; He, J. Influence of CeO2 on Microstructure and Microhardness of TiC4 Coating Produced by Laser-Cladding. Mater. Mech. Eng. 2010, 34, 20–23. [Google Scholar]

- Cai, Y.C.; Luo, Z.; Chen, Y.; Ao, S.S. Influence of CeO2 on tribological behaviour of TiC/ Fe-based composite coating. Surf. Eng. 2017, 33, 1–8. [Google Scholar] [CrossRef]

- Hansen, N. Hall-Petch relation and boundary strengthening. Scr. Mater. 2004, 51, 801–806. [Google Scholar] [CrossRef]

| Powder Ingredient (wt %) | Number Marked | ||

|---|---|---|---|

| TiC | ZrO2 | CeO2 | |

| 80 | 20 | 0 | 0Ce |

| 79 | 1 | 1Ce | |

| 77 | 3 | 3Ce | |

| 75 | 5 | 5Ce | |

| 73 | 7 | 7Ce | |

| Parameter | Value | Unit |

|---|---|---|

| Load | 10 | N |

| Temperature | 25 ± 1 | °C |

| Wear time | 30 | min |

| Rotation radius | 5 | mm |

| Rotation speed | 200 | rad/min |

| Solution | SBF | - |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, T.; Liu, D.; Wu, F.; Wang, H. Effect of CeO2 on Microstructure and Wear Resistance of TiC Bioinert Coatings on Ti6Al4V Alloy by Laser Cladding. Materials 2018, 11, 58. https://doi.org/10.3390/ma11010058

Chen T, Liu D, Wu F, Wang H. Effect of CeO2 on Microstructure and Wear Resistance of TiC Bioinert Coatings on Ti6Al4V Alloy by Laser Cladding. Materials. 2018; 11(1):58. https://doi.org/10.3390/ma11010058

Chicago/Turabian StyleChen, Tao, Defu Liu, Fan Wu, and Haojun Wang. 2018. "Effect of CeO2 on Microstructure and Wear Resistance of TiC Bioinert Coatings on Ti6Al4V Alloy by Laser Cladding" Materials 11, no. 1: 58. https://doi.org/10.3390/ma11010058

APA StyleChen, T., Liu, D., Wu, F., & Wang, H. (2018). Effect of CeO2 on Microstructure and Wear Resistance of TiC Bioinert Coatings on Ti6Al4V Alloy by Laser Cladding. Materials, 11(1), 58. https://doi.org/10.3390/ma11010058