Tensile and Creep Testing of Sanicro 25 Using Miniature Specimens

Abstract

:1. Introduction

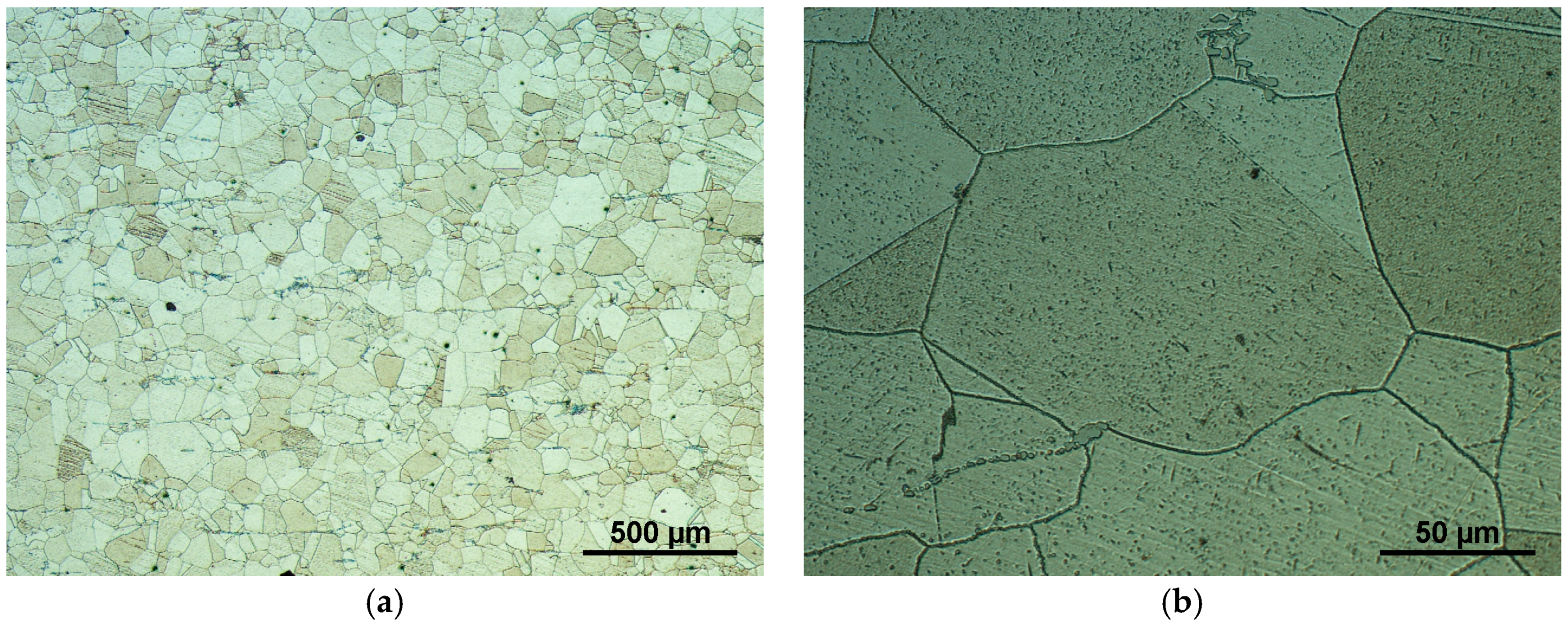

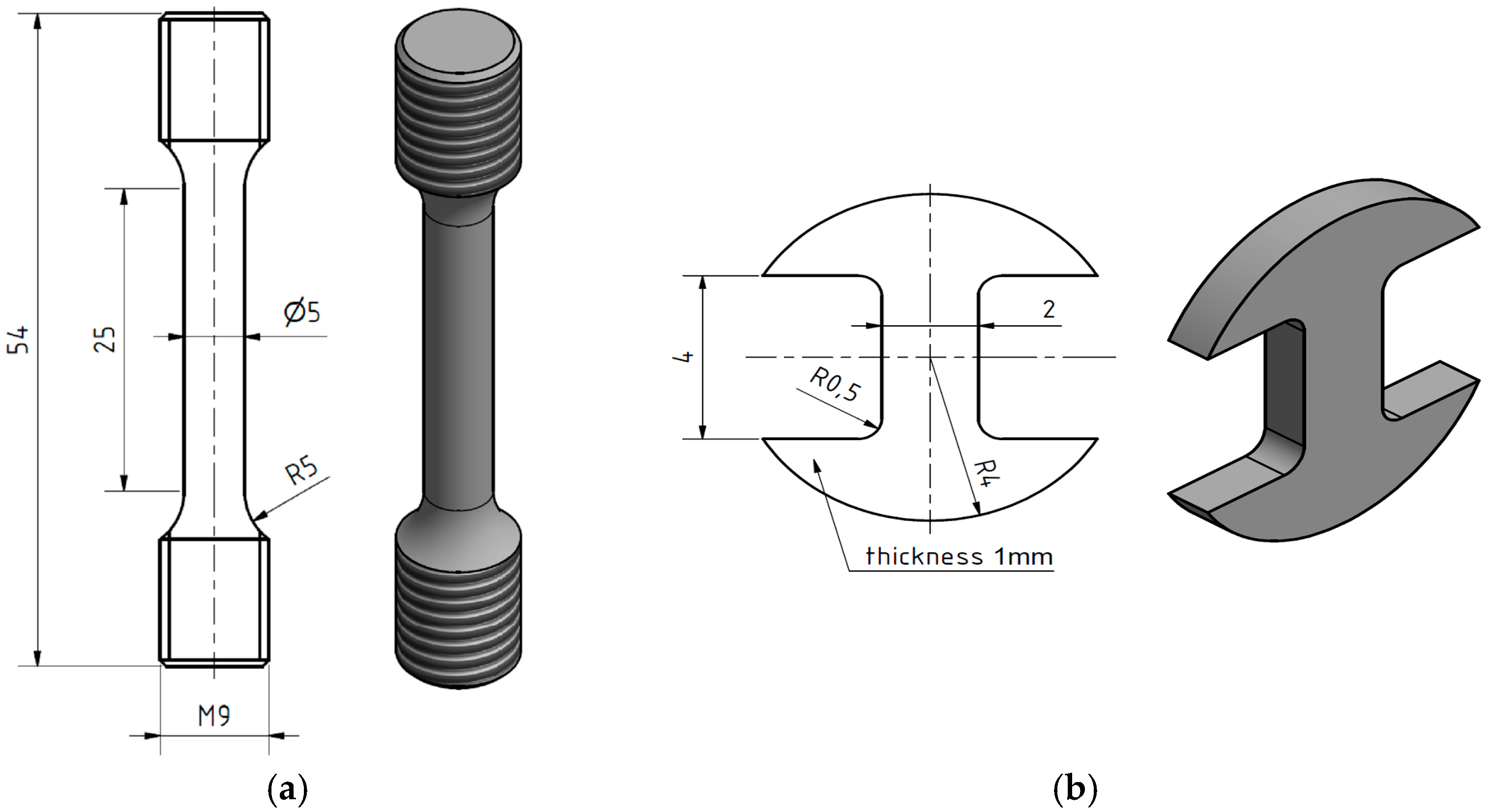

2. Materials and Methods

3. Results and Discussion

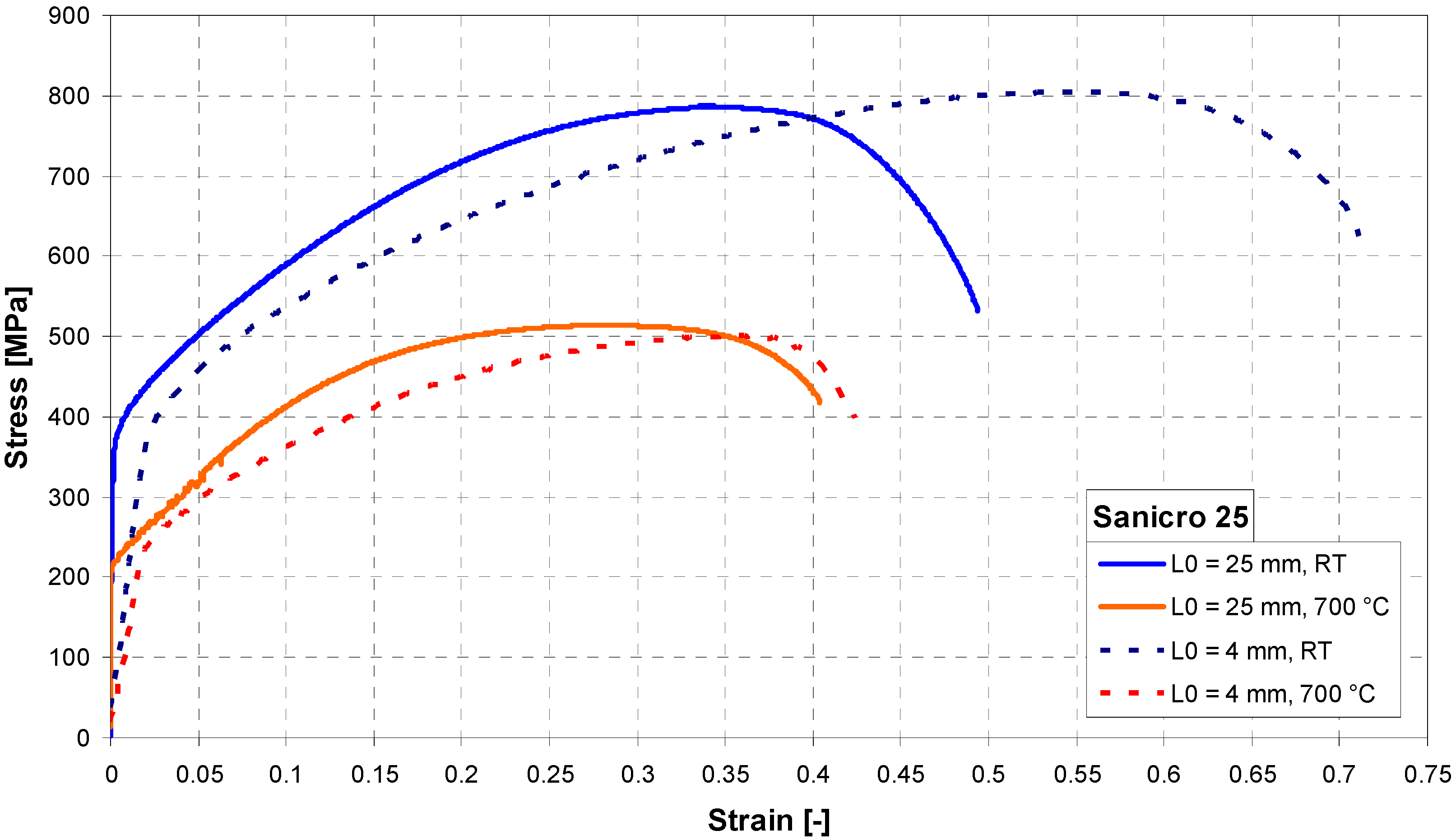

3.1. Tensile Properties

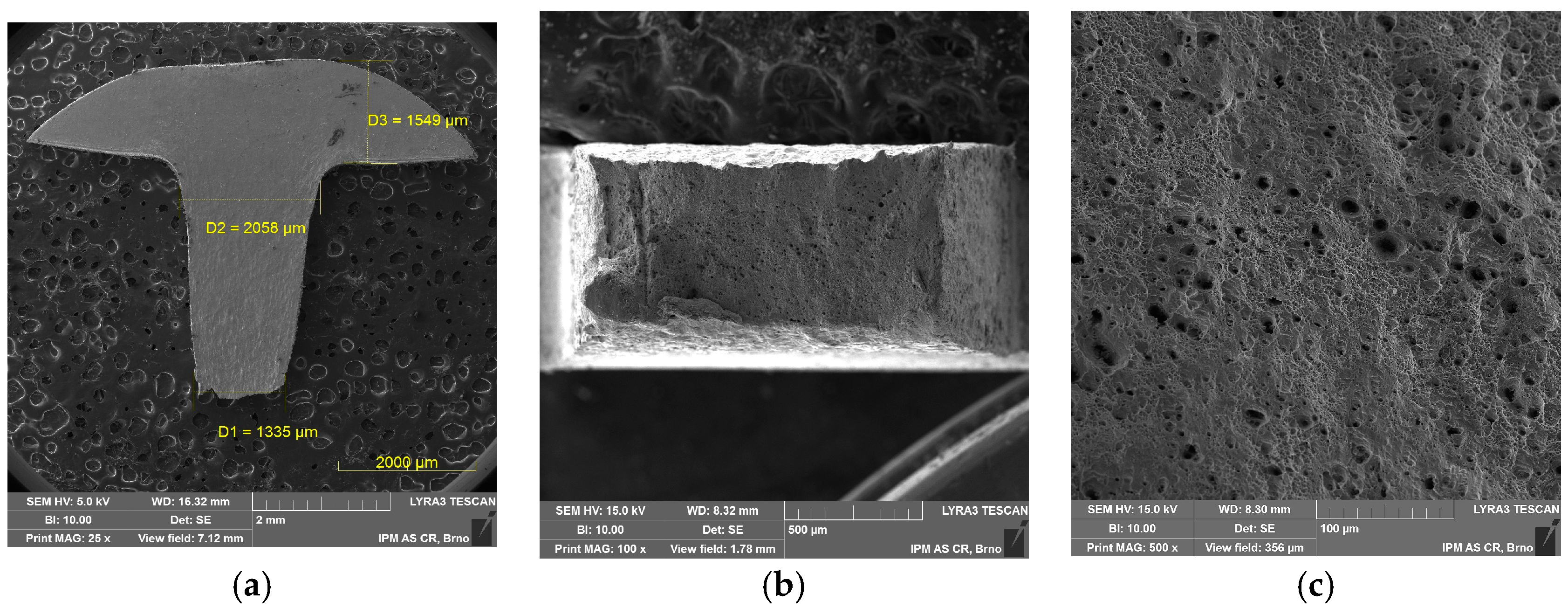

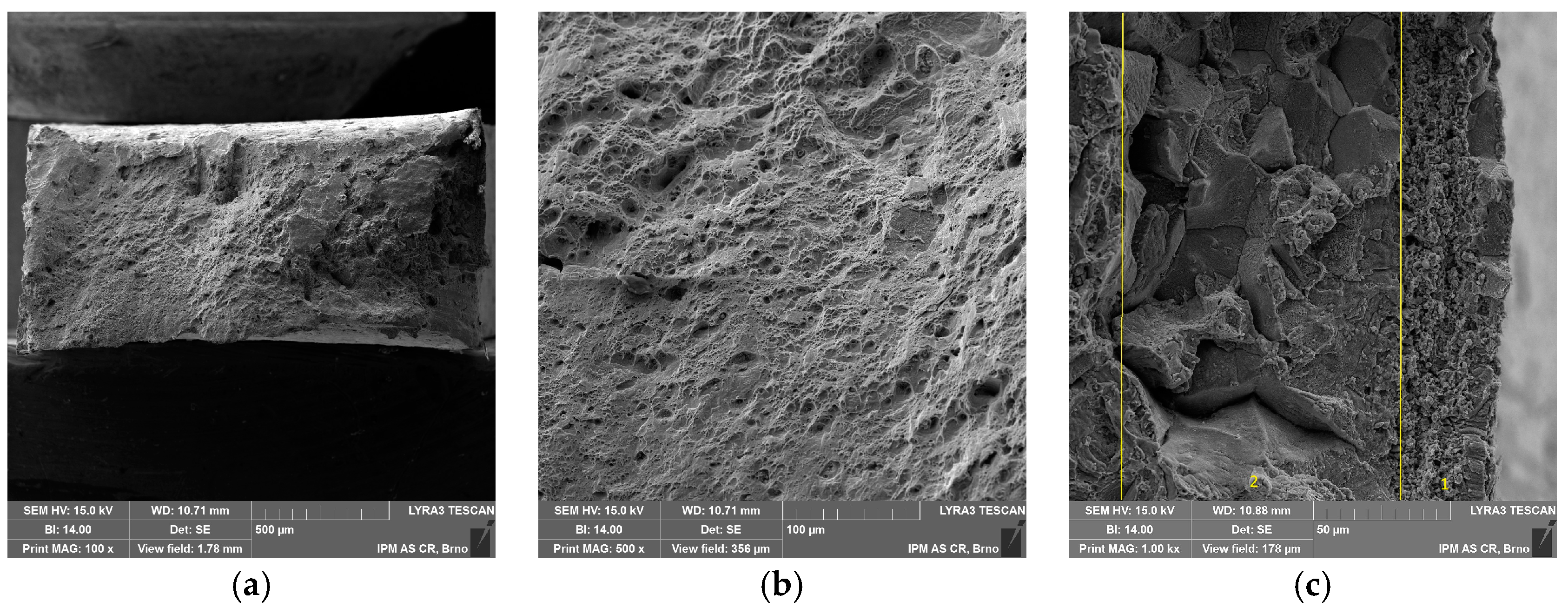

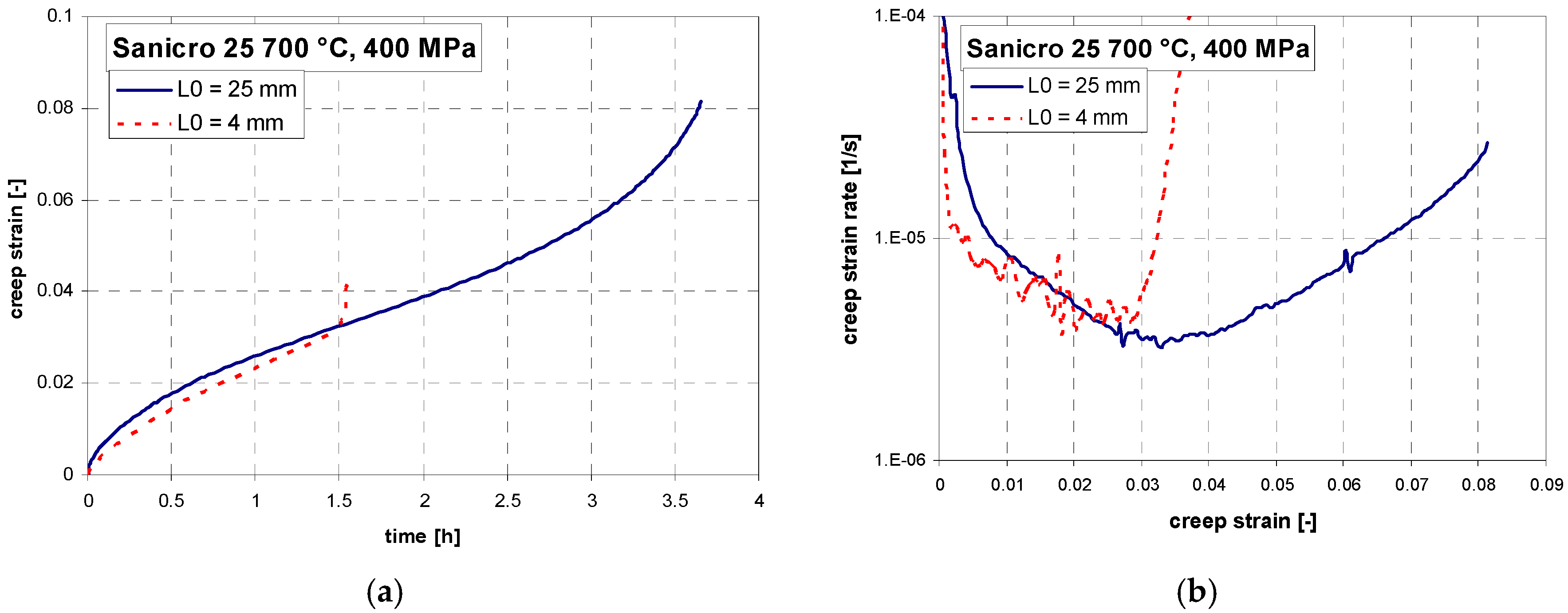

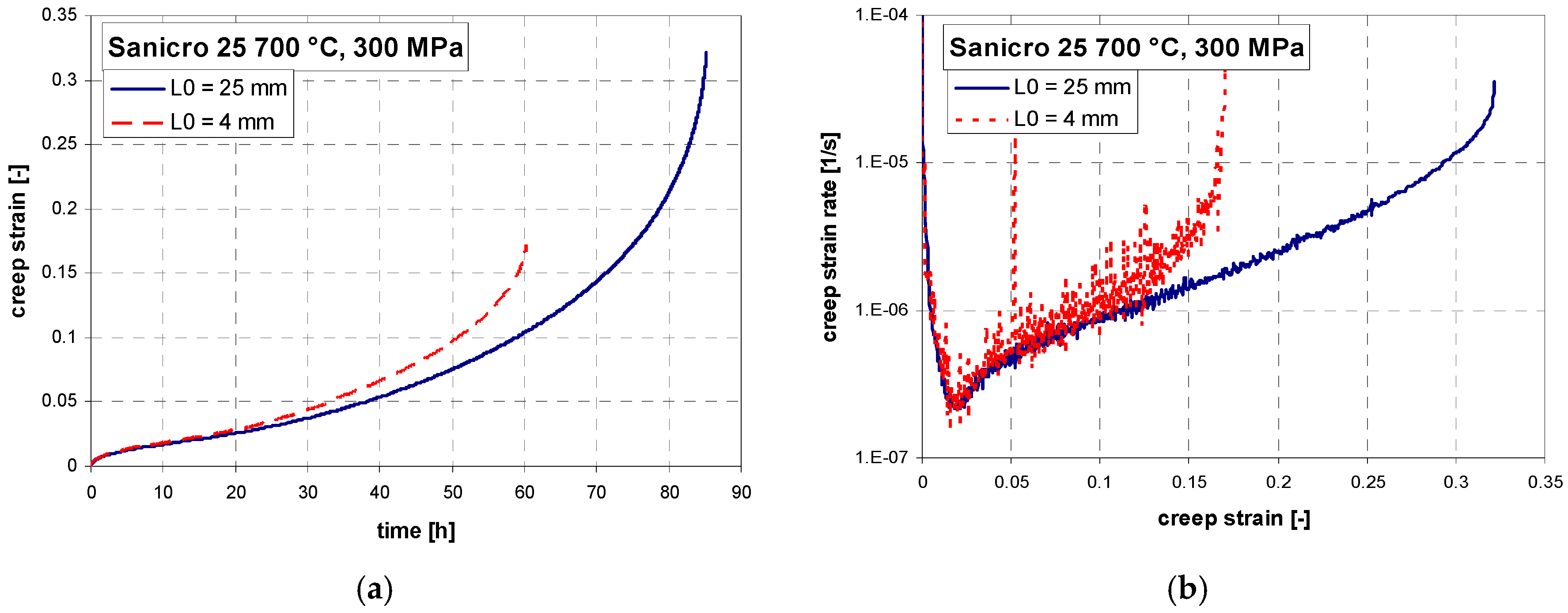

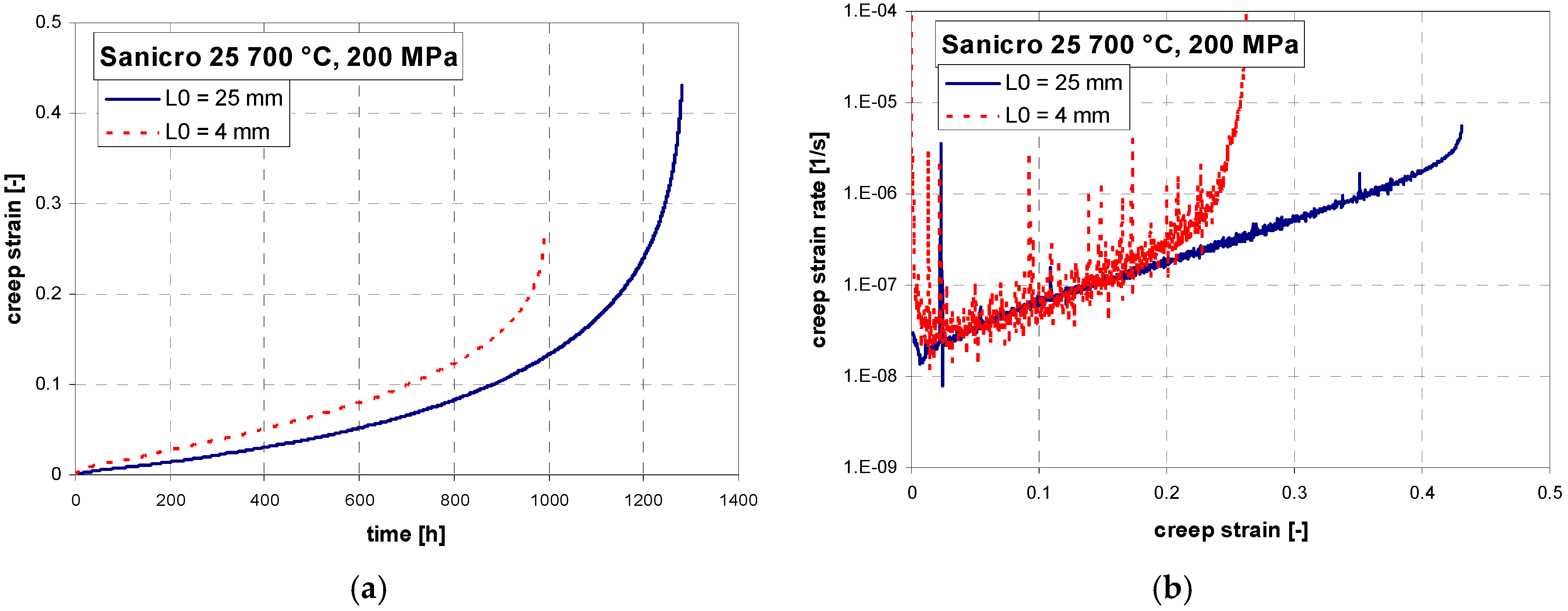

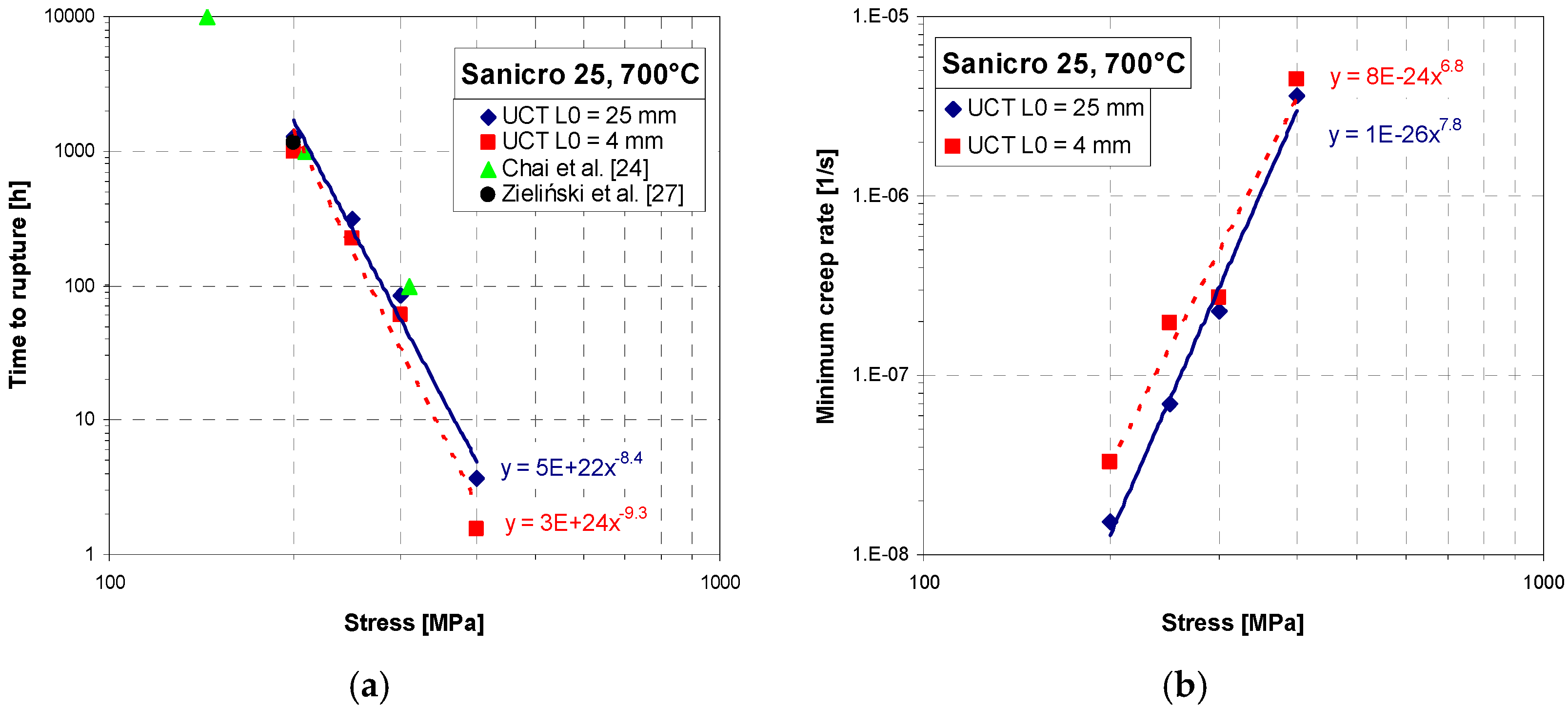

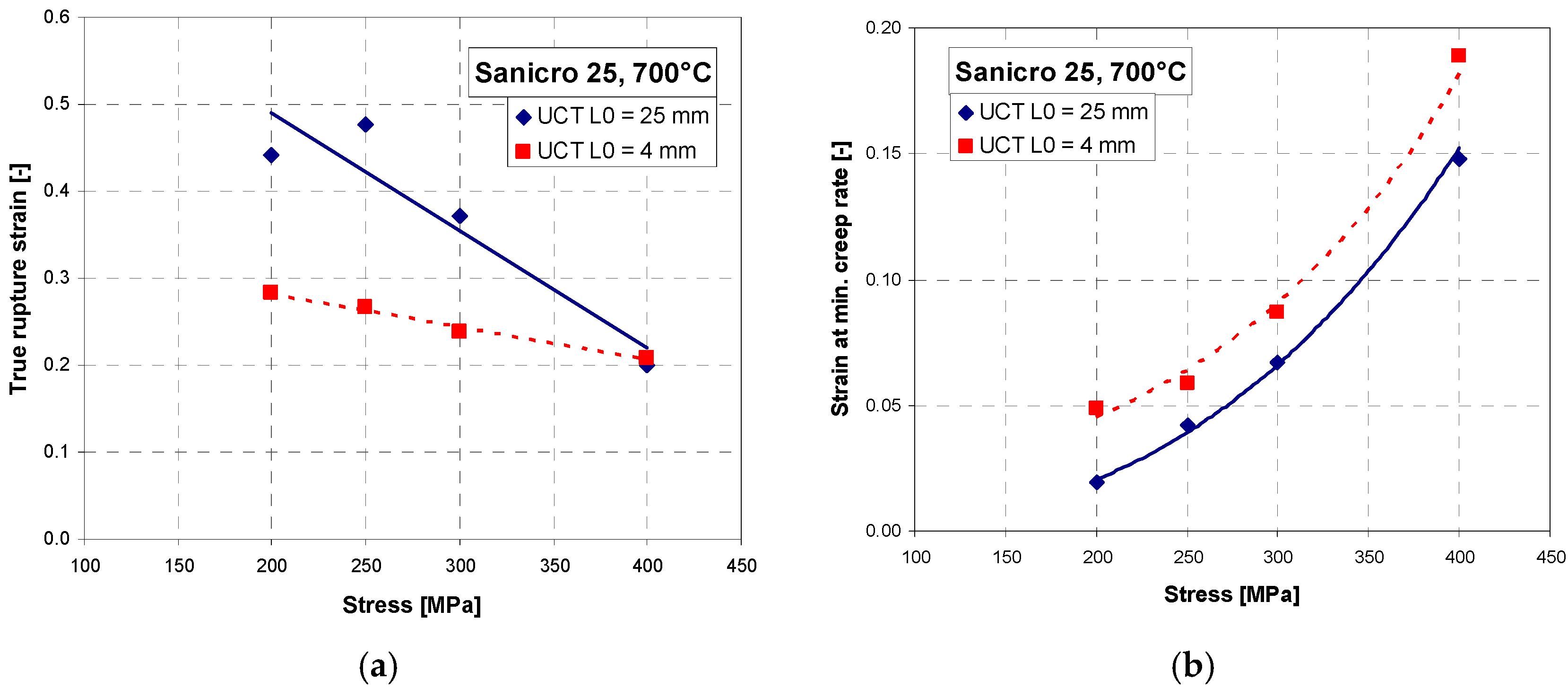

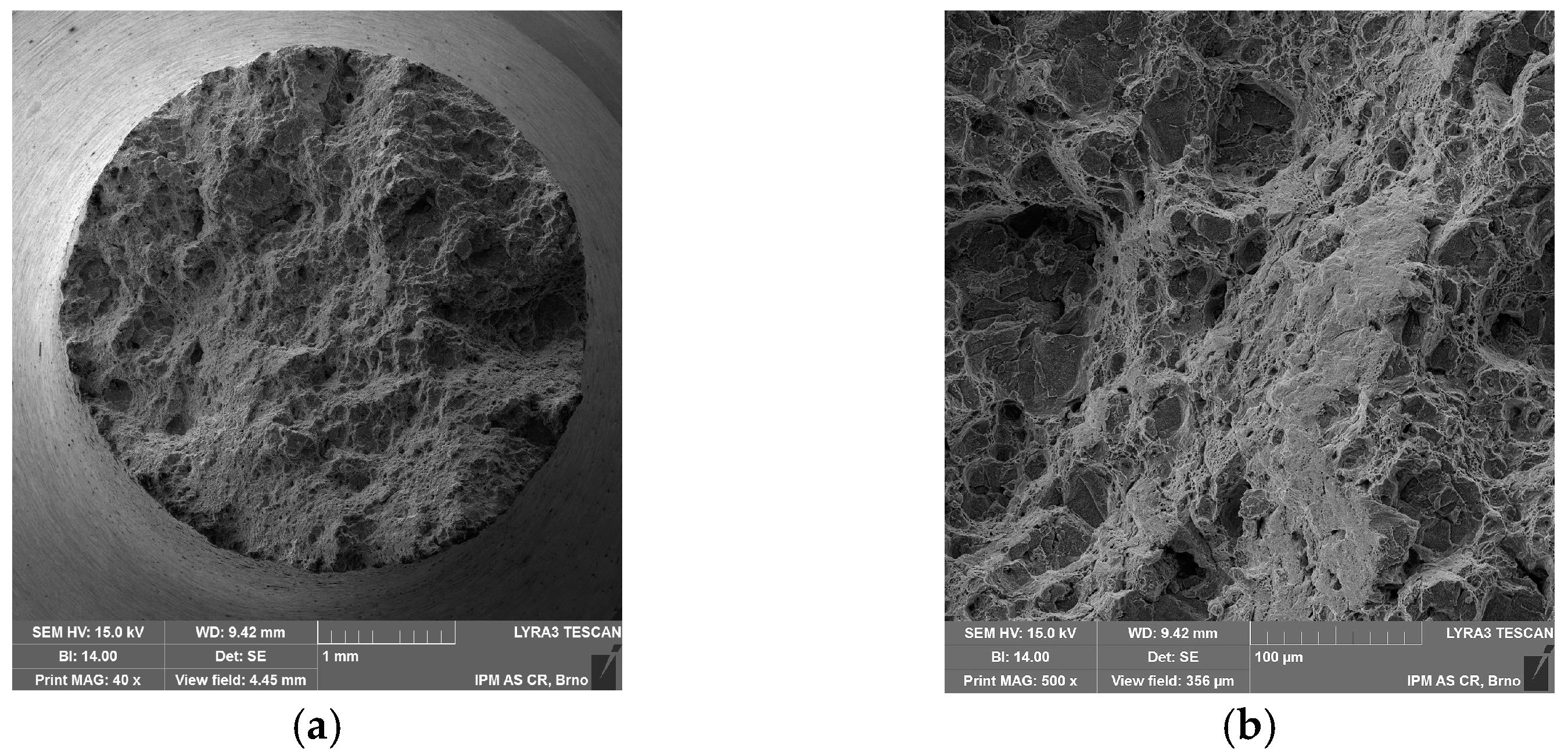

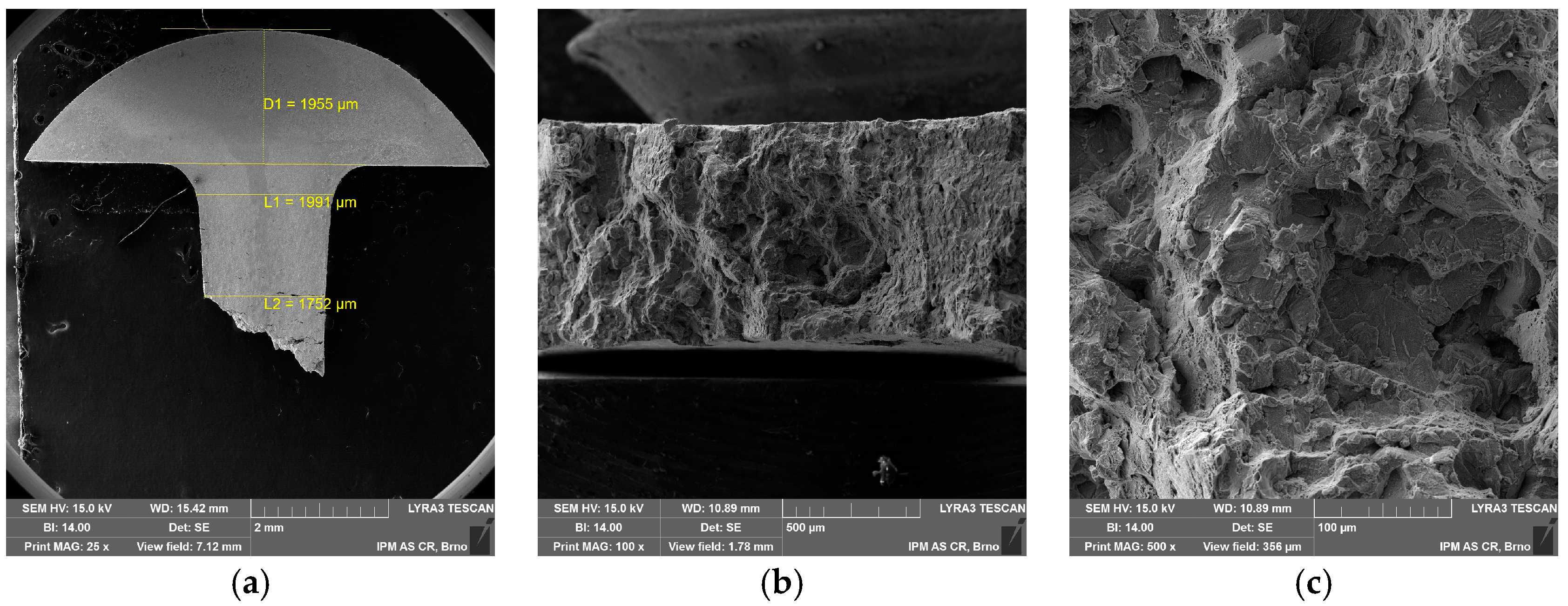

3.2. Creep

3.3. Perspective of Miniature Specimen Testing

4. Conclusions

- Miniature specimens can give very precise estimation of mechanical properties from a very small volume of material

- The creep life of miniature specimens was about 30–40% lower than that of standard ones, and the difference decreased with lower stress, mainly due to lower ductility

- Comparable minimum creep rates at the same stress were obtained from both types of tests

- Special care must be paid if the miniature specimens are prepared by different technology than the standard specimens (here machining and grinding vs. grinding and EDM), since changes in the fracture behavior of the steel at elevated temperature were demonstrated in a small local area.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yuan, J.; Zhang, Z.L.; Su, Y.J.; Qiao, L.J.; Chu, W.Y. Influence of specimen thickness with rectangular cross-section on the tensile properties of structural steels. Mater. Sci. Eng. A 2012, 532, 601–605. [Google Scholar] [CrossRef]

- Olbricht, J.; Bismarck, M.; Skrotzki, B. Characterization of the creep properties of heat resistant 9–12% chromium steels by miniature specimen testing. Mater. Sci. Eng. A 2013, 585, 335–342. [Google Scholar] [CrossRef]

- Cao, L.; Bürger, D.; Wollgramm, P.; Neuking, K.; Eggeler, G. Testing of Ni-base superalloy single crystals with circular notched miniature tensile creep (CNMTC) specimens. Mater. Sci. Eng. A 2018, 712, 223–231. [Google Scholar]

- Kurumlu, D.; Payton, E.J.; Young, M.L.; Schöbel, M.; Requena, G.; Eggeler, G. High-temperature strength and damage evolution in short fiber reinforced aluminum alloys studied by miniature creep testing and synchrotron microtomography. Acta Mater. 2012, 60, 67–78. [Google Scholar] [CrossRef]

- Džugan, J.; Rund, M.; Prantl, A.; Konopík, P. Mini-tensile specimen application for sheets characterization. IOP Conf. Ser. Mater. Sci. Eng. 2017, 179, 012020. [Google Scholar] [CrossRef]

- Džugan, J.; Sibr, M.; Konopík, P.; Procházka, R.; Rund, M. Mechanical properties determination of AM components. IOP Conf. Ser. Mater. Sci. Eng. 2017, 179, 012019. [Google Scholar] [CrossRef]

- European Committee for Standardization. Small Punch Test Method for Metallic Materials, CWA 15627. Part A: A Code of Practice for Small Punch Creep Testing and Part B: A Code of Practice for Small Punch Testing for Tensile and Fracture Behaviour, Documents of CEN WS21; European Committee for Standardization: Brussels, Belgium, 2007. [Google Scholar]

- Milička, K.; Dobeš, F. Small punch testing of P91 steel. Int. J. Press. Vessel. Pip. 2006, 83, 625–634. [Google Scholar] [CrossRef]

- Song, M.; Guan, K.; Qin, W.; Szpunar, J.A. Comparison of mechanical properties in conventional and small punch tests of fractured anisotropic A350 alloy forging flange. Nucl. Eng. Des. 2012, 247, 58–65. [Google Scholar] [CrossRef]

- García, T.E.; Rodríguez, C.; Belzunce, F.J.; Suárez, C. Estimation of the mechanical properties of metallic materials by means of the small punch test. J. Alloys Compd. 2014, 582, 708–717. [Google Scholar] [CrossRef]

- Dymáček, P.; Milička, K. Small punch testing and its numerical simulations under constant deflection force conditions. Strength Mater. 2008, 40, 24–27. [Google Scholar] [CrossRef]

- Dymáček, P.; Seitl, S.; Milička, K.; Dobeš, F. Influence of friction on stress and strain distributions in small punch creep test models. Key Eng. Mater. 2010, 417–418, 561–564. [Google Scholar] [CrossRef]

- Dymáček, P. Recent developments in small punch testing: Applications at elevated temperatures. Theor. Appl. Fract. Mech. 2016, 86, 25–33. [Google Scholar] [CrossRef]

- Dobeš, F.; Dymáček, P. Fracture-based correlation of uniaxial and small punch creep data. Theor. Appl. Fract. Mech. 2016, 86, 34–38. [Google Scholar] [CrossRef]

- Ganesh Kumar, J.; Laha, K. Small Punch Creep deformation and rupture behavior of 316L (N) stainless steel. Mater. Sci. Eng. A 2015, 641, 315–322. [Google Scholar] [CrossRef]

- Wen, Ch.; Xu, T.; Guan, K. Correlation Factor Study of Small Punch Creep Test and Its Life Prediction. Materials 2016, 9, 796. [Google Scholar] [CrossRef] [PubMed]

- Guan, K.; Szpunar, J.A.; Matocha, K.; Wang, D. Study on Temper Embrittlement and Hydrogen Embrittlement of a Hydrogenation Reactor by Small Punch Test. Materials 2017, 10, 671. [Google Scholar] [CrossRef] [PubMed]

- Matocha, K.; Dorazil, O.; Hurst, R. The Present SP Tests for Determining the Transition Temperature TSP on “U” Notch Disc Specimens. Materials 2017, 10, 490. [Google Scholar] [CrossRef] [PubMed]

- Haroush, S.; Moreno, D.; Silverman, I.; Turgeman, A.; Shneck, R.; Gelbstein, Y. The Mechanical Behavior of HAVAR Foils Using the Small Punch Technique. Materials 2017, 10, 491. [Google Scholar] [CrossRef] [PubMed]

- Gülçimen Çakan, B.; Soyarslan, C.; Bargmann, S.; Hähner, P. Experimental and Computational Study of Ductile Fracture in Small Punch Tests. Materials 2017, 10, 1185. [Google Scholar]

- Rund, M.; Procházka, R.; Konopík, P.; Džugan, J.; Folgar, H. Investigation of sample-size influence on tensile test results at different strain rates. Procedia Eng. 2015, 114, 410–415. [Google Scholar] [CrossRef]

- Konopík, P.; Rund, M.; Džugan, J. Investigation of the mechanical behaviour of zirconium alloy at different strain rates using sub-size tensile specimens. In Proceedings of the 6th International Conference on Mechanics and Materials in Design, Ponta Delgada, Portugal, 26–30 July 2015; pp. 277–284. [Google Scholar]

- Konopík, P.; Džugan, J.; Rund, M.; Procházka, R. Determination of local mechanical properties of metal components by hot micro-tensile test. In Proceedings of the International conference METAL2016, Brno, Czech Republic, 25–27 May 2016; pp. 741–746. [Google Scholar]

- Chai, G.; Boström, M.; Olaison, M.; Forsberg, U. Creep and LCF behaviors of newly developed advanced heat resistant austenitic stainless steel for A-USC. Procedia Eng. 2013, 55, 232–239. [Google Scholar] [CrossRef]

- KMM-VIN. Available online: https://www.kmm-vin.info/energy-materials (accessed on 21 December 2017).

- Polák, J.; Petráš, R.; Heczko, M.; Kuběna, I.; Kruml, T.; Chai, G. Low cycle fatigue behavior of Sanicro 25 steel at room and at elevated temperature. Mater. Sci. Eng. A 2014, 615, 175–182. [Google Scholar] [CrossRef]

- Zieliński, A.; Dobrzański, J.; Purzyńska, H.; Sikora, R.; Dziuba-Kałuża, M.; Kania, Z. Evaluation of creep strength of heterogeneous welded joint in HR6W alloy and Sanicro 25 steel. Arch. Metall. Mater. 2017, 62, 2057–2064. [Google Scholar] [CrossRef]

- Rutkowski, B.; Gil, A.; Czyrska-Filemonowicz, A. Microstructure and chemical composition of the oxide scale formed on the Sanicro 25 steel tubes after fireside corrosion. Corros. Sci. 2016, 102, 373–383. [Google Scholar] [CrossRef]

- Polák, J.; Petráš, R.; Heczko, M.; Kruml, T.; Chai, G. Analysis of cyclic plastic response of heat resistant Sanicro 25 steel at ambient and elevated temperatures. Procedia Eng. 2014, 74, 68–73. [Google Scholar] [CrossRef]

- Sroka, M.; Zieliński, A.; Dziuba-Kałuża, M.; Kremzer, M.; Macek, M.; Jasiński, A. Assessment of the Residual Life of Steam Pipeline Material beyond the Computational Working Time. Met. Basel. 2017, 7, 82. [Google Scholar] [CrossRef]

- Zieliński, A.; Golański, G.; Sroka, M. Comparing the methods in determining residual life on the basis of creep tests of low-alloy Cr-Mo-V cast steels operated beyond the design service life. Int. J. Press. Vessel. Pip. 2017, 152, 1–6. [Google Scholar] [CrossRef]

| Element | C | Ni | Cr | W | Co | Cu | Mn |

| wt % | 0.064 | 25.36 | 22.35 | 3.37 | 1.44 | 2.98 | 0.51 |

| Element | Nb | N | Si | N | P | B | Fe |

| wt % | 0.49 | 0.23 | 0.18 | 0.23 | 0.016 | 0.0035 | balance |

| Method/Condition | Ultimate Tensile Strength Rm (MPa) | Proof Yield Strength Rp0.2 (MPa) | ||

|---|---|---|---|---|

| Temperature | RT | 700 °C | RT | 700 °C |

| Miniature tensile test | 804 | 500 | 376 | 238 |

| Standard tensile test | 787 | 514 | 375 | 217 |

| Inspection certificate tensile test | 786 | 514 | 369 | 202 |

| Difference miniature vs. standard | +2.2% | −2.7% | +0.3% | +9.7% |

| Method/Condition | Maximum Force Fm (N) | |

|---|---|---|

| Temperature | RT | 700 °C |

| Miniature tensile test | 1551 | 955 |

| Standard tensile test | 15,450 | 10,086 |

| Ratio Fm standard/Fm miniature | 9.96 | 10.56 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dymáček, P.; Jarý, M.; Dobeš, F.; Kloc, L. Tensile and Creep Testing of Sanicro 25 Using Miniature Specimens. Materials 2018, 11, 142. https://doi.org/10.3390/ma11010142

Dymáček P, Jarý M, Dobeš F, Kloc L. Tensile and Creep Testing of Sanicro 25 Using Miniature Specimens. Materials. 2018; 11(1):142. https://doi.org/10.3390/ma11010142

Chicago/Turabian StyleDymáček, Petr, Milan Jarý, Ferdinand Dobeš, and Luboš Kloc. 2018. "Tensile and Creep Testing of Sanicro 25 Using Miniature Specimens" Materials 11, no. 1: 142. https://doi.org/10.3390/ma11010142

APA StyleDymáček, P., Jarý, M., Dobeš, F., & Kloc, L. (2018). Tensile and Creep Testing of Sanicro 25 Using Miniature Specimens. Materials, 11(1), 142. https://doi.org/10.3390/ma11010142