Tribological Properties of AlSi12-Al2O3 Interpenetrating Composite Layers in Comparison with Unreinforced Matrix Alloy

Abstract

1. Introduction

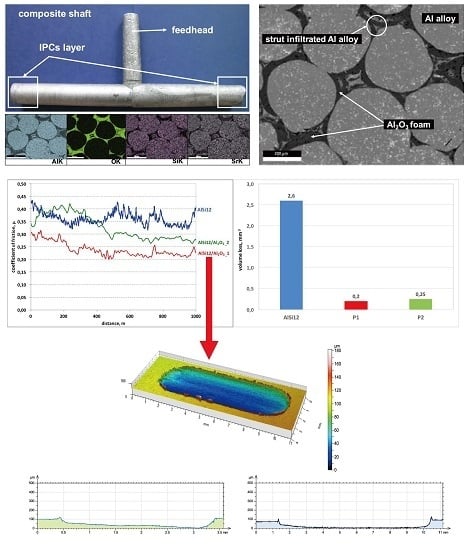

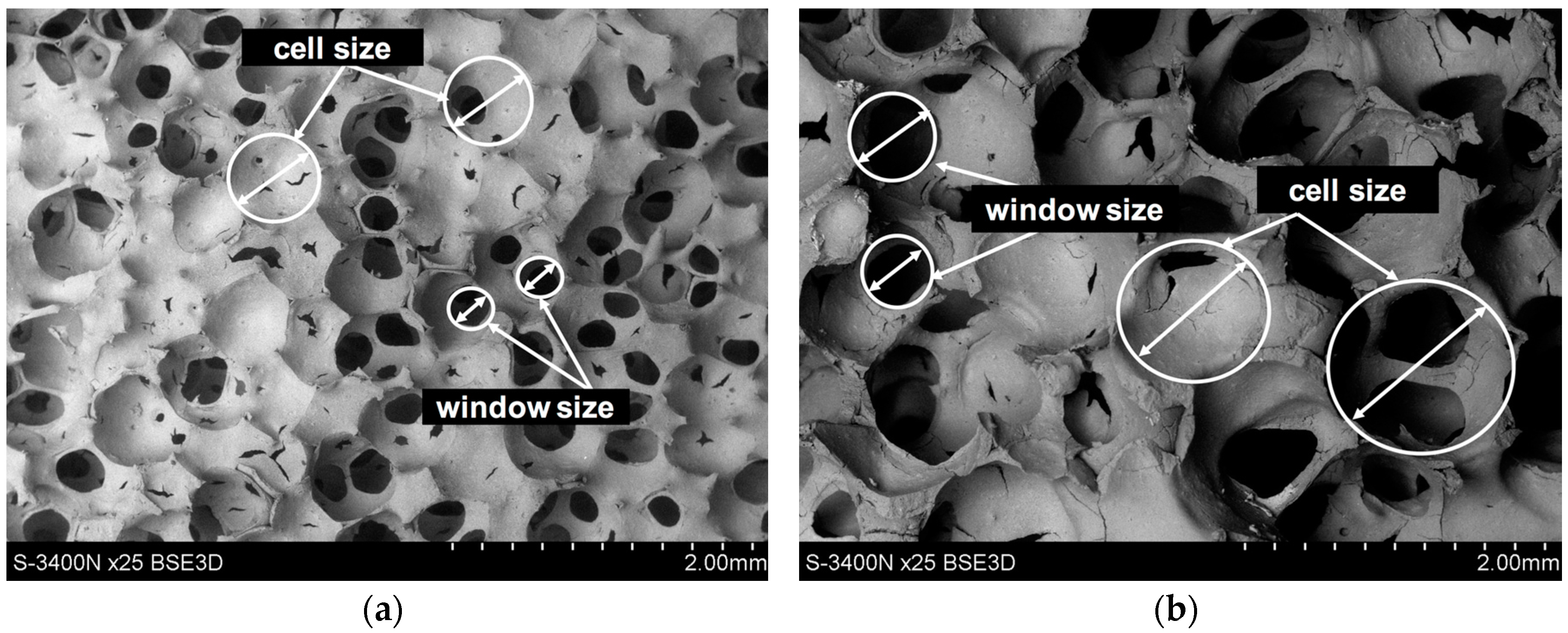

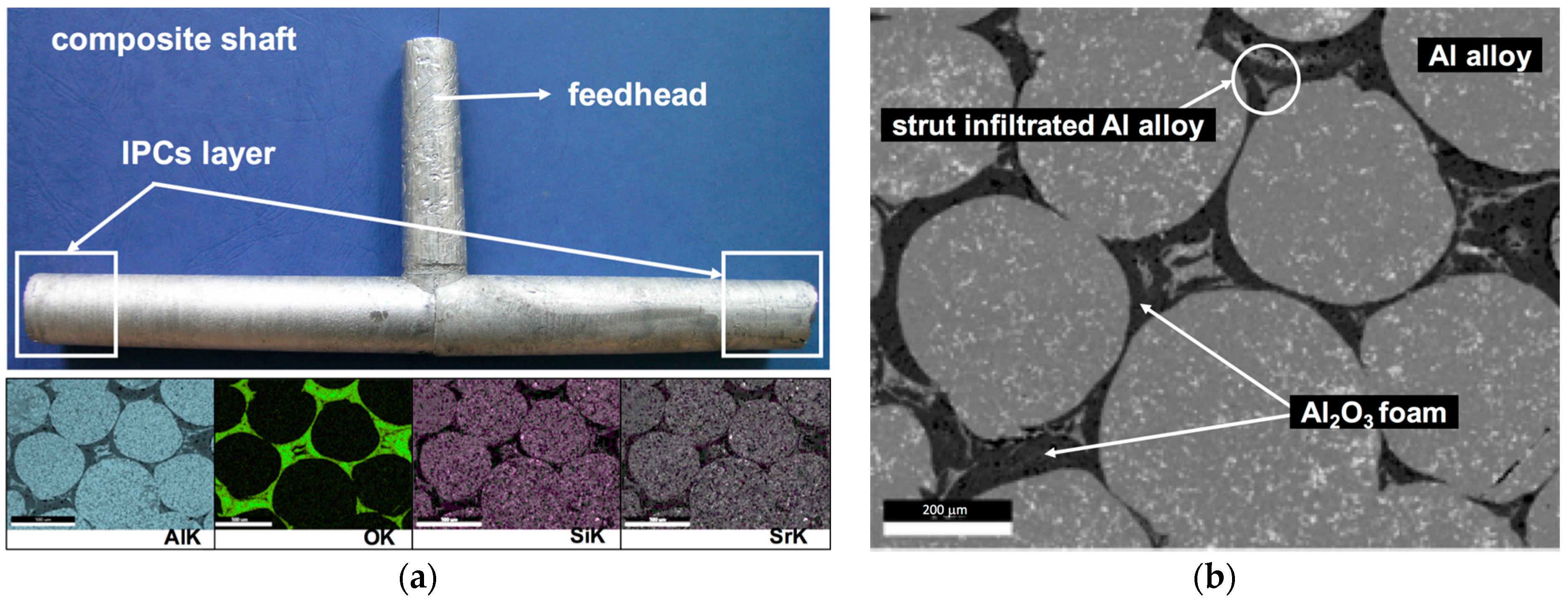

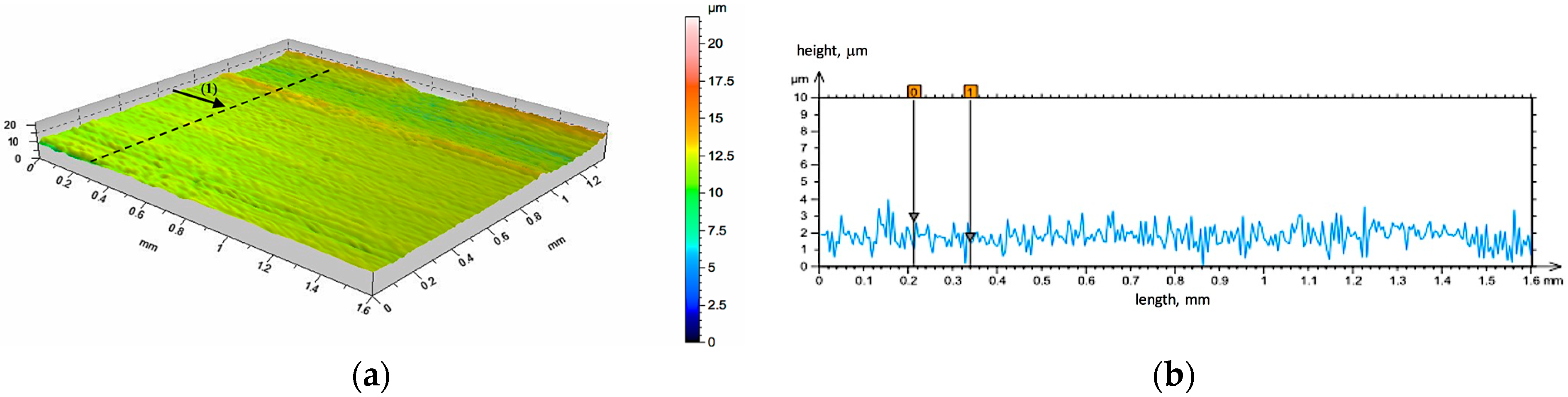

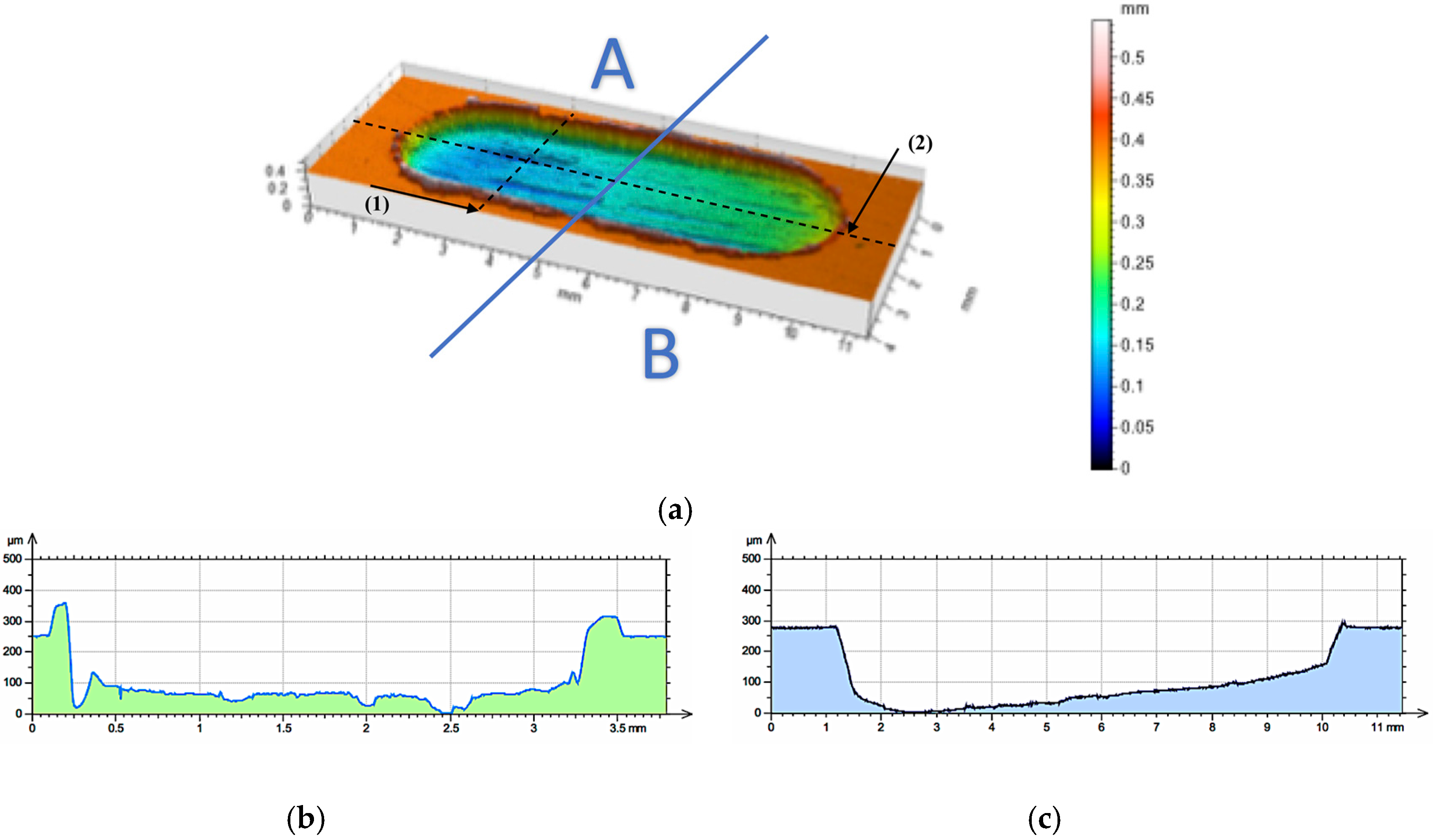

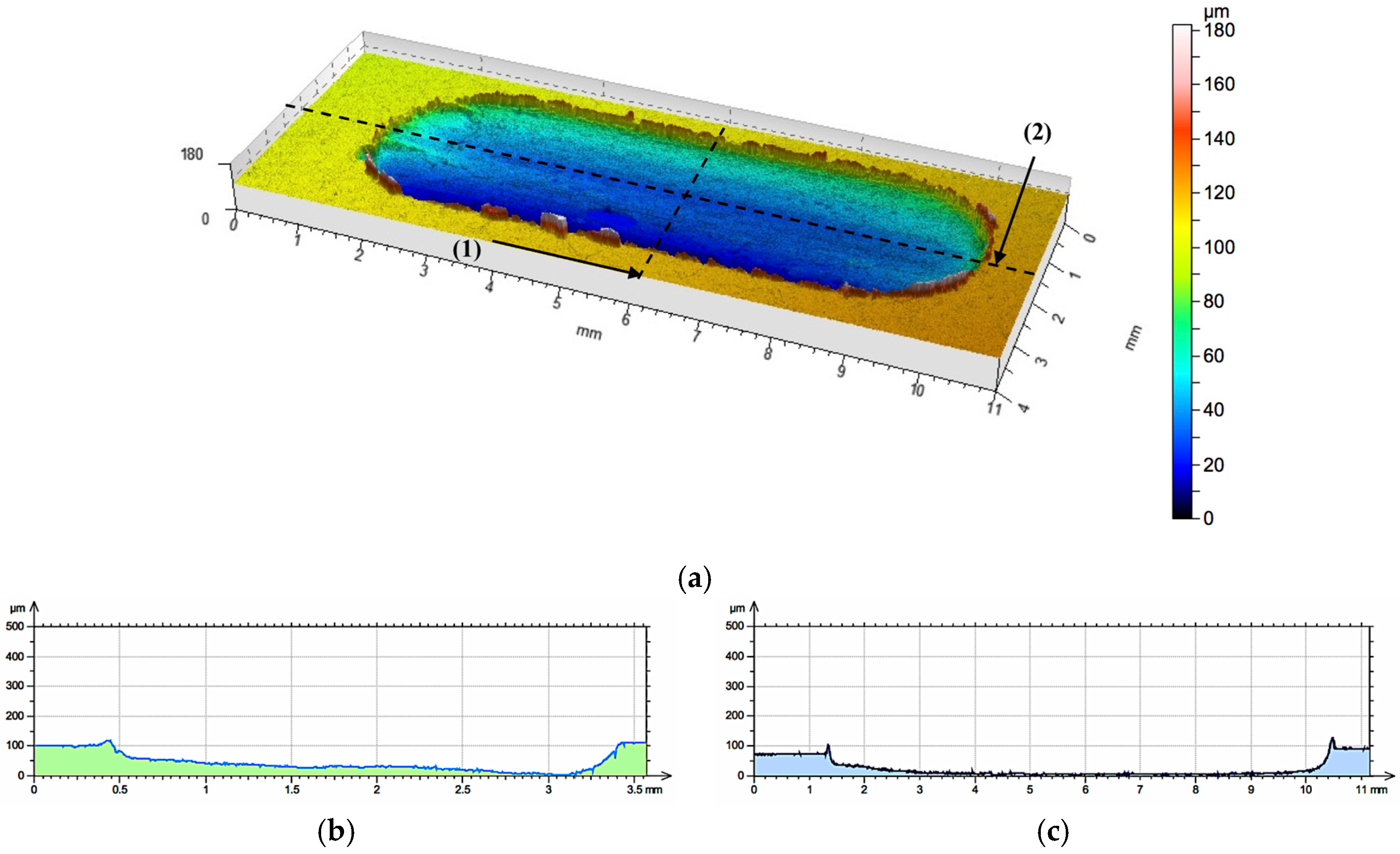

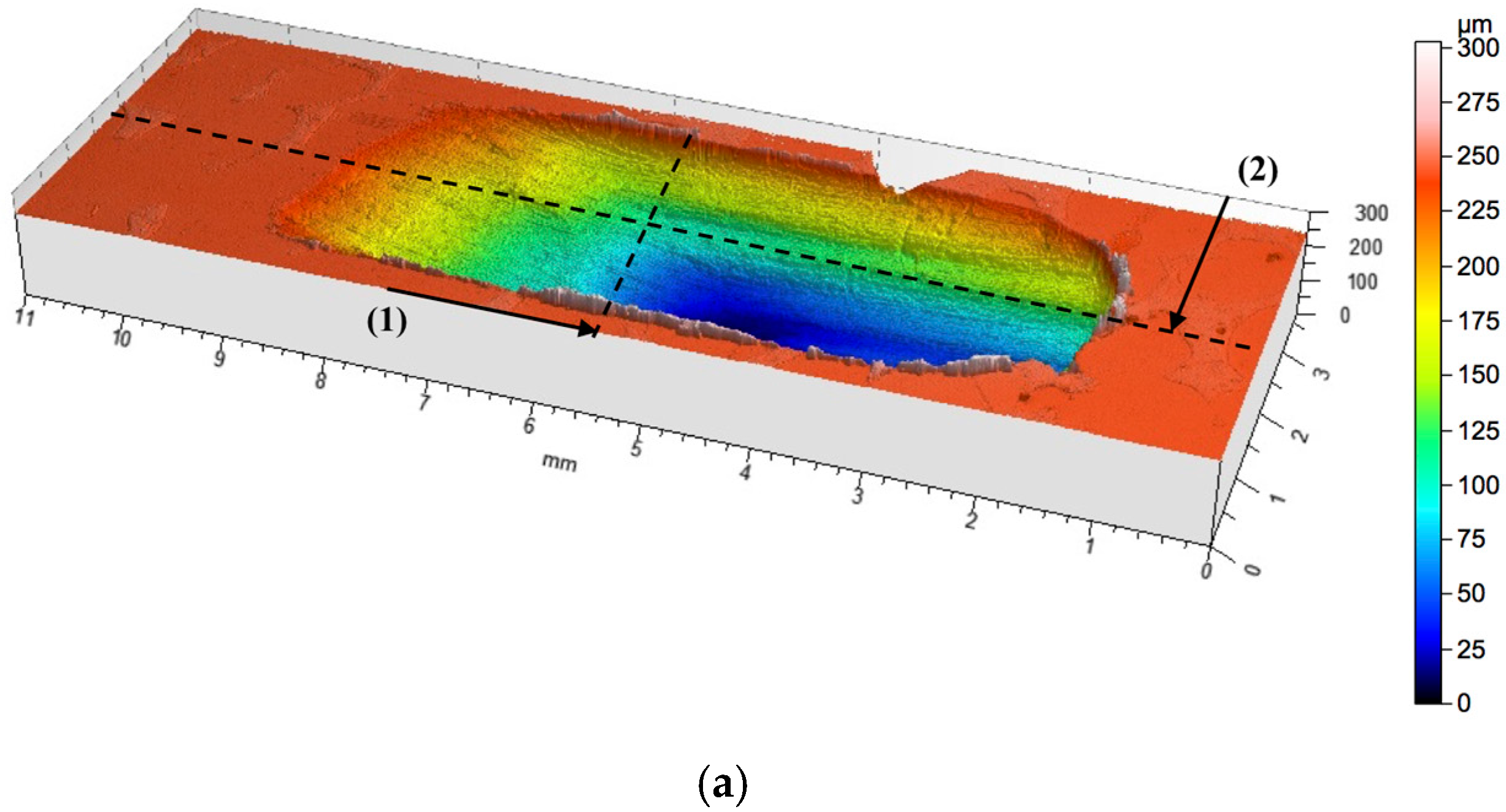

2. Materials and Methods

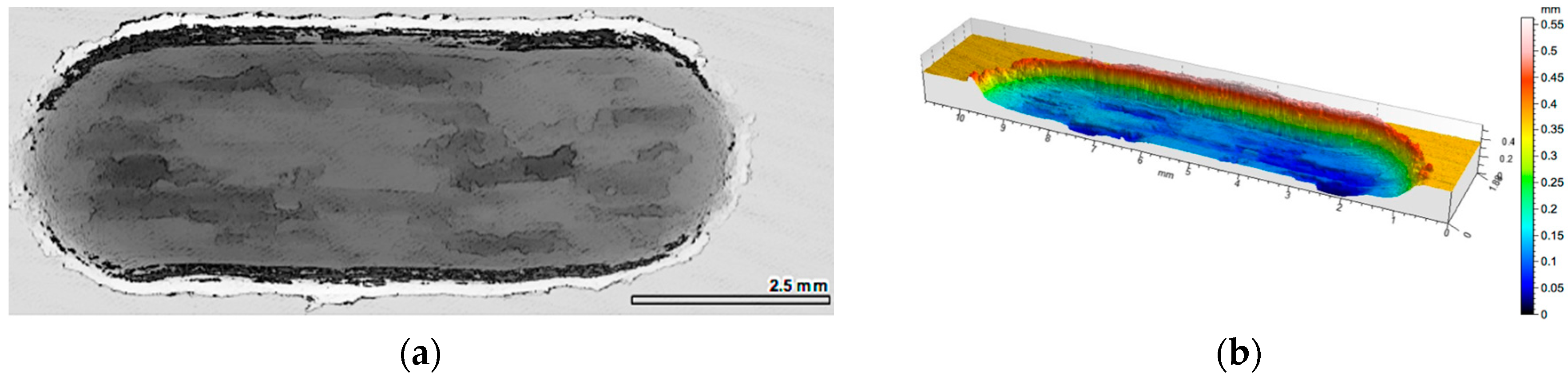

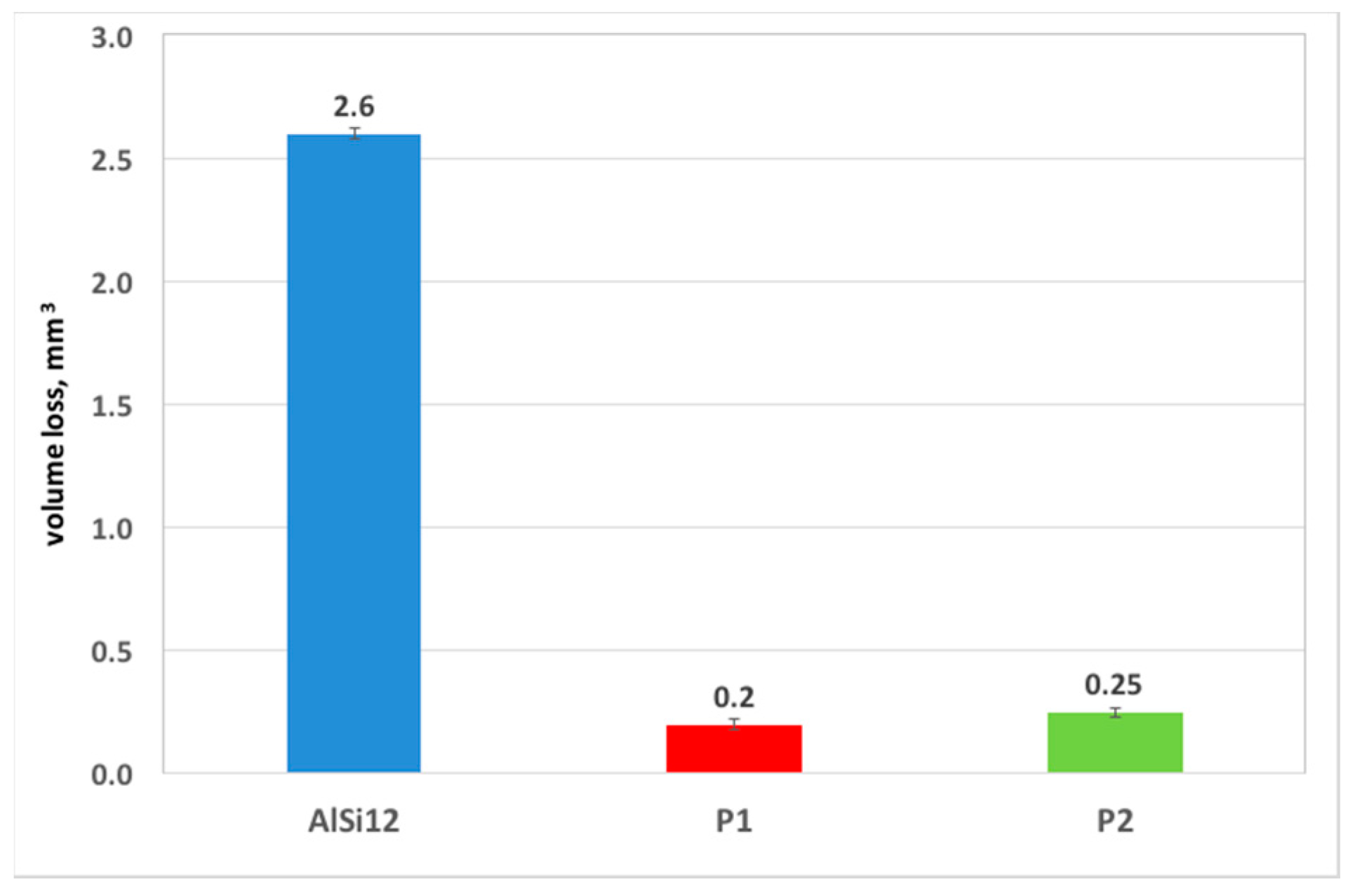

3. Results and Discussion

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Golak, S.; Dyzia, M. Creating local reinforcement of a channel in a composite casting using electromagnetic separation. J. Mater. Sci. Technol. 2015, 31, 918–922. [Google Scholar] [CrossRef]

- Olejnik, E.; Sobula, S.; Tokarski, T.; Sikora, G. Composite zones obtained by in situ synthesis in steel castings. Arch. Metall. Mater. 2013, 58, 769–773. [Google Scholar] [CrossRef]

- Kang, H.G.; Zhang, D.L.; Cantor, B. The microstructures of locally reinforced squeeze-cast Al-alloy metal-matrix composites. J. Microsc. 1993, 169, 239–245. [Google Scholar] [CrossRef]

- Pourmajidian, M.; Akhlagh, F. Fabrication and characterization of functionally graded Al/SiCp composites produced by remelting and sedimentation process. J. Mater. Eng. Perform. 2014, 23, 444–450. [Google Scholar] [CrossRef]

- Sobczak, J.J.; Drenchev, L. Metallic functionally graded materials: A specific class of advanced composites. J. Mater. Sci. Technol. 2013, 29, 297–316. [Google Scholar] [CrossRef]

- Golak, S.; Dolata, A.J. Fabrication of functionally graded composites using a homogenised low-frequency electromagnetic field. J. Compos. Mater. 2016, 50, 1751–1760. [Google Scholar] [CrossRef]

- Ahlatci, H.; Koçer, T.; Candan, E.; Çimenoğlu, H. Wear behaviour of Al/(Al2O3p + SiCp) hybrid composites. Tribol. Int. 2006, 39, 213–220. [Google Scholar] [CrossRef]

- Kaczmar, J.W.; Naplocha, K.; Morgiel, J. Microstructure and strength of Al2O3 and carbon fiber reinforced 2024 aluminum alloy composites. J. Mater. Eng. Perform. 2014, 23, 2801–2808. [Google Scholar] [CrossRef]

- Dyzia, M. AlSi7Mg/SiC and heterophase SiC(p)+C(g) composite for use in cylinder-piston system of air compressor. Solid State Phenom. 2011, 176, 49–54. [Google Scholar] [CrossRef]

- Wieczorek, J.; Dyzia, M.; Dolata, A.J. Machinability of aluminium matrix composites. Solid State Phenom. 2012, 191, 75–80. [Google Scholar] [CrossRef]

- Bodunrin, M.O.; Alaneme, K.K.; Chown, L.H. Aluminium matrix hybrid composites: A review of reinforcement philosophies; mechanical, corrosion and tribological characteristics. J. Mater. Res. Technol. 2015, 4, 434–445. [Google Scholar] [CrossRef]

- Cree, D.; Pugh, M. Dry Wear and Friction Properties of an A356/SiC Foam Interpenetrating Phase Composite. Wear 2011, 272, 88–96. [Google Scholar] [CrossRef]

- Han, G.; Feng, D. Synthesis of SiC/Al Co-Continuous Composite by Spontaneous Melt Infiltration. J. Mater. Sci. Technol. 2000, 16, 466–470. [Google Scholar]

- Zulfia, A.; Hand, R.J. The Production of Al-Mg Alloy/SiC Metal Matrix Composites by Pressureless Infiltration. J. Mater. Sci. 2002, 37, 955–961. [Google Scholar] [CrossRef]

- Rao, S.B.; Jayaram, V. Pressureless Infiltration of Al-Mg Based Alloys into Al2O3 Preforms: Mechanisms and Phenomenology. Acta Mater. 2001, 49, 2373–2385. [Google Scholar]

- Binner, J.; Chang, H.; Higginson, R. Processing of Ceramic-Metal Interpenetrating Composites. J. Eur. Ceram. Soc. 2009, 29, 837–842. [Google Scholar] [CrossRef]

- Potoczek, M.; Sliwa, R.E. Microstructure and Physical Properties of AlMg/Al2O3 Interpenetrating Composites Fabricated by Metal Infiltration into Ceramic Foams. Arch. Metall. Mater. 2011, 56, 1265–1269. [Google Scholar] [CrossRef]

- Gawdzińska, K.; Chybowski, L.; Przetakiewicz, W. Proper matrix-reinforcement bonding in cast metal matrix composites as a factor of their good quality. Arch. Civ. Mech. Eng. 2016, 16, 553–563. [Google Scholar] [CrossRef]

- Peng, H.X.; Fan, Z.; Evans, J.R.G. Bi-Continuous Metal Matrix Composites. Mater. Sci. Eng. A 2001, 303, 37–45. [Google Scholar] [CrossRef]

- Chang, H.; Binner, J.; Higginson, R. Dry Sliding wear behaviour of Al(Mg)/Al2O3 interpenetrating composites produced by a pressureless infiltration technique. Wear 2010, 268, 166–171. [Google Scholar] [CrossRef]

- Chang, H.; Binner, J.; Higginson, R. Dry sliding wear behaviour of co-continuous ceramic foam/aluminium alloy interpenetrating composites produced by pressureless infiltration. Wear 2012, 276, 94–104. [Google Scholar]

- Boczkowska, A.; Chabera, P.; Dolata, A.J.; Dyzia, M.; Kozera, R.; Oziębło, A. Fabrication of Ceramic-Metal Composites with Percolation of Phases Using GPI. Solid State Phenom. 2012, 191, 57–66. [Google Scholar] [CrossRef]

- Boczkowska, A.; Chabera, P.; Dolata, A.J.; Dyzia, M.; Oziębło, A. Porous Ceramic-Metal Composites Obtained by Infiltration Methods. Metalurgija 2013, 52, 345–348. [Google Scholar]

- Gawdzińska, K.; Bryll, K.; Nagolska, D. Influence of heat treatment on abrasive wear resistance of silumin matrix composite castings. Arch. Metall. Mater. 2016, 61, 177–182. [Google Scholar] [CrossRef]

- Hekner, B.; Myalski, J. Correlations between stereological parameters of carbon component and tribological properties of heterophase composites Al-Al2O3+C. Compos. Theory Pract. 2016, 16, 67–73. [Google Scholar]

- Hekner, B.; Myalski, J.; Pawlik, T.; Sopicka-Lizer, M. Effect of carbon in fabrication Al-SiC nanocomposites for tribological application. Materials 2017, 10, 679. [Google Scholar] [CrossRef]

- Dolata, A.J. Structure of aluminium matrix composite with ceramic preform obtained by centrifugal infiltration process. Solid State Phenom. 2014, 212, 7–10. [Google Scholar] [CrossRef]

- Dolata, A.J. Centrifugal castings locally reinforced with porous Al2O3 preform. Arch. Metall. Mater. 2014, 59, 345–348. [Google Scholar] [CrossRef]

- Dolata, A.J. Centrifugal infiltration of porous ceramic preforms by the liquid Al alloy—Theoretical background and experimental verification. Arch. Metall. Mater. 2016, 61, 411–418. [Google Scholar] [CrossRef]

- Dolata, A.J. Fabrication and Structure Characterization of Alumina-Aluminum Interpenetrating Phase Composites. J. Mater. Eng. Perform. 2016, 25, 3098–3106. [Google Scholar] [CrossRef]

- Wieczorek, J. Tribological properties and a wear model of aluminium matrix composites—SiC particles designed for metal forming. Arch. Metall. Mater. 2015, 60, 111–115. [Google Scholar] [CrossRef]

| Designation | Material | Volume of Al2O3 [%] | Pore size [μm] |

|---|---|---|---|

| P0 | AlSi12 matrix | - | - |

| P1 | AlSi12/Al2O3_1 | 22 | 350–550 |

| P2 | AlSi12/Al2O3_2 | 18 | 300–1100 |

© 2017 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dolata, A.J. Tribological Properties of AlSi12-Al2O3 Interpenetrating Composite Layers in Comparison with Unreinforced Matrix Alloy. Materials 2017, 10, 1045. https://doi.org/10.3390/ma10091045

Dolata AJ. Tribological Properties of AlSi12-Al2O3 Interpenetrating Composite Layers in Comparison with Unreinforced Matrix Alloy. Materials. 2017; 10(9):1045. https://doi.org/10.3390/ma10091045

Chicago/Turabian StyleDolata, Anna Janina. 2017. "Tribological Properties of AlSi12-Al2O3 Interpenetrating Composite Layers in Comparison with Unreinforced Matrix Alloy" Materials 10, no. 9: 1045. https://doi.org/10.3390/ma10091045

APA StyleDolata, A. J. (2017). Tribological Properties of AlSi12-Al2O3 Interpenetrating Composite Layers in Comparison with Unreinforced Matrix Alloy. Materials, 10(9), 1045. https://doi.org/10.3390/ma10091045