A Novel Approach to Eliminate the Effect of External Stress on Interdiffusivity Measurement

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Procedure

2.2. Wagner Method for Binary Interdiffusivity Calculation

2.3. Numerical Inverse Method for Binary Interdiffusivity Calculation

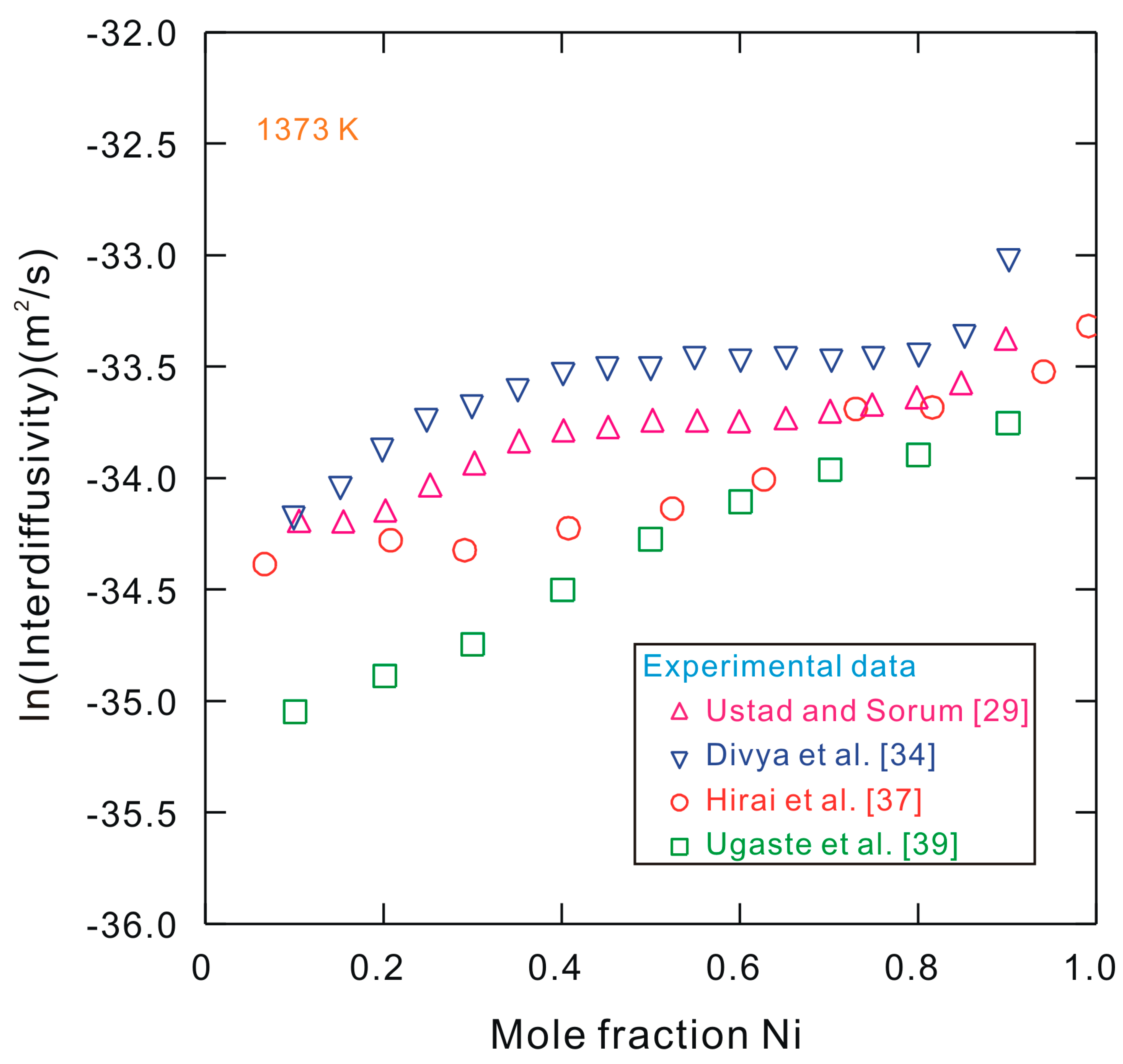

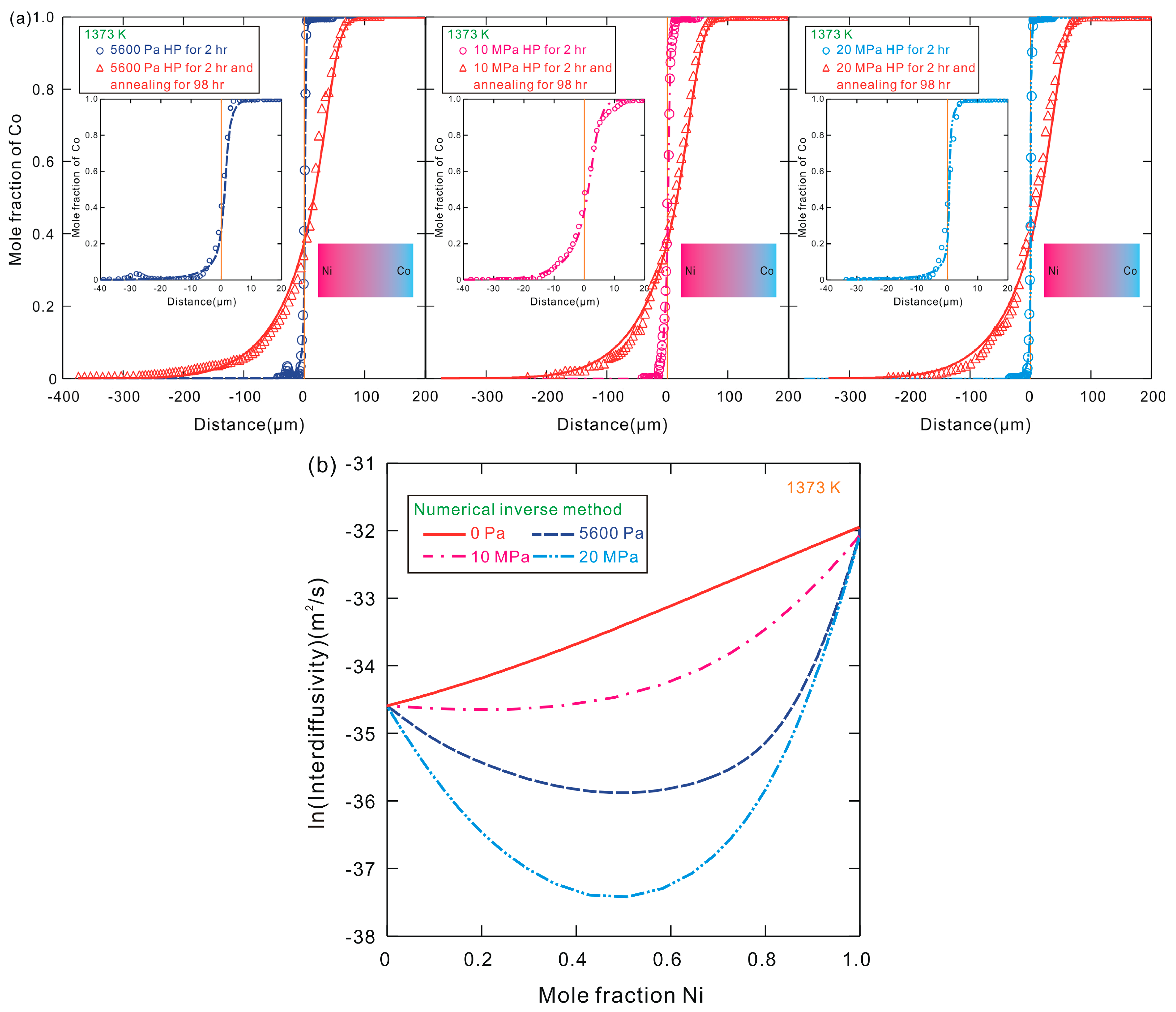

3. Results and Discussion

4. Conclusions

- We pointed out the noticeable influence of different diffusion couple preparation approaches on the determined interdiffusivities, which was neglected in numerous previous studies. Based on the measured composition profiles of binary fcc Co/Ni diffusion couples prepared by different experimental methods, the unified Wagner method was adopted for a quantitative analysis of the effect of different preparation methods.

- We proposed a two-step diffusion couple technique combined with the pragmatic numerical inverse method for obtaining the accurate interdiffusivities without any external stress, and it was successfully demonstrated in binary fcc Co–Ni alloys. Moreover, it should be noted that the variations of composition profiles and/or interdiffusion flux obtained in the first step are also considered in the determination of the interdiffusivity in the second step, which is always neglected prior to this work.

- The proposed novel approach is anticipated to be a generally applicable approach for other binary and multicomponent systems, and the resultant accurate interdiffusivities without any external stress may serve as a benchmark for future experimental and theoretical studies.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Firstenberg, O.; Shuker, M.; Ron, A.; Davidson, N. Colloquium: Coherent diffusion of polaritons in atomic media. Rev. Mod. Phys. 2013, 85, 941–960. [Google Scholar] [CrossRef]

- Krishna, R. Uphill diffusion in multicomponent mixtures. Chem. Soc. Rev. 2015, 44, 2812–2836. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Rong, C.; Lu, T. Electronic forces as descriptors of nucleophilic and electrophilic regioselectivity and stereoselectivity. Phys. Chem. Chem. Phys. 2017, 19, 1496–1503. [Google Scholar] [CrossRef] [PubMed]

- Hayashi, H.; Abe, H. Gel–state dependencies of brown patterns of Mn–Fe-based prussian blue analogues studied by combined X-ray spectroscopies. Bull. Chem. Soc. Jpn. 2017, 90, 807–819. [Google Scholar] [CrossRef]

- Miyabe, K.; Suzuki, N. Moment analysis theory for kinetic study of intermolecular interaction by affinity capillary electrophoresis. Bull. Chem. Soc. Jpn. 2016, 89, 746–753. [Google Scholar] [CrossRef]

- Chiu, W.S.; Belsey, N.A.; Garrett, N.L.; Moger, J.; Delgado-Charro, M.B.; Guy, R.H. Molecular diffusion in the human nail measured by stimulated raman scattering microscopy. Proc. Natl. Acad. Sci. USA 2015, 112, 7725–7730. [Google Scholar] [CrossRef] [PubMed]

- Ganguly, J.; Tirone, M.; Hervig, R.L. Diffusion kinetics of samarium and neodymium in garnet, and a method for determining cooling rates of rocks. Science 1998, 281, 805–807. [Google Scholar] [CrossRef] [PubMed]

- Li, J. Dislocation nucleation: Diffusive origins. Nat. Mater. 2015, 14, 656–657. [Google Scholar] [CrossRef] [PubMed]

- Tao, X.; Wang, J.; Liu, C.; Wang, H.; Yao, H.; Zheng, G.; Seh, Z.W.; Cai, Q.; Li, W.; Zhou, G.; et al. Balancing surface adsorption and diffusion of lithium-polysulfides on nonconductive oxides for lithium-sulfur battery design. Nat. Commun. 2016, 7, 11203. [Google Scholar] [CrossRef] [PubMed]

- Fick, A. Ueber diffusion. Ann. Phys. 1855, 170, 59–86. [Google Scholar] [CrossRef]

- Wang, K.; Wei, M.; Zhang, L. Anomalous halo formation in an arc-melted ScNi-Sc2Ni off-eutectic binary alloy. Materials 2016, 9, 584. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Stratmann, M.; Du, Y.; Sundman, B.; Steinbach, I. Incorporationg the CALPHAD sublattice approach of ordering into the phase-field model with finite interface dissipation. Acta Mater. 2015, 88, 156–169. [Google Scholar] [CrossRef]

- Faupel, F.; Frank, W.; Macht, M.P.; Mehrer, H.; Naundorf, V.; Rätzke, K.; Schober, H.R.; Sharma, S.K.; Teichler, H. Diffusion in metallic glasses and supercooled melts. Rev. Mod. Phys. 2003, 75, 237–280. [Google Scholar] [CrossRef]

- Divinski, S.V.; Reglitz, G.; Golovinb, I.S.; Peterlechner, M.; Lapovok, R.; Estrin, Y.; Wilde, G. Effect of heat treatment on diffusion, internal friction, microstructure and mechanical properties of ultra-fine-grained nickel severely deformed by equal-channel angular pressing. Acta Mater. 2015, 82, 11–21. [Google Scholar] [CrossRef]

- Großberger, S.; Fey, T.; Lee, G. Tortuosity of aligned channels in alumina membranes produced by vacuum—Induced surface directional freezing. Materials 2017, 10, 409. [Google Scholar] [CrossRef] [PubMed]

- Hoo, Y.L.; Jin, W.; Ho, H.L.; Wang, D.N. Measurement of gas diffusion coefficient using photonic crystal fiber. IEEE Photononics Technol. Lett. 2003, 15, 1434–1436. [Google Scholar] [CrossRef]

- Zhao, J.-C. Combinatorial approaches as effective tools in the study of phase diagrams and composition-structure-property relationships. Prog. Mater. Sci. 2006, 51, 557–631. [Google Scholar] [CrossRef]

- Kuhn, P.; Horbach, J.; Kargl, F.; Meyer, A.; Voigtmann, T. Diffusion and interdiffusion in binary metallic melts. Phys. Rev. B 2014, 90, 024309. [Google Scholar] [CrossRef]

- Häusler, I.; Schwarze, C.; Bilal, M.U.; Ramirez, D.V.; Hetaba, W.; Kamachali, R.D.; Skrotzki, B. Precipitation of T1 and θ’ phase in Al-4Cu-1Li-0.25Mn during age hardening: Microstructural investigation and phase-field simulation. Materials 2017, 10, 117. [Google Scholar]

- Li, J.; Chen, W.; Liu, D.; Sun, W.; Zhang, L.; Du, Y.; Xu, H. Interdiffusivities and atomic mobilities in fcc Ni–Cu–Si alloys. J. Phase Equilib. Diffus. 2013, 34, 484–492. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, L.; Du, Y.; Huang, B. Diffusivities and atomic mobilities of an Sn–Ag–Bi–Cu–Pb melt. Int. J. Mater. Res. 2014, 105, 827–839. [Google Scholar] [CrossRef]

- Deng, S.; Chen, W.; Zhong, J.; Zhang, L.; Du, Y.; Chen, L. Diffusion study in bcc_A2 Fe–Mn–Si system: Experimental measurement and CALPHAD assessment. CALPHAD 2017, 56, 230–240. [Google Scholar] [CrossRef]

- Samoila, C.; Ursutiu, D.; Schleer, W.-H.; Jinga, V.; Nascov, V. Using noise and fluctuations for In Situ measurements of nitrogen diffusion depth. Materials 2016, 9, 819. [Google Scholar] [CrossRef] [PubMed]

- Matano, C. The relation between the diffusion coefficients and concentrations of solid metals (the Nickel-Copper system). Jpn. J. Phys. 1933, 8, 109–113. [Google Scholar]

- Chen, W.; Zhang, L.; Du, Y.; Tang, C.; Huang, B. A pragmatic method to determine the composition-dependent interdiffusivities in ternary systems by using a single diffusion couple. Scr. Mater. 2014, 90–91, 53–56. [Google Scholar] [CrossRef]

- Chen, W.; Zhong, J.; Zhang, L. An augmented numerical inverse method for determining the composition-dependent interdiffusivities in alloy systems by using a single diffusion couple. MRS Commun. 2016, 6, 295–300. [Google Scholar] [CrossRef]

- Abdellah, A.B.; Gasser, J.G.; Bouziane, K.; Grosdidier, B.; Busaidi, M. Experimental procedure to determine the interdiffusion coefficient of miscibility gap liquid alloys: Case of GaPb system. Phys. Rev. B 2007, 76, 174203. [Google Scholar] [CrossRef]

- Lechelle, J.; Noyau, S.; Aufore, L.; Arredondo, A.; Audubert, E. Volume interdiffusion coefficient and uncertainty assessment for polycrystalline materials. Diffus. Fundam. 2012, 17, 1–39. [Google Scholar]

- Ustad, T.; Sørum, H. Interdiffusion in the Fe–Ni, Ni–Co, and Fe–Co systems. Phys. Status Solid A 1973, 20, 285–294. [Google Scholar] [CrossRef]

- Whittenberger, J.D.; Dayananda, M.A. Diffusion studies in Cu–Mn alloys at 850 °C. Metall. Trans. 1970, 1, 2023–2025. [Google Scholar] [CrossRef]

- Stalker, M.K.; Morral, J.E.; Romig, A.D., Jr. Application of the square root diffusivity to diffusion in Ni–Cr–Al–Mo alloys. Metall. Mater. Trans. A 1992, 23, 3245–3249. [Google Scholar] [CrossRef]

- Sohn, Y.H.; Dayananda, M.A. A double-serpentine diffusion path for a ternary diffusion couple. Acta Mater. 2000, 48, 1427–1433. [Google Scholar] [CrossRef]

- Zhang, L.; Du, Y.; Ouyang, Y.; Xu, H.; Lu, X.G.; Liu, Y.; Kong, Y.; Wang, J. Atomic mobilities, diffusivities and simulation of diffusion growth in the Co–Si system. Acta Mater. 2008, 56, 3940–3950. [Google Scholar] [CrossRef]

- Divya, V.D.; Ramamurty, U.; Paul, A. Diffusion in Co–Ni system studied by multifoil technique. Defect Diffus. Forum 2011, 312–315, 466–471. [Google Scholar] [CrossRef]

- Divya, V.D.; Ramamurty, U.; Paul, A. Interdiffusion and solid solution strengthening in Ni–Co–Pt and Ni–Co–Fe ternary systems. Philos. Mag. 2013, 93, 2090–2206. [Google Scholar] [CrossRef]

- Xu, H.; Chen, W.; Zhang, L.; Du, Y.; Tang, C. High-throughput determination of the composition-dependent interdiffusivities in Cu-rich fcc Cu–Ag–Sn alloys at 1073 K. J. Alloys Compd. 2015, 644, 687–693. [Google Scholar] [CrossRef]

- Hirai, Y.; Tasaki, Y.; Kosaka, M. A study on the friction-welded diffusion couples-chemical diffusion of Co–Ni alloy at 1100 C. Nagoya Kogyo Gijutso Shikenso Hokoku 1973, 22, 125–131. [Google Scholar]

- Nesbitt, J.A.; Heckel, R.W. Interdiffusion in Ni-rich, Ni–Cr–Al alloys at 1100 and 1200 C Part I. Diffusion paths and microstructures. Metall. Mater. Trans. A 1987, 18, 2061–2073. [Google Scholar] [CrossRef]

- Ugaste, Y.E.; Kodentsov, A.A.; van Loo, F. Compositional dependence of diffusion coefficients in the Co–Ni, Fe–Ni, and Co–Fe systems. Phys. Metals Metallogr. 1999, 88, 88–94. [Google Scholar]

- Chen, W.; Zhang, L. High-throughput determination of interdiffusivities for Co–Cr–Fe–Mn–Ni high-entropy alloys. J. Phase Equilib. Diffus. 2017, 38, 457–465. [Google Scholar] [CrossRef]

- Campbell, C.E. A new technique for evaluating diffusion mobility parameters. J. Phase Equilib. Diffus. 2005, 26, 435–440. [Google Scholar] [CrossRef]

- Divya, V.D.; Ramamurty, U.; Paul, A. Interdiffusion and the vacancy wind effect in Ni–Pt and Co–Pt systems. J. Mater. Res. 2011, 26, 2384–2393. [Google Scholar] [CrossRef]

- Li, Y.; Xin, Y.; Chai, L.; Ma, Y.; Xu, H. Microstructures and shape memory characteristics of dual-phase Co–Ni–Ga high–temperature shape memory alloys. Acta Mater. 2010, 58, 3655–3663. [Google Scholar] [CrossRef]

- Prakash, A.; Bitzek, E. Idealized vs. realistic microstructures: An atomistic simulation case study on γ/γ′ microstructures. Materials 2017, 10, 88. [Google Scholar] [CrossRef] [PubMed]

- Wagner, C. The evaluation of data obtained with diffusion couples of binary single-phase and multiphase systems. Acta Metall. 1962, 66, 353–362. [Google Scholar] [CrossRef]

- Santra, S.; Paul, A. Role of the molar volume on estimated diffusion coefficients. Metall. Mater. Trans. A 2015, 46, 3887–3899. [Google Scholar] [CrossRef]

- Onsager, L. Theories and problems of liquid diffusion. Ann. N. Y. Acad. Sci. 1945, 46, 241–265. [Google Scholar] [CrossRef] [PubMed]

- Morral, J.E. Chemical diffusivities and their hidden concentration units. J. Phase Equilib. Diffus. 2014, 35, 581–586. [Google Scholar] [CrossRef]

- Zhang, L.; Du, Y.; Chen, Q.; Steinbach, I.; Huang, B. Atomic mobilities and diffusivities in the fcc, L12, and B2 phases of the Ni–Al system. Int. J. Mater. Res. 2010, 101, 1461–1475. [Google Scholar] [CrossRef]

- Manning, J.R. Diffusion and the kirkendall shift in binary alloys. Acta Metall. 1967, 15, 817–826. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, L.; Du, Y.; Huang, B. Viscosity and diffusivity in melts: From unary to multicomponent systems. Philos. Mag. 2014, 94, 1552–1577. [Google Scholar] [CrossRef]

- Guillermet, A.F. Assessing the thermodynamics of the Fe–Co–Ni system using a Calphad predictive technique. Calphad 1989, 13, 1–22. [Google Scholar] [CrossRef]

- Pan, G.; Wang, S. Effect of pressure on diffusion of element chromium in nickel during hot isostatic pressing. In Hot Isostatic Pressing—Theory and Applications; Koizumi, M., Ed.; Springer: Dordrecht, The Netherlands, 1992; pp. 269–274. [Google Scholar]

- Zhao, J.-C. Phase diagram determination using diffusion multiples. In Methods for Phase Diagram Determination; Zhao, J.-C., Ed.; Elsevier: New York, NY, USA, 2007; pp. 246–272. [Google Scholar]

- Van Loo, F.J.J.; Rieck, G.D. Diffusion in the titanium-aluminium system—I. Interdiffusion between solid Al and Ti or Ti–Al alloys. Acta Metall. 1973, 21, 61–71. [Google Scholar] [CrossRef]

- Yuan, Y.; Guan, Y.; Li, D.; Moelans, N. Investigation of diffusion behavior in Cu–Sn solid state diffusion couples. J. Alloys Compd. 2016, 661, 282–293. [Google Scholar] [CrossRef]

- Elosegui, I.; Alonso, U.; Lopez de Lacalle, L.N. PVD coatings for thread tapping of austempered ductile iron. Int. J. Adv. Manuf. Technol. 2017, 91, 2663–2672. [Google Scholar] [CrossRef]

- Fernández-Valdivielso, A.; López de Lacalle, L.N.; Urbikain, G.; Rodriguez, A. Detecting the key geometrical features and grades of carbide inserts for the turning of nickel-based alloys concerning surface integrity. Proc. Inst. Mech. Eng. Part C 2016, 230, 3725–3742. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, W.; Li, Q.; Zhang, L. A Novel Approach to Eliminate the Effect of External Stress on Interdiffusivity Measurement. Materials 2017, 10, 961. https://doi.org/10.3390/ma10080961

Chen W, Li Q, Zhang L. A Novel Approach to Eliminate the Effect of External Stress on Interdiffusivity Measurement. Materials. 2017; 10(8):961. https://doi.org/10.3390/ma10080961

Chicago/Turabian StyleChen, Weimin, Qin Li, and Lijun Zhang. 2017. "A Novel Approach to Eliminate the Effect of External Stress on Interdiffusivity Measurement" Materials 10, no. 8: 961. https://doi.org/10.3390/ma10080961

APA StyleChen, W., Li, Q., & Zhang, L. (2017). A Novel Approach to Eliminate the Effect of External Stress on Interdiffusivity Measurement. Materials, 10(8), 961. https://doi.org/10.3390/ma10080961