Carbides Evolution in a Ni-16Mo-7Cr Base Superalloy during Long-Term Thermal Exposure

Abstract

:1. Introduction

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

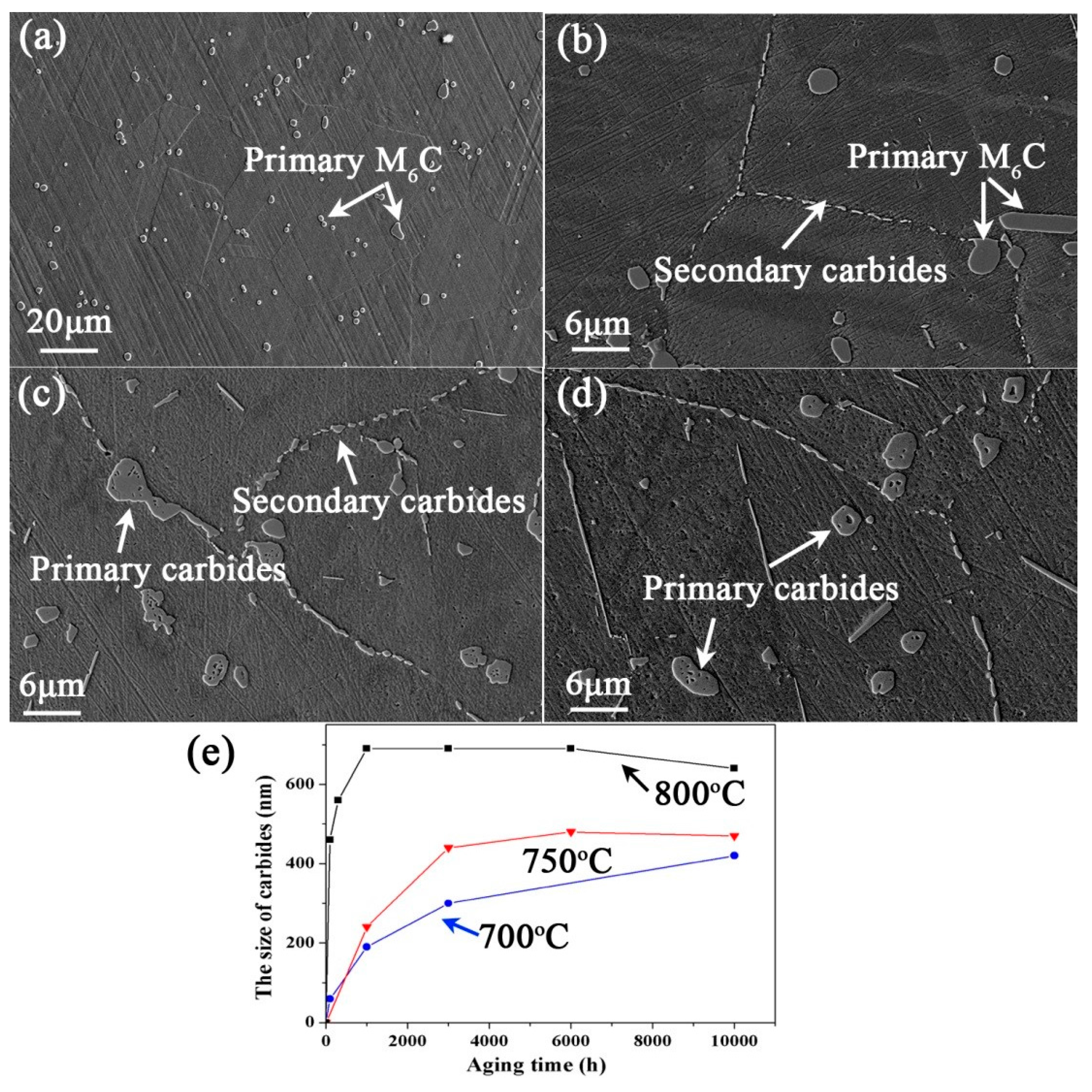

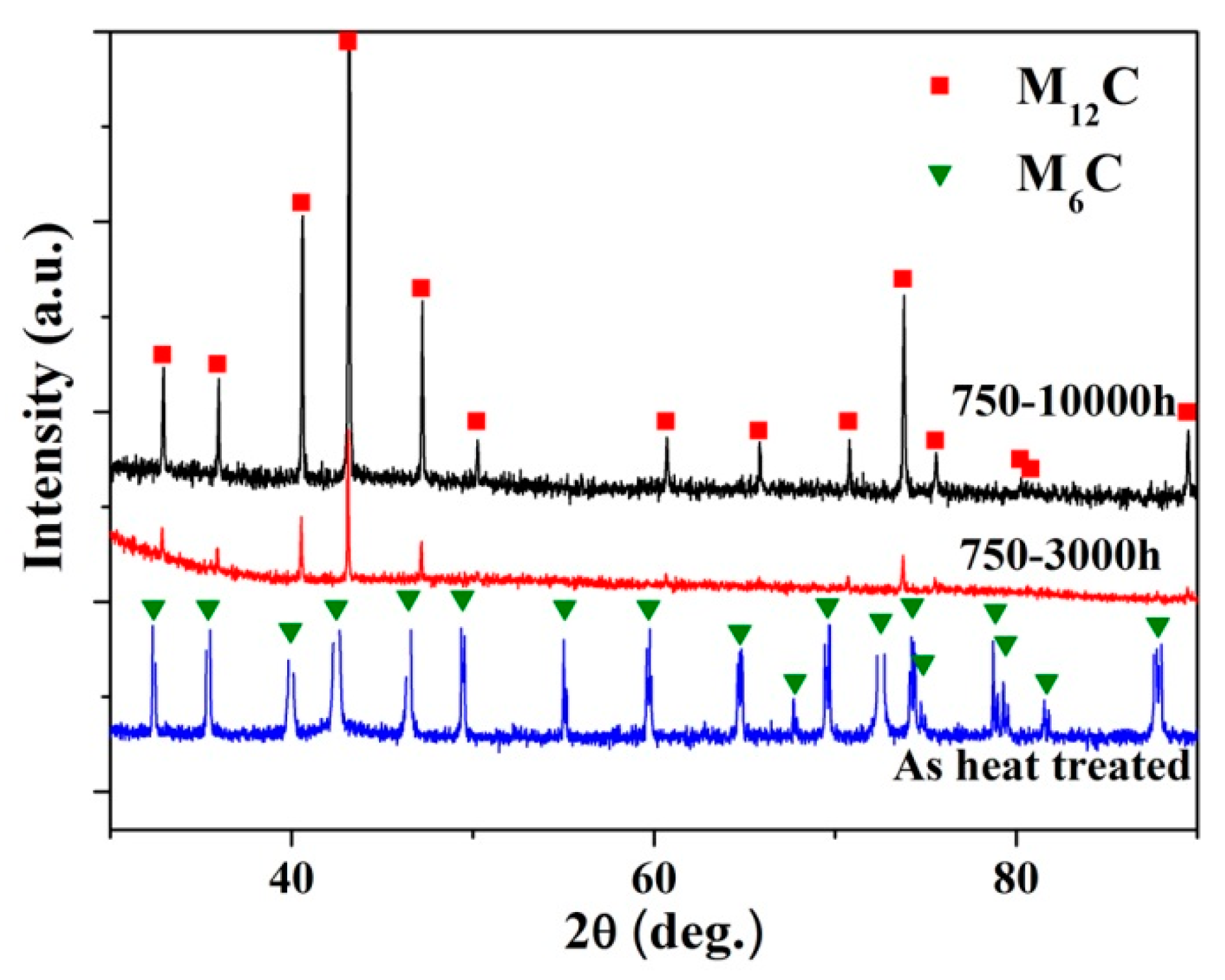

- The secondary M12C carbides are mainly precipitated on the grain boundaries during thermal exposure, and their sizes reach stable state when the alloy is exposed at 750 °C and 800 °C for 3000 h and 1000 h, respectively.

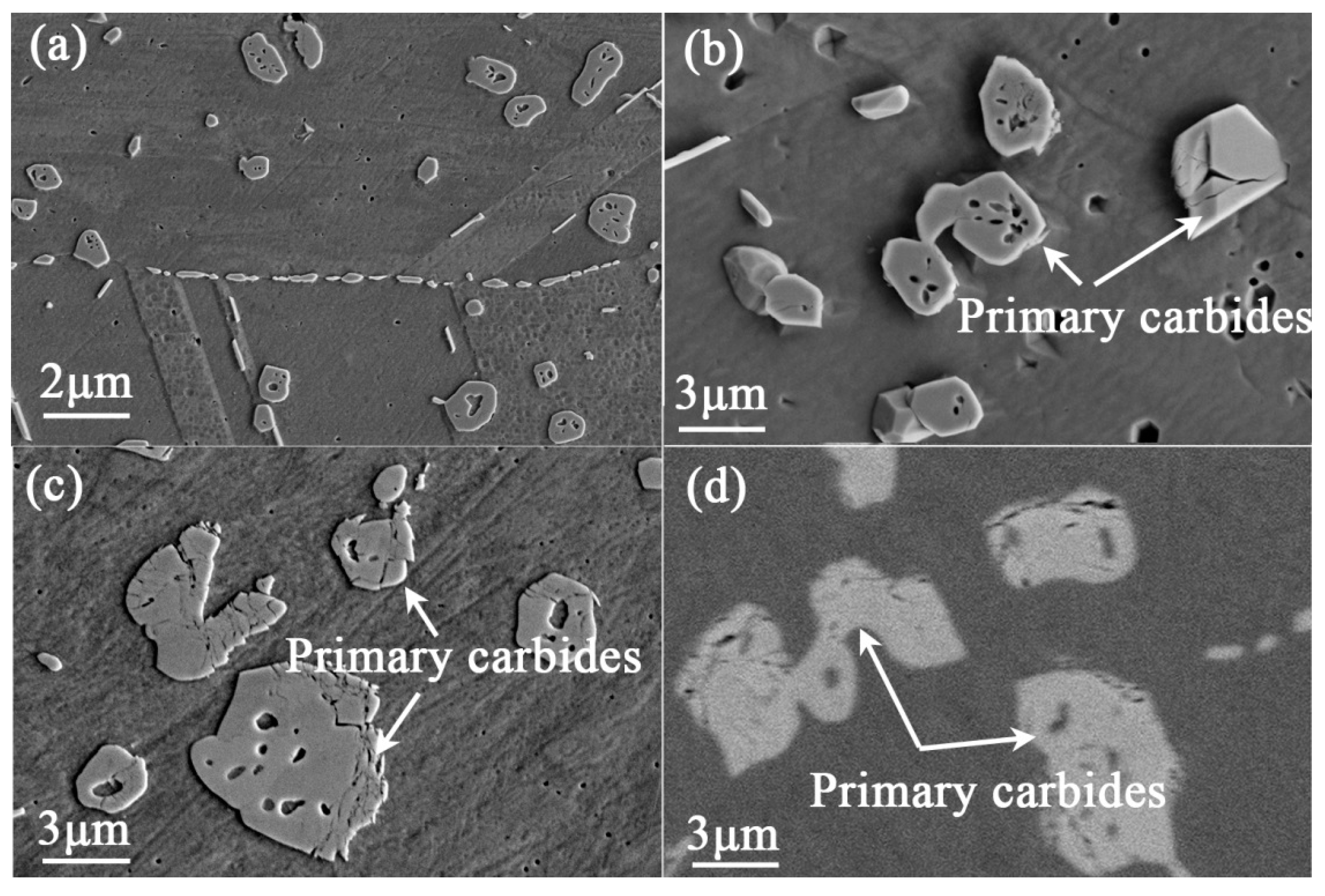

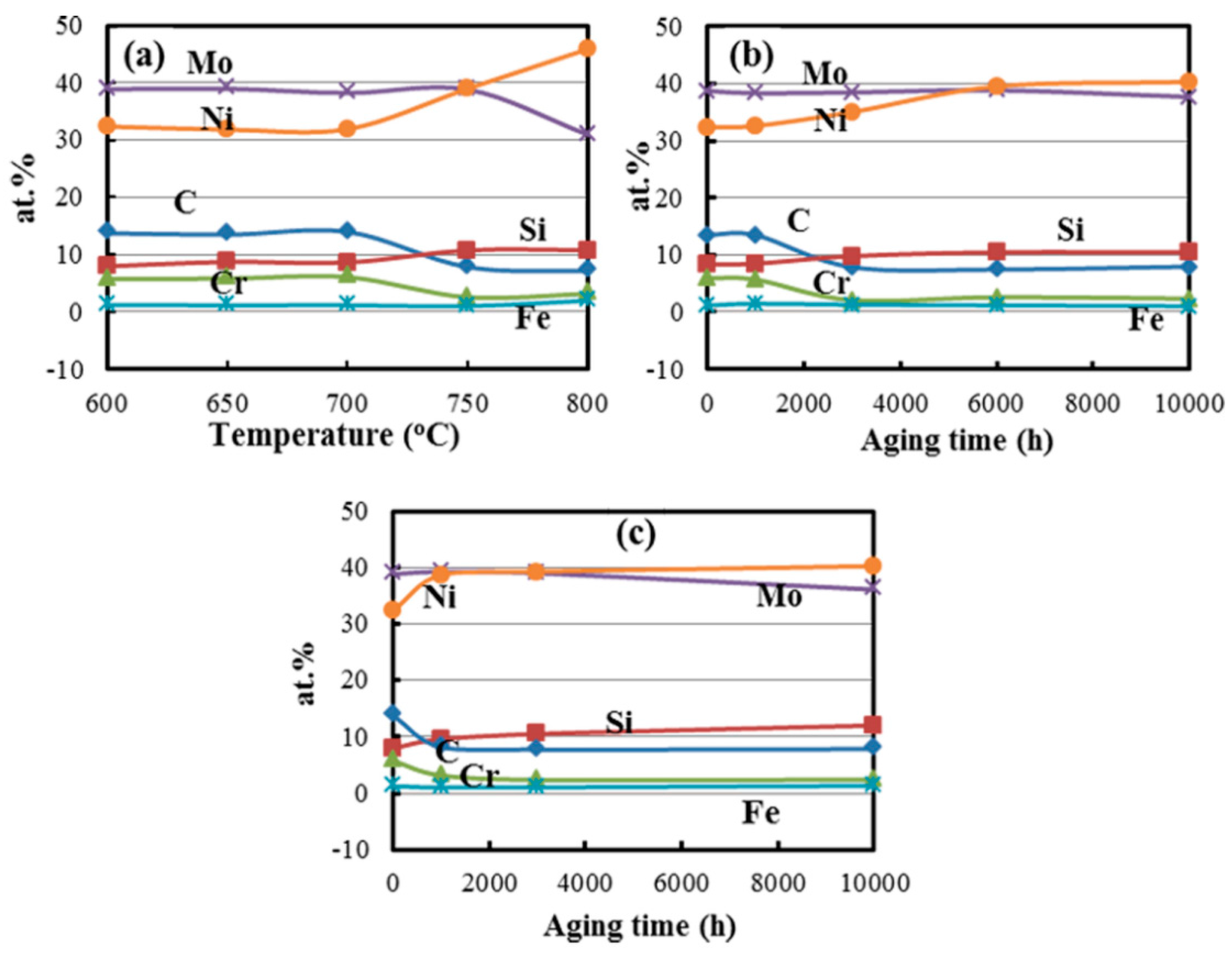

- The primary massive M6C can be completely transformed to M12C in situ at higher temperatures above 750 °C through composition change and lattice reconfiguration.

- The transformation from M6C carbides to M12C carbides is attributed to the release of C atoms from M6C, which results in the morphology changes of massive carbides, and stabilization of the sizes of M12C carbides precipitated on the grain boundaries.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- LeBlanc, D. Molten salt reactors: A new beginning for an old idea. Nucl. Eng. Des. 2010, 240, 1644–1656. [Google Scholar] [CrossRef]

- Mathieu, L.; Heuer, D.; Brissot, R.; Garzenne, C.; LeBrun, C.; Lecarpentier, D.; Liatard, E.; Loiseaux, J.-M.; Méplan, O.; Merle-Lucotte, E.; et al. The thorium molten salt reactor: Moving on from the MSBR. Prog. Nucl. Energ. 2006, 48, 664–679. [Google Scholar] [CrossRef]

- Alekseev, P.N.; Belov, I.A.; Ponomarev-Stepnoi, N.N.; Kukharkin, N.E.; Subbotin, S.A.; Udyanskii, Y.N.; Chibinyaev, A.V.; Shchepetina, T.D.; Fomichenko, P.A. MARS low-power liquid-salt micropellet-fuel reactor. At. Energy 2002, 93, 537–546. [Google Scholar] [CrossRef]

- Li, X.L.; He, S.M.; Zhou, X.T.; Li, Z.J.; Zou, Y.; Li, A.G.; Yu, X.H. Improving oxidation resistance of Ni-16Mo-7Cr-4Fe nickel-based superalloy by yttrium microalloying. Nucl. Sci. Technol. 2015, 26, 33–39. [Google Scholar]

- Shrestha, S.L.; Bhattacharyya, D.; Yuan, G.Z.; Li, Z.J.; Budzakoska-Testonea, E.; De Los Reyesa, M.; Drewa, M.; Edwards, L. Creep resistance and material degradation of a candidate Ni–Mo–Cr corrosion resistant alloy. Mater. Sci. Eng. A 2016, 674, 64–75. [Google Scholar] [CrossRef]

- Hou, J.; Yu, G.J.; Zeng, C.L.; Ai, H.; Xie, R.B.; Chen, Y.J.; Zhou, X.T.; Xie, L.D.; Wang, J.Q. Effects of exposing duration on corrosion performance in weld joint of Ni-Mo-Cr alloy in FLiNaK molten salt. J. Fluorine Chem. 2016, 191, 110–119. [Google Scholar] [CrossRef]

- Liu, T.; Dong, J.S.; Wang, L.; Li, Z.J.; Zhou, X.T.; Lou, L.H.; Zhang, J. Effect of long-term thermal exposure on microstructure and stress rupture properties of GH3535 superalloy. J. Mater. Sci. Technol. 2015, 31, 269–279. [Google Scholar] [CrossRef]

- Gehlbach, R.E.; McCoy, H.E. Phase instability in Hastelloy N. In Proceedings of the International Symposium on Structural Stability in Superalloys, Seven Springs, PA, USA, 4–6 September 1968; pp. 346–366. [Google Scholar]

- Leitnaker, J.M.; Potter, G.A.; Bradley, D.J.; Franklin, J.C.; Laing, W.R. The composition of eta carbide in hastelloy N after aging 10,000 h at 815 °C. Metall. Trans. A 1978, 9, 397–400. [Google Scholar] [CrossRef]

- Han, F.F.; Zhou, B.M.; Huang, H.F.; Leng, B.; Lu, Y.L.; Li, Z.J.; Zhou, X.T. Effect of long-term thermal exposure on the hot ductility behavior of GH3535 alloy. Mater. Sci. Eng. A 2016, 673, 299–306. [Google Scholar] [CrossRef]

- Liu, T.; Dong, J.S.; Wang, L.; Lou, L.H. Effect of silicon on microstructure and stress rupture properties of a corrosion resistant Ni-based superalloy during long term thermal exposure. Mater. Sci. Eng. A 2016, 656, 75–83. [Google Scholar] [CrossRef]

- Fraker, A.C.; Stadelmaier, H.H. The Eta Carbides of Molybdenum–Iron, Molybdenum–Cobalt and Molybdenum–Nickel. Trans. Metall. Soc. AIME 1969, 245, 847–850. [Google Scholar]

- Jiang, L.; Zhang, W.Z.; Xu, Z.F.; Huang, H.F.; Ye, X.X.; Leng, B.; Yan, L.; Li, Z.J.; Zhou, X.T. M2C and M6C carbide precipitation in Ni-Mo-Cr based superalloys containing silicon. Mater. Des. 2016, 112, 300–308. [Google Scholar] [CrossRef]

- Hamar-Thibault, S.; Durand-Charre, M.; Andries, B. Carbide transformations during aging of wear-resistant Cobalt alloys. Metall. Trans. A 1982, 13, 545–550. [Google Scholar] [CrossRef]

- Cho, K.; Schuh, C.A. W-based amorphous phase stable to high temperatures. Acta Mater. 2015, 85, 331–342. [Google Scholar] [CrossRef]

- Newsam, J.M.; Jacobson, A.J.; McCandlish, L.E.; Polizzotti, R.S. The structures of the η-carbides Ni6Mo6C, Co6Mo6C and Co6Mo6C2. J. Solid State Chem. 1988, 75, 296–304. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, F.; Jiang, L.; Ye, X.; Lu, Y.; Li, Z.; Zhou, X. Carbides Evolution in a Ni-16Mo-7Cr Base Superalloy during Long-Term Thermal Exposure. Materials 2017, 10, 521. https://doi.org/10.3390/ma10050521

Han F, Jiang L, Ye X, Lu Y, Li Z, Zhou X. Carbides Evolution in a Ni-16Mo-7Cr Base Superalloy during Long-Term Thermal Exposure. Materials. 2017; 10(5):521. https://doi.org/10.3390/ma10050521

Chicago/Turabian StyleHan, Fenfen, Li Jiang, Xiangxi Ye, Yanling Lu, Zhijun Li, and Xingtai Zhou. 2017. "Carbides Evolution in a Ni-16Mo-7Cr Base Superalloy during Long-Term Thermal Exposure" Materials 10, no. 5: 521. https://doi.org/10.3390/ma10050521

APA StyleHan, F., Jiang, L., Ye, X., Lu, Y., Li, Z., & Zhou, X. (2017). Carbides Evolution in a Ni-16Mo-7Cr Base Superalloy during Long-Term Thermal Exposure. Materials, 10(5), 521. https://doi.org/10.3390/ma10050521