Behaviour of Corroded Single Stud Shear Connectors

Abstract

:1. Introduction

2. Experimental Investigation

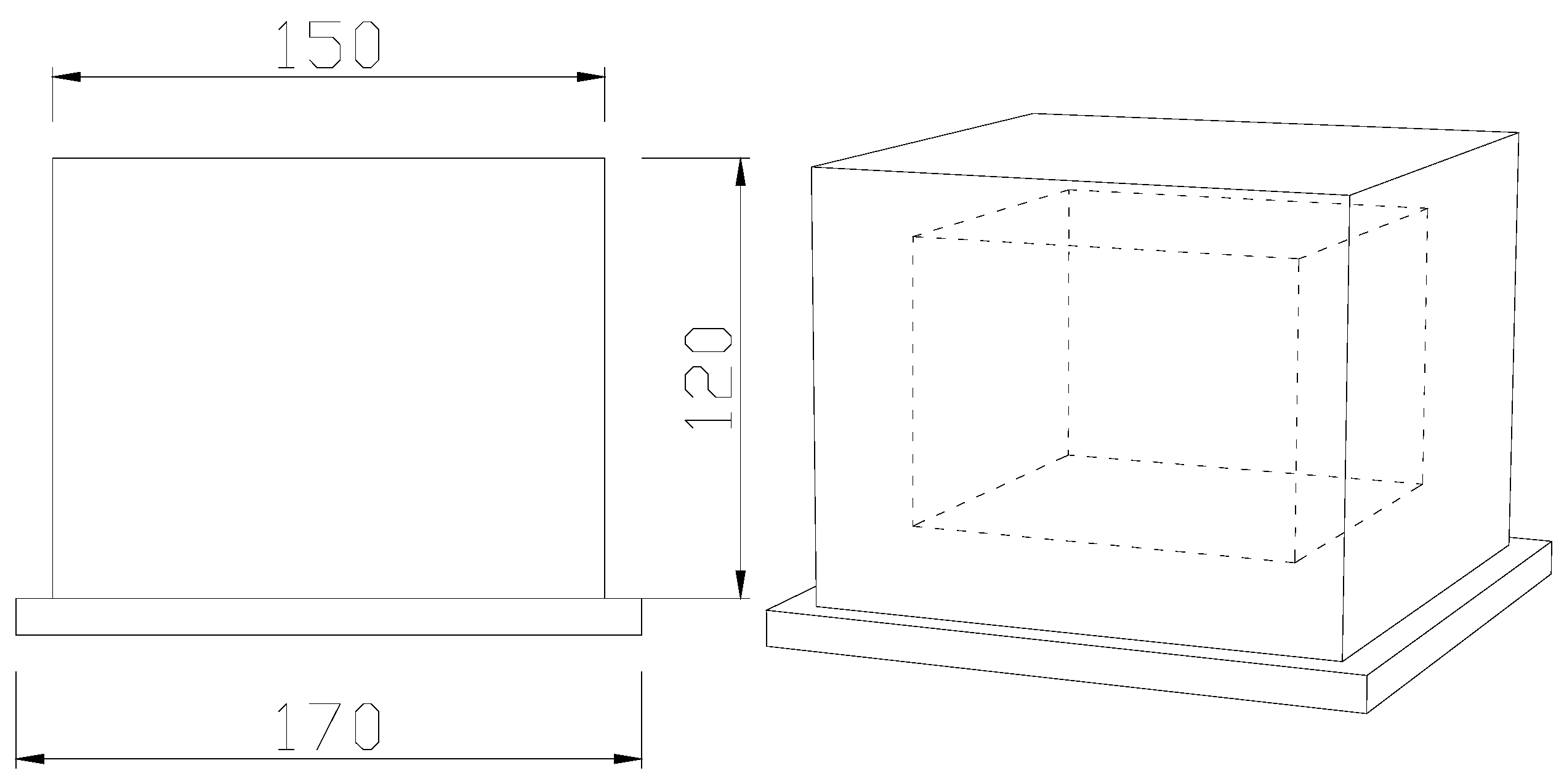

2.1. Test Specimens

- The first letter indicate that the designed corrosion state, where the prefix letter “W” refers to corrosion along the whole stud shank, while the letter “B” refer to corrosion only at the bottom of the stud shank.

- The following three digits (10.0 and 13.0) indicate the nominal diameter of the studs in mm.

- The following one (5) or two digits (10) are the expected corrosion rates of the stud in percentage.

2.2. Material Properties and Measurements

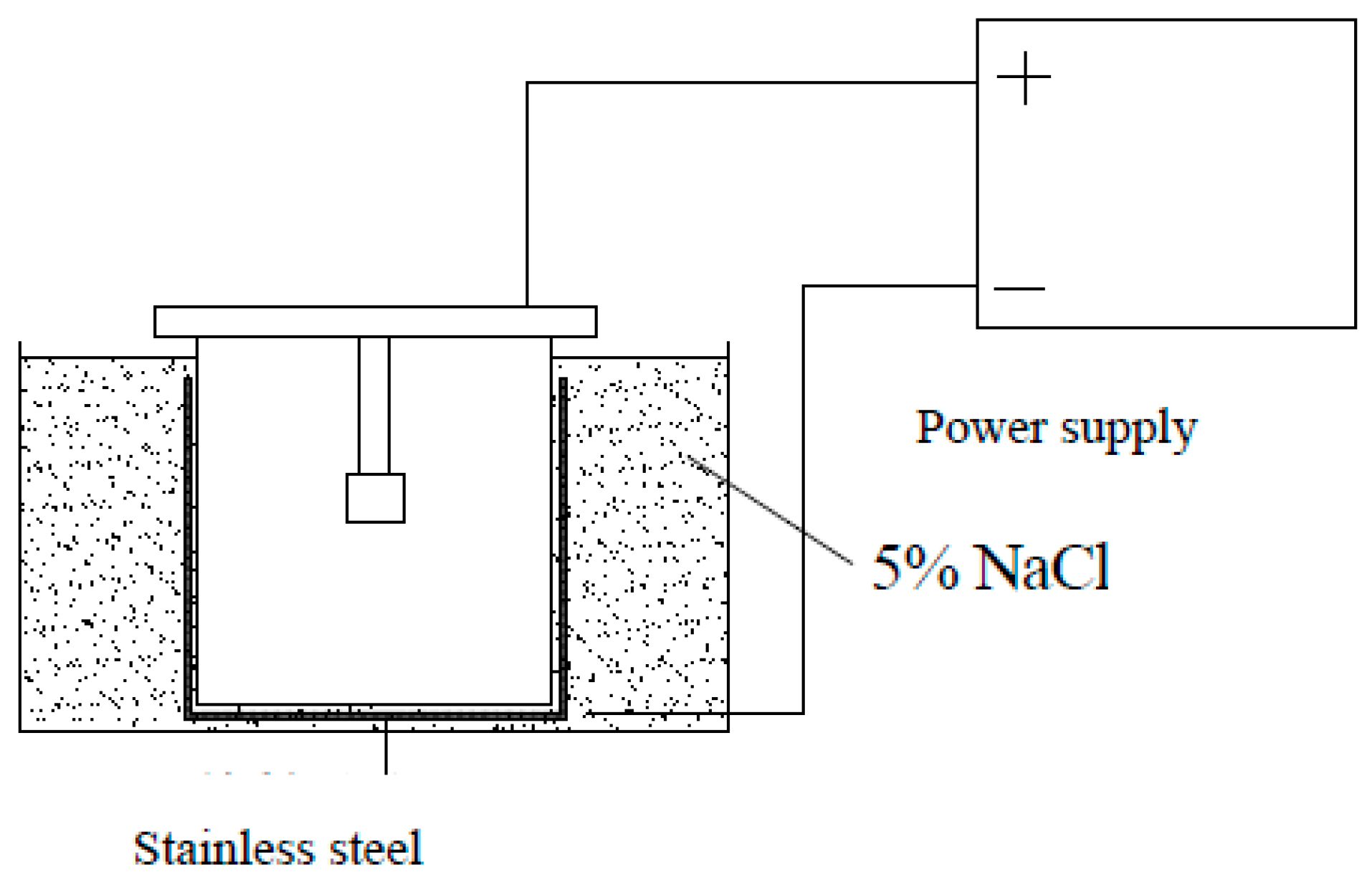

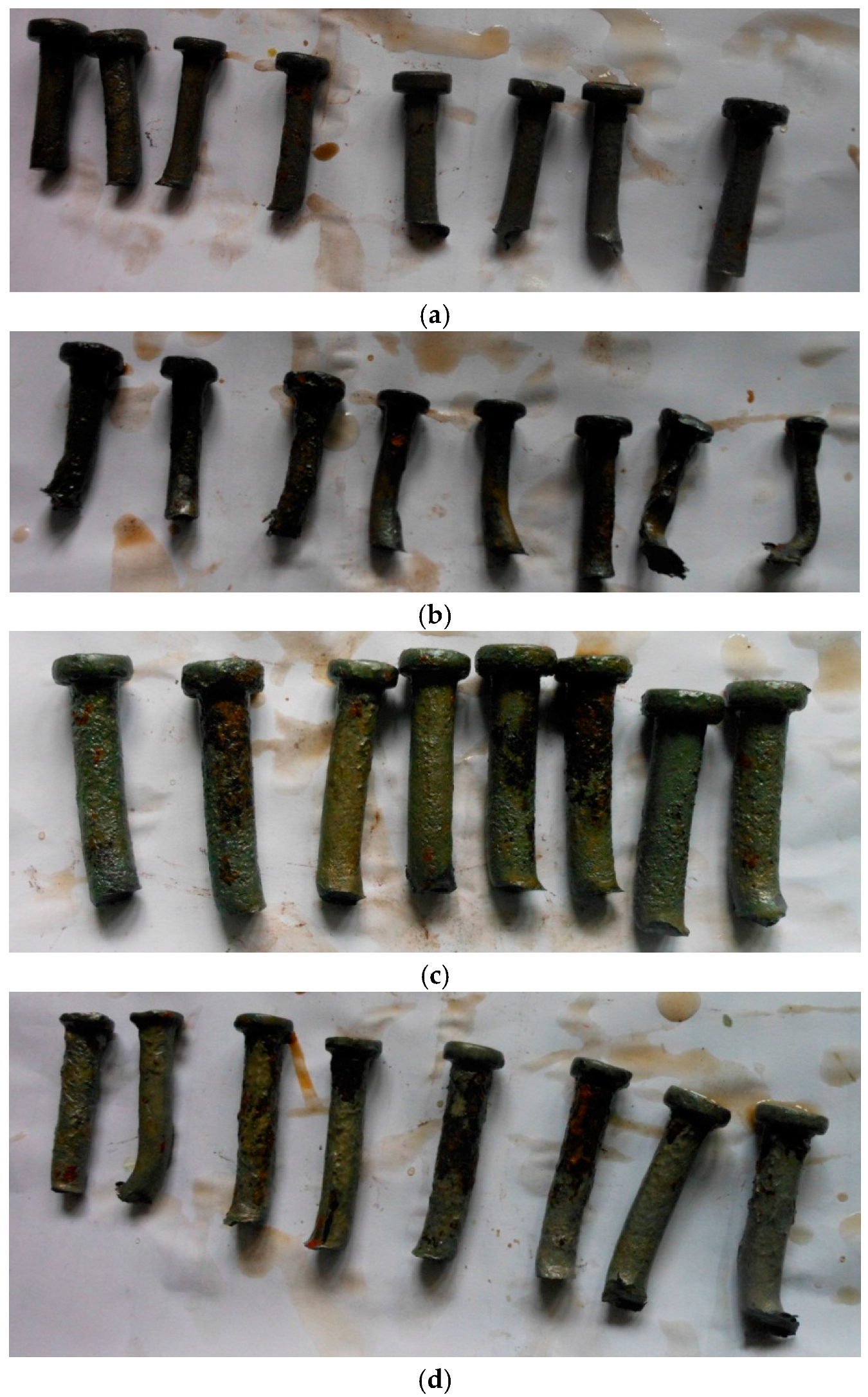

2.3. Accelerating Corrosion Process

2.4. Loading Test Setup and Procedure

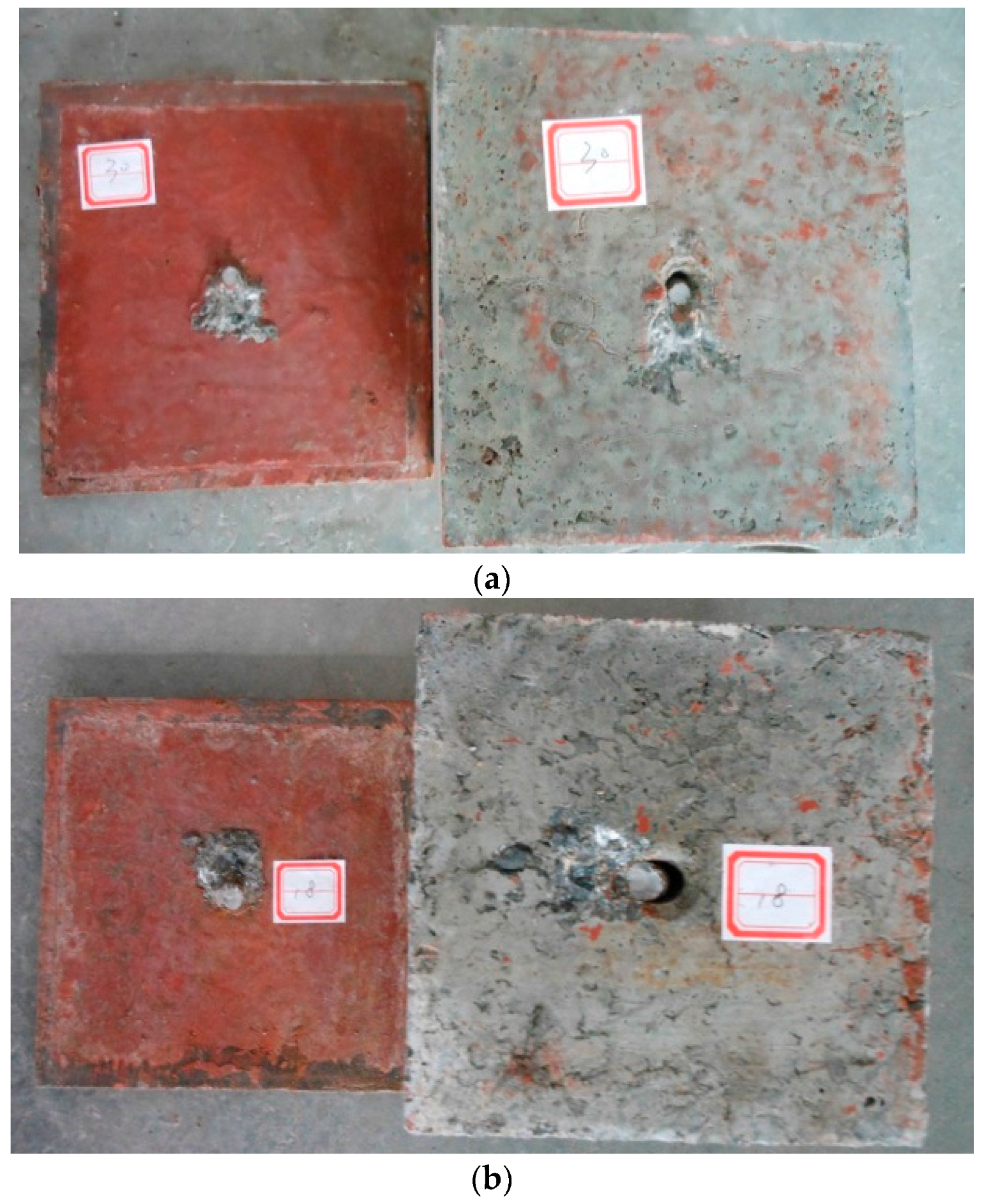

2.5. Corroded Push Out Test

3. Test Results

3.1. Measurement of the Stud Corrosion Rate

3.2. Static Behavior

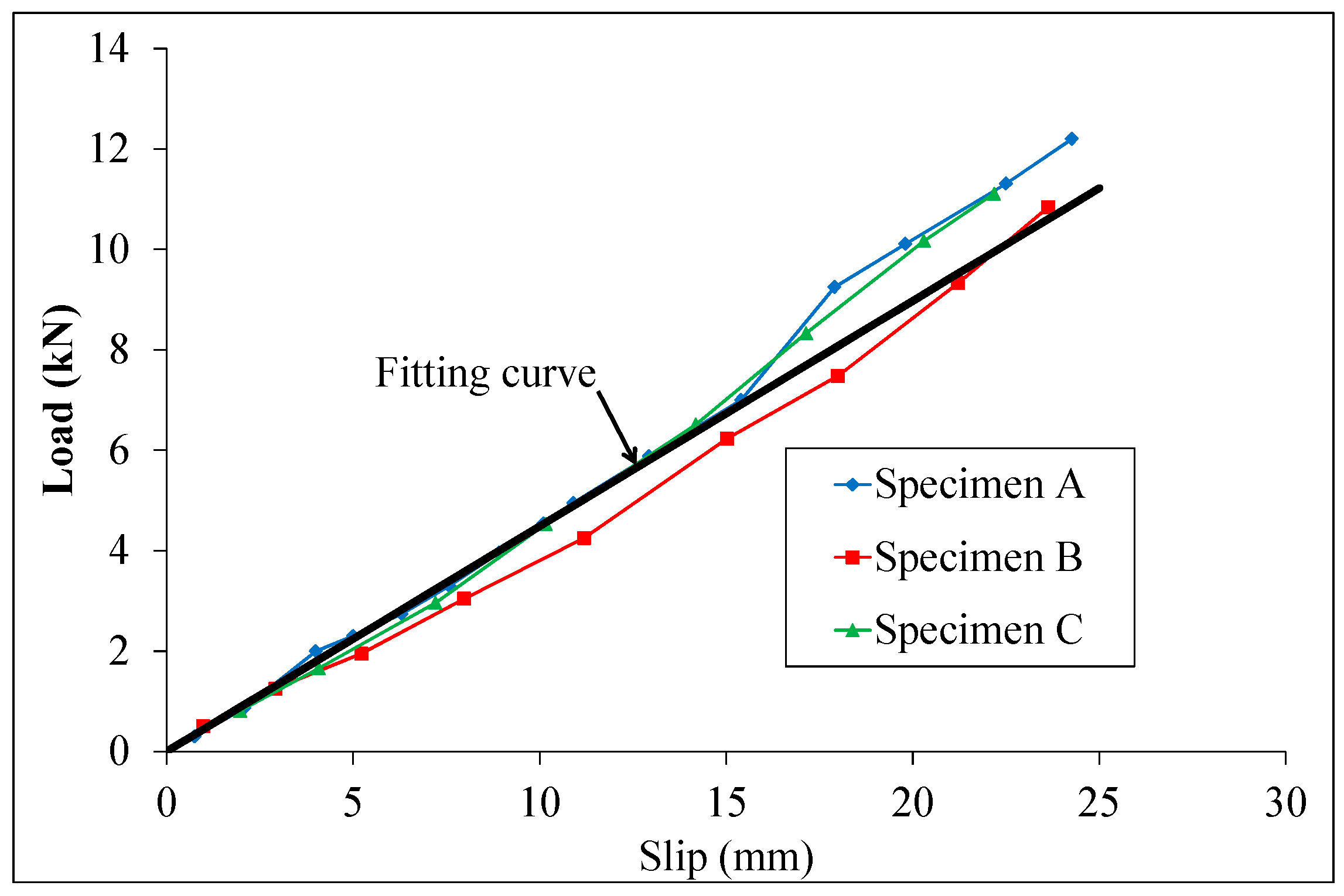

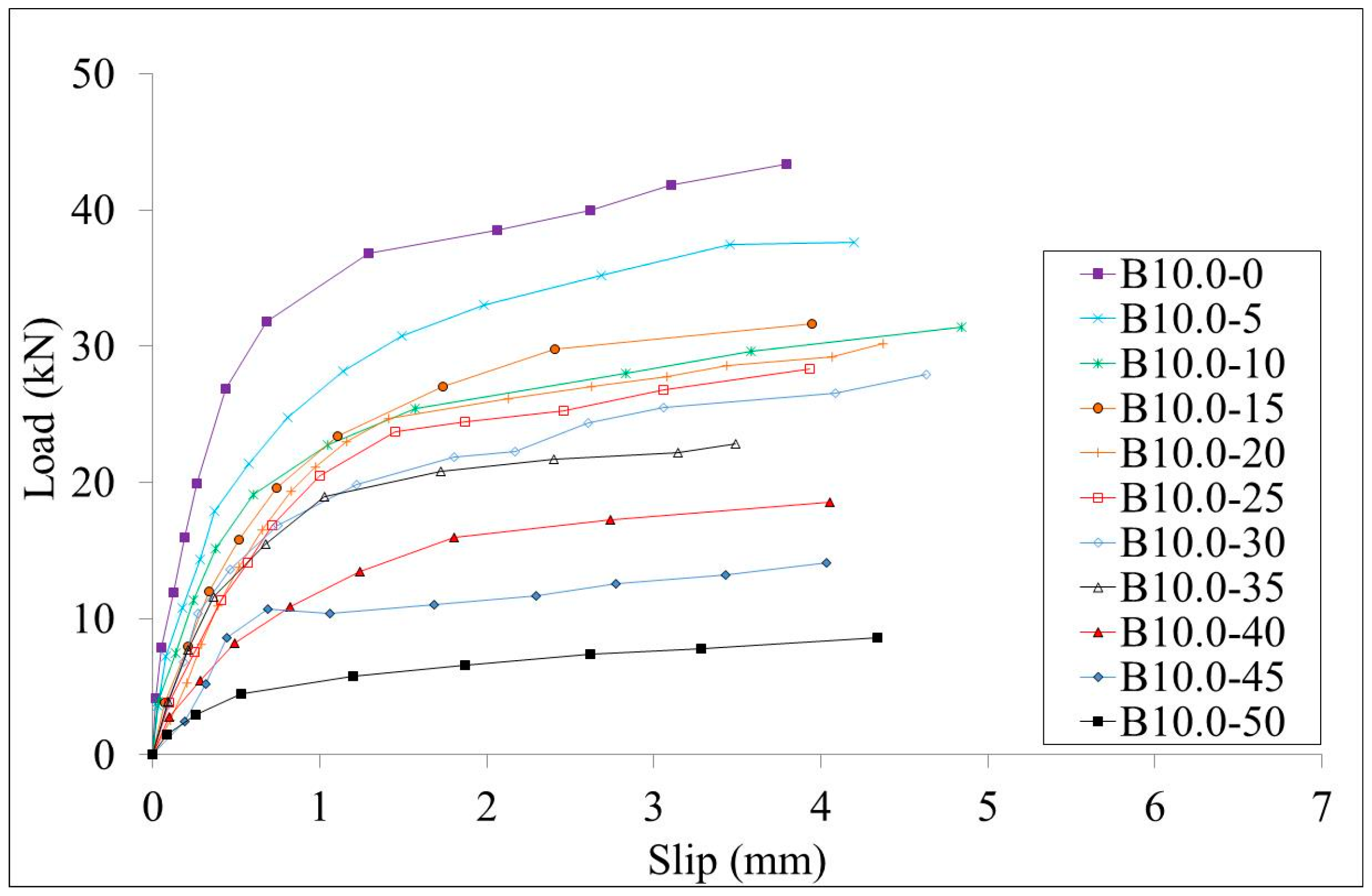

3.2.1. Load-Slip Curves

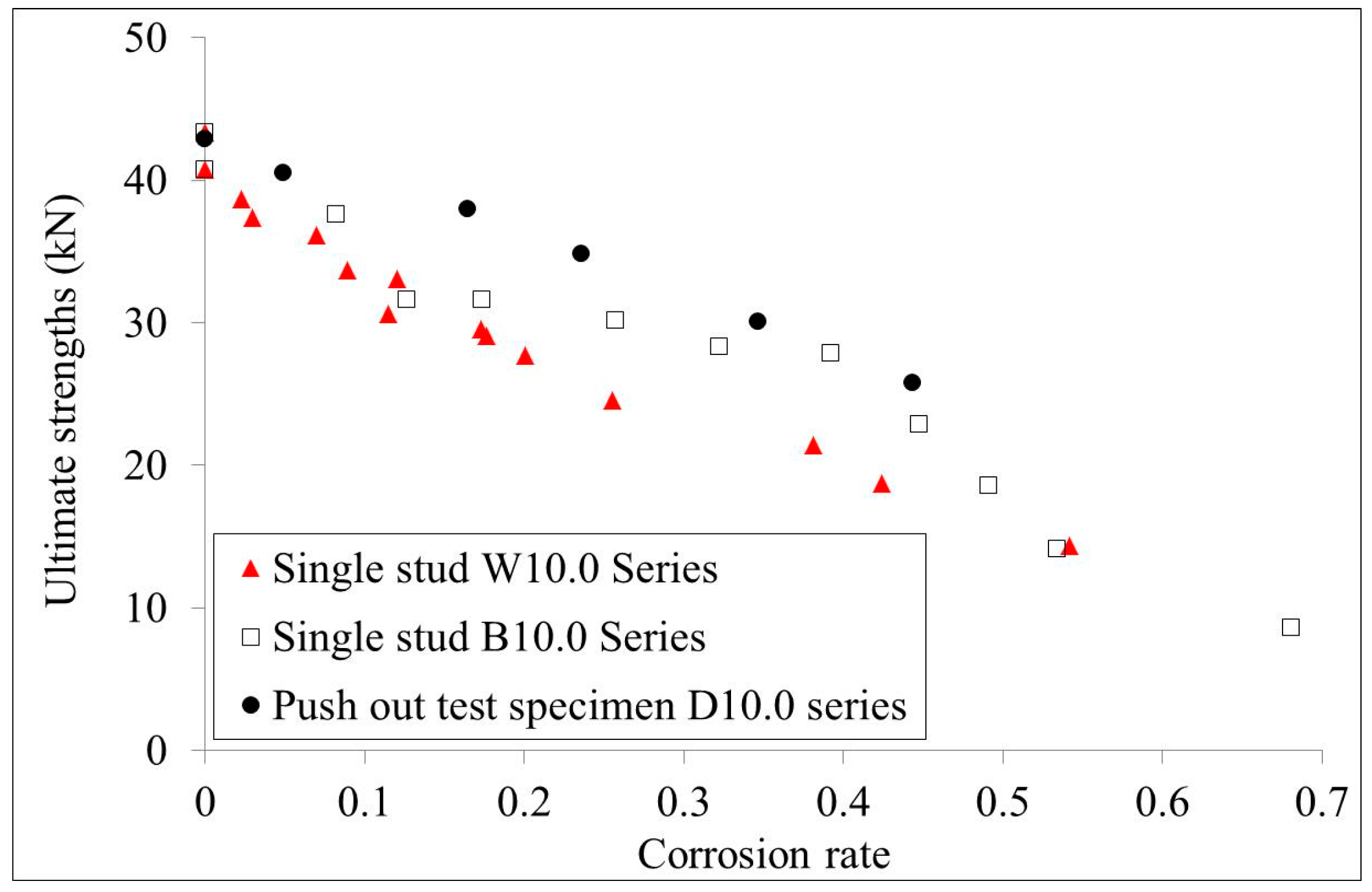

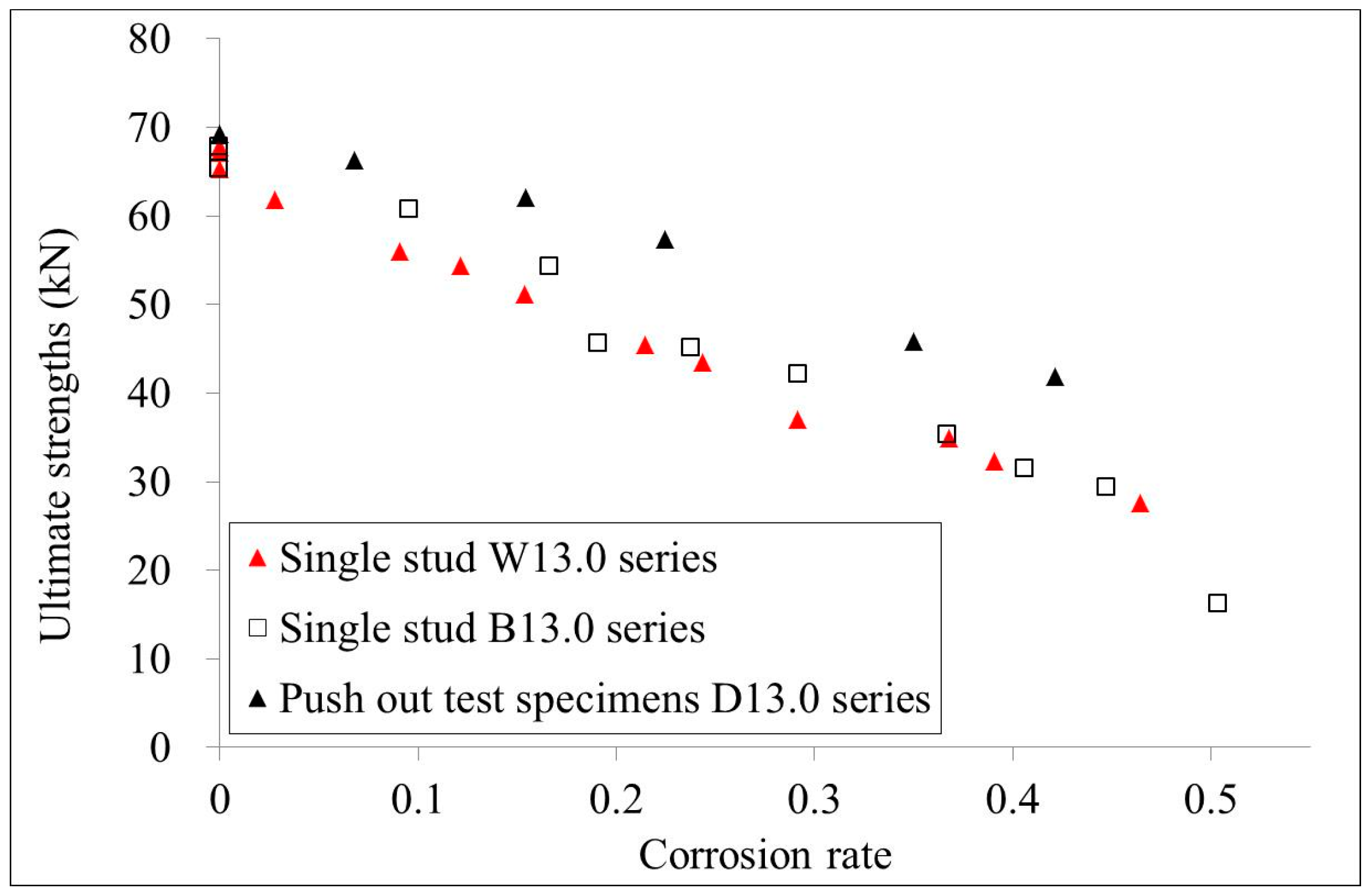

3.2.2. Ultimate Strength

4. Comparison

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| A | = | cross sectional area of the stud; |

| ΔA | = | cross sectional area loss of the stud; |

| d | = | the diameter of the shank of the stud; |

| dc | = | the diameter of the shank of the corroded stud; |

| Ec | = | the elastic modulus of the concrete at 28 days; |

| Ecm | = | the elastic modulus of the concrete slab; |

| fck | = | the characteristic cylinder compressive strength of the concrete at the age considered; |

| fcu | = | the compressive strength of the concrete at 28 days; |

| fu | = | specified ultimate tensile strength of the material of the stud; |

| Ptest | = | ultimate strength obtained from the test results; |

| ψ | = | corrosion rate of the stud. |

References

- Bazant, Z.P. Physical model for steel corrosion in sea structures-applications. J. Struct. Div. 1979, 105, 1137–1153. [Google Scholar]

- Vassie, P. Reinforcement corrosion and the durability of concrete bridges. Proc. Inst. Civ. Eng. 1984, 76, 713–723. [Google Scholar] [CrossRef]

- Asami, K.; Kikuchi, M. In-depth distribution of rusts on a plain carbon steel and weathering steels exposed to coastal–industrial atmosphere for 17 years. Corros. Sci. 2003, 45, 2671–2688. [Google Scholar] [CrossRef]

- Duffó, G.S.; Morris, W.; Raspini, I.; Saragovi, C. A study of steel rebars embedded in concrete during 65 years. Corros. Sci. 2004, 46, 2143–2157. [Google Scholar] [CrossRef]

- Caré, S.; Nguyen, Q.T.; L’Hostis, V.; Berthaud, Y. Mechanical properties of the rust layer induced by impressed current method in reinforced mortar. Cem. Concr. Res. 2008, 38, 1079–1091. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, Y.X.; Wu, L.; Jin, W.L. Experimental investigation and design of corroded stud shear connectors. Adv. Struct. Eng. 2016, 19, 218–226. [Google Scholar]

- Wang, W.L.; Chen, J.; Jin, W.L. Experimental Investigation of Corroded Stud Shear Connectors Subjected to Fatigue Loading. J. Mater. Civ. Eng. 2016. [Google Scholar] [CrossRef]

- Lam, D.; Ellobody, E. Behavior of Headed Stud Shear Connectors in Composite Beam. J. Struct. Eng.-ASCE 2005, 131, 96–107. [Google Scholar] [CrossRef]

- Nie, J.G.; Fan, J.S.; Cai, C.S. Experimental study of partially shear-connected composite beams with profiled sheeting. Eng. Struct. 2008, 30, 1–12. [Google Scholar] [CrossRef]

- Xue, W.; Ding, M.; Wang, H.; Luo, Z. Static Behavior and Theoretical Model of Stud Shear Connectors. J. Bridge Eng.-ASCE 2008, 13, 623–634. [Google Scholar] [CrossRef]

- Smith, A.L.; Couchman, G.H. Strength and ductility of headed stud shear connectors in profiled steel sheeting. J. Constr. Steel Res. 2010, 66, 748–754. [Google Scholar] [CrossRef]

- Mirza, O.; Uy, B. Finite element model for the long-term behaviour of composite steel-concrete push tests. Steel Compos. Struct. 2010, 10, 45–67. [Google Scholar] [CrossRef]

- Kim, S.; Jung, C.; Ahn, J. Ultimate strength of composite structure with different degrees of shear connection. Steel Compos. Struct. 2011, 11, 375–390. [Google Scholar] [CrossRef]

- Coughlan, C.G. The stiffness of stud shear connections in composite beams subjected to static and fatigue loading. Master Thesis, National University of Ireland, Cork, Ireland, April 1987. [Google Scholar]

- Oehlers, D.J. Deterioration in strength of stud connectors in composite bridge beams. J. Struct. Eng.–ASCE 1990, 116, 3417–3431. [Google Scholar] [CrossRef]

- Johnson, R.P. Resistance of stud shear connectors to fatigue. J. Constr. Steel Res. 2000, 56, 101–116. [Google Scholar] [CrossRef]

- Dai, X.X.; Richard Liew, J.Y. Fatigue performance of lightweight steel–concrete–steel sandwich systems. J. Constr. Steel Res. 2010, 66, 256–276. [Google Scholar] [CrossRef]

- Dogan, O.; Roberts, T.M. Fatigue performance and stiffness variation of stud connectors in steel–concrete–steel sandwich systems. J. Constr. Steel Res. 2012, 70, 86–92. [Google Scholar] [CrossRef]

- Lin, W.; Yoda, T.; Taniguchi, N. Fatigue tests on straight steel–concrete composite beams subjected to hogging moment. J. Constr. Steel Res. 2013, 80, 42–56. [Google Scholar] [CrossRef]

- Wang, Y.H.; Nie, J.G.; Li, J.J. Study on fatigue property of steel–concrete composite beams and studs. J. Constr. Steel Res. 2014, 94, 1–10. [Google Scholar]

- Dong, C.X.; Kwan, A.K.H.; Ho, J.C.M. A constitutive model for predicting the lateral strain of confined concrete. Eng. Struct. 2015, 91, 155–166. [Google Scholar] [CrossRef]

- Classen, M.; Gallwoszus, J. Concrete fatigue in composite dowels. Struct. Concr. 2016, 17, 63–73. [Google Scholar] [CrossRef]

- Gattesco, N.; Giuriani, E. Experimental Study on Stud Shear connectors subjected to cyclic loading. J. Constr. Steel Res. 1996, 38, 1–12. [Google Scholar] [CrossRef]

- Bertoa, L.; Simionib, B.; Saettab, B. Numerical modelling of bond behaviour in RC structures affected by reinforcement corrosion. Eng. Struct. 2008, 30, 1375–1385. [Google Scholar] [CrossRef]

| Specimen | Ec(MPa) | fcu (MPa) |

|---|---|---|

| 1 | 3.32 × 104 | 45.4 |

| 2 | 3.38 × 104 | 45.8 |

| 3 | 3.40 × 104 | 46.7 |

| Average | 3.37 × 104 | 46.0 |

| Specimen | Elastic Modulus (MPa) | Yield Stress (MPa) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|---|

| 10.0 mm | 1.94 × 105 | 462.7 | 512.0 | 26.4 |

| 13.0 mm | 1.98 × 105 | 431.2 | 490.6 | 24.9 |

| Specimen | Expected Corrosion Rate (%) | Corrosion Time (Hours) | Measured Corrosion Rate (%) |

|---|---|---|---|

| W10.0-0 | 0 | 0 | 0 |

| B10.0-0 | 0 | ||

| W10.0-5 | 5 | 461 | 2.97 |

| B10.0-5 | 8.23 | ||

| W10.0-10 | 10 | 923 | 8.93 |

| B10.0-10 | 12.68 | ||

| W10.0-15 | 15 | 1384 | 12.01 |

| B10.0-15 | 17.38 | ||

| W10.0-20 | 20 | 1845 | 17.65 |

| B10.0-20 | 25.71 | ||

| W10.0-25 | 25 | 2307 | 20.06 |

| B10.0-25 | 32.23 | ||

| W10.0-30 | 30 | 2768 | 25.55 |

| B10.0-30 | 39.19 | ||

| W10.0-35 | 35 | 3230 | --- |

| B10.0-35 | 44.78 | ||

| W10.0-40 | 40 | 3691 | 38.15 |

| B10.0-40 | 49.09 | ||

| W10.0-45 | 45 | 4152 | 42.41 |

| B10.0-45 | 53.43 | ||

| W10.0-50 | 50 | 4614 | 54.14 |

| B10.0-50 | 68.09 |

| Specimen | Expected Corrosion Rate (%) | Corrosion Time (Days) | Measured Corrosion Rate (%) |

|---|---|---|---|

| W13.0-0 | 0 | 0 | 0 |

| B13.0-0 | 0 | ||

| W13.0-5 | 5 | 599 | 2.77 |

| B13.0-5 | 9.56 | ||

| W13.0-10 | 10 | 1199 | 9.09 |

| B13.0-10 | 16.67 | ||

| W13.0-15 | 15 | 1798 | 12.15 |

| B13.0-15 | 19.08 | ||

| W13.0-20 | 20 | 2398 | 15.35 |

| B13.0-20 | 23.81 | ||

| W13.0-25 | 25 | 2997 | 21.46 |

| B13.0-25 | 29.22 | ||

| W13.0-30 | 30 | 3596 | 24.35 |

| B13.0-30 | 36.74 | ||

| W13.0-35 | 35 | 4196 | 29.13 |

| B13.0-35 | 40.62 | ||

| W13.0-40 | 40 | 4795 | 36.78 |

| B13.0-40 | 44.78 | ||

| W13.0-45 | 45 | 5394 | 39.07 |

| B13.0-45 | 50.04 | ||

| W13.0-50 | 50 | 5994 | 46.44 |

| B13.0-50 | ---- |

| Specimen | Measured Corrosion Rate (%) | Ultimate Strength (kN) |

|---|---|---|

| W10.0-0 | 0 | 43.37 |

| B10.0-0 | 0 | 43.37 |

| W10.0-5 | 2.97 | 38.67 |

| B10.0-5 | 8.23 | 37.6 |

| W10.0-10 | 8.93 | 36.11 |

| B10.0-10 | 12.68 | 31.62 |

| W10.0-15 | 12.01 | 30.62 |

| B10.0-15 | 17.38 | 31.62 |

| W10.0-20 | 17.65 | 29.53 |

| B10.0-20 | 25.71 | 30.16 |

| W10.0-25 | 20.06 | 27.68 |

| B10.0-25 | 32.23 | 28.34 |

| W10.0-30 | 25.55 | 24.59 |

| B10.0-30 | 39.19 | 27.89 |

| W10.0-35 | --- | --- |

| B10.0-35 | 44.78 | 22.86 |

| W10.0-40 | 38.15 | 21.38 |

| B10.0-40 | 49.09 | 18.54 |

| W10.0-45 | 42.41 | 18.75 |

| B10.0-45 | 53.43 | 14.09 |

| W10.0-50 | 54.14 | 14.38 |

| B10.0-50 | 68.09 | 8.61 |

| Specimen | Measured Corrosion Rate (%) | Ultimate Strength (kN) |

|---|---|---|

| W13.0-0 | 0 | 65.28 |

| B13.0-0 | 0 | 65.28 |

| W13.0-5 | 2.77 | 61.76 |

| B13.0-5 | 9.56 | 60.68 |

| W13.0-10 | 9.09 | 55.95 |

| B13.0-10 | 16.67 | 54.2 |

| W13.0-15 | 12.15 | 54.42 |

| B13.0-15 | 19.08 | 45.51 |

| W13.0-20 | 15.35 | 51.16 |

| B13.0-20 | 23.81 | 45.1 |

| W13.0-25 | 21.46 | 45.5 |

| B13.0-25 | 29.22 | 42.14 |

| W13.0-30 | 24.35 | 43.5 |

| B13.0-30 | 36.74 | 35.25 |

| W13.0-35 | 29.13 | 37.01 |

| B13.0-35 | 40.62 | 31.44 |

| W13.0-40 | 36.78 | 34.95 |

| B13.0-40 | 44.78 | 29.35 |

| W13.0-45 | 39.07 | 32.34 |

| B13.0-45 | 50.04 | 16.21 |

| W13.0-50 | 46.44 | 27.6 |

| B13.0-50 | ---- | 65.28 |

| Specimen | Measured Corrosion Rate (%) | Ultimate Strength (kN) Test (Ptest) |

|---|---|---|

| D10.0-0A | 0 | 42.9 |

| D10.0-10 | 4.93 | 40.5 |

| D10.0-20 | 16.44 | 38 |

| D10.0-30 | 23.61 | 34.8 |

| D10.0-40 | 34.66 | 30.1 |

| D10.0-50 | 44.33 | 25.8 |

| Specimen | Measured Corrosion Rate (%) | Ultimate Strength (kN) Test (Ptest) |

|---|---|---|

| D13.0-0A | 0 | 69.3 |

| D13.0-10 | 6.78 | 66.3 |

| D13.0-20 | 15.41 | 62.1 |

| D13.0-30 | 22.43 | 57.3 |

| D13.0-40 | 34.99 | 45.8 |

| D13.0-50 | 42.12 | 41.9 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, W.; Chen, J.; Zhu, J.-H. Behaviour of Corroded Single Stud Shear Connectors. Materials 2017, 10, 276. https://doi.org/10.3390/ma10030276

Xue W, Chen J, Zhu J-H. Behaviour of Corroded Single Stud Shear Connectors. Materials. 2017; 10(3):276. https://doi.org/10.3390/ma10030276

Chicago/Turabian StyleXue, Wen, Ju Chen, and Ji-Hua Zhu. 2017. "Behaviour of Corroded Single Stud Shear Connectors" Materials 10, no. 3: 276. https://doi.org/10.3390/ma10030276

APA StyleXue, W., Chen, J., & Zhu, J.-H. (2017). Behaviour of Corroded Single Stud Shear Connectors. Materials, 10(3), 276. https://doi.org/10.3390/ma10030276