Modeling of Processing-Induced Pore Morphology in an Additively-Manufactured Ti-6Al-4V Alloy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Microstructure

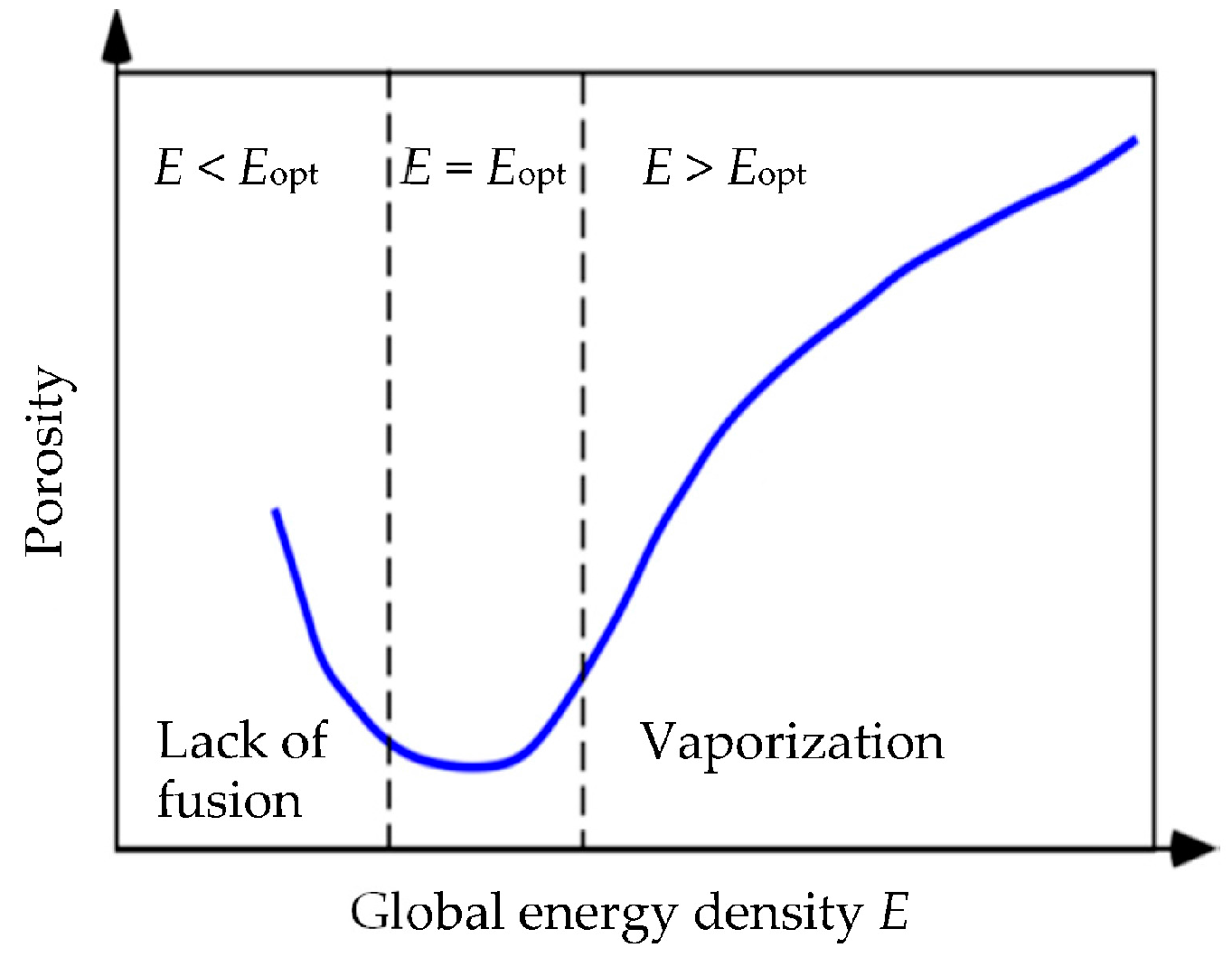

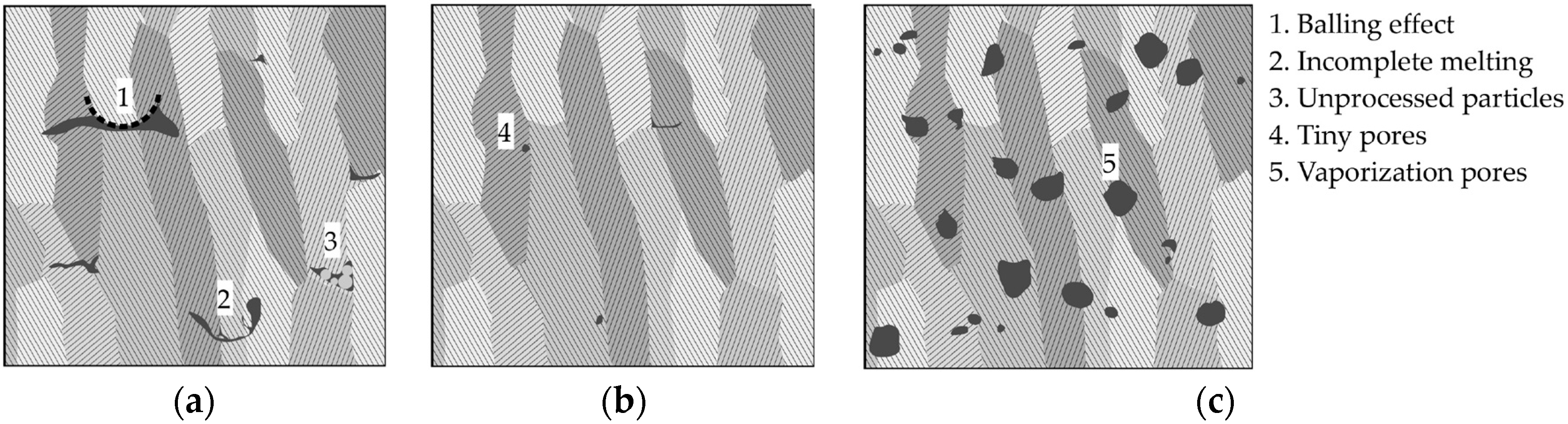

2.2. Processing-Induced Porosity

2.3. Pore Geometry Characterization

3. Modeling Strategy

3.1. Overview

3.2. Modeling of the Grain Microstructure

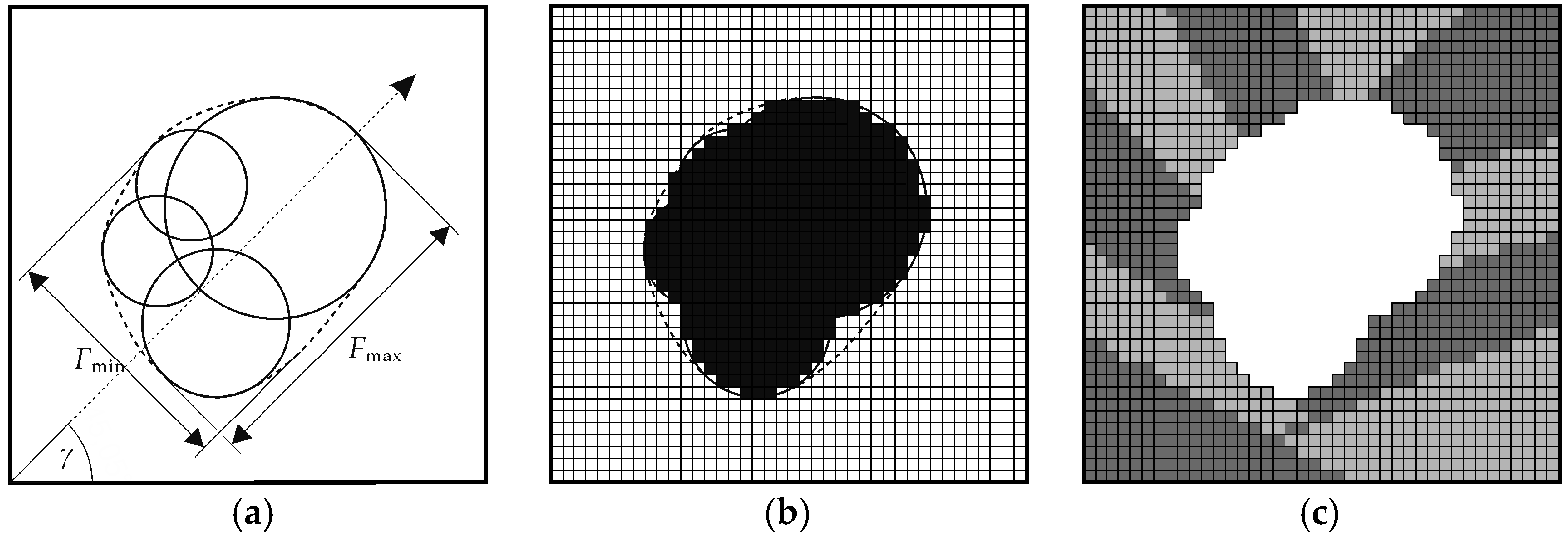

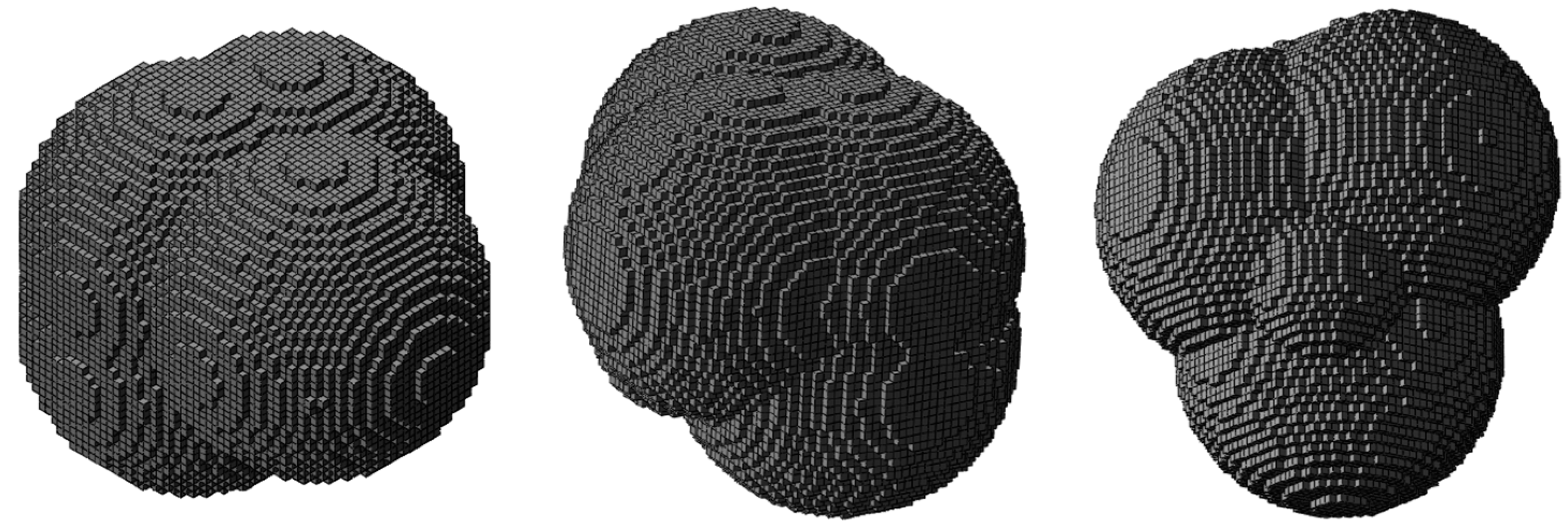

3.3. Modeling of Pores with Convex Boundaries

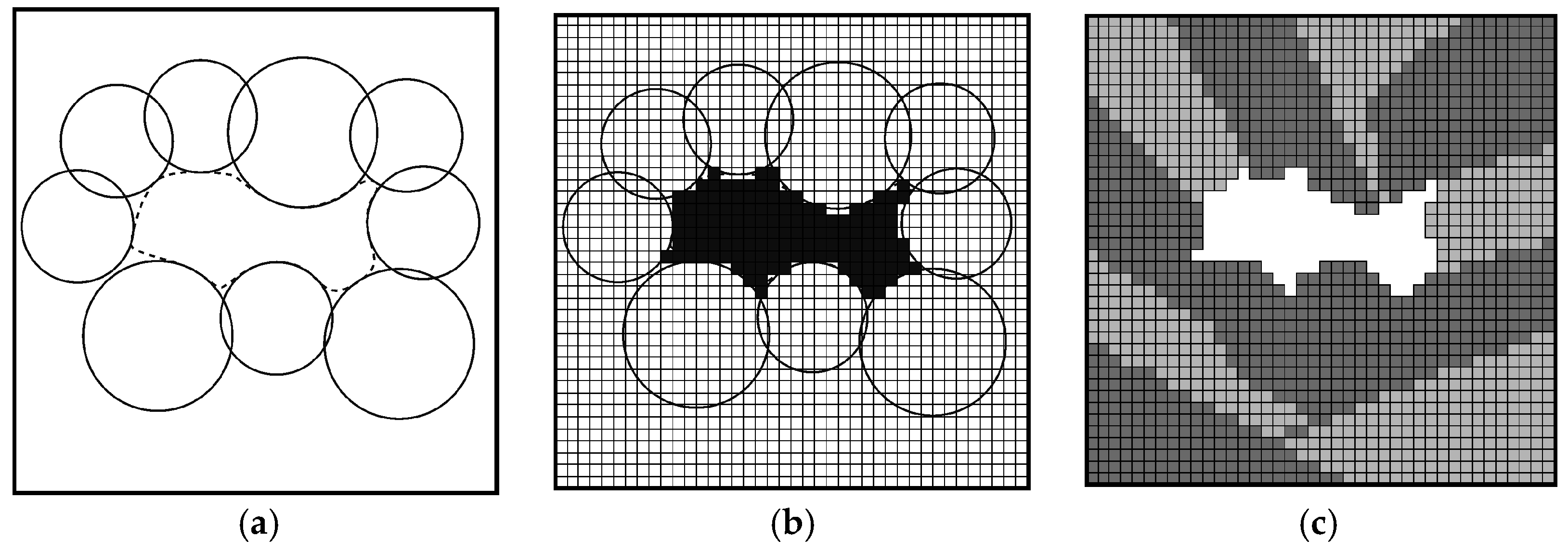

3.4. Modeling of Pores with Concave Boundaries

4. Results

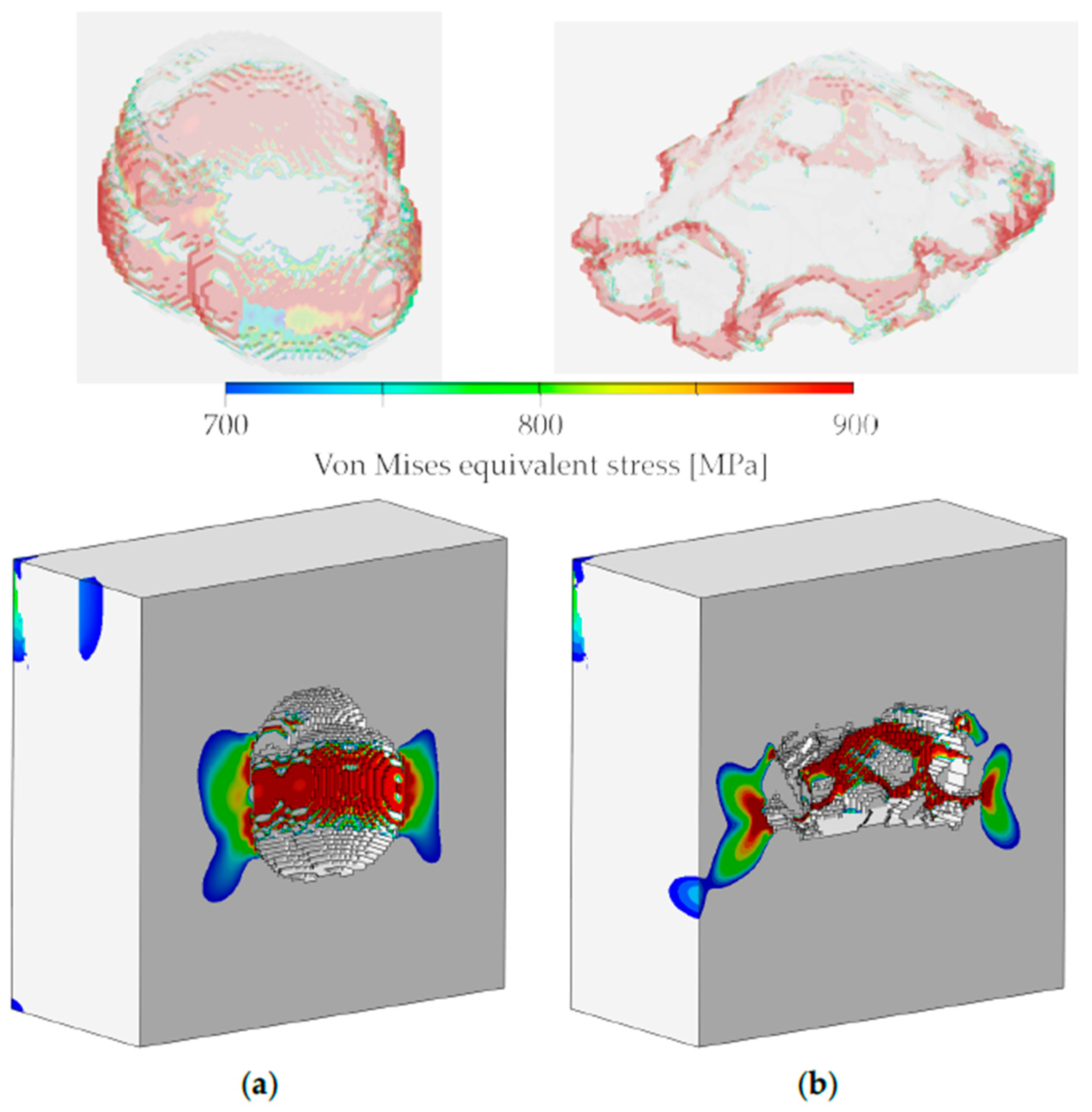

4.1. Finite-Element Analyses

4.2. Effect of Pore Morphology on Stress Distribution

5. Discussion

6. Summary

- (1)

- The polycrystalline microstructure, consisting of elongated grains with acicular phases typical for Ti-6Al-4V processed via SLM with different process parameters, can be modeled by manipulating the seed generation and Voronoi tessellation within the software tool Neper [34]. A control script has been developed to achieve virtual microstructures that contain the relevant characteristic details of actual material specimens.

- (2)

- Processing-induced pores with complex geometries can be approximated by strategically arranging (partly) overlapping spheres of varied sizes in a predefined bounding box. Statistical equivalence of the morphological characteristics of such virtual pores can be conveniently evaluated and compared with data obtained by microanalytical analyses of actual material specimens. Voxel discretization via a self-written script makes it possible to export the pore geometry to any finite-element software.

- (3)

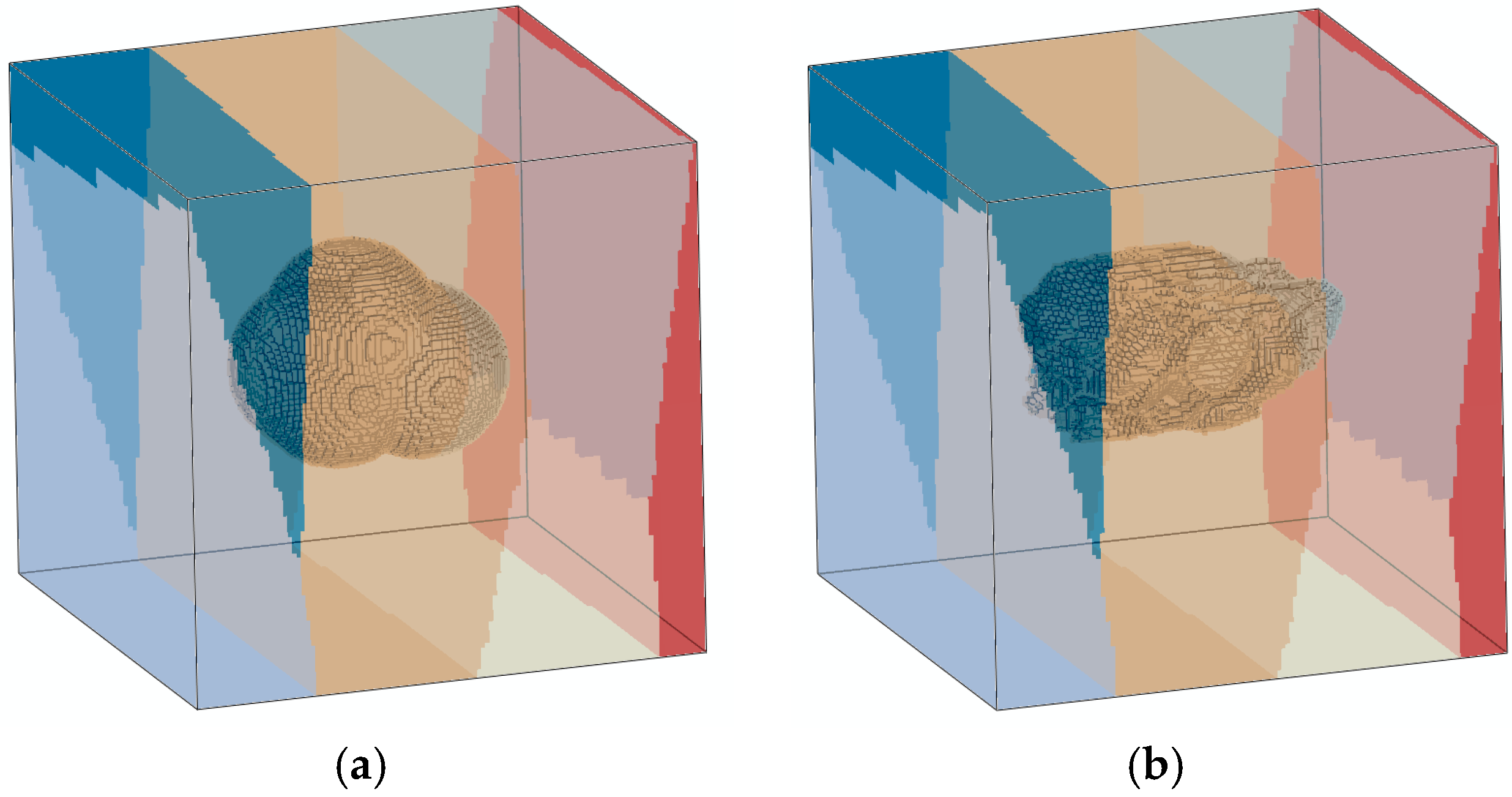

- A mesh superposition technique has been used in order to combine two or more microstructure models. For a successful application of this superposition technique, all microstructure models need to be discretized with preferably fine voxels, using an equal voxel size for all models. The technique, which is particularly suitable for microstructure models with a complex geometry, has been successfully applied to models representing the microstructure of the SLM-processed Ti-6Al-4V alloy.

- (4)

- The outlined modeling strategy is capable of taking into account microstructure statistics of the grains (grain size distribution, grain orientation, and arrangement of the acicular phases) and pores (pore volume content, spatial distribution of pores, pore size distribution, and pore orientation).

- (5)

- The virtual microstructure models generated via the proposed modeling strategy can be applied to investigate the correlation between the mechanical properties and process parameters of an additively-manufactured Ti-6Al-4V alloy. In addition, the microstructure models can be used to predict effective mechanical properties, using homogenization principles. The damage behavior in the presence of pores and crack-like voids can also be studied, to identify critical pore sizes and shapes with regard to material failure.

- (6)

- The modeling strategy has been exemplarily applied to generate different pore geometries commonly found in a SLM-processed Ti-6Al-4V alloy for different process parameters. Due to generalities of the modeling strategy, it can also be used to model other types of porous metallic microstructures.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humbeeck, J.; Kruth, J.-P. A study of the microstructural evolution during selective laser melting of Ti-6Al-4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Spierings, A.B.; Wegener, K.; Levy, G. Designing material properties locally with additive manufacturing technology SLM. In Proceedings of the Conference International Solid Freeform Fabrication Symposium; The University of Texas in Austin: Austin, TX, USA, 2012; pp. 447–455. [Google Scholar]

- Kasperovich, G.; Haubrich, J.; Gussone, J.; Requena, G. Correlation between porosity and processing parameters in TiAl6V4 produced by selective laser melting. Mater. Des. 2016, 105, 160–170. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.-P.; Van Humbeeck, J. Heat treatment of Ti6Al4V produced by selective laser melting: Microstructure and mechanical properties. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef]

- Hua, T.; Jing, C.; Fengying, Z.; Xin, L.; Weidong, H. Microstructure and mechanical properties of laser solid formed Ti-6Al-4V from blended elemental powders. Rare Met. Mater. Eng. 2009, 38, 574–578. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.-P.; Van Humbeeck, J. Microstructure and mechanical properties of a novel β titanium metallic composite by selective laser melting. Acta Mater. 2014, 68, 150–158. [Google Scholar] [CrossRef]

- Xu, W.; Sun, S.; Elambasseril, J.; Liu, Q.; Brandt, M.; Qian, M. Ti-6Al-4V Additively manufactured by selective laser melting with superior mechanical properties. JOM 2015, 67, 668–673. [Google Scholar] [CrossRef]

- Chastanda, V.; Tezenas, A.; Cadoret, Y.; Quaegebeur, P.; Maia, W.; Charkaluk, E. Fatigue characterization of titanium Ti-6Al-4V samples produced by additive manufacturing. Procedia Struct. Integr. 2016, 2, 3168–3176. [Google Scholar] [CrossRef]

- Song, B.; Dong, S.; Zhang, B.; Liao, H.; Coddet, C. Effects of processing parameters on microstructure and mechanical property of selective laser melted Ti6Al4V. Mater. Des. 2012, 35, 120–125. [Google Scholar] [CrossRef]

- Hrabe, N.; Quinn, T. Effects of processing on microstructure and mechanical properties of a titanium alloy (Ti-6Al-4V) fabricated using electron beam melting (EBM), Part 2: Energy input, orientation, and location. Mater. Sci. Eng. A 2013, 573, 271–277. [Google Scholar] [CrossRef]

- Rafi, H.K.; Karthik, N.V.; Gong, H.; Starr, T.L.; Stucker, B.E. Microstructures and mechanical properties of Ti6Al4V parts fabricated by selective laser melting and electron beam melting. J. Mater. Eng. Perform. 2013, 22, 3872–3883. [Google Scholar] [CrossRef]

- Edwards, P.; Ramulu, M. Fatigue performance evaluation of selective laser melted Ti-6Al-4V. Mater. Sci. Eng. A 2014, 598, 327–337. [Google Scholar] [CrossRef]

- Ries, M.; Krempaszky, C.; Hadler, B.; Werner, E. The influence of porosity on the elastoplastic behavior of high performance cast alloys. PAMM Proc. Appl. Math. Mech. 2006, 7, 2150005–2150006. [Google Scholar] [CrossRef]

- Taxer, T.; Schwarz, C.; Smarsly, W.; Werner, E. A finite element approach to study the influence of cast pores on the mechanical properties of the Ni-base alloy MAR-M247. Mater. Sci. Eng. A 2013, 575, 144–151. [Google Scholar] [CrossRef]

- Wicke, M.; Luetje, M.; Bacaicoa, I.; Brueckner-Foit, A. Characterization of casting pores in Fe-rich Al-Si-Cu alloys by microtomography and finite element analysis. Procedia Struct. Integr. 2016, 2, 2643–2649. [Google Scholar] [CrossRef]

- Simonovski, I.; Cizelj, L. Grain-scale modeling approaches for polycrystalline aggregates. In Polycrystalline Materials—Theoretical and Practical Aspect; Zakhariev, Z., Ed.; InTech Europe: Rijeka, Croatia, 2012; pp. 49–74. [Google Scholar]

- Pokharel, R.; Lind, J.; Kanjarla, A.K.; Lebensohn, R.A.; Li, S.F.; Kenesei, P.; Suter, R.M.; Rollett, A.D. Polycrystal plasticity: Comparison between grain-scale observations of deformation and simulations. Annu. Rev. Condens. Matter Phys. 2014, 5, 317–346. [Google Scholar] [CrossRef]

- Tammas-Williams, S.; Zhao, H.; Léonard, F.; Derguti, F.; Todd, I.; Prangnell, P.B. XCT analysis of the influence of melt strategies on defect population in Ti-6Al-4V components manufactured by selective electron beam melting. Mater. Charact. 2015, 102, 47–61. [Google Scholar] [CrossRef]

- Cunningham, R.; Narra, S.P.; Outurk, T.; Beuth, J.; Rolett, A.D. Evaluating the effect of processing parameters on porosity in electron beam melted Ti-6Al-4V via synchrotron X-ray microtomography. JOM 2016, 68, 765. [Google Scholar] [CrossRef]

- Galarraga, H.; Ladosa, D.A.; Dehoff, R.R.; Kirka, M.; Nandwana, P. Effects of the microstructure and porosity on properties of Ti-6Al-4VELI alloy fabricated by electron beam melting (EBM). Addit. Manuf. 2016, 10, 47–57. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. Microstructure of Ti-6Al-4V produced by selective laser melting. J. Phys. Conf. Ser. 2012, 371. [Google Scholar] [CrossRef]

- Kasperovich, G.; Hausmann, J. Improvement of fatigue resistance and ductility of TiAl6V4 processed by selective laser melting. J. Mater. Process. Technol. 2015, 220, 202–214. [Google Scholar] [CrossRef]

- Introduction to Additive Manufacturing Technology: A Guide for Designer and Engineers; European Powder Metallurgy Association: Shrewsbury, UK, 2015.

- Zhu, H.H.; Fuh, J.Y.H.; Lu, L. The influence of powder apparent density on the density in direct laser-sintered metallic parts. Int. J. Mach. Tools Manuf. 2007, 47, 294–298. [Google Scholar] [CrossRef]

- Gu, H.; Gong, H.; Dilip, J.J.S.; Pal, D.; Hicks, A.; Doak, H.; Stucker, B. Effects of powder variation on the microstructure and tensile strength of Ti6Al4V parts fabricated by selective laser melting. In Proceedings of the 25th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 4–6 August 2014.

- Tolochko, N.K.; Mozzharov, S.E.; Yadroitsev, I.A.; Laoui, T.; Froyen, L.; Titov, V.I.; Ignatiev, M.B. Balling processes during selective laser treatment of powders. Rapid Prototyp. J. 2004, 10, 78–87. [Google Scholar] [CrossRef]

- Vilaro, T.; Colin, C.; Bartout, J.D. As-fabricated and heat-treated microstructures of the Ti-6Al-4V alloy processed by selective laser melting. Metall. Mater. Trans. A 2011, 42A, 3190–3199. [Google Scholar] [CrossRef]

- Gong, H.; Rafi, K.; Gu, H.; Starr, T.; Stucker, B. Analysis of defect generation in Ti-Al-4V parts made using powder bed fusion additive manufacturing processes. Addit. Manuf. 2014, 1, 87–98. [Google Scholar] [CrossRef]

- Zhou, X.; Wanga, D.; Liu, X.; Zhang, D.D.; Qua, S.; Ma, J.; London, G.; Shen, Z.; Liu, W. 3D imaging of selective laser melting defects in a Co–Cr–Mo alloy by synchrotron radiation micro-CT. Acta Mater. 2015, 98, 1–16. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef]

- Gong, H.; Gu, H.; Zeng, K.; Dilip, J.J.S.; Pal, D.; Stucker, B.; Christiansen, D.; Beuth, J.; Lewandowski, J.J. Melt pool characterization for selective laser melting of Ti-6Al-4V pre-alloyed powder. In Proceedings of the 25th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 4–6 August 2014.

- Akman, E.; Demir, A.; Canel, T.; Sinmazçelik, T. Laser welding of Ti6Al4V titanium alloys. J. Mater. Process. Technol. 2009, 209, 3705–3713. [Google Scholar] [CrossRef]

- Quey, R.; Dawson, P.R.; Barbe, F. Large-scale 3D random polycrystals for the finite element method: Generation, meshing and remeshing. Comput. Methods Appl. Mech. Eng. 2011, 200, 1729–1745. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. Effect of the build orientation on the mechanical properties and fracture modes of SLM Ti-6Al-4V. Mater. Sci. Eng. A 2014, 616, 1–11. [Google Scholar] [CrossRef]

- Uchic, M.D. Serial sectioning methods for generating 3D characterization data of grain and precipitate-scale microstructures. In Computational Methods for Microstructure-Property; Ghosh, S., Dimiduk, D., Eds.; Springer: New York, NY, USA, 2011; pp. 31–52. [Google Scholar]

- Bodla, K.K.; Garimella, S.V.; Murthy, J.Y. 3D reconstruction and design of porous media from thin sections. Int. J. Heat Mass Transf. 2014, 73, 250–264. [Google Scholar] [CrossRef]

- Maire, E.; Withers, P.J. Quantitative X-ray tomography. Int. Mater. Rev. 2014, 59, 1–43. [Google Scholar] [CrossRef]

- Taubin, G.A. Signal processing approach to fair surface design. In SIGGRAPH ’95 Proceedings of the 22nd Annual Conference on Computer Graphics and Interactive Techniques; Mair, S.G., Cook, R., Eds.; ACM Press: New York, NY, USA, 1995; pp. 351–358. [Google Scholar]

- Camacho, D.L.A.; Hopper, R.H.; Lin, G.M.; Myers, B.S. An improved method for finite element mesh generation of geometrically complex structures with application to the skullbase. J. Biomech. 1997, 30, 1067–1070. [Google Scholar] [CrossRef]

- Boyd, S.K. Müller, R. Smooth surface meshing for automated finite element model generation from 3D image data. J. Biomech. 2006, 39, 1287–1295. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.J.; Swan, C.C. Algorithms for automated meshing and unit cell analysis of periodic composites with hierarchical tri-quadratic tetrahedral elements. Int. J. Numer. Methods Eng. 2003, 58, 1683–1711. [Google Scholar] [CrossRef]

- Sukumar, N.; Chopp, D.L.; Moës, N.; Belytschko, T. Modeling holes and inclusions by level sets in the extended finite-element method. Comput. Methods Appl. Mech. Eng. 2001, 190, 6183–6200. [Google Scholar] [CrossRef]

- Yang, Z.; Ruess, M.; Kollmannsberger, S.; Düster, A.; Rank, E. An efficient integration technique for the voxel-based finite cell method. Int. J. Numer. Methods Eng. 2012, 91, 457–471. [Google Scholar] [CrossRef]

| Exemplary Pore Geometry | Net Pore Surface Area A (mm2) | Pore Volume V (mm3) | Sphericity ψ |

|---|---|---|---|

| convex boundary | 6.2 1 | 1.2 | 0.83 |

| concave boundary | 9.9 1 | 1.2 | 0.41 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kabir, M.R.; Richter, H. Modeling of Processing-Induced Pore Morphology in an Additively-Manufactured Ti-6Al-4V Alloy. Materials 2017, 10, 145. https://doi.org/10.3390/ma10020145

Kabir MR, Richter H. Modeling of Processing-Induced Pore Morphology in an Additively-Manufactured Ti-6Al-4V Alloy. Materials. 2017; 10(2):145. https://doi.org/10.3390/ma10020145

Chicago/Turabian StyleKabir, Mohammad Rizviul, and Henning Richter. 2017. "Modeling of Processing-Induced Pore Morphology in an Additively-Manufactured Ti-6Al-4V Alloy" Materials 10, no. 2: 145. https://doi.org/10.3390/ma10020145

APA StyleKabir, M. R., & Richter, H. (2017). Modeling of Processing-Induced Pore Morphology in an Additively-Manufactured Ti-6Al-4V Alloy. Materials, 10(2), 145. https://doi.org/10.3390/ma10020145