Characterization and Monitoring of a Self-Constructible Photovoltaic-Based Refrigerator

Abstract

:1. Introduction

- Low market price compared with products currently available in Africa, since shipping and manufacturing costs are strongly reduced; the objective is to maintain the final cost of the system below 1000 € for a standard module with 250 L of net capacity;

- High availability; the system can be easily repaired by local people; in addition, full operability without solar power is ensured by the thermal storage; the aim of the research is to ensure the air temperature inside the fridge is always below 10 °C even after 48 h without solar radiation;

- Reduction in the environmental impact during and at the end of the working life; in the proposed system all of the components can be re-used or recycled;

- Active participation of the population during the manufacturing phase, in order to achieve economic benefits and improve technical knowledge. The entire system can be assembled locally without specific expertise or technical equipment. Importing ready-to-use products from developed countries has, in fact, a negative impact on the local technical knowledge.

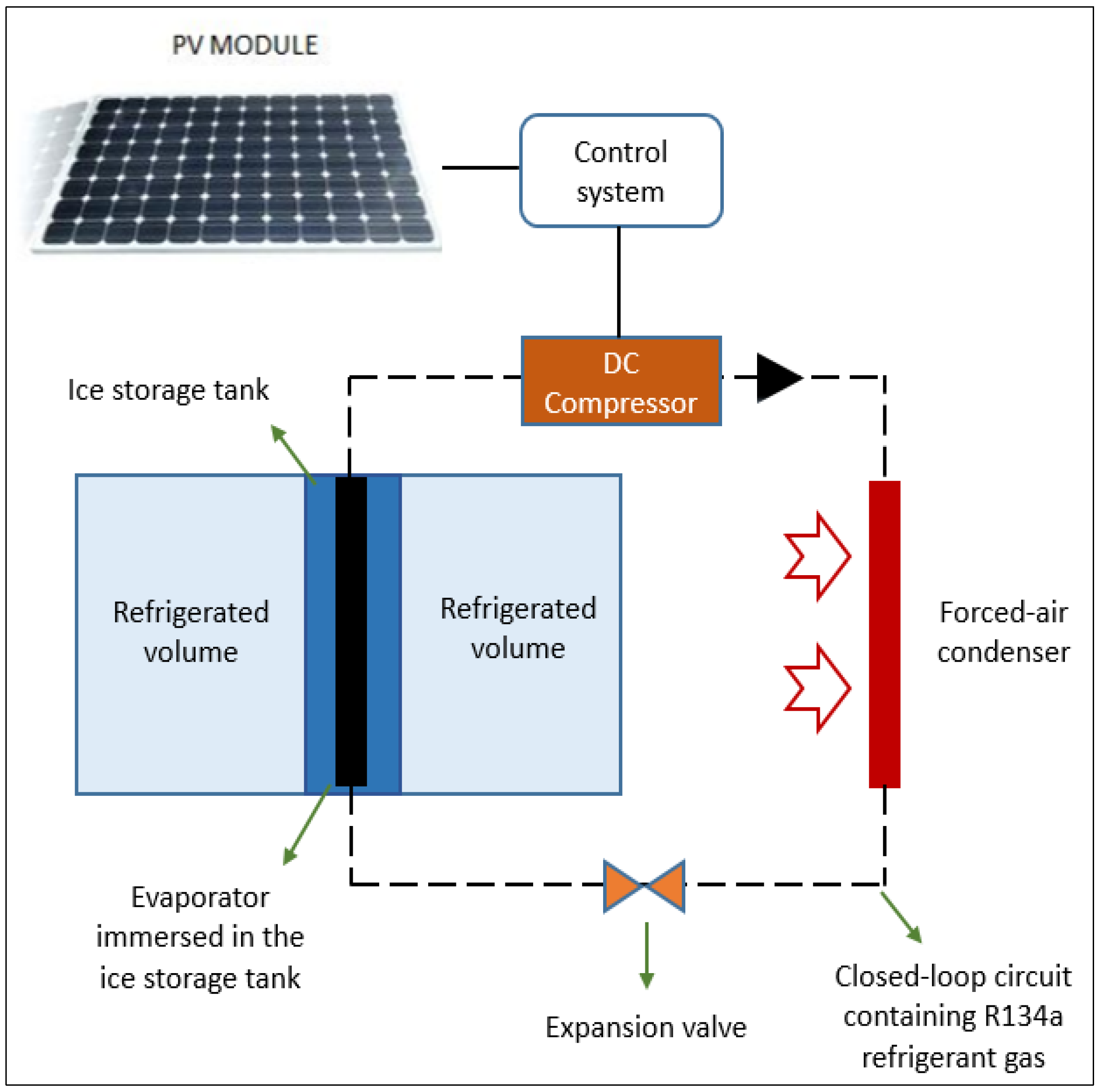

2. System Description

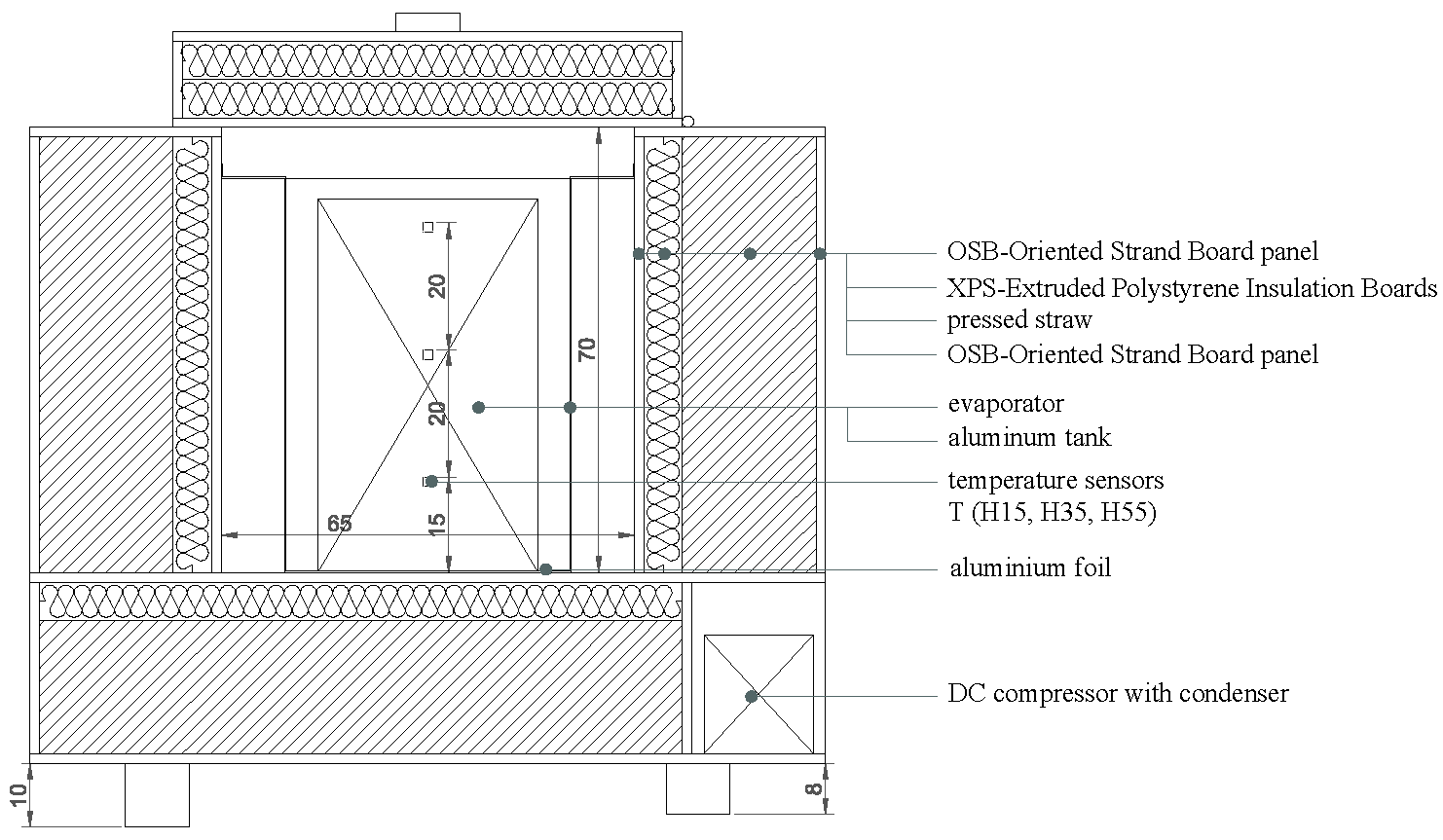

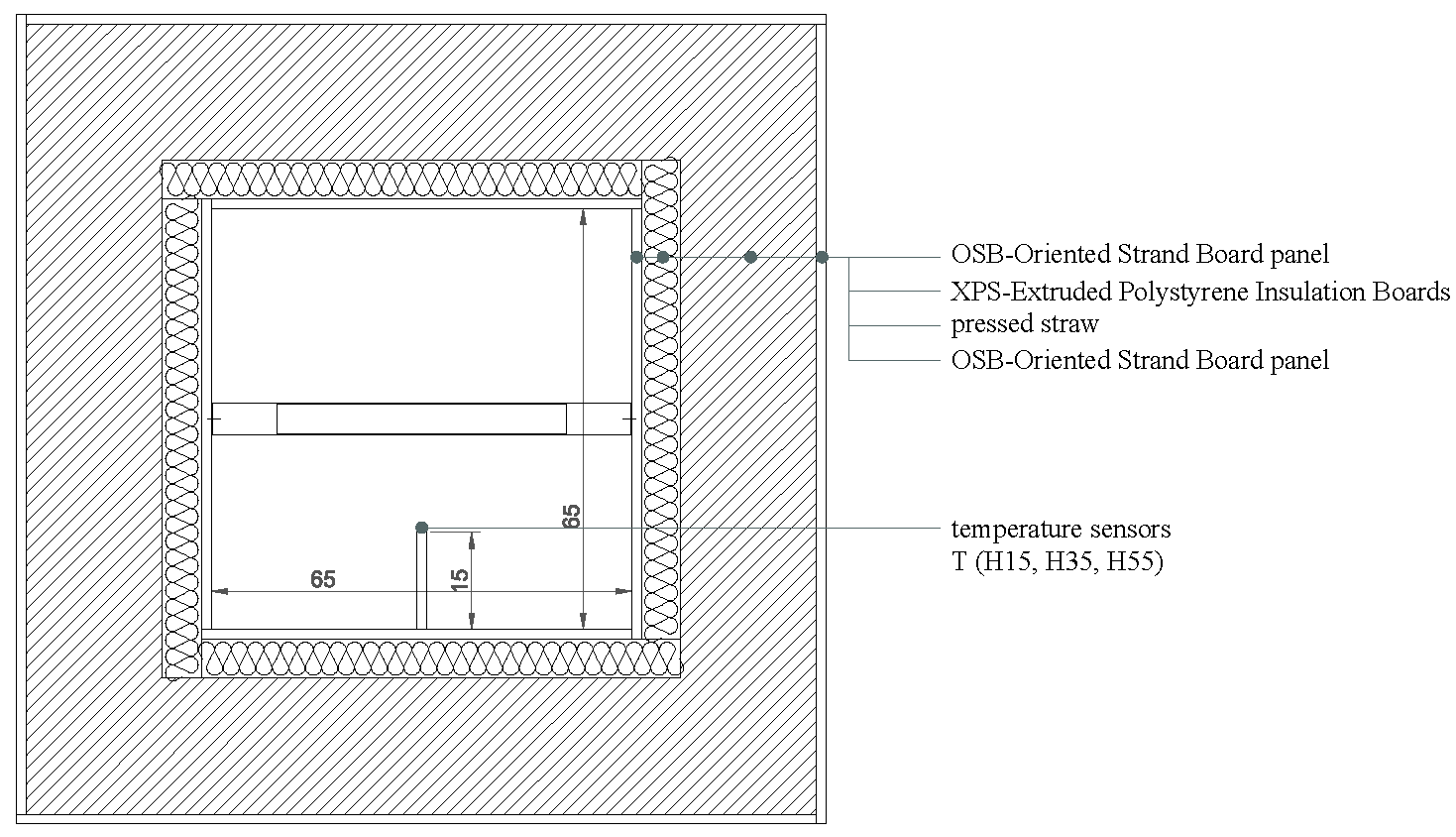

- Internal layer: oriented strand board (OSB) panel (1 cm thick);

- Thermal insulation: wood-fiber insulation (6 cm thick) and compressed straw (21 cm thick);

- External layer: OSB panel (1 cm thick).

3. Energy Model

- The external air temperature at each time step, Text,n;

- The average irradiance on the module surface at a certain time step In, in W/m2;

- The internal air temperature and the water temperature in the storage (Tint,0 and Tw,0) at the initial time t0;

- The specific heat, cpload, and the mass, mload, of the items placed inside the refrigerator; and

- If there are openings of the refrigerator during a certain time interval.

3.1. Thermal Balance of Internal Air

3.2. Thermal Balance of the System

4. Instrumentation and Data Logging

- Mean water temperature inside the storage (Tw);

- Temperature of the air in the environment in which the fridge is located (Text);

- Temperature of the air inside the fridge 15 cm from the bottom (Tint,15);

- Temperature of the air inside the fridge 35 cm from the bottom (Tint,35);

- Temperature of the air inside the fridge 55 cm from the bottom (Tint,55);

- Mean temperature of the load inside the fridge (Tload).

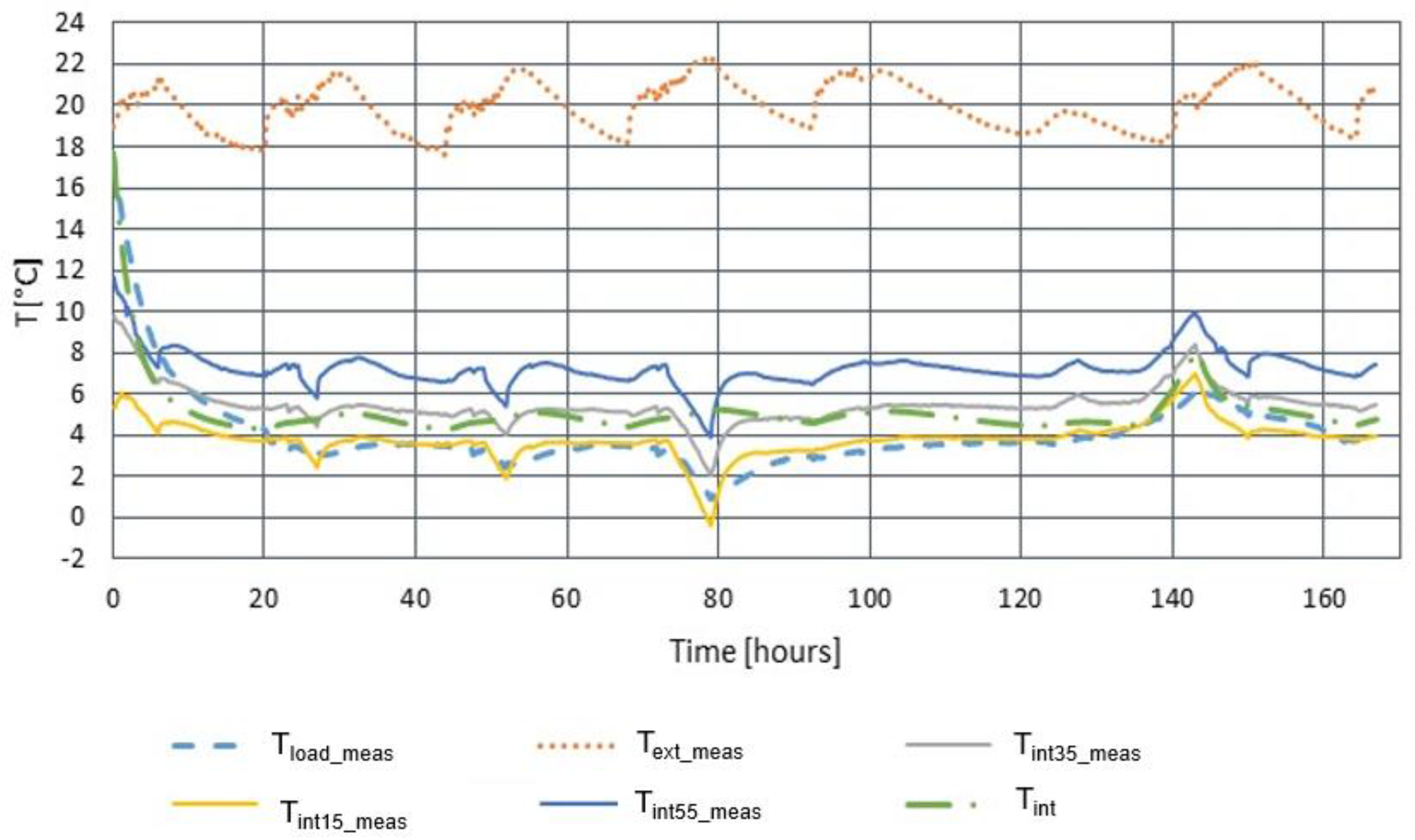

5. Experimental Results and Model Validation

- The average air temperature measured inside the refrigerator is always below 10 °C, even if a new thermal load is introduced in the course of the completely cloudy days, when the compressor is off. This result preliminarily confirms the adequate design of the system;

- The error between the temperature calculated and that measured is, on average, lower than ±10% and can be mainly attributed to the impossibility to estimate precisely the heat transfer coefficient of the thermal load inside the refrigerator. In any case, as stated before, since the objective of the model is to assess the proper functioning of the system (i.e., to maintain acceptable set-point temperatures in steady state conditions), the approximation introduced can be considered non-relevant.

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| In | Average irradiance on the PV module surface at a certain time step n (W/m2) |

| Ecom,n | Electric energy required by the compressor at a certain time step n (Wh) |

| Pcom,n | Electric power required by the compressor at a certain time step n (W) |

| Qeva,n | Thermal energy removed from the evaporator at a certain time step n (Wh) |

| Qenv,n | Thermal energy dissipated on the envelope at a certain time step n (Wh) |

| Qsto,n | Thermal energy dissipated by the thermal storage at a certain time step n (Wh) |

| Qload,n | Thermal energy needed to cool the load (food/beverages) inside the fridge at a certain time step n (Wh) |

| Qw,n | Thermal energy absorbed by the water inside the thermal storage at a certain time step n (Wh) |

| Qo,n | Thermal energy dissipated by the repeated opening of the fridge at a certain time step n (Wh) |

| COPn | Coefficient of performance of the compressor at a certain time step n (dimensionless) |

| COPn,rif | Reference coefficient of performance of the compressor at a certain time step n (dimensionless) |

| Uenv | Thermal transmittance of the envelope of the fridge (W/m2·K) |

| Senv | Internal surface of the envelope of the fridge (m2) |

| Usto | Heat transfer coefficient of the thermal storage tank (W/m2·K) |

| Ssto | Heat loss surface of the thermal storage tank (W/m2·K) |

| Teva,n | Mean temperature of the evaporator at a certain time step n (°C) |

| Text,n | Temperature of the air in the environment in which the fridge is located at a certain time step n (°C) |

| Tint,n | Mean temperature of the air inside the fridge at a certain time step n (°C) |

| Tw,n | Temperature of the water inside the thermal storage at a certain time step n (°C) |

| Tload,n | Temperature of the load (food/beverage) at a certain time step n (°C) |

| cpload | Specific heat of the load (food/beverages) inside the fridge (Wh/kg·K) |

| mload | Mass of the load (food/beverages) inside the fridge (kg) |

| cpair | Specific heat of the air inside the fridge (Wh/kg·K) |

| Vair | Net volume of the internal air (m3) |

| mair | Mass of the air inside the fridge (kg) |

| mw,tot | Total mass of the water inside the thermal storage (kg) |

| mw,ice,n | Mass of the water inside the thermal storage which is solidified at a certain time step n (kg) |

| cw | Specific heat of the water in the thermal storage (Wh/kg·K) |

| λ | Latent heat of the water (Wh/kg) |

| k | Factor that considers the percentage of the net volume of air changed every time step, due to infiltration and door openings (dimensionless) |

| ∆t | Length of the time step (h) |

| Note | The quantities measured have the same nomenclature of the ones calculated, but are identified by the subscript meas |

References

- Haver, K.; Harmer, A.; Taylor, G. Evaluation of European Commission Integrated Approach of Food Security and Nutrition in Humanitarian Context. Available online: http://ec.europa.eu/echo/files/evaluation/2013/food_security_and_nutrition.pdf (accessed on 9 September 2016).

- IMECHE. A Tank of Cold: Cleantech Leapfrog to a More Food Secure World. Available online: https://www.imeche.org/docs/default-source/reports/a-tank-of-cold-cleantech-leapfrog-to-a-more-food-secure-world.pdf?sfvrsn=0 (accessed on 9 September 2016).

- Tassou, S.A.; Lewis, J.S.; Gea, Y.T.; Hadawey, A.; Chaer, I. A review of emerging technologies for food refrigeration applications. Appl. Therm. Eng. 2010, 30, 263–276. [Google Scholar] [CrossRef]

- Somerton, C.W.; Aslam, N.; McPhail, K.; McPhee, R.; Rowland, B.; Tingwall, E. Vaccine Refrigerator for Developing Nations; Michigan State University: East Lansing, MI, USA, 2009. [Google Scholar]

- N’Tsoukpoe, K.E.; Yamegueu, D.; Bassole, J. Solar sorption refrigeration in Africa. Renew. Sustain. Energy Rev. 2014, 35, 318–335. [Google Scholar] [CrossRef]

- Metcalf, S.J.; Zacharie, T.-T.; Critoph, R.E. Application of a compact sorption generator to solar refrigeration: Case study of Dakar (Senegal). Appl. Therm. Eng. 2011, 31, 2197–2204. [Google Scholar] [CrossRef]

- Santori, G.; Santamaria, S.; Sapienza, A.; Brandani, S.; Freni, A. A stand-alone solar adsorption refrigerator for humanitarian aid. Solar Energy 2014, 100, 172–178. [Google Scholar] [CrossRef]

- Yildiz, A. Thermoeconomic analysis of diffusion absorption refrigeration systems. Appl. Therm. Eng. 2016, 99, 23–31. [Google Scholar] [CrossRef]

- Feldman, D.; Barbose, G.; Margolis, R.; Wiser, R.; Darghouth, N.; Goodrich, A. Photovoltaic (PV) Pricing Trends: Historical, Recent, and Near-Term Projections; Technical Report DOE/GO-102012-3839; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2012.

- Nemet, G.F. Beyond the learning curve: Factors influencing cost reductions in photovoltaics. Energy Policy 2006, 34, 3218–3232. [Google Scholar] [CrossRef]

- Practical Action. Refrigeration for Developing Countries. Available online: http://www.score.uk.com/research/Shared%20Documents/Techno-Social/refrigeration_for_dev_countries.pdf (accessed on 9 September 2016).

- Ewert, M.K.; Bergeron, D.J. Development of a Battery-Free Solar Refrigerator. Available online: https://ntrs.nasa.gov/search.jsp?R=20100042308 (accessed on 9 September 2016).

- Ewert, M.K.; Frahm, J.; Bergeron, D.J.; Berchowits, D. Experimental evaluation of a solar PV refrigerator with thermoelectric, stirling and vapor compression heat pumps. In Proceedings of the 27th Annual Technical Conference (SOLAR 98), Albuquerque, NM, USA, 13–17 June 1998.

- Kim, D.S.; Infante Ferreira, C.A. Solar refrigeration options—A state-of-the-art review. Int. J. Refrig. 2008, 31, 3–15. [Google Scholar] [CrossRef]

- Practical Action. Solar Photovoltaic Refrigeration of Vaccines. Available online: https://practicalaction.org/docs/technical_information_service/solar_refrigeration_vaccines.pdf (accessed on 9 September 2016).

- SolarChill—Refrigerators and Vaccine Coolers Powered by the Sun. Available online: http://www.solarchill.org/wp-content/uploads/2014/02/SolarChill-Technology-Brief.pdf (accessed on 9 September 2016).

- IDEASS France. Solaref—100% Autonomous Solar Ice Fridge Solar and Cooperative Trade for Durable Cooler Engine. Available online: http://www.ideassonline.org/pdf/br_46_01.pdf (accessed on 9 September 2016).

- Critoph, R.E.; Thompson, K. Solar Energy for Cooling and Refrigeration; University of Warwick: Coventry, UK, 2002. [Google Scholar]

- Freni, A.; Maggio, G.; Vasta, S.; Santori, G.; Polonara, F.; Restuccia, G. Optimization of a solar-powered adsorptive ice-maker by a mathematical method. Sol. Energy 2008, 82, 965–976. [Google Scholar] [CrossRef]

- Kanade, A.V.; Kulkarni, A.V.; Deshmukh, D.A. Solar power adsorption ice maker system. Int. Res. J. Eng. Technol. 2015, 2, 477–486. [Google Scholar]

- Dulas. VC65-2 Solar Medical Refrigerator. Available online: http://www.dulas.org.uk/products/vc65-solar-medical-refrigerator.cfm (accessed on 9 September 2016).

- Olk, H.; Mundt, J. Photovoltaics for Productive Use Applications. Available online: http://thecleannetwork.org/downloads/97-GIZ_(2016)_Catalogue_PV_Appliances_for_Micro_Enterprises.pdf (accessed on 9 September 2016).

- Del Pero, C.; Butera, F.M.; Buffoli, M.; Piegari, L.; Capolongo, L.; Fattore, M. Feasibility Study of a Solar Photovoltaic Adaptable Refrigeration Kit for Remote Areas in Developing Countries. In Proceedings of the 2015 International Conference on Clean Electrical Power (ICCEP), Taormina, Italy, 16–18 June 2015; pp. 701–708.

- Refrigerant Compressors—Rating Conditions, Tolerances and Presentation of Manufacturer’s Performance Data; Standard UNI EN 12900:2013; Italian Standards: Milan, Italy, 2013.

- Kim, J.K.; Kim, J.B. Modulation characteristics of a linear compressor for evaporating and condensing temperature variations for household refrigerators. Int. J. Refrig. 2014, 40, 370–379. [Google Scholar] [CrossRef]

- Laguerre, O. Heat Transfer and Air Flow in a Domestic Refrigerator. In Mathematical Modelling of Food Processing; Farid, M.M., Ed.; CRC Press: Boca Raton, FL, USA, 2011; pp. 445–474. [Google Scholar]

- Aste, N.; Tagliabue, L.C.; Del Pero, C.; Testa, D.; Fusco, R. Performance analysis of a large-area luminescent solar concentrator module. Renew. Energy 2015, 76, 330–337. [Google Scholar] [CrossRef]

| Type of Refrigerator | Initial Cost (€) | Operative Cost | Environmental Impact | Reliability | Need for Specialized Personnel |

|---|---|---|---|---|---|

| Vapour compression connected to the electricity grid | 500–1000 | Cost of electricity, maintenance costs | Linked to the production of electricity | High | Only for maintenance |

| Vapour compression powered by fossil fuels | 700–1500 | Fuel cost, cost of fuel transport, maintenance costs | CO2, NOx, sulphur oxides, and particulate emissions | Medium | Only for maintenance |

| Vapour compression powered by PV modules with electric storage | 2000–4000 | Batteries cost, maintenance costs | Battery disposal | Medium | Only for maintenance |

| Vapour compression powered by PV modules with thermal storage | 2000–6000 | Maintenance costs | None | High | Only for maintenance |

| Absorption powered by fossil fuels | 1000–2500 | Fuel cost, cost of fuel transport, maintenance costs | CO2, NOx, sulphur oxides, and particulate emissions | Medium | For maintenance and during installation |

| Absorption powered by solar collectors | 1500–3500 | Maintenance costs | None | High | For maintenance and during installation |

| Absorption powered by biomass | 2000–3500 | Fuel cost, cost of fuel transport, maintenance costs | CO2, NOx, sulphur oxides, and particulate emissions | High | For maintenance and during installation |

| Adsorption powered by solar energy | 1500–4500 | Maintenance costs | None | High | For maintenance and during installation |

| Component | Manufacturer | Specification |

|---|---|---|

| DC-powered compressor unit | Secop | BD35F–80 W–R134a |

| Condenser | Vitrifrigo | ND350R2-V |

| PV module | Sharp | ND-R240A5–240 Wp |

| Evaporator | Vitrifrigo | PT13 |

| Refrigerated volume | self-constructible | Wood panels and thermal insulation |

| Ice storage | self-constructible | Aluminium box |

| Parameter | Symbol | Value | Unit | |

|---|---|---|---|---|

| General features | Air volume | Vair | 0.295 | m3 |

| Air density | ρair | 1.22 | kg/m3 | |

| Air thermal capacity | cpair | 1006 | J/(kg K) | |

| Mass of the load | mload | 9 | kg | |

| Load thermal capacity | cpload | 4186 | J/(kg K) | |

| Opening coefficient | k | 0 | - | |

| Time step | ∆t | 10 | min | |

| Internal surface of the envelope | Senv | 2.665 | m2 | |

| Thermal insulation | Thickness | - | 0.3 | m |

| Average conductivity | - | 0.114 | W/mK | |

| Storage system | Mass of water in tank | mw | 12.5 | kg |

| Water thermal capacity | cw | 4186 | J/(kg K) | |

| External area of the storage tank | Ssto | 0.54 | m2 | |

| Water latent heat of fusion | λ | 333500 | J/kg | |

| Heat loss coefficient of the storage tank | Usto | 6 | W/m2K | |

| Day | Condition | Start | Stop |

|---|---|---|---|

| Day 1 | Sunny | 09:00 a.m. | 04:00 p.m. |

| Day 2 | Partially cloudy | 09:00 a.m. | 01:00 p.m. |

| Day 3 | Partially cloudy | 09:00 a.m. | 02:00 p.m. |

| Day 4 | Sunny | 09:00 a.m. | 05:00 p.m. |

| Day 5 | Cloudy | - | - |

| Day 6 | Cloudy | - | - |

| Day 7 | Sunny | 09:00 a.m. | 04:00 p.m. |

| Day | Working Period of the Compressor (h) | New Load (kg) | Number of Openings | Tint,35_meas after 12 h from the Introduction of the Load | Tint (°C) after 12 h from the Introduction of the Load |

|---|---|---|---|---|---|

| Day 1 | 7 | 9 | 8 | 5.21 | 4.96 |

| Day 2 | 4 | 4.5 | 4 | 4.68 | 4.38 |

| Day 3 | 5 | 4.5 | 4 | 4.87 | 4.64 |

| Day 4 | 8 | 9 | 8 | 4.69 | 4.98 |

| Day 5 | 0 | 9 | 8 | 6.24 | 5.61 |

| Day 6 | 0 | 9 | 8 | 9.26 | 7.85 |

| Day 7 | 7 | 0 | 0 | 5.49 | 5.52 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Del Pero, C.; Butera, F.M.; Piegari, L.; Faifer, M.; Buffoli, M.; Monzani, P. Characterization and Monitoring of a Self-Constructible Photovoltaic-Based Refrigerator. Energies 2016, 9, 749. https://doi.org/10.3390/en9090749

Del Pero C, Butera FM, Piegari L, Faifer M, Buffoli M, Monzani P. Characterization and Monitoring of a Self-Constructible Photovoltaic-Based Refrigerator. Energies. 2016; 9(9):749. https://doi.org/10.3390/en9090749

Chicago/Turabian StyleDel Pero, Claudio, Federico M. Butera, Luigi Piegari, Marco Faifer, Maddalena Buffoli, and Paolo Monzani. 2016. "Characterization and Monitoring of a Self-Constructible Photovoltaic-Based Refrigerator" Energies 9, no. 9: 749. https://doi.org/10.3390/en9090749

APA StyleDel Pero, C., Butera, F. M., Piegari, L., Faifer, M., Buffoli, M., & Monzani, P. (2016). Characterization and Monitoring of a Self-Constructible Photovoltaic-Based Refrigerator. Energies, 9(9), 749. https://doi.org/10.3390/en9090749