A Novel Dynamic Co-Simulation Analysis for Overall Closed Loop Operation Control of a Large Wind Turbine

Abstract

:1. Introduction

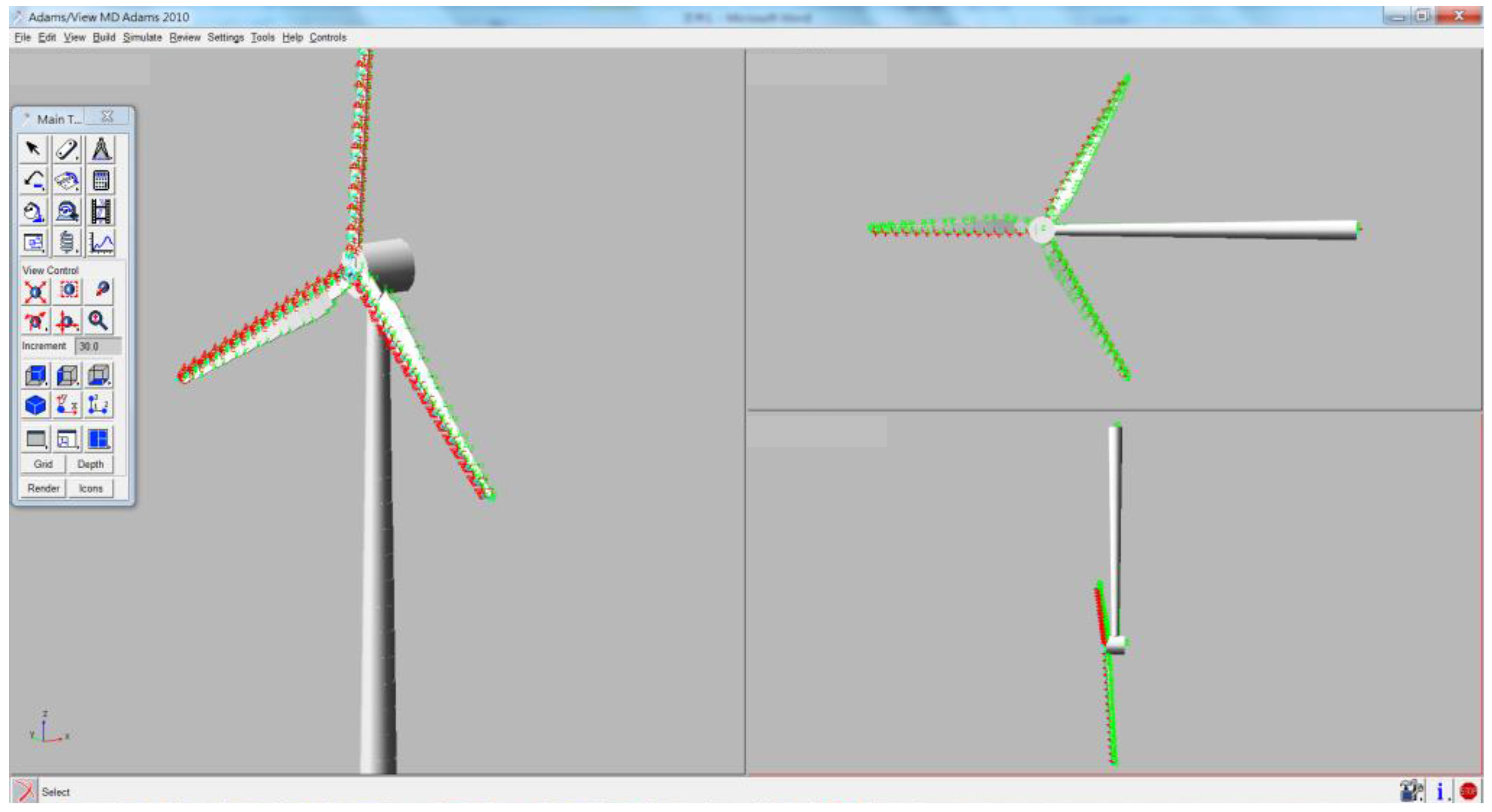

2. System Model Build Up

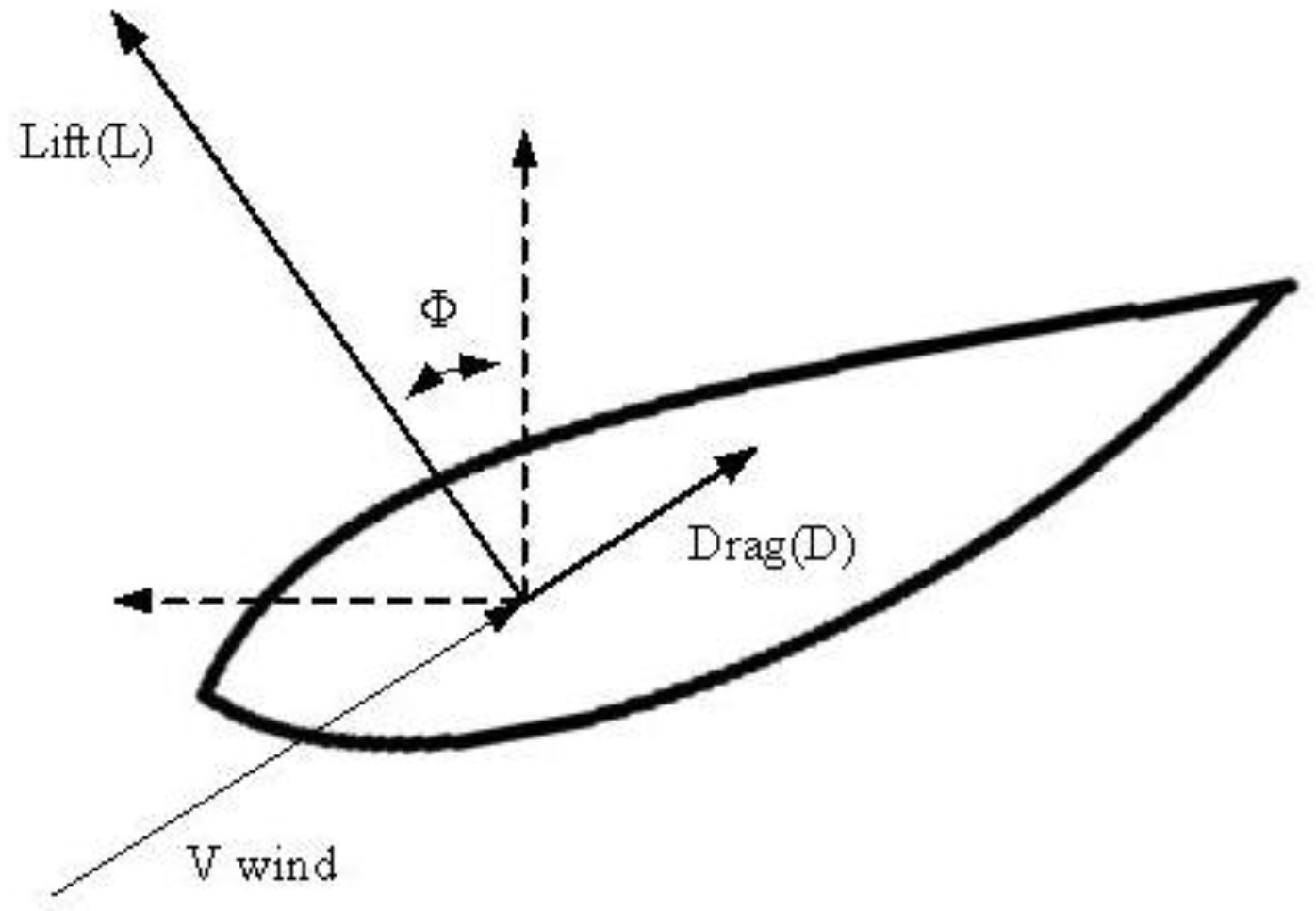

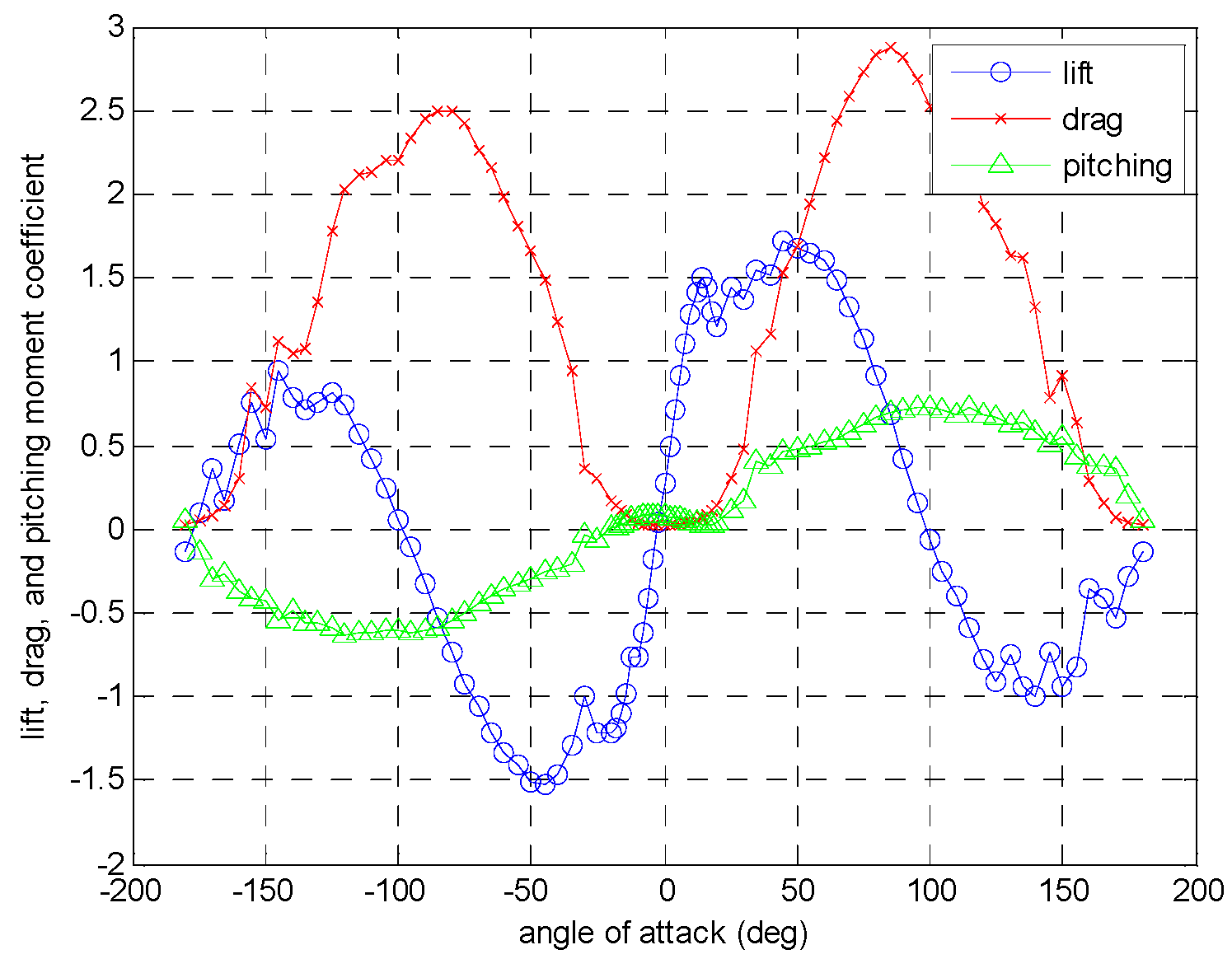

2.1. Mathematic Model of Wind Turbine System

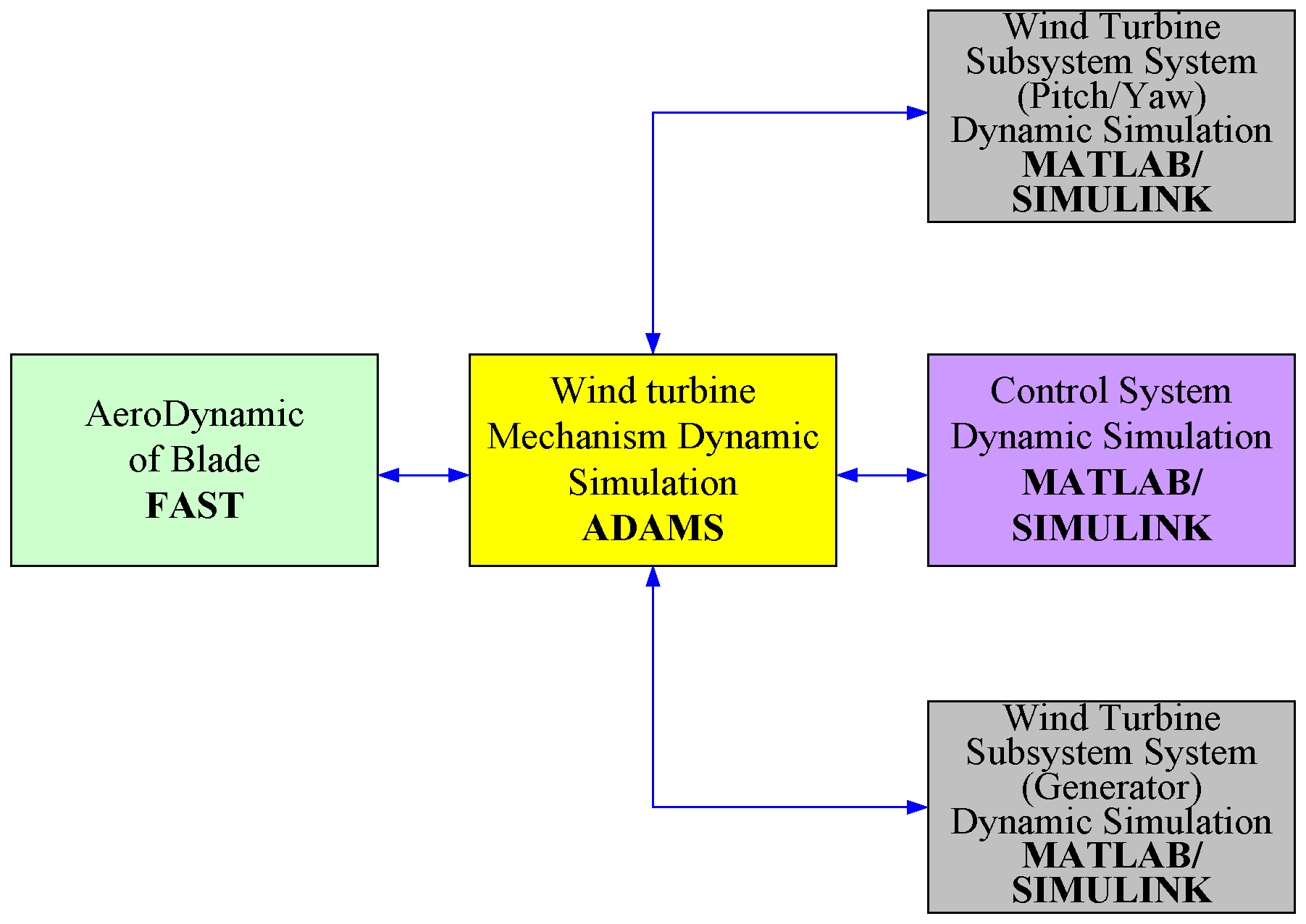

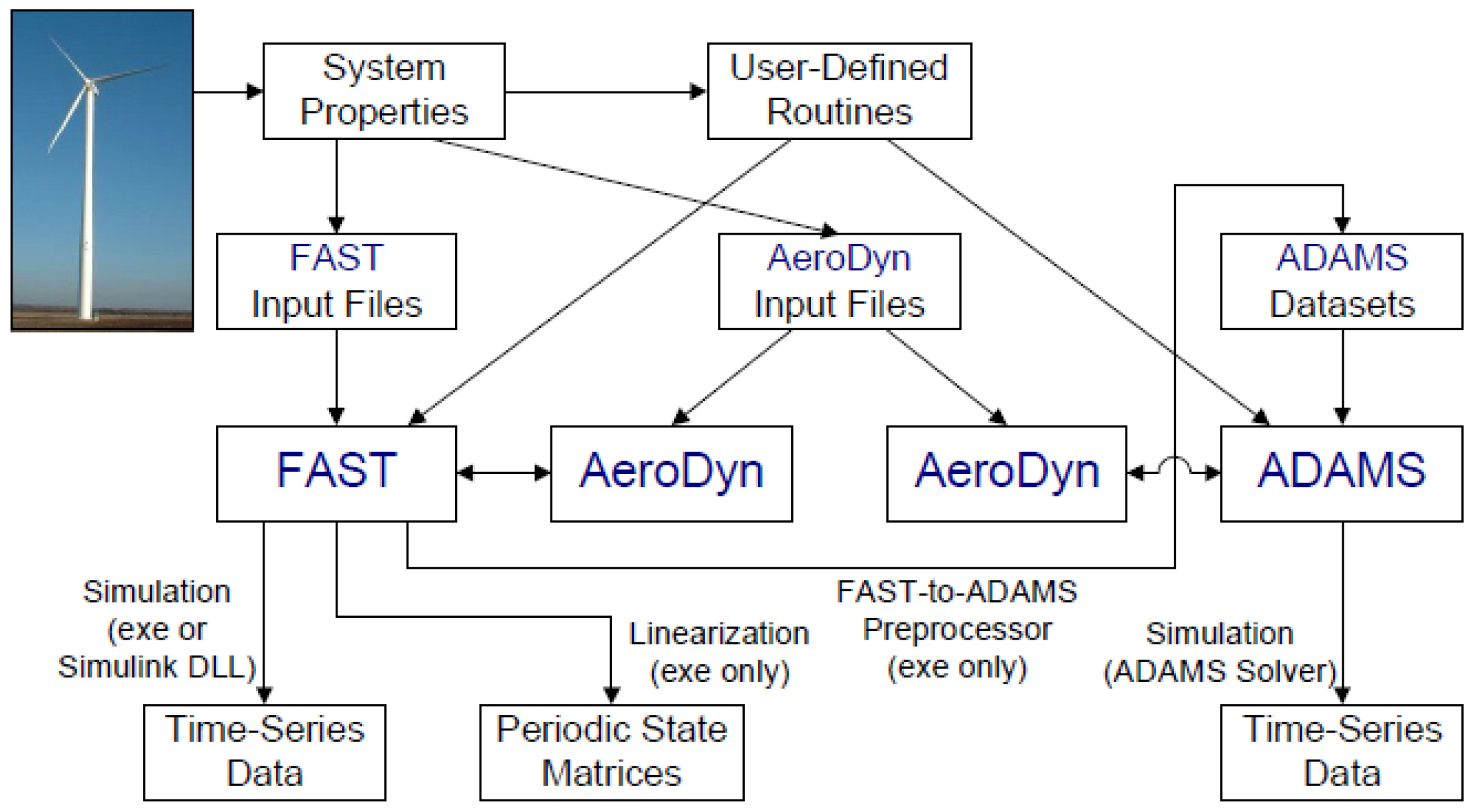

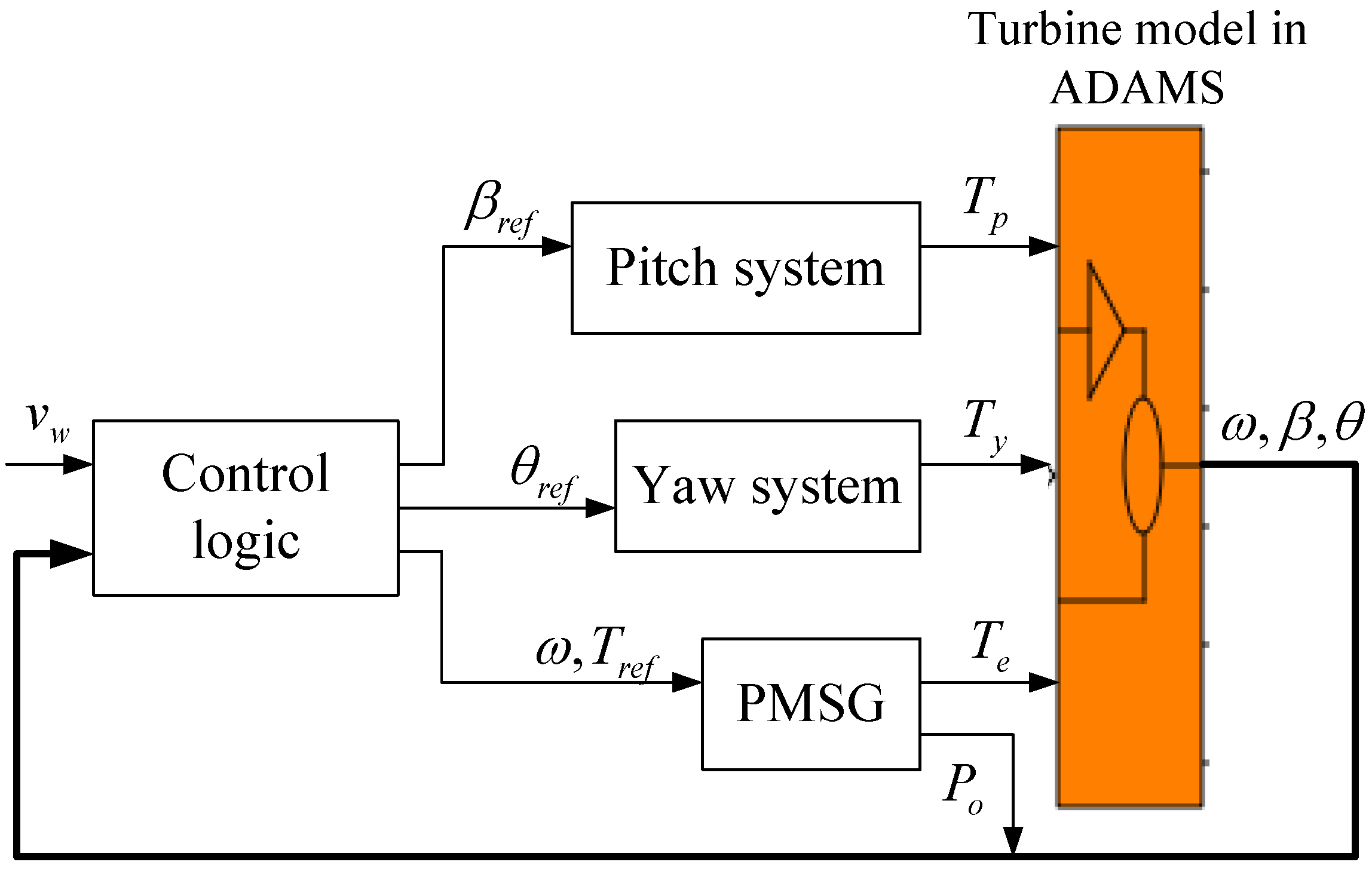

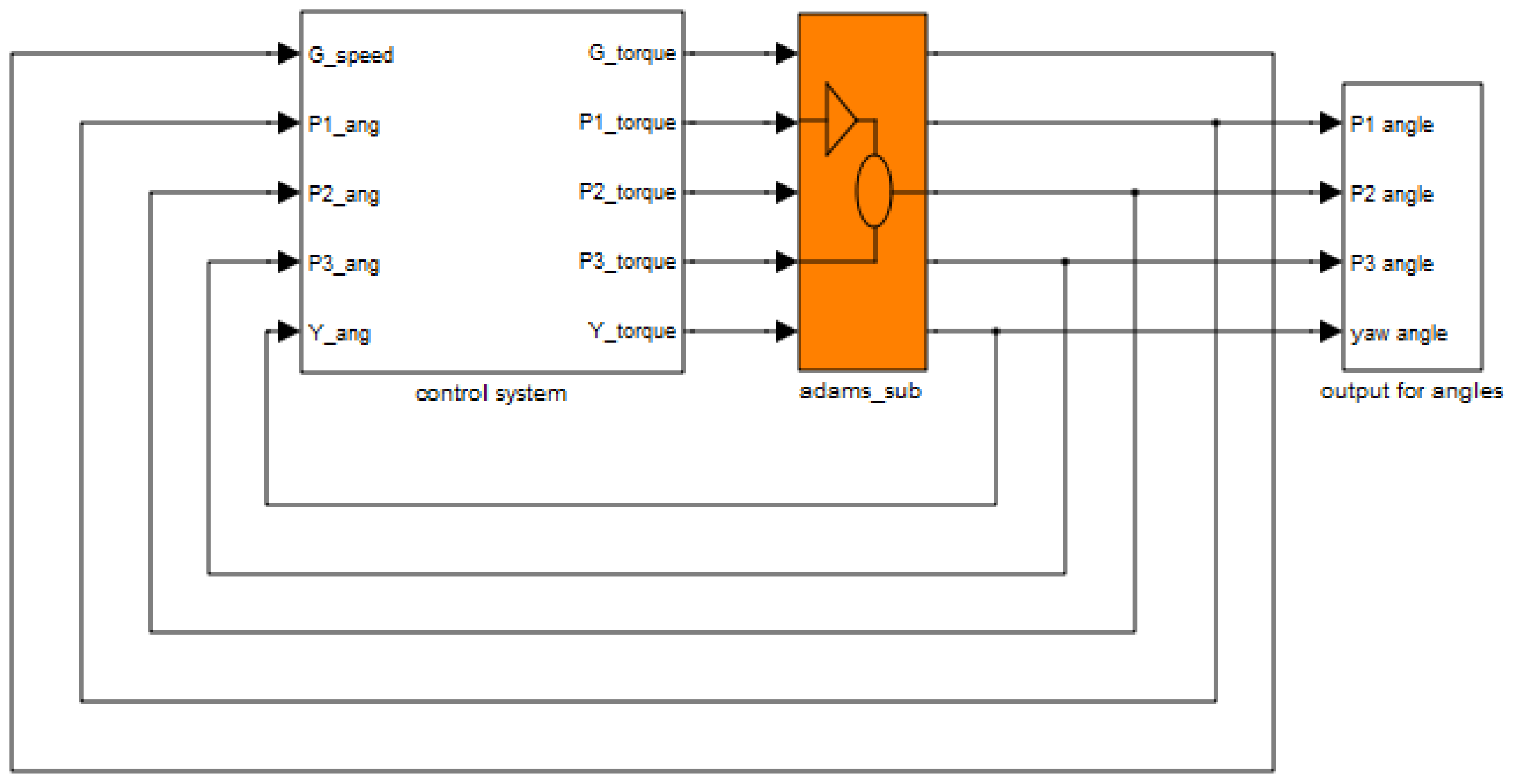

2.2. Co-Simulation Wind Turbine Interface

3. Modeling of Turbine Subsystem

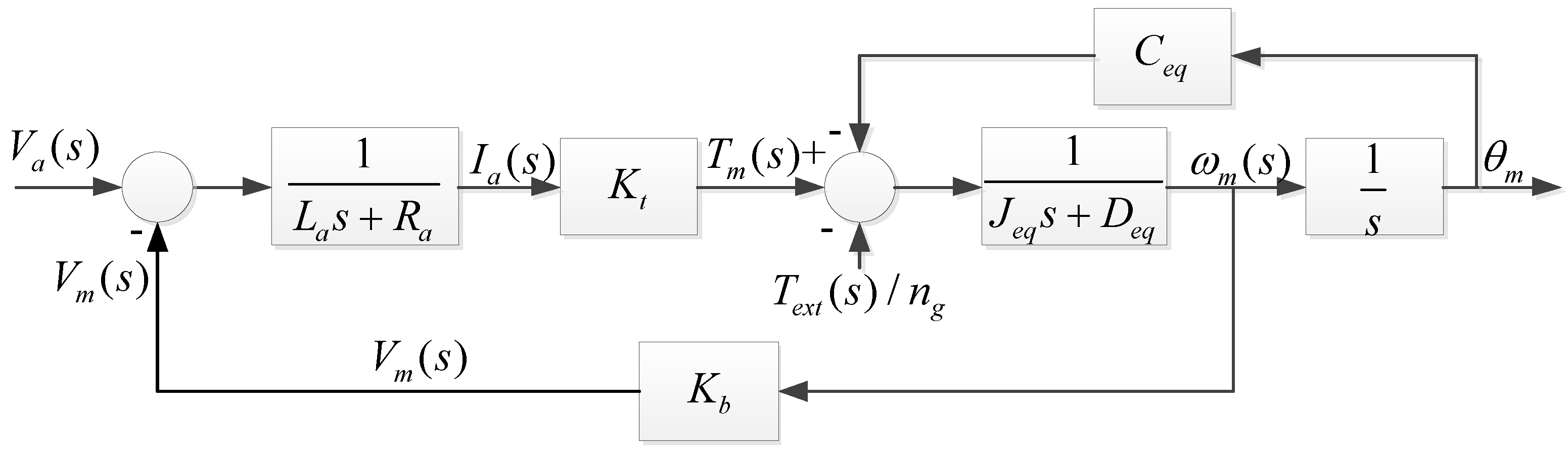

3.1. Modeling of DC Servo Motor in Pitch Control System

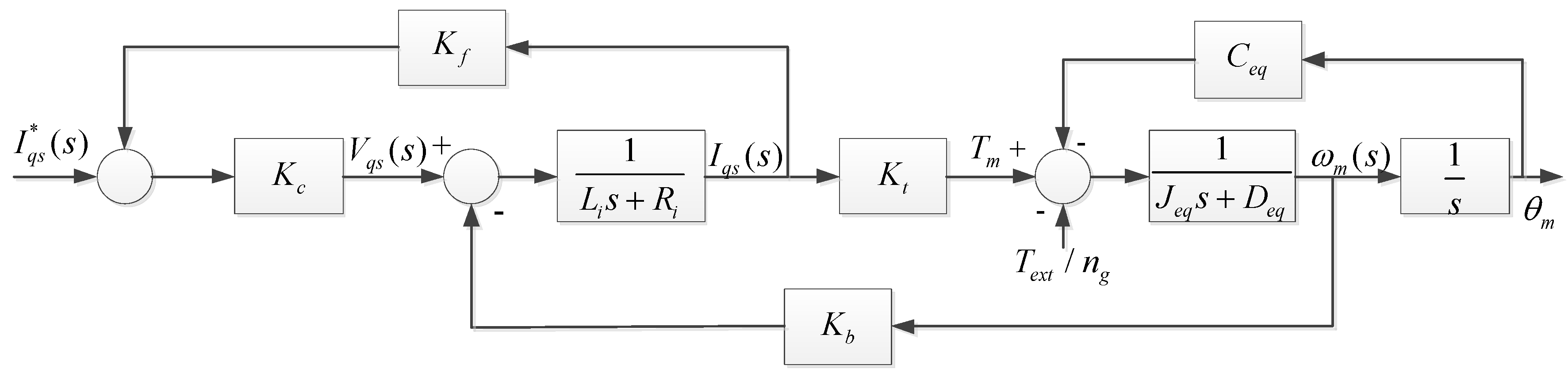

3.2. Modeling of AC Induction Motor in Yaw Control System

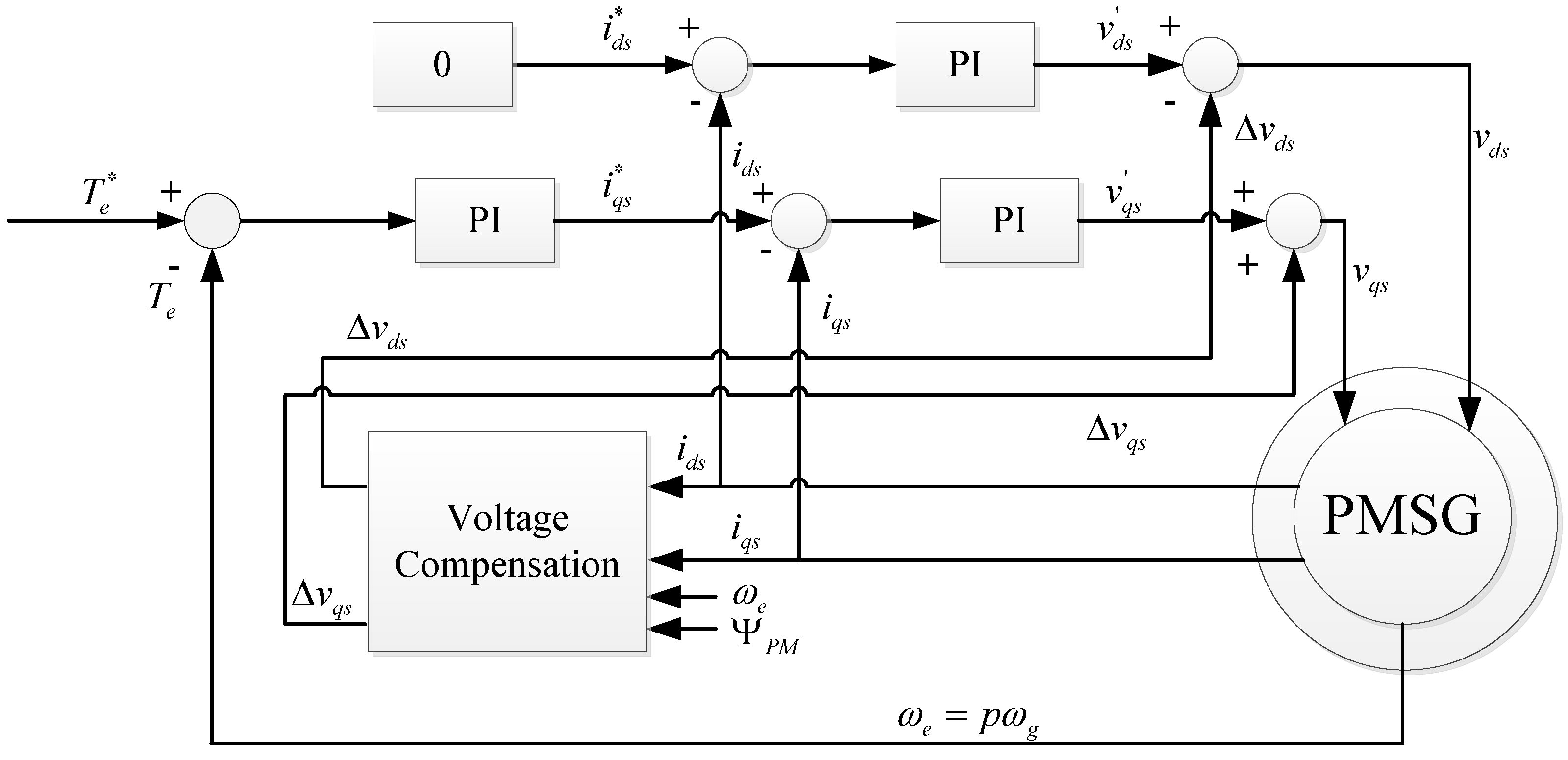

3.3. Modeling of Permanent Magnetic Synchronous Generator System

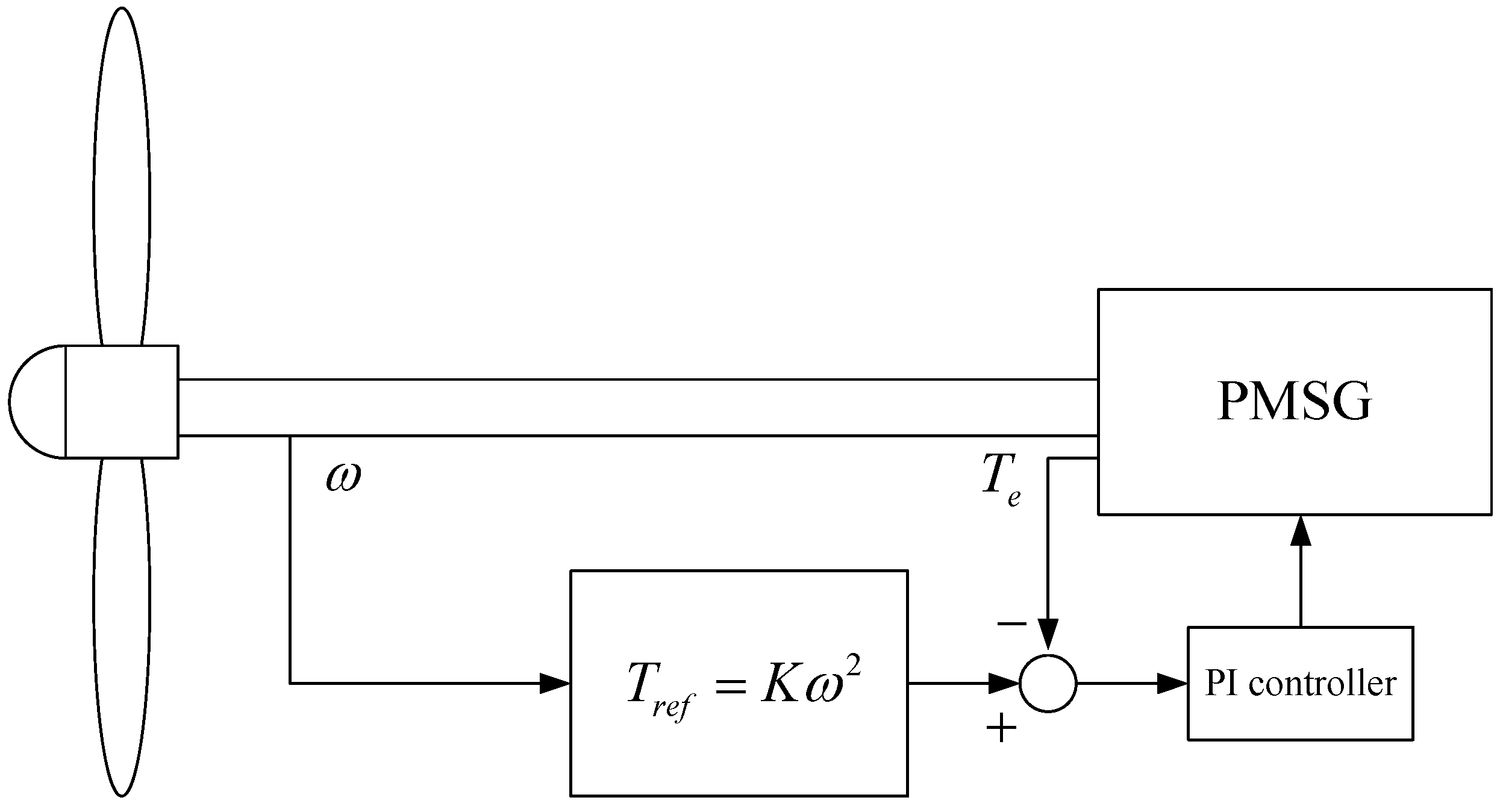

4. MPPT Controller Design

Control Regions in Wind Turbine

5. Simulation Results and Comparison

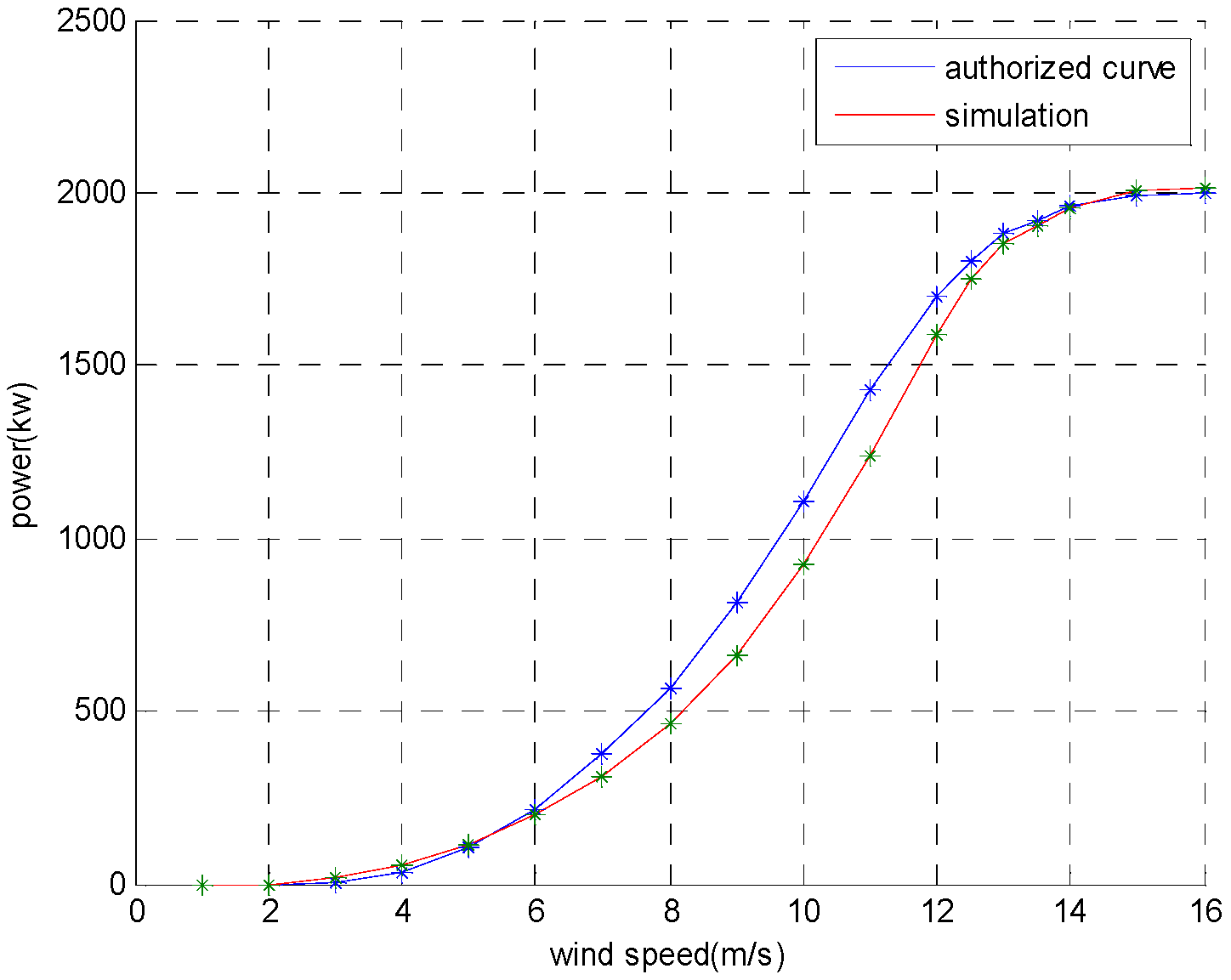

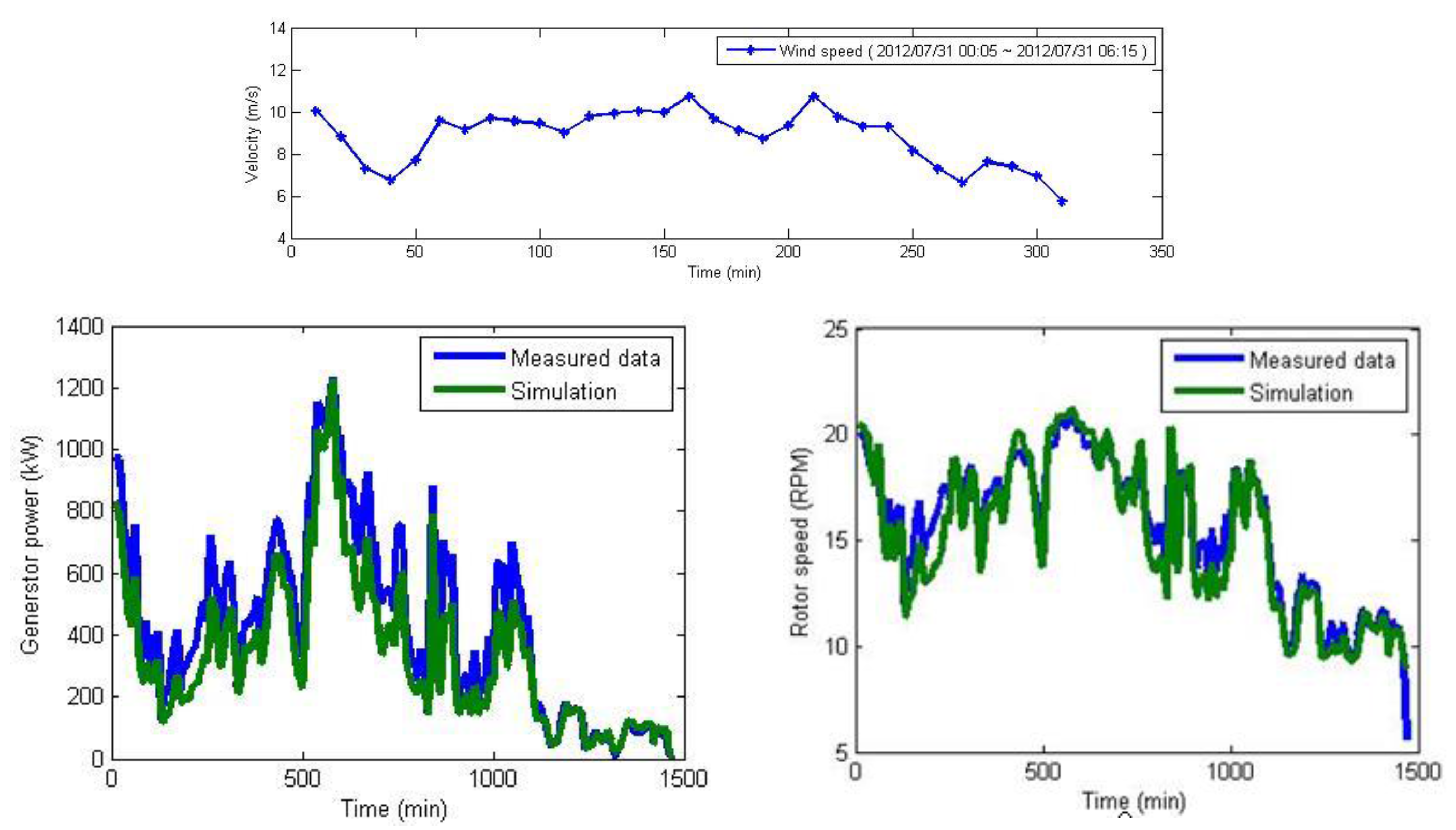

5.1. Comparison of Wind Turbine Characteristics

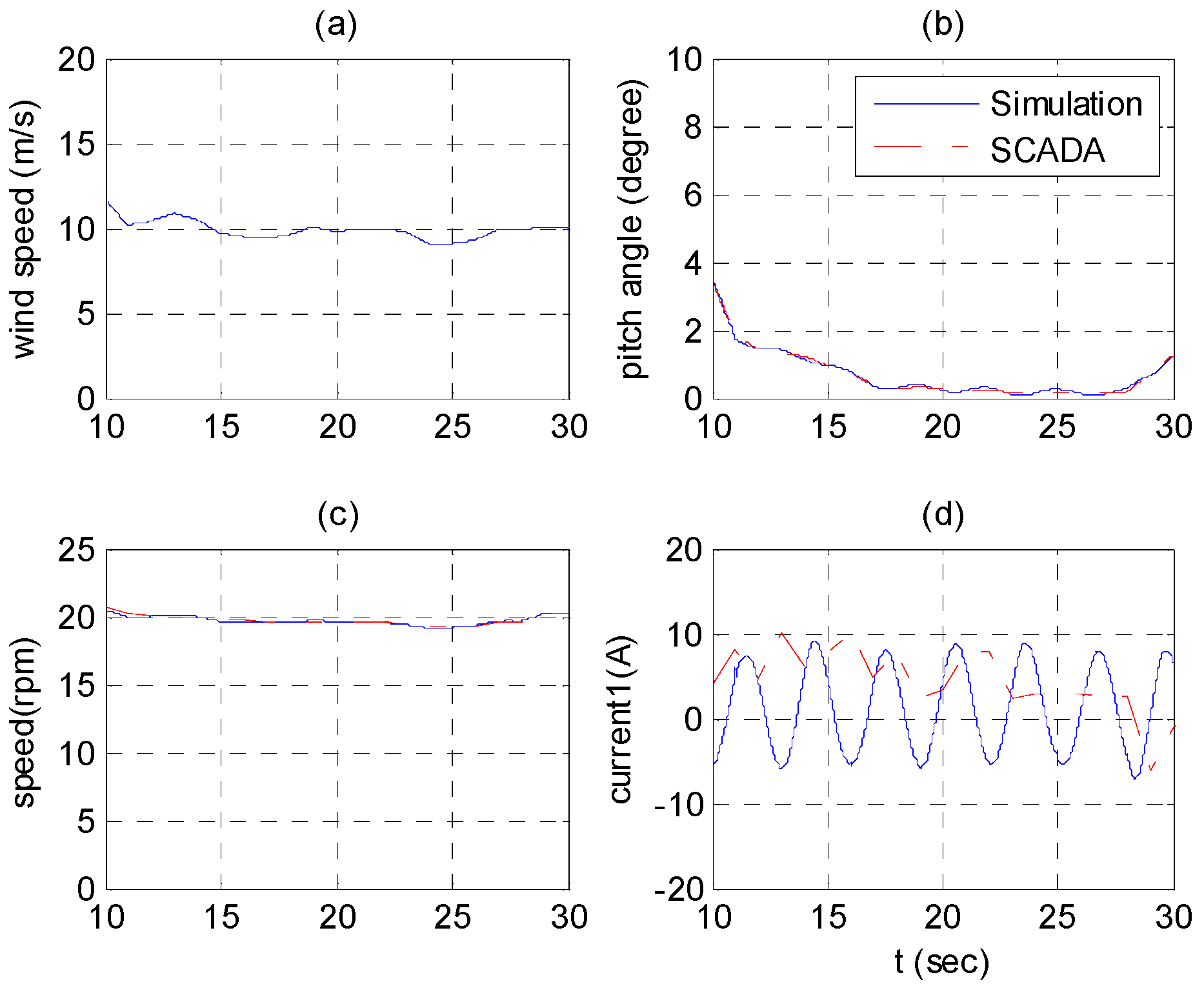

5.2. Comparison of Simulation Results with SCADA

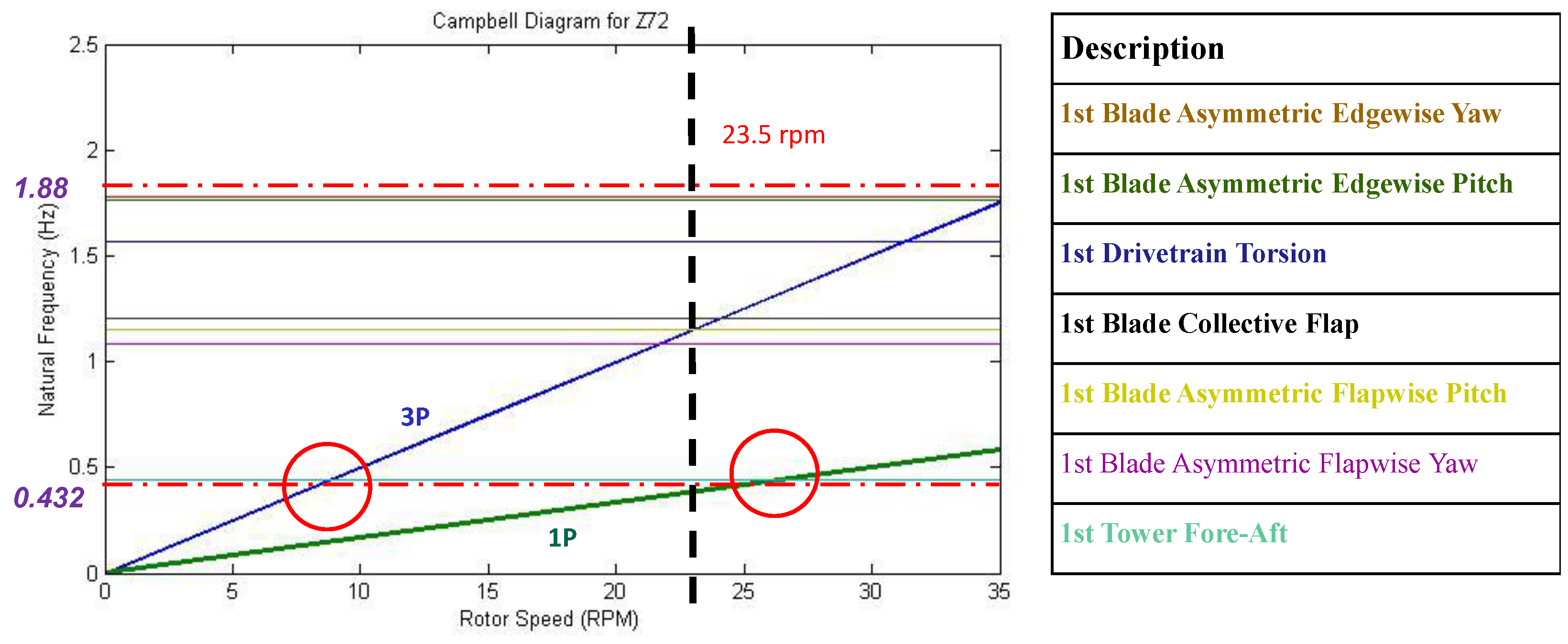

5.3. Mode Shape Analysis of Wind Turbine

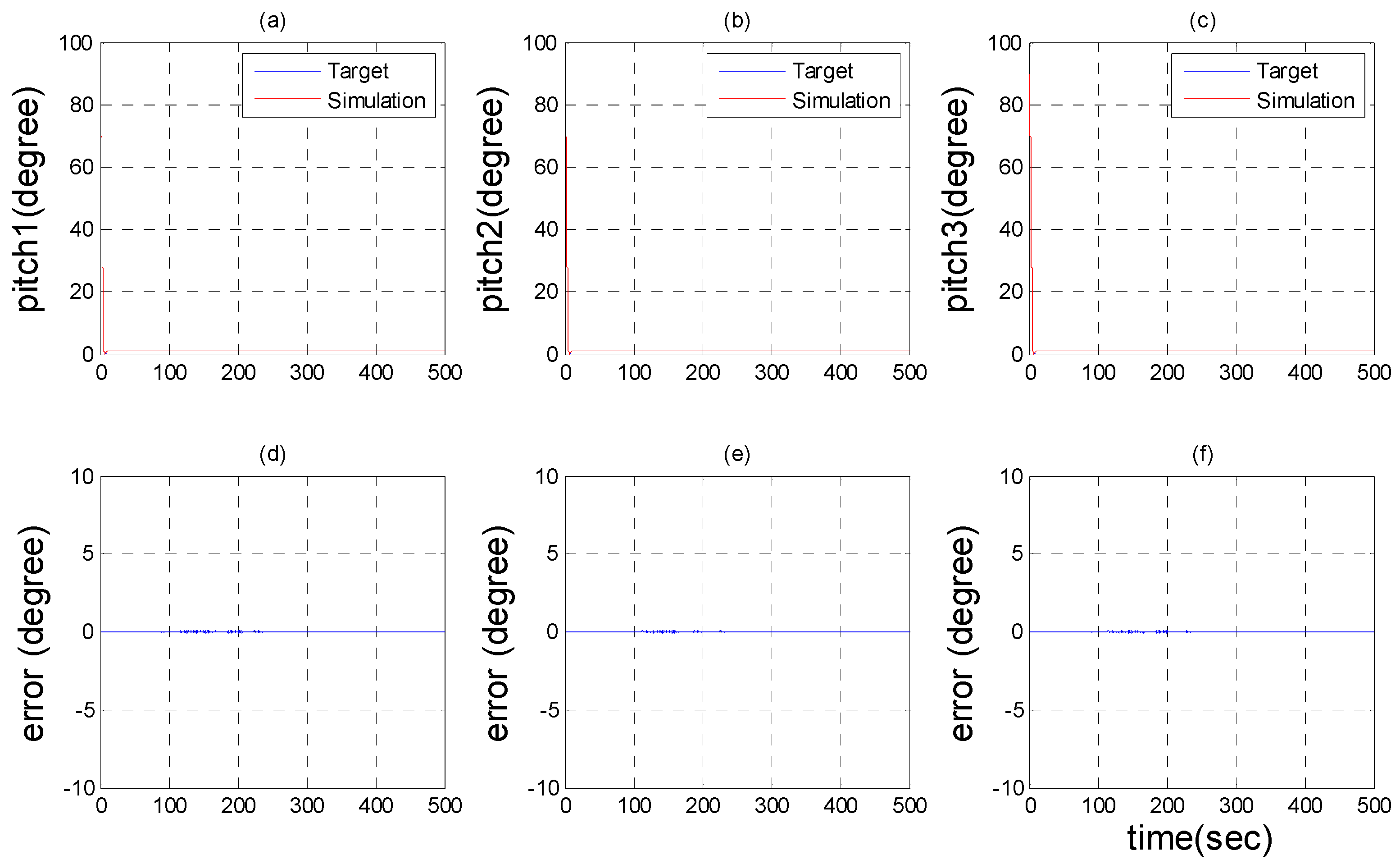

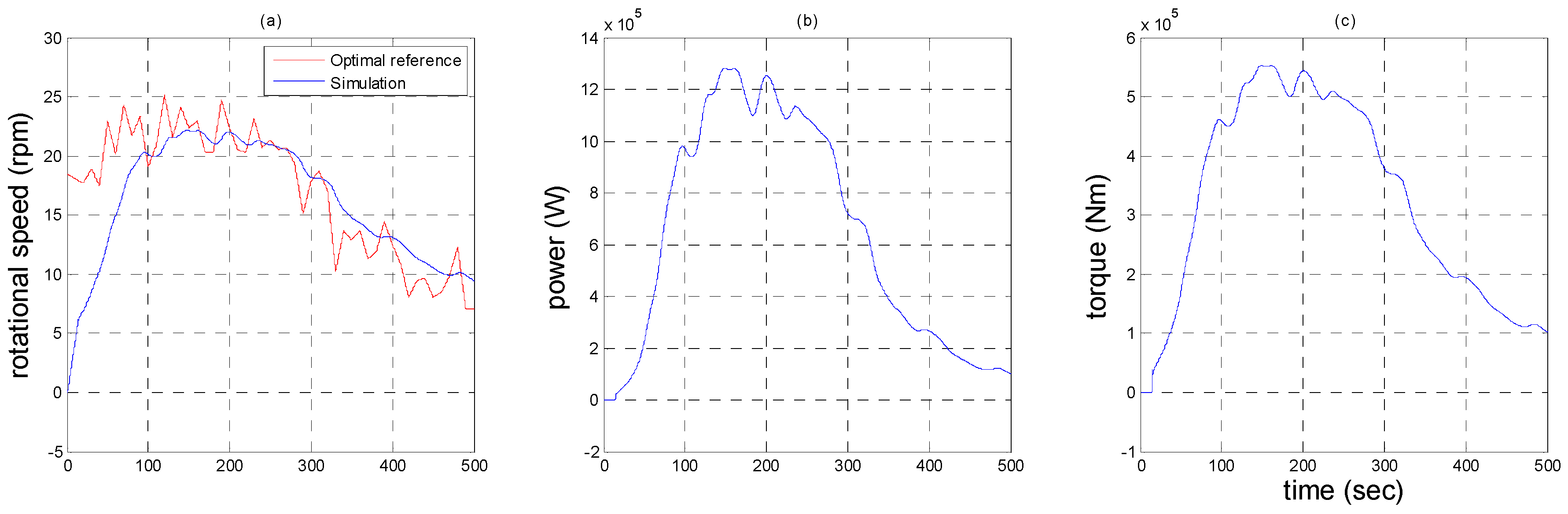

5.4. Overall Simulation in Region 2

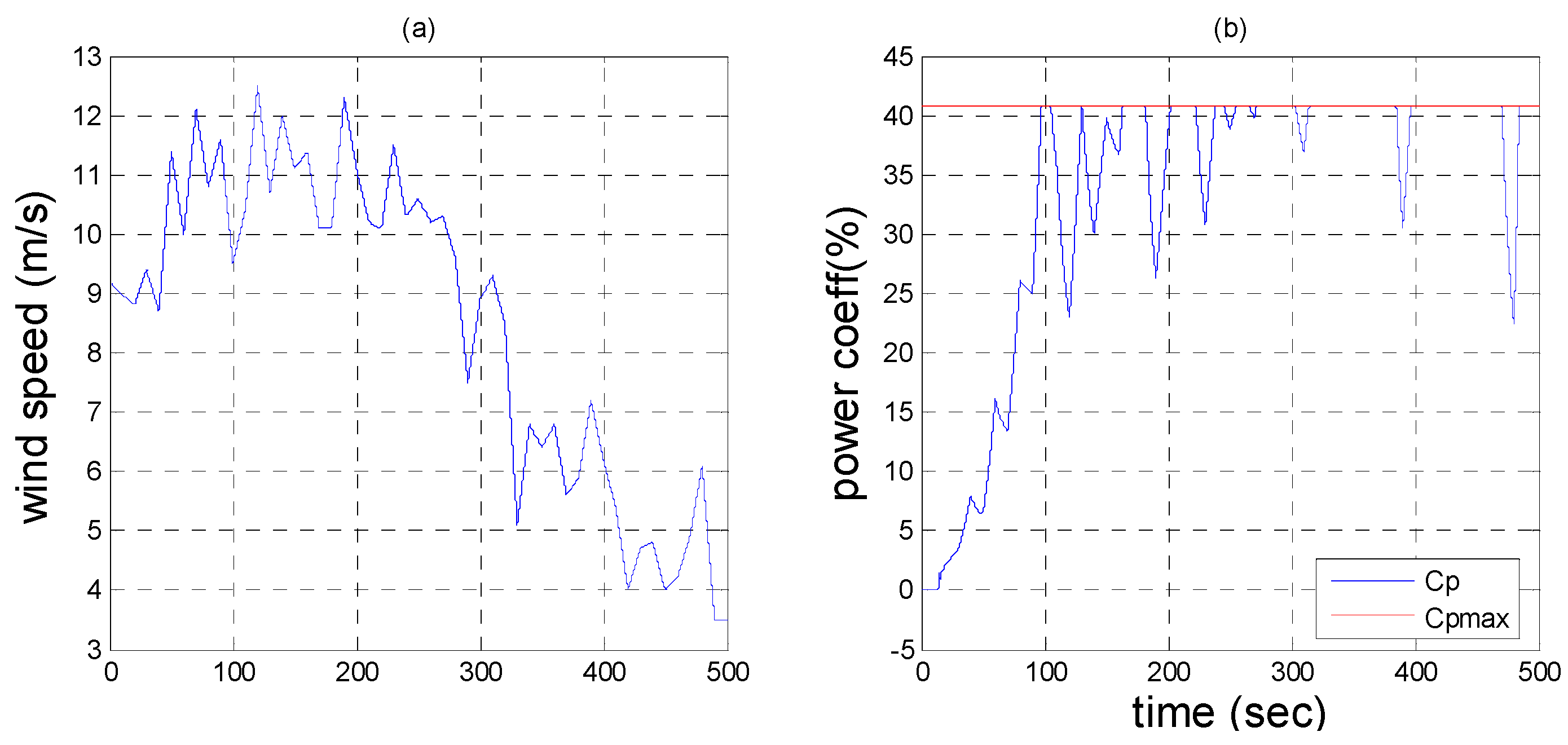

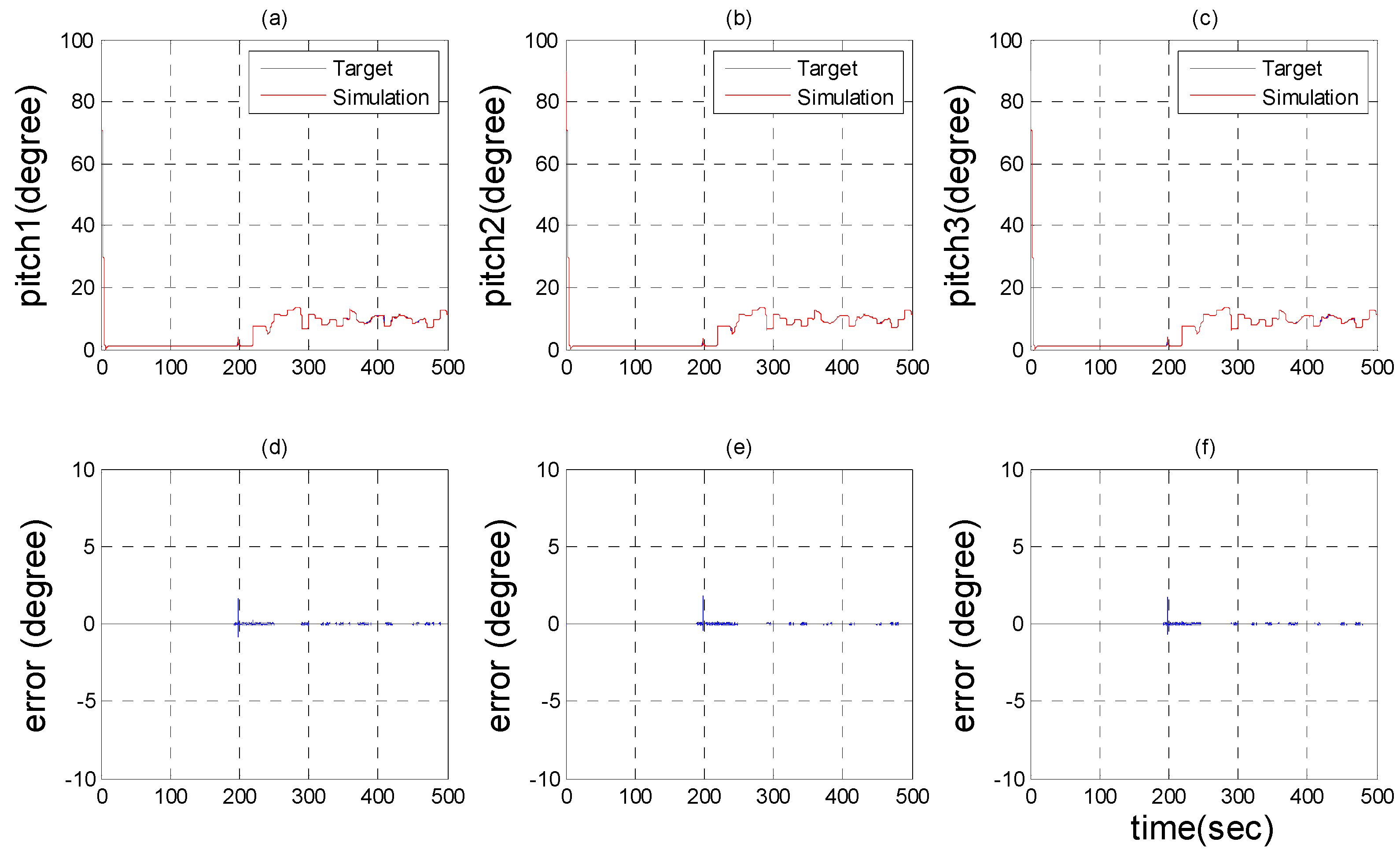

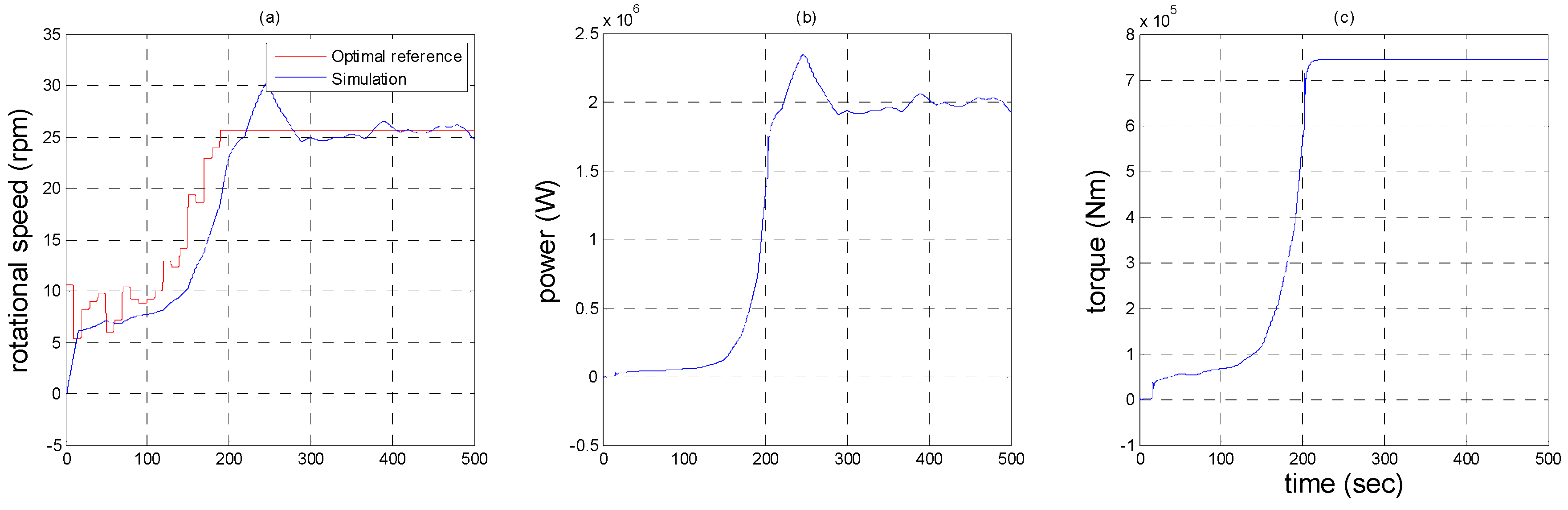

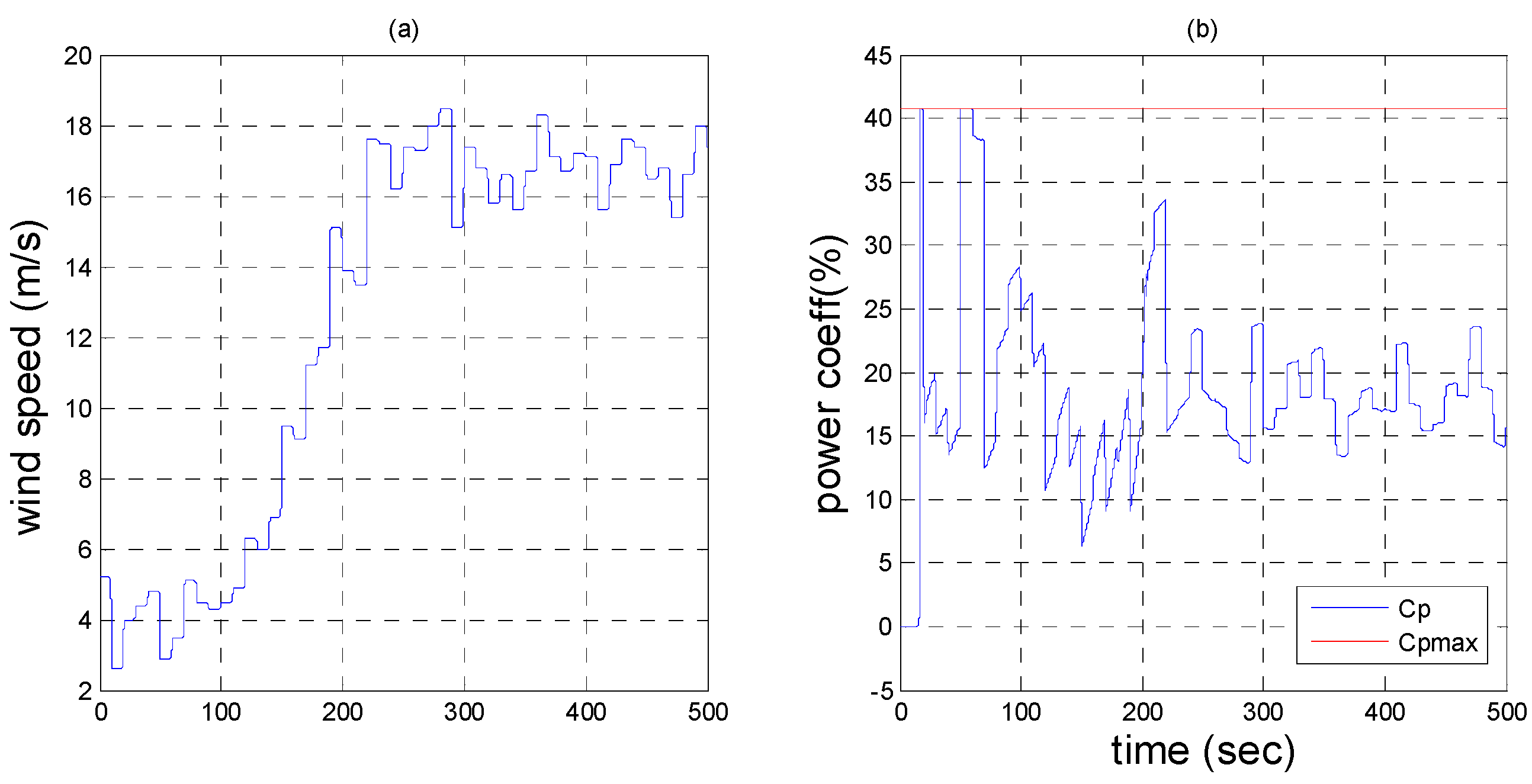

5.5. Overall Simulation of MPPT

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| SCADA | Supervisory Control And Data Acquisition |

| HAWT | Horizontal-Axis Wind Turbine |

| VAWT | Vertical-Axis Wind Turbine |

| NREL | National Renewable Energy Laboratory |

| PMSG | Permanent Magnetic Synchronize Generator |

| ADAMS | Automatic Dynamic Analysis of Mechanical Systems |

| BEM | Blade Element Momentum theory |

| MPPT | Maximum Power Point Tracking |

| FAST | Fatigue, Aerodynamics, Structures, and Turbulence |

| PID | Proportional Integral Derivative |

| PI | Proportional Integral |

| LQG | Linear Quadratic Gaussian |

References

- Burton, D.S.T.; Jenkins, N.; Bossanyi, E. Wind Energy Handbook; John Wiley &sons Ltd.: Chichester, UK, 2001. [Google Scholar]

- Wang, Y.; Li, Q.; Qin, S. A new method of wind turbines modeling based on combined simulation. In Proceedings of the 2014 International Conference on Power System Technology (POWERCON), Chengdu, China, 20–22 October 2014.

- MATLAB Homepage. Available online: http//www.mathworks.com (accessed on 17 June 2016).

- Younsi, R.; El-Batanony, I.; Tritsch, J.-B.; Naji, H.; Landjerit, B. Dynamic study of a wind turbine blade with horizontal axis. Eur. J. Mech. A Solids 2010, 20, 241–252. [Google Scholar] [CrossRef]

- Howell, R.; Qin, N.; Edwards, J.; Durrani, N. Wind tunnel and numerical study of a small vertical axis wind turbine. Renew. Energy 2010, 35, 412–422. [Google Scholar] [CrossRef]

- Wilmshurst, S.M.B. Control Strategies for Wind Turbines; National Renewable Energy Laboratory: Washington, DC, USA, 1988. [Google Scholar]

- Freeman, J.B.; Balas, M.J. An investigation of variable speed horizontal-axis wind turbines using direct model-reference adaptive control. In Proceedings of the 18th ASME (American Society of Mechanical Engineers) Wind Energy Symposium, Reno, NV, USA, 11–14 January 1999.

- Jones, R.; Smith, G.A. High quality mains power from variable-speed wind turbines. In Proceedings of the 2001 International Conference on Renewable Energy—Clean Power, London, UK, 17–19 November 1993.

- Idan, M.; Lior, D. Continuously variable speed wind turbine: Transmission concept and robust control. Wind Eng. 2000, 24, 151–167. [Google Scholar] [CrossRef]

- Song, Y.D.; Dhinakaran, B.; Bao, X.Y. Variable speed control of wind turbines using nonlinear and adaptive algorithms. J. Wind Eng. Ind. Aerodyn. 2000, 85, 293–308. [Google Scholar] [CrossRef]

- Boukhezzar, B.; Siguerdidjane, H. Nonlinear control of variable speed wind turbines without wind speed measurement. In Proceedings of the 44th IEEE Conference on Decision Control/European Control Conference (CCD-ECC), Seville, Spain, 12–15 December 2005.

- Camblong, H.; Tapia, G.; Rodriguez, M. Robust digital control of a wind turbine for rated-speed and variable-power operation regime. Control Theory Appl. IEE Proc. 2006, 153, 81–91. [Google Scholar] [CrossRef]

- Felippa, C.A.; Park, K.C.; Farhat, C. Partitioned analysis of coupled mechanical systems. Comput. Methods Appl. Mech. Eng. 2001, 190, 3247–3270. [Google Scholar] [CrossRef]

- Boukhezzar, B.; Lupu, L.; Siguerdidjane, H.; Hand, M. Multivariable control strategy for variable speed, variable pitch wind turbines. Renew. Energy 2007, 32, 1273–1287. [Google Scholar] [CrossRef]

- Zhang, J.; Cheng, M.; Chen, Z. Design of wind turbine controller by using wind turbine codes. In Proceedings of the 11th International Conference on Electrical Machines and Systems, Wuhan, China, 17–20 October 2008.

- Fadaeinedjad, R.; Moschopoulos, G.; Moallem, M. Simulation of a wind turbine with doubly-fed induction machine using FAST and Simulink. In Proceedings of the 2006 IEEE International Symposium on Industrial Electronics, Montreal, Canada, 9–13 July 2006.

- Lu, R.K.; Chang, C.R. Load Computation of a 150 kW wind turbine by IEC-61400-1via FAST/SIMULINK. In Proceedings of the Taiwan Wind Energy Conference, Taipei, Taiwan, 1–6 December 2009.

- Mandic, G.; Nasiri, A. Modeling and simulation of a wind turbine system with ultracapacitors for short-term power smoothing. In Proceedings of the 2010 IEEE International Symposium on Industrial Electronics (ISIE), Bari, Italy, 4–7 July 2010.

- Sicklinger, S.; Lerch, C.; Wüchner, R.; Bletzinger, K.-U. Fully coupled co-simulation of a wind turbine emergency brake maneuver. J. Wind Eng. Ind. Aerodyn. 2015, 144, 134–145. [Google Scholar] [CrossRef]

- Sicklinger, S.A. Stabilized Co-Simulation of Coupled Problems Including Fields and Signals. Ph.D. Thesis, Technische Universität München, München, Gemany, 2014. [Google Scholar]

- Anis, A. Simulation of slider crank mechanism using Adams software. Int. J. Eng. Technol. 2012, 12, 108–112. [Google Scholar]

- Jingjun, Z.; Jitao, Z.; Ruizhen, G.; Lili, H. The application of co-simulation technology of ANSYS and MSC.ADAMS in structural engineering. In Proceedings of the 2010 International Conference on Mechanic Automation and Control Engineering (MACE), Wuhan, China, 26–28 June 2010.

- Li, T.; Zhang, J.; Chen, D.F.; Zhang, Z.; Hu, J. Dynamics researches of megawatt wind turbine gear increaser based on Adams. In Proceedings of the 2011 6th International Conference on Pervasive Computing and Applications (ICPCA), Port Elizabeth, South Africa, 26–28 October 2011.

- Bak, C.A.M.; Aagaard, H.; Johansen, J. Influence from blade-tower interaction on fatigue loads and dynamics (poster). In Proceedings of the Wind energy for the new millennium, Copenhagen, Denmark, 2–7 July 2001.

- Jonkman, J.M.; Buhl, M.L., Jr. FAST User’s Guide; National Renewable Energy Laboratory: Washington, DC, USA, 2005. [Google Scholar]

- Uddin, M.N.; Radwan, T.S.; Azizur Rahman, M. Performances of fuzzy-logic-based indirect vector control for induction motor drive. Ind. Appl. IEEE Trans. 2002, 38, 1219–1225. [Google Scholar] [CrossRef]

- Gaeid, K.S.; Hew, P.; Mohamed, H.A.F. Indirect vector control of a variable frequency induction motor drive (VCIMD). In Proceedings of the 2009 International Conference on Instrumentation, Communications, Information Technology, and Biomedical Engineering (ICICI-BME), Bandung, Indonesia, 23–25 November 2009.

- Rolan, A.; Luna, A.; Vazquez, G.; Aguilar, D.; Azevedo, G. Modeling of a variable speed wind turbine with a Permanent Magnet Synchronous Generator. In Proceedings of the IEEE International Symposium on Industrial Electronics (ISIE 2009), Seoul, Korea, 5–8 July 2009.

- Busca, C.; Stan, A.I.; Stanciu, T.; Stroe, D.I. Control of Permanent Magnet Synchronous Generator for large wind turbines. In Proceedings of the 2010 IEEE International Symposium on Industrial Electronics (ISIE), Bari, Italy, 4–7 July 2010.

- Merabet, A.; Thongam, J.; Gu, J. Torque and pitch angle control for variable speed wind turbines in all operating regimes. In Proceedings of the 2011 10th International Conference on Environment and Electrical Engineering (EEEIC), Rome, Italy, 8–11 May 2011.

- Johnson, E.; Balas, M.J.; Pao, L.Y. Methods for increasing region 2 power capture on a variable speed HAWT. In Proceedings of the 23rd ASME (American Society of Mechanical Engineers) Wind Energy Symposium, Reno, NV, USA, 5–8 January 2004.

- Hu, W.H.; Sebastian, T.; Samir, S.; Werner, R. Resonance phenomenon in a wind turbine system under operational conditions. In Proceedings of the 9th International Conference on Structural Dynamics, Porto, Portugal, 30 June–2 July 2014.

| Software | Version |

|---|---|

| IEC | v5.01.01 (2010-03-18) |

| AeroDyn | v13.00.00a-bjj (2010-03-31) |

| FAST | v7.00.01a-bjj (2010-11-05) |

| ADAMS | v2010 |

| SIMULINK | v7.11.0.584 (R2010b) |

| Name | Dimensions (m) | Mass (kg) |

|---|---|---|

| Generator | 4900 | |

| Nacelle | 12,000 | |

| Hub | 19,000 | |

| Blade | 34 | 5500 |

| Tower | 61.859 | 100,000 |

| Name | Values | Unit |

|---|---|---|

| 25.6771 | ||

| 7.44×105 | ||

| 7.37 | ||

| 40.08 |

| Tower | 1st fore-aft | 2nd fore-aft |

| Experiment | 0.432 | 3.281 |

| ADAMS | 0.441 | 3.813 |

| Blade | 1st fore-aft | 2nd fore-aft |

| Experiment | 1.880 | 3.000 |

| ADAMS | 1.151 | 3.193 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.-S.; Chiang, M.-H. A Novel Dynamic Co-Simulation Analysis for Overall Closed Loop Operation Control of a Large Wind Turbine. Energies 2016, 9, 637. https://doi.org/10.3390/en9080637

Wang C-S, Chiang M-H. A Novel Dynamic Co-Simulation Analysis for Overall Closed Loop Operation Control of a Large Wind Turbine. Energies. 2016; 9(8):637. https://doi.org/10.3390/en9080637

Chicago/Turabian StyleWang, Ching-Sung, and Mao-Hsiung Chiang. 2016. "A Novel Dynamic Co-Simulation Analysis for Overall Closed Loop Operation Control of a Large Wind Turbine" Energies 9, no. 8: 637. https://doi.org/10.3390/en9080637

APA StyleWang, C.-S., & Chiang, M.-H. (2016). A Novel Dynamic Co-Simulation Analysis for Overall Closed Loop Operation Control of a Large Wind Turbine. Energies, 9(8), 637. https://doi.org/10.3390/en9080637