Performance Analysis of a Grid-Connected Upgraded Metallurgical Grade Silicon Photovoltaic System

Abstract

:1. Introduction

2. PV System and Database

3. Methods

3.1. Evaluation of PV Performance

3.2. Estimation of Degradation Rate

4. Results and Discussion

4.1. PV Performance

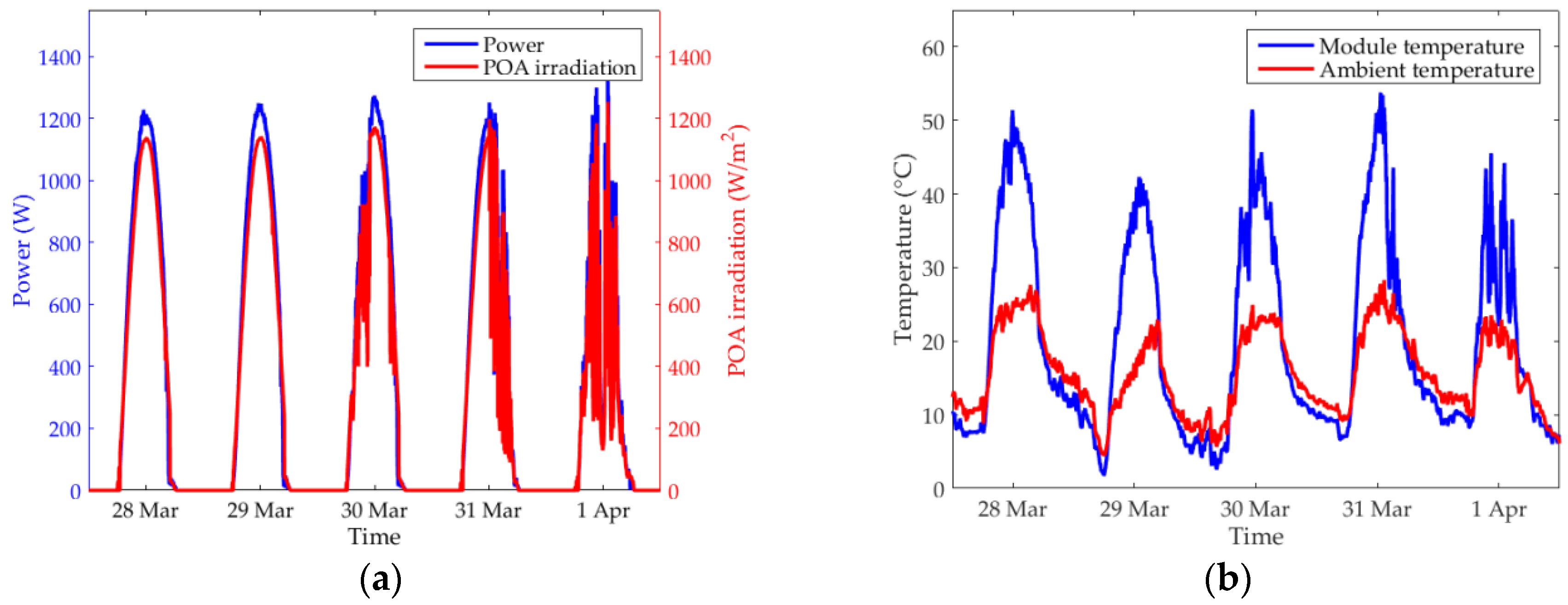

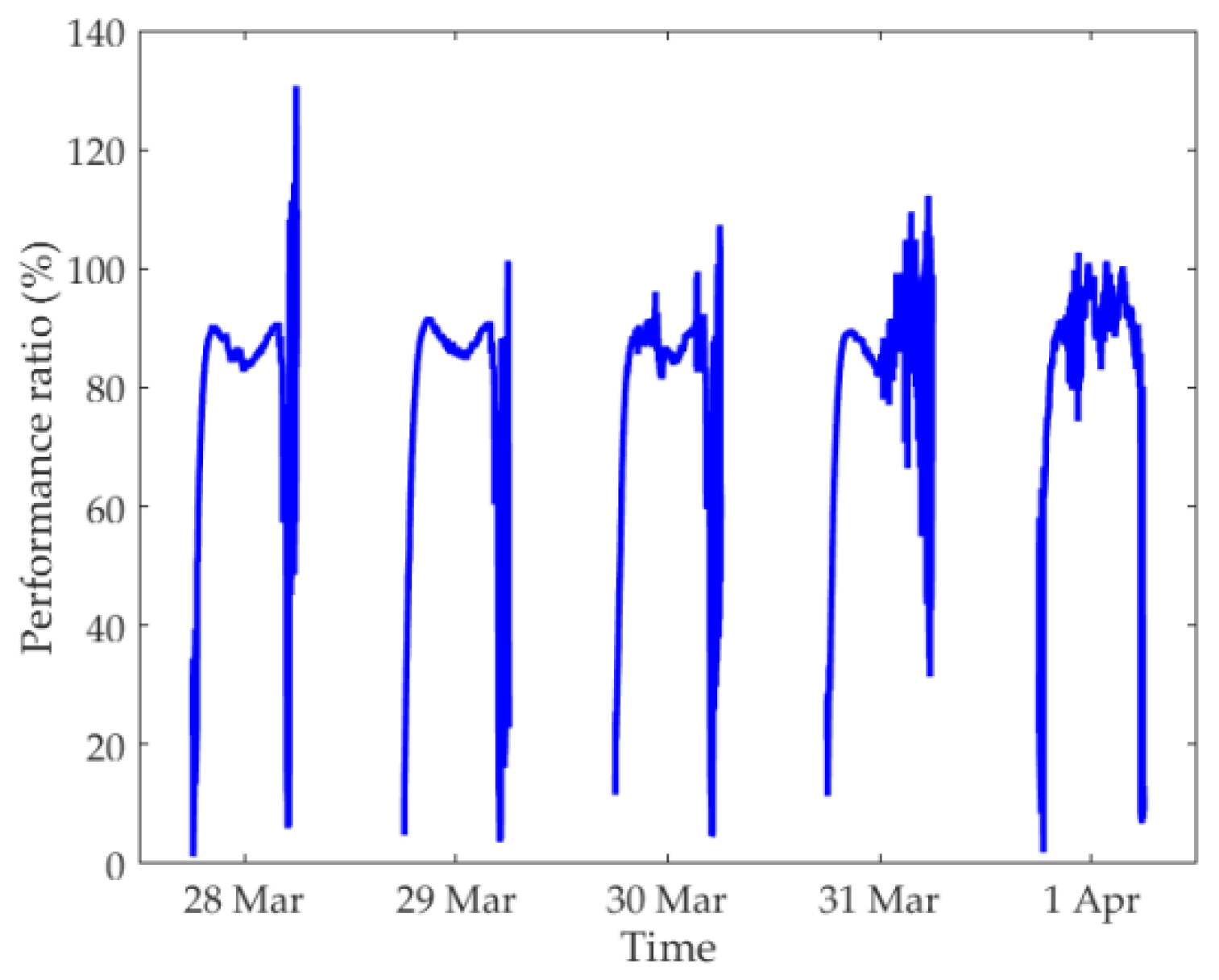

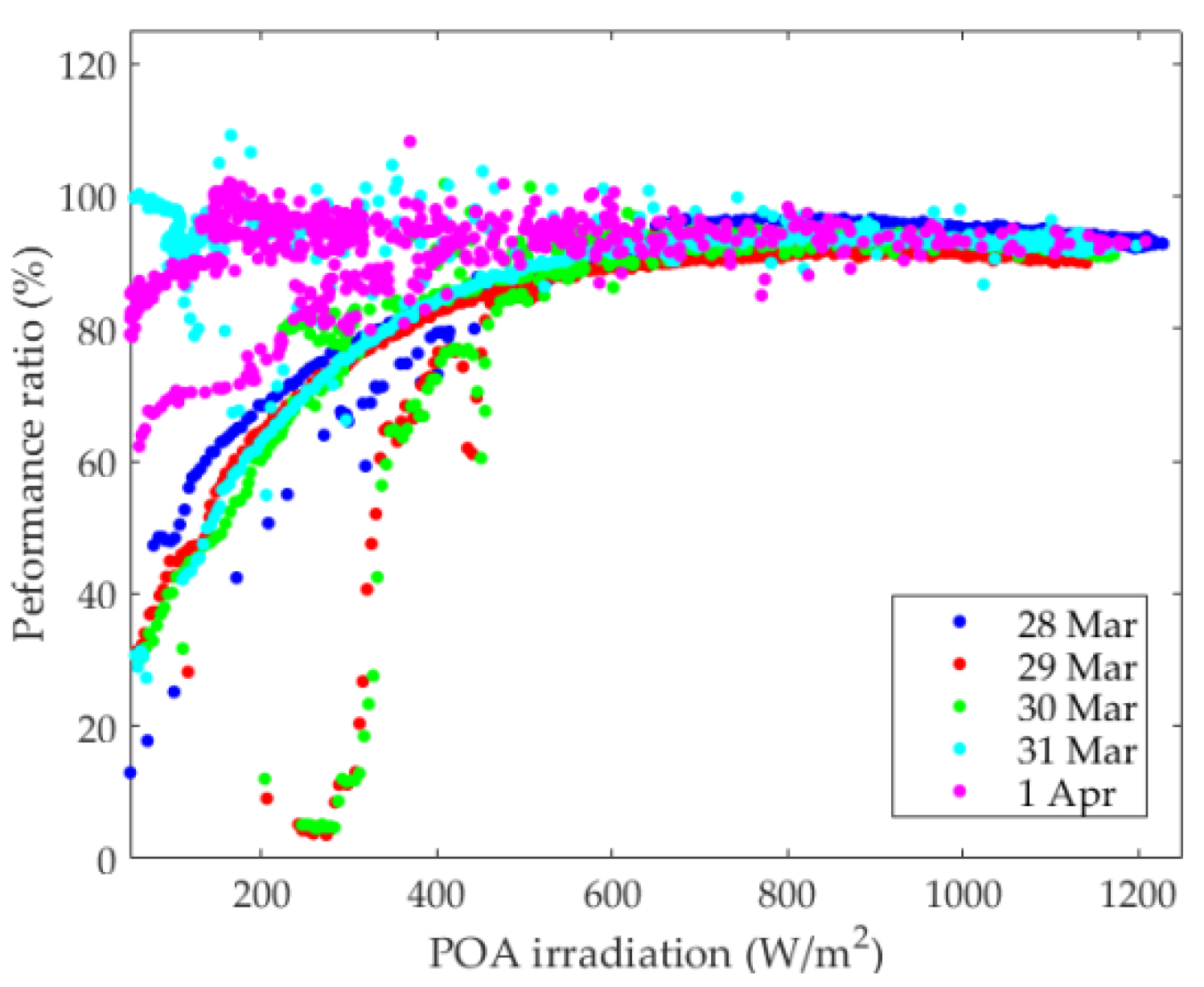

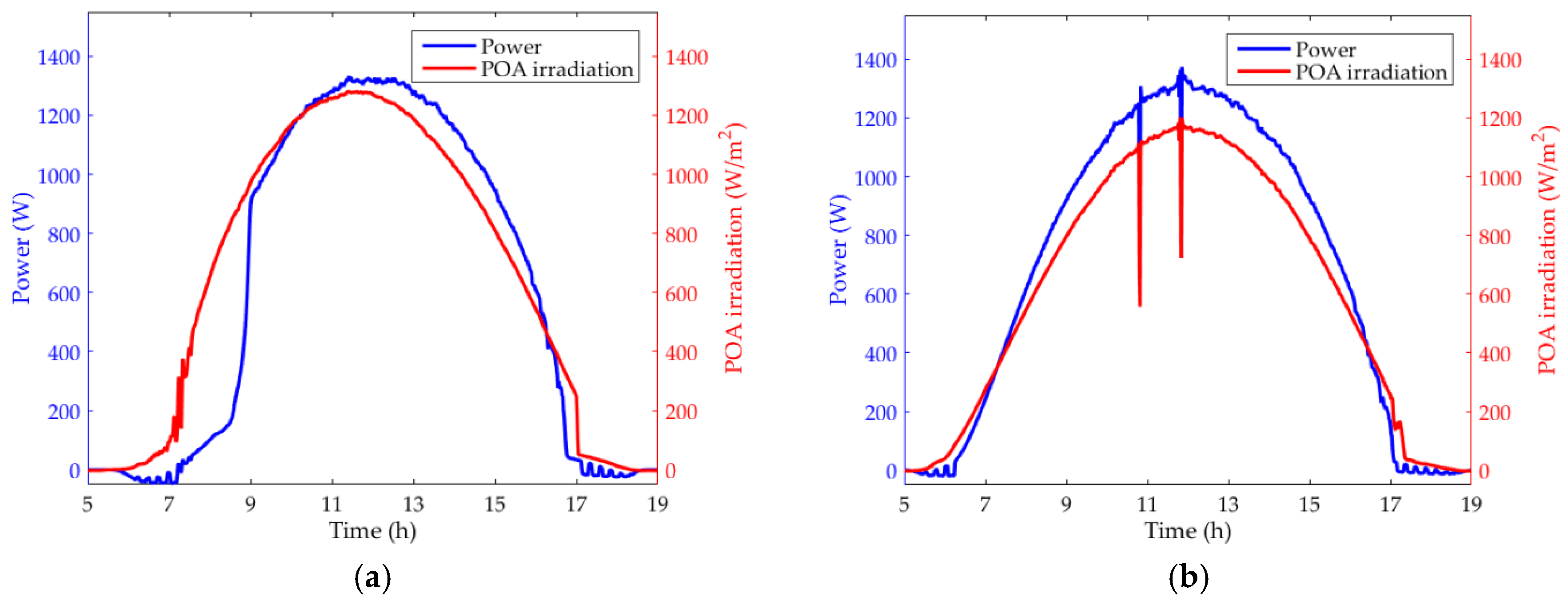

4.1.1. Instantaneous Performance

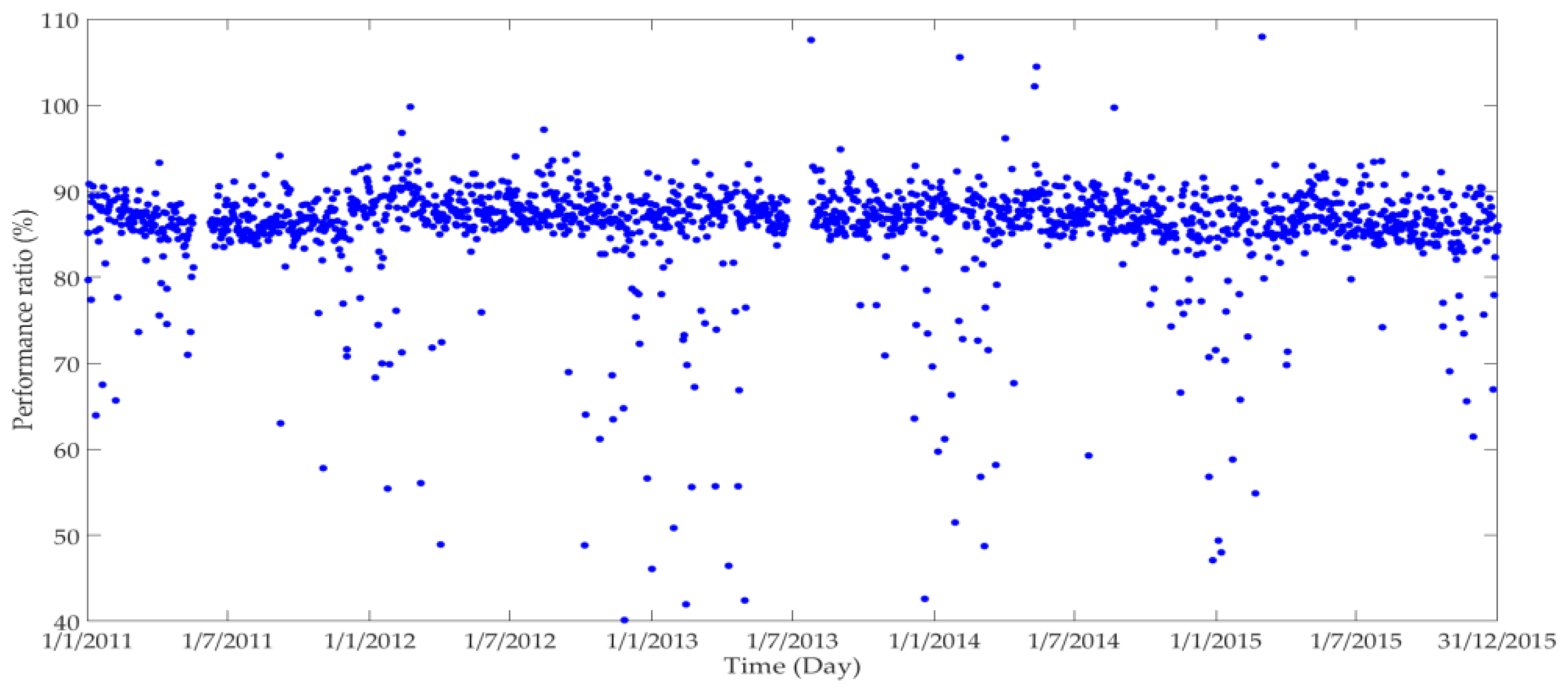

4.1.2. Daily Performance

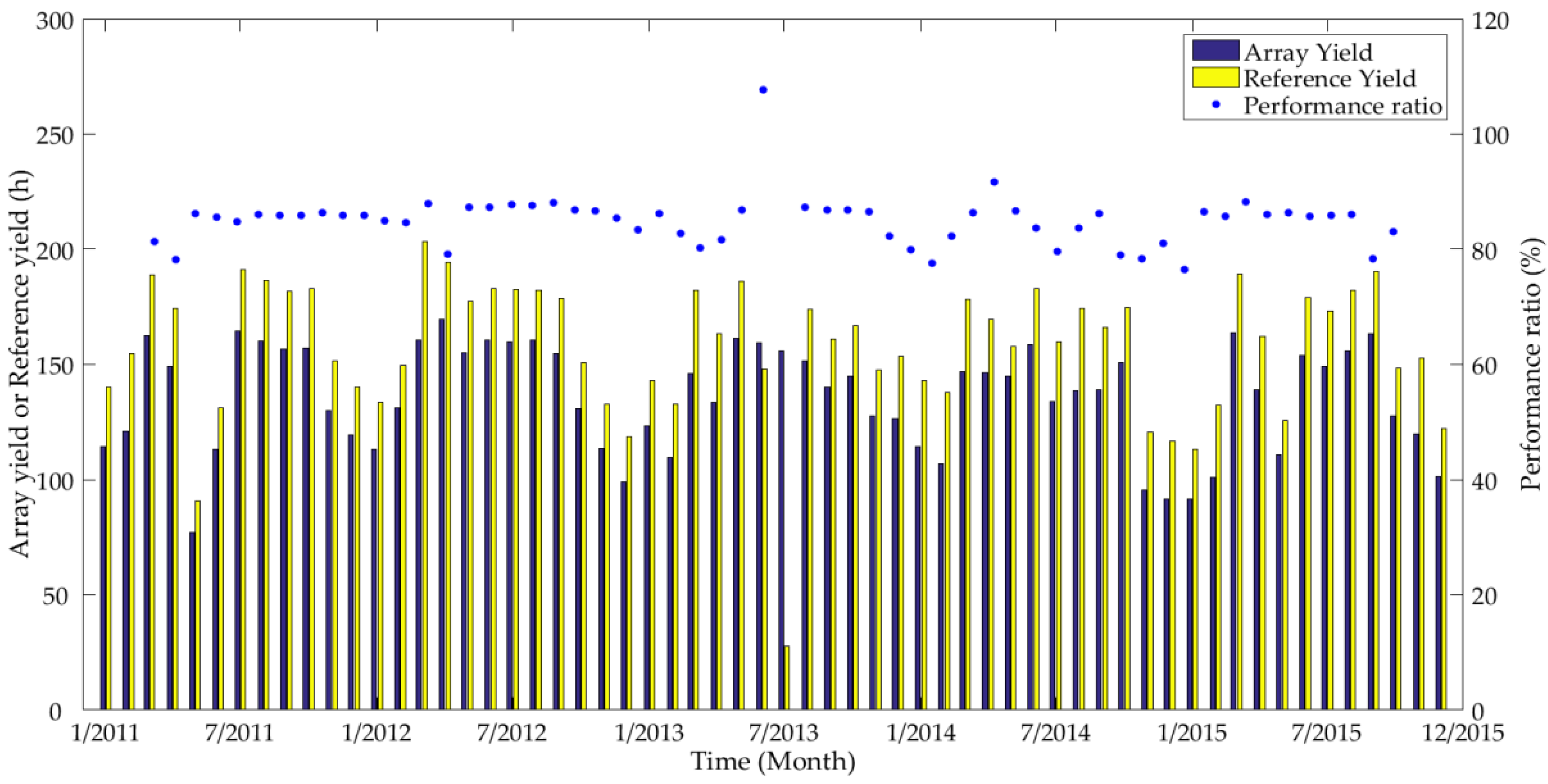

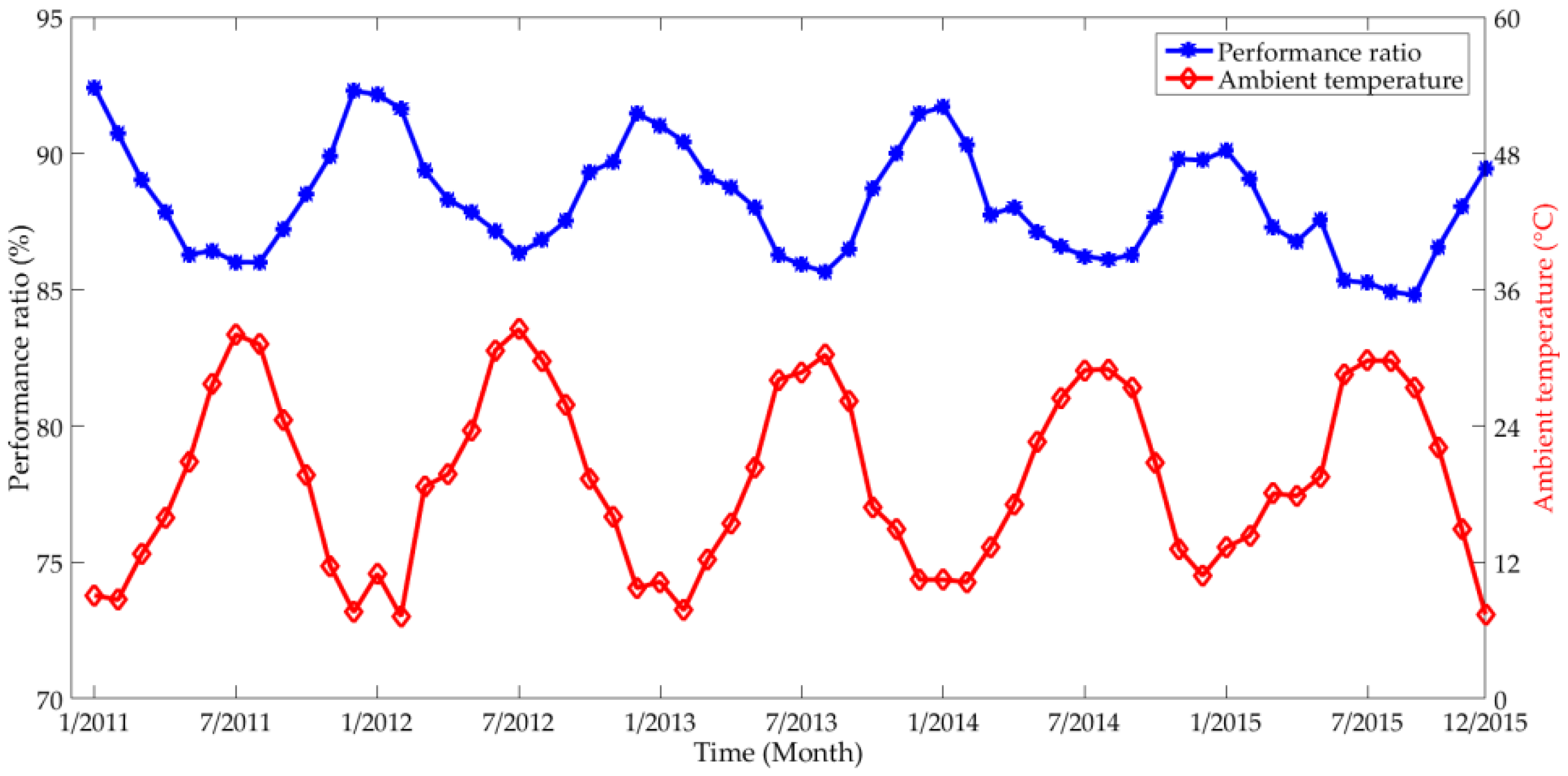

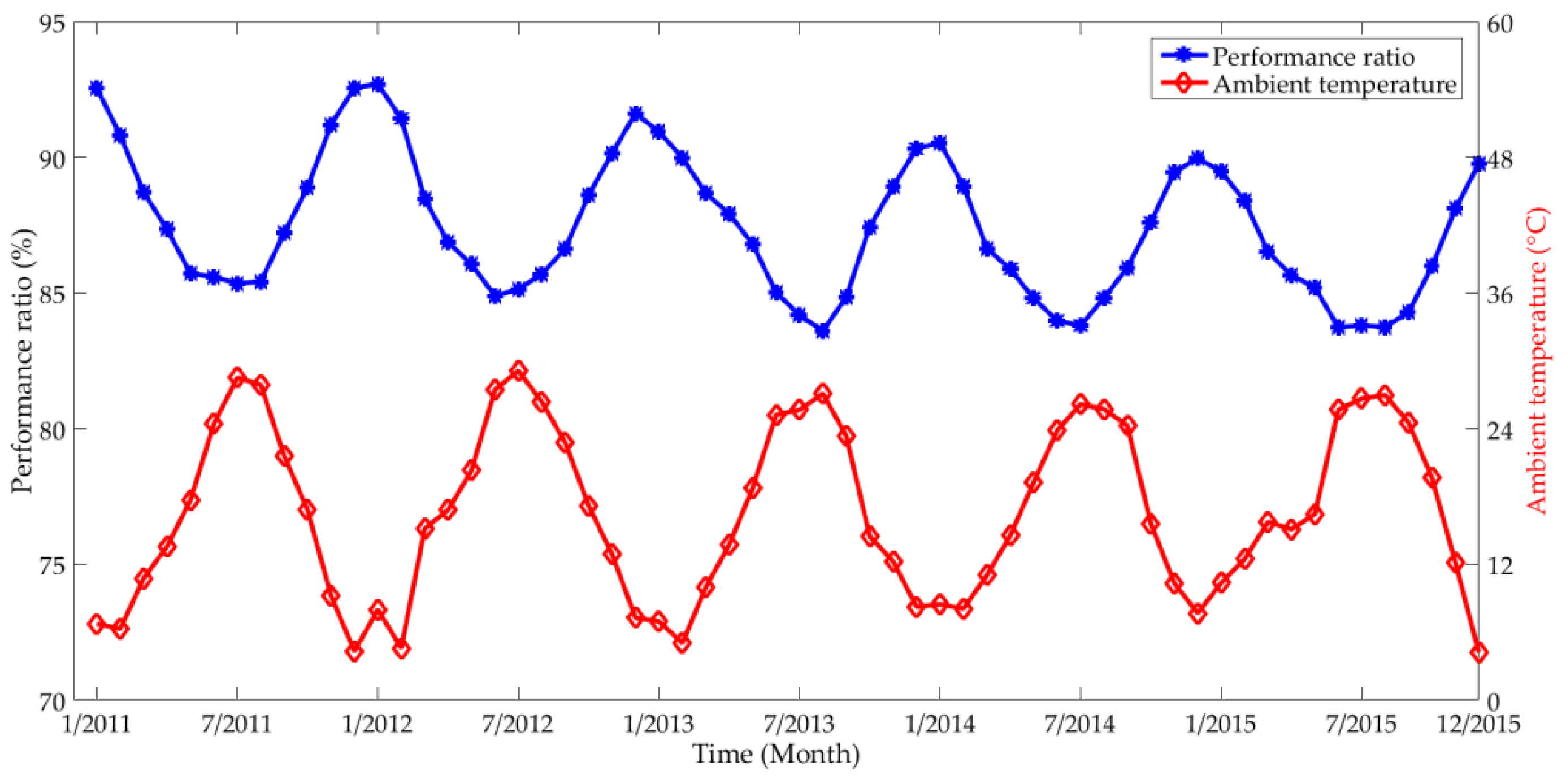

4.1.3. Monthly Performance

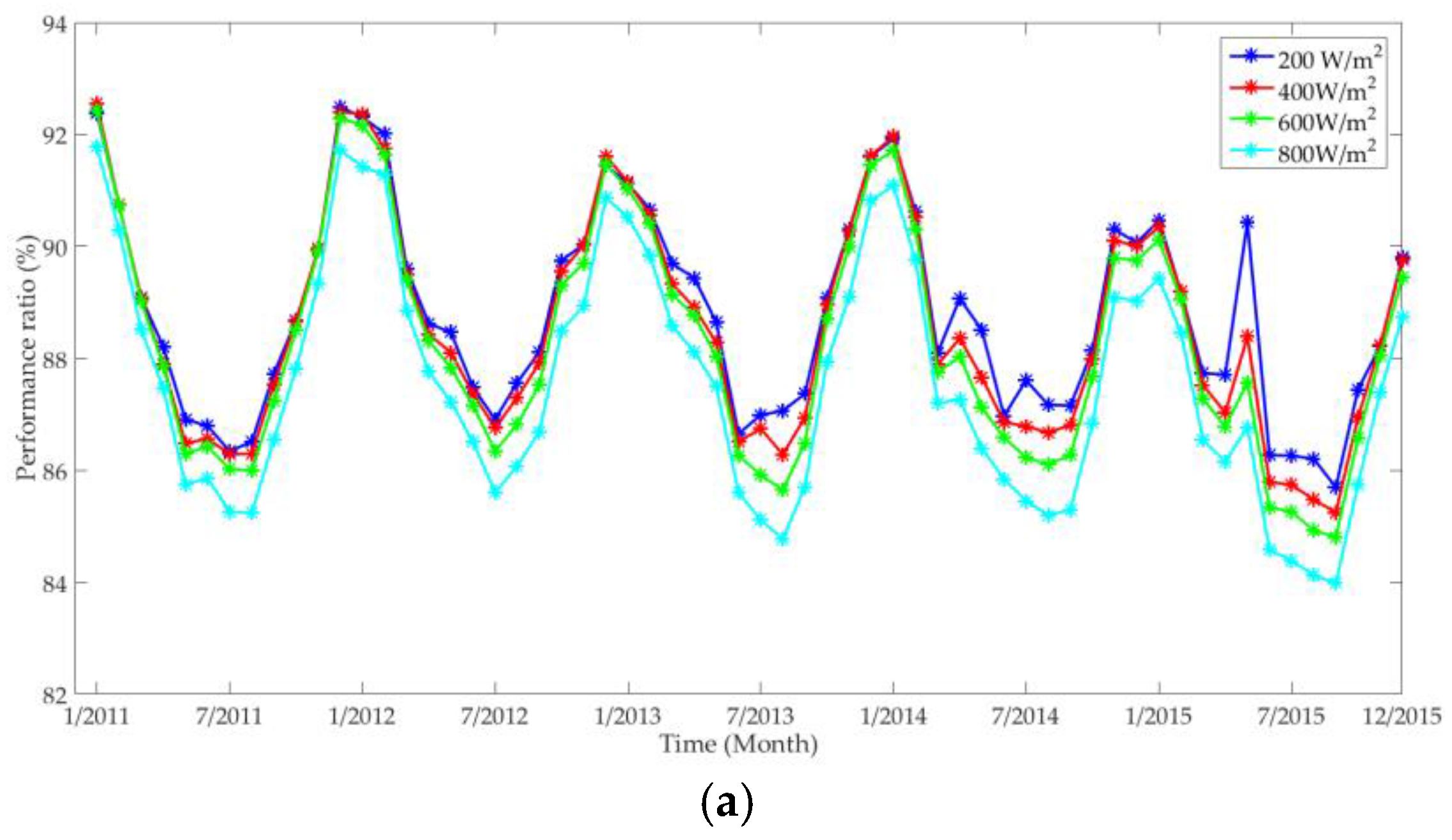

4.1.4. Performance after Data Filtering

- Discarding data points with POA irradiation less than 600 W/m2 to reduce the impact of solar angle-of-incidence and solar spectrum.

- Eliminating data points when the change of POA irradiation is more than 20 W/m2/min to reduce the impact of large fluctuations in irradiation on the precision of performance metrics.

- Removing outliers based on instantaneous PR. Data points exceeding the lower or upper limit of PR, and data points with large deviation from the mean PR over a given period are considered outliers. In this study, the lower limit and upper limit of instantaneous PR are 75% and 100%, respectively, and the limit of deviation is ±5%.

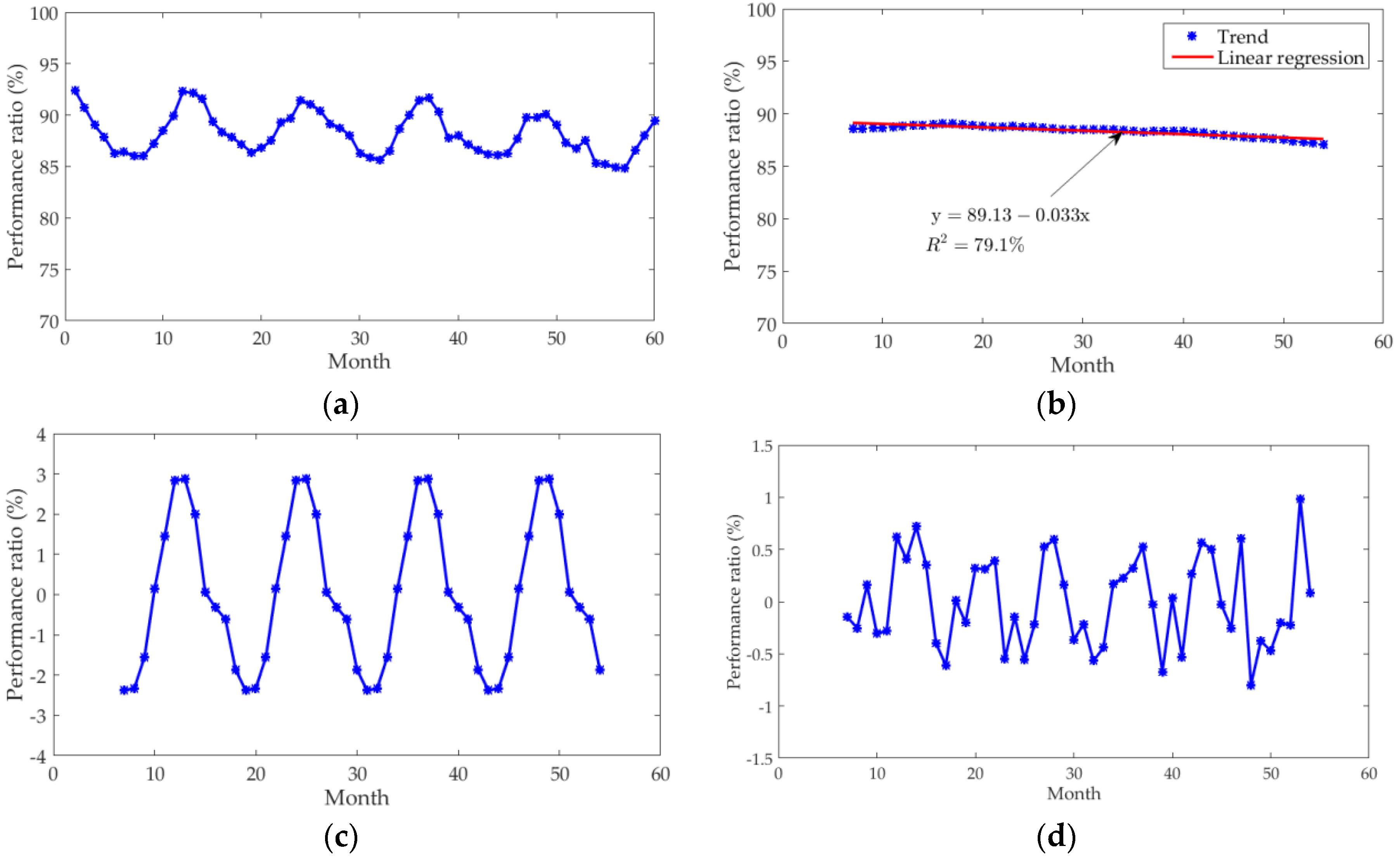

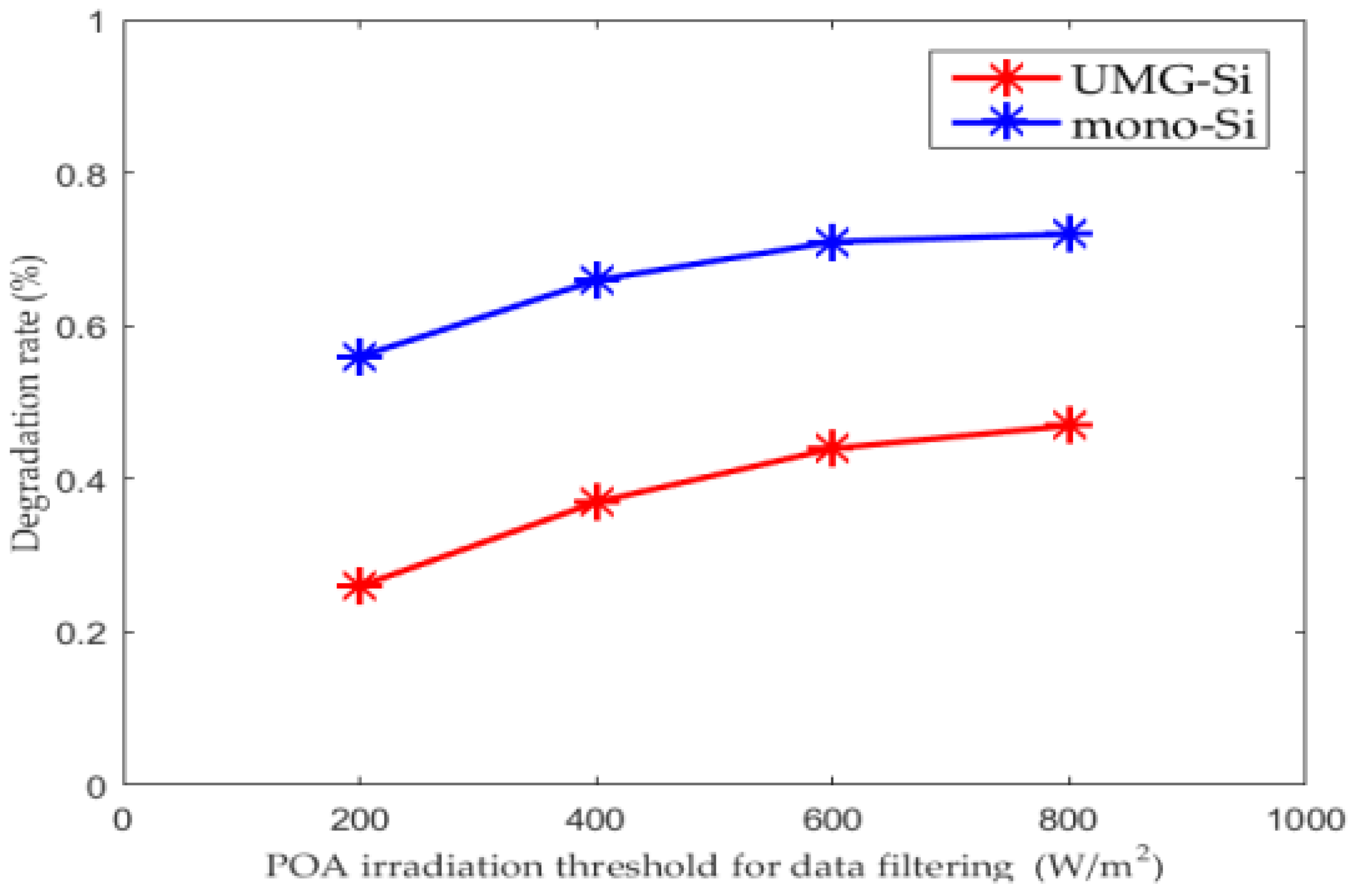

4.2. Annual Degradation Rate

4.3. Performance of the Mono-Si PV System

4.4. Comparison of PV Performance with Different Data Filtering Criteria

5. Performance Comparison

6. Conclusions

- PR tends to be high and steady at high levels of POA irradiation where the impacts of solar angle-of-incidence and solar spectrum are weak.

- PR is more variable and unreliable under cloudy conditions where irradiation largely fluctuates.

- Outliers due to snowing, shading, system down-time, data availability, measurement errors, etc. make PR inefficiently reflect the response of the PV array to irradiation.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| AM | Air Mass |

| AOI | Angle of Incidence |

| ARIMA | Autoregressive Integrated Moving Average |

| NREL | National Renewable Energy Laboratory |

| POA | Plane of Array |

| PR | Performance Ratio |

| PV | Photovoltaic |

| UMG-Si | Upgraded Metallurgical Grade Silicon |

References

- Gan, P.Y.; Li, Z.D. Quantitative study on long term global solar photovoltaic market. Renew. Sustain. Energy Rev. 2015, 46, 88–99. [Google Scholar] [CrossRef]

- del Coso, G.; del Canizo, C.; Sinke, W.C. The impact of silicon feedstock on the PV module cost. Solar Energy Mater. Solar Cells 2010, 94, 345–349. [Google Scholar] [CrossRef]

- Jeong, K.P.; Kim, Y.K. Electrical properties of the multi-crystalline silicon ingots grown with UMG (upgraded metallurgical grade) silicon materials. Solar Energy Mater. Solar Cells 2012, 107, 201–204. [Google Scholar] [CrossRef]

- Rougieux, F.; Samundsett, C.; Fong, K.C.; Fell, A.; Zheng, P.; Macdonald, D.; Degoulange, J.; Einhaus, R.; Forster, M. High efficiency UMG silicon solar cells: Impact of compensation on cell parameters. Prog. Photovolt. Res. Appl. 2016, 24, 725–734. [Google Scholar] [CrossRef]

- Modanese, C.; Di Sabatino, M.; Søiland, A.-K.; Peter, K.; Arnberg, L. Investigation of bulk and solar cell properties of ingots cast from compensated solar grade silicon. Prog. Photovolt. Res. Appl. 2011, 19, 45–53. [Google Scholar] [CrossRef]

- Odden, J.O.; Lommasson, T.C.; Tayyib, M.; Vedde, J.; Buseth, T.; Friestad, K.; Date, H.; Tronstad, R. Results on performance and ageing of solar modules based on Elkem Solar Silicon (ESS (TM)) from installations at various locations. Solar Energy Mater. Solar Cells 2014, 130, 673–678. [Google Scholar] [CrossRef]

- Zheng, P.; Rougieux, F.E.; Samundsett, C.; Yang, X.; Wan, Y.; Degoulange, J.; Einhaus, R.; Rivat, P.; Macdonald, D. Upgraded metallurgical-grade silicon solar cells with efficiency above 20%. Appl. Phys. Lett. 2016, 108, 122103. [Google Scholar] [CrossRef]

- Forster, M.; Wagner, P.; Degoulange, J.; Einhaus, R.; Galbiati, G.; Rougieux, F.E.; Cuevas, A.; Fourmond, E. Impact of compensation on the boron and oxygen-related degradation of upgraded metallurgical-grade silicon solar cells. Solar Energy Mater Solar Cells 2014, 120, 390–395. [Google Scholar] [CrossRef]

- NREL. Available online: http://maps.nrel.gov/pvdaq (accessed on 15 January 2016).

- Yang, H.; Wang, H.; Wang, H.; Ding, J. Experimental verification of upgraded metallurgical silicon photovoltaic power plant. Clean Technol. Environ. Policy 2014, 17, 281–285. [Google Scholar] [CrossRef]

- Nofuentes, G.; Garcia-Domingo, B.; Munoz, J.V.; Chenlo, F. Analysis of the dependence of the spectral factor of some PV technologies on the solar spectrum distribution. Appl. Energy 2014, 113, 302–309. [Google Scholar] [CrossRef]

- King, D.L.; Kratochvil, J.A.; Boyson, W.E. Measuring solar spectral and angle-of-incidence effects on photovoltaic modules and solar irradiance sensors. In Proceedings of the 1997 Twenty-Sixth IEEE Conference on Photovoltaic Specialists, Anaheim, CA, USA, 29 September–3 October 1997; pp. 1113–1116.

- Jordan, D.C.; Kurtz, S.R. Photovoltaic degradation rates-an analytical review. Prog. Photovolt. Res. Appl. 2013, 21, 12–29. [Google Scholar] [CrossRef]

- Makrides, G.; Zinsser, B.; Schubert, M.; Georghiou, G.E. Performance loss rate of twelve photovoltaic technologies under field conditions using statistical techniques. Solar Energy 2014, 103, 28–42. [Google Scholar] [CrossRef]

- Ishii, T.; Takashima, T.; Otani, K. Long-term performance degradation of various kinds of photovoltaic modules under moderate climatic conditions. Prog. Photovolt. Res. Appl. 2011, 19, 170–179. [Google Scholar] [CrossRef]

- Jordan, D.C.; Kurtz, S.R. The Dark Horse of Evaluaitng Long-Term Field Performance—Data Filtering. IEEE J. Photovolt. 2014, 4, 317–323. [Google Scholar] [CrossRef]

- Phinikarides, A.; Kindyni, N.; Makrides, G.; Georghiou, G.E. Review of photovoltaic degradation rate methodologies. Renew. Sustain. Energy Rev. 2014, 40, 143–152. [Google Scholar] [CrossRef]

- Jordan, D.C.; Kurtz, S.R. Analytical improvements in PV degradation rate determination. In Proceedings of the 35th IEEE Photovoltaic Specialists Conference, Honolulu, HI, USA, 20–25 June 2010; pp. 2688–2693.

- International Eelectrotechnical Commission (IEC). IEC Standard 61724: Photovoltaic System Performance Monitoring-Guidelines for Measurement, Data Exchange, and Analysis; IEC: Geneva, Switzerland, 1998. [Google Scholar]

- Damrongkulkamjorn, P.; Churueang, P. Monthly energy forecasting using decomposition method with application of seasonal ARIMA. In Proceedings of the 2005 International Power Engineering Conference, Singapore, Singapore, 29 November 2015–2 December 2005; pp. 224–229.

- Theodosiou, M. Forecasting monthly and quarterly time series using STL decomposition. Int. J. Forecast. 2011, 27, 1178–1195. [Google Scholar] [CrossRef]

- Canete, C.; Carretero, J.; Sidrach-de-Cardona, M. Energy performance of different photovoltaic module technologies under outdoor conditions. Energy 2014, 65, 295–302. [Google Scholar] [CrossRef]

- Mondol, J.D.; Yohanis, Y.; Smyth, M.; Norton, B. Long term performance analysis of a grid connected photovoltaic system in Northern Ireland. Energy Convers. Manag. 2006, 47, 2925–2947. [Google Scholar] [CrossRef]

- Sharma, V.; Kumar, A.; Sastry, O.S.; Chandel, S.S. Performance assessment of different solar photovoltaic technologies under similar outdoor conditions. Energy 2013, 58, 511–518. [Google Scholar] [CrossRef]

- Osterwald, C.R.; Adelstein, J.; del Cueto, J.A.; Kroposki, B.; Trudell, D.; Moriarty, T. Comparison of degradation rates of individual modules held at maximum power. In Proceedings of the 2006 IEEE 4th World Conference on Photovoltaic Energy Conversion, Waikoloa, HI, USA, 7–12 May 2006; pp. 2085–2088.

- Polverini, D.; Field, M.; Dunlop, E.; Zaaiman, W. Polycrystalline silicon PV modules performance and degradation over 20 years. Prog. Photovolt. Res. Appl. 2013, 21, 1004–1015. [Google Scholar] [CrossRef]

| Property | UMG-Si | mono-Si |

|---|---|---|

| Maximal power at STC (Pmax) | 210 W | 200 W |

| Maximal power voltage (Vmp) | 29.0 V | 55.8 V |

| Maximal power current (Imp) | 7.25 A | 3.59 A |

| Open circuit voltage (Voc) | 36.4 V | 68.7 V |

| Short circuit current (Isc) | 7.89 A | 3.83 A |

| Temperature coefficient (Pmax) | −0.42%/°C | −0.29%/°C |

| Technology | PR (%) | Rd (%) | Reference | Comments |

|---|---|---|---|---|

| poly-Si | 90–110 | 0.24–0.46 | [15] | Data filtering: G > 750 W/m2, stability, and outliers Analytical: linear regression on monthly PR (3 years) |

| mono-Si | 90–110 | 0.64–0.92 | [15] | Data filtering: G > 750 W/m2, stability and outliers Analytical: linear regression on monthly PR (3 years) |

| poly-Si | 75–98 | 0.78–1.30 | [14] | Analytical: classical decomposition on monthly PR (5 years) |

| mono-Si | 65–98 | 0.77–1.37 | [14] | Analytical: classical decomposition on monthly PR (5 years) |

| poly-Si | 92.9 | \ | [22] | Annual average daily performance ratio of 1 year |

| mono-Si | 60–62 | \ | [23] | Annual average monthly performance ratio of 3 years |

| poly-Si | 76–95 | \ | [24] | Monthly performance ratio of 1 year |

| mono-Si | \ | 0.25 | [ 25] | Analytical: linear regression on monthly maximal power using PVUSA (8 years) |

| poly-Si | \ | 0.22 | [26] | Average decay of maximal power (I-V curves) of 70 modules over 20 years |

| mono-Si | \ | 0.71 | Present study | Data filtering: G > 600 W/m2, stability, and outlier Analytical: classical decomposition on monthly PR (5 years) |

| UMG-Si | 84-93 | 0.44 | Present study | Data filtering: G > 600 W/m2, stability, and outlier Analytical: classical decomposition on monthly PR (5 years) |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, C.; Edesess, M.; Bensoussan, A.; Tsui, K.L. Performance Analysis of a Grid-Connected Upgraded Metallurgical Grade Silicon Photovoltaic System. Energies 2016, 9, 342. https://doi.org/10.3390/en9050342

Huang C, Edesess M, Bensoussan A, Tsui KL. Performance Analysis of a Grid-Connected Upgraded Metallurgical Grade Silicon Photovoltaic System. Energies. 2016; 9(5):342. https://doi.org/10.3390/en9050342

Chicago/Turabian StyleHuang, Chao, Michael Edesess, Alain Bensoussan, and Kwok L. Tsui. 2016. "Performance Analysis of a Grid-Connected Upgraded Metallurgical Grade Silicon Photovoltaic System" Energies 9, no. 5: 342. https://doi.org/10.3390/en9050342

APA StyleHuang, C., Edesess, M., Bensoussan, A., & Tsui, K. L. (2016). Performance Analysis of a Grid-Connected Upgraded Metallurgical Grade Silicon Photovoltaic System. Energies, 9(5), 342. https://doi.org/10.3390/en9050342