On the Front Lines of a Sustainable Transportation Fleet: Applications of Vehicle-to-Grid Technology for Transit and School Buses

Abstract

:1. Introduction

2. Background Information

3. Materials and Methods

3.1. Environmental Emission Calculation Methods

3.2. Air Pollution Externatilty Calculation Methods

3.3. Cash Flow and Net Revenue Calculation Methods

4. Data Collection

4.1. Transit and School Bus Specifications

4.2. Vehicle-to-Grid System Specifications

5. Results

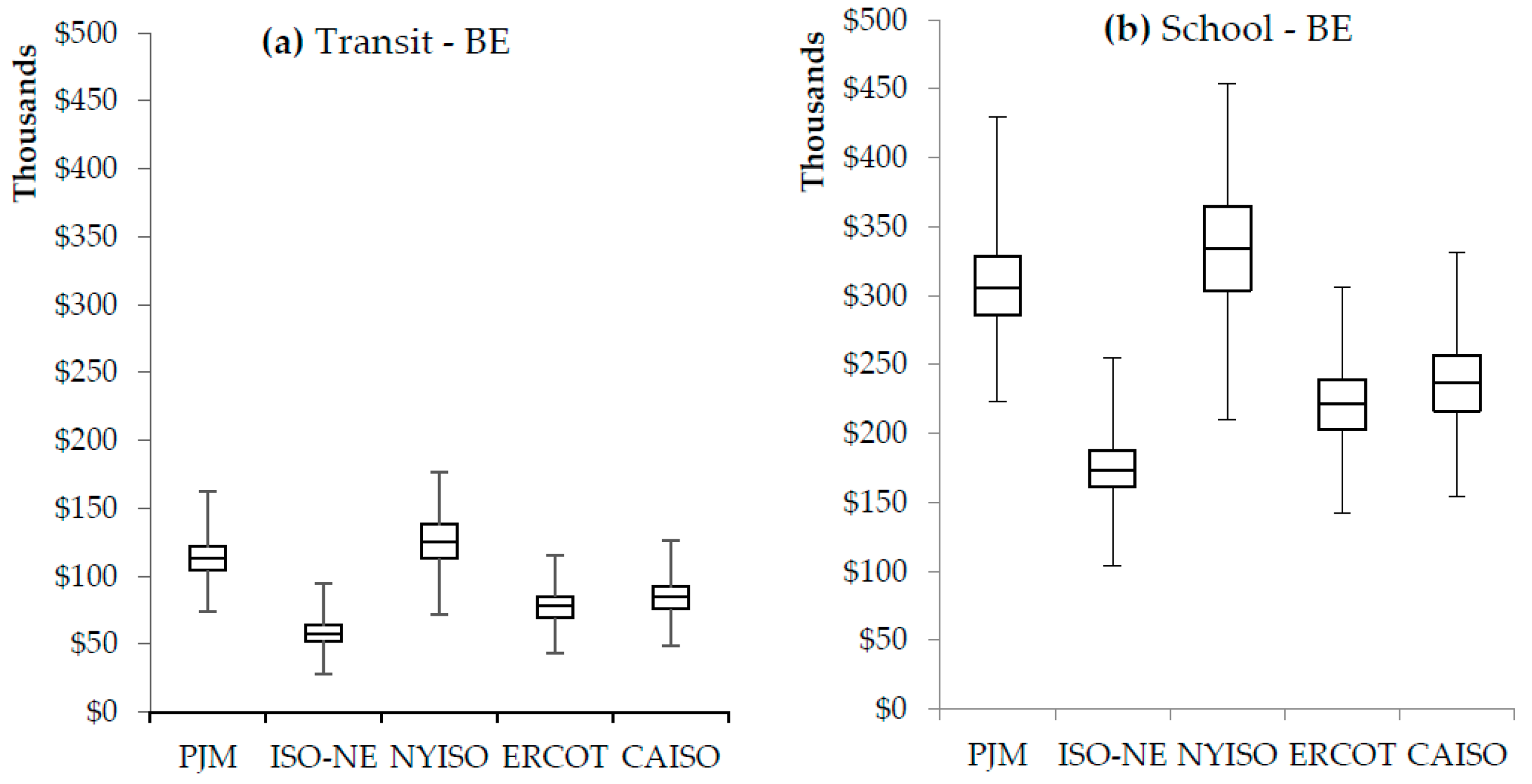

5.1. Cash Flow Results

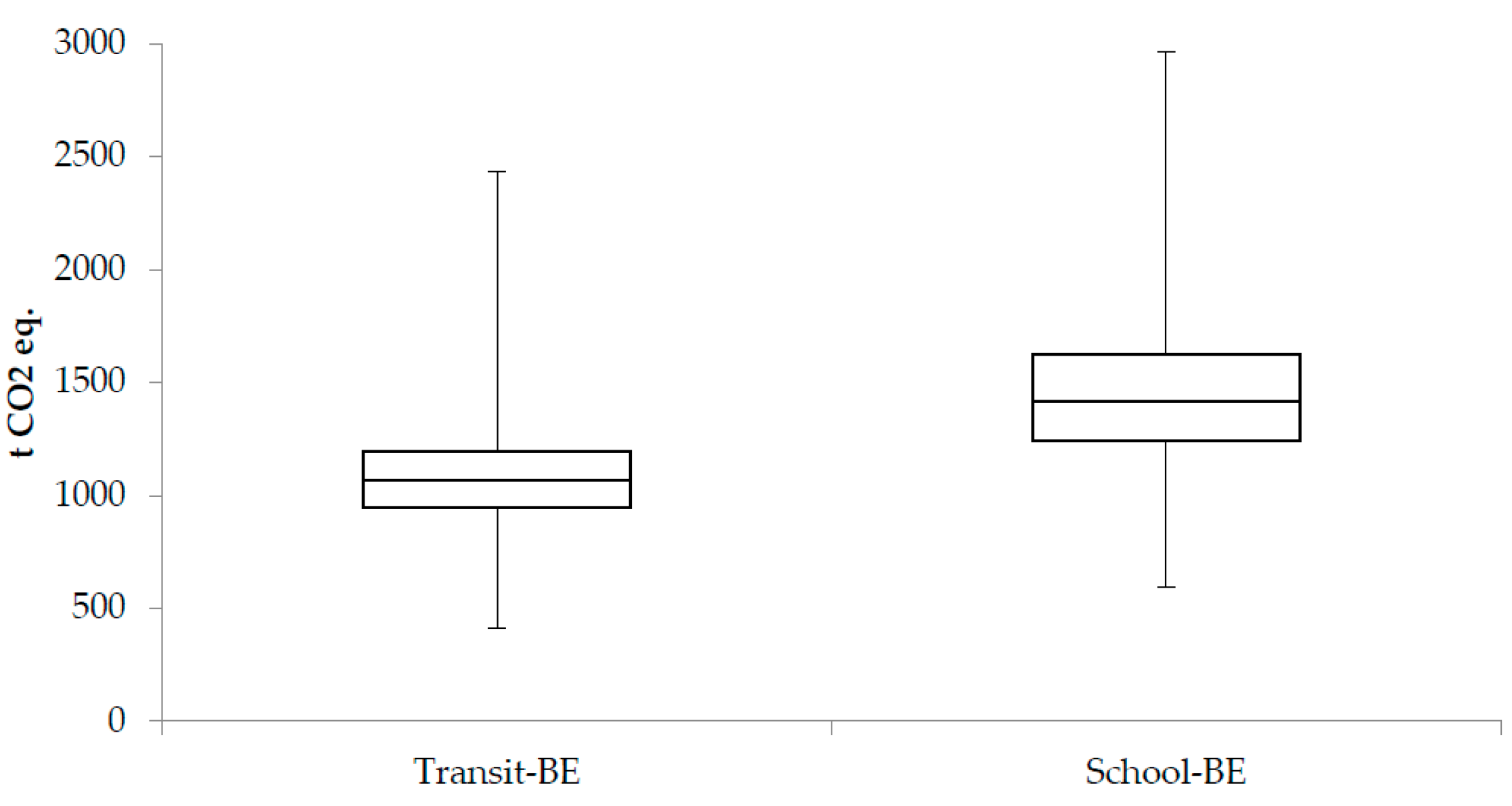

5.2. Environmental Emission Results

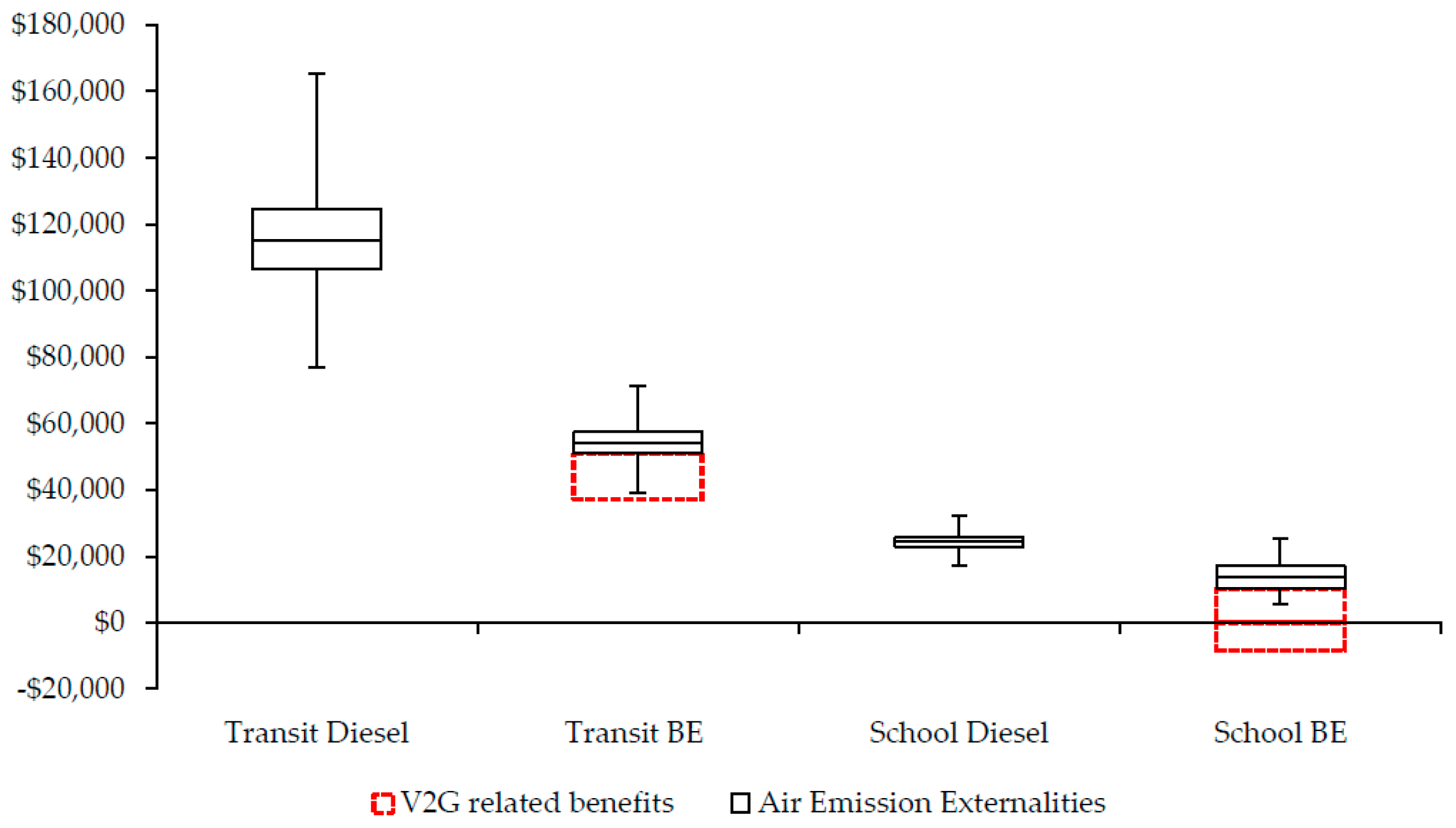

5.3. Air Pollution Externatilty Results

6. Discussion

- The cash flow analysis results in this study indicated that BE transit buses are not economically feasible to operate even with V2G net revenues taken into account, and the initial purchase price of a BE transit bus is especially discouraging for fleet owners compared to those of diesel buses and buses with other alternative fuel options. However, this could change in the near future with battery development and market demand trends for alternative fuel transit buses. On the other hand, BE school buses effectively eliminated their high initial cost requirements throughout their lifetimes, whereas diesel school buses did not.

- Transit buses also yielded less net revenue for fleet owners from V2G service. However, this result does not mean that V2G services are not feasible or applicable for BE transit buses. It should be noted that the primary duty of transit buses is to serve society for reliable public transportation and to provide a source of revenue for transit agencies. It is therefore still beneficial for transit agencies to collect additional revenue from BE transit buses even while they are not in use. Conversely, with extensive cash flow benefits, BE school buses can easily substitute diesel school buses for the fleet owners’ cost perspective.

- If the total number of transit and school bus fleets in the U.S. is taken into account, the overall potential of V2G system applications and BE bus adoption can be significant. However, it is not clear if the current electricity generation and distribution infrastructure could support that adoption. Therefore, BE bus deployment levels should be studied further and optimized parallel to current development trends in the utility generation and supply system.

- In addition to V2G technology, there are other new technologies similar to V2G that provide power as needed from plugged-in electric vehicles back to a home (V2H) or back to a building (V2B). These similar technologies could be an interesting future area of study through which to present the possible benefits of providing electricity from an electric vehicle fleet back to the workplace buildings (administrative, maintenance, etc.) of a fleet operator. That said, as highlighted in this research, buses have a significant amount of power available from their batteries compared to any passenger vehicle’s capacity. Thus, heavy-duty vehicles are more capable of providing power support to a building than light-duty vehicles are. This concept can also lead to another research area where there is potential of V2G, V2H, or V2B technologies to enhance the resiliency of grid/building during extreme events.

- The air emission externality results in this study are especially noteworthy because this study focuses on vehicles operating in or near highly populated areas. This is particularly true for school buses, the tailpipe emissions of which are emitted mainly near a non-adult population. Moreover, since air emission externalities are not defined specifically for non-adult populations, the public health damage rates for school bus emissions could be even higher than the average rates used in this study. Also, although electricity generation does not usually occur near populated areas, conventional power generation methods still have high emission rates of hazardous pollutants due to the high fossil fuel dependency of the U.S. power generation sector. These per-kWh emission rates for electricity generation are expected to decrease in future years as the U.S. invests more and more in renewable energy sources and technologies. However, this study shows that V2G technology can already provide significant air emission externality reduction benefits from BE transit buses and school buses.

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| AFLEET | Alternative fuel life-cycle environmental and economic transportation |

| APEEP | Air pollution emission experiments and policy analysis |

| BE | Battery electric |

| CAISO | California independent system operators |

| CNG | Compressed natural gas |

| EIA | Energy information administration |

| EPA | Environmental protection agency |

| ERCOT | Electric Reliability Council of Texas |

| GHG | Greenhouse gases |

| GREET | Greenhouse-gases Regulated Emissions, and Energy use in Transportation |

| ISO-NE | Independent system operators of new England region |

| ISO | International standards organization |

| ISO/RTO | Independent system operators/regional transmission organizations |

| LCA | Life cycle assessment |

| LNG | Liquefied natural gas |

| MOVES | Motor vehicle emission simulation |

| MPDGE | Miles per diesel gallon equivalent |

| NERC | North American electricity reliability corporation |

| NREL | National renewable energy laboratory |

| NYISO | New York independent system operators |

| PJM | Pennsylvania-New Jersey-Maryland interconnection RTO |

| SOC | State-of-charge |

| TBW | Tire & brake wear |

| V2G | Vehicle-to-grid |

| WTP | Well-to-pump |

| WTW | Well-to-wheel |

References

- Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2013; U.S. Environmental Protection Agency: Washington, DC, USA, 2015.

- Onat, N.C.; Kucukvar, M.; Tatari, O.; Zheng, Q.P. Combined application of multi-criteria optimization and life-cycle sustainability assessment for optimal distribution of alternative passenger cars in U.S. J. Clean. Prod. 2015, 112, 291–307. [Google Scholar] [CrossRef]

- Onat, N.C.; Gumus, S.; Kucukvar, M.; Tatari, O. Application of the TOPSIS and intuitionistic fuzzy set approaches for ranking the life cycle sustainability performance of alternative vehicle technologies. Sustain. Prod. Consum. 2016, 6, 12–25. [Google Scholar] [CrossRef]

- U.S. Department of Energy—Energy Information Administration. Annual Energy Outlook 2015 with Projections to 2040; U.S. Energy Information Administration: Washington, DC, USA, 2015.

- The Clean Air Act Amendments. The Clean Air Act Amendments. Available online: https://www.epa.gov/clean-air-act-overview/clean-air-act-text#toc (accessed on 15 Novmber 2015).

- California Environmental Protection Agency Air Resources Board. Technology Assessment: Medium- and Heavy- Duty Battery Electric Trucks and Buses. Available online: http://www.arb.ca.gov/msprog/tech/techreport/bev_tech_report.pdf (accessed on 1 December 2015).

- 2015 Public Transportation Fact Book Appendix A: Historical Tables; American Public Transportation Association: Washington, DC, USA, 2015.

- Neff, J.; Dickens, M. 2015 Public Transportation Fact Book; American Public Transportation Association: Washington, DC, USA, 2015. [Google Scholar]

- Laughlin, M. Analysis of U.S. School Bus Populations and Alternative Fuel Potential; Antares Group Inc.: Washington, DC, USA, 2004. [Google Scholar]

- Public Transportation Fact Book; American Public Transportation Association: Washington, DC, USA, 2014.

- Chandler, K.; Walkowicz, K.; Eudy, L. New York City Transit Diesel Hybrid-Electric Buses: Final Results; National Renewable Energy Laboratory: Golden, CO, USA, 2002. [Google Scholar]

- Noel, L.; McCormack, R. A cost benefit analysis of a V2G-capable electric school bus compared to a traditional diesel school bus. Appl. Energy 2014, 126, 246–255. [Google Scholar] [CrossRef]

- Mikulecky, M. Number of Instructional Days/Hours in the School; Education Commission of the States: Denver, CO, USA, 2013. [Google Scholar]

- Kempton, W.; Tomić, J. Vehicle-to-grid power fundamentals: Calculating capacity and net revenue. J. Power Sources 2005, 144, 268–279. [Google Scholar] [CrossRef]

- Kempton, W.; Tomić, J. Vehicle-to-grid power implementation: From stabilizing the grid to supporting large-scale renewable energy. J. Power Sources 2005, 144, 280–294. [Google Scholar] [CrossRef]

- Kempton, W.; Udo, V.; Huber, K.; Komara, K.; Letendre, S.; Baker, S.; Brunner, D.; Pearre, N. A Test of Vehicle-to-Grid (V2G) for Energy Storage and Frequency Regulation in the PJM System; Industry-University Research Partnership: Newark, DE, USA.

- Frey, H.C.; Rouphail, N.M.; Zhai, H.; Farias, T.L.; Gonçalves, G.A. Comparing real-world fuel consumption for diesel- and hydrogen-fueled transit buses and implication for emissions. Transp. Res. D Transp. Environ. 2007, 12, 281–291. [Google Scholar] [CrossRef]

- Hess, D. What is a clean bus? Object conflicts in the greening of urban transit. Sustain. Sci. Pract. Policy 2007, 3, 45–58. [Google Scholar]

- Ally, J.; Pryor, T. Life-cycle assessment of diesel, natural gas and hydrogen fuel cell bus transportation systems. J. Power Sources 2007, 170, 401–411. [Google Scholar] [CrossRef]

- Chester, M.V.; Horvath, A. Environmental assessment of passenger transportation should include infrastructure and supply chains. Environ. Res. Lett. 2009, 4. [Google Scholar] [CrossRef]

- Ou, X.; Zhang, X.; Chang, S. Alternative fuel buses currently in use in China: Life-cycle fossil energy use, GHG emissions and policy recommendations. Energy Policy 2010, 38, 406–418. [Google Scholar] [CrossRef]

- Ou, X.; Zhang, X.; Chang, S. Scenario analysis on alternative fuel/vehicle for China’s future road transport: Life-cycle energy demand and GHG emissions. Energy Policy 2010, 38, 3943–3956. [Google Scholar] [CrossRef]

- Cooney, G.; Hawkins, T.R.; Marriott, J. Life Cycle Assessment of Diesel and Electric Public Transportation Buses. J. Ind. Ecol. 2013, 17, 689–699. [Google Scholar] [CrossRef]

- Sánchez, J.A.G.; Martínez, J.M.L.; Martín, J.L.; Holgado, M.N.F.; Morales, H.A. Impact of Spanish electricity mix, over the period 2008–2030, on the Life Cycle energy consumption and GHG emissions of Electric, Hybrid Diesel-Electric, Fuel Cell Hybrid and Diesel Bus of the Madrid Transportation System. Energy Convers. Manag. 2013, 74, 332–343. [Google Scholar] [CrossRef]

- Lajunen, A. Energy consumption and cost-benefit analysis of hybrid and electric city buses. Transp. Res. C Emerg. Technol. 2014, 38, 1–15. [Google Scholar] [CrossRef]

- Onat, N.C.; Kucukvar, M.; Tatari, O. Towards Life Cycle Sustainability Assessment of Alternative Passenger Vehicles. Sustainability 2014, 6, 9305–9342. [Google Scholar] [CrossRef]

- Donateo, T.; Ingrosso, F.; Licci, F.; Laforgia, D. A method to estimate the environmental impact of an electric city car during six months of testing in an Italian city. J. Power Sources 2014, 270, 487–498. [Google Scholar] [CrossRef]

- Xu, Y.; Gbologah, F.E.; Lee, D.Y.; Liu, H.; Rodgers, M.O.; Guensler, R.L. Assessment of alternative fuel and powertrain transit bus options using real-world operations data: Life-cycle fuel and emissions modeling. Appl. Energy 2015, 154, 143–159. [Google Scholar] [CrossRef]

- Rogge, M.; Wollny, S.; Sauer, D. Fast Charging Battery Buses for the Electrification of Urban Public Transport—A Feasibility Study Focusing on Charging Infrastructure and Energy Storage Requirements. Energies 2015, 8, 4587–4606. [Google Scholar] [CrossRef]

- Ercan, T.; Tatari, O. A hybrid life cycle assessment of public transportation buses with alternative fuel options. Int. J. Life Cycle Assess. 2015, 20, 1213–1231. [Google Scholar] [CrossRef]

- Turton, H.; Moura, F. Vehicle-to-grid systems for sustainable development: An integrated energy analysis. Technol. Forecast. Soc. Chang. 2008, 75, 1091–1108. [Google Scholar] [CrossRef]

- Kudoh, Y.; Motose, R.; Tahara, K.; Genchi, Y. A potential CO2 reduction of vehicle to home system from life cycle perspective. In Proceedings of the IEEE Electric Vehicle Symposium and Exhibition (EVS27), Barcelona, Spain, 17–20 November 2013; pp. 1–10.

- Muller, N.Z.; Mendelsohn, R. The Air Pollution Emission Experiments and Policy Analysis Model (APEEP) Technical Appendix; Yale University: New Haven, CT, USA, 2006; Volume 1. [Google Scholar]

- Muller, N.Z.; Mendelsohn, R. Measuring the damages of air pollution in the United States. J. Environ. Econ. Manag. 2007, 54, 1–14. [Google Scholar] [CrossRef]

- Michalek, J.J.; Chester, M.; Jaramillo, P.; Samaras, C.; Shiau, C.S.N.; Lave, L.B. Valuation of plug-in vehicle life-cycle air emissions and oil displacement benefits. Proc. Natl. Acad. Sci. USA 2011, 108, 16554–16558. [Google Scholar] [CrossRef] [PubMed]

- Gouge, B.; Dowlatabadi, H.; Ries, F.J. Minimizing the health and climate impacts of emissions from heavy-duty public transportation bus fleets through operational optimization. Environ. Sci. Technol. 2013, 47, 3734–3742. [Google Scholar] [CrossRef] [PubMed]

- Ercan, T.; Zhao, Y.; Tatari, O.; Pazour, J.A. Optimization of transit bus fleet’s life cycle assessment impacts with alternative fuel options. Energy 2015, 93, 323–334. [Google Scholar] [CrossRef]

- Motor Vehicle Emission Simulator (MOVES); U.S. Environmental Protection Agency: Washington, DC, USA, 2010.

- The Greenhouse Gases, Regulated Emissions, and Energy Use in Transportation (GREET) Model; Argonne National Laboratory: Lemont, IL, USA, 2015.

- U.S. Environmental Protection Agency. eGRID2012 Summary Tables; EPA: Washington, DC, USA, 2015; Volume 1.

- Donateo, T.; Congedo, P.M.; Malvoni, M.; Ingrosso, F.; Laforgia, D. An Integrated Tool to Monitor Renewable Energy Flows and Optimize the Recharge of a Fleet of Plug-in Electric Vehicles in the Campus of the University of Salento: Preliminary Results. In Proceedings of the 19th World Congress of The International Federation of Automatic Control, Cape Town, South Africa, 24–29 August 2014; pp. 7861–7866.

- Makarov, Y.V.; Du, P.; Kintner-Meyer, M.C.W.; Jin, C.; Illian, H.F. Sizing energy storage to accommodate high penetration of variable energy resources. IEEE Trans. Sustain. Energy 2012, 3, 34–40. [Google Scholar] [CrossRef]

- Lin, J.; Damato, G.; Hand, P. Energy Storage—A Cheaper, Faster, & Cleaner Alternative to Conventional Frequency Regulation; California Energy Storage Alliance: Berkeley, CA, USA, 2011. [Google Scholar]

- Amarakoon, S.; Smith, J.; Segal, B. Lithium-ion Batteries and Nanotechnology for Electric Vehicles: A Life Cycle Assessment; U.S. Environnemental Protection Agency: Washington DC, USA, 2012.

- U.S. Department of Energy—Energy Efficiency & Renewable Energy. Alternative Fuel Data Center—State Incentives 2015. Available online: http://www.afdc.energy.gov/laws/all?state= (accessed on 1 October 2015).

- New York State. New York State Electric Vehicle—Voucher Incentive Fund (NYSEV-VIF) 2015. Available online: https://truck-vip.ny.gov/NYSEV-VIF-vehicle-list.php (accessed on 1 October 2015).

- California HVIP. California Hybrid and Zero-Emission Truck and Bus Voucher Incentive Project (HVIP) 2015. Available online: https://www.californiahvip.org/default.aspx (accessed on 1 October 2015).

- Brecher, A.; Energy Analysis and Sustainability Division; Energy and Environmental Systems Technical Center; Volpe National Transportation Research Center. Transit Bus Applications of Lithium Ion Batteries: Progress and Prospects; CreateSpace Independent Publishing Platform: North Charleston, SC, USA, 2012. [Google Scholar]

- Hill, D.M.; Agarwal, A.S.; Ayello, F. Fleet operator risks for using fleets for V2G regulation. Energy Policy 2012, 41, 221–231. [Google Scholar] [CrossRef]

- Peterson, S.B.; Apt, J.; Whitacre, J.F. Lithium-ion battery cell degradation resulting from realistic vehicle and vehicle-to-grid utilization. J. Power Sources 2010, 195, 2385–2392. [Google Scholar] [CrossRef]

- Clements, J.D.; Nagrani, U. Central Valley Electric School Bus Demonstration Project; Kings Canyon Unified School District: Reedley, CA, USA, 2014. [Google Scholar]

- Proterra. Proterra Catalyst XR Specifications 2015. Available online: http://www.proterra.com/wp-content/uploads/2015/05/Tearsheets_CatalystPlatform.pdf (accessed 1 October 2015).

- Sioshansi, R.; Denholm, P. The value of plug-in hybrid electric vehicles as grid resources. Energy J. 2010, 31, 1–23. [Google Scholar] [CrossRef]

- Chang, D.; Erstad, D.; Lin, E.; Rice, A.F.; Goh, C.T.; Angel, A. Financial Viability of Non-Residential Electric Vehicle Charging Stations; Luskin Center for Innovation: Los Angeles: CA, USA, 2012. [Google Scholar]

- Burnham, A. Alternative Fuel Life-Cycle Environmental and Economic Transportation (AFLEET) Tool 2013; Argonne National Laboratory: Lemont, IL, USA, 2013. [Google Scholar]

- Pitkanen, W.; Van Amburg, B. Best Fleet Uses, Key Challenges and the Early Business Case for E-Trucks: Findings and Recommendations of the E-Truck Task Force; Calstart: Pasadena, CA, USA, 2012; Volume 1. [Google Scholar]

- Bankrate CD Investment rates results. Available online: http://www.bankrate.com/funnel/cd-investments/cd-investment-results.aspx?&prods=15&local=false (accessed on 1 November 2015).

- The Budget and Economic Outlook: 2015-2025; Congressional Budget Office: Washington DC, USA, 2015.

- Zhao, Y.; Noori, M.; Tatari, O. Vehicle to Grid regulation services of electric delivery trucks: Economic and environmental benefit analysis. Appl. Energy 2016, 168, 146–158. [Google Scholar] [CrossRef]

- Noori, M.; Zhao, Y.; Onat, N.; Gardner, S.; Tatari, O. Light-duty electric vehicles to improve the integrity of the electricity grid through vehicle-to-grid technology: Analysis of regional net revenue and emissions savings. Appl. Energy 2016, 170, 161–175. [Google Scholar] [CrossRef]

- Zhao, Y.; Tatari, O. A hybrid life cycle assessment of the vehicle-to-grid application in light duty commercial fleet. Energy 2015, 93, 1277–1286. [Google Scholar] [CrossRef]

- Noori, M.; Gardner, S.; Tatari, O. Electric vehicle cost, emissions, and water footprint in the United States: Development of a regional optimization model. Energy 2015, 89, 610–625. [Google Scholar] [CrossRef]

- Noori, M.; Kucukvar, M.; Tatari, O. Environmental Footprint Analysis of On-shore and Off-shore Wind Energy Technologies. In Proceedings of the IEEE International Symposium on Sustainable Systems and Technology, Boston, MA, USA, 16–18 May 2012.

- Noori, M.; Kucukvar, M.; Tatari, O. Economic Input–Output Based Sustainability Analysis of Onshore and Offshore Wind Energy Systems. Int. J. Green Energy 2015, 12, 939–948. [Google Scholar] [CrossRef]

- Noori, M.; Kucukvar, M.; Tatari, O. A macro-level decision analysis of wind power as a solution for sustainable energy in the USA. Int. J. Sustain. Energy 2015, 34, 629–644. [Google Scholar] [CrossRef]

- Nam, B.; Golestani, B.; Noori, M.; Tatari, O.; An, J. Investigation of Reflective Cracking Mitigation Techniques; Final Report; University of Central Florida: Orlando, FL, USA, 2014. [Google Scholar]

- Noori, M. Sustainability Assessment of Wind Energy for Buildings; University of Central Florida: Orlando, FL, USA, 2013. [Google Scholar]

- Consoli, F.A.; Alomari, A.H.; Al-Deek, H.; Rogers, J.; Sandt, A.; Noori, M.; Tatari, O.; Hadi, M. Evaluation of Conditional Transit Signal Priority Technology for Regional Implementation. Transp. Res. Rec. J. Transp. Res. Board 2015. [Google Scholar] [CrossRef]

- Ercan, T.; Kucukvar, M.; Tatari, O.; Al-Deek, H. Congestion Relief Based on Intelligent Transportation Systems in Florida. Transp. Res. Rec. J. Transp. Res. Board 2013, 2380, 81–89. [Google Scholar] [CrossRef]

- Noori, M.; Tatari, O.; Nam, B.; Golestani, B.; Greene, J. A stochastic optimization approach for the selection of reflective cracking mitigation techniques. Transp. Res. A Policy Pract. 2014, 69, 367–378. [Google Scholar] [CrossRef]

- Kucukvar, M.; Noori, M.; Egilmez, G.; Tatari, O. Stochastic decision modeling for sustainable pavement designs. Int. J. Life Cycle Assess. 2014, 19, 1185–1199. [Google Scholar] [CrossRef]

- Kay, M.; Clark, M.; Duffy, C.; Laube, M.; Lian, F.S. Bus Lifecycle Cost Model for Federal Land Management Agencies: User’s Guide; U.S. Department of Transportation Research and Innovative Technology Administration John A. Volpe National Transportation Systems Center: Cambridge, MA, USA, 2011. [Google Scholar]

- Neff, J.; Dickens, M. 2013 Public Transportation Fact Book; American Public Transportation Association: Washington, DC, USA, 2013. [Google Scholar]

- BYD. BYD 40′ Electric Transit Bus 2015. Available online: http://www.byd.com/na/auto/40feet.html (accessed on 20 May 2010).

- Cicconi, P.; Landi, D.; Morbidoni, A.; Germani, M. Feasibility analysis of second life applications for Li-ion cells used in electric powertrain using environmental indicators. In Proceedings of the IEEE International Energy Conference and Exhibition (Energycon), Florence, Italy, 9–12 September 2012; pp. 985–990.

- Amarakoon, S.; Smith, J.; Segal, B. Application of Life- Cycle Assessment to Nanoscale Technology: Lithium-ion Batteries for Electric Vehicles; EPA: Washington, DC, USA, 2013. [Google Scholar]

- Barnitt, R.; Gonder, J. Drive Cycle Analysis, Measurement of Emissions and Fuel Consumption of a PHEV School Bus Preprint. National Renewable Energy Laboratory (NREL): Golden, CO. USA, 2011. [Google Scholar]

- De Filippo, G.; Marano, V.; Sioshansi, R. Simulation of an Electric Transportation System at The Ohio State. Appl. Energy 2014, 113, 1686–1691. [Google Scholar] [CrossRef]

| Study type | Reference | Short description of the articles |

|---|---|---|

| LCA studies | Frey et al. [17] | Comparison of the LCA results for diesel and hydrogen fuel cell transit buses. |

| Hess [18] | Evaluating the environmental emissions of alternative fuel transit buses. | |

| Ally and Pryor [19] | Comparison of diesel, natural gas, and fuel cell bus options by using process-LCA tool GaBI and fuel cycle models. | |

| Chester and Horvath [20] | It defines and quantifies all of the public transportation modes’ LCA analysis results, but although it is an important study in terms of methods and data, the study itself is beyond the scope of this research which will assume that the infrastructure of BE and diesel buses will be the same except for the charging infrastructure of each bus type, as will be further explained in later sections. | |

| Ou et al. [21] | Alternative fuel use level scenarios for future years under various scenarios related to the adoption of alternative fuels for transit buses are investigated. | |

| Ou et al. [22] | Evaluation of different policy recommendations for reducing GHG emissions and fossil fuel consumption in China by using alternative fuels for transit buses. | |

| Cooney et al. [23] | A hybrid-LCA approach to evaluate the environmental emission impacts of BE and diesel transit buses, taking the different state-based electricity grid mixes into account. | |

| García Sánchez et al. [24] | Comparison of the GHG emissions and energy consumption rates of BE, hybrid, and diesel buses for Spain’s current and future electricity generation mixes. | |

| Lajunen [25] | The lifetime energy consumption rates and cost-benefit analysis results of BE and hybrid transit buses are presented. | |

| Onat et al. [26] | Hybrid and BE passenger vehicles are analyzed for their LCA impacts for environmental, social, and economic concerns. | |

| Donateo et al. [27] | Real life experiment (driving cycles) for electric vehicle related environmental emissions. | |

| Xu et al. [28] | The environmental emission performance of various alternative fuel options for transit buses in different U.S. cities under different operational conditions is investigated. | |

| Rogge et al. [29] | Drive range anxiety of battery electric transit buses are studied for feasible charging solutions of uninterrupted service. | |

| Ercan and Tatari [30] | Diesel, hybrid, BE, biodiesel, Compressed Natural Gas (CNG), and Liquefied Natural Gas (LNG) fuel options of transit buses in terms of their lifetime environmental emissions and water withdrawal impacts with the consideration of regional electricity generation mixes. | |

| V2G studies | Kempton and Tomic [14] | Comparison of V2G ancillary service revenues as well as the costs incurred due to battery degradation. |

| Kempton and Tomic [15] | Business models for the incorporation of V2G and fluctuated renewable energy. | |

| Noel and McCormack [12] | Comparison of V2G available BE and diesel school buses for life cycle cost and environmental emission externalities. | |

| Turton and Moura [31] | V2G system is analyzed with an energy-system model has been used to project the future changes of both energy and transportation systems. | |

| Kudoh et al. [32] | Vehicle to Home (V2H) systems are analyzed with LCA perspective. | |

| Externality studies | Muller and Mendelsohn [33,34] | Air Pollution Emission Experiments and Policy (APEEP) analysis model to quantify conventional air emissions’ human health impacts. |

| Michalek et al. [35] | Quantified air emission externalities for vehicle manufacturing, fuel production, electricity generation, and tailpipe emissions. | |

| Gouge et al. [36] | Optimal transit bus operation for reducing air pollution externalities. | |

| Ercan et al. [37] | Optimal bus fleet in terms of life cycle cost, CO2 emissions, and air emission externalities with different alternative fuel choices for transit buses under different driving conditions. |

| Notation | Explanation | Type | Index |

|---|---|---|---|

| j | Air pollutant type | GHG | j = 1 |

| CO | j = 2 | ||

| NOx | j = 3 | ||

| PM10 | j = 4 | ||

| PM2.5 | j = 5 | ||

| SOx | j = 6 | ||

| VOC | j = 7 | ||

| p | Power plant type | Coal | p = 1 |

| Oil | p = 2 | ||

| Gas | p = 3 | ||

| Other Fossil | p = 4 | ||

| Nuclear | p = 5 | ||

| Hydro | p = 6 | ||

| Biomass | p = 7 | ||

| Wind | p = 8 | ||

| Solar | p = 9 | ||

| Geo-Thermal | p = 10 | ||

| r | ISO/RTO regions | PJM | r = 1 |

| ISO-NE | r = 2 | ||

| NYISO | r = 3 | ||

| ERCOT | r = 4 | ||

| CAISO | r = 5 | ||

| y | Analysis period years | - | y = 2015 - 2027 |

| i | Bus type | Transit | i = 1 |

| School | i = 2 | ||

| eGRIDjry | Yearly (y) emission rate of energy losses in r region for j air pollutant based on eGRID data (lb/kWh) | ||

| GLFr | Grid loss factor (GLF) for r region based on eGRID data | ||

| UGjp | Well-to-pump (WTP) analysis emissions of energy source for p power plant for j air pollutant (lb/kWh) | ||

| EMpry | Yearly (y) emission rate of electricity production at p power plant in r region (lb/kWh) | ||

| UEij | Upstream j type of emissions for diesel i type of bus | ||

| UAij | Upstream j type of air externality cost for diesel i type of bus | ||

| DEij | Downstream j type of emissions for diesel i type of bus | ||

| DAij | Downstream j type of air externality cost for diesel i type of bus | ||

| Ki | Lifetime electricity consumption of i type bus | ||

| Bj | Air externality cost of per MWh electricity generation for j type of emission | ||

| Notation | Value | Definition | Unit | Reference | |

|---|---|---|---|---|---|

| BE-School Bus | BE-Transit Bus | ||||

| Pcap | 80 | 203 | Battery Capacity or max power available from bus | kWh | [12,30,48] |

| Tbattery | Uniform (2000–6000) | Battery lifetime charging cycles | cycles | [14,23,49,50] | |

| DVMT | 50 | 101 | Daily vehicle miles traveled (VMT) | miles | [23] |

| BRange | 0 | 0 | Buffering range to return safely charging facility | miles | - |

| FE | 0.75–2.00 a | 1.70–2.24 b | Fuel economy | kWh/miles | a Low range: [12]; High range [51]. b Low range: [52]; High range: [23]. |

| Tdispatch | 0.3 | 0.3 | Dispatch time | h | |

| Xconvert | 0.93 | 0.93 | DC to AC conversion factor | - | [53] |

| Pdispatch | 70–140 | 70–140 | Capacity of charging facility could transfer for revenue | kW | - |

| Tplug | 19.5–21 | 8–12 | Number of hours that bus is plugged to the charger | hours | [11,12] |

| Cinstallation | $5000–$10,000 | $5000–$10,000 | Charging facility installation cost | $ (2014) | [54] |

| Cequipment | $12,000–$20,000 | $12,000–$20,000 | Charging facility equipment cost (Level 3) | $ (2014) | [54] |

| CC-Main | $600–$1000 | $600–$1000 | Charging facility annual maintenance cost (5% of Cequipment) | $ (2014)/year | [54] |

| CB-Main | $0.2–$0.75 | $0.75 | Per mile maintenance cost of bus | $(2014)/mile | [12,55] |

| Cbus | $230,000 | $800,000 | Purchase cost of bus | $ (2014) | [6,12,25] |

| Cbat unit | $600 | Battery price per kWh capacity | $-year/kWh | [56] | |

| CV2G | Uniform ($1900–$2100) | Cost of V2G system equipment | $ (2014) | [14] | |

| Drate | 0.65%–1.15% | Annual Discount Rate | percentage | [57] | |

| Irate | ±10% of CBO’s projections | Annual Inflation Rate | percentage | [58] | |

| Value Type | School Bus- BE | School Bus- Diesel | Transit Bus- BE | Transit Bus- Diesel |

|---|---|---|---|---|

| Purchase price (Cbus) | $230,000 | $110,000 | $800,000 | $340,000 |

| Lifetime fuel cost (diesel or electricity) | $21,915 | $82,494 | $87,181 | $500,113 |

| Maintenance cost (CB-Main) | $66,814 | $140,461 | $311,892 | $415,856 |

| Charging station purchase cost (Cinstallation + Cequipment) | $23,446 | $0 | $23,587 | $0 |

| Charging station maintenance cost (CC-Main) | $8971 | $0 | $8979 | $0 |

| Battery replacement cost (due to operation) (Cbattery) | $29,819 | $0 | $76,073 | $0 |

| V2G capacity payment revenue | −$229,498 | $0 | −$96,261 | $0 |

| V2G energy payment revenue (exchanged electricity) | −$56,329 | $0 | −$56,469 | $0 |

| V2G cost (V2G equipment + battery degradation) (Cregu) | $79,285 | $0 | $79,423 | $0 |

| Resale value | −$32,658 | −$17,199 | −$106,123 | −$43,810 |

| Government incentives (if applicable) | −$84,876 | $0 | −$106,146 | $0 |

| Net value | $56,888 | $315,756 | $1,022,135 | $1,212,158 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ercan, T.; Noori, M.; Zhao, Y.; Tatari, O. On the Front Lines of a Sustainable Transportation Fleet: Applications of Vehicle-to-Grid Technology for Transit and School Buses. Energies 2016, 9, 230. https://doi.org/10.3390/en9040230

Ercan T, Noori M, Zhao Y, Tatari O. On the Front Lines of a Sustainable Transportation Fleet: Applications of Vehicle-to-Grid Technology for Transit and School Buses. Energies. 2016; 9(4):230. https://doi.org/10.3390/en9040230

Chicago/Turabian StyleErcan, Tolga, Mehdi Noori, Yang Zhao, and Omer Tatari. 2016. "On the Front Lines of a Sustainable Transportation Fleet: Applications of Vehicle-to-Grid Technology for Transit and School Buses" Energies 9, no. 4: 230. https://doi.org/10.3390/en9040230

APA StyleErcan, T., Noori, M., Zhao, Y., & Tatari, O. (2016). On the Front Lines of a Sustainable Transportation Fleet: Applications of Vehicle-to-Grid Technology for Transit and School Buses. Energies, 9(4), 230. https://doi.org/10.3390/en9040230