Distributed Renewable Generation and Storage System Sizing Based on Smart Dispatch of Microgrids

Abstract

:1. Introduction

- An integrated and comprehensive model that accounts for DR, DESS dispatch and performance degradation, dynamic pricing environments, power distribution loss and irregular renewable generation.

- Intelligent energy management that coincides with a smart grid framework.

- A computationally-efficient optimization method that can be practically used for long-term planning.

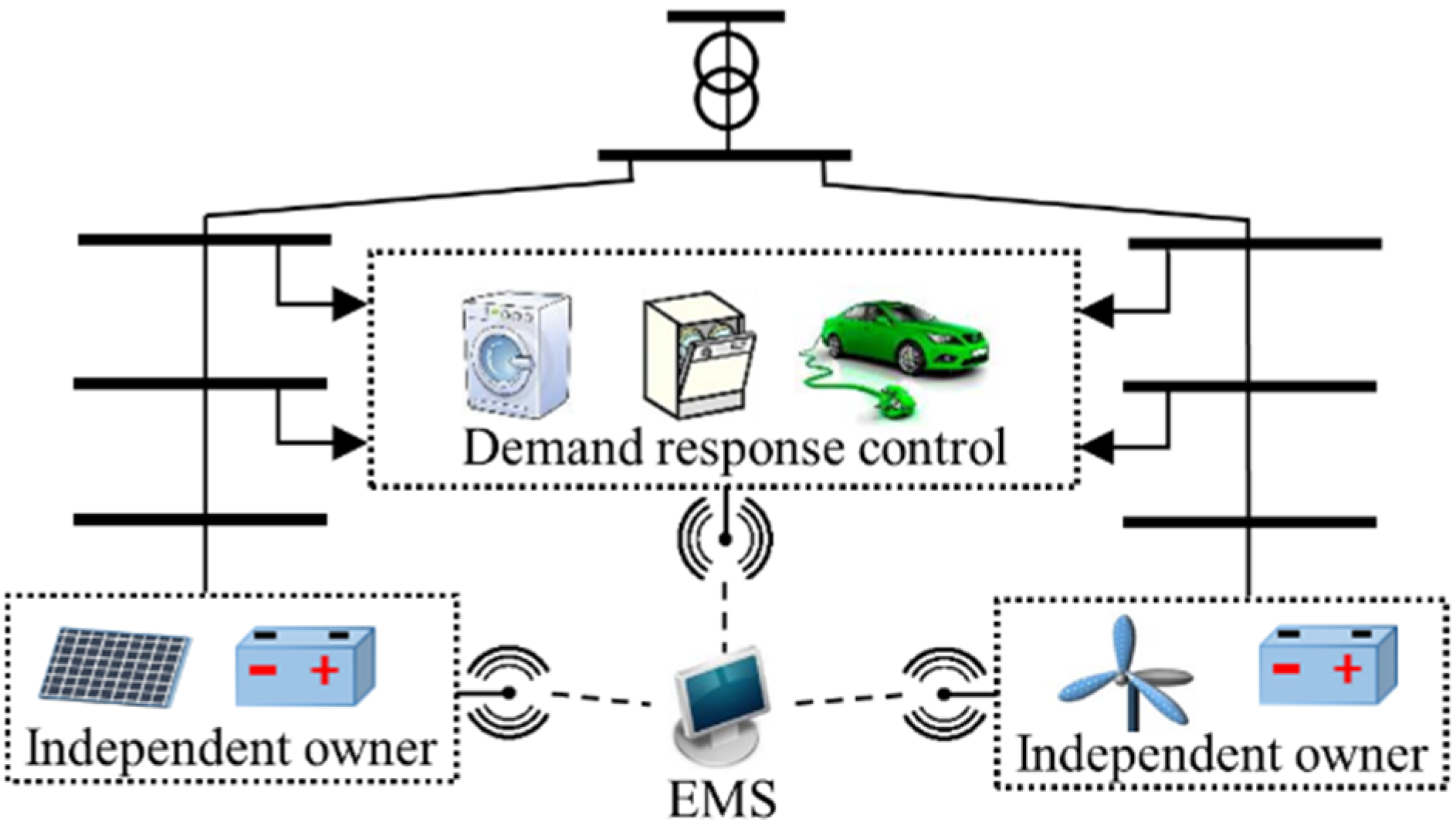

2. System Structure

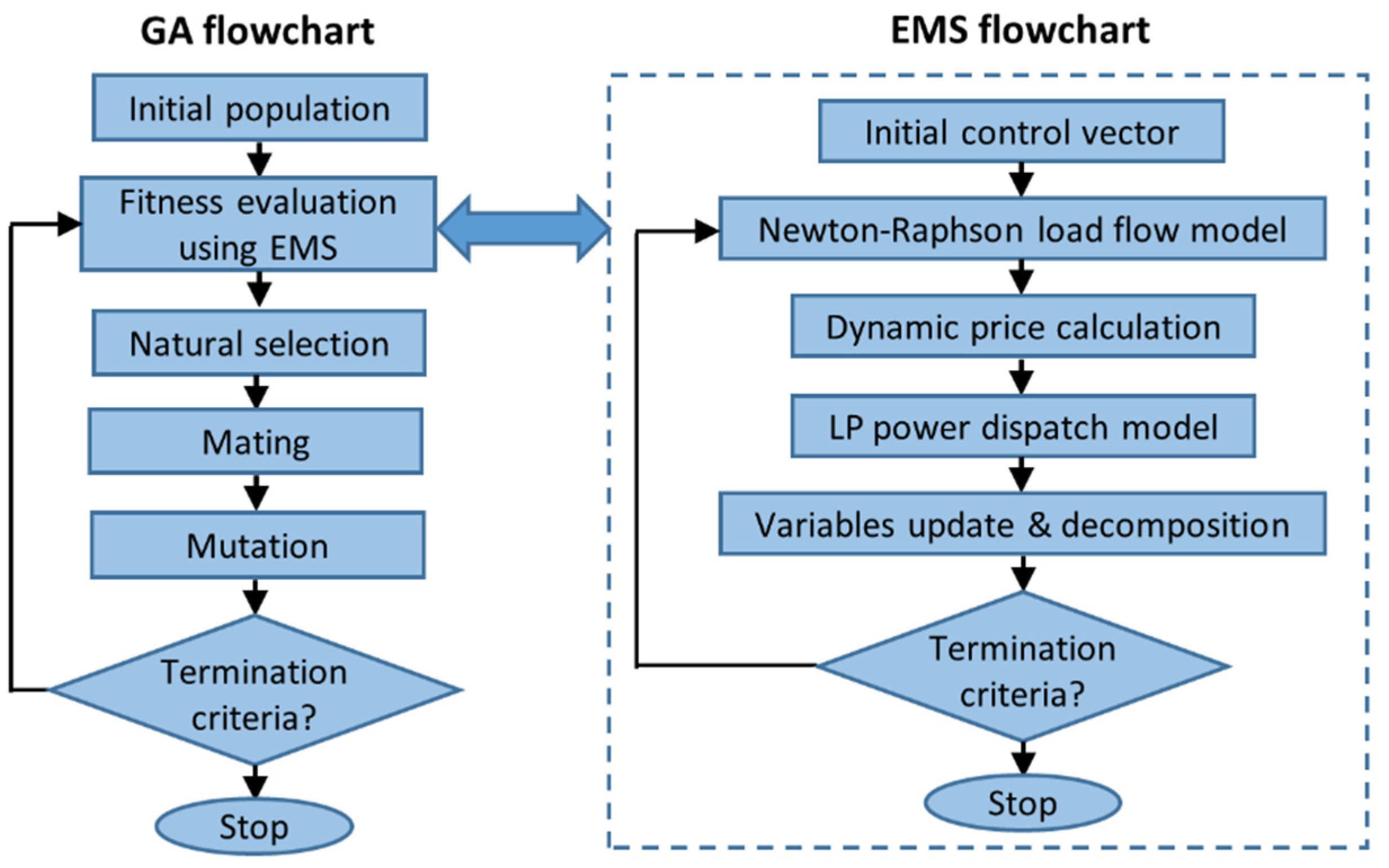

3. Energy Management System

3.1. Newton-Raphson Load Flow Model

3.2. Linear Programming Dispatch Model

3.2.1. Energy Balance and Power Limits

3.2.2. Demand Response Limits

3.2.3. Objective Function

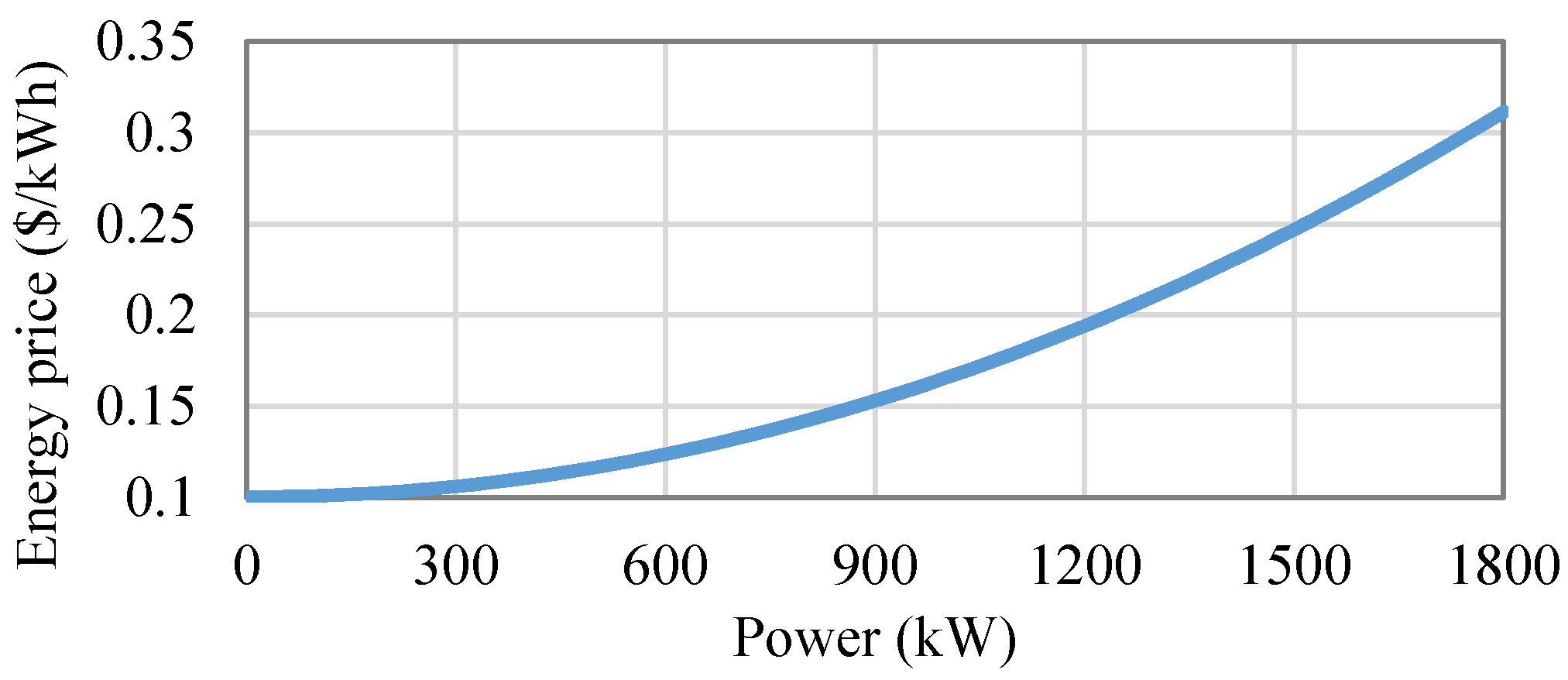

3.3. Variables Update and Decomposition

4. Genetic Algorithm Optimization

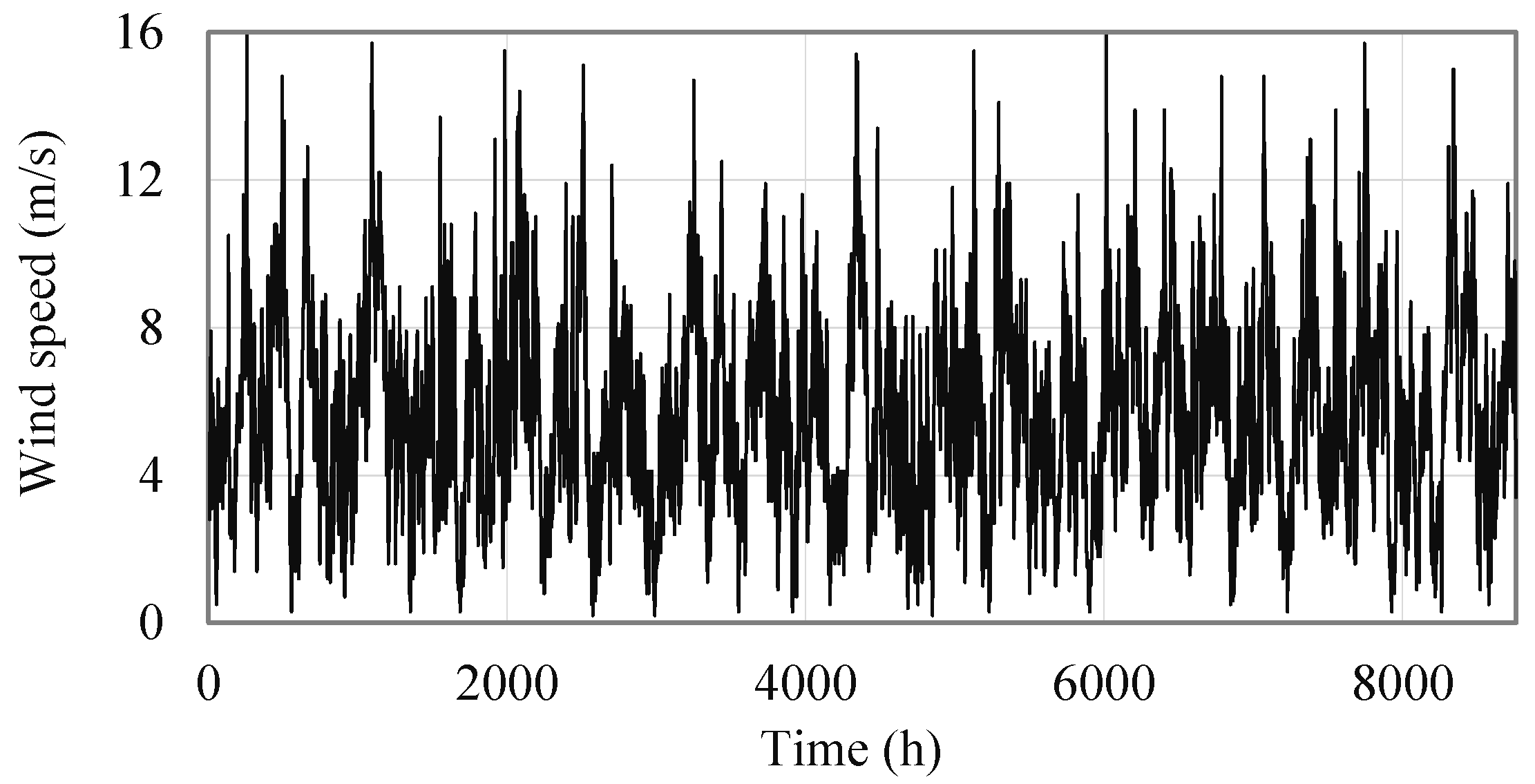

5. Case Study

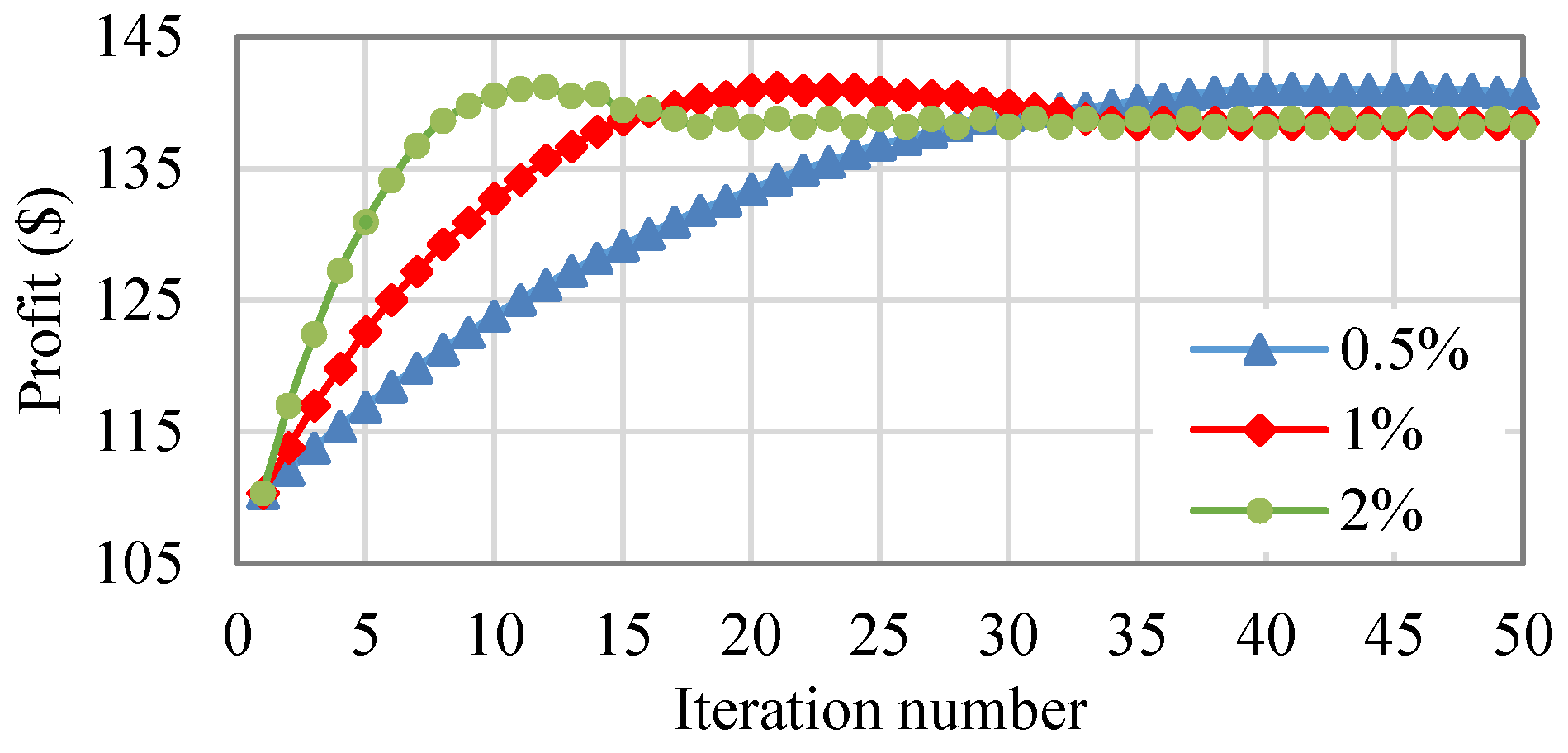

5.1. Case 1

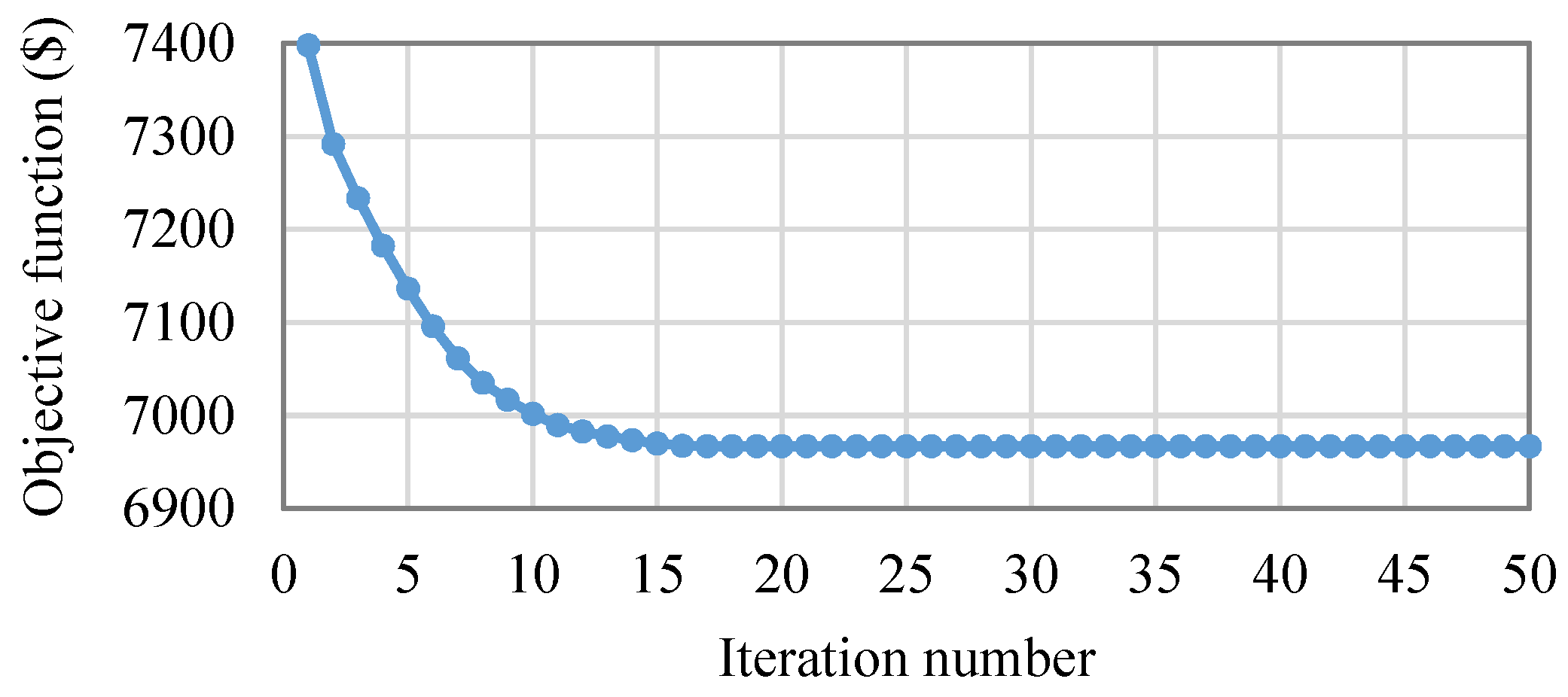

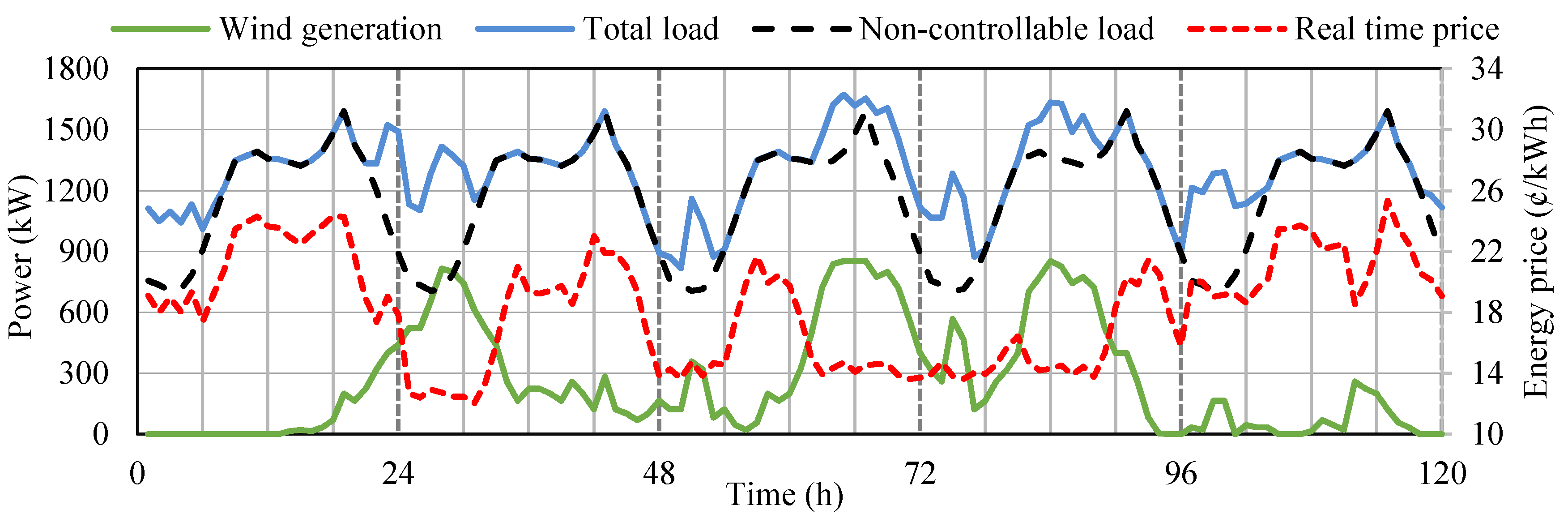

5.2. Case 2

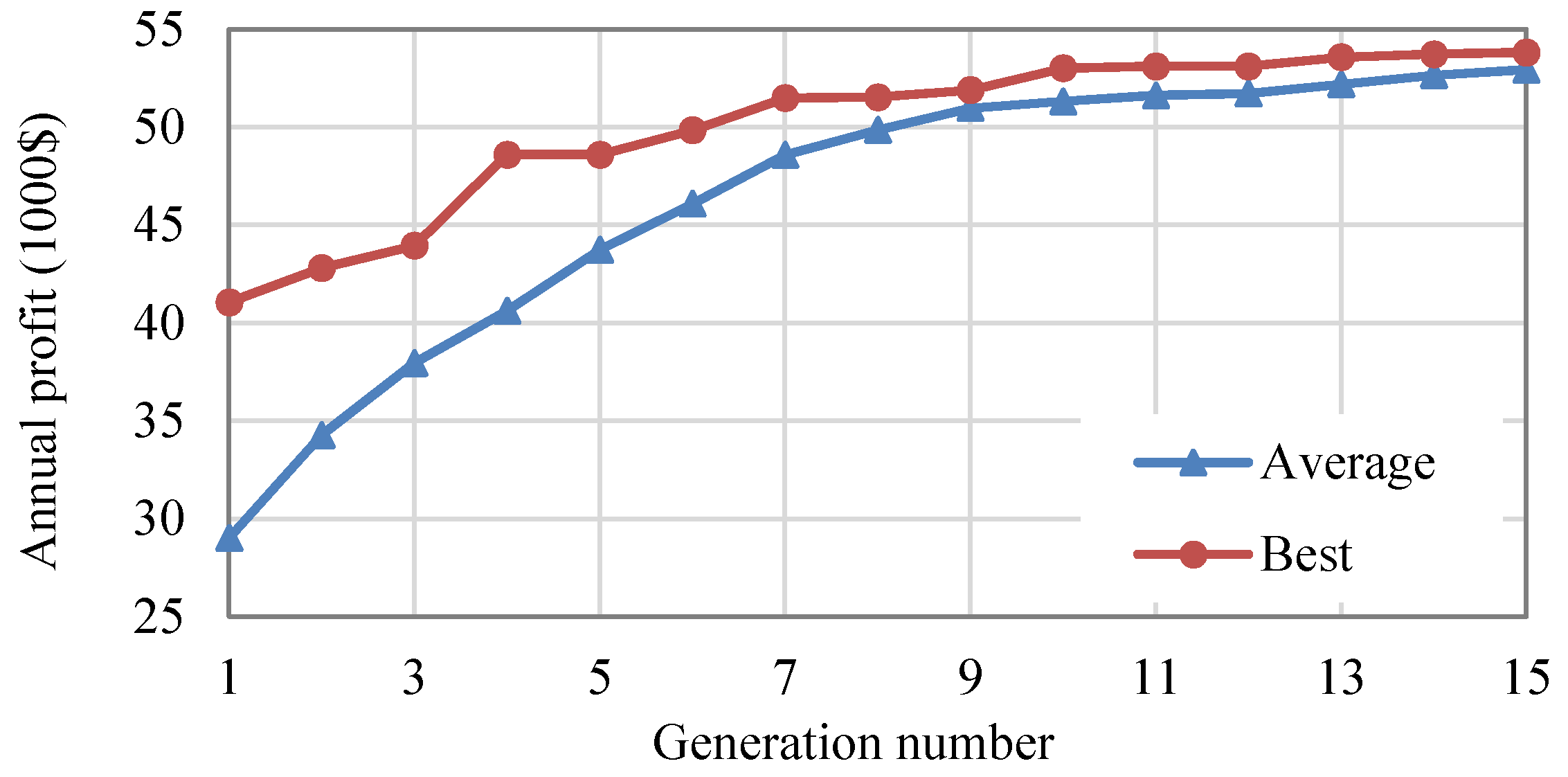

5.3. Case 3

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| EMS | Energy management system |

| EV | Electric vehicle |

| DG | Distributed generation |

| DR | Demand response |

| DRG | Distributed renewable generation |

| DESS | Distributed energy storage system |

| GA | Genetic algorithm |

| IO | Independent owner |

| LP | Linear programming |

| LCE | Levelized cost of energy |

| MG | Microgrid |

| NRLF | Newton-Raphson load flow |

| NRLP | Newton-Raphson linear programming |

| PV | Photovoltaic |

| WT | Wind turbine |

References

- Gautam, D.; Mithulananthan, N. Optimal DG placement in deregulated electricity market. Electr. Power Syst. Res. 2007, 77, 1627–1636. [Google Scholar] [CrossRef]

- Novoa, C.; Jin, T. Reliability centered planning for distributed generation considering wind power volatility. Electr. Power Syst. Res. 2011, 81, 1654–1661. [Google Scholar] [CrossRef]

- Carpinelli, G.; Celli, G.; Mocci, S.; Mottola, F.; Pilo, F.; Proto, D. Optimal integration of distributed energy storage devices in smart grids. IEEE Trans. Smart Grid 2013, 4, 985–995. [Google Scholar] [CrossRef]

- Singh, R.K.; Goswami, S.K. Optimum allocation of distributed generations based on nodal pricing for profit, loss reduction, and voltage improvement including voltage rise issue. Int. J. Electr. Power Energy Syst. 2010, 32, 637–644. [Google Scholar] [CrossRef]

- Tolabi, H.B.; Ali, M.H.; Rizwan, M. Simultaneous reconfiguration, optimal placement of DSTATCOM, and photovoltaic array in a distribution system based on fuzzy-ACO approach. IEEE Trans. Sustain. Energy 2015, 6, 210–218. [Google Scholar] [CrossRef]

- Martinez, J.A.; Guerra, G. A Parallel monte carlo method for optimum allocation of distributed generation. IEEE Trans. Power Syst. 2014, 29, 2926–2933. [Google Scholar] [CrossRef]

- Porkar, S.; Poure, P.; Abbaspour-Tehrani-fard, A.; Saadate, S. A novel optimal distribution system planning framework implementing distributed generation in a deregulated electricity market. Electr. Power Syst. Res. 2010, 80, 828–837. [Google Scholar] [CrossRef]

- Hejazi, H.A.; Araghi, A.R.; Vahidi, B.; Hosseinian, S.H.; Abedi, M. Independent distributed generation planning to profit both utility and DG investors. IEEE Trans. Power Syst. 2013, 28, 1170–1178. [Google Scholar] [CrossRef]

- Shaaban, M.F.; Atwa, Y.M.; El-saadany, E.F. DG allocation for benefit maximization in distribution networks. IEEE Trans. Power Syst. 2012, 28, 1–11. [Google Scholar] [CrossRef]

- Liu, Z.; Wen, F.; Ledwich, G. Optimal siting and sizing of distributed generators in distribution systems considering uncertainties. IEEE Trans. Power Deliv. 2011, 26, 2541–2551. [Google Scholar] [CrossRef]

- Chen, C.; Duan, S.; Cai, T.; Liu, B.; Hu, G. Optimal allocation and economic analysis of energy storage system in microgrids. IEEE Trans. Power Electron. 2011, 26, 2762–2773. [Google Scholar] [CrossRef]

- Zheng, Y.; Dong, Z.Y.; Luo, F.J.; Meng, K.; Qiu, J.; Wong, K.P. Optimal allocation of energy storage system for risk mitigation of discos with high renewable penetrations. IEEE Trans. Power Syst. 2014, 29, 212–220. [Google Scholar] [CrossRef]

- Arefifar, S.A.; Mohamed, Y.A.R.I. DG mix, reactive sources and energy storage units for optimizing microgrid reliability and supply security. IEEE Trans. Smart Grid 2014, 5, 1835–1844. [Google Scholar] [CrossRef]

- El-khattam, W.; Hegazy, Y.G.; Salama, M.M.A. An integrated distributed generation optimization model for distribution system planning. IEEE Trans. Power Syst. 2005, 20, 1158–1165. [Google Scholar] [CrossRef]

- Ghosh, S.; Ghoshal, S.P.; Ghosh, S. Optimal sizing and placement of distributed generation in a network system. Int. J. Electr. Power Energy Syst. 2010, 32, 849–856. [Google Scholar] [CrossRef]

- Ganguly, S.; Samajpati, D. Distributed generation allocation on radial distribution networks under uncertainties of load and generation using genetic algorithm. IEEE Trans. Sustain. Energy 2015, 6, 688–697. [Google Scholar] [CrossRef]

- Peng, X.; Lin, L.; Zheng, W.; Liu, Y. Crisscross Optimization Algorithm and Monte Carlo Simulation for Solving Optimal Distributed Generation Allocation Problem. Energies 2015, 8, 13641–13659. [Google Scholar] [CrossRef]

- Song, I.-K.; Jung, W.-W.; Chu, C.-M.; Cho, S.-S.; Kang, H.-K.; Choi, J.-H. General and Simple Decision Method for DG Penetration Level in View of Voltage Regulation at Distribution Substation Transformers. Energies 2013, 6, 4786–4798. [Google Scholar] [CrossRef]

- Li, R.; Ma, H.; Wang, F.; Wang, Y.; Liu, Y.; Li, Z. Game optimization theory and application in distribution system expansion planning, including distributed generation. Energies 2013, 6, 1101–1124. [Google Scholar] [CrossRef]

- Zhang, X.; Karady, G.; Ariaratnam, S. Optimal allocation of CHP-based distributed generation on urban energy distribution networks. IEEE Trans. Sustain. Energy 2014, 5, 246–253. [Google Scholar] [CrossRef]

- Ghofrani, M.; Arabali, A.; Etezadi-Amoli, M.; Fadali, M.S. A framework for optimal placement of energy storage units within a power system with high wind penetration. IEEE Trans. Sustain. Energy 2013, 4, 434–442. [Google Scholar] [CrossRef]

- Zeng, B.; Zhang, J.; Yang, X.; Wang, J.; Dong, J.; Zhang, Y. Integrated planning for transition to low-carbon distribution system with renewable energy generation and demand response. IEEE Trans. Power Syst. 2014, 29, 1153–1165. [Google Scholar] [CrossRef]

- Arabali, A.; Ghofrani, M.; Etezadi-Amoli, M.; Fadali, M.S. Stochastic performance assessment and sizing for a hybrid power system of solar/wind/energy Storage. IEEE Trans. Sustain. Energy 2014, 5, 363–371. [Google Scholar] [CrossRef]

- Zou, K.; Agalgaonkar, A.P.; Muttaqi, K.M.; Perera, S. Distribution system planning with incorporating DG reactive capability and system uncertainties. IEEE Trans. Sustain. Energy 2012, 3, 112–123. [Google Scholar] [CrossRef]

- Tan, W.S.; Hassan, M.Y.; Majid, M.S.; Rahman, H.A. Optimal distributed renewable generation planning: A review of different approaches. Renew. Sustain. Energy Rev. 2013, 18, 626–645. [Google Scholar] [CrossRef]

- Rahbar, K.; Xu, J.; Zhang, R. Real-time energy storage management for renewable integration in microgrid: An off-line optimization approach. IEEE Trans. Smart Grid 2015, 6, 124–134. [Google Scholar] [CrossRef]

- Rottondi, C.; Duchon, M.; Koss, D.; Palamaraciuc, A.; Piti, A.; Verticale, G.; Schatz, B. An energy management service for the smart office. Energies 2015, 8, 11667–11684. [Google Scholar] [CrossRef]

- Rigo-Mariani, R.; Sareni, B.; Roboam, X.; Turpin, C. Optimal power dispatching strategies in smart-microgrids with storage. Renew. Sustain. Energy Rev. 2014, 40, 649–658. [Google Scholar] [CrossRef]

- Mallol-Poyato, R.; Salcedo-Sanz, S.; Jiménez-Fernández, S.; Díaz-Villar, P. Optimal discharge scheduling of energy storage systems in microgrids based on hyper-heuristics. Renew. Energy 2015, 83, 13–24. [Google Scholar] [CrossRef]

- Bai, H.; Miao, S.; Ran, X.; Ye, C. Optimal dispatch strategy of a virtual power plant containing battery switch stations in a unified electricity market. Energies 2015, 8, 2268–2289. [Google Scholar] [CrossRef]

- Viana, A.; Pedroso, J.P. A new MILP-based approach for unit commitment in power production planning. Int. J. Electr. Power Energy Syst. 2013, 44, 997–1005. [Google Scholar] [CrossRef]

- Carrión, M.; Arroyo, J.M. A computationally efficient mixed-integer linear formulation for the thermal unit commitment problem. IEEE Trans. Power Syst. 2006, 21, 1371–1378. [Google Scholar] [CrossRef]

- Mohsenian-Rad, A.H.; Wong, V.W.S.; Jatskevich, J.; Schober, R.; Leon-Garcia, A. Autonomous demand-side management based on game-theoretic energy consumption scheduling for the future smart grid. IEEE Trans. Smart Grid 2010, 1, 320–331. [Google Scholar] [CrossRef]

- Kunwar, N.; Yash, K.; Kumar, R. Area-load based pricing in DSM through ANN and heuristic scheduling. IEEE Trans. Smart Grid 2013, 4, 1275–1281. [Google Scholar] [CrossRef]

- Nguyen, T.; Negnevitsky, M.; De Groot, M. Pool-based Demand Response Exchange: Concept and modeling. IEEE Trans. Power Syst. 2011, 26, 1677–1685. [Google Scholar] [CrossRef]

- Nguyen, D.T.; Negnevitsky, M.; De Groot, M. Market-based demand response scheduling in a deregulated environment. IEEE Trans. Smart Grid 2013, 4, 1948–1956. [Google Scholar] [CrossRef]

- Chen, C.; Wang, J.; Kishore, S. A distributed direct load control approach for large-scale residential demand response. IEEE Trans. Power Syst. 2014, 29, 2219–2228. [Google Scholar] [CrossRef]

- Safdarian, A.; Fotuhi-Firuzabad, M.; Lehtonen, M. A Distributed algorithm for managing residential demand response in smart grids. IEEE Trans. Ind. Informat. 2014, 10, 2385–2393. [Google Scholar] [CrossRef]

- Malbranche, P.; Delaille, A.; Mattera, F.; Lemaire, E. Assessment of storage ageing in different types of PV systems: Technical and economical aspects. In Proceedings of the 23rd European Photovoltaic Solar Energy Conference and Exhibition, Valencia, Spain, 1–5 September 2008; pp. 2765–2769.

- Atia, R.; Yamada, N. More accurate sizing of renewable energy sources under high levels of electric vehicle integration. Renew. Energy 2015, 81, 918–925. [Google Scholar] [CrossRef]

- Haupt, R.L.; Haupt, S.E. Practical Genetic Algorithm–Second Edition; John Wiley & Sons, Inc.: New York, NY, USA, 2004. [Google Scholar]

- Tokyo Electric Power Company, 8-h Night Service Plan. Available online: http://www.tepco.co.jp/en/customer/guide/ratecalc-e.html (accessed on 15 August 2015).

- Wiser, R.; Lantz, E.; Hand, M. The Past and Future Cost of Wind Energy. In Proceedings of the WREF 2012, Denver, CO, USA, 13–17 May 2012.

- Albright, G.; Edie, J.; Al-Hallaj, S. A Comparison of Lead Acid to Lithium-Ion in Stationary Storage Applications; AllCell Technologies LLC: Chicago, IL, USA, 2012. [Google Scholar]

| WT Cost | Battery Cost | Annual Maintenance | |||

|---|---|---|---|---|---|

| ($/kW) | ($/kWh) | (%) | (kW) | - | - |

| 2500 [43] | 150 [44] | 2 | 0.5 | 3 × 10−4 | 0.86 |

| Bus number | 820 | 834 | 844 | 848 | 890 |

| DESS size (kWh) | 60 | 40 | 0 | 100 | 60 |

| WT size (kW) | 100 | 150 | 225 | 125 | 225 |

| Bus number | 820 | 834 | 844 | 848 | 890 |

| DESS size (kWh) | 30 | 40 | 20 | 30 | 20 |

| WT size (kW) | 75 | 250 | 200 | 150 | 225 |

| Bus number | 820 | 834 | 844 | 848 | 890 |

| DESS size (kWh) | 400 | 380 | 260 | 230 | 210 |

| WT size (kW) | 475 | 475 | 450 | 500 | 325 |

| Bus number | 820 | 834 | 844 | 848 | 890 |

| DESS size (kWh) | 330 | 180 | 40 | 200 | 100 |

| WT size (kW) | 800 | 300 | 225 | 775 | 300 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Atia, R.; Yamada, N. Distributed Renewable Generation and Storage System Sizing Based on Smart Dispatch of Microgrids. Energies 2016, 9, 176. https://doi.org/10.3390/en9030176

Atia R, Yamada N. Distributed Renewable Generation and Storage System Sizing Based on Smart Dispatch of Microgrids. Energies. 2016; 9(3):176. https://doi.org/10.3390/en9030176

Chicago/Turabian StyleAtia, Raji, and Noboru Yamada. 2016. "Distributed Renewable Generation and Storage System Sizing Based on Smart Dispatch of Microgrids" Energies 9, no. 3: 176. https://doi.org/10.3390/en9030176

APA StyleAtia, R., & Yamada, N. (2016). Distributed Renewable Generation and Storage System Sizing Based on Smart Dispatch of Microgrids. Energies, 9(3), 176. https://doi.org/10.3390/en9030176