Renewable energy sources have attracted attention in recent years, due to concerns about nuclear power plants and the depletion of fossil fuels. Since the announcement of the “Solar Heating and Cooling Demonstration Act” in 1974 [

1], the United States (US) have promoted policies supporting the use of renewable energy sources. Japan established the New Energy Development Organization (NEDO) in 1980 to support the development of renewable energy systems and promote the use of renewable energy [

2,

3]. In Korea, the “Act on the Promotion of the Development, Use, and Diffusion of New and Renewable Energy” was revised in 2014. According to the regulation, public facilities of more than 1000 m

2 must cover 12% of their energy needs with renewable energy [

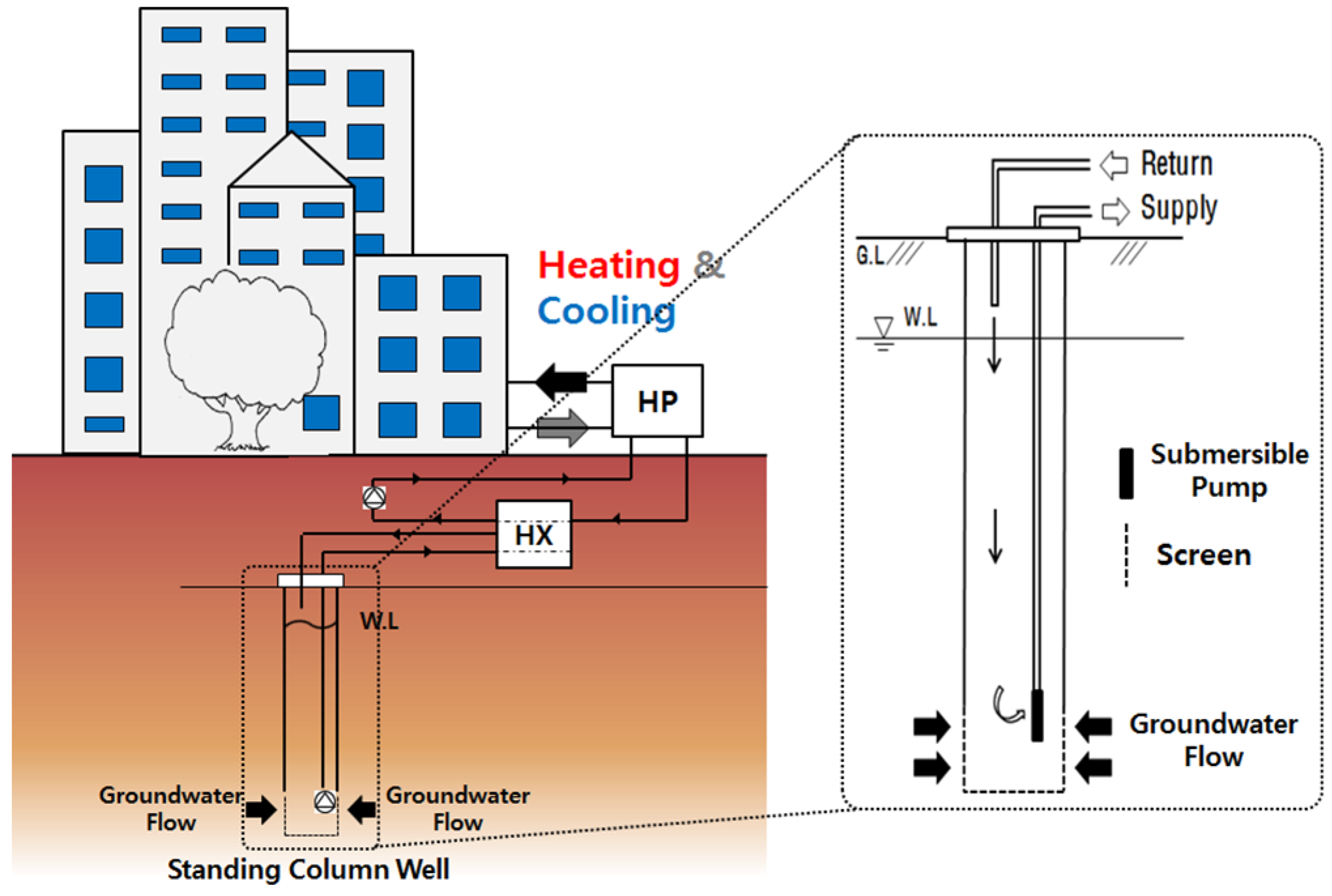

4]. Therefore, various renewable energy systems have been introduced in Korea. The installation of Ground Source Heat Pump (GSHP) systems for the heating and cooling of buildings is rapidly growing in Korea. Generally, GSHPs are divided into closed loop systems, which are based on the circulation of a heat carrier fluid into a buried pipe loop, and open loop systems, which are based on heat exchange with groundwater [

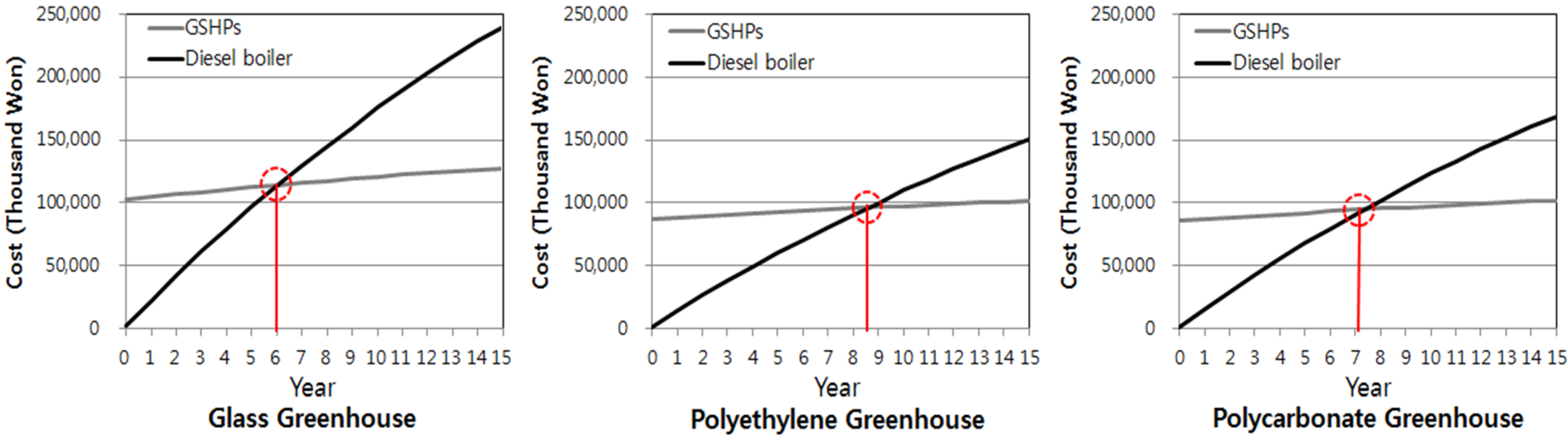

5]. Another classification can be made according to the depth crossed by the ground heat exchangers, which are thus divided into shallow (up to 300 m) and deep (over 300 m) geothermal heat pumps, with shallow systems largely prevailing over deep systems. Although deep geothermal heating systems are more efficient than shallow systems, the research and technological development of these systems is still far from being satisfactory, since the installation costs are still very high. An investigation of the physical and thermal properties of the target area ground, along with a quantitative analysis of the available heat, is required for the use of deep geothermal energy, which has considerable potential due to the high temperature of the source. In addition, the time trend of the energy needs of the facility should be known. For the utilization of deep geothermal energy in the industrial and public welfare sectors, initial costs (considering the potential of deep geothermal energy) should be considered, and an objective Life Cycle Cost (LCC) is also necessary.

Nguyen

et al. [

6] evaluated the influence of groundwater flow in fractured aquifers using a numerical coupled model of the Standing Column Wells (SCW) systems. With their model, they achieved a good agreement with reference numerical solutions. Park

et al. [

7] studied Ground Water Heat Pump (GWHP) systems through a field test and numerical studies. The analysis confirmed that thermal dispersivity is a very important design factor when dealing with larger GWHP systems. Casasso

et al. [

8] developed a model of thermal recycling in GWHPs, which has been validated by numerical simulations with FEFLOW. This tool can be utilized for the design of GWHPs. Lo Russo

et al. [

9,

10,

11] modeled GWHPs to assess the hydrogeological sustainability of water reinjection in a plant installed at the Politecnico di Torino (Italy) for the cooling of various buildings. Different scenarios were analyzed that differ significantly in terms of both overall plant costs (investments, maintenance, and total electricity consumption) and environmental impact. In order to evaluate the Thermally Affected Zone (TAZ), numerical simulations were performed. Minea [

12] conducted an experiment in the heating-cooling mode of two standing column wells that were shallower than the closed-loop system. The author concluded that the heating performance of the system without an artificial groundwater exchange is relatively high for limited periods of time. Efficient dehumidification in the free cooling mode is not achievable.

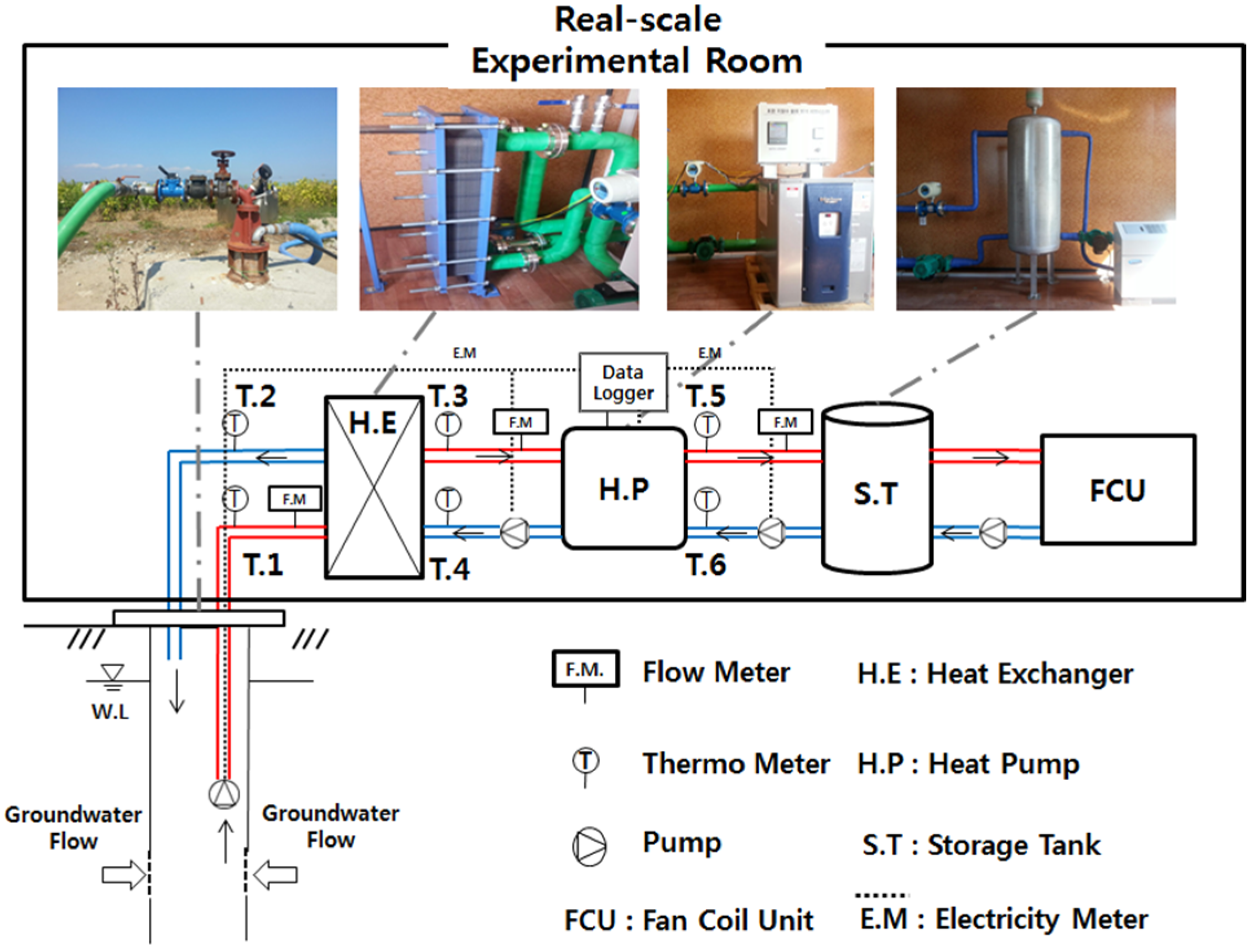

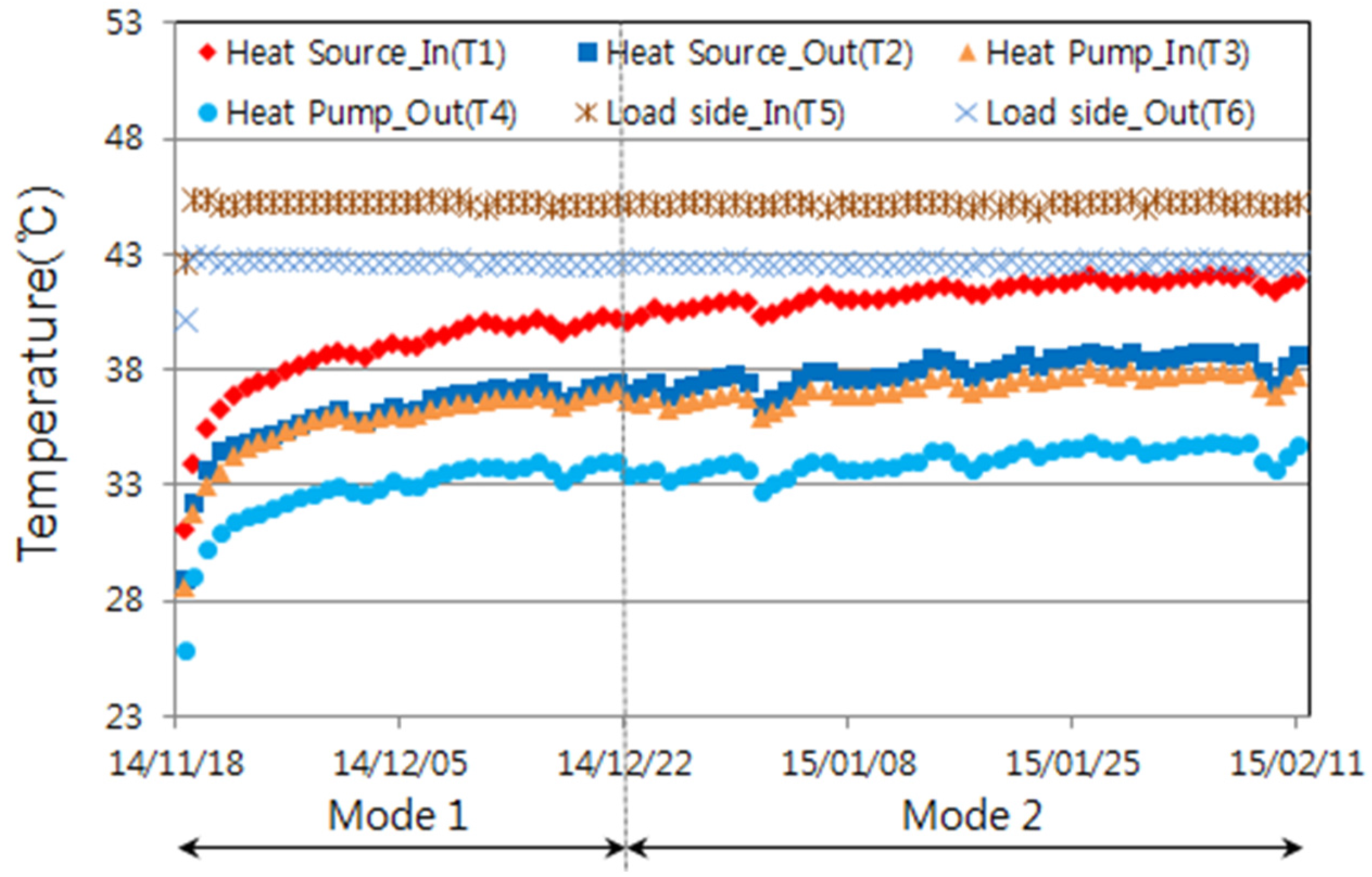

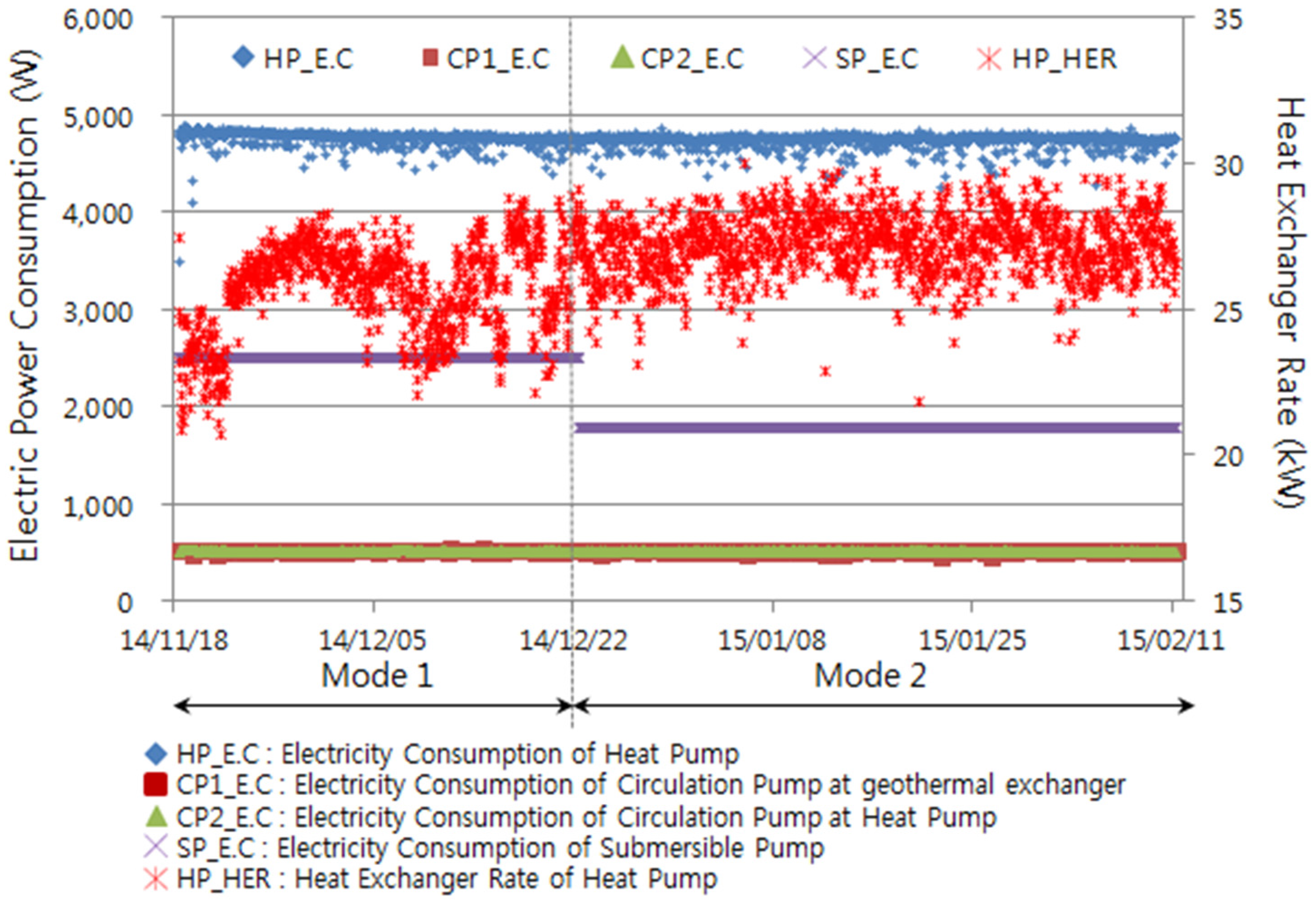

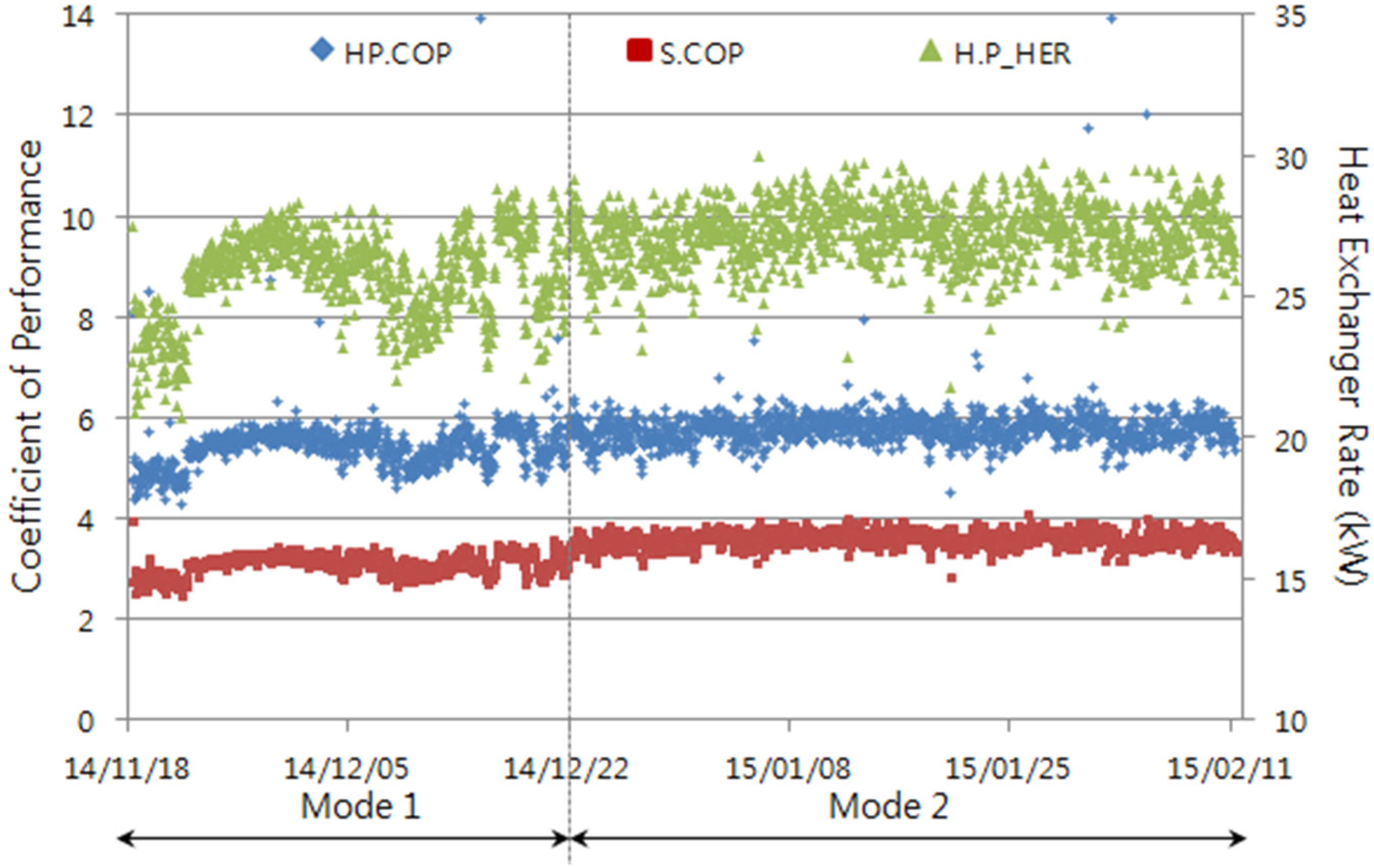

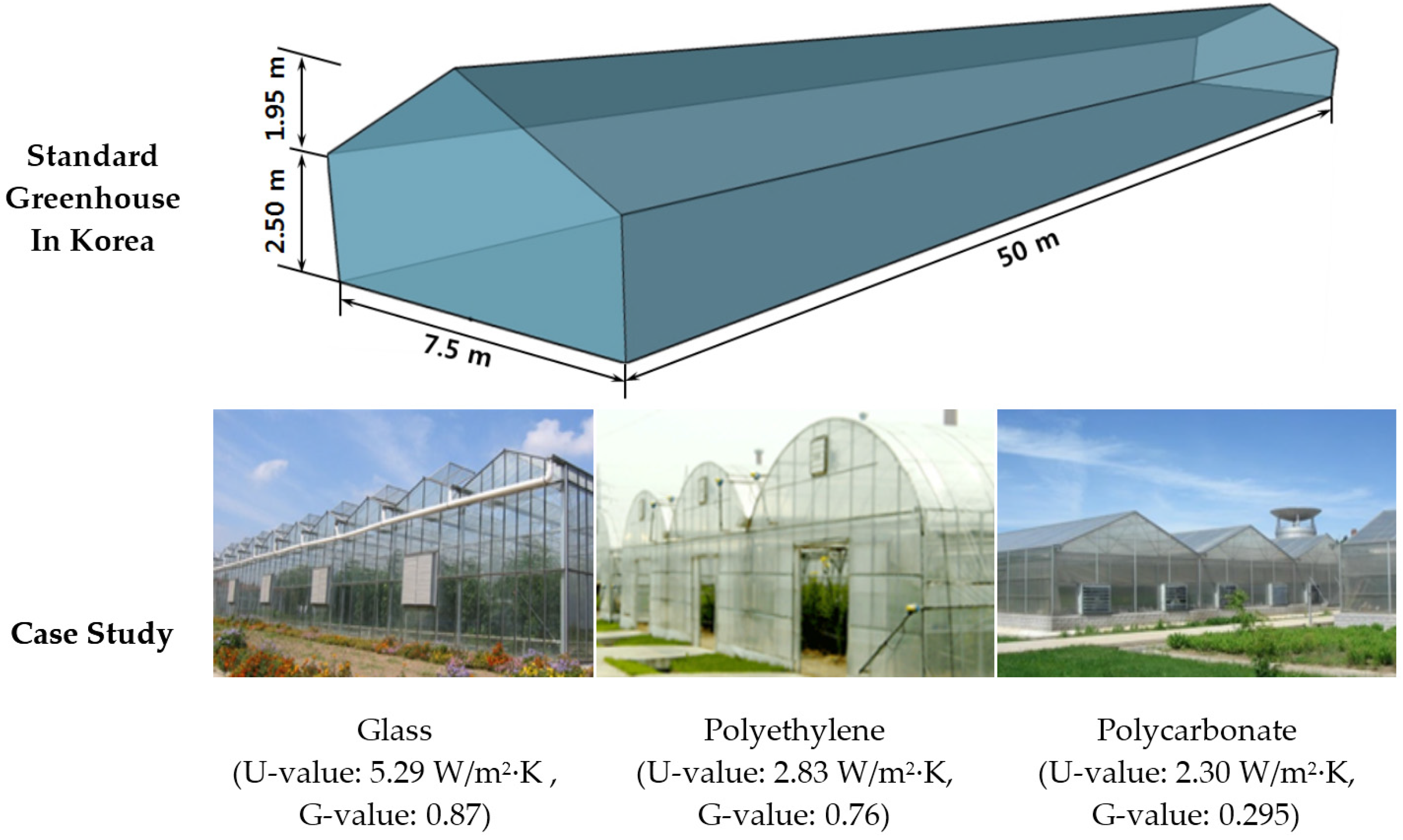

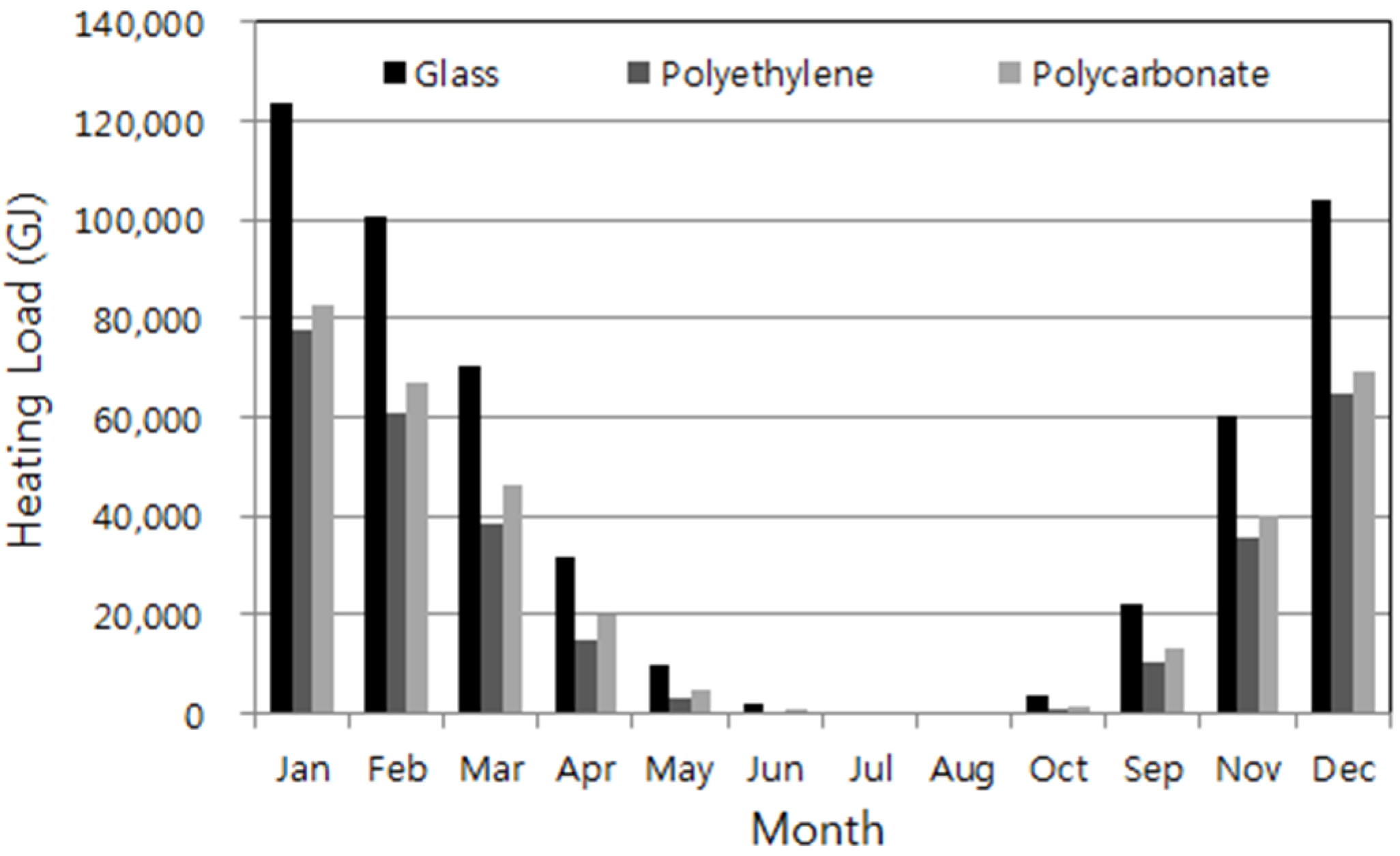

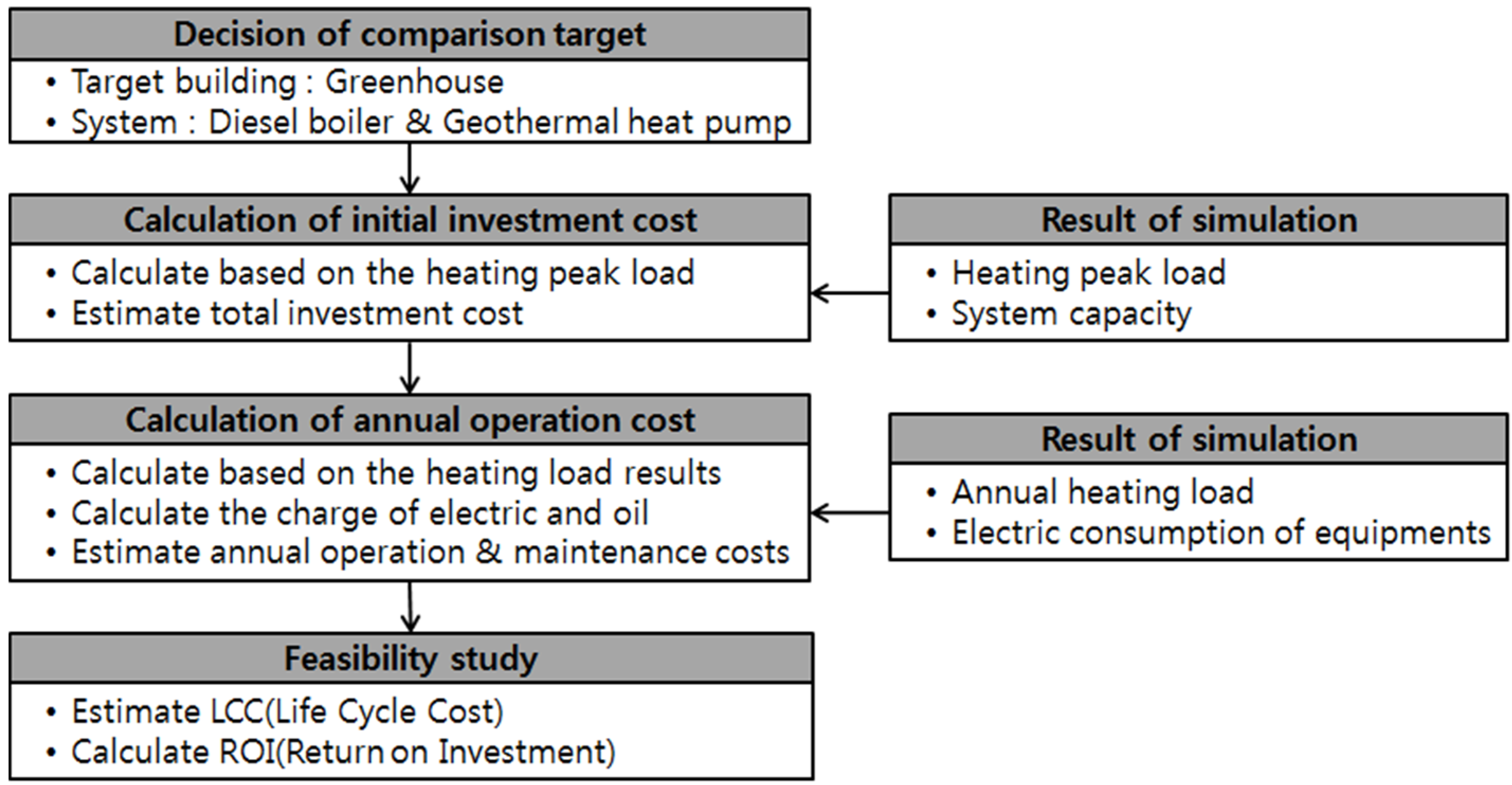

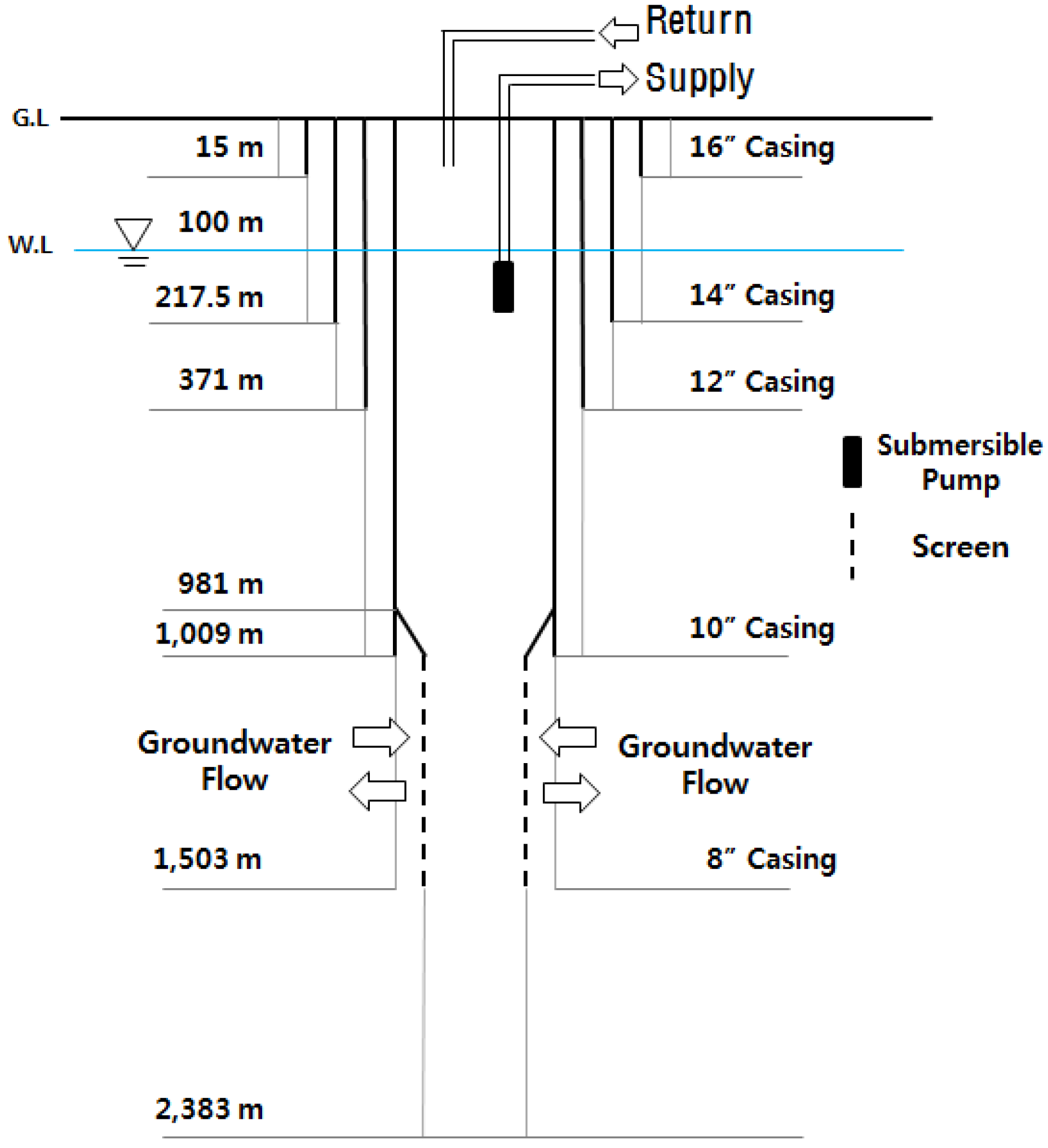

Closed-loop and open-loop systems, using shallow geothermal energy, are predominantly used in research and technological development in order to apply geothermal heat to buildings globally. Little research has been conducted regarding heat source temperature changes and the amount of energy usage. The Korea Institute of Geoscience and Mineral resources (KIGAM) conducted an evaluation of deep geothermal feasibility, aimed at the Korean peninsula, in order to assess the domestic geothermal energy reserves. According to the survey, a temperature of 90 °C was measured at a depth of 2385 m. Assuming the same ground temperature gradient below a depth of 2 km or more, a geothermal reservoir temperature of 180 °C could be obtained at a depth of 5 km [

13,

14]. Thus, in this study, real-scale testing equipment was constructed, and the actual energy availability was calculated for a deep geothermal well installed in Soenggok-ri, Heunghae-eup, Pohang-si, South Korea in order to evaluate the availability of deep geothermal energy. On the basis of the results, an evaluation was performed on each area for its potential use in controlled horticulture. Furthermore, on the basis of the LCC, the economics of the deep geothermal system were analyzed, and a comparison was made with existing heating boilers.