Study on the Optimum Design Method of Heat Source Systems with Heat Storage Using a Genetic Algorithm

Abstract

:1. Introduction

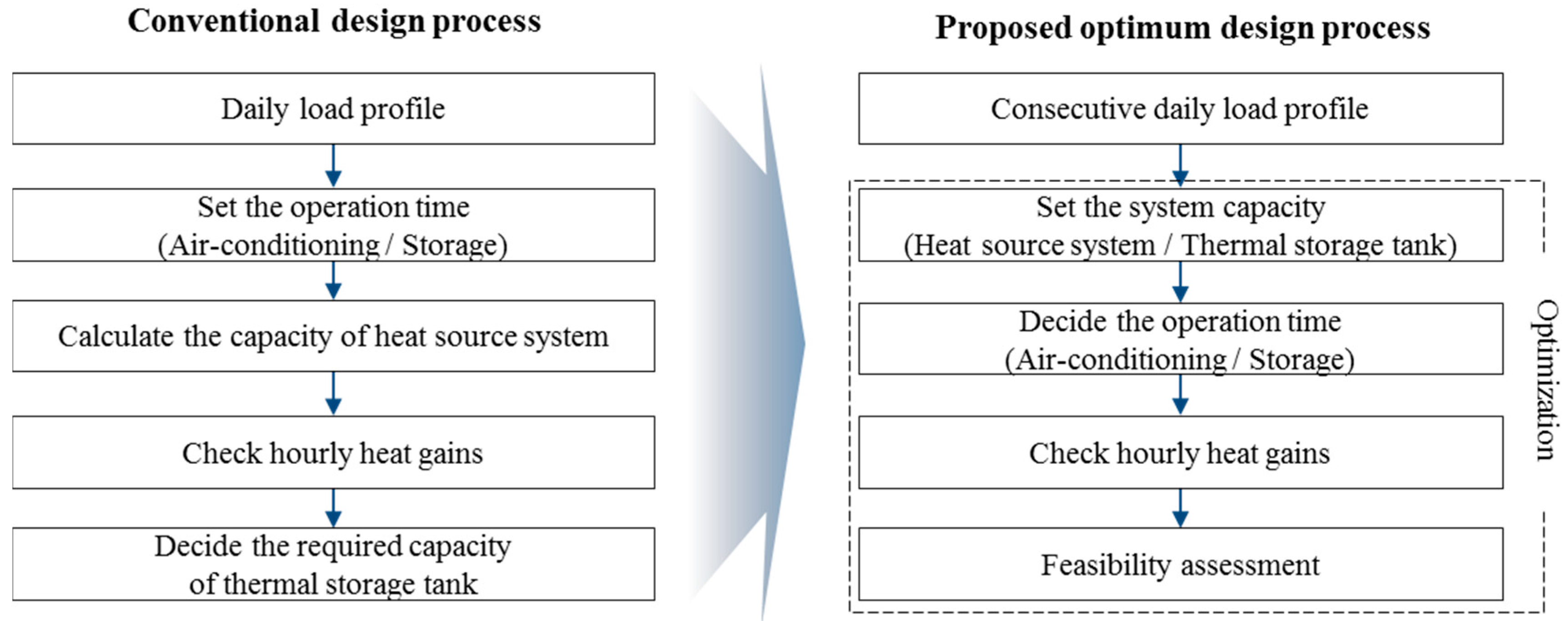

2. Optimum Design Process of Thermal Storage System

2.1. Review of Conventional Design Process of Thermal Storage System

2.2. Outline of Optimal Design Process of Thermal Storage System

2.3. Outline of Genetic Algorithm

3. Examination Method of Proposed Design Process

3.1. Outline of a Specific System

3.2. Design Method of System Capacity

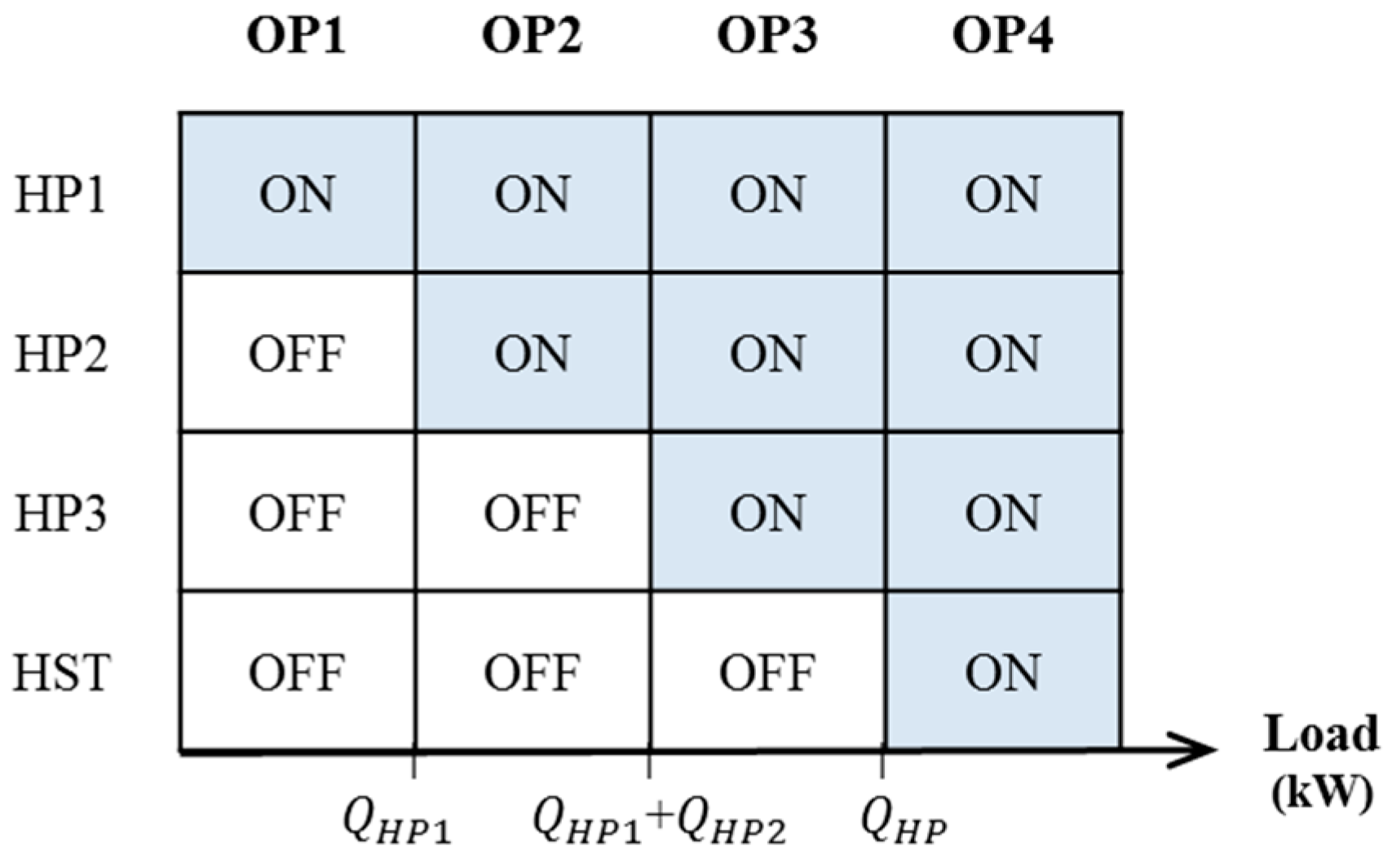

3.3. System Operation Strategy

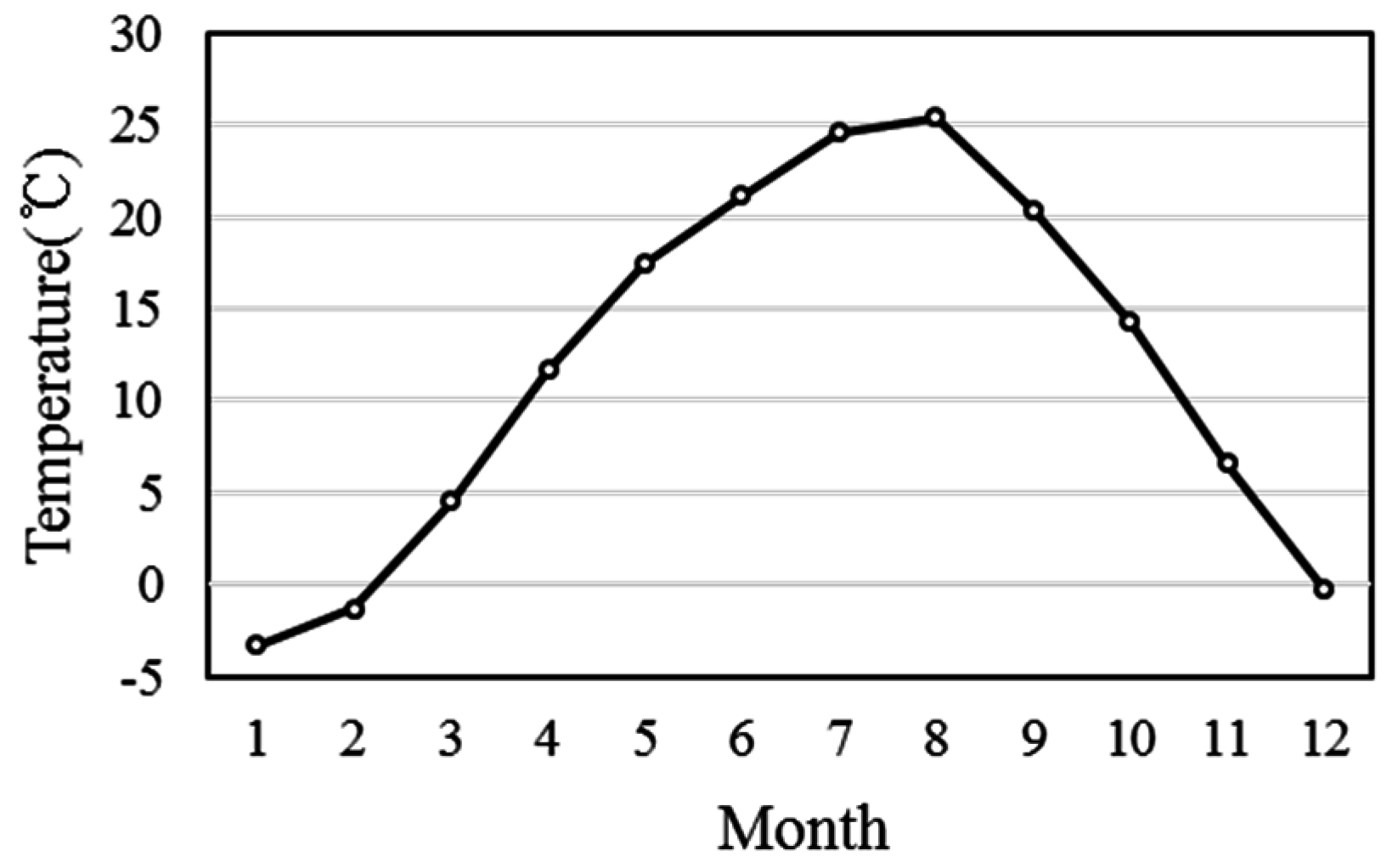

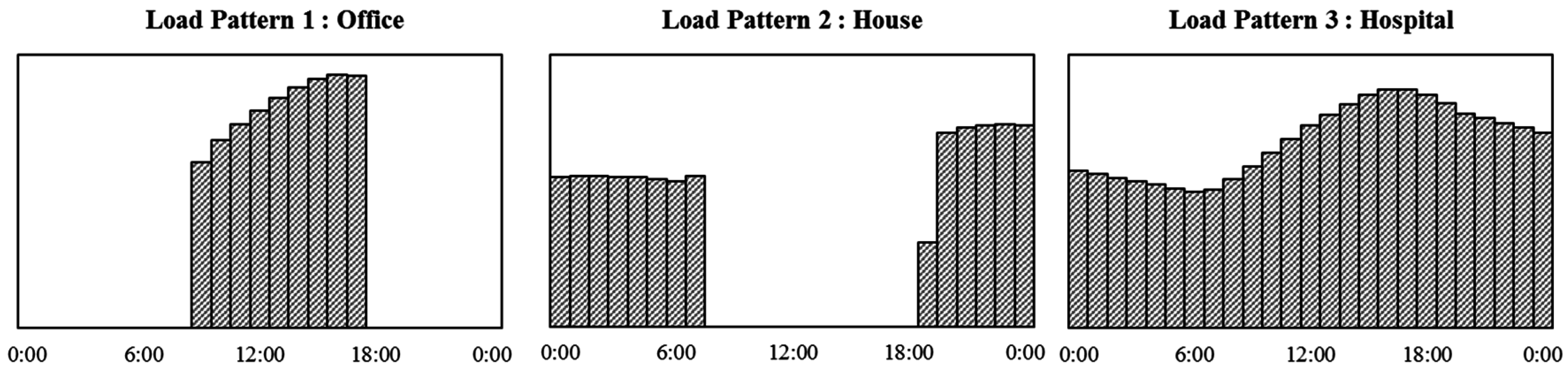

3.4. Conditions of Building Model and Load Patterns

3.5. Calculation Conditions for Optimization

3.5.1. Optimization Variables and Parameter

3.5.2. Objectives

3.5.3. Initial Costs

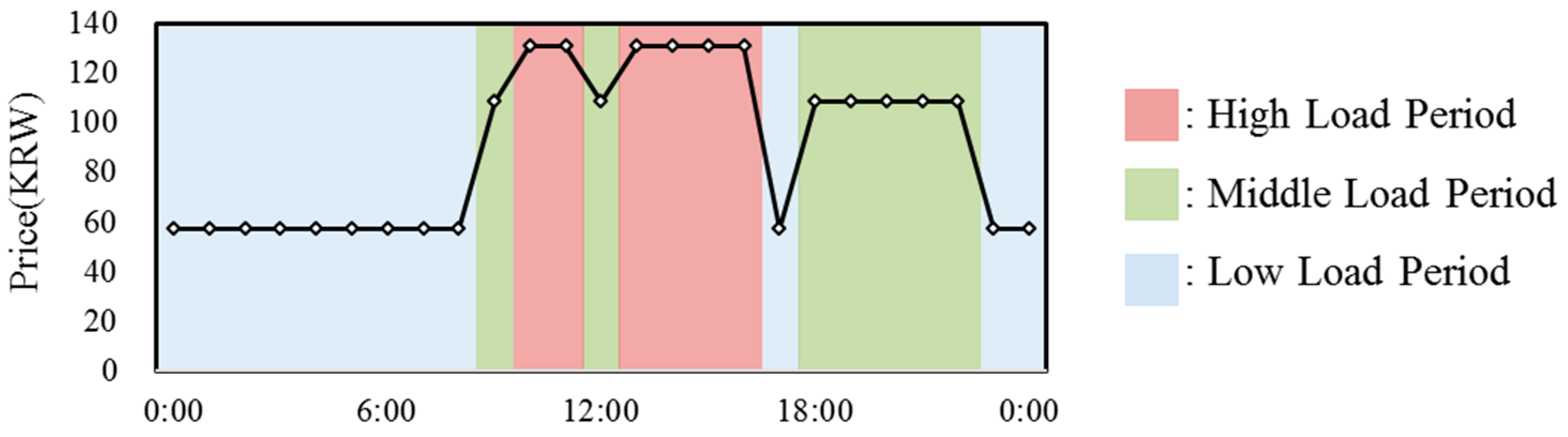

3.5.4. Energy Costs

3.5.5. Maintenance Costs

3.5.6. Life Cycle Cost (LCC)

3.5.7. Constraints

- If the capacity of the heat storage tank is over 0 kW, the capacity of the heat pump should not be 100% of the peak load. On the other hand, if the capacity of the heat storage tank is 0 kW, the capacity of the heat pump should not be less than 100% of the peak load;

- As for design variables, the sum of a, b, and c should be 10.

4. Optimization Results and Discussion

4.1. Optimum Design Solutions Analysis

4.2. Review of Operation Planning

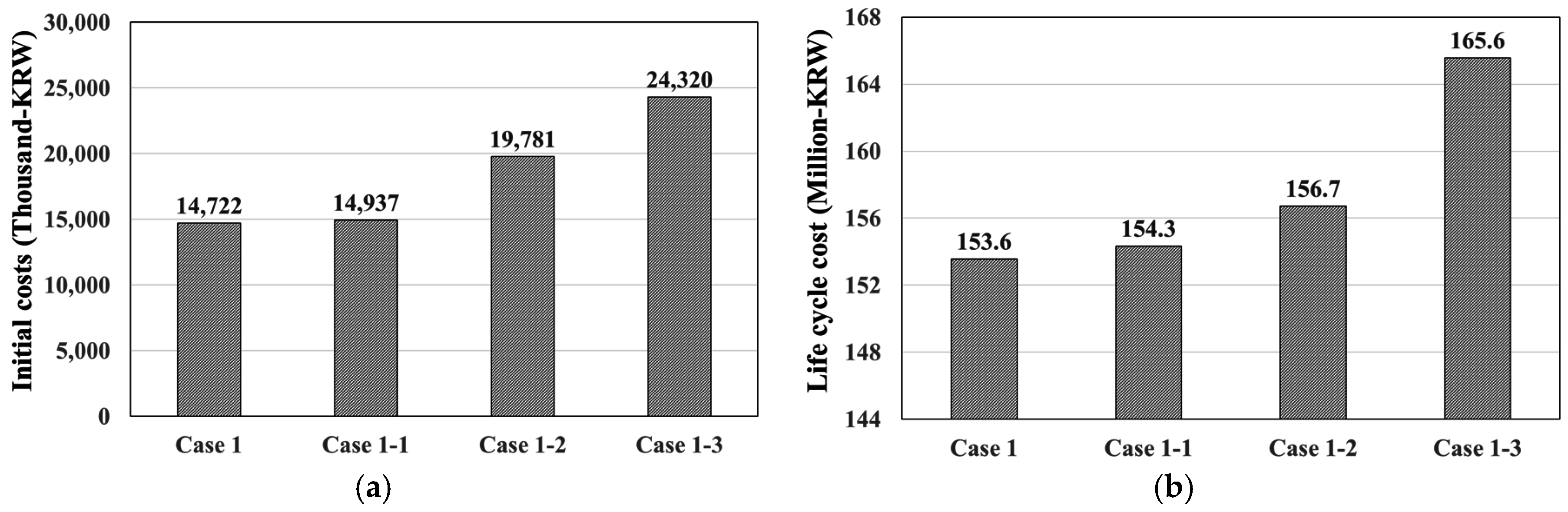

4.3. Feasibility Study

4.4. Optimal Solutions with a Multi Objective Approach

5. Conclusions

- According to the load patterns and objective functions, a range of solutions were derived to meet the design purposes and the costs were different irregularly. When the load occurs during the day, the solutions showed the largest differences with the objective functions.

- By checking the operation planning, the proposed method could consider the efficient operation, oversized-design, heat losses, safety factor, and energy remaining in the heat storage tank.

- The proposed method could make the most efficient design in terms of the initial investment cost and LCC compared to the conventional heat storage designs, as well as the system using only the heat source system. Moreover, it was confirmed that it is necessary to improve the method in the real working-process, which led to energy and economic consumption by oversizing the system.

- Since an oversized design operates inefficiently, it was confirmed that a thermal storage system is required for optimal design.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Key World Energy Statistics 2015; International Energy Agency (IEA): Paris, France, 2015; Available online: http://www.iea.org/publications/freepublications/publication/KeyWorld_Statistics_2015.pdf (accessed on 5 September 2016).

- Annual Energy Outlook 2016; U.S. Energy Information Administration (EIA): Washington, DC, USA, 2016. Available online: http://www.eia.gov/forecasts/aeo/index.cfm (accessed on 5 September 2016).

- Kang, W.K. A tendency of thermal storage for air-conditioning system. J. Electr. World Mon. Mag. 1990, 157, 19–25. [Google Scholar]

- Yu, M.G.; Nam, Y.; Yu, Y.; Seo, J. Study on the system design of a solar assisted ground heat pump system using dynamic simulation. Energies 2016, 9, 291. [Google Scholar] [CrossRef]

- Korean Electric Power Corporation (KEPCO). Available online: http://cyber.kepco.co.kr (accessed on 14 July 2016).

- Sanaye, S.; Hekmatian, M. Ice thermal energy storage (ITES) for air-conditioning application in full and partial load operating modes. Int. J. Refrig. 2016, 66, 181–197. [Google Scholar] [CrossRef]

- Osterman, E.; Butala, V.; Stritih, U. PCM thermal storage system for ‘free’ heating and cooling of buildings. Energy Build. 2015, 106, 125–133. [Google Scholar] [CrossRef]

- Romani, J.; Gracia, A.; Cabeza, L.F. Simulation and control of thermally activated building systems (TABS). Energy Build. 2016, 127, 22–42. [Google Scholar] [CrossRef]

- Yu, M.G.; Nam, Y.; Lee, K.H. Design method of heat storage type ground source heat pump system considering energy load pattern of greenhouse. KIEAE J. 2015, 15, 57–63. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, S.; Xiao, F.; Gao, D. Peak load shifting control using different cold thermal energy storage facilities in commercial buildings: A review. Energy Convers. Manag. 2013, 71, 101–112. [Google Scholar] [CrossRef]

- Ikeda, S.; Ooka, R. Optimal operation of energy systems including energy storage equipment under different connections and electricity prices. Sustain. Cities Soc. 2016, 21, 1–11. [Google Scholar] [CrossRef]

- Renaldi, R.; Kiprakis, A.; Friedrich, D. An optimization framework for thermal energy storage integration in a residential heat pump heating system. Appl. Energy 2016. [Google Scholar] [CrossRef]

- Shirazi, A.; Najafi, B.; Aminyavari, M.; Rinaldi, F.; Taylor, R.A. Thermal-economic-environmental analysis and multi-objective optimization of an ice thermal energy storage system for gas turbine cycle inlet air cooling. Energy 2014, 69, 212–226. [Google Scholar] [CrossRef]

- Wu, Q.; Ren, H.; Gao, W.; Ren, J. Multi-objective optimization of a distributed energy network integrated with heating interchange. Energy 2016, 109, 353–364. [Google Scholar] [CrossRef]

- Park, J.I. Building utility system design criteria. J. SAREK 2004, 33, 31–41. [Google Scholar]

- ASHRAE. ASHRAE Handbook HVAC System and Equipment; ASHRAE: Atlanta, GA, USA, 2012. [Google Scholar]

- Kang, H.K. Thermal storage cooling-heating system by GSHP. In Proceedings of the 2005 HARFKO, Heating, Air-Conditioning, Refrigeration and Fluid Exhibition Korea, Goyang, Korea, 25–27 May 2005.

- Yu, M.G.; Nam, Y. A study on the multi-level optimization method for heat source system design. J. SAREK 2016, 7, 299–304. [Google Scholar] [CrossRef]

- Torcellini, P.; Deru, M.; Griffith, B.; Benne, K. DOE commercial building benchmark models. In Proceedings of the 2008 ACEEE Summer Study on Energy Efficiency in Buildings, Pacific Grove, CA, USA, 17–22 August 2008.

- SAREK. SAREK Handbook HVAC System and Equipment; SAREK: Seoul, Korea, 2011. [Google Scholar]

- Ooka, R.; Komamura, K. Optimal design method for building energy systems using genetic algorithms. Build. Environ. 2009, 44, 1538–1544. [Google Scholar] [CrossRef]

- Ooka, R.; Kayo, G. Building energy system optimizations with utilization of waste heat from cogenerations by means of genetic algorithm. Energy Build. 2010, 42, 985–991. [Google Scholar]

- Korean Energy Agency. Available online: http://www.kemco.or.kr/ (accessed on 5 September 2016).

- Offer & Merchandise Mall (OMMall). Available online: http://ommall.net/ (accessed on 2 February 2016).

- Jun, C.H.; Lee, H.S.; Kim, J.D.; Yoon, J.I. Performance characteristics of air-cooled heat pump system using hydrocarbon refrigerants according to variation of outdoor temperature. Korean J. Air-Cond. Refrig. Eng. 2006, 3, 218–224. [Google Scholar]

- Seo, J.; Ooka, R.; Kim, J.T.; Nam, Y. Optimization of the HVAC system design to minimize primary energy demand. Energy Build. 2014, 79, 102–108. [Google Scholar] [CrossRef]

- Lee, I.G.; Kang, H.W.; Won, Y.M.; Kim, Y.S. Economic Evaluation for Heating and Cooling System by Using Gas Energy and Geothermal Energy Based on LCC Analysis. J. Archit. Inst. Korea 2011, 10, 161–168. [Google Scholar]

- Hafez, O.; Bhattacharya, K. Optimal planning and design of a renewable energy based supply system for microgrids. Renew. Energy 2012, 45, 7–15. [Google Scholar] [CrossRef]

| Cases | Load Pattern | Objective |

|---|---|---|

| Case 1 | Load pattern 1: Daytime | Life Cycle Cost |

| Case 2 | Energy cost | |

| Case 3 | Load pattern 2: Nighttime | Life Cycle Cost |

| Case 4 | Energy cost | |

| Case 5 | Load pattern 3: 24 h | Life Cycle Cost |

| Case 6 | Energy cost |

| Building Parts | Heat Transfer Coefficient (U-Value) (W/m2K) |

|---|---|

| External wall | 0.510 |

| Internal wall | 4.351 |

| Ceiling | 4.158 |

| Floor | 0.039 |

| Roof | 0.316 |

| Window | 2.89 |

| Building Type | Set Temperature | Operation Time | Ventilation | Person | Internal Heat Gain |

|---|---|---|---|---|---|

| Office | 20 °C | 09–18 h | 1/h | 0.2 person/m2 | 40 W/m2 |

| House | 22 °C | 19–08 h | 1/h | 4 person/150 m2 | 30 W/m2 |

| Hospital | 23 °C | 24 h | 2/h | 0.2 person/m2 | 15 W/m2 |

| Variables | Min | Max | Step |

|---|---|---|---|

| X | 0 | 100 | 1 |

| Y | 0 | 100 | 1 |

| A | 1 | 10 | 1 |

| B | 0 | 9 | 1 |

| C | 0 | 9 | 1 |

| Heat storage | 0 | 10 | 1 |

| GA Parameter | Value |

|---|---|

| Size of sub-population | 30 |

| Number of island | 20 |

| Number of generation | 50 |

| Rate of crossover | 1 |

| Rate of mutation | 0.07 |

| Rate of migration | 0.05 |

| System | Cost | Units |

|---|---|---|

| Heat Pump (HP) | 460,000 | KRW/kW |

| Heat storage tank (HST) | 960,000 | KRW/m3 |

| System | Repair | Replacement | ||

|---|---|---|---|---|

| Period | Rate | Period | Rate | |

| Heat pump | 7 years | 7% | 20 years | 100% |

| Cases | HP1 | HP2 | HP3 | HST | Initial Costs | Energy Costs | LCC |

|---|---|---|---|---|---|---|---|

| KRW | KRW | KRW | |||||

| Case 1 | 20.5 kW | 2.6 kW | 2.6 kW | 28.3 kW | 14,722,000 | 9,598,000 | 153,554,000 |

| Case 2 | 6.5 kW | 5.2 kW | 1.3 kW | 127.4 kW | 19,122,000 | 9,432,000 | 154,994,000 |

| Case 3 | 20.1 kW | 2.5 kW | 2.5 kW | 2.9 kW | 11,860,000 | 7,562,000 | 127,391,000 |

| Case 4 | 20.1 kW | 2.5 kW | 2.5 kW | 2.9 kW | 11,860,000 | 7,562,000 | 127,391,000 |

| Case 5 | 43.7 kW | 4.9 kW | 0 kW | 11 kW | 23,456,000 | 17,078,000 | 282,049,000 |

| Case 6 | 45 kW | 5 kW | 0 kW | 11 kW | 24,154,000 | 17,069,000 | 283,041,000 |

| Cases | System | Initial Costs | Energy Costs | LCC | |

|---|---|---|---|---|---|

| HP | HST | KRW | KRW | KRW | |

| Optimum | 25.7 kW | 28.3 kW | 14,722,000 | 9,598,000 | 153,554,000 |

| Case 1-1 | 32.5 kW | 0.0 kW | 14,937,000 | 9,615,000 | 154,322,000 |

| Case 1-2 | 12.4 kW | 136.4 kW | 19,781,000 | 9,508,000 | 156,703,000 |

| Case 1-3 | 16.3 kW | 163.0 kW | 24,320,000 | 9,656,000 | 165,556,000 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, M.G.; Nam, Y. Study on the Optimum Design Method of Heat Source Systems with Heat Storage Using a Genetic Algorithm. Energies 2016, 9, 849. https://doi.org/10.3390/en9100849

Yu MG, Nam Y. Study on the Optimum Design Method of Heat Source Systems with Heat Storage Using a Genetic Algorithm. Energies. 2016; 9(10):849. https://doi.org/10.3390/en9100849

Chicago/Turabian StyleYu, Min Gyung, and Yujin Nam. 2016. "Study on the Optimum Design Method of Heat Source Systems with Heat Storage Using a Genetic Algorithm" Energies 9, no. 10: 849. https://doi.org/10.3390/en9100849

APA StyleYu, M. G., & Nam, Y. (2016). Study on the Optimum Design Method of Heat Source Systems with Heat Storage Using a Genetic Algorithm. Energies, 9(10), 849. https://doi.org/10.3390/en9100849