Theorizing for Maintenance Management Improvements: Using Case Studies from the Icelandic Geothermal Sector

Abstract

:1. Introduction

1.1. Cluster Theory

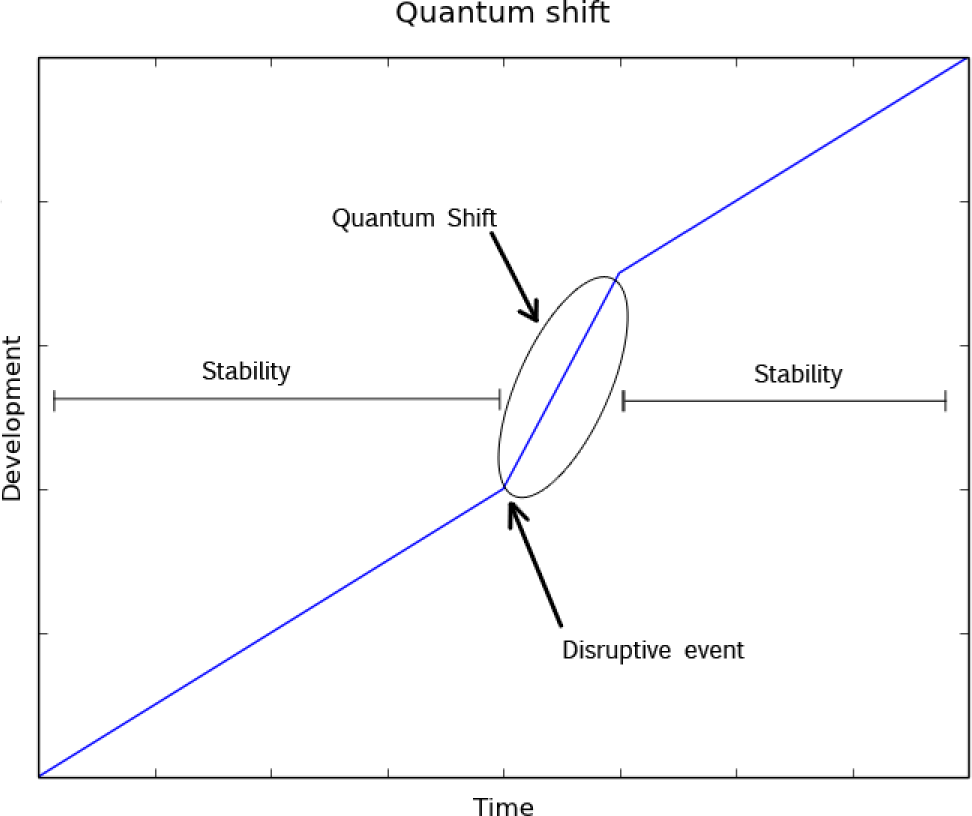

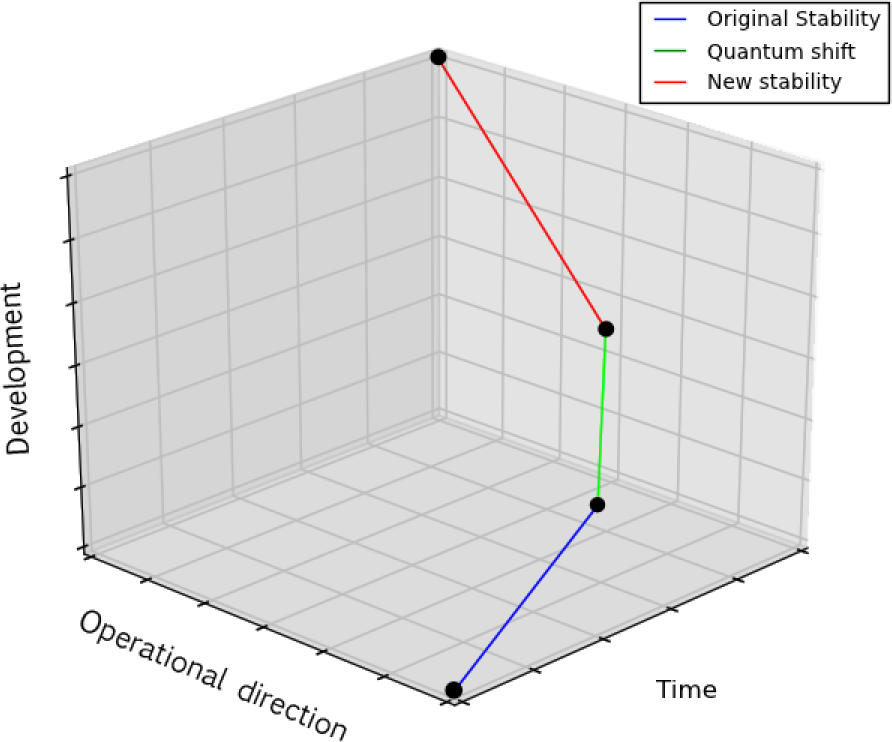

1.2. Quantum Shifts

2. Key Facts about the Icelandic Geothermal Sector

2.1. Icelandic Geothermal Power Plants

2.2. Domestic Collaboration

2.3. Article Intent and Content

3. Methodologies

3.1. Theorizing and Case Studies

- The study is conducted within the natural environment of the phenomena, which allows for an observation of real practice.

- Why, what, and how questions can be answered with a great understanding of the phenomenon.

- Early investigations where variables are unknown and the phenomenon is unclear are suitable for case studies.

3.2. This Research in a Theoretical Context

3.3. Case Studies Conducted

- Domestic service providers in the geothermal industry.This part describes how domestic industries are currently addressing major maintenance issues with regards to geothermal steam turbines in Iceland. It will examine how they collaborate and which products are being manufactured domestically [33,34]. When critical failures occurred, the repair process was visualised and the communication chain was identified. It was seen that domestic repairs were conducted in a more economical and faster way. This resulted in shorter down-time of the turbine and a subsequent lower loss of output. It was also shown that knowledge was building up within the machine shops and the energy company. During one study, where the current turbine operations and maintenance procedures were examined, it was seen that the operations and frequency of overhauls on geothermal turbines is changing as the staff becomes more experienced. Problems are analysed in collaboration with the Icelandic innovation center and also with the machine shops. If a solution is viable when looking at performance, then it was developed further. In this case, a faulty setting on a valve lead to the breakdown of the labyrinth packing. The problem was analysed and a repair, with an improved version of the labyrinth packing, was conducted on-site in collaboration with a domestic machine shop.

- Corporate culture with regard to innovation.The development of a geothermal control valve was examined: first, from the corporate viewpoint of how the development process occurred within the company; and secondly, from the technical side of how the valve operates, is manufactured, and tested [35,36]. This allowed for a clear visualisation of a successful innovation process within the geothermal industry. A willingness to try the development of a solution posed by a staff member was observed because of a lack of solutions available to the problem observed and also because of the possible financial viability of the solution since it was to be produced domestically. It was shown that the CEO of the energy company allowed the staff member a certain degree of freedom to develop the proposed valve solution. This included funds for prototyping, and specialised consulting and testing. The valve became the standard for control valves within that particular company. A machine shop was included in the development process, allowing for the knowledge about the manufacturing side of the valve to be located in a geographic proximity to its final use. The valve is currently fully manufactured and used domestically.

- The effects of the operation engineer’s previous experience.This research also outlined the Icelandic geothermal cluster, and described who the main players are and how they are interconnected. It was seen that maintenance engineers operating within the energy companies possess a certain characteristic, perhaps because of their naval experience. The mentality brought to the geothermal power plants by naval engineers was statistically examined [24]. The engineers were found to be less considerate and less likely to seek supervisory opinion than regular workers on the market. It was noted that the naval engineers need to repair any failures on board while on the ocean. The same was seen with maintenance engineers in the geothermal power plants, who are very confident and willing to try developing domestic solutions.

- The effects of operational experienceThe way that operational experience effects planning was visualised with regards to the wellheads at Hellisheidi geothermal power plants. Real data was gathered and statistically analysed [37]. This study was conducted to analyse how a maintenance pattern evolves with time as operational experience is gathered among staff. By using a Weibull survival distribution for the analysis, it was shown that the frequency of maintenance does in fact change with time, diverting from the original recommendations made by engineering consulting firms. This is also in line with the previous observations of the engineers’ characteristics.

- Identification of future developmentsA quantitative Kano model was used to identify the solutions sought after by Icelandic geothermal power plant maintenance engineers [38]. This study demonstrated how a model for customer satisfaction can be utilised within the renewable energy sector. When applied to the geothermal sector, it demonstrated which maintenance management tools are wanted by maintenance engineers. The problems to be addressed include the long documentation time and the uncertainty of postponing maintenance, among others. The Kano analysis tool can be used to visualise the needs of domestic industries while the other industries within the cluster can use the results to develop these solutions.

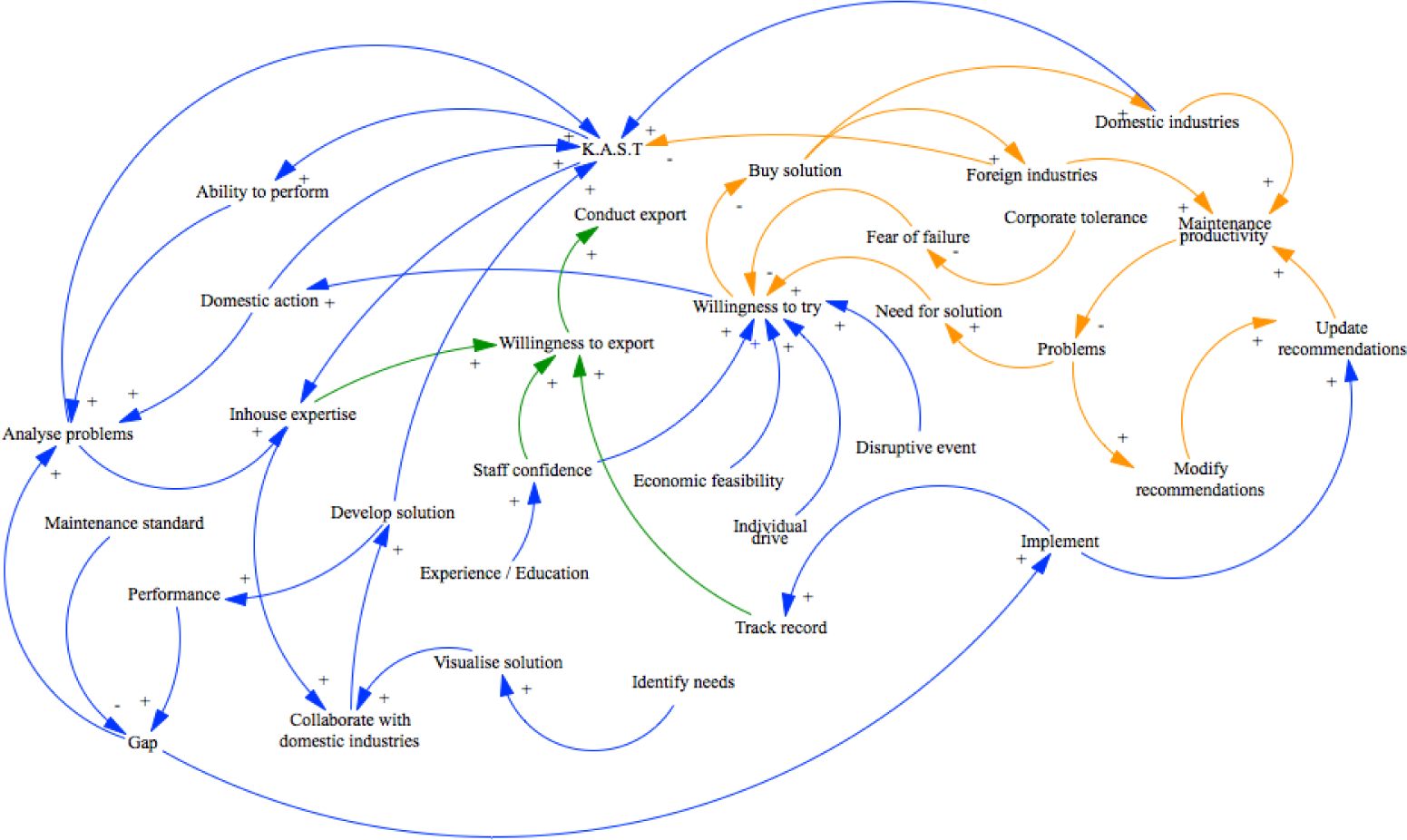

4. Results

4.1. Initial Behaviour

4.2. Willingness to Try

4.3. Domestic Action

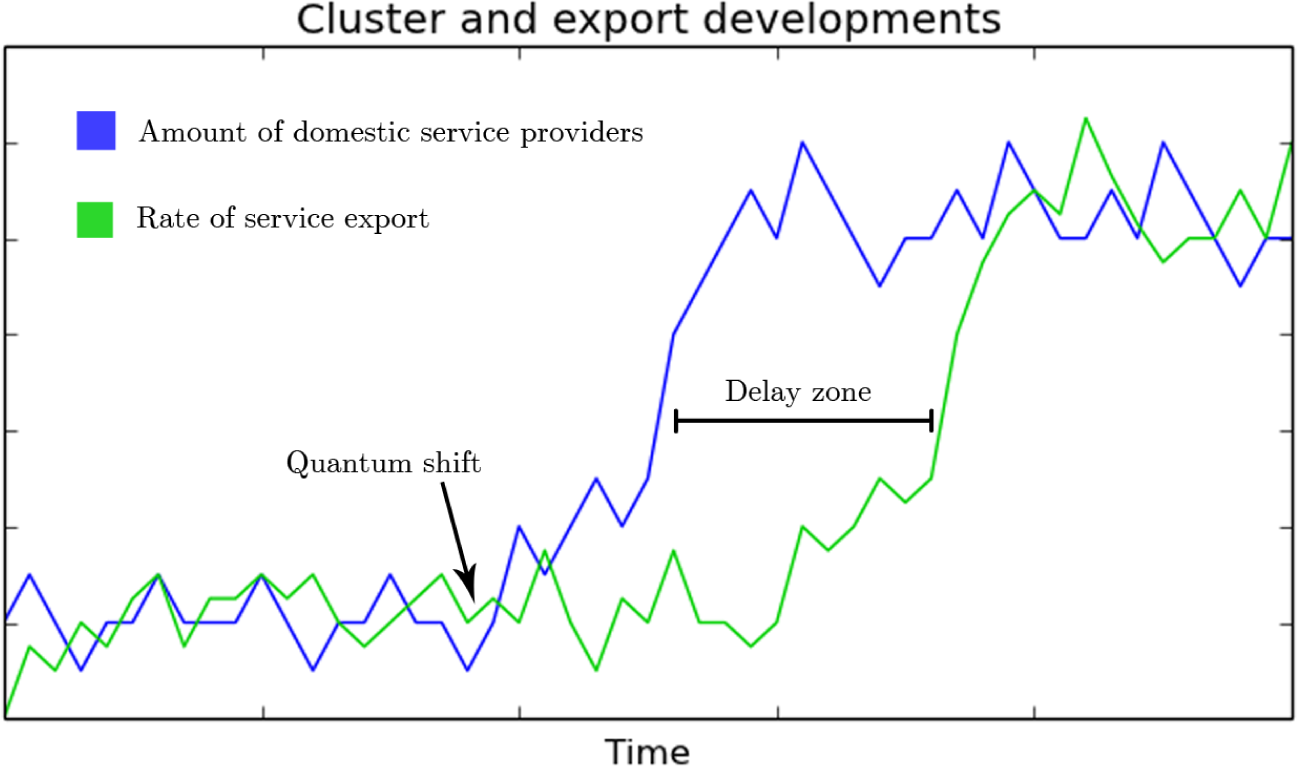

4.4. Export

4.5. Balancing Variables

5. Discussion

6. Conclusions

Future Work

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Shafiee, S.; Topal, E. When will fossil fuel reserves be diminished? Energy Policy 2009, 37, 181–189. [Google Scholar]

- Field, C.; van Aalst, M. Climate Change 2014: Impacts, Adaptation, and Vulnerability; IPCC (Intergovernmental panel on climate change): Geneva, Switzerland, 2014; Volume 1. [Google Scholar]

- BP Energy Outlook 2035; BP plc: London, UK, 2014.

- Mitigation, C.C. IPCC Special Report on Renewable Energy Sources and Climate Change Mitigation; Technical Report; Cambridge University Press: Cambridge, UK, 2011. [Google Scholar]

- Filippetti, A.; Archibugi, D. Innovation in times of crisis: National systems of innovation, structure, and demand. Res. Policy 2011, 40, 179–192. [Google Scholar]

- Porter, M.E. Location, competition, and economic development: Local clusters in a global economy. Econ. Dev. Q. 2000, 14, 15–34. [Google Scholar]

- Porter, M.E. Clusters and the New Economics of Competition. Harvard Bus. Rev. 1998, 14, 77–90. [Google Scholar]

- Malerba, F. Sectoral systems of innovation and production. Res. Policy 2002, 31, 247–264. [Google Scholar]

- Giuliani, E. Cluster absorptive capacity why do some clusters forge ahead and others lag behind? Eur. Urban Regional Stud. 2005, 12, 269–288. [Google Scholar]

- Giuliani, E. The structure of cluster knowledge networks: Uneven and selective, not pervasive and collective, Proceedings of DRUID Tenth Anniversary Summer Conference, Copenhagen, Denmark, 27–29 June 2005; pp. 27–29.

- Kogut, B. The network as knowledge: Generative rules and the emergence of structure. Strateg. Manag. J. 2000, 21, 405–425. [Google Scholar]

- Porter, M.E. Competitive Advantage: Creating and Sustaining Superior Performance; Simon and Schuster: New York, NY, USA, 2008. [Google Scholar]

- Furman, J.L.; Porter, M.E.; Stern, S. The determinants of national innovative capacity. Res. Policy 2002, 31, 899–933. [Google Scholar]

- Lin, C.-H.; Tung, C.-M.; Huang, C.-T. Elucidating the industrial cluster effect from a system dynamics perspective. Technovation 2006, 26, 473–482. [Google Scholar]

- Dangelico, R.M.; Garavelli, A.C.; Petruzzelli, A.M. A system dynamics model to analyze technology districts’ evolution in a knowledge-based perspective. Technovation 2010, 30, 142–153. [Google Scholar]

- Youngblood, M.D. Winning cultures for the new economy. Strateg. Leadersh. 2000, 28, 4–9. [Google Scholar]

- Gould, S.J.; Eldredge, N. Punctuated equilibria: The tempo and mode of evolution reconsidered. Paleobiology 1977, 3, 115–151. [Google Scholar]

- Orkustofnun. Jardvarmavirkjanir. Retrieved 09.01.2013 Available online: http://www.orkustofnun.is/jardhiti/jardhitanotkun/jardvarmavirkjanir/ accessed on 9 January 2013.

- Thorolfsson, G. Maintenance history of a geothermal plant: Svartsengi Iceland, Proceedings of World Geothermal Congress 2005, Antalya, Turkey, 24–29 April 2005.

- Geothermal Power Plant Technician. Keilir Technological Institute. Available online: http://en.keilir.net/kit/kit/education/geothermal-power-plant-technician accessed on 10 February 2013.

- Hagalin, G.; (Reykjavik Energy); Reynir S. Atlason (University of Iceland). Personal Communication, 2013.

- Fuller, N. Beyond the core. Supply Manag. 2002, 29, 39. [Google Scholar]

- Porter, M. The Icelandic geothermal cluster: Enhancing competitiveness and creating a new engine of Icelandic growth, Proceedings of Icelandic Geothermal Conference, Reykjavik, Iceland, 1 November 2010.

- Atlason, R.S.; Unnthorsson, R. Operation and maintenance in Icelandic geothermal power plants: Structure and Hierarchy, Proceedings of the POWER Conference, American Society of Mechanical Engineers, San Diego, CA, USA, 15–21 November 2013.

- Geothermal Research Group. Geothermal Research Group. Retrieved 01.08.2013 Available online: http://georg.hi.is/efni/georg_geothermal_research_group accessed on 1 August 2013.

- Eisenhardt, K.M.; Graebner, M.E. Theory building from cases: Opportunities and challenges. Acad. Manag. J. 2007, 50, 25–32. [Google Scholar]

- Voss, C.; Tsikriktsis, N.; Frohlich, M. Case research in operations management. Int. J. Oper. Prod. Manag. 2002, 22, 195–219. [Google Scholar]

- Lewis, M.W. Iterative triangulation: A theory development process using existing case studies. J. Oper. Manag. 1998, 16, 455–469. [Google Scholar]

- Stuart, I.; McCutcheon, D.; Handfield, R.; McLachlin, R.; Samson, D. Effective case research in operations management: A process perspective. J. Oper. Manag. 2002, 20, 419–433. [Google Scholar]

- Meredith, J.; Vineyard, M. A longitudinal study of the role of manufacturing technology in business strategy. Int. J. Oper. Prod. Manag. 1993, 13, 3–14. [Google Scholar]

- Handfield, R.B.; Melnyk, S.A. The scientific theory-building process: A primer using the case of tqm. J. Oper. Manag. 1998, 16, 321–339. [Google Scholar]

- Wallace, W.L.X. The Logic of Science in Sociology; Transaction Publishers: Piscataway, NJ, USA, 1971. [Google Scholar]

- Atlason, R.S.; Gunnarsson, A.; Unnthorsson, R. Turbine repair at nesjavellir geothermal power plant: An icelandic case study. Geothermics 2015, 53, 166–170. [Google Scholar]

- Atlason, R.S.; Unnthorsson, R.; Oddsson, G.V. Innovation and development in geothermal turbine maintenance based on Icelandic experience. Geothermics 2015. accepted. [Google Scholar]

- Atlason, R.S.; Unnthorsson, R. New design solves scaling problems on geothermal control valves. Power 2013, 157, 18–21. [Google Scholar]

- Atlason, R.S.; Unnthorsson, R. Wellhead Scaling Problems in Geothermal Power Plants Addressed Using a Needle Valve Derivative; American Society of Mechanical Engineers: New York, NY, 2014. [Google Scholar]

- Atlason, R.S.; Geirsson, O.; Elisson, A.; Unnthorsson, R. Geothermal wellhead maintenance: A statistical model based on documented icelandic experience. Geothermics 2015, 53, 147–153. [Google Scholar]

- Atlason, R.S.; Oddsson, G.V.; Unnthorsson, R. Geothermal power plant maintenance: Evaluating maintenance system needs using quantitative kano analysis. Energies 2014, 7, 4169–4184. [Google Scholar]

- Klein, K.J.; Knight, A.P. Innovation implementation overcoming the challenge. Curr. Dir. Psychol. Sci. 2005, 14, 243–246. [Google Scholar]

| Purpose | Research Question | Research Structure | Examples of Data Collection Techniques | Examples of Data Analysis Procedures |

|---|---|---|---|---|

| 1a. Discovery * Uncover areas for research and theory development | * What is going on here? * Is there something interesting enough to justify research | * In-depth case studies * Unfocused, longitudinal field study | * Observation * Interviews * Documents * Elite interviewing | * Insight * Categorization * Expert opinion * Descrptions |

| 1b. Description * Explore territory | * What is there? * What are the key issues? * What is happening? | * In-depth case studies * Unfocused, longitudinal field study | * Observation interviews * Documents * Elite interviewing * Critical incident * Technique | * Insight * Categorization * Expert opinion * Descriptions * Content analysis |

| 2. Mapping * Identify/describe key variables * Draw maps of the territory | * What are the key variables? * What are the salient/critical themes, patterns, categories? | * Few focused case studies * In-depth field studies * Multi-site case studies * Best-in-class case studies | * Observation * In-depth interviews * Diaries survey questionnaires * History * Unobtrusive measures | * Verbal protocol * Analysis * Cognitive mapping * Repertory grid technique * Effects matrix * Content analysis |

| 3. Relationship building * Improve maps by identifying the linkages between variables * Identify the “why” underlying these relationships | * What are the patterns or links between variables? * Can an order in the relationship be identified? * Why should these relationship exist? | * Few focused case studies * In-depth field studies * Multi-site case studies * Best-in-class case studies | * Observation * In-depth interviews * Diaries survey questionnaires * History * Unobtrusive measures | * Verbal protocol * Analysis * Cognitive mapping * Repertory grid technique * Effects matrix * Content analysis * Factor analysis * Multidimensional * Scaling * Correlation analysis * Nonparametric analysis |

| 4. Theory validation * Test the theories developed in the previous stages * Predict future outcomes | * Are the theories we have generated able to survive the test of empirical data? * Did we get the behavior that was predicted by the theory? | * Experiment * Quasi-experiment * Large scale sample of population | * Structured interviews * Documents * Open and closed-ended questionnaires * Lab experiments * Field experiments * Quasi experiments * Surveys | * Triangulation * Analysis of variance * Regression * Analysis * Path analysis * Survival analysis * Multiple comparison procedures * Nonparametric statistics |

| 5. Theory extension/Refinement * Expand the map of the theory * Better structure the theories in light of the observed results | * How widely applicable/genera-lizable are the theories developed? * Where do the theories apply? * Where do they not apply? | * Experiment * Quasi experiment * Large scale sample of population | * Structured interviews * Documents * Open and closed-ended questionnaires * Lab experiments * Field experiments * Quasi experiments * Surveys * Documentation * Archival research | * Triangulation * Analysis of variance * Regression * Analysis * Path analysis * Survival analysis * Multiple comparison procedures * Nonparametric statistics * Meta analysis |

| Case Study | Intention | Stage in Theory Building according to [31] | Research Structure | Method of Data Collection according to [31] |

|---|---|---|---|---|

| [35] | Explore how staff has influenced innovation within geothermal firms. | 1a. Discovery | - Interviews - Observation | - Insight - Expert opinion - Descriptions |

| [24] | Get an overview of the Icelandic geoth. sector. Who are the players and what are the characteristics of plant maintenance engineers. | 1a. Discovery | - In-depth case study | - Description - Insight |

| [38] | Visualise how operations management can be improved using staff knowledge. | 1a. Discovery | - Interviews | - Expert opinion - Insight |

| [33] | Identify the current benefits of the geothermal cluster collaboration within Iceland. an acute repair of a geoth. turbine was examined | 1b. Description | - In-depth case study | - Critical incident - Documents |

| [36] | Visualise how domestic industries can influence innovation process. | 1b. Description | - In-depth field study | - Observation interviews - Documents - Technical specifications |

| [34] | Get an overview on how maintenance on geoth. turbines is conducted. Who are the main actors and what are the challenges ahead. | 2. Mapping | - In-depth field study | - Verbal protocol - Analysis |

| [37] | Explore how experience influences the operations management in geothermal power plants. | 2. Mapping | - In-depth field study | - Analysis |

© 2015 by the authors; licensee MDPI, Basel, Switzerland This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Atlason, R.S.; Oddsson, G.V.; Unnthorsson, R. Theorizing for Maintenance Management Improvements: Using Case Studies from the Icelandic Geothermal Sector. Energies 2015, 8, 4943-4962. https://doi.org/10.3390/en8064943

Atlason RS, Oddsson GV, Unnthorsson R. Theorizing for Maintenance Management Improvements: Using Case Studies from the Icelandic Geothermal Sector. Energies. 2015; 8(6):4943-4962. https://doi.org/10.3390/en8064943

Chicago/Turabian StyleAtlason, Reynir Smari, Gudmundur Valur Oddsson, and Runar Unnthorsson. 2015. "Theorizing for Maintenance Management Improvements: Using Case Studies from the Icelandic Geothermal Sector" Energies 8, no. 6: 4943-4962. https://doi.org/10.3390/en8064943

APA StyleAtlason, R. S., Oddsson, G. V., & Unnthorsson, R. (2015). Theorizing for Maintenance Management Improvements: Using Case Studies from the Icelandic Geothermal Sector. Energies, 8(6), 4943-4962. https://doi.org/10.3390/en8064943