Adaptive Micro-Grid Operation Based on IEC 61850

Abstract

:1. Introduction

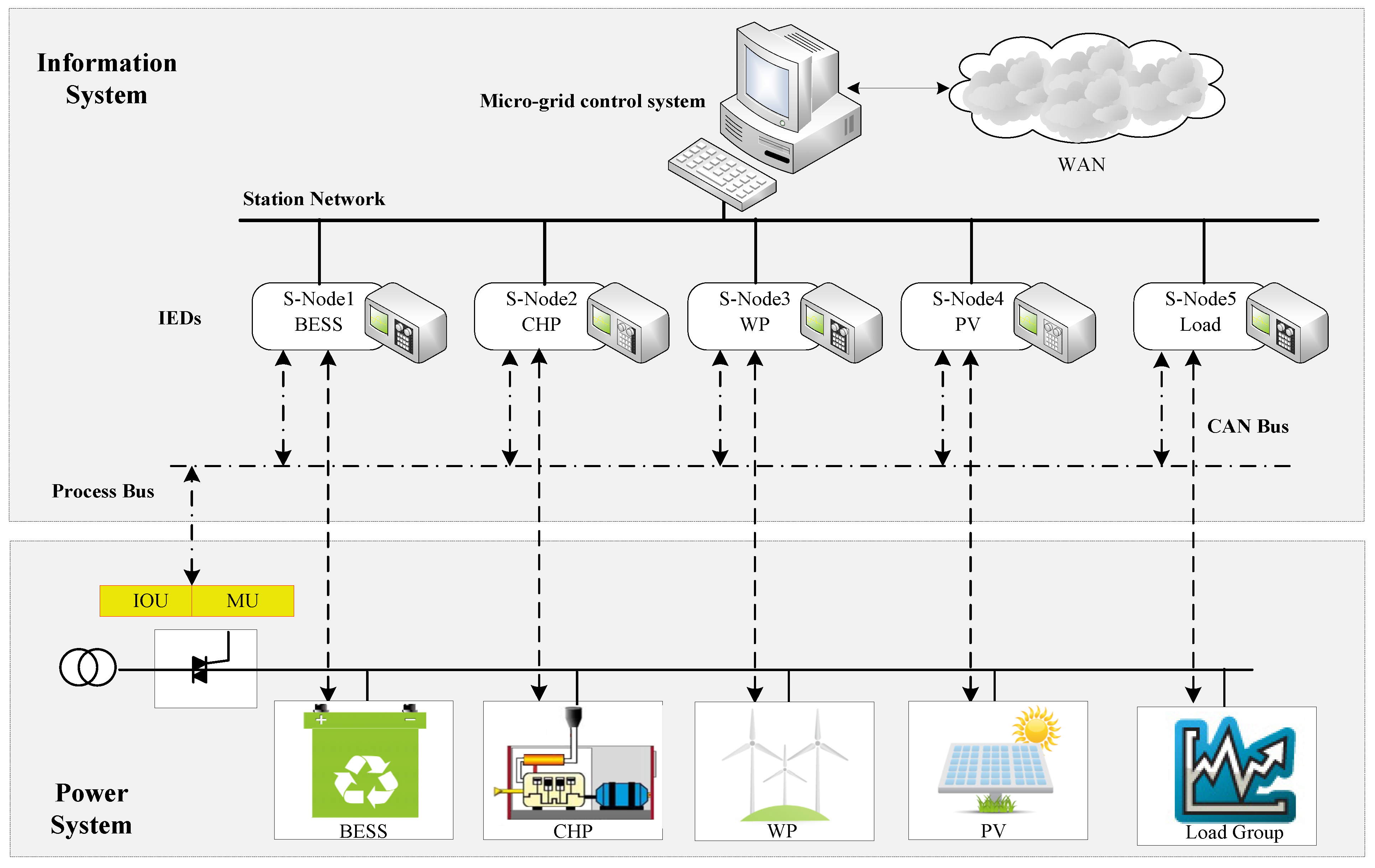

2. System Description

- (1)

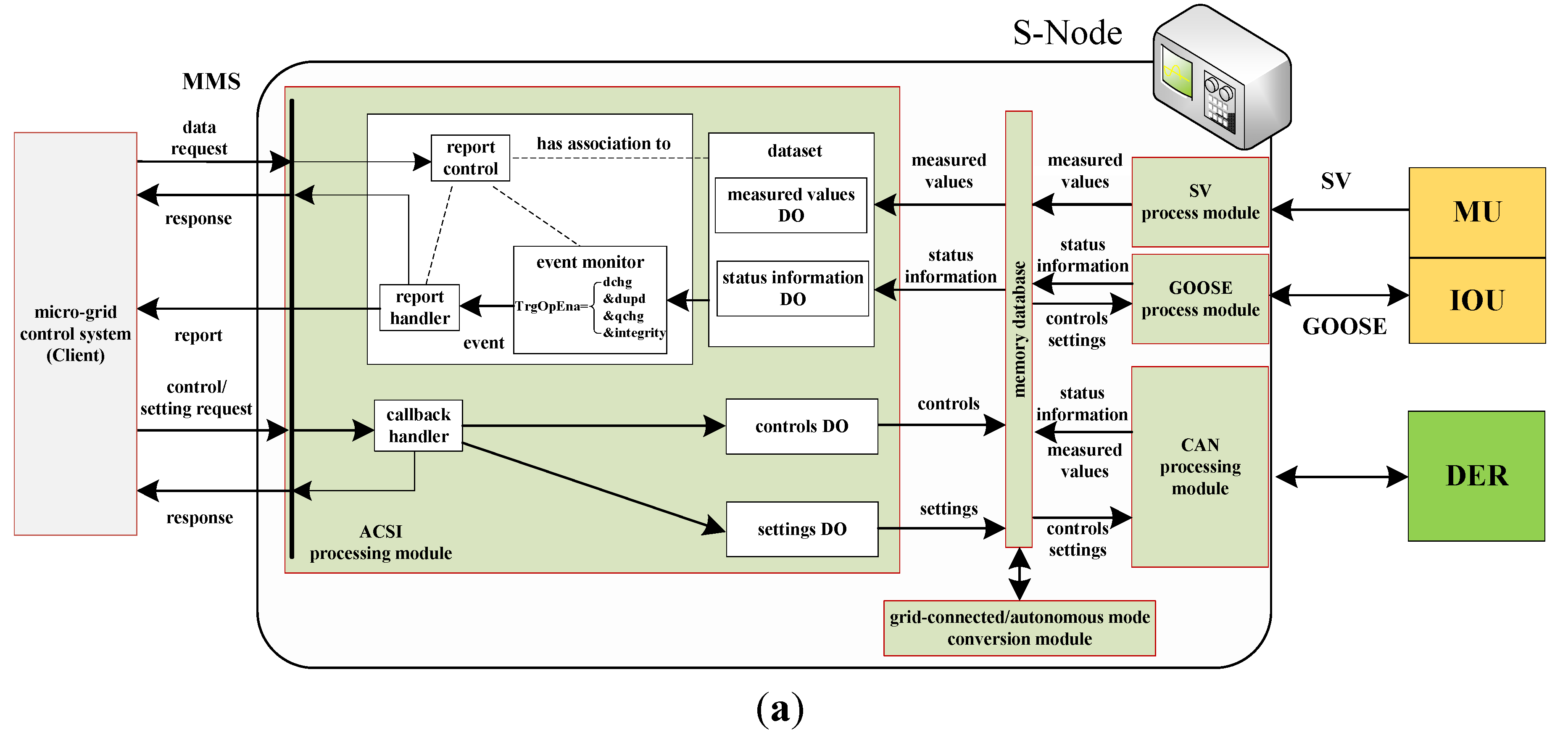

- Station network between station level and bay level: mainly exchanges low-speed or middle-speed messages (such as automatic control and operation power data), files (such as protection events and settings value), and time synchronization messages. Manufacturing message specification (MMS) is the common message.

- (2)

- Process bus between the bay level and equipment which has a 61850 information interface in the process level: mainly exchanges fast-speed messages (such as trip commands and lock instructions) and original data messages (such as voltage and current sampling data). On the other hand, S-Node subscribes the generic object oriented substation event (GOOSE) messages published by intelligent input/output units (IOUs), and sampled values (SV) messages published by merging units (MUs), through the process bus. On the other hand, the S-Node publishes the control commands including locking and tripping using GOOSE messages through the process bus, and accordingly manages the process level equipment.

- (3)

- CAN bus between the bay level and traditional equipment in the process level: provides real-time data communication, and ensures the reliability of data transmissions by its redundancy structure.

3. Design and Implementation of Micro-Grid Operation Based on IEC 61850

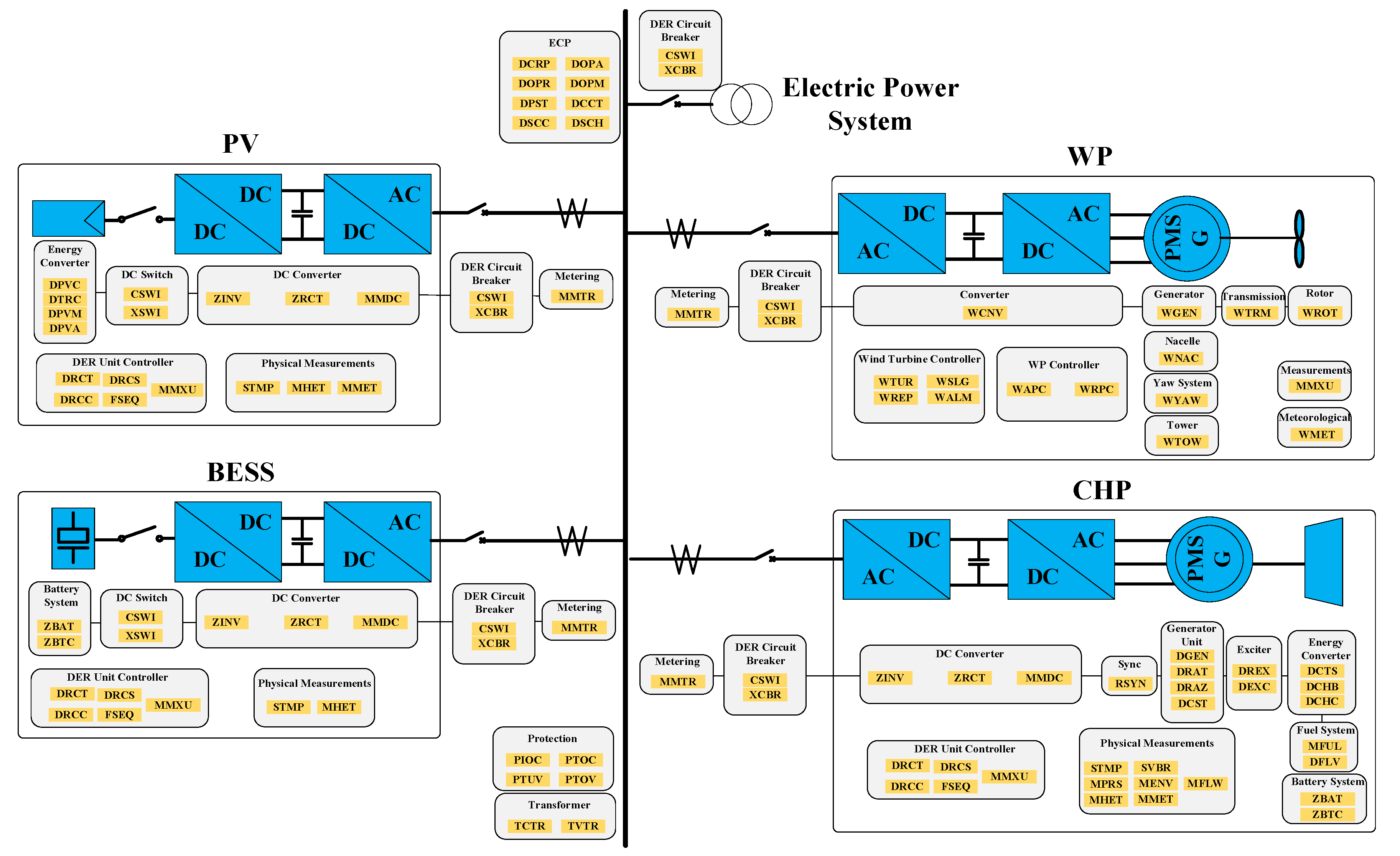

3.1. Plug and Play

- ➢

- ECP: defines the characteristics of the DER plant at the point of electrical connection between the DER and the micro-grid bus, and its LNs should cover corporate characteristics, operational authority, operating mode, status information, economic dispatch parameters, energy and/or ancillary services schedule control, etc.

- ➢

- Generator Unit: describes the generator characteristics of the DER unit with different prime movers depending upon the type of DER device, and its LNs should cover generator operations, generator ratings, advanced generator features, cost, etc.

- ➢

- Exciter: comprises the components of a DER that handle the excitation systems used to start the generator, and its LNs should cover excitation ratings and operations.

- ➢

- DC converter: defines the characteristics of the converter, which converts AC to DC or DC to AC, and its LNs should cover rectifier, inverter, and measurement of intermediate DC, etc.

- ➢

- Energy converter: describes the different primary energy converter characteristics of the DER unit depending upon the type of DER device, and its LNs should cover the photovoltaics system (such as module, array), CHP thermal storage, CHP boiler, etc.

- ➢

- DER unit controller: defines the operational characteristics of a single DER device, regardless of the type of prime mover or generator, and its LNs should cover controller characteristics, controller status, supervisory control, etc.

- ➢

- Auxiliary systems: describes the characteristics of auxiliary systems, and its LNs should cover fuel systems, batteries (such as systems, charger), physical measurements (such as temperature, pressure, heat, meteorological information), electric metering, etc.

| Object | Dictionary Services | Real Time Data Services |

|---|---|---|

| Server | GetServerDirectory | --- |

| LD | GetLogicalDeviceDirectory | --- |

| LN | GetLogicalNodeDirectory | GetAllDataValues |

| Data | GetDataDirectory, GetDataDefination | GetDataValues, SetDataValues |

| Report control block | --- | Report, GetBRCBValues, GetURCBValues |

| Control | --- | Select, SelectWithValue, Cancel, Operate |

| Data (which be changed and needs to be monitored or utilized) | Data (which be used for characterization of normal or reasonable system operation) | |

|---|---|---|

| Measured values | Total DER/load input and output watt-hours; DER current/active power/reactive power; load current/active power/reactive power; ECP accumulated input/output energy; ECP current/voltage/frequency/active power/reactive power | ECP current ECP voltage ECP frequency ECP active power ECP reactive power |

| Controls | DER operating mode; DER energy schedule; DER start/stop; DER test; DER/load breaker turned on/off | |

| Status information | Type of ECP; ECP connection status; DER controller status; DER start/stop status; voltage high or overcharged; voltage low or undercharged; DER/load breaker status; load demand | |

| Settings | Nominal, min, and max aggregated DER watts/var rating at ECP; nominal, min, and max voltage level/frequency at ECP; DER operational authority at the ECP; DER economic dispatch parameters; ECP energy and ancillary services schedule; set-point for DER power factor/frequency/output voltage; DER output target active/reactive power set-point; DER charge curve; controllable load dispatch schedule | |

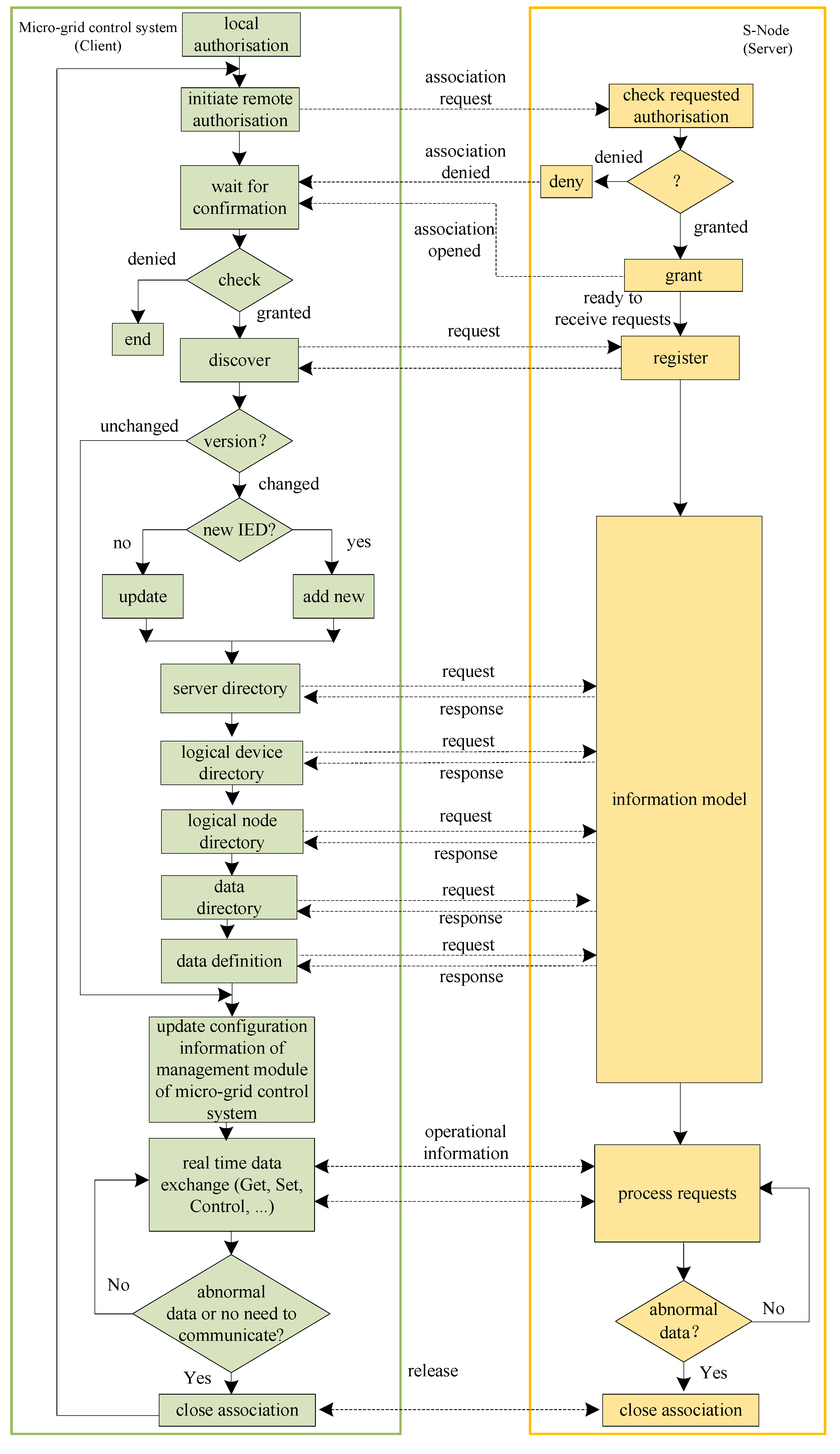

- Step 1:

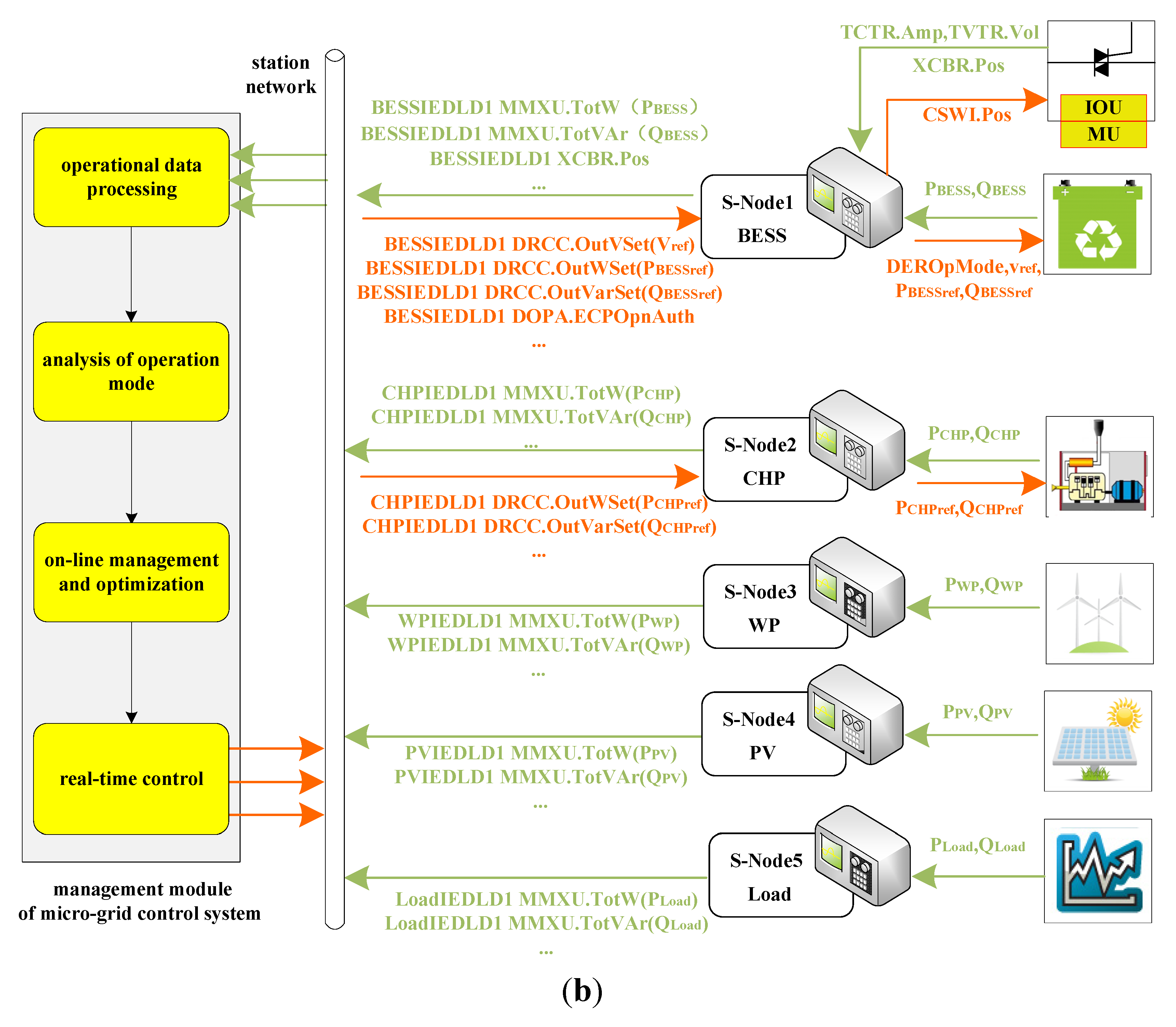

- Operational data processing, obtains the valid data from IEC 61850 messages.

- Step 2:

- Analysis of operation mode, and determines the current operation mode by the real-time state of XCBR.Pos.

- Step 3:

- On-line management and optimization based on the actual data of DER and load, combined with the related optimization objective and constraints, to generate the controls and settings for optimization operation in the current states, such as and , for BESS using the power control strategies in the grid-connected mode, or for BESS using the voltage source control strategies in the autonomous mode.

- Step 4:

- Real-time control, updates controls DOs and settings DOs for the corresponding S-Node, and send the requests to the station network.

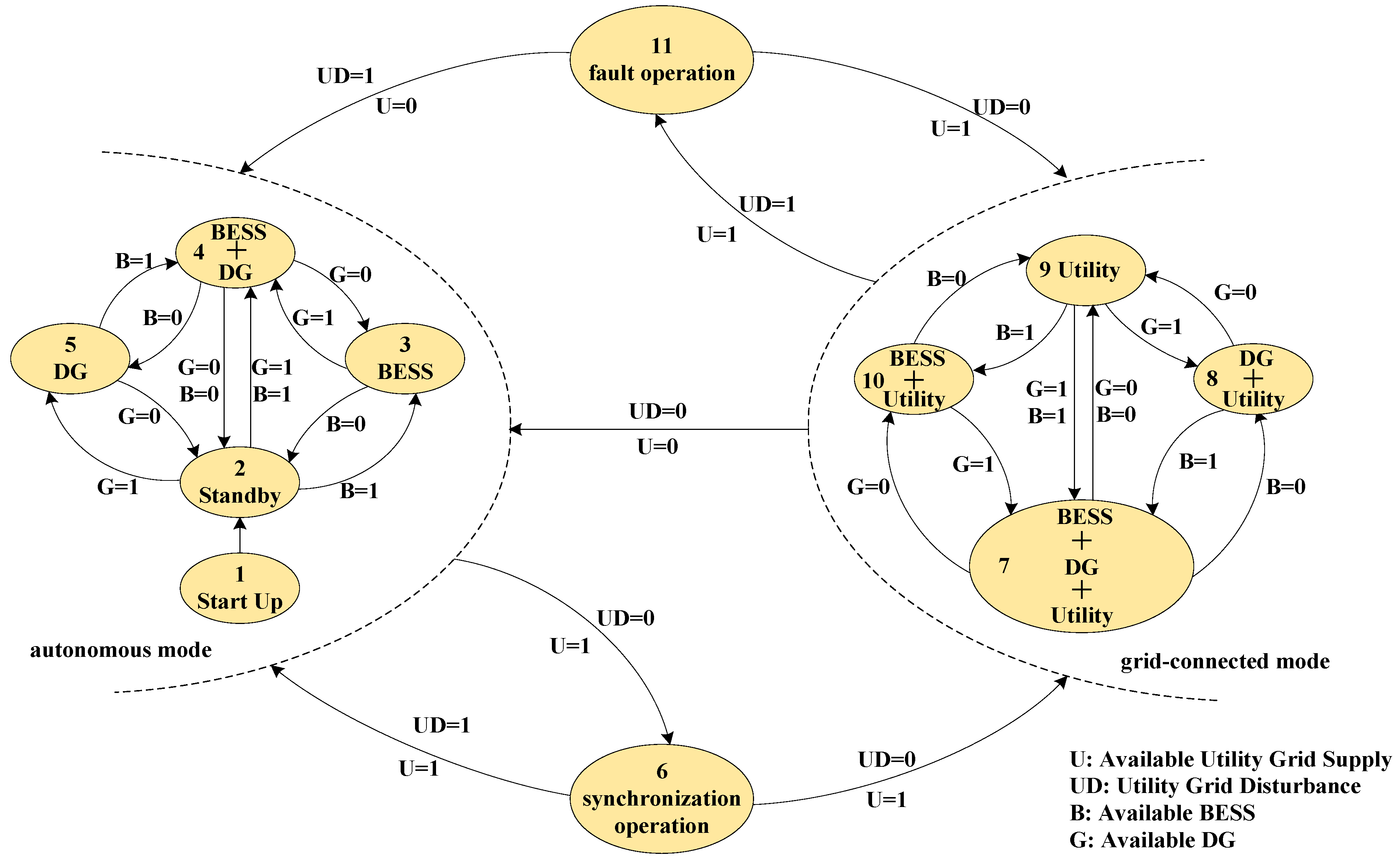

3.2. Grid-Connected/Autonomous Mode Conversion

- (1)

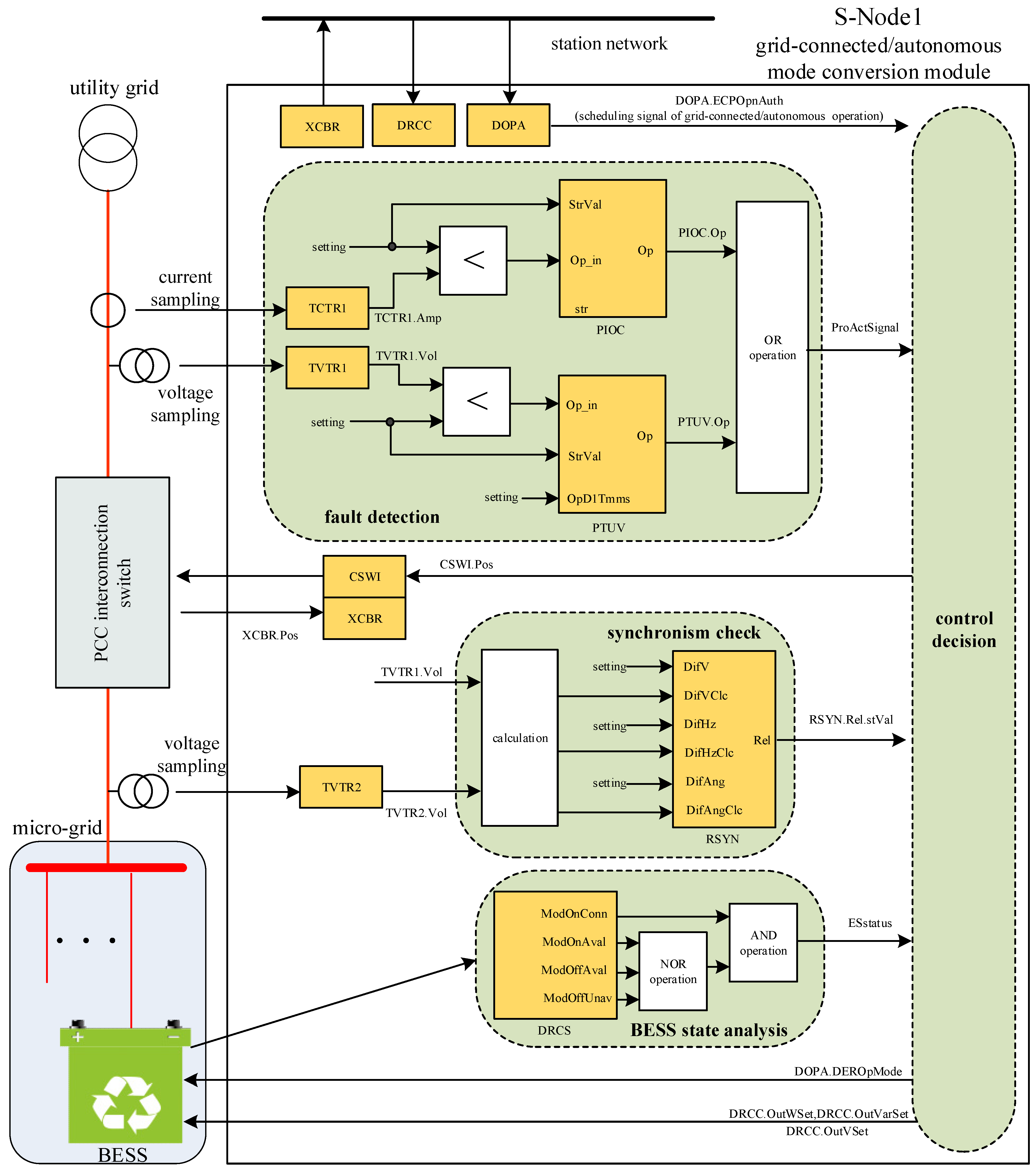

- The fault detection sub-module:TCTR1 and TVTR1 respectively subscribe the PCC current and voltage published by the equipped MU through the process bus. Then the sub-module will detect the utility grid fault and correspondingly output the protection signal represented as ProActSignal (ProActSignal == 1 means that current or voltage faults have been detected, ProActSignal == 0 means no faults).

- (2)

- The synchronism check sub-module: TVTR2 subscribes the micro-grid bus voltage published by equipped MU through the process bus, and provide data for sub-module combing with TVTR1. Then the sub-module will check the synchronization conditions including amplitude and phase, and correspondingly output the synchronization signal represented as RSYN.Rel.stVal (RSYN.Rel.stVal == 1 means that synchronization is ready, RSYN.Rel.stVal == 0 means that synchronization is not ready).

- (3)

- The BESS state analysis sub-module: It output the availability of BESS based on its operation state, represented as ESstatus (ESstatus == 1 means available BESS, ESstatus == 0 means that BESS is not available).

- (4)

- The control decision sub-module: the micro-grid control system transfers scheduling signal to S-Node1, which is represented as DOPA.ECPOpnAuth.setVal (DOPA.ECPOpnAuth.setVal == 1 means micro-grid autonomous operation, DOPA.ECPOpnAuth.setVal == 0 means micro-grid grid-connected operation). Based on the key data including DOPA.ECPOpnAuth.setVal, ProActSignal, RSYN.Rel.stVal, and ESstatus, this sub-module will generate the management orders according to rules as follows:

4. Test Results

- (1)

- Power-system: the nominal voltage is 220 V, the nominal frequency is 50 Hz, and the rated capacity of distribution network transformer is 1 MVA (10 kV/0.4 kV); BESS uses valve-regulated lead acid (VRLA) batteries whose rated capacity is 150 kWh, and the rated capacity of the BESS inverter is 30 kVA, which adopts the voltage source control strategies in the autonomous mode to provide the stable system voltage, or the power control strategies in the grid-connected mode to participate in power dispatching; PV uses a polycrystalline silicon cell array, and the rated capacity of its inverter is 18 kW, which adopts the current source control strategies to realize the maximum power point tracking (MPPT) of solar energy; WP uses the direct-drive permanent-magnet synchronous generator (PMSG), and the rated capacity of the inverter is 4 kW, which adopts the current source control strategies to realize the MPPT of wind energy; CHP uses the Capstone C30 set, and its rated capacity is 30 kVA, and adopts the power control strategies to accept the power dispatching; The peak power of controllable load is 37 kVA.

- (2)

- Information system: MU supports the synchronous sampling of 32-channels, IEEE 1588 time synchronization, and IEC 61850-9-2 messages; IOU supports the GOOSE publish/subscribe pattern, and it can drive the PCC interconnection switch; S-Node has multiple Ethernet ports, and it supports IEC 61850 MMS messages, GOOSE publish/subscribe pattern, and SV publish/subscribe pattern.

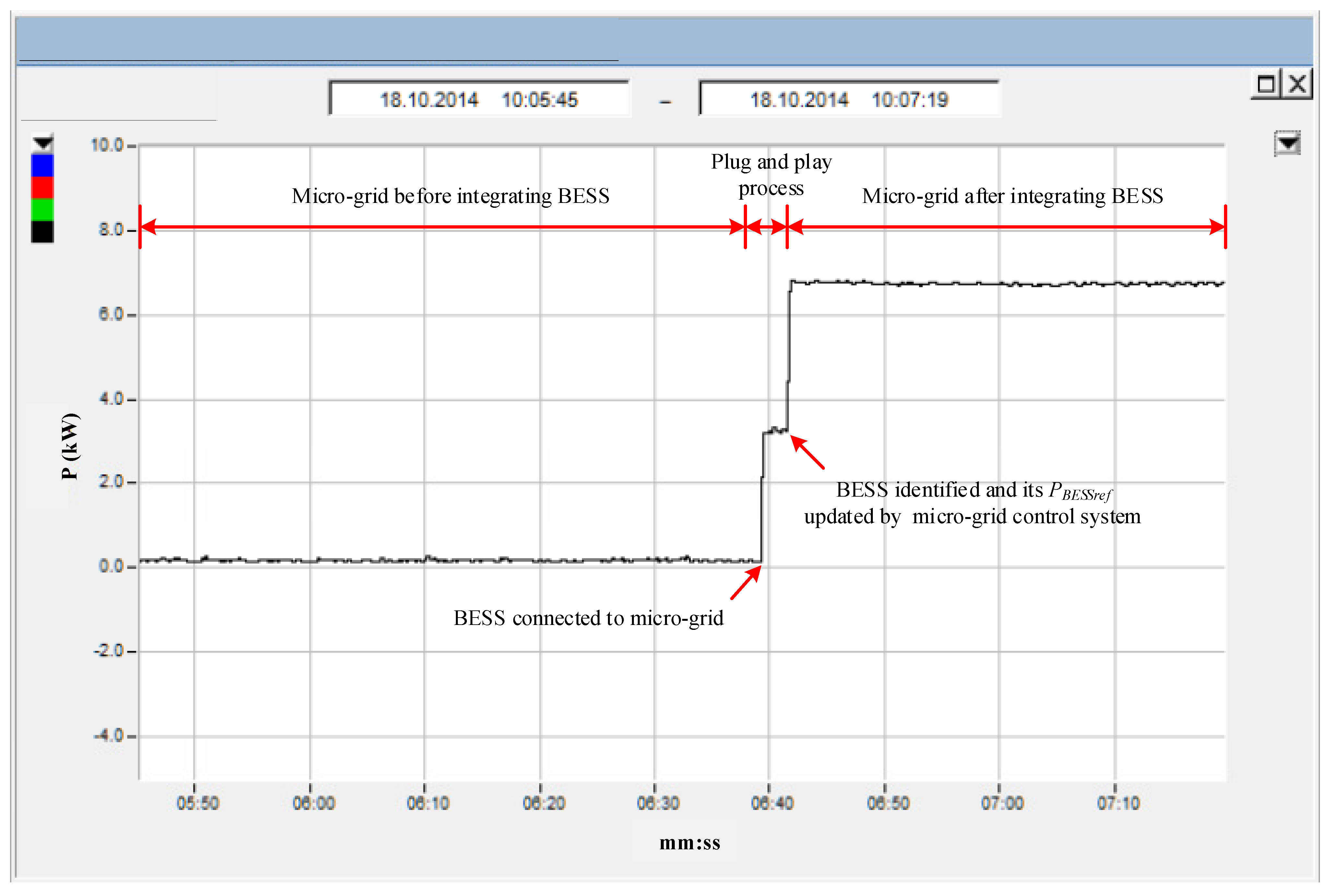

4.1. “Plug and Play” Test

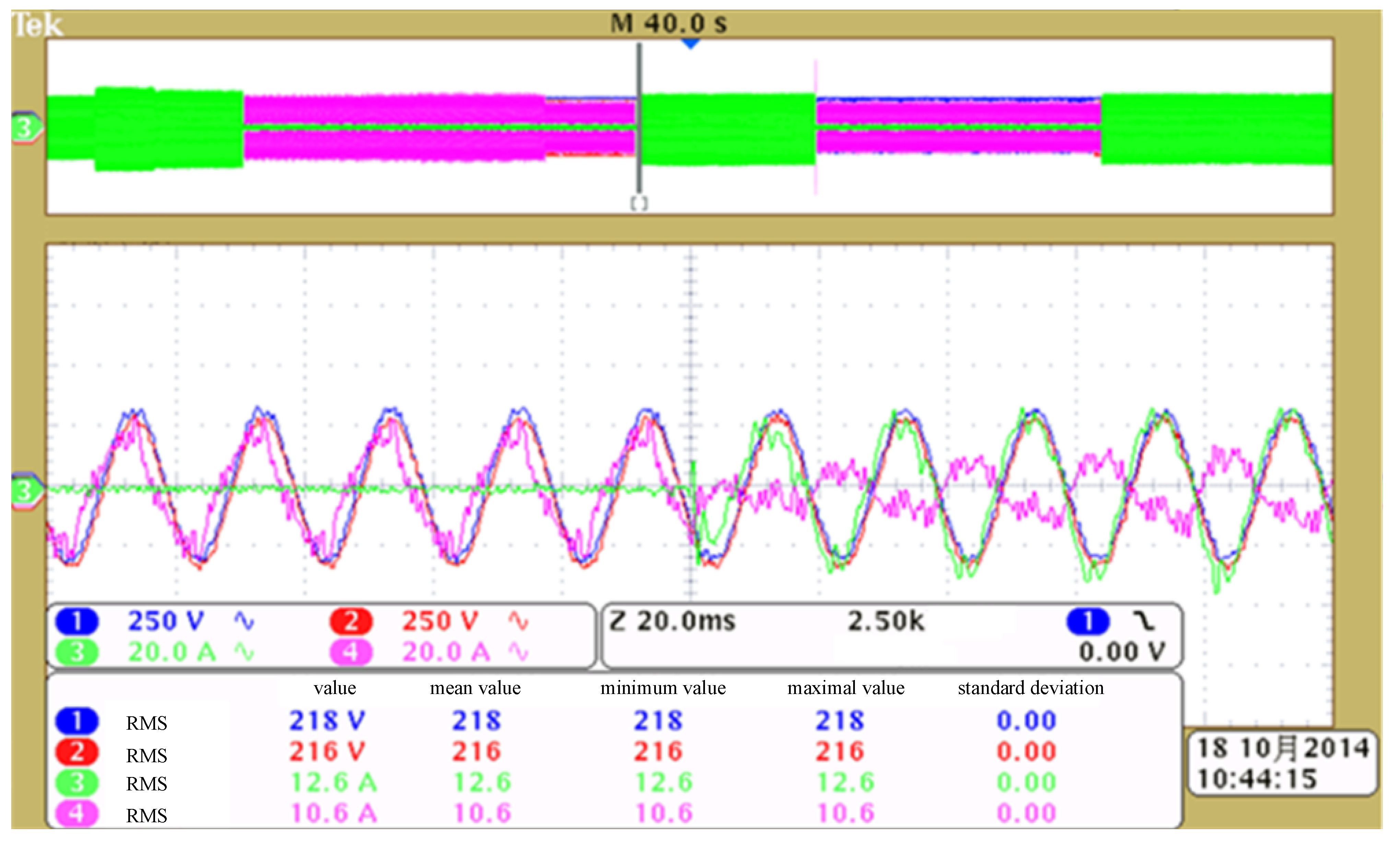

4.2. Grid-Connected/Autonomous Mode Conversion Test

5. Conclusions

Acknowledgments

Author Contributions

Acronyms

| DER | Distributed energy resources |

| CHP | Combined heat and power |

| WP | Wind power |

| PV | Photovoltaic system |

| SCADA | Supervisory control and data acquisition system |

| EMS | Energy management system |

| ACSI | Abstract communication service interfaces |

| CDC | Common data classes |

| LN | Logical node |

| EV | Electric vehicles |

| IED | Intelligent electronic devices |

| WAN | Wide area network |

| CAN | Controller area network |

| IOU | Input/output unit |

| MU | Merging unit |

| DG | Distributed generation |

| BESS | Battery energy storage system |

| PCC | Point of common connection |

| ECP | Electrical connection point |

| SCL | Substation configuration language |

| MMS | Manufacturing message specification |

| GOOSE | Generic object oriented substation event |

| SV | Sampled values |

| DO | Data objects |

| XCBR | Circuit breakers |

| CSWI | Switch controller |

| DCRP | DER plant corporate characteristics at the ECP |

| DOPA | DER operational authority at the ECP |

| DOPR | Operational characteristics at ECP |

| DOPM | Operating mode at ECP |

| DPST | Status information at the ECP |

| DCCT | DER economic dispatch parameters |

| DSCC | DER energy and/or ancillary services schedule control |

| DSCH | DER energy and/or ancillary services schedule |

| MMTR | Metering |

| DPVC | Photovoltaics array controller |

| DTRC | Tracking controller |

| DPVM | Photovoltaic module characteristics |

| DPVA | Photovoltaics array characteristics |

| XSWI | Switch |

| ZINV | Inverter |

| ZRCT | Rectifier |

| MMDC | Measurement of intermediate DC |

| DRCT | DER controller characteristics |

| DRCS | DER controller status |

| DRCC | DER supervisory control |

| FSEQ | Sequencer |

| MMXU | Electrical measurements |

| STMP | Temperature measurements |

| MHET | Heat measured values |

| MMET | Meteorological conditions |

| ZBAT | Battery systems |

| ZBTC | Battery charger |

| WCNV | Wind turbine converter information |

| WGEN | Wind turbine generator information |

| WTRM | Wind turbine transmission information |

| WROT | Wind turbine rotor information |

| WTUR | Wind turbine general information |

| WSLG | Wind turbine state log information |

| WREP | Wind turbine report information |

| WALM | Wind power plant alarm information |

| WAPC | Wind power plant active power controller |

| WRPC | Wind power plant reactive power controller |

| WNAC | Wind turbine nacelle information |

| WYAW | Wind turbine yawing information |

| WTOW | Wind turbine tower information |

| WMET | Wind turbine melerological information |

| RSYN | Synchronization |

| DGEN | DER unit generator |

| DRAT | DER generator ratings |

| DRAZ | DER advanced generator ratings |

| DCST | Generator cost |

| DREX | Excitation ratings |

| DEXC | Excitation operations |

| DCTS | CHP thermal storage |

| DCHB | CHP Boiler System |

| DCHC | CHP system controller |

| MFUL | Fuel characteristics |

| DFLV | Fuel delivery system |

| SVBR | Vibration conditions |

| MPRS | Pressure measurements |

| MENV | Emissions measurements |

| MFLW | Flow measurements |

| PIOC | Instantaneous over current |

| PTOC | Time over current |

| PTUV | Time under voltage |

| PTOV | Time over voltage |

| TCTR | Current transformer |

| TVTR | Voltage transformer |

| LD | Logical device |

| VRLA | Valve-regulated lead acid |

| MPPT | Maximum power point tracking |

| PMSG | Permanent-magnet synchronous generator |

Conflicts of Interest

References

- Eghtedarpour, N.; Farjah, E. Power control and management in a hybrid AC/DC microgrid. IEEE Trans. Smart Grid 2014, 5, 1494–1505. [Google Scholar] [CrossRef]

- Zamani, M.A.; Sidhu, T.S.; Yazdani, A. Investigations into the control and protection of an existing distribution network to operate as a microgrid: A case study. IEEE Trans. Ind. Electron. 2014, 61, 1904–1915. [Google Scholar] [CrossRef]

- Alegria, E.; Brown, T.; Minear, E.; Lasseter, R.H. CERTS microgrid demonstration with large-scale energy storage and renewable generation. IEEE Trans. Smart Grid 2014, 5, 937–943. [Google Scholar] [CrossRef]

- Duong, T.; Khambadkone, A.M. Energy management for lifetime extension of energy storage system in micro-grid applications. IEEE Trans. Smart Grid 2013, 4, 1289–1296. [Google Scholar] [CrossRef]

- Deng, W.; Pei, W.; Qi, Z.P. Micro-grid information exchange based on IEC 61850. Proc. Autom. Electr. Power Syst. 2013, 37, 6–11. (In Chinese) [Google Scholar]

- Ren, Y.M.; Cao, F.M. New development and new application of IEC 61850. Proc. Autom. Electr. Power Syst. 2013, 37, 1–6. (In Chinese) [Google Scholar]

- Ustun, T.S.; Ozansoy, C.R.; Zayegh, A. Modeling of a centralized microgrid protection system and distributed energy resources according to IEC 61850-7-420. IEEE Trans. Power Syst. 2012, 27, 1560–1567. [Google Scholar] [CrossRef]

- Timbus, A.; Larsson, M.; Yuen, C. Active management of distributed energy resources using standardized communications and modern information technologies. IEEE Trans. Ind. Electron. 2009, 56, 4029–4037. [Google Scholar] [CrossRef]

- Colet-Subirachs, A.; Ruiz-Alvarez, A.; Gomis-Bellmunt, O.; Alvarez-Cuevas-Figuerola, F.; Sudria-Andreu, A. Centralized and distributed active and reactive power control of a utility connected microgrid using IEC61850. IEEE Syst. J. 2012, 6, 58–67. [Google Scholar] [CrossRef]

- Yoo, B.K.; Yang, S.H.; Yang, H.S.; Kim, W.Y.; Jeong, Y.S.; Han, B.M.; Jang, K.S. Communication architecture of the IEC 61850-based micro grid system. J. Electr. Eng. Technol. 2011, 6, 605–612. [Google Scholar] [CrossRef]

- Stjepan, S.; Tomislav, D.; Tomislav, C.; Marko, D. Economic dispatch of virtual power plants in an event-driven service-oriented framework using standards-based communications. Electr. Power Syst. Res. 2011, 81, 2108–2119. [Google Scholar] [CrossRef]

- Petersen, B.; Winther, D.; Pedersen, A.; Poulsen, B.; Traeholt, C. Integrating intelligent electric devices into distributed energy resources in a cloud-based environment. In Proceedings of the 4th IEEE/PES Innovative Smart Grid Technologies Europe (ISGT EUROPE), Lyngby, Denmark, 6–9 October 2013; Volume 1, pp. 1–5.

- Schmutzler, J.; Groning, S.; Wietfeld, C. Management of distributed energy resources in IEC 61850 using Web services on devices. In Proceedings of the 2011 IEEE International Conference on Smart Grid Communications (SmartGridComm), Brussels, Belgium, 17–20 October 2011; Volume 1, pp. 315–320.

- Stjepan, S.; Juraj, G.; Tomislav, D. A device-level service-oriented middleware platform for self-manageable DC microgrid applications utilizing semantic-enabled distributed energy resources. Electr. Power Energy Syst. 2014, 54, 576–588. [Google Scholar] [CrossRef]

- Communication Networks and Systems for Power Utility Automation—Part 7–420: Basic Communication Structure–Distributed Energy Resources Logical Nodes; IEC Std. 61850 Ed 1.0; International Electrotechnical Commission (IEC): Geneva, Switzerland, 2009.

- Communication Networks and Systems for Power Utility Automation—Part 7–1: Basic Communication Structure—Principles and Models; IEC Std. 61850 Ed 2.0; International Electrotechnical Commission (IEC): Geneva, Switzerland, 2011.

- Communication Networks and Systems for Power Utility Automation—Part 7–2: Basic Information and Communication Structure—Abstract Communication Service Interface (ACSI); IEC Std. 61850 Ed 2.0; International Electrotechnical Commission (IEC): Geneva, Switzerland, 2010.

- Communication Networks and Systems for Power Utility Automation—Part 7–3: Basic Communication Structure-Common Data Classes; IEC Std. 61850 Ed 2.0; International Electrotechnical Commission (IEC): Geneva, Switzerland, 2010.

- Communication Networks and Systems for Power Utility Automation—Part 7–4: Basic Communication Structure—Compatible Logical Node Classes and Data Object Classes; IEC Std. 61850 Ed 2.0; International Electrotechnical Commission (IEC): Geneva, Switzerland, 2010.

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, W.; Pei, W.; Shen, Z.; Zhao, Z.; Qu, H. Adaptive Micro-Grid Operation Based on IEC 61850. Energies 2015, 8, 4455-4475. https://doi.org/10.3390/en8054455

Deng W, Pei W, Shen Z, Zhao Z, Qu H. Adaptive Micro-Grid Operation Based on IEC 61850. Energies. 2015; 8(5):4455-4475. https://doi.org/10.3390/en8054455

Chicago/Turabian StyleDeng, Wei, Wei Pei, Ziqi Shen, Zhenxing Zhao, and Hui Qu. 2015. "Adaptive Micro-Grid Operation Based on IEC 61850" Energies 8, no. 5: 4455-4475. https://doi.org/10.3390/en8054455

APA StyleDeng, W., Pei, W., Shen, Z., Zhao, Z., & Qu, H. (2015). Adaptive Micro-Grid Operation Based on IEC 61850. Energies, 8(5), 4455-4475. https://doi.org/10.3390/en8054455