1. Introduction

Despite several efforts, from 2000 to 2010, global greenhouse gas (GHG) emissions grew more quickly (2.2%/year) during that period than in each of the three previous decades (1.3%/year) and reached 49 Gt CO

2e/year in 2010 [

1]. Development of new infrastructure in rapidly developing countries, especially in transition countries such as India and China, accounts for much of the increase [

2]. This trajectory shows that the avoidance of two degrees of warming proposed by the United Nations Framework Convention on Climate Change (UNFCCC) at Cancun is problematic to reach. In order to meet the two degrees target, the current de-carbonization rate of 1.2%/year needs to be increased to 6.2%/year, every year from now till 2100 [

3]. If we stick with current trajectory we will end up at four degrees increase by the end of 2100 [

3]. When climate change policy was being developed in the 1990s, developing countries accounted for only 40% of global emissions and this increased to 54.3% in 2004 and is expected to increase to 66% by 2030 [

4]. Therefore, every country, whether developed or developing, needs to share emissions reduction responsibility [

5].

As a developed country and a major party of UNFCCC, Australia has a significant responsibility for emissions reduction. Currently, Australia shares 1.18% of global GHG emissions, 1.21% of global GDP and 0.33% of the global population [

6]. From 2008 to 2013, Australia reduced its annual average carbon intensity by 4.6% [

3], and in fact, this was the world record. This was achieved mainly by structural changes, new technologies, fuel switching and improvements in energy efficiency [

7]. However, as noted, this is not enough yet.

Globally, agriculture is one of the major sources of energy consumption and therefore GHG emissions. With more intensive and modernized farming systems, during the period 1990–2005, global GHG emissions from agriculture increased by 14%, at an annual rate of 49 Mt CO

2e/year [

8]. In 2010, GHG emissions from agriculture are estimated to be 5.6 Gt CO

2e/year to 6.4 Gt CO

2e/year [

9,

10,

11],

i.e., about 11.4% to 13.1% of global emissions. If the production of agricultural inputs and various downstream activities are considered, the agricultural sector contributes a further 3% to 6% of global emissions [

12].

Australia is one of the largest GHG emitting countries from the agriculture sector in the world. Its agricultural sector accounts for 15% of national GHG emissions and is the second largest source of emissions [

13]. This proportion is significantly higher than those in Central and Eastern Europe, the former Soviet Union and the USA [

14]. In order to reduce GHG emissions from the agricultural sector, the previous Australian Government implemented Carbon Farming Initiatives (CFIs). The current Government replaced it with the Direct Action Plan called “Emission Reduction Fund (ERF)” and allocated A$2.55 billion to establish the Fund in the 2014–2015 budgets [

15]. ERF allows farmers and other land managers to earn carbon credits by storing carbon or reducing GHG emissions on land. This would allow them to adopt some best management practices and earn carbon credits and reputational benefits at the same time.

The uptake of ERF is likely to be good. As of 31 August 2015, 390 projects are registered and 16.3 million Australian Carbon Credit Units (ACCUs) have been issued to these projects [

16]. Australia has set 5% unconditional emission reduction targets for 2020 from 2000 levels, and with this initiative agriculture is expected to meet this target [

16]. So far, the majority of the registered projects under the ERF are from sequestration projects, mainly from forestry activities. However, the grain industry in Australia could have a good opportunity in reducing energy consumption and thereby GHG emissions. However, due to limited research the grain industry is not able to target where they have an opportunity to increase energy efficiency and participate in the ERF. This study aims to examine and compare on-farm energy use for three high value grain crops grown under three major farming practices in three agro-ecological zones in Australia. This will help farmers to understand the range of energy uses and also to pinpoint where their energy use is highest and the potential savings achievable.

Several studies have quantified the energy consumption associated with crop production in various countries including: (1) sugar beet production in the UK [

17]; (2) arable and outdoor vegetable production in New Zealand [

18]; (3) field crops (wheat, cotton, maize, sesame) and vegetables (tomato, melon, watermelon) [

19], tomato [

20], sugar beet [

21], stake-tomato [

22] and grape production [

23] in Turkey; (4) wheat production in India [

24]; and cotton and lucerne production in Australia [

25,

26,

27]. However, these studies have not compared the energy consumption from a broad range of farming practices currently in practice such as zero tillage, conventional tillage and irrigated farming systems. This paper is the first in this direction.

In this study, direct energy used for various on-farm operations such as tillage, fertiliser application, boom spraying, planting, aerial spraying and water pumping is considered. A large amount of indirect energy is also required for: (1) the production, packaging, storing and transportation of various farm inputs such as fertilisers, chemicals (herbicides, insecticides, fungicides and plant regulator), fuels and farm machineries; and (2) post-harvesting operations such as transportation and drying of harvested products. However, energy used for these operations are not considered in this study. Similarly, human energy is also required for on-farm operation but it is insignificant as the production system in Australia is highly mechanised. Therefore, human energy is also not considered in this study.

2. A Brief Snapshot of the Grain Industry in Australia and Rationale for Selecting Three Farming Practices

The grain industry in Australia operates in all states and makes a major contribution to the state and national economies. Australia produced over 48.5 million tonnes of grain in 2011–2012. However, in 2012–2013, grain production in Australia fell to 38.7 million tonnes [

27]. Reduced grain production was a result of increased climatic variability, and decreased production area largely due to rising input prices—including those for energy—and volatility of grain prices [

28].

The grain industry in Australia is broadly divided into three agro-ecological regions: (1) the Southern Region that covers south-eastern Australia, including central and southern New South Wales, Victoria, Tasmania, and south-eastern South Australia. Soils in this area are generally poor (low fertility) with many subsoil constraints, such as salinity, sodicity and toxic levels of some elements; (2) the Northern Region which covers Queensland and northern New South Wales. This region has relatively good soils, but relatively high seasonal rainfall variability and therefore production; and (3) the Western Region which covers Western Australia. This region has poor soils and crop yields largely depend on the winter and spring rainfall [

28].

Due to large geographical dispersion, there is a wide range of climatic conditions within each region. In general, rainfall decreases from north to south and from coastal to inland areas. Northern Region has a tropical and subtropical climate, whereas the Southern Region has a temperate climate and the Western Region has a Mediterranean climate.

Depending on the availability and price of water for irrigation, grains in these regions are produced either on irrigated or dryland “rain-fed” conditions. Overall, grain growers are increasingly moving from conventional tillage systems to reduced or zero tillage systems because: (1) continuing cultivation systems result in a loss of soil carbon, and about 75% of Australian agricultural lands have less than 1% soil organic carbon [

29]. For example, over a 60 year period, cereal cropping soils of Northern New South Wales and Southern Queensland have lost over 40 t C/ha (146.7 t CO

2e) and 4 t N/ha [

30]; (2) the loss of soil carbon adversely affects soil fertility, the soil water holding capacity and plant-available water capacity [

31]; and (3) continuous cultivation systems leave soils vulnerable to water and wind erosion, increasing agricultural runoff, degrading soil productivity and releasing GHG by disturbing soils and burning fossil fuels for farm machinery [

32,

33].

On the other hand, the zero tillage practice reverses these processes by minimizing mechanical soil disturbance, providing permanent soil cover by organic materials and diversifying crop species grown in sequence and/or association [

33]. Zero tillage also has adaptation benefits. Soils under zero tillage can hold more moisture and therefore under drought conditions the crops are more resilient and produce more [

34]. Therefore, state agriculture departments, regional natural resources management organisations, and local landholder groups generally recommend that farmers move from traditional dryland farming systems to reduced tillage systems and where appropriate towards a zero tillage system [

35]. This system is also an eligible activity through the Australian Government ERF, and participating landholders may claim a refundable tax offset of 15% of the purchase price of an eligible no-till seeder. It is likely that a higher proportion of grain production in dryland area will be grown under zero till practices in the future [

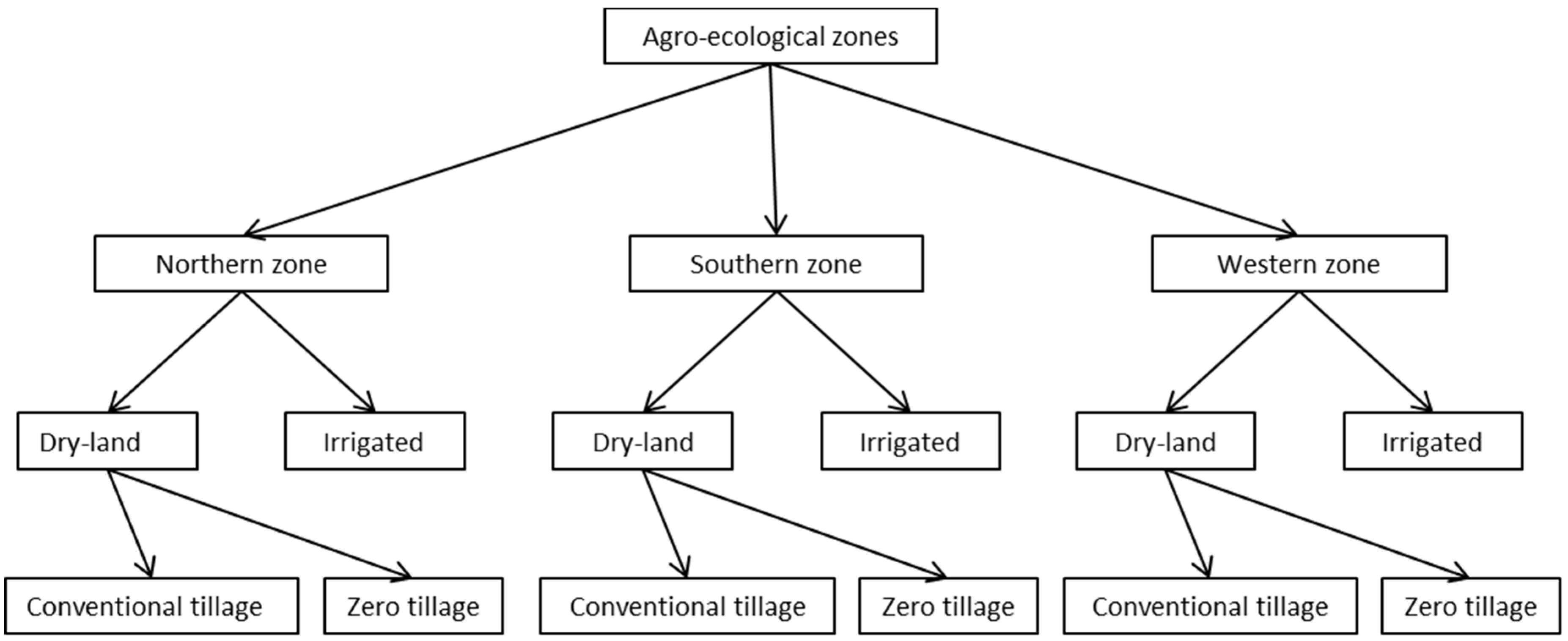

36]. Therefore, this study aims to examine and compare direct on-farm energy use for all three agro-ecological regions, under both irrigated and dry-land conditions and under dry-land both for conventional and zero-tillage systems (

Figure 1).

Now a question may arise why irrigated farming systems are not divided into two categories as in the dry-land farming system. As noted, zero tillage has been largely practiced with rain-fed (dryland) crops as farmers are increasingly realising its value for soil moisture conservation [

37]. A global meta-analysis shows that zero tillage performs best under rain-fed conditions in dry climates, either matching or exceeding conventional tillage yields for crops, whereas crop yields declined in irrigated conditions [

38]. However, in recent years there are some practices of zero tillage in irrigated crops but they are not common and also the data are not available [

36,

39]. Therefore, in this study, irrigated condition is not divided into different categories.

Figure 1.

Showing different farming practices in the three agro-ecological regions in Australia.

Figure 1.

Showing different farming practices in the three agro-ecological regions in Australia.

5. Conclusions and Recommendations

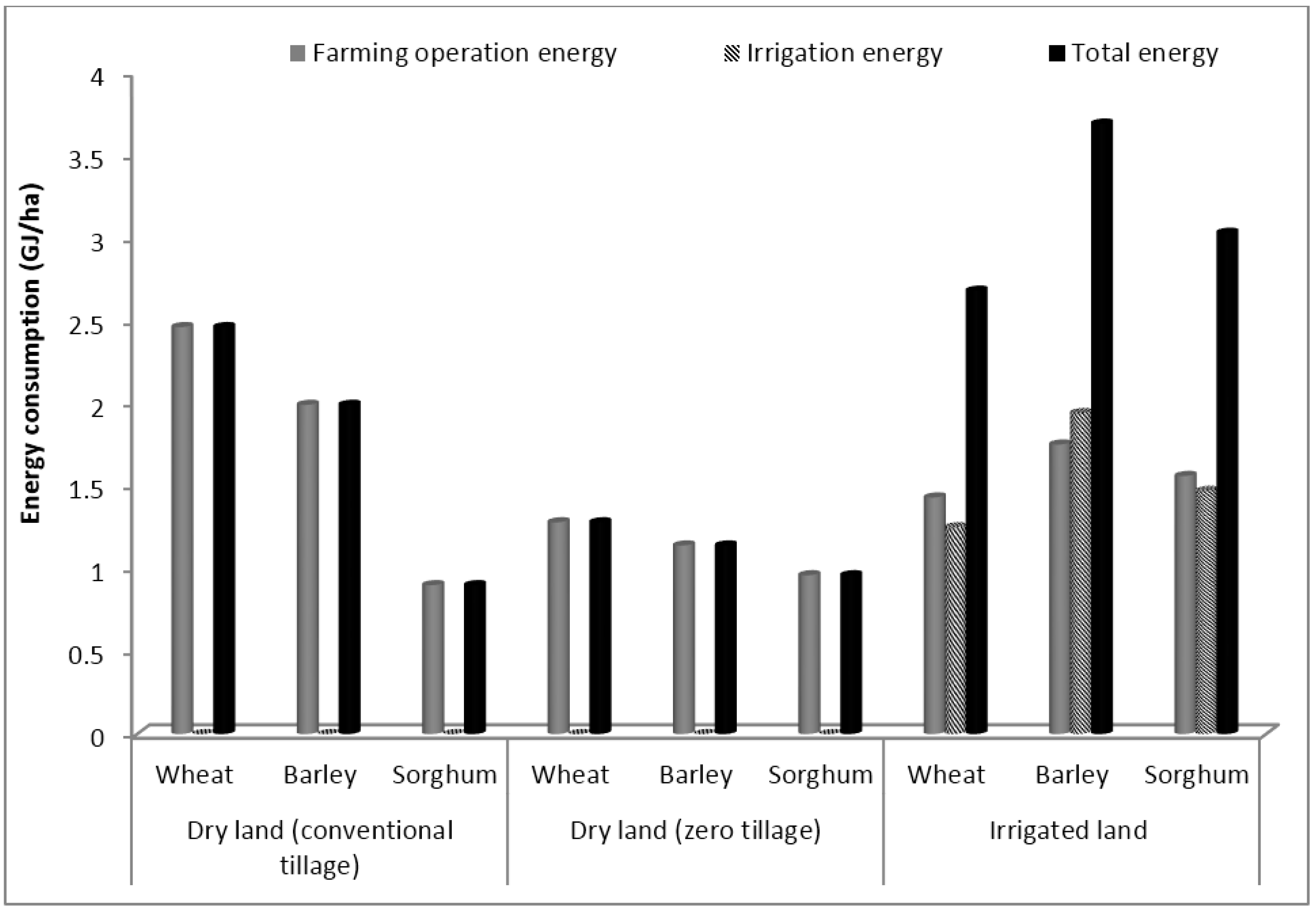

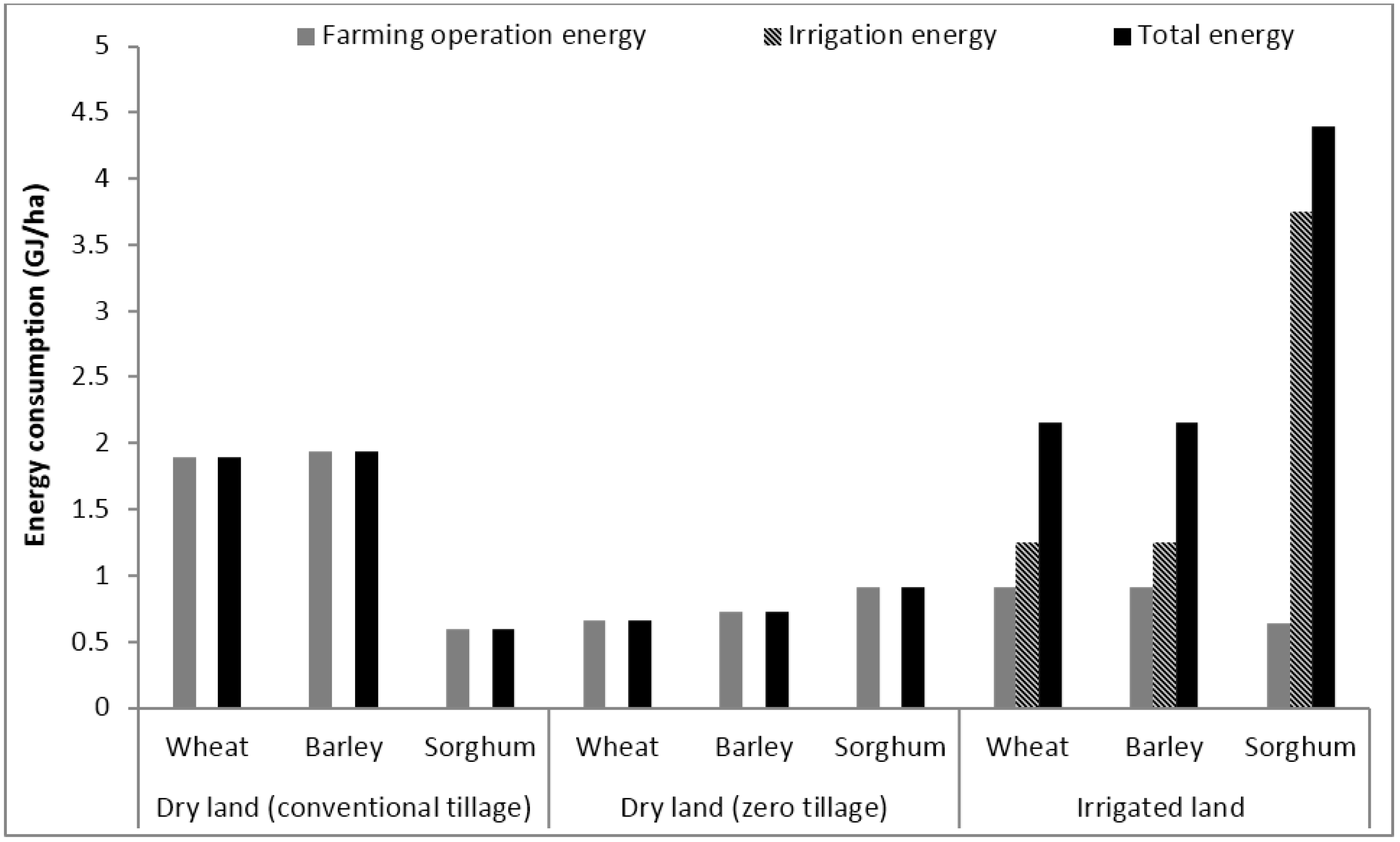

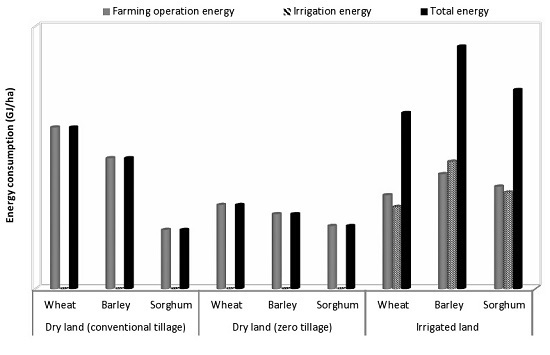

This study has assessed on-farm energy usages for three high value grain crops grown under three major farming practices in three agro-ecological zones of Australia. As expected, it has been found that fuel input in grain production in dryland systems is less than in irrigated systems. The highest amount of energy is required for sorghum crops (4.4 GJ/ha) grown under irrigated systems in the Southern Grain Region, followed by barley (3.7 GJ/ha) and sorghum (3.0 GJ/ha) grown under irrigation in the Northern Grain Region. Under dryland conditions, crops under zero tillage require less energy per hectare for each crop than conventional tillage. Among the three regions, Western Australia requires less energy for each crop, mainly due to its easily workable sandy soils. The lowest energy requirements (0.4 GJ/ha) are for wheat and barley grown in dryland by zero tillage methods in Western Australia. This data provides significant insights for energy use by different crops in different farming systems.

In irrigated crops, irrigation energy has been identified as a major contributor (47%–86%) of total energy use. It is noted that farmers are now increasingly utilising pressurised irrigation systems powered by electricity. Therefore, identifying strategies that are both water and energy efficient would be a matter of priority for further research.

Energy consumption for on-farm cropping activities depends on several factors such as tillage practices, irrigation type, water source, depth of ground water and soil type. Australia being a diverse continent, these factors not only vary between the different grain regions, but also vary within a grain region. However, in this study, only the most common (“average farm”) attributes are considered for each region, which may not necessarily reflect specific areas within the region. Therefore, more research across a larger number of sites is recommended in order to determine if the results found in this project are sufficiently indicative of the given regions.

Furthermore, in order to improve the sustainability of food production, a complete life cycle analysis may be needed. This is because energy is not only consumed for the direct on-farm operations such as cultivation, fertilising, irrigating and harvesting activities, but also indirectly for production, storage and transportation of several other farm inputs such as machinery, fertiliser, herbicides, insecticides, fungicides, and plant growth regulators,

etc. [

52,

53]. The first part, also called direct energy, is covered by this study but the second part, called indirect energy, is not covered.