The Analysis of the Aerodynamic Character and Structural Response of Large-Scale Wind Turbine Blades

Abstract

:1. Introduction

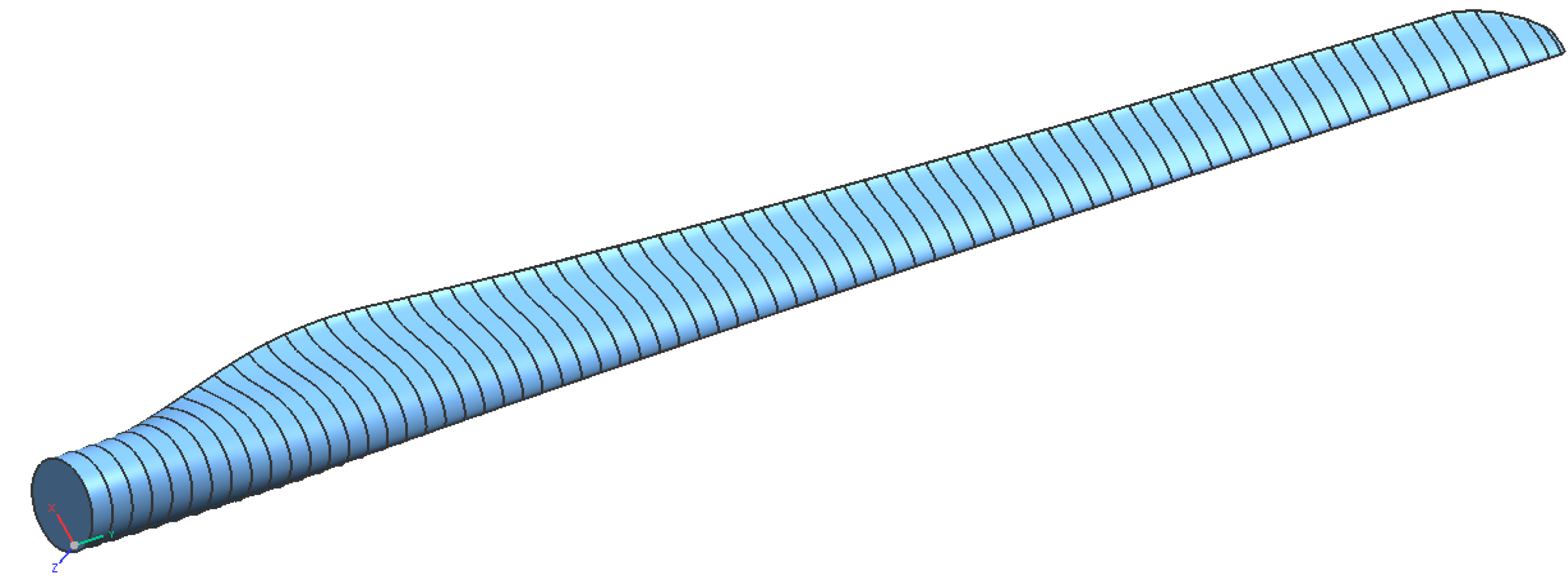

2. Specifications of 1.5 MW Wind Turbine Blade

| Parameters | Value |

|---|---|

| Rated wind speed (m/s) | 11.5 |

| Rated rotor speed (rpm) | 19.0 |

| Cut in wind speed (m/s) | 3.5 |

| Cut out wind speed (m/s) | 25.0 |

| Extreme wind speed (m/s) | 59.0 |

| Rotor overhang (m) | 4.2 |

3. Aerodynamic Analysis

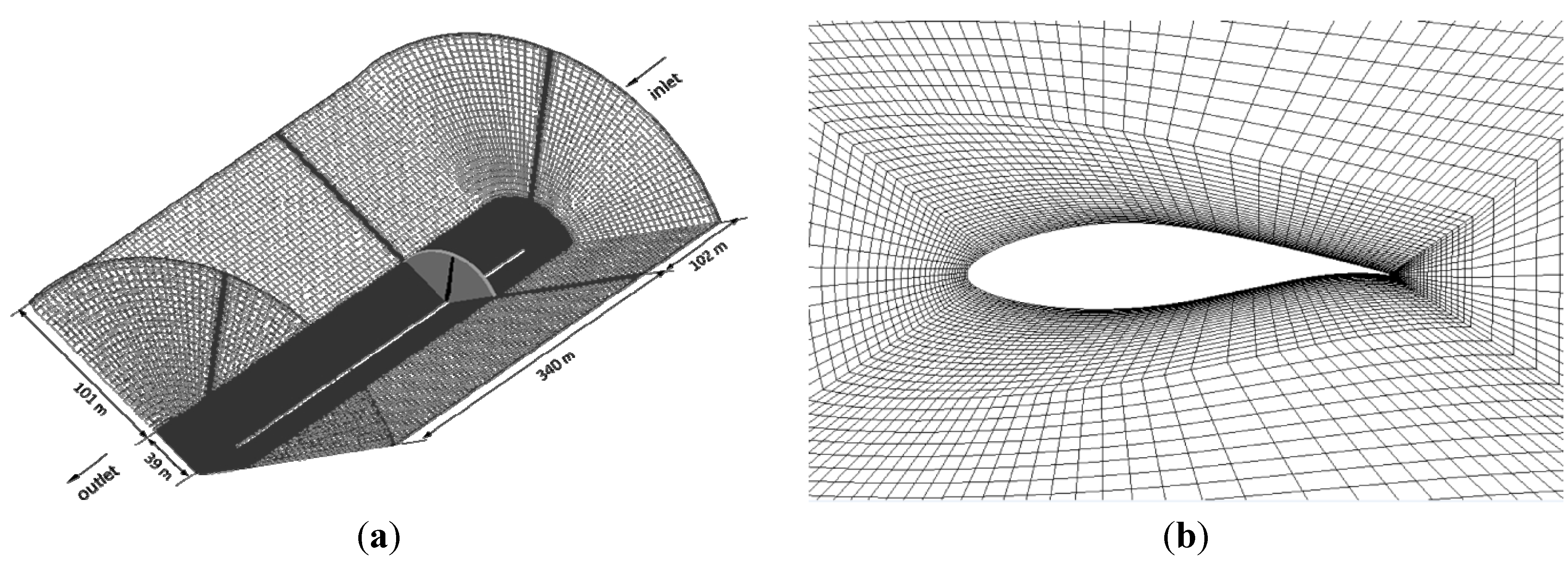

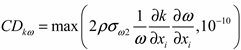

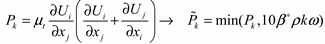

3.1. Simulation Method

; y is the distance to the nearest wall; v is the kinematic viscosity.

; y is the distance to the nearest wall; v is the kinematic viscosity.

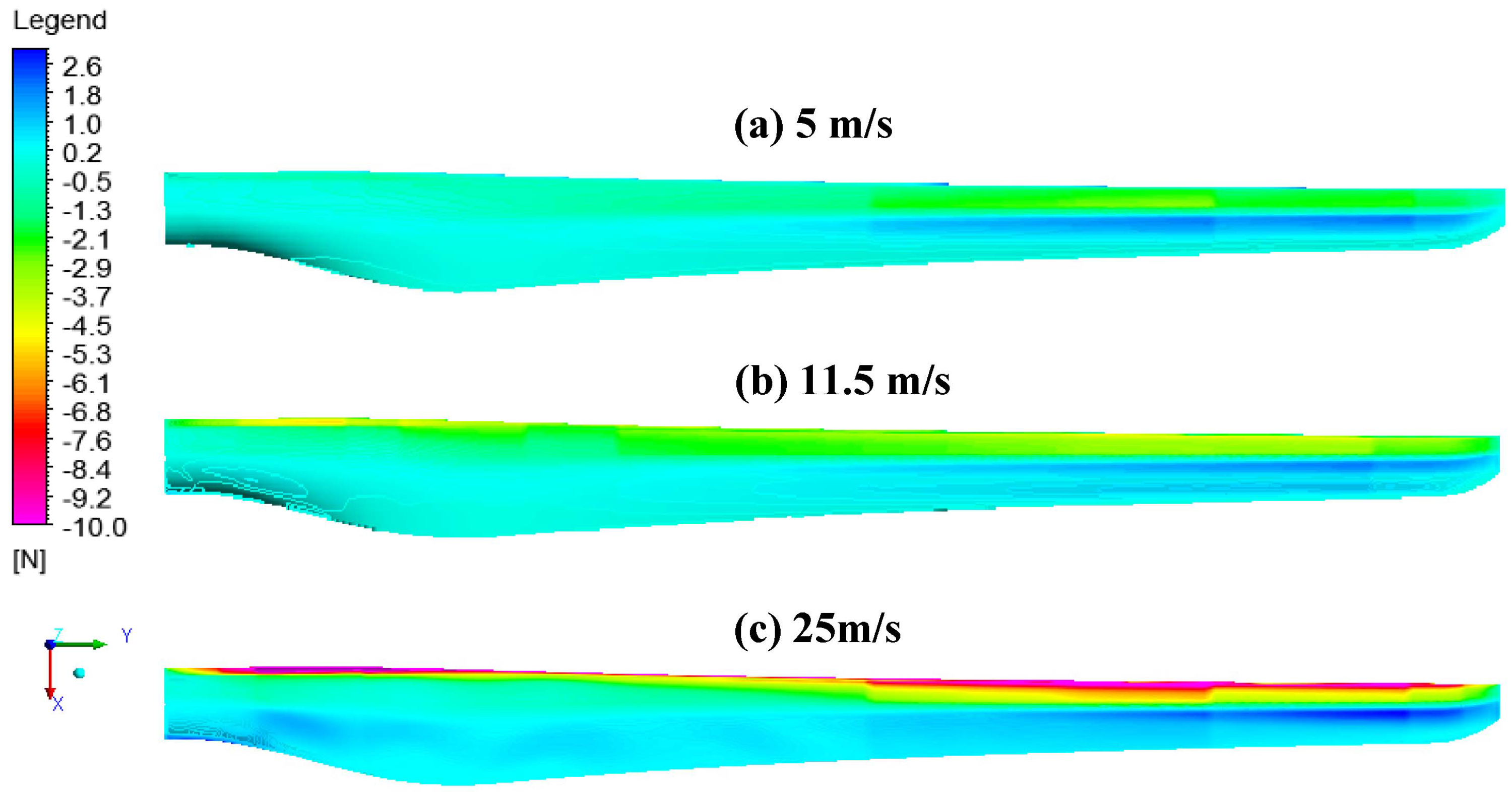

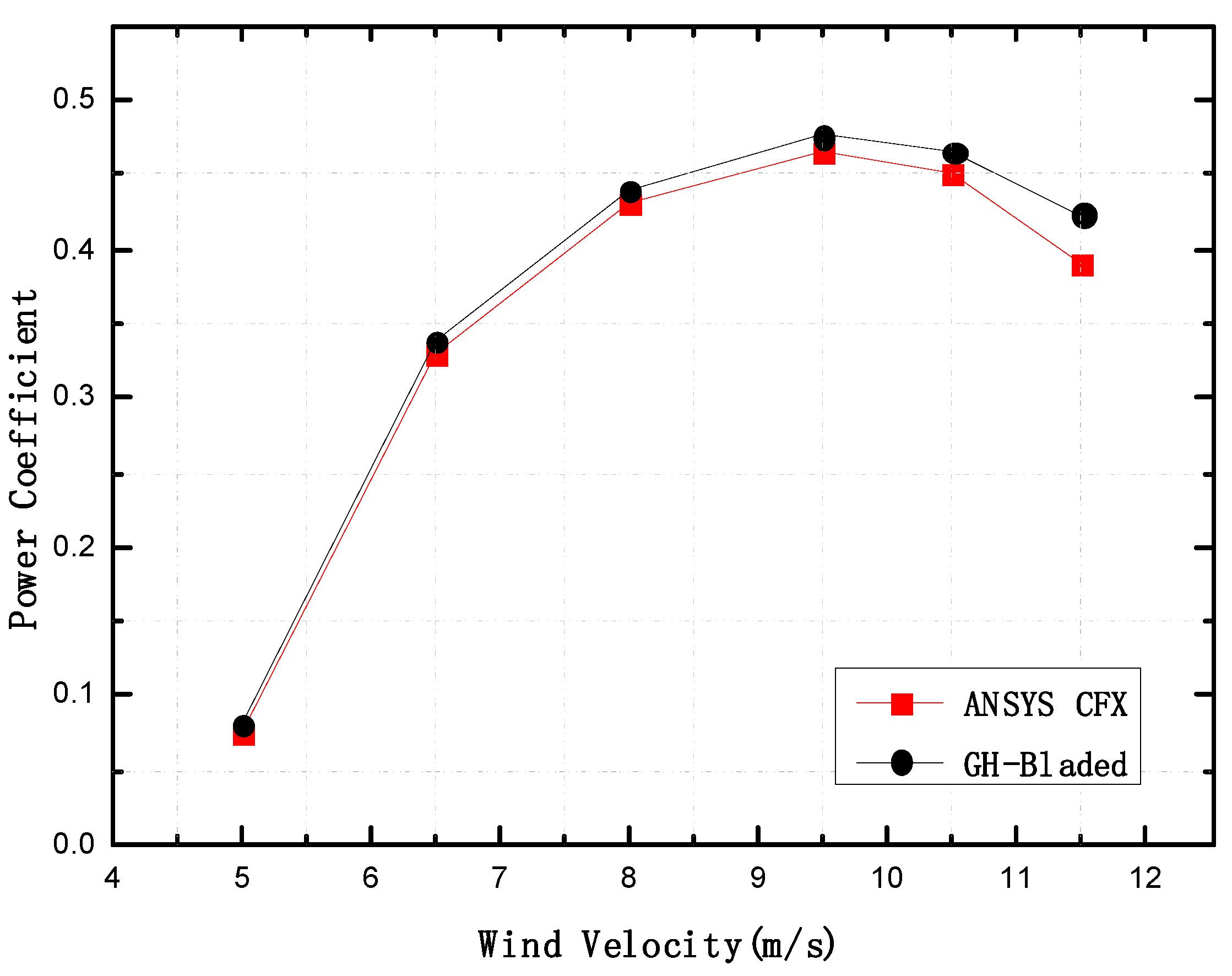

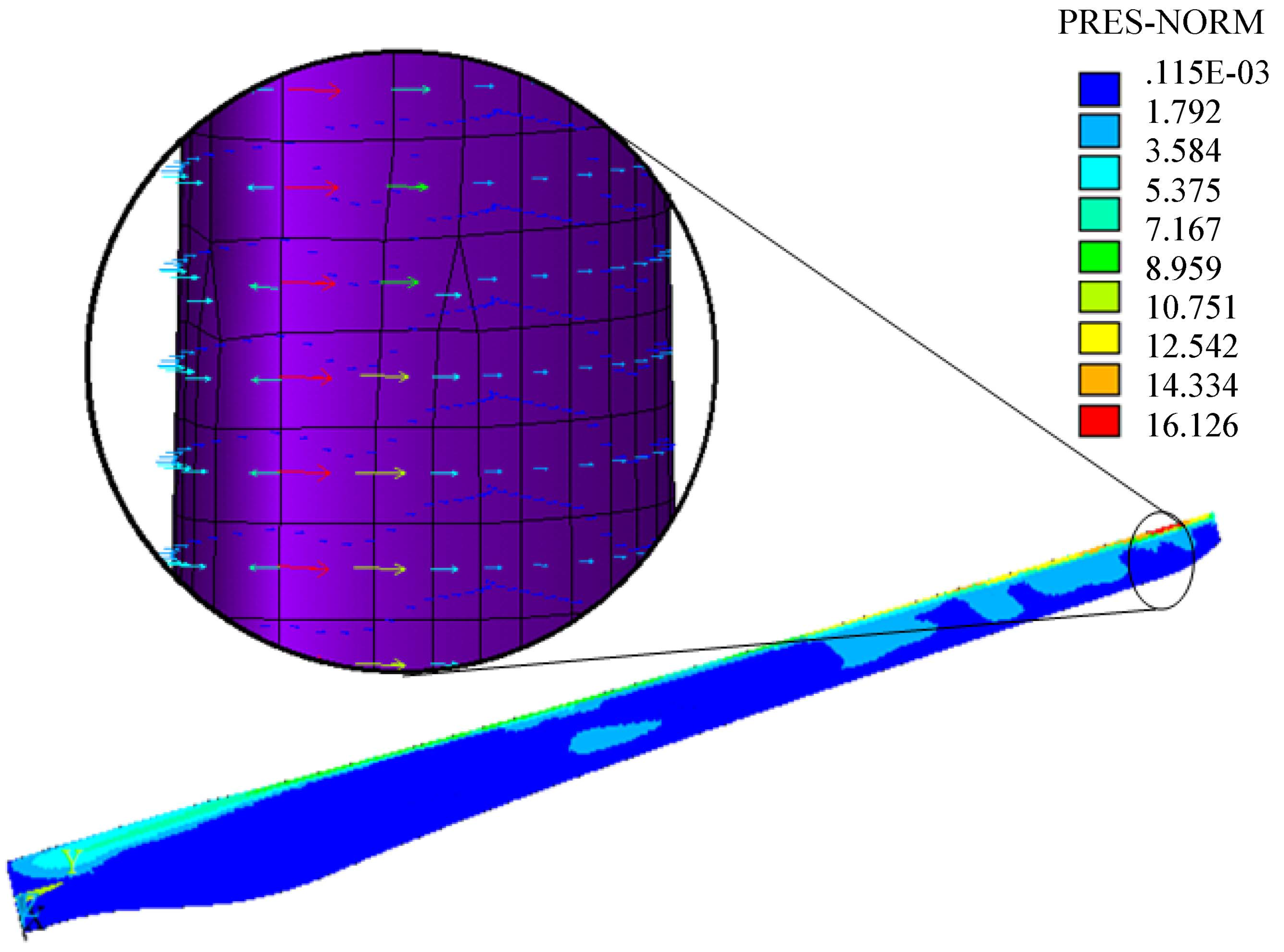

3.2. CFD Results and Discussion

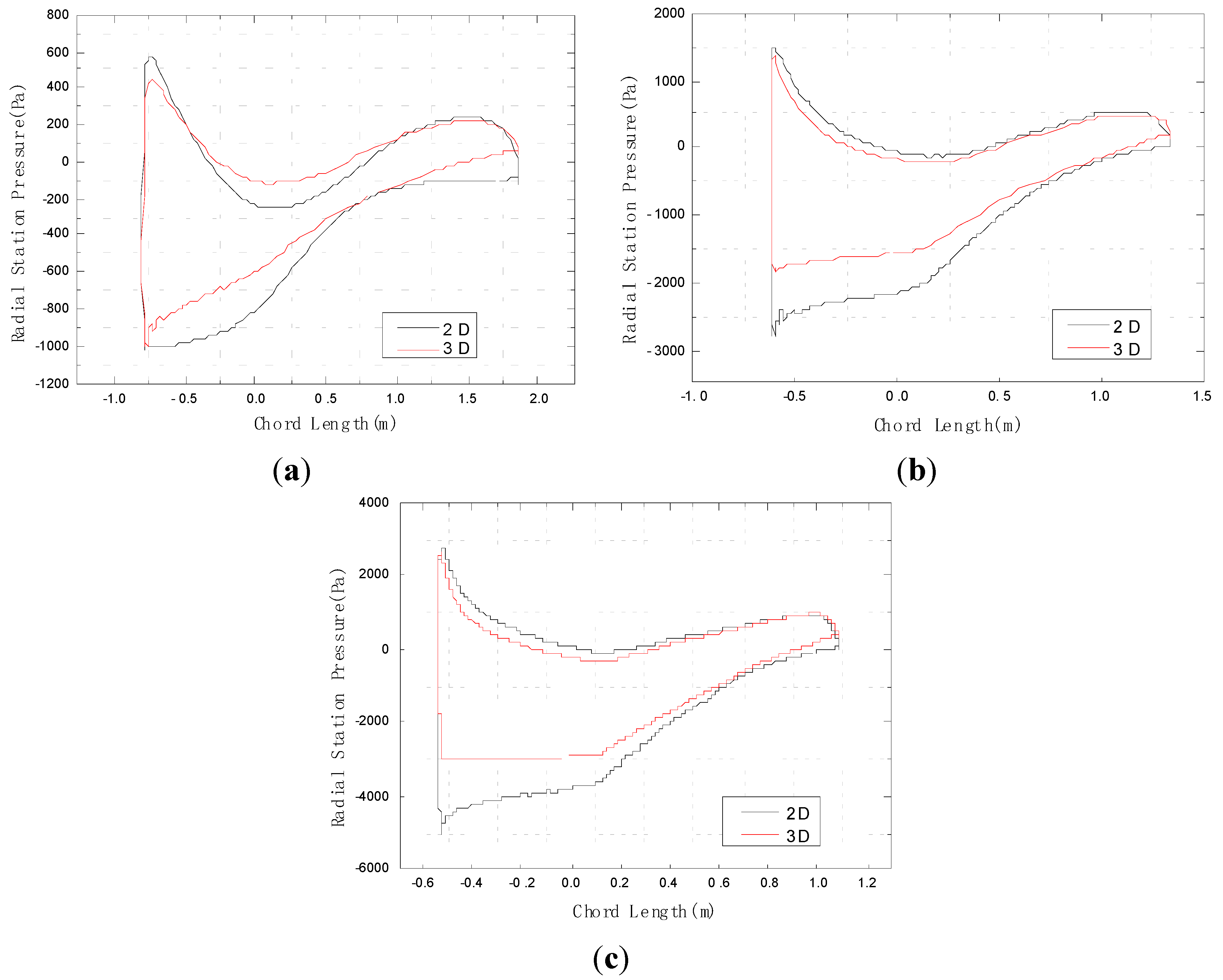

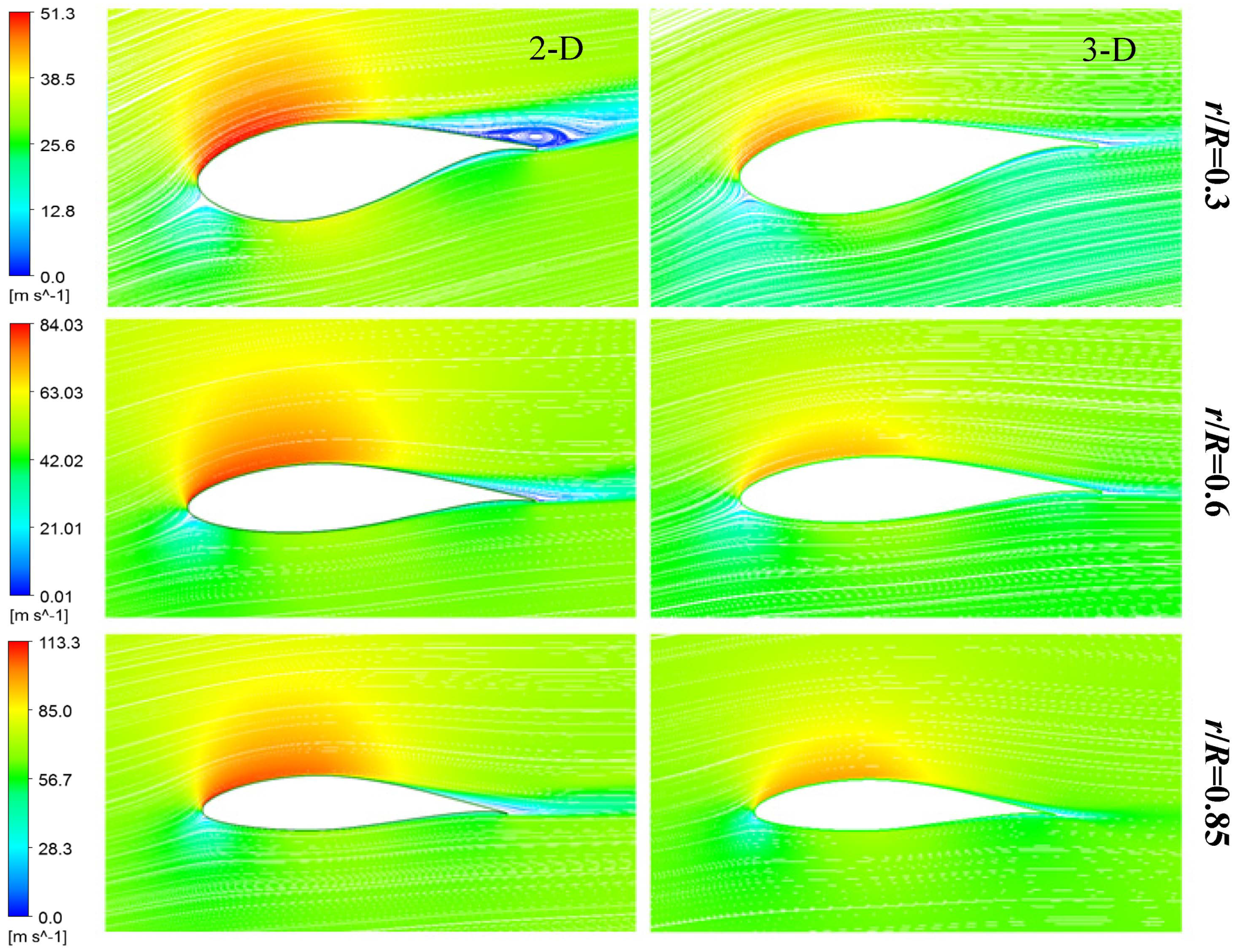

3.3. Rotational Effects

4. Structural Analysis

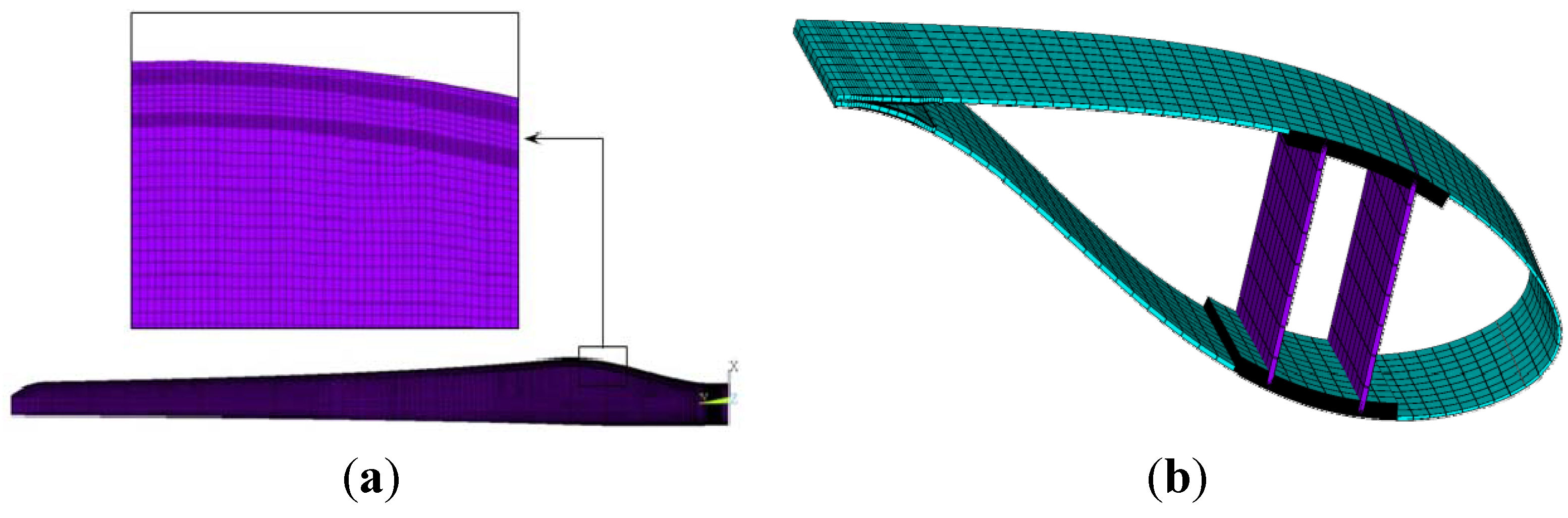

4.1. Finite Element Modeling of the Blade

| Material name | Position | E11 (GPa) | E22 (GPa) | E12 (GPa) | Density (kg/m3) | NUXY |

|---|---|---|---|---|---|---|

| UD | Spar | 42.19 | 12.53 | 3.52 | 1910 | 0.24 |

| 3AX | Skin | 26.90 | 13.41 | 7.53 | 1910 | 0.47 |

| 2AX | Skin | 11.47 | 11.47 | 11.70 | 1909 | 0.614 |

| Balsa Wood | Core | 3.5 | 0.85 | 0.15 | 151 | 0.30 |

| PVC Foam | Core | 0.05 | 0.05 | 0.02 | 60 | 0.085 |

| PET Foam | Core | 0.06 | 0.06 | 0.02 | 110 | 0.085 |

4.2. Dynamic Behavior

| Mode order | Shape | Calculated frequence (Hz) | Natural frequence (Hz) | Absolute error |

|---|---|---|---|---|

| 1 | flapwise | 1.01 | 0.96 | 5.21% |

| 2 | edgewise | 1.49 | 1.48 | 0.67% |

| 3 | flapwise | 3.02 | 2.88 | 4.86% |

| 4 | edgewise | 4.84 | 4.93 | 1.82% |

| 6 | torsional | 8.42 | 8.40 | 0.23% |

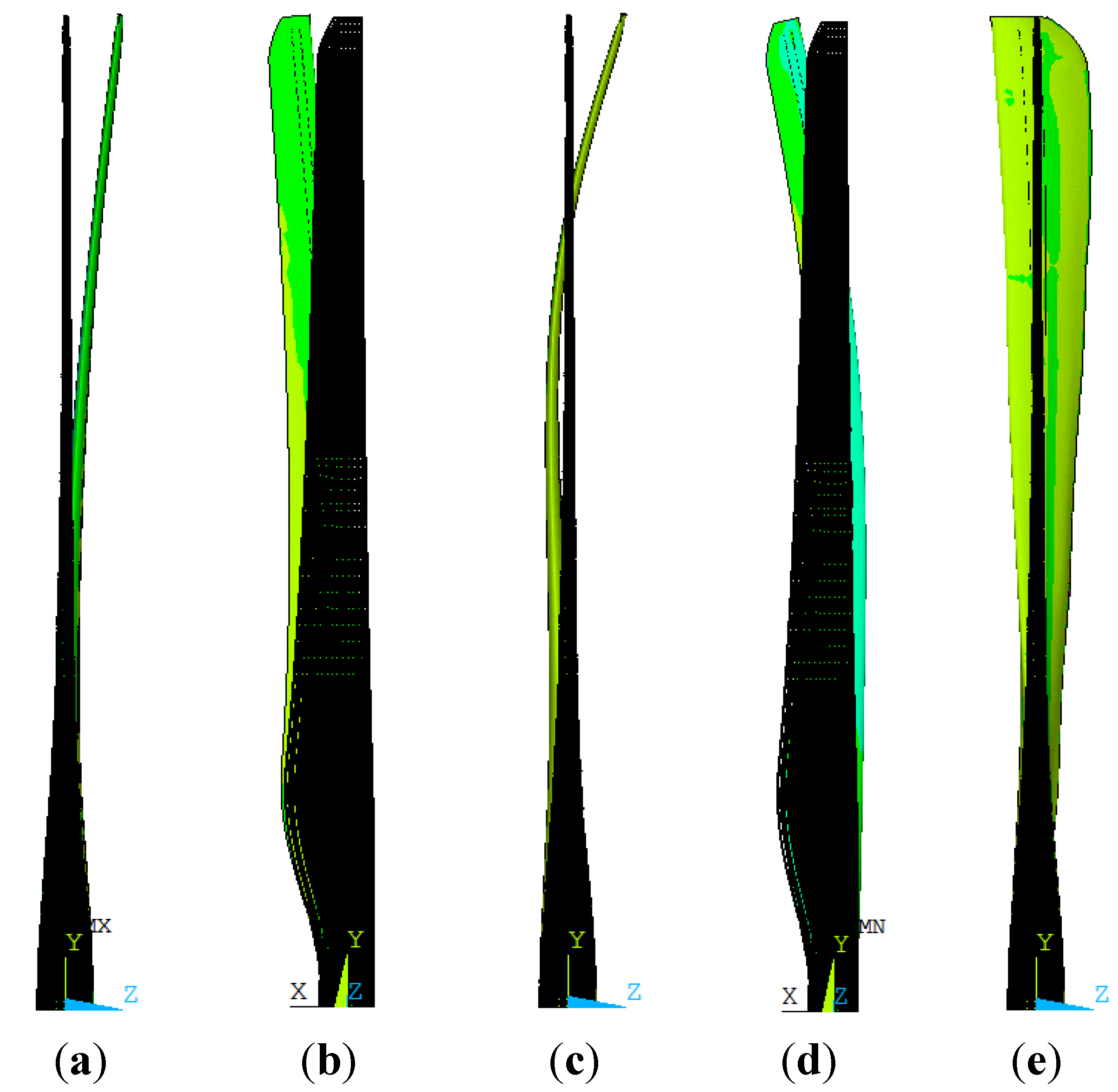

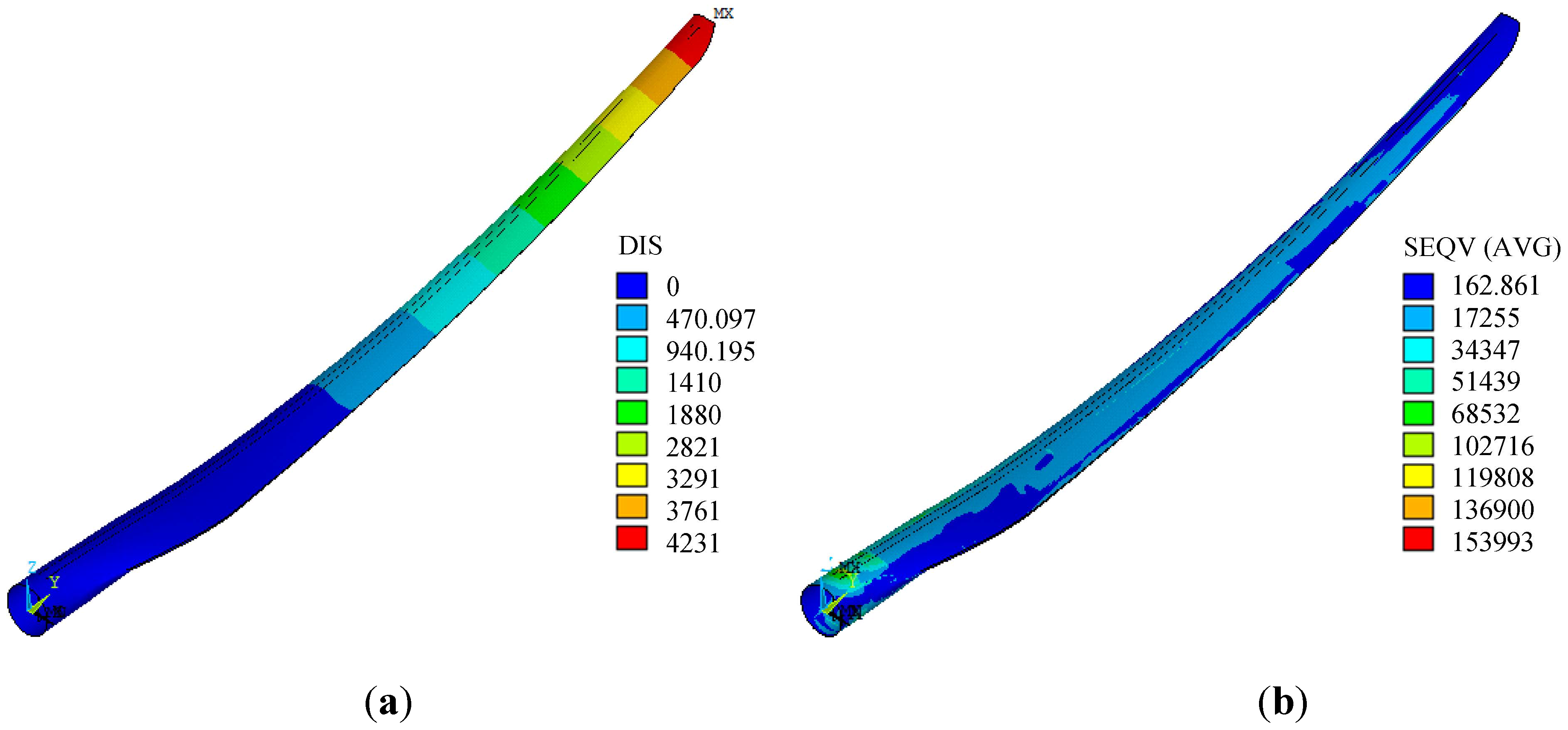

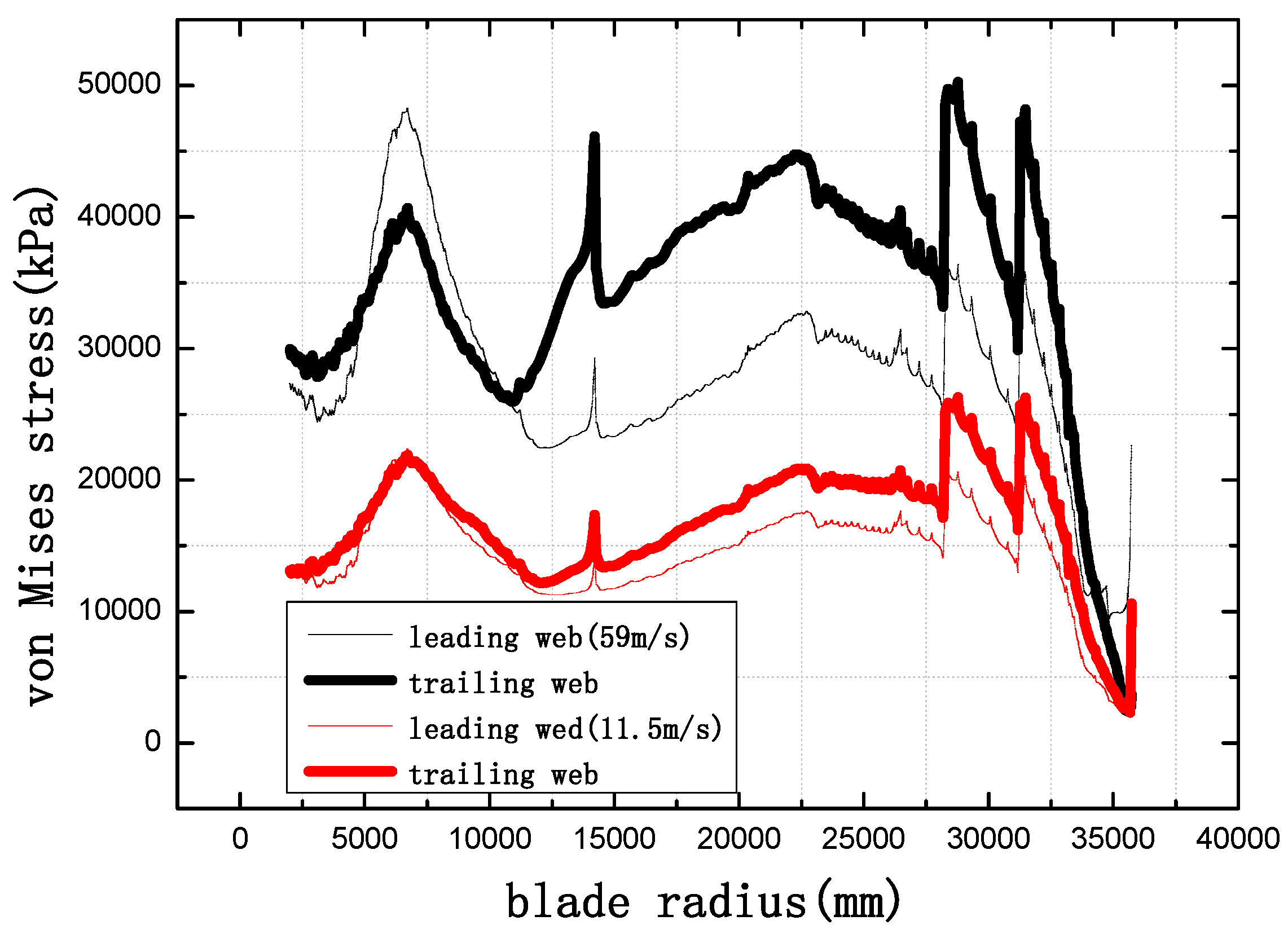

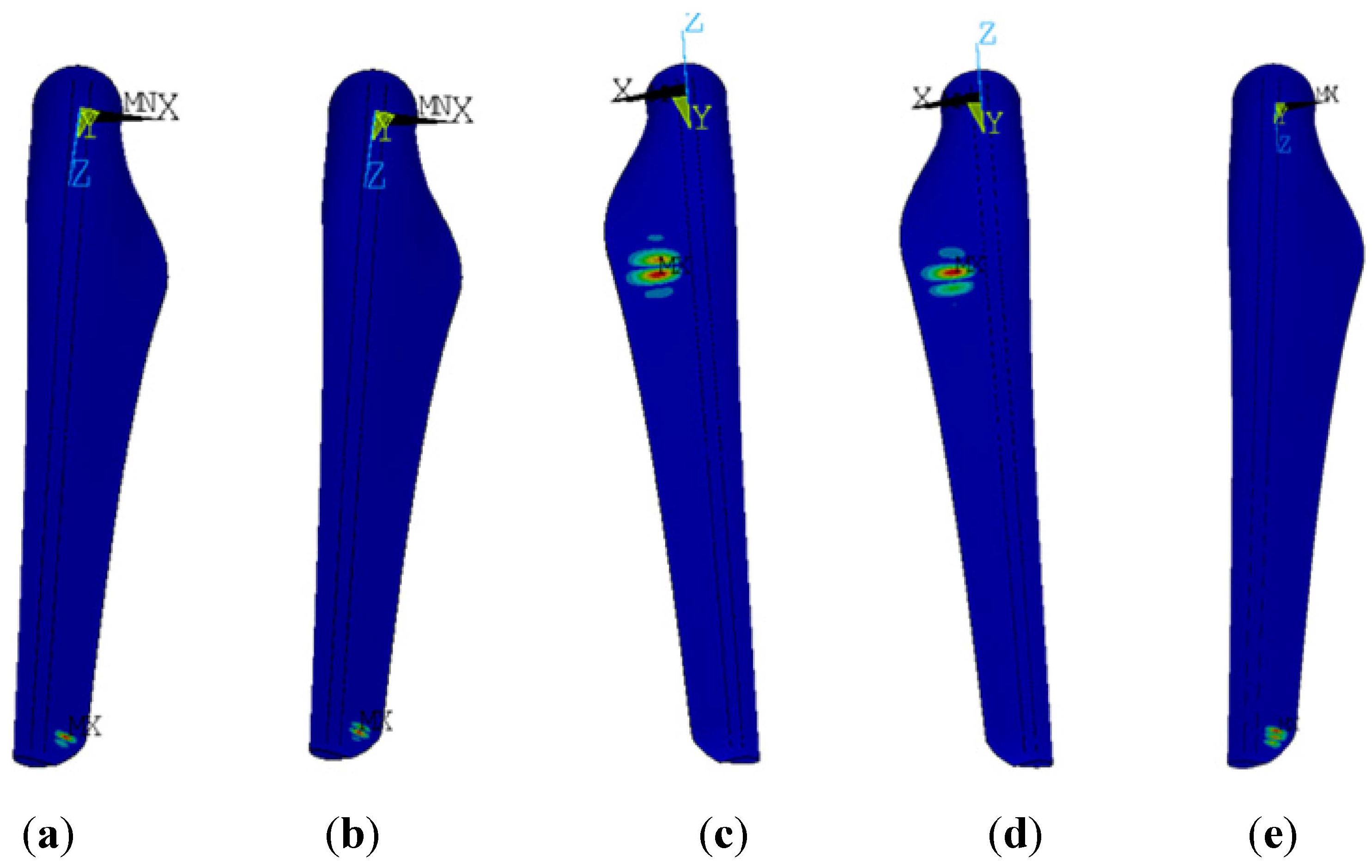

4.3. Static Analysis under Limit Load

| Model number | Load factor | Location |

|---|---|---|

| 1st mode (a) | 1.5303 | Tip |

| 2nd mode (b) | 1.6779 | Tip |

| 3rd mode (c) | 2.2855 | Shoulder |

| 4th mode (d) | 2.3458 | Shoulder |

| 5th mode (e) | 2.3481 | Tip |

5. Conclusions

- (1)

- When using the SST turbulence model, the CFD method predicts reasonably well compared with GH-bladed, however, as the wind speed rises, the CFD underestimates the power output. Further work with other turbulence models is required;

- (2)

- At the design point, the BEM method predicts much higher aerodynamic loads than the CFD method while the rotational effect could promote the power output above rated working condition as it stabilizes vortex shedding and limits the growth of the separation layer. It is of great importance for sizing generator and other mechanical with accurate prediction of rotor blade loads in rotational state;

- (3)

- The peak loads derived by considering a 50-year extreme gust of 59 m/s are unidirectionally coupled to the FE-model. The calculated frequencies agree well with the test results. The blade has sufficient flap-wise bending stiffness to maintain the minimal clearance between the blade tip and the turbine tower. The blade material can provide enough resistance to extreme winds, and the buckling would appear when the distributed load exceeds 1.53 times the computed extreme wind load.

Conflict of Interest

References

- Manwell, J.F.; Mcgowan, J.G.; Rogers, A.L. Wind Energy Explained, Theory, Design and Application, 2nd ed.; John Wiley and Sons: West Sussex, UK, 2009; pp. 101–121. [Google Scholar]

- Curuin, H.D.; Coton, F.N. Validation of a Dynamic Prescribed Vortex Wake Model for Horizontal Axis wind Turbines. In Proceedings of the ASME/JSME 2007 5th Joint Fluids Engineering Conference, Fluids Engineering Division, San Diego, CA, USA, 30 July–2 August 2007; pp. 1069–1075.

- Duque, E.P.N.; Burklund, M.D.; Johnson, W. Navier-Stokes and comprehensive analysis performance predictions of the NREL phase VI experiment. J. Sol. Energy Eng. 2003, 125, 457–467. [Google Scholar] [CrossRef]

- Virk, M.S.; Homola, M.C.; Nicklasson, P.J. Effect of rime ice accretion on aerodynamic characteristics of wind turbine blade profiles. Wind Eng. 2010, 34, 207–218. [Google Scholar] [CrossRef]

- Keck, R.-E. A numerical investigation of nacelle anemometry for a HAWT using actuator disc and line models in CFX. Renew. Energy 2012, 48, 72–84. [Google Scholar] [CrossRef]

- Wuchner, R.; Kupzok, A.; Bletzinger, K.U. A framework for stabilized partitioned analysis of thin membrane-wind interaction. Int. J. Mumer. Methods Fluids 2007, 54, 945–963. [Google Scholar] [CrossRef]

- Jensen, F.M.; Falzon, B.G.; Ankersen, J.; Stang, H. Structural testing and numerical simulation of a 34 m composite wind turbine blade. Compos. Struct. 2006, 76, 52–61. [Google Scholar] [CrossRef]

- Hermann, T.M.; Mamarthupatti, D.; Locke, J.E. Postbuckling analysis of a wind turbine blade substructure. J. Sol. Energy Eng. 2005, 127, 262–280. [Google Scholar] [CrossRef]

- Rajadurai, J.S.; Christopher, T.; Thanigaiyarasu, G.; Nageswara Rao, B. Finite element analysis with an improved failure criterion for composite wind turbine blades. Forsch. Ing. 2008, 72, 193–207. [Google Scholar] [CrossRef]

- Grujicic, M.; Arakere, G.; Sellappan, V.; Vallejo, A.; Ozen, M. Structural-response analysis, fatigue-life prediction and material selection for 1 MW horizontal-axis wind-turbine blades. J. Mater. Eng. Perform. 2010, 19, 780–801. [Google Scholar]

- Grujicic, M.; Arakere, G.; Pandurangan, B.; Sellappan, V.; Vallejo, A.; Ozen, M. Multidisciplinary optimization for fiber-glass reinforced epoxy-matrix composite 5 MW horizontal-axis wind-turbine blades. J. Mater. Eng. Perform. 2010, 19, 1116–1127. [Google Scholar] [CrossRef]

- Sutherland, H.J. On the Fatigue Analysis of Wind Turbines; SANDA99-0089; Sandia National Laboratories: Albuquerque, NM, USA, 1999. [Google Scholar]

- Menter, F.R.; Kuntz, M.; Langtry, R. Ten years of industrial experience with the SST turbulence model. Heat Mass Transf. 2003, 4, 625–632. [Google Scholar]

- International Electrotechnical Commission. IEC International Standard 61400-1, Part I: Design Requirements, 3rd ed.; International Electrotechnical Commission: Geneva, Switzerland, 2005. [Google Scholar]

- Cimbala, J.M. Introduction to Computational Fluid Dynamics, 2nd ed.; Penn State University: University Park, PA, USA, 2012. [Google Scholar]

- Carcangiu, C.E. CFD-RANS Study of Horizontal Axis Wind Turbines. Ph.D. Thesis, University of Cagliari, Cagliari, Italy, 2008. [Google Scholar]

- McKittrick, L.R.; Cairns, D.S.; Mandell, J.; Combs, D.C.; Rabern, D.A.; VanLuchene, D.V. Analysis of a Composite Blade Design for the AOC 15/50 Wind Turbine Using a Finite Element Model; SAND 2001–1441; Sandia National Laboratories: Albuquerque, NM, USA, 2001. [Google Scholar]

- Larsen, G.C.; Hansen, M.H.; Baumgart, A.; Carlén, I. Modal Analysis of Wind Turbine Blades; Risø National Laboratory: Roskilde, Denmark, 2002. [Google Scholar]

- Todd, G.D.; Carne, T. Experimental modal analysis of research-sized wind turbine blades. Sound Vib. 2010, 44, 8–11. [Google Scholar]

- Bir, G.; Migliore, P. A Computerized Method for Preliminary Structural Design of Composite Wind Turbine Blades; AIAA-2001-0022; National Wind Technology Center, National Renewable Energy Laboratory: Golden, CO, USA, 2001. [Google Scholar]

- Hu, W.F.; Han, I.; Park, S.C.; Choi, D.H. Multi-objective structural optimization of a HAWT composite blade based on ultimate limit state analysis. J. Mech. Sci. Technol. 2012, 26, 129–135. [Google Scholar] [CrossRef]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license ( http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Cai, X.; Pan, P.; Zhu, J.; Gu, R. The Analysis of the Aerodynamic Character and Structural Response of Large-Scale Wind Turbine Blades. Energies 2013, 6, 3134-3148. https://doi.org/10.3390/en6073134

Cai X, Pan P, Zhu J, Gu R. The Analysis of the Aerodynamic Character and Structural Response of Large-Scale Wind Turbine Blades. Energies. 2013; 6(7):3134-3148. https://doi.org/10.3390/en6073134

Chicago/Turabian StyleCai, Xin, Pan Pan, Jie Zhu, and Rongrong Gu. 2013. "The Analysis of the Aerodynamic Character and Structural Response of Large-Scale Wind Turbine Blades" Energies 6, no. 7: 3134-3148. https://doi.org/10.3390/en6073134

APA StyleCai, X., Pan, P., Zhu, J., & Gu, R. (2013). The Analysis of the Aerodynamic Character and Structural Response of Large-Scale Wind Turbine Blades. Energies, 6(7), 3134-3148. https://doi.org/10.3390/en6073134