Simultaneous Optimization for Hybrid Electric Vehicle Parameters Based on Multi-Objective Genetic Algorithms

Abstract

:1. Introduction

2. HEV Parameter Optimization Problem Formulation

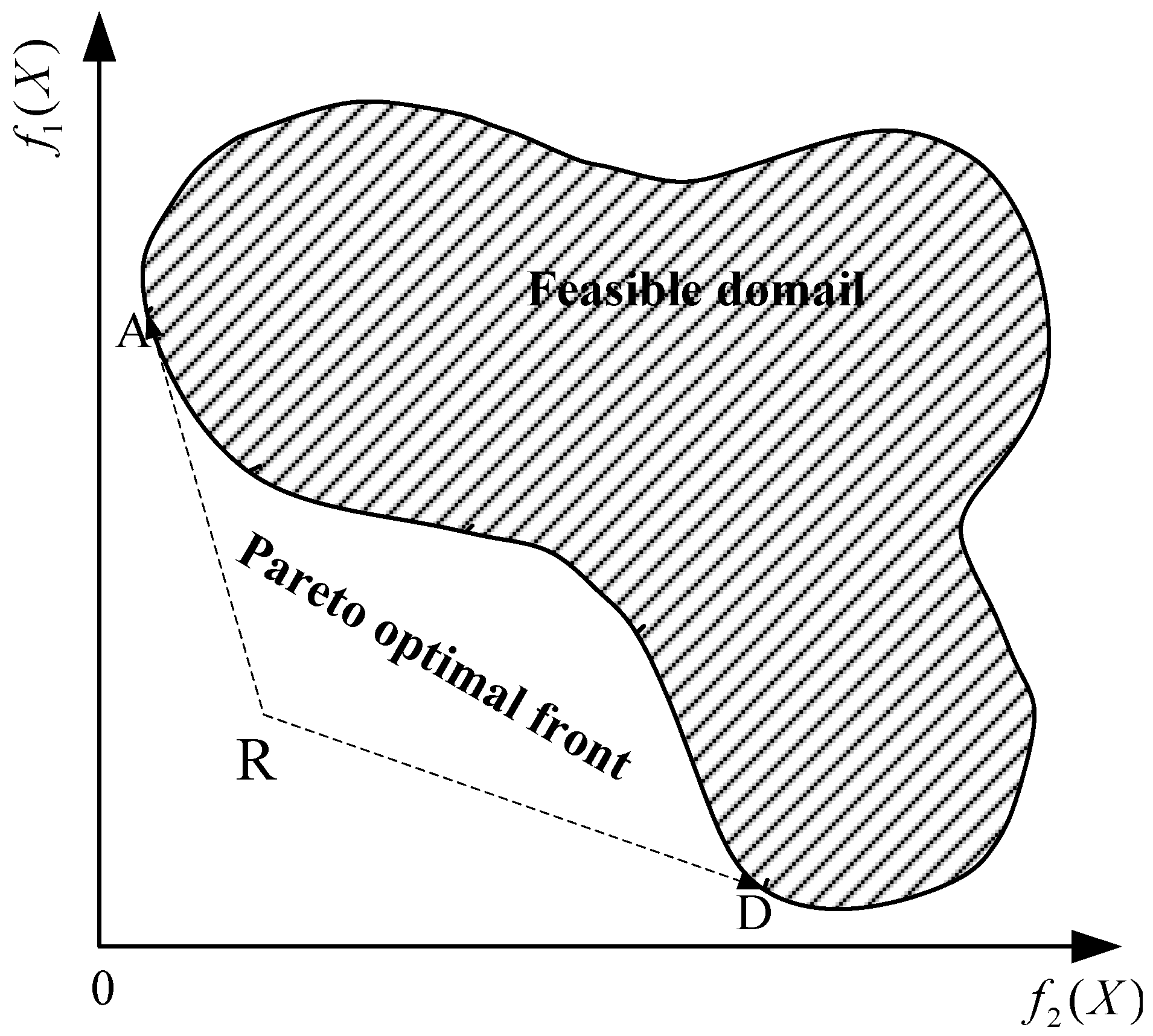

2.1. Statement of Multi-Objectives Optimization

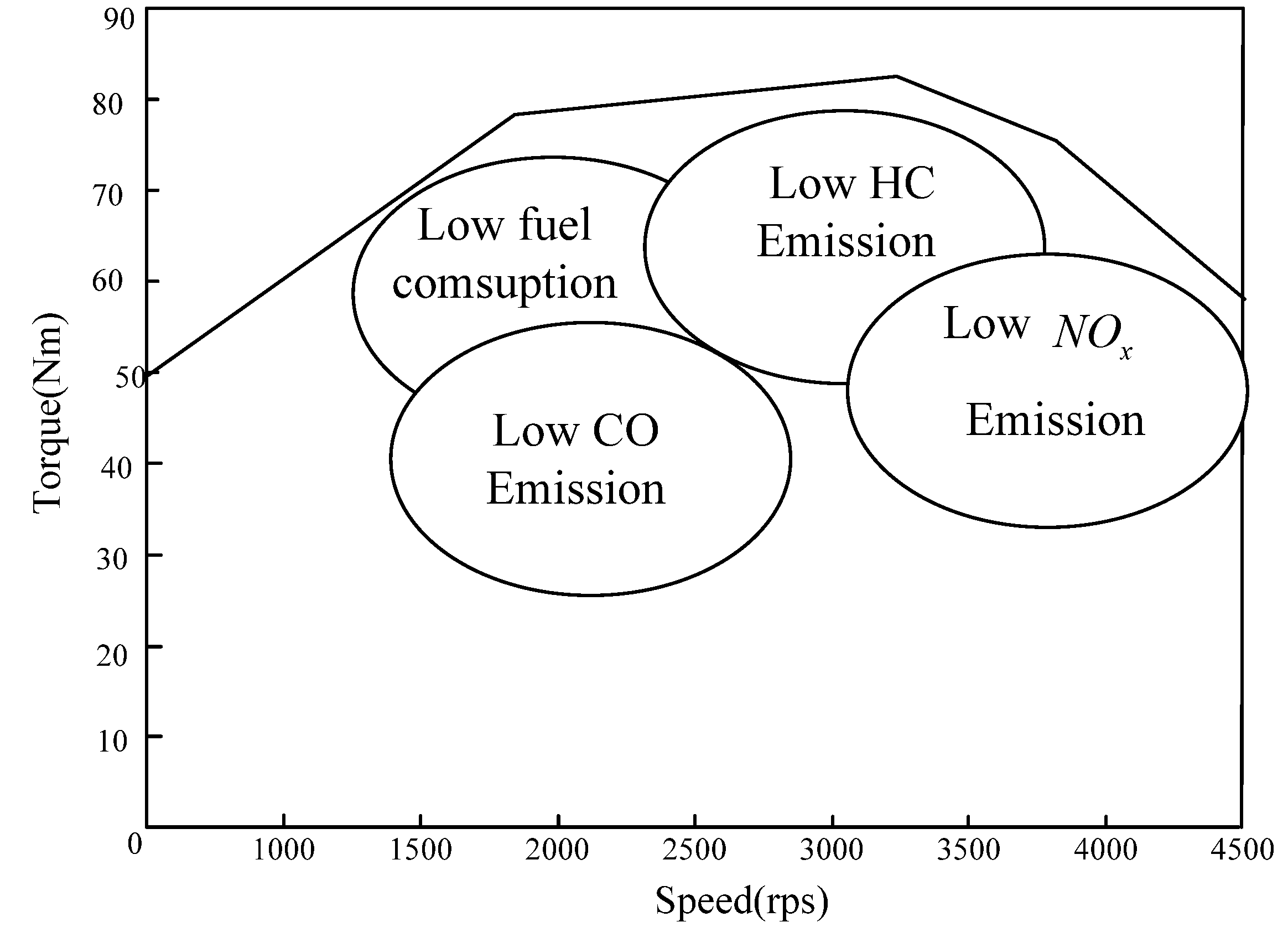

2.2. Objective of HEV Optimization

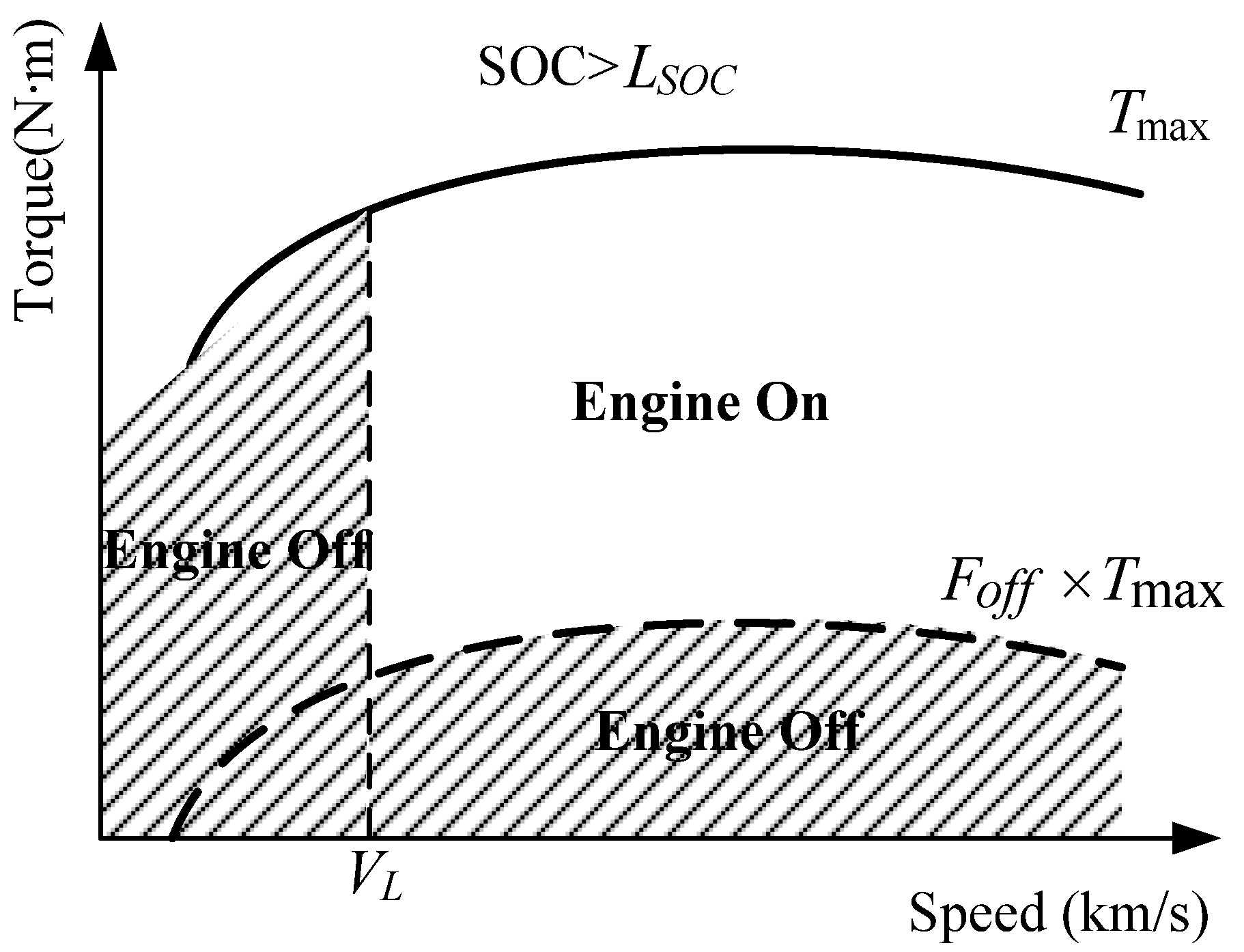

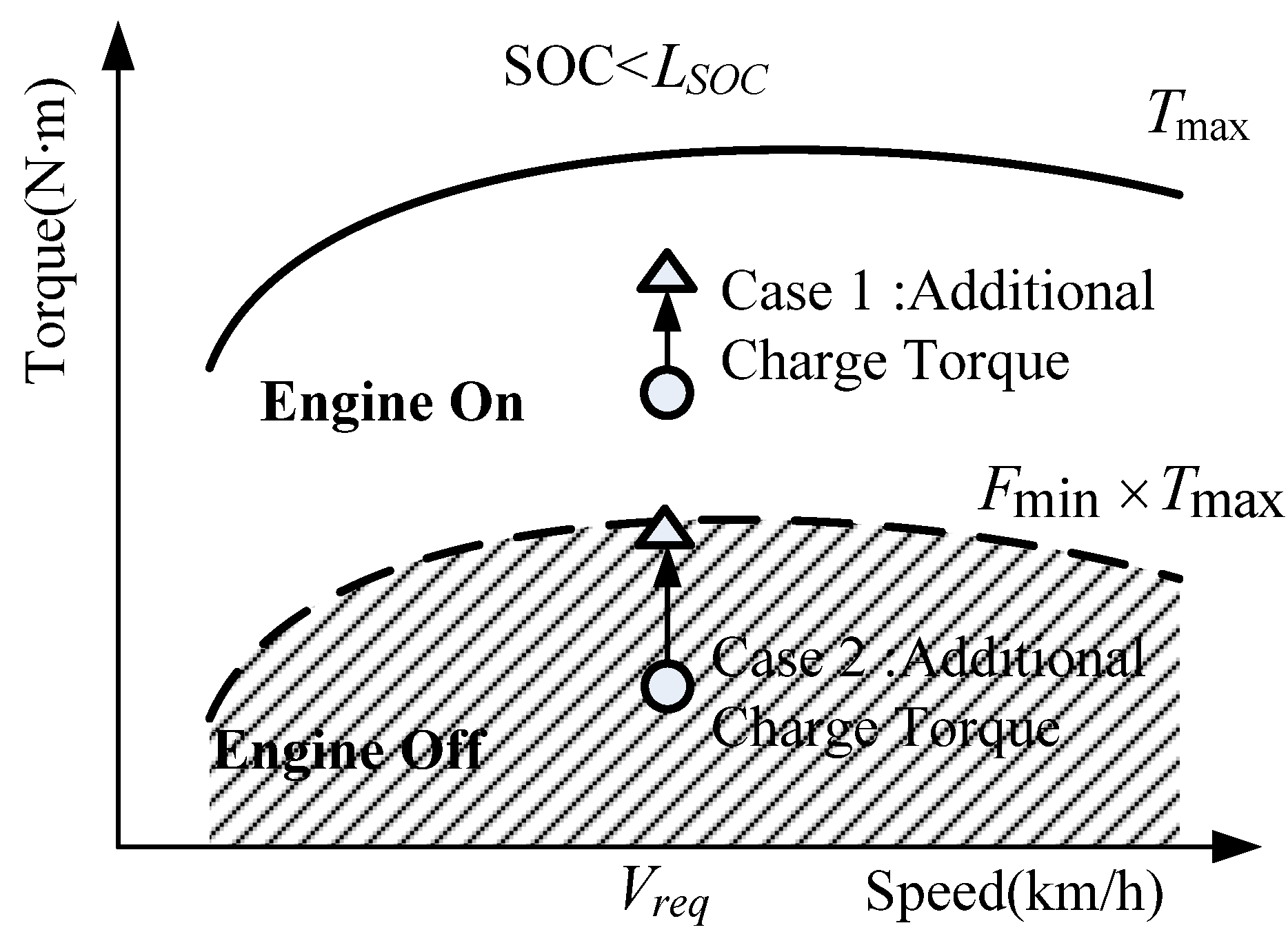

2.3. Optimization of the Powertrain and Control Strategy Parameters

| Variable | Description |

|---|---|

| PICE | Peak power of ICE |

| PEM | Rating power of EM |

| Cbat | Capacity of the battery |

| Fd | Finial reduction ratio |

| Name | Description |

|---|---|

| Highest desired battery SOC | |

| Lowest desired battery SOC; | |

| Vehicle speed threshold, below this speed the ICE turn off | |

| The minimum torque fraction of ICE turn-off | |

| The minimum torque of charge | |

| Torque fraction of charge |

2.4. Constraints of the Optimization Problem

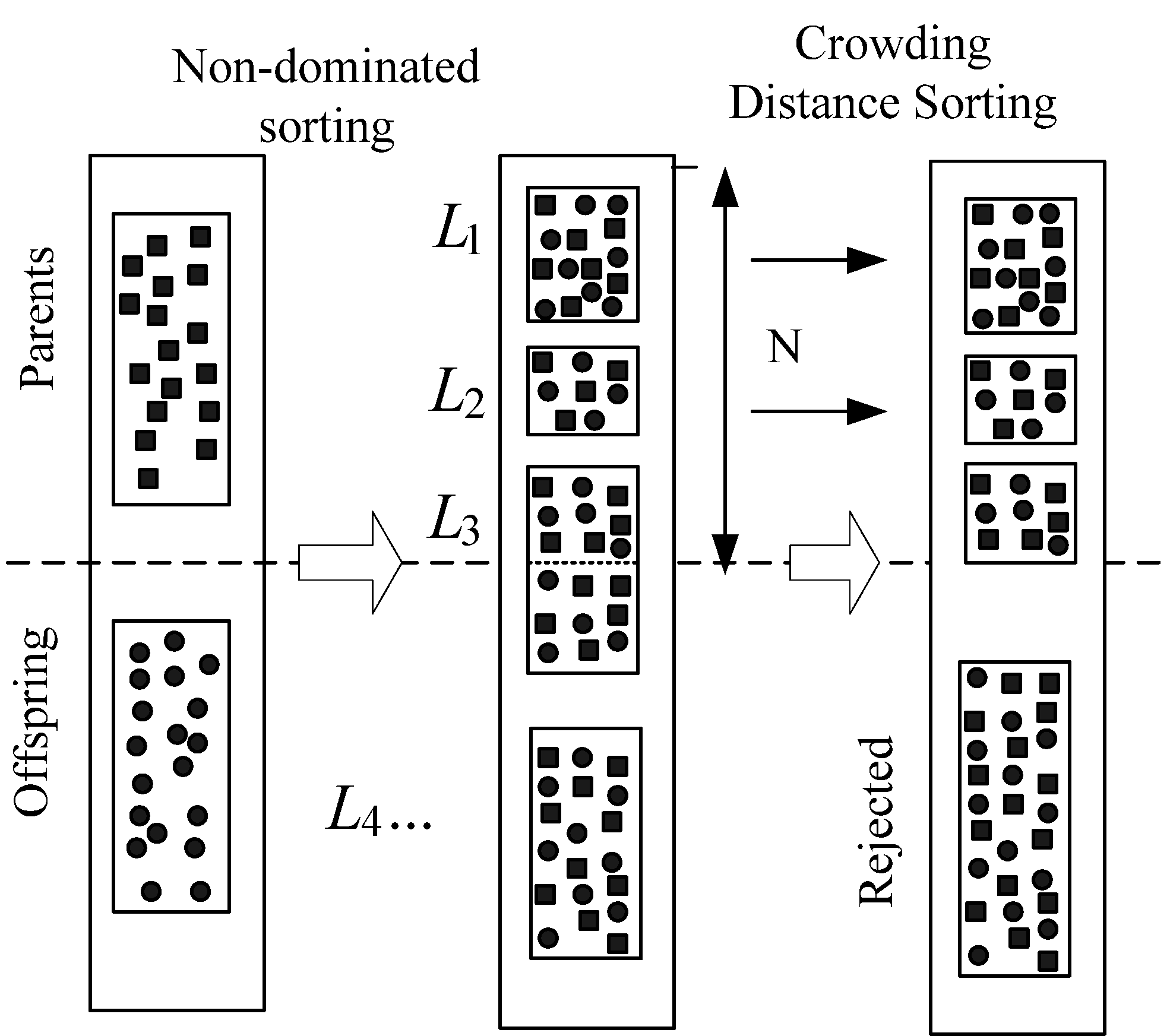

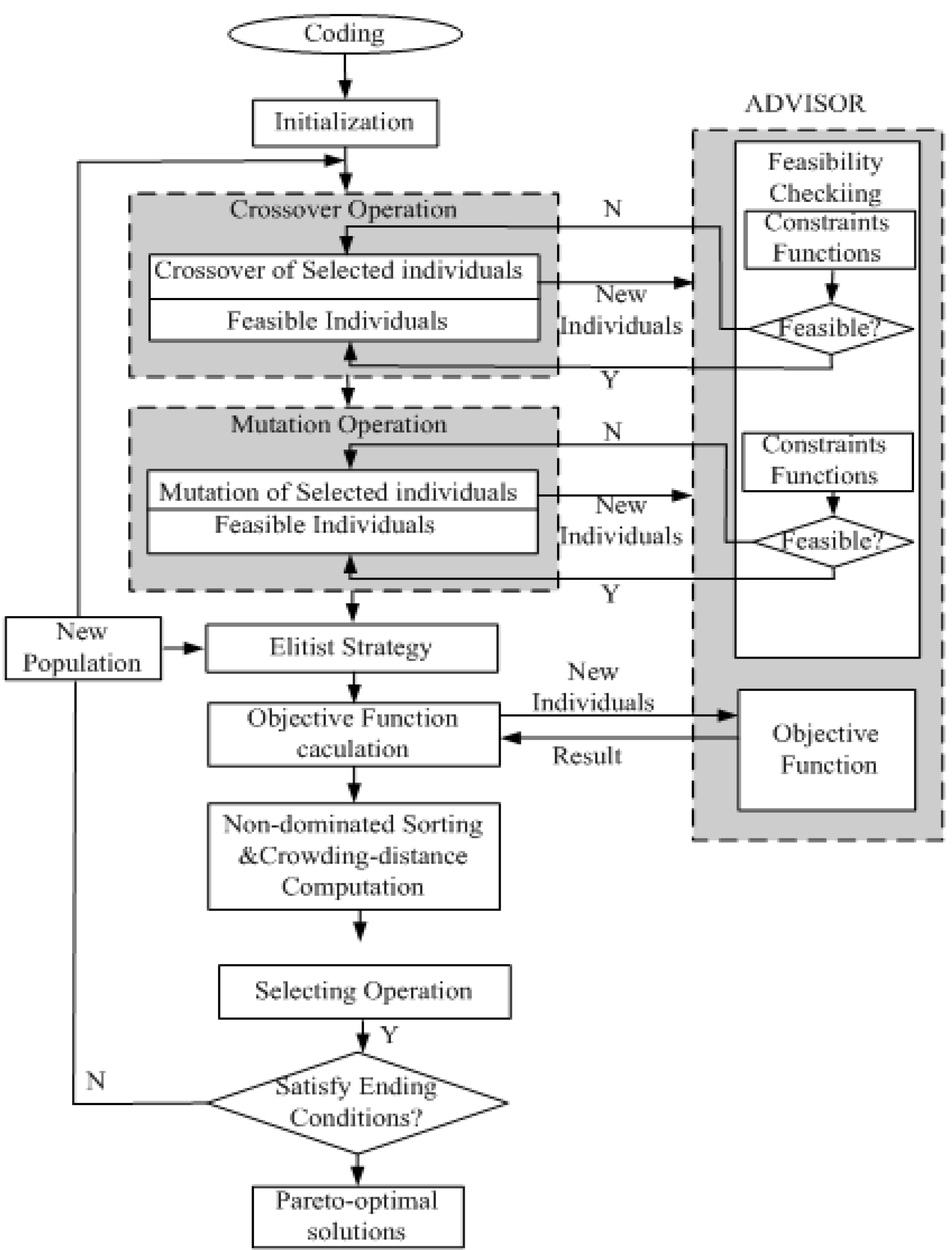

3. Optimization Based on Non-Dominated Sorting Genetic Algorithm

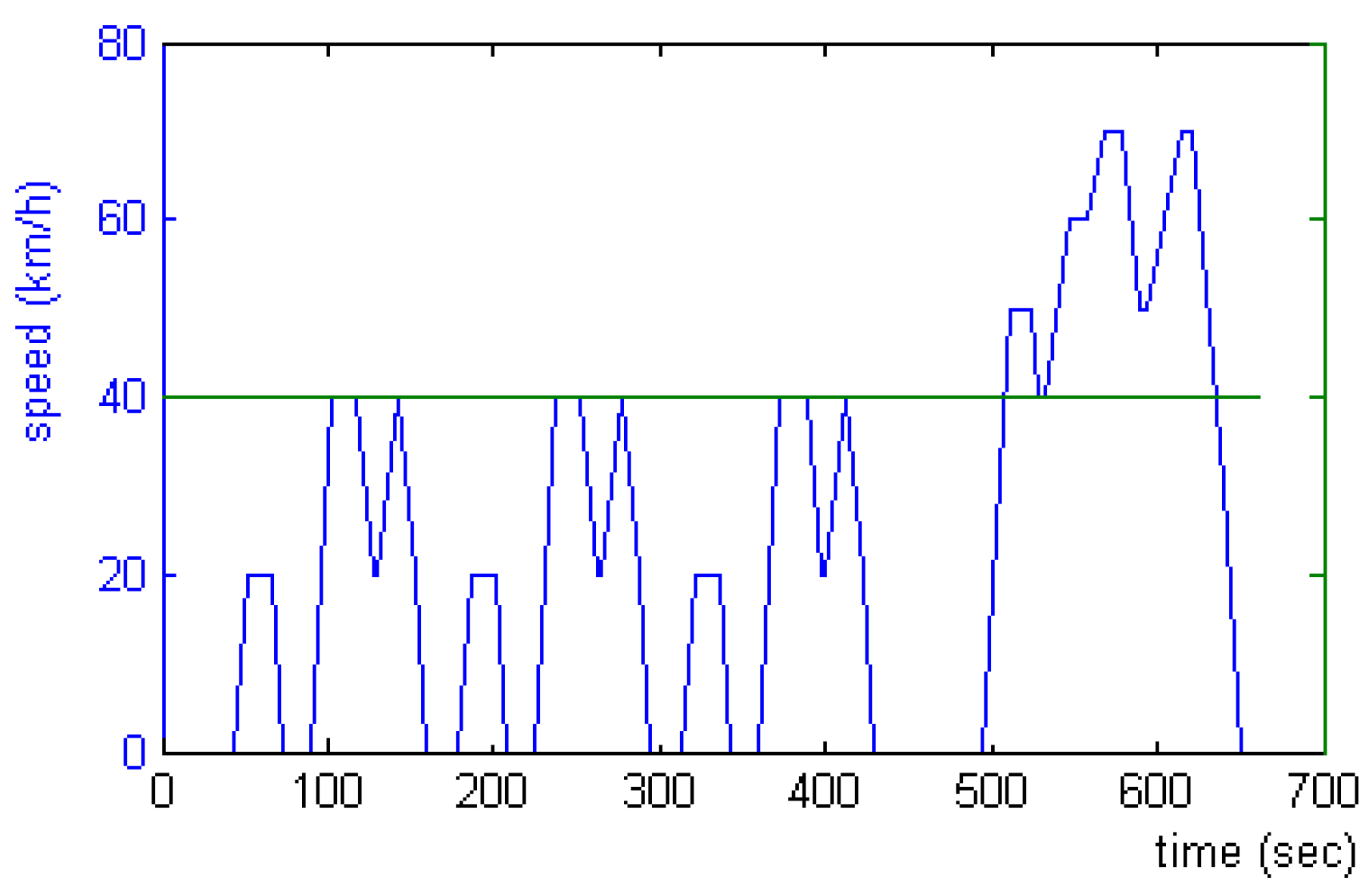

4. Case Simulation

| Design Variable | Initial Value |

|---|---|

| Calculated mass | >1350 kg |

| Transmission | >5-speed manual transmission |

| Aerodynamic drag coefficient | >0.335 |

| Vehicle front area: | >2 m2 |

| Peak power of ICE | >41 kW |

| Rating power of EM | >75 kW |

| Capacity of the battery | >26 Ah |

| Finial reduction ratio | >3.28 |

| Items | Unit | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | Initial Value | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Variables | Kw | 41 | 37 | 35 | 35 | 33 | 39 | 40 | 31 | 41 | |

| Kw | 60 | 58 | 59 | 60 | 57 | 56 | 60 | 56 | 75 | ||

| 24 | 23 | 20 | 24 | 21 | 22 | 23 | 19 | 25 | |||

| 0.75 | 0.81 | 0.82 | 0.80 | 0.82 | 0.8 | 0.8 | 0.84 | 0.7 | |||

| 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.37 | 0.6 | 0.6 | |||

| 0.15 | 0.12 | 0.1 | 0.18 | 0.1 | 0.13 | 0.12 | 0.22 | 0 | |||

| 0.45 | 0.6 | 0.5 | 0.5 | 0.45 | 0.52 | 0.6 | 0.6 | 0.4 | |||

| N·m | 20 | 15 | 19 | 17 | 18 | 16 | 12 | 17 | 15.25 | ||

| Km/h | 12 | 11 | 18 | 15 | 15 | 10 | 8 | 15 | 0 | ||

| Fd | 3.46 | 3.93 | 3.82 | 3.92 | 3.60 | 3.61 | 3.56 | 3.9 | 3.28 | ||

| Constraint | S | 9.7 | 9.8 | 9.9 | 9.7 | 10 | 9 | 10.2 | 10.3 | 9 | |

| S | 5 | 5 | 4.9 | 4.8 | 5.2 | 4.5 | 5.3 | 5.1 | 4.5 | ||

| S | 20.3 | 20.7 | 21.7 | 21.1 | 21.2 | 18.2 | 21.6 | 22.9 | 18.4 | ||

| Grad | % | 20.6 | 19.6 | 20.4 | 20.4 | 19.3 | 20.9 | 20 | 18.8 | 21.5 | |

| % | −0.4 | −0.3 | −0.2 | −0.3 | −0.4 | −0.3 | −0.04 | −0.4 | −0.1 | ||

| Objective | Fuel | L/100 km | 6.3 | 6.2 | 6.0 | 6.0 | 5.9 | 6.2 | 6.4 | 5.9 | 7.5 |

| CO | g/km | 1.958 | 2.371 | 2.493 | 2.228 | 2.989 | 2.361 | 2.100 | 3.179 | 2.601 | |

| HC | g/km | 0.374 | 0.350 | 0.324 | 0.330 | 0.306 | 0.372 | 0.365 | 0.291 | 0.401 | |

| NOx | g/km | 0.339 | 0.330 | 0.319 | 0.326 | 0.289 | 0.328 | 0.337 | 0.273 | 0.357 | |

- Fuel: [5.9, 6.5] (L/100km)

- CO: [1.960, 3.179] (g/km)

- HC: [0.291, 0.374] (g/km)

- NOx: [0.289, 0.329] (g/km)

- Fuel: 7.5L/100 km, CO: 2.601 g/km, HC: 0.401 g/km, NOx: 0.357 g/km.

5. Conclusions

References

- Gao, W.; Porandla, S.K. Design Optimization of a Parallel Hybrid Electric Powertrain. In Proceedings of 2005 IEEE Conference on Vehicle Power and Propulsion, Mississippi, MS, USA, 7–9 September 2005.

- Gakdi, V.; Ippolite, L.; Piccolo, A.; Vaccaro, A. Evaluation of Emissions Influence on Hybrid electric vehicles Sizing. In Proceedings of International Conference on Power Electronics, Electrical Drives, Advanced Machines and Power Quality, Ischia, Italy, 13–16 June 2000.

- Zhu, Y.; Chen, Y.; Tian, G. A Four-Step Method to Design an Energy Management Strategy for Hybrid Vehicle. In Proceedings of the 2004 American Control Conference, Boston, MA, USA, 30 June–2 July 2004.

- Fellini, R.; Michelena, N.; Papalambros, P.; Sasena, M. Optimal Design of Automotive Hybrid Powertrain Systems. In Proceedings of First International Symposium On Environmentally Conscious Design and Inverse Manufacturing, Tokyo, Japan, 3 February 1999.

- Wipke, K.; Markel, T. Optimization Techniques for Hybrid Electric Vehicle Analysis Using ADVISOR. In Proceedings of ASME, International Mechanical Engineering Congress and Exposition, New York, NY, USA, 11–16 November 2001.

- Piccolo, A.; Ippolito, L.; Galdi, V.; Vaccaro, A. Optimization of energy flow management in hybrid electric vehicles via genetic algorithms. IEEE/ASME Int. Conf. Adv. Intell. Mechatron. 2001, 1, 434–439. [Google Scholar]

- Chen, J.; Li, Y.; Wang, J. Simultaneous optimization of fuel consumption and emissions for a parallel hybrid electric SUV using fuzzy logic control. Int. J. Veh. Des. 2008, 46, 204–218. [Google Scholar]

- Montazeri-Gh, M.; Poursamad, A.; Ghalichi, B. Application of genetic algorithm for optimization of control strategy in parallel hybrid electric vehicles. J. Franklin Inst. 2006, 343, 420–435. [Google Scholar]

- Schwarzer, V. Stochastic of an energy management controller for hybrid electric vehicles. In Proceedings of The 25th World Battery, Hybrid and Fuel Cell Vehicle Symposium and Exhibition, Shenzhen, China, 5–9 November 2010.

- Cook, R.; Molina-Cristobal, A.; Parks, G.T.; Correa, C.O.; Clarkson, P.J. Multi-objective Optimisation of a Hybrid Electric Vehicle: Drive Train and Driving Strategy. In Proceedings of the Fourth International Conference on Evolutionary Multi-Criterion Optimization, Matsushima, Japan, 5–8 March 2007.

- Hui, S. Multi-objective optimization for hydraulic hybrid vehicle based on adaptive simulated annealing genetic algorithm. J. Eng. Appl. Artif. Intell. 2010, 23, 27–33. [Google Scholar]

- Wang, Z.; Huang, B.; Li, W.; Xu, Y. Particle Swarm Optimization for Operational Parameters of Series Hybrid Electric Vehicle. In Proceedings of IEEE International Conference on Robotics and Biomimetics, Kunming, China, 17–20 December 2006.

- Wu, X.; Cao, B.; Wen, J.; Bian, Y. Particle swarm optimization for plug-in hybrid electric vehicle control strategy parameter. IEEE Veh. Power Propul. Conf. 2008. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, C.H.; Cui, N.X. PSO Algorithm-Based Parameter Optimization for HEV Powertrain and its Control Strategy. Int. J. Automot. Technol. 2008, 9, 53–69. [Google Scholar]

- Johnson, V.H.; Wipke, K.B.; Rausen, D.J. HEV Control Strategy for Real-time Optimization of Fuel Economy and Emissions. SAE Paper 2000. [Google Scholar] [CrossRef]

- Kimura, A.; Abe, T.; Saski, S. Drive force control of a Parallel-series Hybrid System. JSAE Rev. 1999, 20, 337–341. [Google Scholar]

- Ishibuchi, H.; Murata, T. A multi-objective genetic local search algorithm and its application to flowshop scheduling. IEEE Trans. Syst. Man Cybern. 1998, 28, 392–403. [Google Scholar]

- Fonseca, C.M.; Fleming, P.J. Multi-objective optimization and multiple constraint handling with evolutionary algorithms—Part I: Unified formulation. IEEE Trans. Syst. Man Cybern. 1998, 28, 26–37. [Google Scholar]

- Kelly, K.J.; Rajagopalan, A. Benchmarking of OEM Hybrid Electric Vehicles on NREL; Technical Report Number NREL/TP-540-31086; National Renewable Energy Laboratory: Golden, CO, USA, 2001. [Google Scholar]

- Cuddy, M.R.; Wipke, K.B. Analysis of the fuel benefit of drivetrain hybridization. In Proceedings of SAE International World Congress Exposition, Detroit, MI, USA, 24–27 February 1997.

- Moore, T.C.; Lovins, A.B. Vehicle design strategies to meet and exceed PNGV goals, Electric and Hybrid Vehicles—Implementation of Technology. SAE Spec. Publ. 1995, 79–121. [Google Scholar]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A Fast and Elitist Multi-objective Genetic Algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 16, 182–197. [Google Scholar]

- Ishibashi, H.; Aguirre, H.E.; Tanaka, K.; Sugimura, T. Multi-objective optimization with improved genetic algorithm. IEEE Int. Conf. Syst. Man Cybern. 2000, 5, 3852–3857. [Google Scholar]

- Venkatraman, S.; Yen, G. A simple elitist genetic algorithm for constrained optimization. Congr. Evol. Comput. 2004, 1, 288–295. [Google Scholar]

- Markel, T.; Brooker, A.; Hendricks, T. ADVISOR: A Systems Analysis Tool for Advanced Vehicle Modeling. J. Power Sour. 2002, 110, 255–260. [Google Scholar]

© 2011 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Fang, L.; Qin, S.; Xu, G.; Li, T.; Zhu, K. Simultaneous Optimization for Hybrid Electric Vehicle Parameters Based on Multi-Objective Genetic Algorithms. Energies 2011, 4, 532-544. https://doi.org/10.3390/en4030532

Fang L, Qin S, Xu G, Li T, Zhu K. Simultaneous Optimization for Hybrid Electric Vehicle Parameters Based on Multi-Objective Genetic Algorithms. Energies. 2011; 4(3):532-544. https://doi.org/10.3390/en4030532

Chicago/Turabian StyleFang, Lincun, Shiyin Qin, Gang Xu, Tianli Li, and Kemin Zhu. 2011. "Simultaneous Optimization for Hybrid Electric Vehicle Parameters Based on Multi-Objective Genetic Algorithms" Energies 4, no. 3: 532-544. https://doi.org/10.3390/en4030532

APA StyleFang, L., Qin, S., Xu, G., Li, T., & Zhu, K. (2011). Simultaneous Optimization for Hybrid Electric Vehicle Parameters Based on Multi-Objective Genetic Algorithms. Energies, 4(3), 532-544. https://doi.org/10.3390/en4030532