Battery Health Diagnosis via Neural Surrogate Model: From Lab to Field

Abstract

:1. Introduction

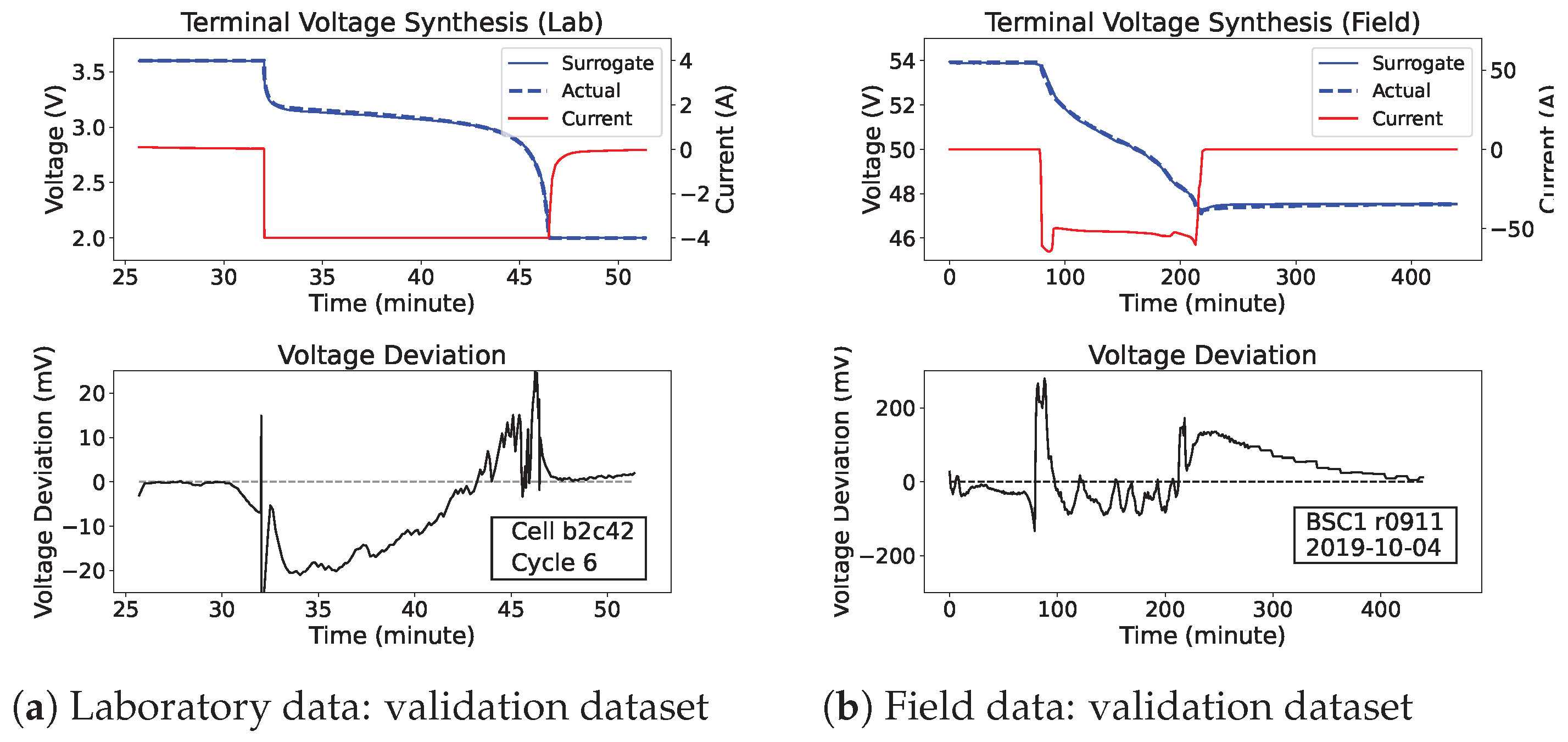

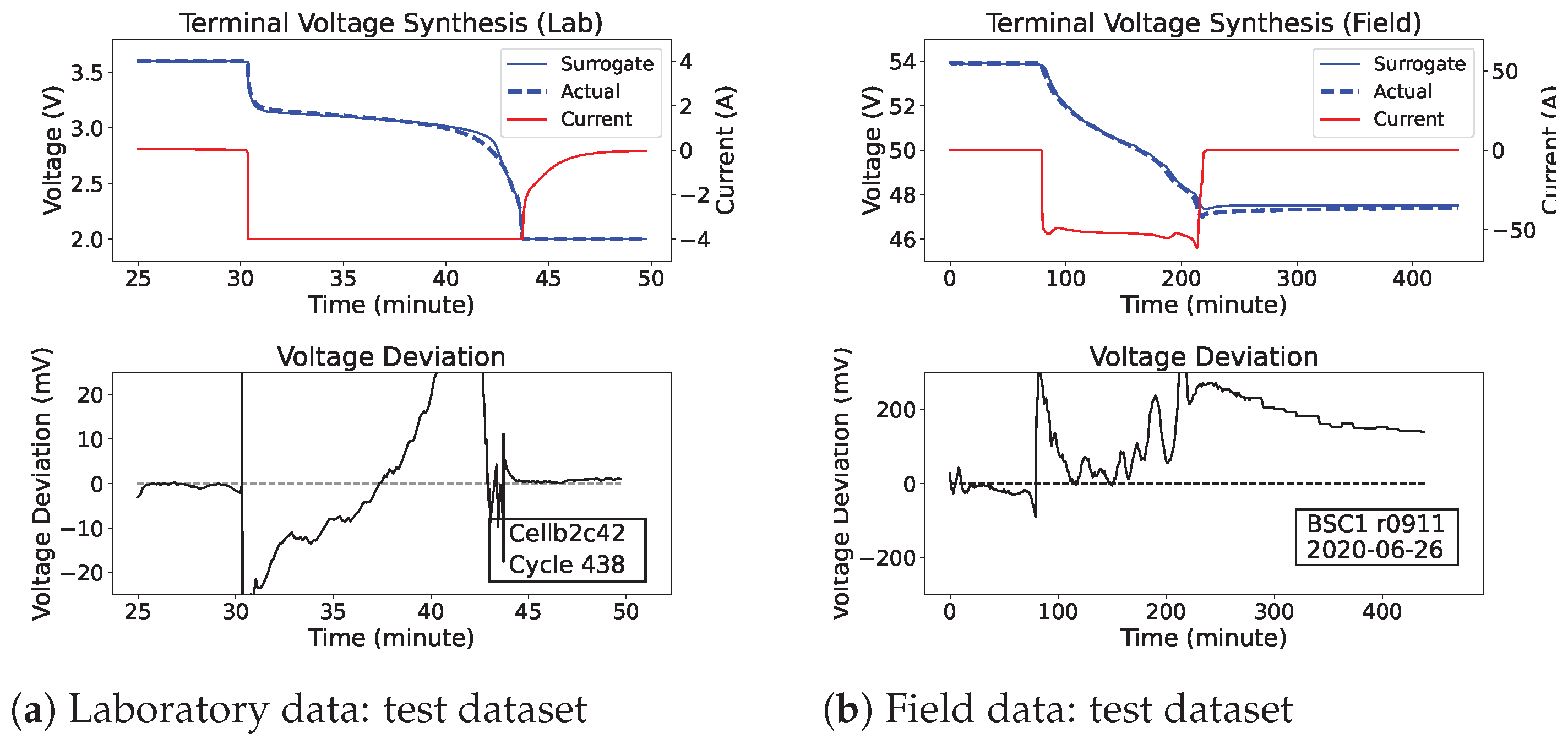

- We propose a neural surrogate model for battery modeling with instant characterization. The model synthesizes terminal voltage with mean absolute errors (MAEs) of 6.4 mV and 49 mV for laboratory and field data, respectively, which are only 0.4% and 0.29% of the voltage swing.

- The proposed model is applicable to various materials and configurations. We validate the model using two datasets: a field dataset from a PV-integrated BESS with 306 nickel–cobalt–manganese (NCM) modules (over 12,000 cells), and a laboratory dataset with 124 lithium–iron–phosphate (LFP) cells. By learning battery characteristics directly from the data, the model enables accurate modeling without battery characterization tests.

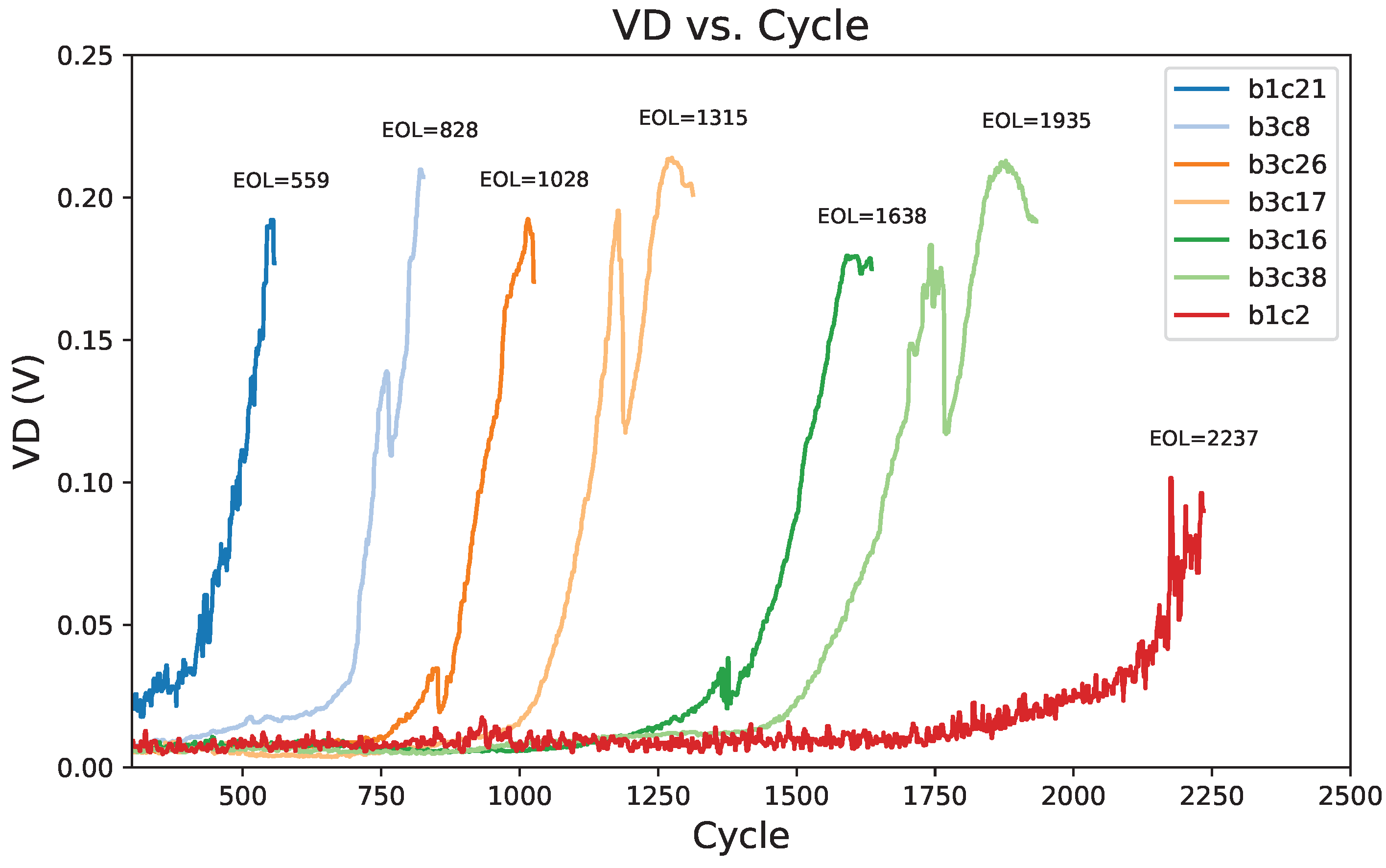

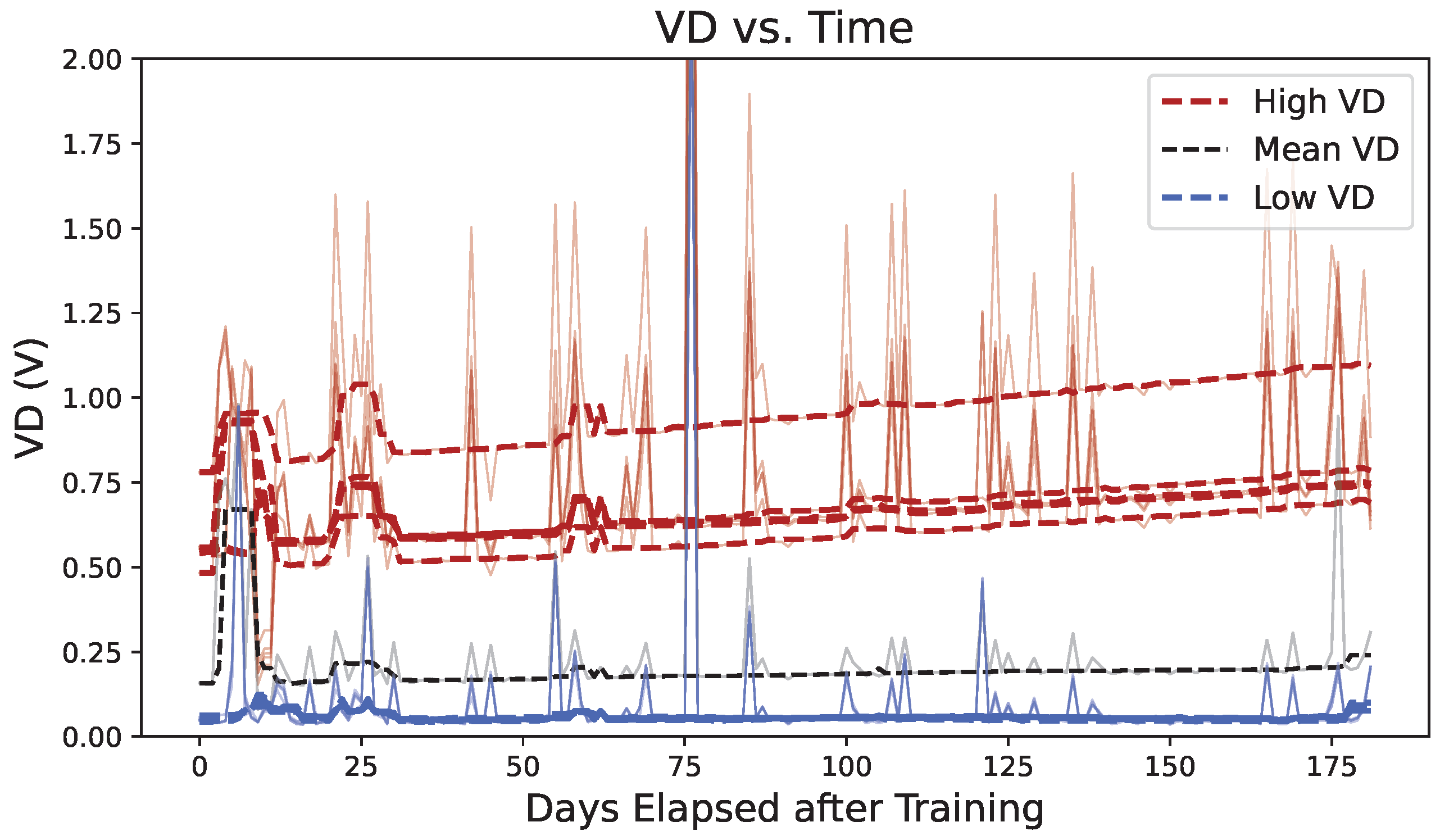

- We propose a new battery health indicator, termed voltage deviation (VD), defined as the difference between the actual terminal voltage and the voltage synthesized by the surrogate model. This allows the measurement of changes in the battery’s dynamic behavior without requiring predefined feature extraction or controlled experiments; and thus, it is possible to estimate battery health directly from operational data.

- The proposed method is not restricted to specific charging or discharging protocols. We demonstrate the method with a laboratory dataset with multi-step CC charging protocols, and a field dataset with fluctuating PV-generated currents.

2. Methodology

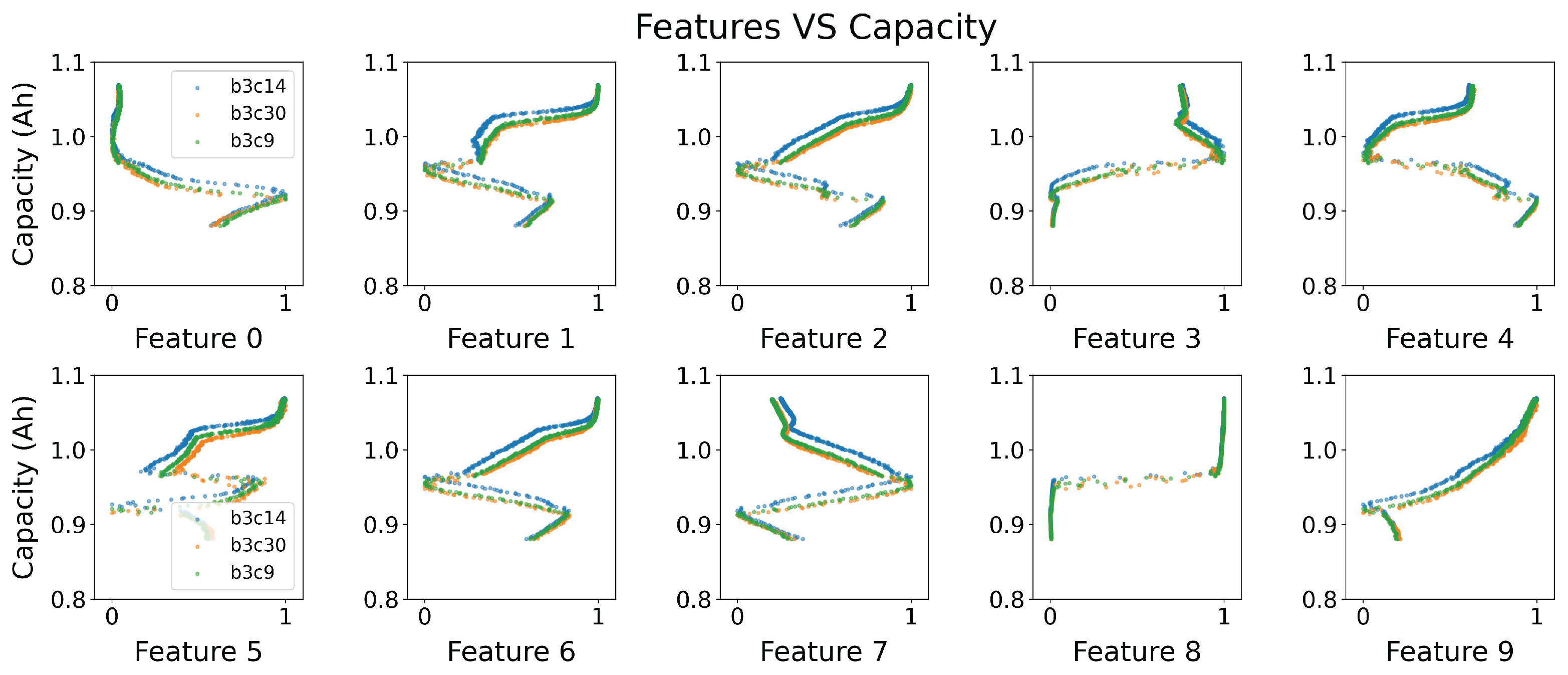

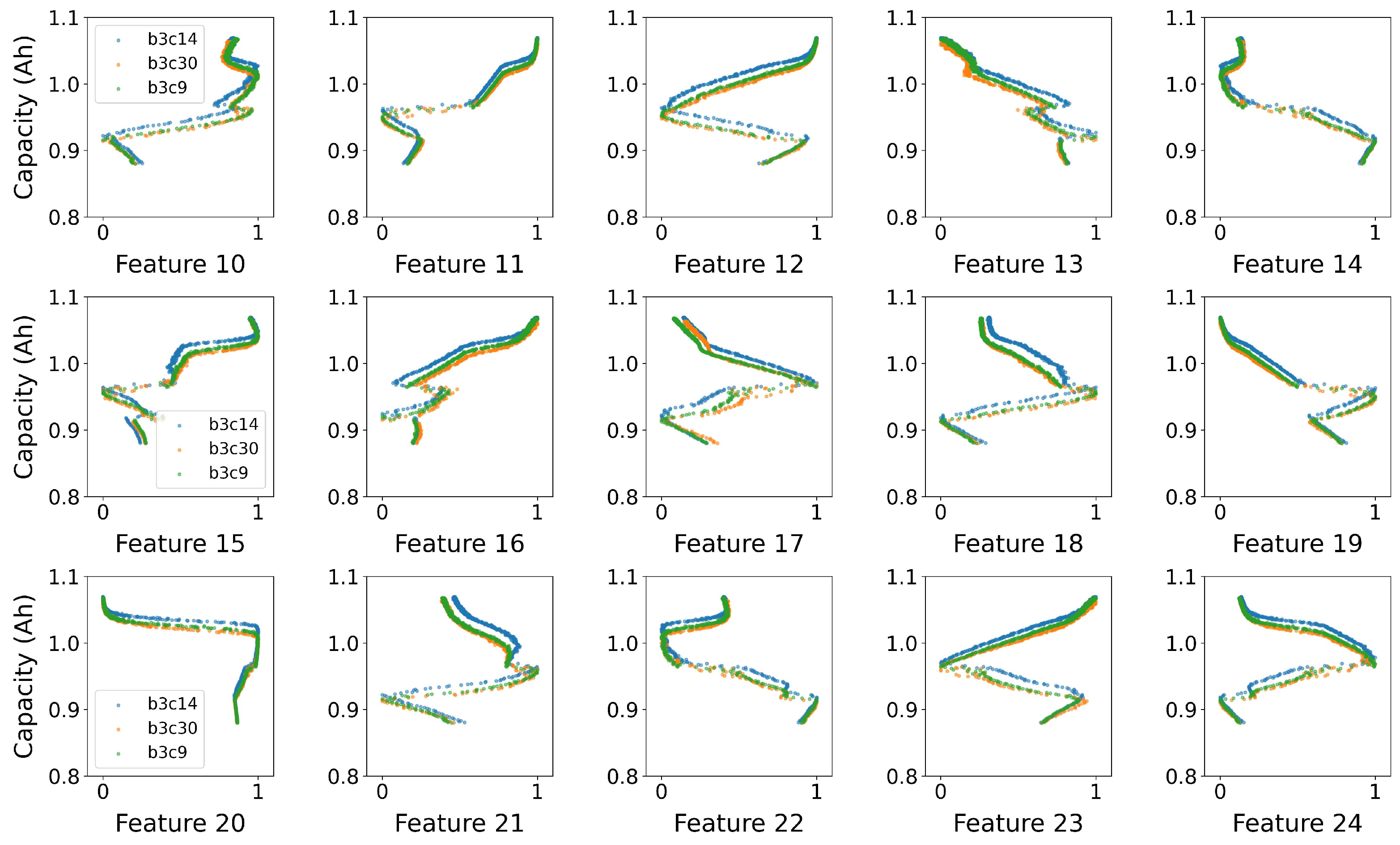

2.1. Data

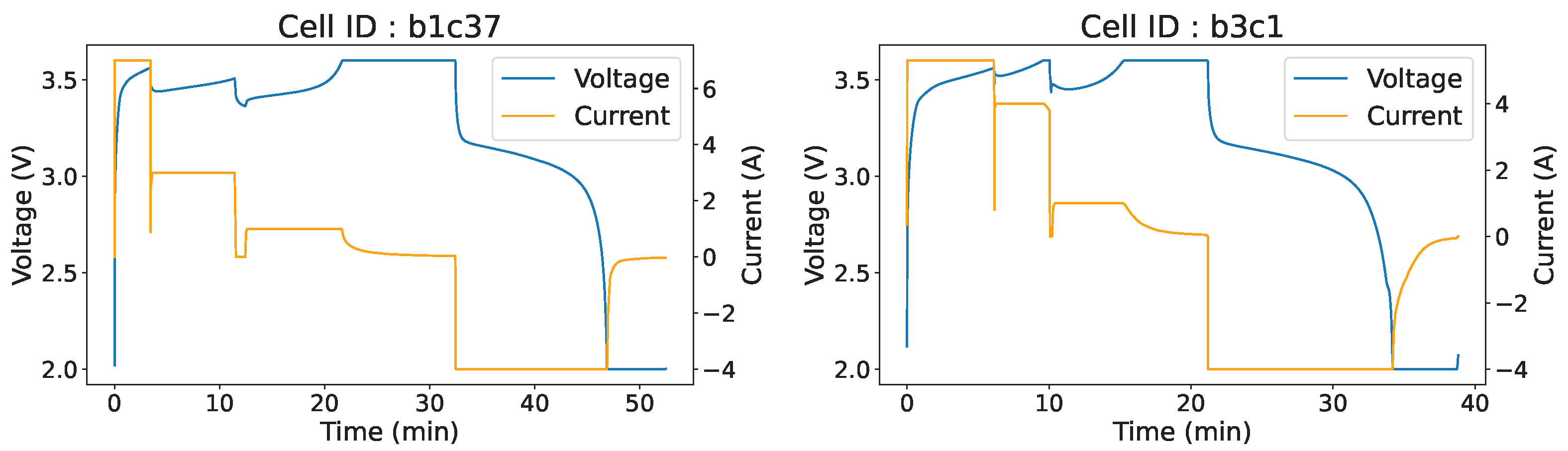

2.1.1. Laboratory Data

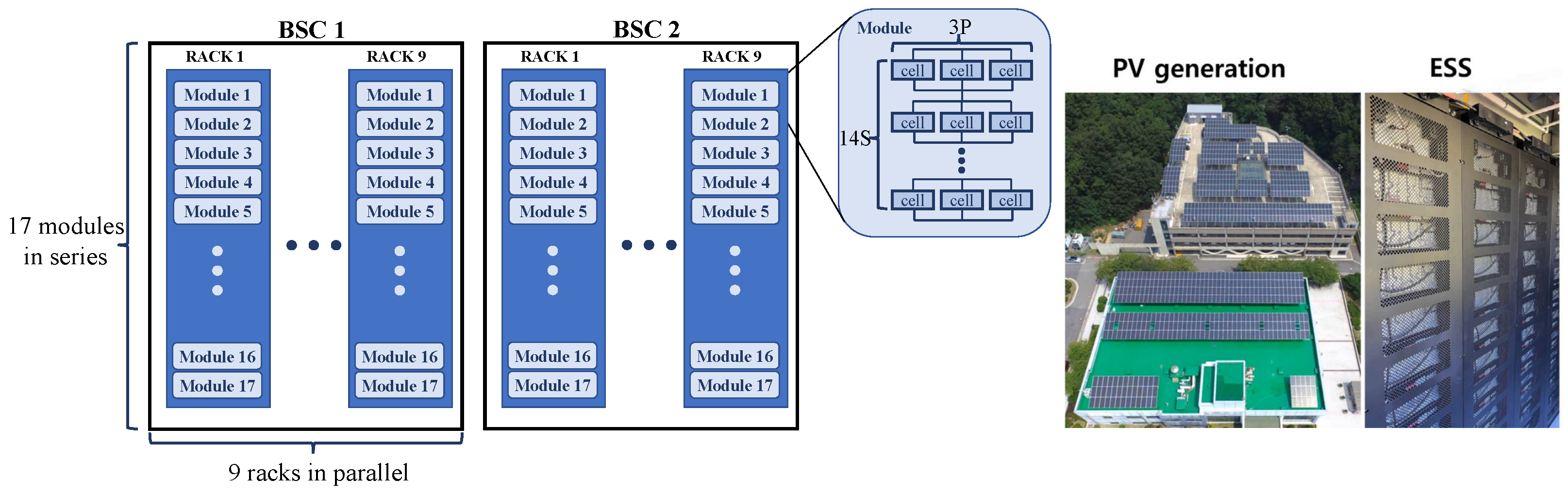

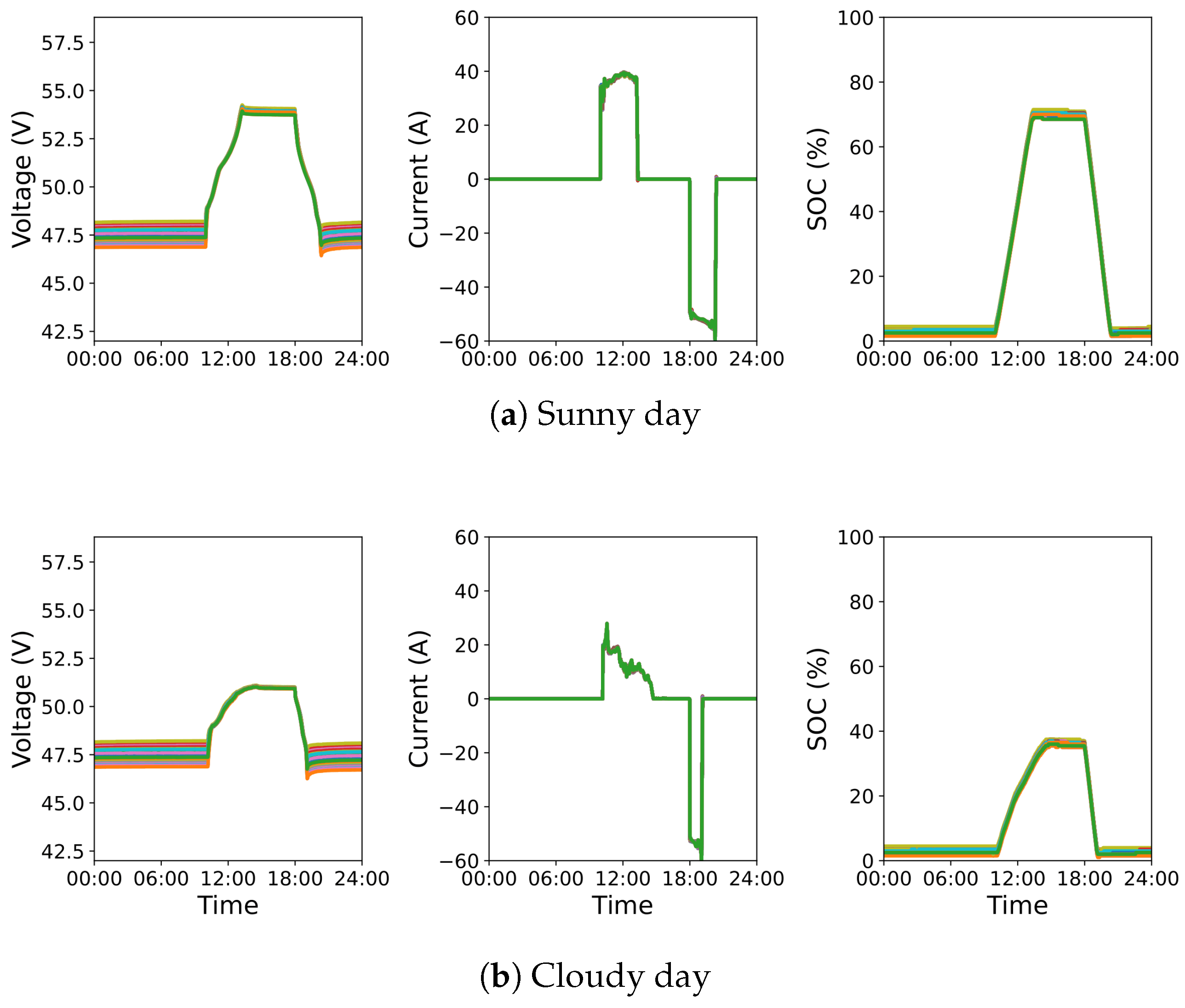

2.1.2. Field Data

2.1.3. Data Preprocessing

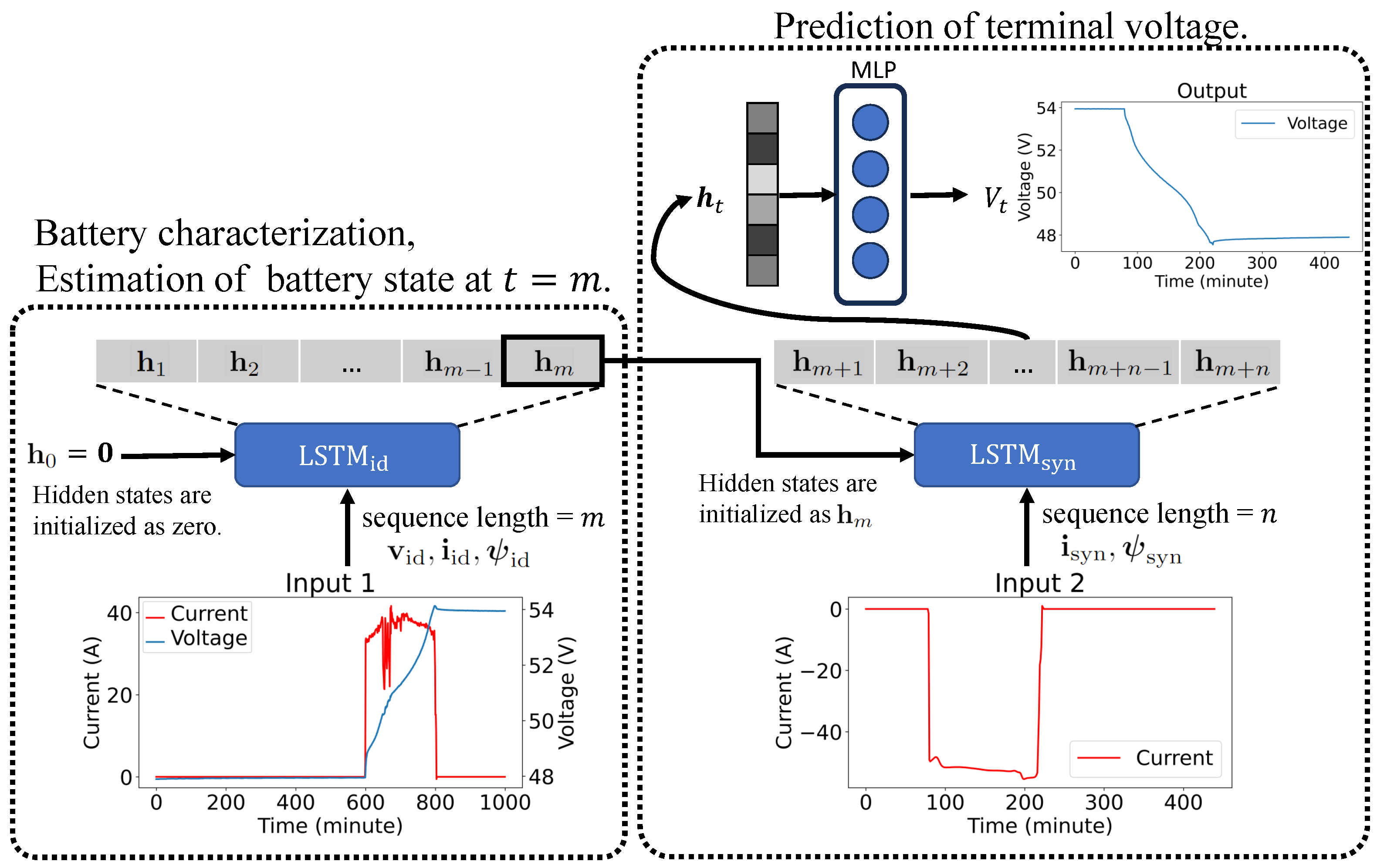

2.2. Proposed Battery Neural Surrogate Model Architecture

3. Model Selection

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Edge, J.S.; O’Kane, S.; Prosser, R.; Kirkaldy, N.D.; Patel, A.N.; Hales, A.; Ghosh, A.; Ai, W.; Chen, J.; Yang, J.; et al. Lithium ion battery degradation: What you need to know. Phys. Chem. Chem. Phys. 2021, 23, 8200–8221. [Google Scholar] [CrossRef]

- Kabir, M.; Demirocak, D.E. Degradation mechanisms in Li-ion batteries: A state-of-the-art review. Int. J. Energy Res. 2017, 41, 1963–1986. [Google Scholar] [CrossRef]

- Birkl, C.R.; Roberts, M.R.; McTurk, E.; Bruce, P.G.; Howey, D.A. Degradation diagnostics for lithium ion cells. J. Power Sources 2017, 341, 373–386. [Google Scholar] [CrossRef]

- Semeraro, C.; Caggiano, M.; Olabi, A.G.; Dassisti, M. Battery monitoring and prognostics optimization techniques: Challenges and opportunities. Energy 2022, 255, 124538. [Google Scholar] [CrossRef]

- Hu, X.; Xu, L.; Lin, X.; Pecht, M. Battery lifetime prognostics. Joule 2020, 4, 310–346. [Google Scholar] [CrossRef]

- Hu, X.; Li, S.; Peng, H. A comparative study of equivalent circuit models for Li-ion batteries. J. Power Sources 2012, 198, 359–367. [Google Scholar] [CrossRef]

- Tran, M.K.; Fowler, M. A review of lithium-ion battery fault diagnostic algorithms: Current progress and future challenges. Algorithms 2020, 13, 62. [Google Scholar] [CrossRef]

- Tran, M.K.; Mathew, M.; Janhunen, S.; Panchal, S.; Raahemifar, K.; Fraser, R.; Fowler, M. A comprehensive equivalent circuit model for lithium-ion batteries, incorporating the effects of state of health, state of charge, and temperature on model parameters. J. Energy Storage 2021, 43, 103252. [Google Scholar] [CrossRef]

- Sihvo, J.; Roinila, T.; Stroe, D.I. SOH analysis of Li-ion battery based on ECM parameters and broadband impedance measurements. In Proceedings of the IECON 2020 the 46th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 18–21 October 2020; pp. 1923–1928. [Google Scholar] [CrossRef]

- Miyake, T.; Suzuki, T.; Funabashi, S.; Saito, N.; Kamezaki, M.; Shoda, T.; Saigo, T.; Sugano, S. Bayesian Estimation of Model Parameters of Equivalent Circuit Model for Detecting Degradation Parts of Lithium-Ion Battery. IEEE Access 2021, 9, 159699–159713. [Google Scholar] [CrossRef]

- Amir, S.; Gulzar, M.; Tarar, M.O.; Naqvi, I.H.; Zaffar, N.A.; Pecht, M.G. Dynamic equivalent circuit model to estimate state-of-health of lithium-ion batteries. IEEE Access 2022, 10, 18279–18288. [Google Scholar] [CrossRef]

- Wang, J.; Jia, Y.; Yang, N.; Lu, Y.; Shi, M.; Ren, X.; Lu, D. Precise equivalent circuit model for Li-ion battery by experimental improvement and parameter optimization. J. Energy Storage 2022, 52, 104980. [Google Scholar] [CrossRef]

- Rukavina, F.; Leko, D.; Matijašić, M.; Bralić, I.; Ugalde, J.M.; Vašak, M. Identification of equivalent circuit model parameters for a Li-ion battery cell. In Proceedings of the 2023 IEEE 11th International Conference on Systems and Control (ICSC), Sousse, Tunisia, 18–20 December 2023; IEEE: New York, NY, USA, 2023; pp. 671–676. [Google Scholar]

- Xu, W.; Wang, S.; Jiang, C.; Fernandez, C.; Yu, C.; Fan, Y.; Cao, W. A novel adaptive dual extended Kalman filtering algorithm for the Li-ion battery state of charge and state of health co-estimation. Int. J. Energy Res. 2021, 45, 14592–14602. [Google Scholar] [CrossRef]

- Ling, L.; Wei, Y. State-of-charge and state-of-health estimation for lithium-ion batteries based on dual fractional-order extended Kalman filter and online parameter identification. IEEE Access 2021, 9, 47588–47602. [Google Scholar] [CrossRef]

- Fan, Y.; Shi, H.; Wang, S.; Fernandez, C.; Cao, W.; Huang, J. A Novel Adaptive Function—Dual Kalman Filtering Strategy for Online Battery Model Parameters and State of Charge Co-Estimation. Energies 2021, 14, 2268. [Google Scholar] [CrossRef]

- Li, X.; Yuan, C.; Wang, Z.; He, J.; Yu, S. Lithium battery state-of-health estimation and remaining useful lifetime prediction based on non-parametric aging model and particle filter algorithm. Etransportation 2022, 11, 100156. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, X.; Zhang, H.; Yang, F.; Tong, L.; Yang, Y.; Yan, D.; Yang, A.; Yu, M.; Liu, Z.; et al. Online identification of battery model parameters and joint state of charge and state of health estimation using dual particle filter algorithms. Int. J. Energy Res. 2022, 46, 19615–19652. [Google Scholar] [CrossRef]

- Qiao, J.; Wang, S.; Yu, C.; Yang, X.; Fernandez, C. A chaotic firefly-Particle filtering method of dynamic migration modeling for the state-of-charge and state-of-health co-estimation of a lithium-ion battery performance. Energy 2023, 263, 126164. [Google Scholar] [CrossRef]

- Abdelhafiz, S.M.; Fouda, M.E.; Radwan, A.G. Parameter identification of li-ion batteries: A comparative study. Electronics 2023, 12, 1478. [Google Scholar] [CrossRef]

- Hossain, M.; Saha, S.; Haque, M.E.; Arif, M.T.; Oo, A.M.T. A parameter extraction method for the Thevenin equivalent circuit model of Li-ion batteries. In Proceedings of the 2019 IEEE Industry Applications Society Annual Meeting, Baltimore, MD, USA, 29 September–3 October 2019; IEEE: New York, NY, USA, 2019; pp. 1–7. [Google Scholar]

- Sun, J.; Kainz, J. Optimization of hybrid pulse power characterization profile for equivalent circuit model parameter identification of Li-ion battery based on Taguchi method. J. Energy Storage 2023, 70, 108034. [Google Scholar] [CrossRef]

- Vyroubal, P.; Kazda, T. Equivalent circuit model parameters extraction for lithium ion batteries using electrochemical impedance spectroscopy. J. Energy Storage 2018, 15, 23–31. [Google Scholar] [CrossRef]

- Li, D.; Yang, D.; Li, L.; Wang, L.; Wang, K. Electrochemical impedance spectroscopy based on the state of health estimation for lithium-ion batteries. Energies 2022, 15, 6665. [Google Scholar] [CrossRef]

- Doyle, M.; Fuller, T.F.; Newman, J. Modeling of galvanostatic charge and discharge of the lithium/polymer/insertion cell. J. Electrochem. Soc. 1993, 140, 1526. [Google Scholar] [CrossRef]

- Atlung, S.; West, K.; Jacobsen, T. Dynamic aspects of solid solution cathodes for electrochemical power sources. J. Electrochem. Soc. 1979, 126, 1311. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, K.; Zhu, C.; Zhang, X.; Zhang, D. Co-Estimation of State-of-Charge and State-of- Health for Lithium-Ion Batteries Using an Enhanced Electrochemical Model. IEEE Trans. Ind. Electron. 2022, 69, 2684–2696. [Google Scholar] [CrossRef]

- Sadabadi, K.K.; Jin, X.; Rizzoni, G. Prediction of remaining useful life for a composite electrode lithium ion battery cell using an electrochemical model to estimate the state of health. J. Power Sources 2021, 481, 228861. [Google Scholar] [CrossRef]

- Li, Y.; Liu, G.; Deng, W.; Li, Z. Comparative study on parameter identification of an electrochemical model for lithium-ion batteries via meta-heuristic methods. Appl. Energy 2024, 367, 123437. [Google Scholar] [CrossRef]

- Jiang, B.; Zhu, J.; Wang, X.; Wei, X.; Shang, W.; Dai, H. A comparative study of different features extracted from electrochemical impedance spectroscopy in state of health estimation for lithium-ion batteries. Appl. Energy 2022, 322, 119502. [Google Scholar] [CrossRef]

- Fan, M.; Geng, M.; Yang, K.; Zhang, M.; Liu, H. State of health estimation of lithium-ion battery based on electrochemical impedance spectroscopy. Energies 2023, 16, 3393. [Google Scholar] [CrossRef]

- Li, Y.; Maleki, M.; Banitaan, S. State of health estimation of lithium-ion batteries using EIS measurement and transfer learning. J. Energy Storage 2023, 73, 109185. [Google Scholar] [CrossRef]

- Li, X.; Yuan, C.; Li, X.; Wang, Z. State of health estimation for Li-Ion battery using incremental capacity analysis and Gaussian process regression. Energy 2020, 190, 116467. [Google Scholar] [CrossRef]

- Wang, C.; Sun, Y.; Gao, Y.; Yan, P. The incremental capacity curves and frequency response characteristic evolution of lithium titanate battery during ultra-high-rate discharging cycles. Energies 2023, 16, 3434. [Google Scholar] [CrossRef]

- Wei, M.; Balaya, P.; Ye, M.; Song, Z. Remaining useful life prediction for 18650 sodium-ion batteries based on incremental capacity analysis. Energy 2022, 261, 125151. [Google Scholar] [CrossRef]

- Choi, Y.; Ryu, S.; Park, K.; Kim, H. Machine learning-based lithium-ion battery capacity estimation exploiting multi-channel charging profiles. IEEE Access 2019, 7, 75143–75152. [Google Scholar] [CrossRef]

- Park, K.; Choi, Y.; Choi, W.J.; Ryu, H.Y.; Kim, H. LSTM-Based Battery Remaining Useful Life Prediction With Multi-Channel Charging Profiles. IEEE Access 2020, 8, 20786–20798. [Google Scholar] [CrossRef]

- Kim, S.W.; Oh, K.Y.; Lee, S. Novel informed deep learning-based prognostics framework for on-board health monitoring of lithium-ion batteries. Appl. Energy 2022, 315, 119011. [Google Scholar] [CrossRef]

- Chen, D.; Zhou, X. AttMoE: Attention with Mixture of Experts for remaining useful life prediction of lithium-ion batteries. J. Energy Storage 2024, 84, 110780. [Google Scholar] [CrossRef]

- Reza, M.; Mannan, M.; Mansor, M.; Ker, P.J.; Mahlia, T.I.; Hannan, M. Recent advancement of remaining useful life prediction of lithium-ion battery in electric vehicle applications: A review of modelling mechanisms, network configurations, factors, and outstanding issues. Energy Rep. 2024, 11, 4824–4848. [Google Scholar] [CrossRef]

- Oka, K.; Tanibata, N.; Takeda, H.; Nakayama, M.; Noguchi, S.; Karasuyama, M.; Fujiwara, Y.; Miyuki, T. Deep learning based emulator for predicting voltage behaviour in lithium ion batteries. Sci. Rep. 2024, 14, 28905. [Google Scholar] [CrossRef]

- Liu, H.; Li, C.; Hu, X.; Li, J.; Zhang, K.; Xie, Y.; Wu, R.; Song, Z. Multi-modal framework for battery state of health evaluation using open-source electric vehicle data. Nat. Commun. 2025, 16, 1137. [Google Scholar] [CrossRef]

- Tang, T.; Yang, X.; Li, M.; Li, X.; Huang, H.; Guan, C.; Huang, J.; Wang, Y.; Zhou, C. Deep learning model-based real-time state-of-health estimation of lithium-ion batteries under dynamic operating conditions. Energy 2025, 317, 134697. [Google Scholar] [CrossRef]

- Severson, K.A.; Attia, P.M.; Jin, N.; Perkins, N.; Jiang, B.; Yang, Z.; Chen, M.H.; Aykol, M.; Herring, P.K.; Fraggedakis, D.; et al. Data-driven prediction of battery cycle life before capacity degradation. Nat. Energy 2019, 4, 383–391. [Google Scholar] [CrossRef]

- Hochreiter, S.; Schmidhuber, J. Long short-term memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef] [PubMed]

- Sutskever, I.; Vinyals, O.; Le, Q.V. Sequence to sequence learning with neural networks. Adv. Neural Inf. Process. Syst. 2014, 27, 3104–3112. [Google Scholar]

- Bergstra, J.; Bardenet, R.; Bengio, Y.; Kégl, B. Algorithms for hyper-parameter optimization. Adv. Neural Inf. Process. Syst. 2011, 24, 2546–2554. [Google Scholar]

- Akiba, T.; Sano, S.; Yanase, T.; Ohta, T.; Koyama, M. Optuna: A Next-generation Hyperparameter Optimization Framework. In Proceedings of the 25th ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, Anchorage, AK, USA, 4–8 August 2019. [Google Scholar]

| fc_dim | fc_Layers | Hidden_Size | lstm_Layers | Loss (MSE) | RMSE (mV) | |

|---|---|---|---|---|---|---|

| 126 | 1 | 188 | 3 | 7.89 × | 10.97 | 0.9871 |

| 153 | 1 | 172 | 2 | 9.41 × | 12.41 | 0.9867 |

| 103 | 1 | 174 | 4 | 9.72 × | 12.88 | 0.9869 |

| 159 | 1 | 172 | 5 | 1.01 × | 12.91 | 0.9866 |

| 103 | 1 | 172 | 3 | 1.08 × | 13.33 | 0.9868 |

| fc_dim | fc_Layers | Hidden_Size | lstm_Layers | Loss (MSE) | RMSE (mV) | |

|---|---|---|---|---|---|---|

| 171 | 2 | 90 | 2 | 1.78 × | 59.42 | 0.9948 |

| 185 | 3 | 109 | 3 | 1.90 × | 68.96 | 0.9957 |

| 192 | 1 | 110 | 2 | 1.99 × | 64.10 | 0.9938 |

| 137 | 2 | 60 | 2 | 2.01 × | 65.06 | 0.9940 |

| 155 | 3 | 127 | 2 | 2.11 × | 68.50 | 0.9941 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheon, H.; Jeon, J.; Jung, B.; Kim, H. Battery Health Diagnosis via Neural Surrogate Model: From Lab to Field. Energies 2025, 18, 2405. https://doi.org/10.3390/en18092405

Cheon H, Jeon J, Jung B, Kim H. Battery Health Diagnosis via Neural Surrogate Model: From Lab to Field. Energies. 2025; 18(9):2405. https://doi.org/10.3390/en18092405

Chicago/Turabian StyleCheon, Hojin, Jihun Jeon, Byungil Jung, and Hongseok Kim. 2025. "Battery Health Diagnosis via Neural Surrogate Model: From Lab to Field" Energies 18, no. 9: 2405. https://doi.org/10.3390/en18092405

APA StyleCheon, H., Jeon, J., Jung, B., & Kim, H. (2025). Battery Health Diagnosis via Neural Surrogate Model: From Lab to Field. Energies, 18(9), 2405. https://doi.org/10.3390/en18092405