Multilayer Gas-Bearing System and Productivity Characteristics in Carboniferous–Permian Tight Sandstones: Taking the Daning–Jixian Block, Eastern Ordos Basin, as an Example

Abstract

1. Introduction

2. Geological Setting

2.1. Block Location

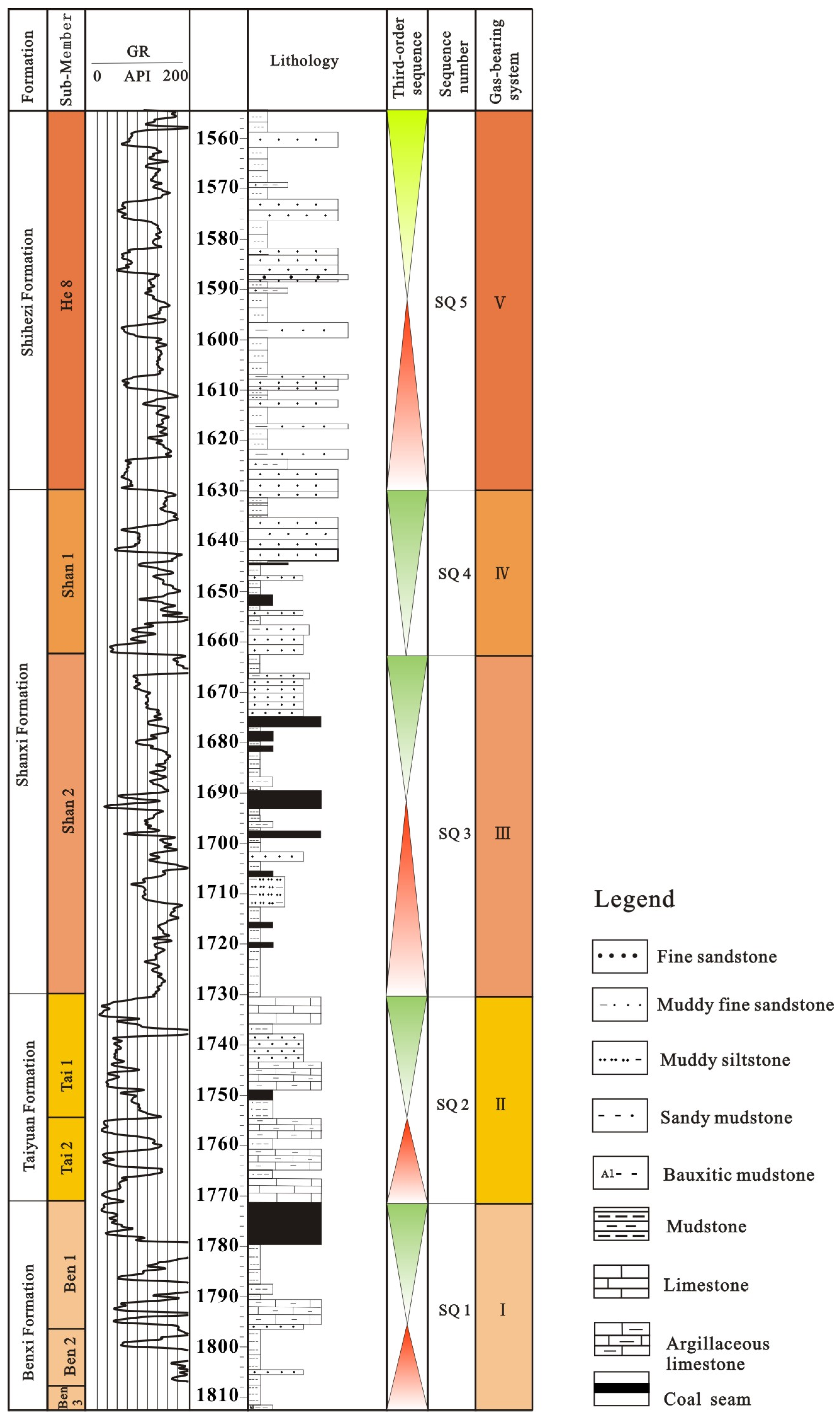

2.2. Stratigraphic Sequence

3. Characterization and Division of Gas-Bearing Systems

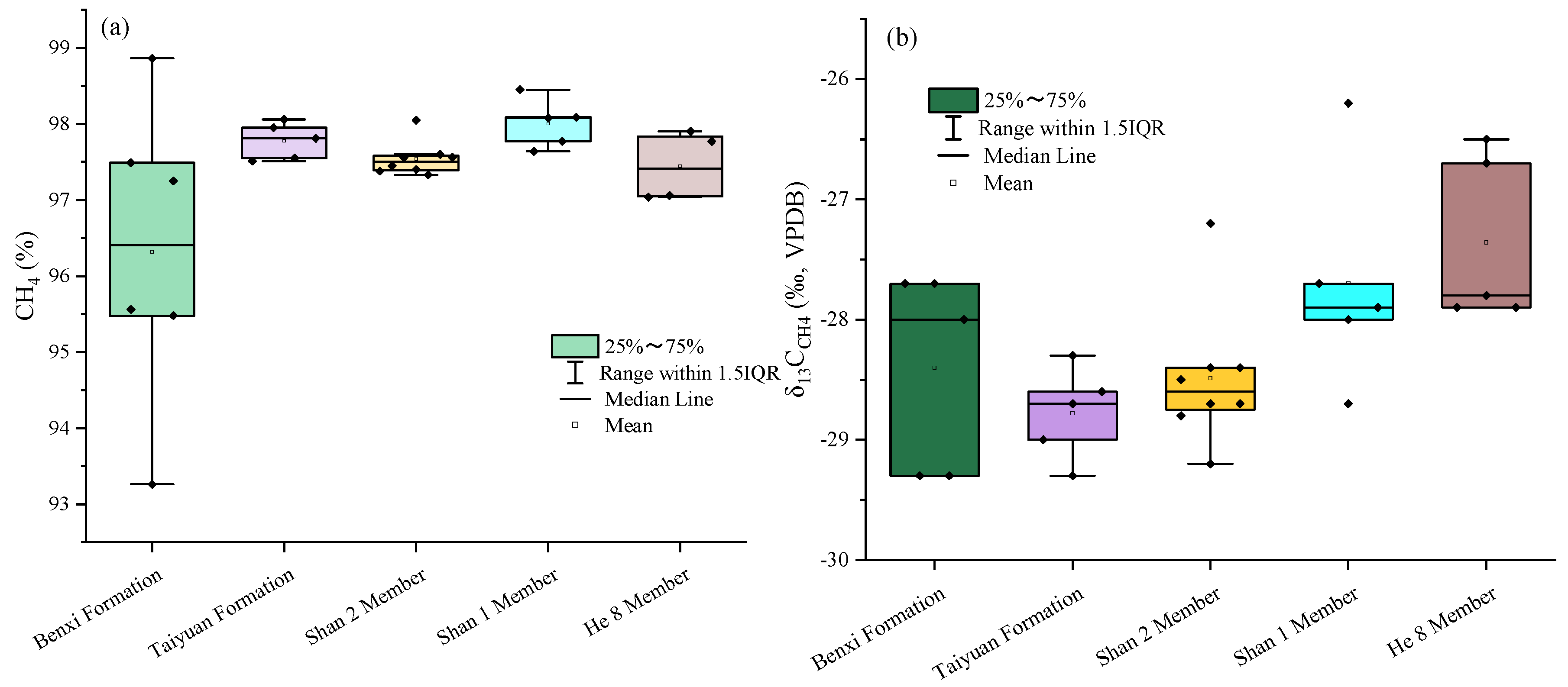

3.1. Gas Geochemical Characteristics

3.2. Reservoir Pressure System

3.3. Division of Gas-Bearing Systems

4. Reservoir Characteristics in Different Gas-Bearing Systems

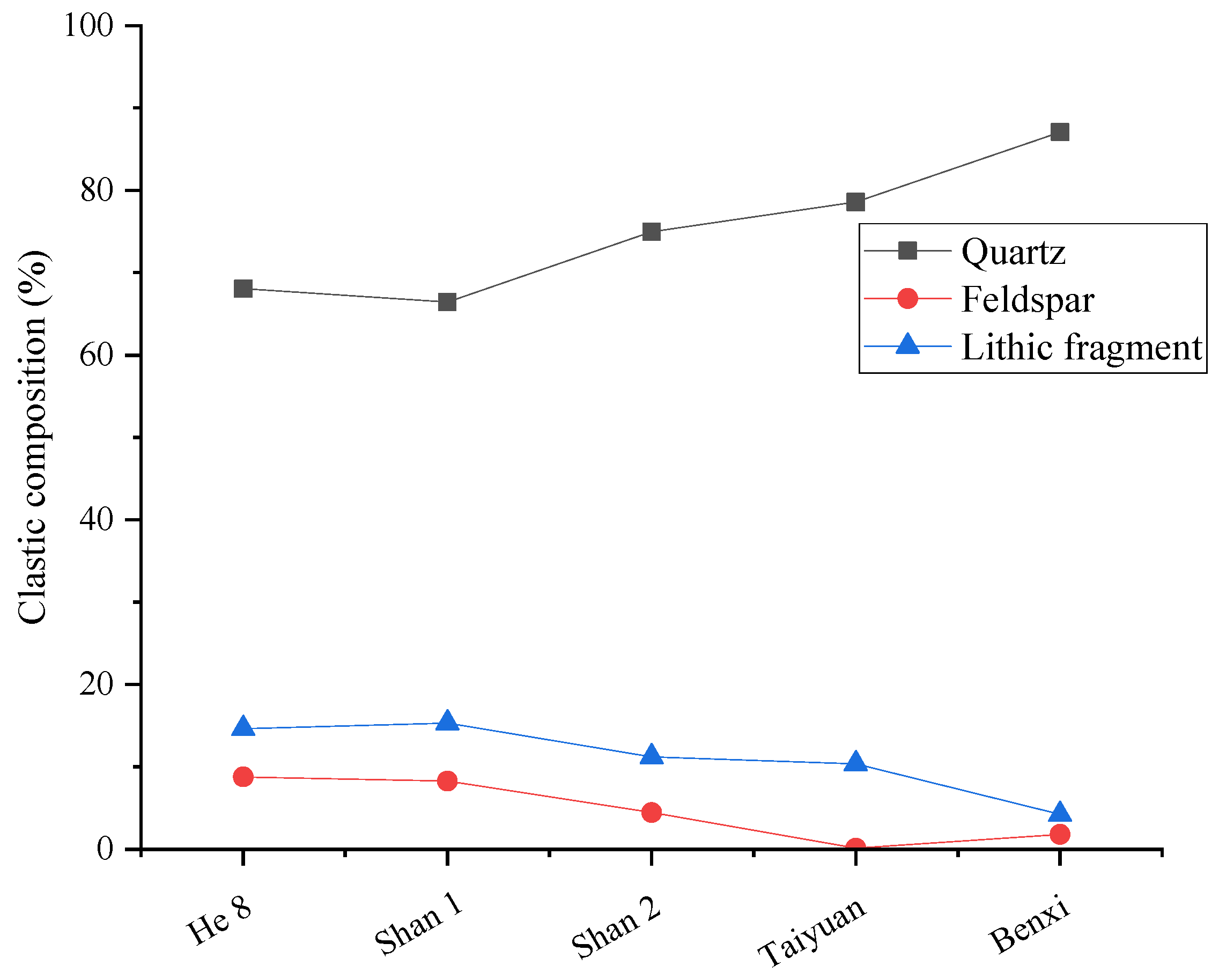

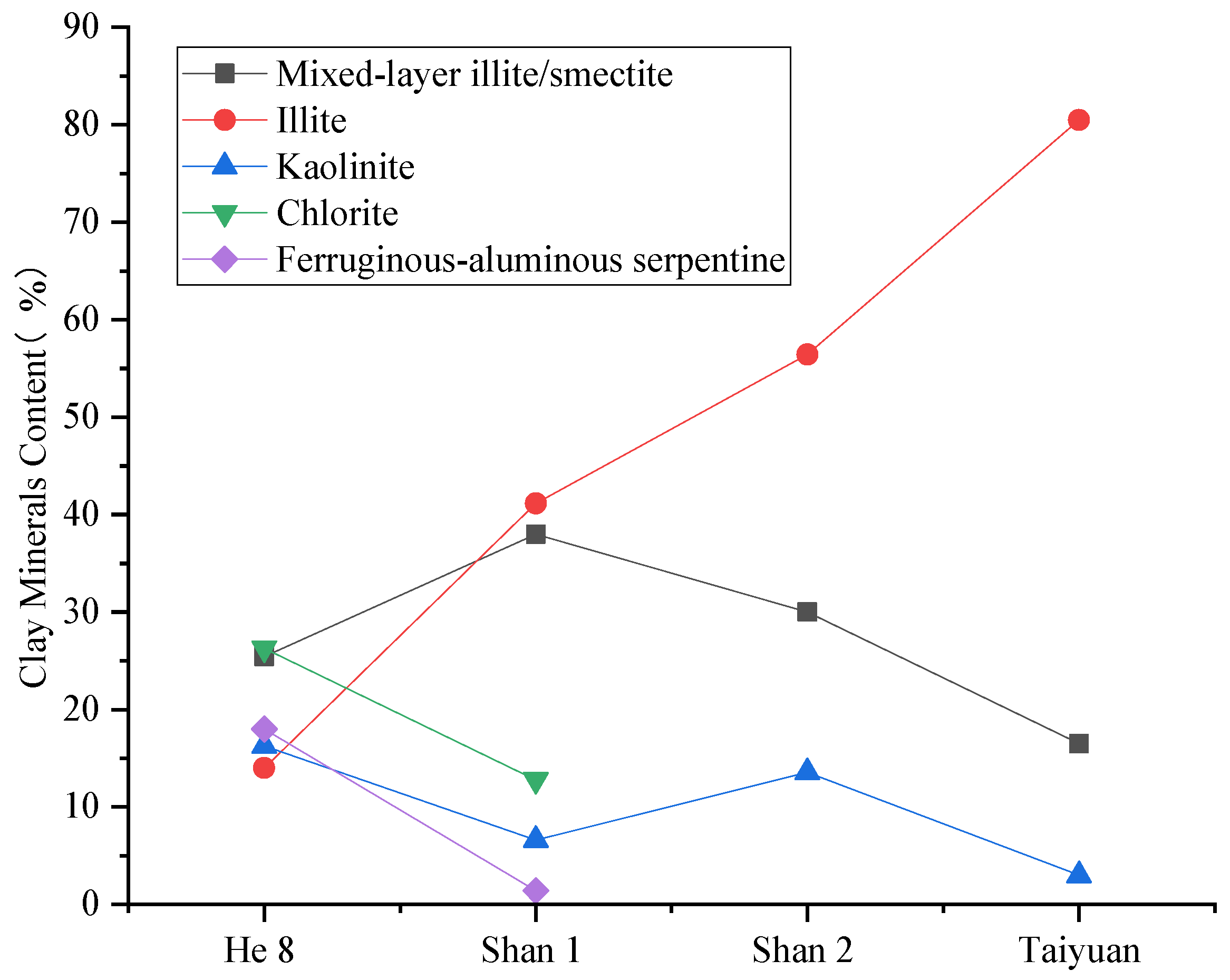

4.1. Litho-Mineralogical Characteristics

4.2. Pore Types

4.3. Pore Throat Structure

4.4. Reservoir Physical Properties

4.5. Analysis of Sedimentary Environment

5. Productivity Characteristics

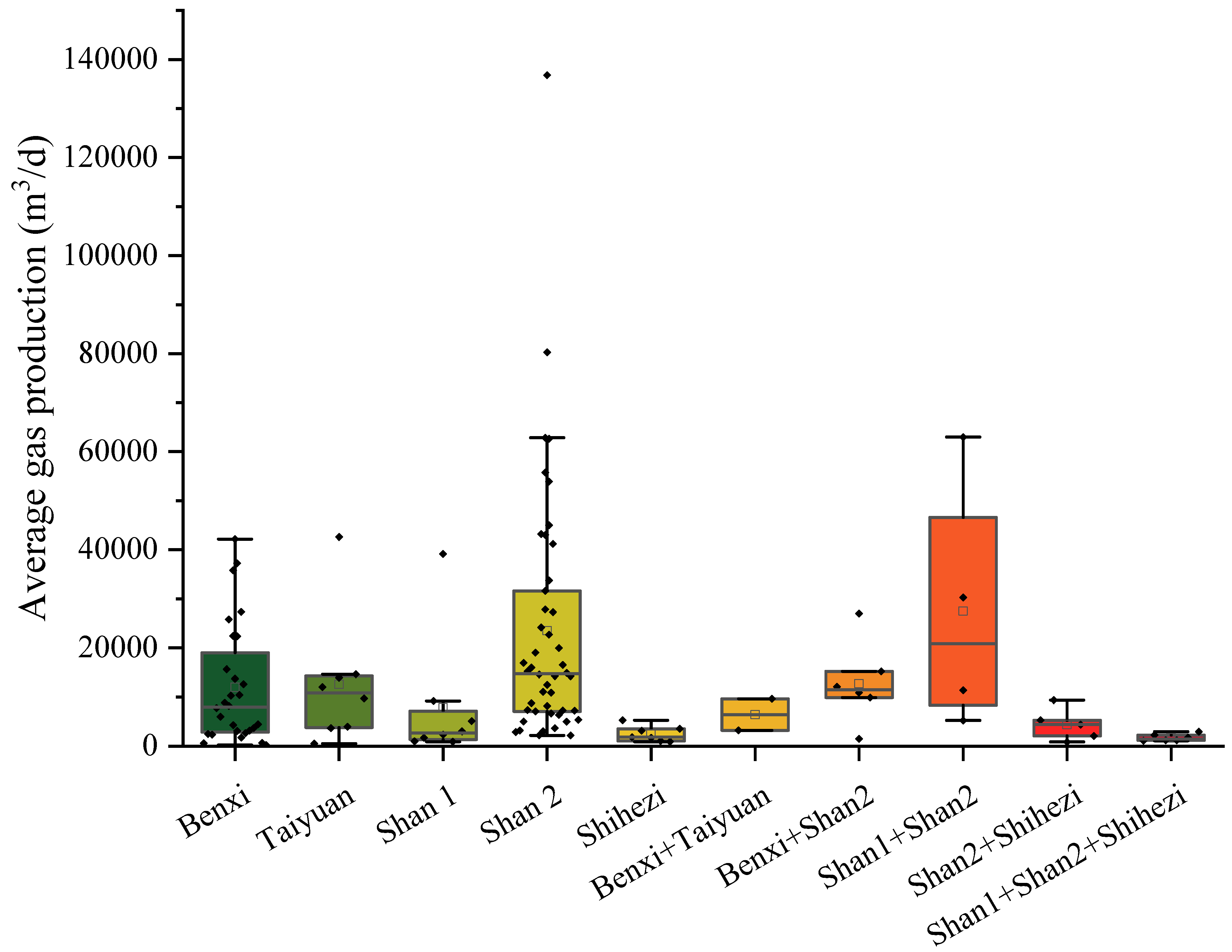

5.1. Single-Layer Production

5.2. Multi-Layer Co-Production

6. Conclusions

- (1)

- The Carboniferous–Permian tight sandstone gas systems in the Daning–Jixian Block are categorized into upper and lower systems, separated by the regionally extensive Taiyuan Formation limestone. The upper system is further divided into four distinct subsystems based on geochemical signatures, reservoir pressure coefficients, and sequence stratigraphy.

- (2)

- The depositional environments play a critical role in controlling the lithological and petrophysical characteristics of the reservoirs. The Shan 1 and He 8 Members, formed in low-energy delta-front subaqueous distributary channels with gentle topography, display lower quartz content and higher proportions of lithic fragments, matrix, and clay minerals (especially chlorite), leading to higher displacement and median pressures, which negatively impact reservoir quality. In contrast, the Shan 2 Member, deposited in high-energy, narrow delta-front subaqueous distributary channels, is characterized by medium- to fine-grained (lithic) quartz sandstone with low clay content, offering improved petrophysical performance. The Benxi Formation, deposited in barrier coast facies with strong tidal influence, consists of pebbly sandstones, conglomeratic sandstones, and coarse-grained quartz sandstone with low matrix, cement, and clay content, collectively contributing to low displacement/median pressures and favorable reservoir properties.

- (3)

- During single-layer production, the Shan 2 Member exhibits the highest gas production, followed by the Taiyuan and Benxi Formations, while the He 8 Member demonstrates the lowest yield. In multi-layer co-production scenarios, certain combinations (e.g., Benxi + Shan 2) yield intermediate production between their individual single-layer outputs, while others (e.g., Benxi + Taiyuan) produce less than the output of two or three individual layers, indicating poor interlayer compatibility. Future strategies should prioritize enhancing reservoir stimulation intensity in these non-dominant layers to boost gas recovery and carefully managing interlayer effects to maximize gas production.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Iqbal, S.M.; Hu, D.; Hussain, J.; Ali, N.; Hussain, W.; Hussain, A.; Nyakilla, E.E. Integrated reservoir characterization and simulation approach to enhance production of tight sandstone gas reservoir, Sulige gas field, Ordos Basin, China. Phys. Chem. Earth Parts A/B/C 2025, 138, 103846. [Google Scholar] [CrossRef]

- Kadkhodaie, R.; Kadkhodaie, A.; Rezaee, R. Study of pore system properties of tight gas sandstones based on analysis of the seismically derived velocity deviation log: A case study from the Perth Basin of western Australia. J. Pet. Sci. Eng. 2021, 196, 108077. [Google Scholar] [CrossRef]

- Shen, J.; Li, K.; Zhang, H.; Shabbiri, K.; Hu, Q.; Zhang, C. The geochemical characteristics, origin, migration and accumulation modes of deep coal-measure gas in the west of Linxing block at the eastern margin of Ordos Basin. J. Nat. Gas Sci. Eng. 2021, 91, 103965. [Google Scholar] [CrossRef]

- Qu, J.; Shen, J.; Guo, Y.; Sang, G.; Cao, Y.; Li, W. Variations of CH4 release pathways and processes in progressively pulverized Coals: Insights from multi-fractal analysis and experimental Validation. Fuel 2025, 381, 133471. [Google Scholar] [CrossRef]

- Zheng, D.; Ozbayoglu, E.; Miska, S.; Zhang, J. Experimental study of anisotropic strength properties of shale. In Proceedings of the ARMA US Rock Mechanics/Geomechanics Symposium, Atlanta, GA, USA, 25–28 June 2023; p. ARMA-2023. [Google Scholar]

- Rafieepour, S.; Zheng, D.; Miska, S.; Ozbayoglu, E.; Takach, N.; Yu, M.; Zhang, J. Combined experimental and well log evaluation of anisotropic mechanical properties of shales: An application to wellbore stability in bakken formation. In Proceedings of the SPE Annual Technical Conference and Exhibition, Virtual, 26–29 October 2020; p. D021S015R006. [Google Scholar]

- Yu, H.J.; Wang, Z.J.; Li, J.B. Key technological progress and breakthrough direction for the development of complex tight gas reservoirs in Changqing gas field, Ordos Basin. Acta Pet. Sin. 2023, 44, 698–712. [Google Scholar]

- Liu, E.R. Study on Tight Gas Enriching Mechanism of the Shanxi Formation in the Eastern Zhoukou Depression of the Southern North China Basin. Ph.D. Thesis, China University of Petroleum, Beijing, China, 2023. [Google Scholar]

- Dong, X.X.; Meng, X.Z.; Pu, R.H. Occurrence characteristics of movable fluids based on the division of pore throat system in tight gas reservoir by fractal theory. Nat. Gas Ind. 2023, 43, 78–90. [Google Scholar]

- Dai, J.X.; Dong, D.Z.; Ni, Y.Y.; Gong, D.Y.; Huang, S.; Hong, F.; Zhang, Y.; Liu, Q.Y.; Wu, X.Q.; Feng, Z.Q. Distribution patterns of tight sandstone gas and shale gas. Pet. Explor. Dev 2024, 51, 667–678. [Google Scholar] [CrossRef]

- Shen, Y.L.; Qin, Y.; Shen, J. Sedimentary control mechanism of the superimposed gas bearing system development in the Upper Palaeozoic coal measures along the eastern margin of the Ordos Basin. Nat. Gas Ind. 2017, 37, 29–35. [Google Scholar]

- Shen, J.; Qin, Y.; Zhang, B.; Li, G. Superimposing gas-bearing system in coal measures and its compatibility in Linxing block,east Ordos Basin. J. China Coal Soc. 2018, 43, 1614–1619. [Google Scholar]

- Cheng, C. Influencing factors of productivity of tight sandstone gas in the Xiashihezi Formation of the Yanchuannan gas field. J. Geol. 2015, 39, 133–137. [Google Scholar]

- Shi, S. Study on Comprehensive Evaluation Method of Tight Sandstone Gas Reservoir. Master’s Thesis, Xi’an Shiyou University, Xi’an, China, 2016. [Google Scholar]

- Dong, Q. A Research of Geological Controlling Factors of Gas Well Productivity in Tight Gas Reservoir: An Example from SuX Area in Sulige Gas Field. Master’s Thesis, Yangtze University, Jingzhou, China, 2023. [Google Scholar]

- Liu, H.; Gao, S.; Fang, F.; Jiao, C.; Li, Q.; Ye, L.; An, W.; Zhang, J. Model of cross-flow interference index and application for multi-layer commingled production in Sulige tight sandstone gas reservoir, Ordos Basin. Nat. Gas Geosci. 2023, 34, 950–962. [Google Scholar] [CrossRef]

- Liao, Y. Experimental Simulation and Field Application of Multi-Layer Combined Production in Tight Sandstone Gas Reservoirs. Master’s Thesis, Xi’an Shiyou University, Xi’an, China, 2014. [Google Scholar]

- Tan, Y.H.; Guo, J.Z.; Zheng, F.; Xu, W.F. Physical simulation on seepage features of commingled production and right time of production conversion for gas wells. Oil Gas Geol. 2015, 36, 1009–1015. [Google Scholar]

- Zhang, M.Y. Numerical Simulation Study of Influence Factors of Multilayer Fractured Vertical Well Productivity in Tight Gas Reservoir. Master’s Thesis, Yangtze University, Jingzhou, China, 2016. [Google Scholar]

- Xu, X.H.; Wang, Y.; Lin, J.D.; Liu, X.W.; Gan, Y. Commingled production characteristics of multi-pressure-system tight gas reservoirs and experiment of the developing mode optimization. Pet. Geol. Oilfield Dev. Daqing 2020, 39, 153–161. [Google Scholar]

- Zhao, L.; Wen, G.; Li, X.; Li, X.; Li, Y.; Shi, X.; Yang, M. Evaluation of the “Sweet Spot Area” of Tight Sandstone Gas Reservoirs in the Shanxi Formation 2-3 Sub-member of the Daning-Jixian Block in the Ordos Basin. Nat. Gas Ind. 2018, 38, 5–10. [Google Scholar]

- Dong, L.; Lin, Y.X.; Wu, Y.C.; Li, X.; Xing, Y.S.; Ma, X.W.; Shu, Y. Physical property and gas content characters of sandstone in Daning-Jixian Area Upper Paleozoic. China Energy Environ. Prot. 2018, 40, 87–94. [Google Scholar]

- Tian, W.; Zhao, S.; Tian, F.; Li, X.; Huo, W.; Zhong, G.; Li, S. Symbiotic Combination and Accumulation of Coal Measure Gas in the Daning–Jixian Block, Eastern Margin of Ordos Basin, China. Energies 2023, 16, 1737. [Google Scholar] [CrossRef]

- Yang, S.; Li, S.; Tian, W.; Zhong, G.; Wang, J. Sequence stratigraphic analysis of superimposed coal measure gas-bearing system in Daning-Jixian block, eastern margin of Ordos Basin, China. Front. Earth Sci. 2024, 18, 611–622. [Google Scholar] [CrossRef]

- Xiang, Y.J.; Lou, L.; Sun, J. Marine-continental transitional sequence and coal accumulation model during Late Carboniferous to Early Permian in the southeast margin of Ordos Basin. J. Northeast Pet. Univ. 2023, 47, 104–116. [Google Scholar]

- Qin, Y.; Shen, J.; Shen, Y.L. Joint mining compatibility of superposed gas-bearing systems: A general geological problem for extraction of three natural gases and deep CBM in coal series. J. China Coal Soc. 2016, 41, 14–23. [Google Scholar]

- Wang, M.Z. Study on the Characteristics of Sandstone Reservoir of Benxi-Taiyuan Formation in Daning Block. Master’s Thesis, China University of Geosciences, Beijing, China, 2020. [Google Scholar]

- Li, Z.X. The Research of Characteristies and Its Controlling Factors of Sandstone Reservoir Lithogenous Phase of Taiyuan-Shanxi Formation in Daning-Jixian Area. Master’s Thesis, China University of Geosciences, Beijing, China, 2014. [Google Scholar]

- Dang, J.C. Study on Natural Gas Enrichment Rules and Sweet Spot Evaluation of He 8 Member in Daning-Jixian Area. Master’s Thesis, Xi’an Shiyou University, Xi’an, China, 2023. [Google Scholar]

- Shi, S.; Er, C.; Zhang, W. Pore Structure Characteristics of Upper Paleozoic Tight Reservoir in Daning—Jixian Area of Ordos Basin and Its Relationship with Clay Minerals. J. Xi’an Shiyou Univ. (Nat. Sci. Ed.) 2023, 38, 1–9. [Google Scholar]

- Guo, L.L.; Li, Z.B.; Zhang, W.; Lin, W.G.; Yang, M.M.; Zhao, Y. Analysis of pore structure of main tight sandstone reservoirs in Daning-Jixian Block of Ordos Basi. Nat. Gas Ind. 2018, 38, 18–23. [Google Scholar]

- Kadkhodaie-Ilkhch, R.; Kadkhodaie, A.; Rezaee, R.; Mehdipour, V. Unraveling the reservoir heterogeneity of the tight gas sandstones using the porosity conditioned facies modeling in the Whicher Range field, Perth Basin, Western Australia. J. Pet. Sci. Eng. 2019, 176, 97–115. [Google Scholar] [CrossRef]

- Teng, Y.X. Study on the Pore Structure and Seepage Characteristics of the Shanxi Formation in the Daning-Jixian Area of Eastern Ordos. Master’s Thesis, Xi’an Shiyou University, Xi’an, China, 2023. [Google Scholar]

- Sun, J.; Chen, M.; Wang, B.; Wang, G.; Tian, H.; Hou, J.; Zhu, B. Analysis of Factors Influencing Tight Sandstone Gas Production and Identification of Favorable Gas Layers in the Shan 23 Sub-Member of the Daning-Jixian Block, Eastern Ordos Basin. Processes 2024, 12, 1810. [Google Scholar] [CrossRef]

- Zhong, G.; Li, S.; Tang, D.; Tian, W.; Lin, W.; Feng, P. Study on Co-production compatibility evaluation method of multilayer tight gas reservoir. J. Nat. Gas Sci. Eng. 2022, 108, 104840. [Google Scholar] [CrossRef]

| Layers | Number of Samples | Clastic Composition (%) | Interstitial Material (%) | |||||

|---|---|---|---|---|---|---|---|---|

| Quartz | Feldspar | Lithic Fragment | Total | Matrix | Cement | Total | ||

| He 8 | 50 | 68.06 | 8.77 | 14.63 | 91.46 | 1.48 | 7.06 | 8.54 |

| Shan 1 | 73 | 66.44 | 8.25 | 15.32 | 90.00 | 2.20 | 7.79 | 10.00 |

| Shan 2 | 49 | 74.95 | 4.44 | 11.20 | 90.59 | 1.52 | 7.89 | 9.41 |

| Taiyuan | 23 | 78.57 | 0.11 | 10.35 | 89.03 | 0.00 | 10.96 | 10.96 |

| Benxi | 20 | 87.07 | 1.77 | 4.23 | 93.07 | 0.05 | 6.89 | 6.93 |

| Layers | Mixed-Layer Illite/Smectite (%) | Illite (%) | Kaolinite (%) | Chlorite (%) | Ferruginous–Aluminous Serpentine (%) |

|---|---|---|---|---|---|

| He 8 | 25.45 | 14.00 | 16.27 | 26.27 | 18.00 |

| Shan 1 | 38.00 | 41.16 | 6.63 | 12.79 | 1.42 |

| Shan 2 | 30.00 | 56.43 | 13.57 | / | / |

| Taiyuan | 16.50 | 80.50 | 3.00 | / | / |

| Layers | Number of Samples | Quartz (%) | Plagioclase (%) | Calcite (%) | Dolomitic (%) | Siderite (%) | Clay Minerals (%) |

|---|---|---|---|---|---|---|---|

| He 8 | 22 | 73.40 | 2.13 | 6.38 | / | / | 18.09 |

| Shan 1 | 19 | 69.92 | 4.18 | 3.99 | / | 1.13 | 20.78 |

| Shan 2 | 7 | 84.36 | 1.26 | / | 4.83 | 0.57 | 8.99 |

| Taiyuan | 6 | 56.37 | / | / | 18.57 | / | 25.07 |

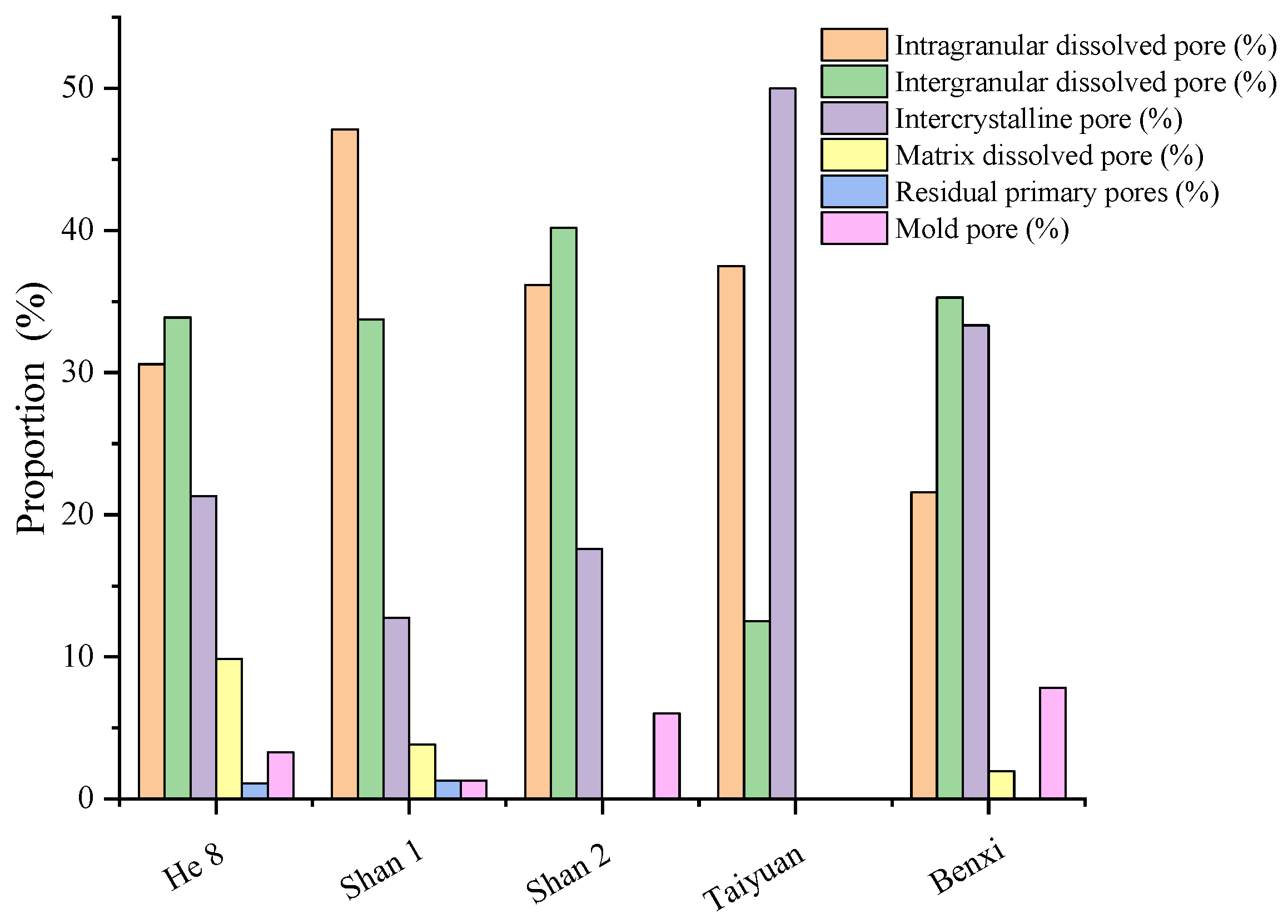

| Layers | Number of Samples | Intragranular Dissolved Pore (%) | Intergranular Dissolved Pore (%) | Intercrystalline Pore (%) | Matrix Dissolved Pore (%) | Residual Primary Pores (%) | Mold Pore (%) | Pore Area Percentage (%) |

|---|---|---|---|---|---|---|---|---|

| He 8 | 41 | 30.60 | 33.88 | 21.31 | 9.84 | 1.09 | 3.28 | 4.91 |

| Shan 1 | 46 | 47.13 | 33.76 | 12.74 | 3.82 | 1.27 | 1.27 | 2.86 |

| Shan 2 | 42 | 36.18 | 40.20 | 17.59 | 0.00 | 0.00 | 6.03 | 4.41 |

| Taiyuan | 10 | 37.50 | 12.50 | 50.00 | 0.00 | 0.00 | 0.00 | 1.60 |

| Benxi | 22 | 21.57 | 35.29 | 33.33 | 1.96 | 0.00 | 7.84 | 3.48 |

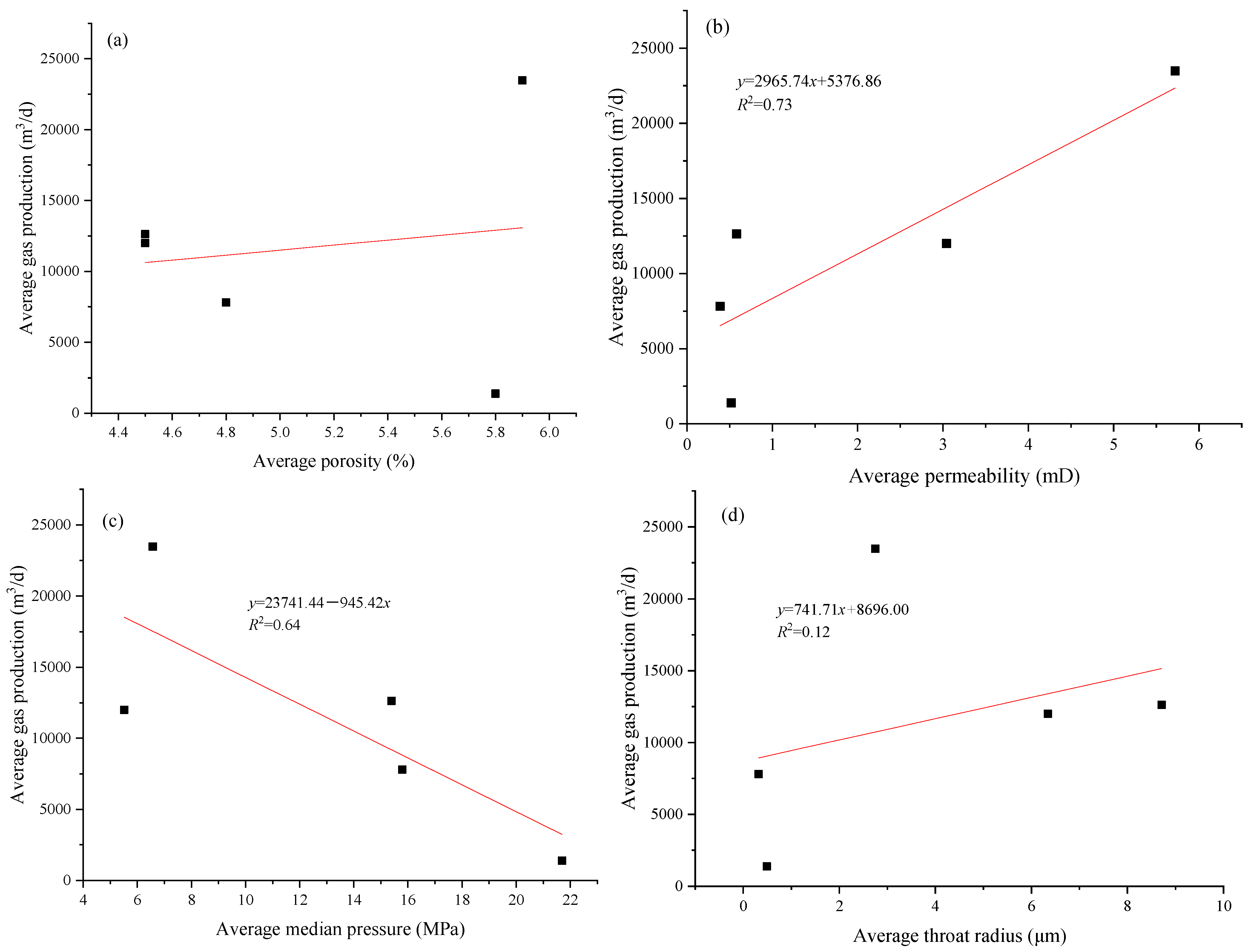

| Layers | Number of Samples | Displacement Pressure (MPa) | Median Pressure (MPa) | Average Throat Radius (μm) | Sorting Coefficient | Maximum Mercury Saturation (%) | Mercury Withdrawal Efficiency (%) | Residual Mercury Saturation (%) |

|---|---|---|---|---|---|---|---|---|

| He 8 | 52 | 0.86 | 21.70 | 0.49 | 2.46 | 80.14 | 38.83 | 47.29 |

| Shan 1 | 41 | 0.64 | 15.79 | 0.32 | 2.23 | 83.50 | 40.55 | 44.79 |

| Shan 2 | 49 | 0.51 | 6.57 | 2.75 | 2.57 | 81.15 | 28.45 | 59.51 |

| Taiyuan | 10 | 1.06 | 15.39 | 8.71 | 1.41 | 79.54 | 35.55 | 60.41 |

| Benxi | 18 | 0.44 | 5.52 | 6.34 | 2.19 | 84.05 | 22.67 | 38.74 |

| Stratigraphic Unit | Reservoir Lithology | Depositional Setting | Hydrodynamic Characteristics | Litho-Mineralogical Features |

|---|---|---|---|---|

| He 8 | Fine-grained lithic quartz sandstone, feldspar lithic sandstone | Delta-front subaqueous distributary channels | Gentle topography, moderate hydrodynamic energy | Relatively low quartz content; dominated by lithic quartz sandstone and feldspathic litharenite; elevated lithic fragments, matrix, clay minerals (notably chlorite). |

| Shan 1 | ||||

| Shan 2 | Medium- to fine-grained (lithic) quartz sandstone | Delta-front subaqueous distributary channels constrained by erosional paleotopography | Narrow channels, high hydrodynamic energy | Elevated matrix content; low total clay minerals; clay fraction dominated by kaolinite. |

| Taiyuan | Fine-grained quartz sandstone | Barrier bar deposits in barrier coast facies | Strong tidal influence | Low matrix content; high cementation; elevated total clay minerals (predominantly kaolinite). |

| Benxi | Pebbly sandstone, conglomeratic sandstone, coarse-grained quartz sandstone | Barrier bar and tidal channel deposits in barrier coast facies | Strong tidal influence | Low matrix and cement content; reduced total clay minerals. |

| Single-Layer Production | Benxi | Taiyuan | Shan 2 | Shan 1 | He 8 | |

|---|---|---|---|---|---|---|

| Gas production (m3/d) | Minimum | 209.72 | 512.21 | 2185.05 | 915.10 | 1050.30 |

| Maximum | 42,160.17 | 42,605.77 | 13,6806.99 | 39,145.97 | 1721.75 | |

| Average | 11,998.15 | 12,628.45 | 23,469.23 | 7801.31 | 1386.03 | |

| Multi-Layer Co-Production | Benxi+ Taiyuan | Benxi+ Shan 2 | Shan 1 + Shan 2 | Shihezi + Shan 2 | Shihezi + Shan 1 + Shan 2 | |

| Gas production (m3/d) | Minimum | 3223.65 | 1492.42 | 5248.38 | 865.79 | 1087.74 |

| Maximum | 9629.97 | 26,965.00 | 62,991.64 | 9362.28 | 2984.00 | |

| Average | 6426.81 | 12,765.43 | 27,477.10 | 4406.05 | 1736.80 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, M.; Wang, B.; Tian, H.; Sun, J.; Liu, L.; Liang, X.; Chen, B.; Yu, B.; Zhang, Z. Multilayer Gas-Bearing System and Productivity Characteristics in Carboniferous–Permian Tight Sandstones: Taking the Daning–Jixian Block, Eastern Ordos Basin, as an Example. Energies 2025, 18, 2398. https://doi.org/10.3390/en18092398

Chen M, Wang B, Tian H, Sun J, Liu L, Liang X, Chen B, Yu B, Zhang Z. Multilayer Gas-Bearing System and Productivity Characteristics in Carboniferous–Permian Tight Sandstones: Taking the Daning–Jixian Block, Eastern Ordos Basin, as an Example. Energies. 2025; 18(9):2398. https://doi.org/10.3390/en18092398

Chicago/Turabian StyleChen, Ming, Bo Wang, Haonian Tian, Junyi Sun, Lei Liu, Xing Liang, Benliang Chen, Baoshi Yu, and Zhuo Zhang. 2025. "Multilayer Gas-Bearing System and Productivity Characteristics in Carboniferous–Permian Tight Sandstones: Taking the Daning–Jixian Block, Eastern Ordos Basin, as an Example" Energies 18, no. 9: 2398. https://doi.org/10.3390/en18092398

APA StyleChen, M., Wang, B., Tian, H., Sun, J., Liu, L., Liang, X., Chen, B., Yu, B., & Zhang, Z. (2025). Multilayer Gas-Bearing System and Productivity Characteristics in Carboniferous–Permian Tight Sandstones: Taking the Daning–Jixian Block, Eastern Ordos Basin, as an Example. Energies, 18(9), 2398. https://doi.org/10.3390/en18092398