1. Introduction

The world’s current energy supply is largely derived from non-renewable energy sources—fossil fuels. These fuels have limited supply and high costs and contribute significantly to greenhouse gas (GHG) emissions and air pollution. A sustainable way to mitigate the environmental, social, and economic problems associated with these non-renewable energy sources is through the promotion of renewable energies, particularly biomass, and the conversion of waste into bioenergy [

1].

The increase in GHG emissions over recent years requires Brazil to intensify its efforts to meet its GHG reduction targets under the Paris Agreement by 2025. Since 2003, methane recovery initiatives through biogas generation in waste management have been observed. In 2022, 526 thousand tons of methane (CH

4) were recovered in 51 sanitary landfills, representing a 5% increase compared to the previous year. Biogas recovery is responsible for avoiding the emission of 20% of all methane generated in final waste disposal [

2].

The Brazilian government has committed to reducing its GHG emissions by 37% by 2025 and contributing to a 43% reduction by 2030, compared to estimated 2005 levels [

3]. Brazil also agreed to increase the share of sustainable bioenergy in its energy matrix by 18%, restore 12 million hectares of forests, and achieve 45% of renewable energy use by 2030 [

4].

Brazil has a competitive advantage due to the lower cost of crops and industrial residues. There is significant potential to scale up the industrial exploitation of biogas, particularly from agro-industrial waste. The main commercial applications of biogas include electricity generation through combustion in generator sets, biomethane production (after CO

2 and contaminant removal) to replace natural gas, especially in transportation, and the use of residual materials as fertilizers [

5].

The use of biogas through the conversion of solid waste into energy is relatively recent in Brazil. This sector is still in the process of consolidation and is subject to constant regulatory and policy changes. The greatest challenges in harnessing biogas for energy production are linked to the development of actions by the private sector, government, and research and development institutions. These factors further hinder the political, social, environmental, and technical structuring of the biogas sector in Brazil [

6].

According to the CIBiogás [

7] report, in 2022, Brazil had 885 existing and operational biogas plants, with a cumulative production of 2,886,462,729.75 Nm

3/year. Regarding the number of existing biogas plants by state in 2022, Minas Gerais ranks first with a total of 224 existing plants and 25 new plants, followed by Paraná with 139 existing plants and 29 new plants. In third place is Santa Catarina, with 55 existing plants and 15 new plants, while São Paulo ranks fourth with 54 existing plants and seven new plants. Goiás comes fifth, with 52 existing plants and 12 new plants. Although São Paulo accounts for 74 biogas plants and ranks fourth in terms of the number of installations, it is the largest biogas-producing state, with a total production of 1,016,642,220.10 Nm

3/year [

7]. For biogas production in the Southern Region of Brazil, the main substrate source used for biogas generation comes from municipal solid waste and sewage, followed by industrial and agricultural residues. The primary use of the biogas is for electricity generation [

7].

The main forms of energy conversion are direct combustion (with or without physical processes, such as drying, sorting, compression, and cutting/breaking), thermochemical processes (gasification, pyrolysis, liquefaction, and transesterification), or biological processes (anaerobic digestion and fermentation) [

8]. Biomass is then transformed into various energy products, such as heat, electricity, liquid fuels, and gaseous fuels [

9].

This study focuses on the thermal conversion process of pyrolysis and the biological conversion process of digestion, aiming at the generation of biogas and liquid and gaseous biofuels (bio-oil and syngas) [

10].

Among the conversion processes, pyrolysis has proven to be a promising technology for obtaining renewable fuels. It is a thermochemical process that involves heating organic materials in the absence of oxidizing agents. The final products of the pyrolysis process depend on several factors: pyrolysis temperature, heating rate, condensation temperature, the nature of the feedstock, and particle size [

11].

Pyrolysis is an analysis or decomposition reaction that occurs under the action of high temperatures. When the raw material is exposed to these high temperatures, the molecular structure of the compound breaks down due to the heat in an environment with little or no oxygen. The process is energy self-sustaining, as the chemical decomposition produces more energy than it consumes. Also known as carbonization, pyrolysis thermally decomposes carbon-containing materials, such as wood, agricultural waste, and any other organic matter, resulting in three phases: a solid phase (charcoal), a gaseous phase, and a liquid phase called the pyroligneous fraction (extract or bio-oil) [

12].

The temperatures applied during the pyrolysis process influence the production of each phase (char, gas, or liquid). Lower temperatures combined with longer vapor residence times favor the production of charcoal, high temperatures and long residence times increase the conversion of biomass into gas, and moderate temperatures with short vapor residence times are ideal for liquid production. Fast pyrolysis for liquid production is particularly advantageous due to the ease of storage and lower transportation costs compared to solid biomass [

10].

Biogas is a gas rich in methane (CH

4), carbon dioxide (CO

2), and other minor compounds, such as hydrogen sulfide (H

2S), nitrogen (N

2), water vapor (H

2O), and ammonia (NH

3). It is produced through the anaerobic digestion of industrial effluents, animal manure, and/or sewage sludge [

13]. This is a complex process that depends on the activity of various microorganisms that transform the organic matter in the substrates into biogas through biochemical reactions, acting synergistically and in proto-cooperation [

8]. Biogas generation depends on several factors, including the type of waste used, the methane content, and the quality of the biodigester [

14].

The process takes place in the absence of oxygen in equipment known as biodigesters. It offers advantages, such as production from locally available organic waste, generation near the consumption site, which avoids large investments or pipelines, and the conversion of environmental liabilities into energy assets. Designing a biodigestion plant involves several steps, from selecting and conditioning the raw material to the reactor itself and subsequent stages of separation and purification of the generated products [

15].

The biodigester is the main component of a biodigestion plant, where residual or cultivated biomass is converted by the action of microorganisms. There are different types of biodigesters or anaerobic reactors, including Upflow Anaerobic Sludge Blanket (UASB) reactor, Continuous Stirred Tank Reactor (CSTR),Covered Lagoon or Plug-Flow Reactor, Fixed-Bed Anaerobic Reactor, Rotating-Bed Anaerobic Reactor, Fluidized-Bed Anaerobic Reactor, and Solid-Phase Reactor [

13].

The CSTR reactor was developed to achieve a high reaction rate, applying engineering principles to reduce the hydraulic retention time by using mixing, heating, and strategies to retain microorganisms within the reactor. The covered lagoon biodigester, also known as the Canadian model or BLC, is the least technologically advanced. It is designed to operate with a total solid content of 0.5% to 5% and a hydraulic retention time of 30 to 60 days, making it suitable for warm climate regions.

The complete mix biodigester, which is a continuous stirred tank reactor (CSTR), features a higher technological level, operates with a solids content of 12% to 15%, and requires a minimum liquid retention time of 20 days. It is suitable for all types of climates and allows for the co-digestion of feedstocks (a mixture of two or more complementary substrates) [

13].

The CSTR biodigester model is more complex. The Continuous Stirred Tank Reactor (CSTR) was designed to handle large volumes and is characterized by its stirring system, which keeps the contents homogenized while controlling parameters, such as temperature, pH, and biomass level [

15].

The Covered Lagoon Biodigester (BLC) is commonly found in rural areas and is installed by excavating a tank in the ground, which is then waterproofed and covered with a geosynthetic material (a synthetic or natural polymer product in the form of a sheet or strip), such as PVC (polyvinyl chloride) and HDPE (High-Density Polyethylene). This is considered a low-tech model characterized by its low permeability to fluids and gases. It has a rectangular shape, and its slope and installation depend on the soil characteristics of each property [

15].

Multicriteria Decision Analysis (MCDA) methods aim to support decision-makers in choices involving multiple criteria, providing guidance for more effective and consistent decisions. It is an inherently complex process. MCDA addresses three main decision-making problems: selection, classification, and ranking. The first two are more commonly studied, while the third provides a way to handle MCDA problems that require alternatives to be assigned to ordered categories [

16].

A study by San Cristobal [

17] analyzed decisionmaking using the VIKOR method, a decision approach that considers multiple conflicting objectives across social, economic, technological, and environmental factors. The study assessed the specific measure of proximity to the ideal solution. The VIKOR method was applied alongside AHP to compare sustainable energy generation alternatives, including wind, hydro, solar thermal, solar thermoelectric, photovoltaic, biomass, biogas, and biofuels. The most advantageous option identified was a biomass power plant with co-firing in a conventional power plant.

Aghajani Mir et al. [

18] applied the TOPSIS decision-making method to determine the best municipal solid waste (MSW) management approach by comparing and ranking different scenarios. The defined and compared MSW treatment scenarios showed that the optimal decision involves a combination of recycling, anaerobic digestion, and landfill with electricity generation.

Similarly, Irfan [

19] used AHP and G-TOPSIS methods to analyze the energy barriers of biomass. The main barrier identified was technological and infrastructural, followed by economic and financial barriers, political and institutional obstacles, cultural and behavioral factors, and meteorological challenges.

Ramanathan and Ganesha [

20] proposed a model for domestic energy resource allocation. The suggested model included natural gas, firewood, and solar thermal energy for cooking; biogas and electricity generated from firewood for water pumping; and all electricity generation technologies for lighting and operating household appliances. Grid electricity was preferred only for lighting.

Based on a set of criteria, Kheybari, Kazemi, and Rezaei [

21] identified the best location for a bioethanol plant. Using the three dimensions of sustainability (economic, environmental, and social), they applied the Best–Worst Method (BWM) to calculate the overall score for each province, identifying Khuzestan Province as the most suitable location for bioethanol production in Iran.

The Analytic Hierarchy Process (AHP) method was developed in the 1970s by Thomas Saaty and can be applied in various fields of knowledge due to its ability to incorporate both qualitative and quantitative data into the analysis [

16].

Saaty [

22] describes AHP as a general measurement theory used to derive ratio scales from discrete and continuous paired comparisons. Measurements can be obtained from actual data or from a fundamental scale that reflects the relative strength of preferences and feelings. AHP finds broad applications in multicriteria decisionmaking, planning, resource allocation, and conflict resolution. Generally, a hierarchical model of a problem starts with the goal, followed by criteria and sub-criteria (which are subdivisions of the criteria), leading to the selection of alternatives.

The Technique for Order of Preference by Similarity to Ideal Solution(TOPSIS) was developed by Hwang and Yoon in 1981. It was designed to select the best alternative based on the shortest Euclidean distance from the positive ideal solution and the farthest from the negative ideal solution. The chosen alternative should be as close as possible to the “positive ideal” and as far as possible from the “negative ideal” [

16].

Implementing a biogas project involves several stages, including feasibility studies, plant planning, and operation. For the sustainable development of the biogas value chain, it is essential to understand the sector’s capacities and strategies to support stakeholders and decision-makers. This knowledge enables the identification of growth opportunities, technological improvements, and policies to stabilize the sector. A robust political, regulatory, and technological framework is crucial to sustaining and incentivizing the sector. Once consolidated, public policies will directly influence the development and strengthening of renewable energy sources [

6].

The success of biogas generation is directly linked to the design and sizing of the biodigestion plant, while inefficiency is often related to improper plant sizing, bioreactor loading, substrate agitation, and temperature control within the bioreactors [

23]. Given the numerous variables involved in biogas and biofuel production, this study aims to apply a multicriteria model to assist public decision-makers in selecting among three conversion pathways: pyrolysis, covered lagoon biodigester, and continuous stirred-tank reactor (CSTR) biodigester. The analysis is based on environmental, social, economic, and technical criteria, applying the multicriteria methods AHP (Analytic Hierarchy Process) and TOPSIS (Technique for Order of Preference by Similarity to Ideal Solution) to rank the criteria and determine which of the technologies is the most advantageous for biogas and biofuel production.

2. Materials and Methods

This study aims to assist public decision-makers by analyzing environmental, economic, social, and technical criteria related to biogas and biofuels. The methodological approach employs the multicriteria AHP method for ranking the criteria and the TOPSIS method for selecting the best conversion pathway. The objective is to guide public managers in decision making for the implementation of biogas plants at the municipal level, considering the key factors for choosing among the conversion routes: pyrolysis, anaerobic digestion using the covered lagoon biodigester model, and the CSTR biodigester.

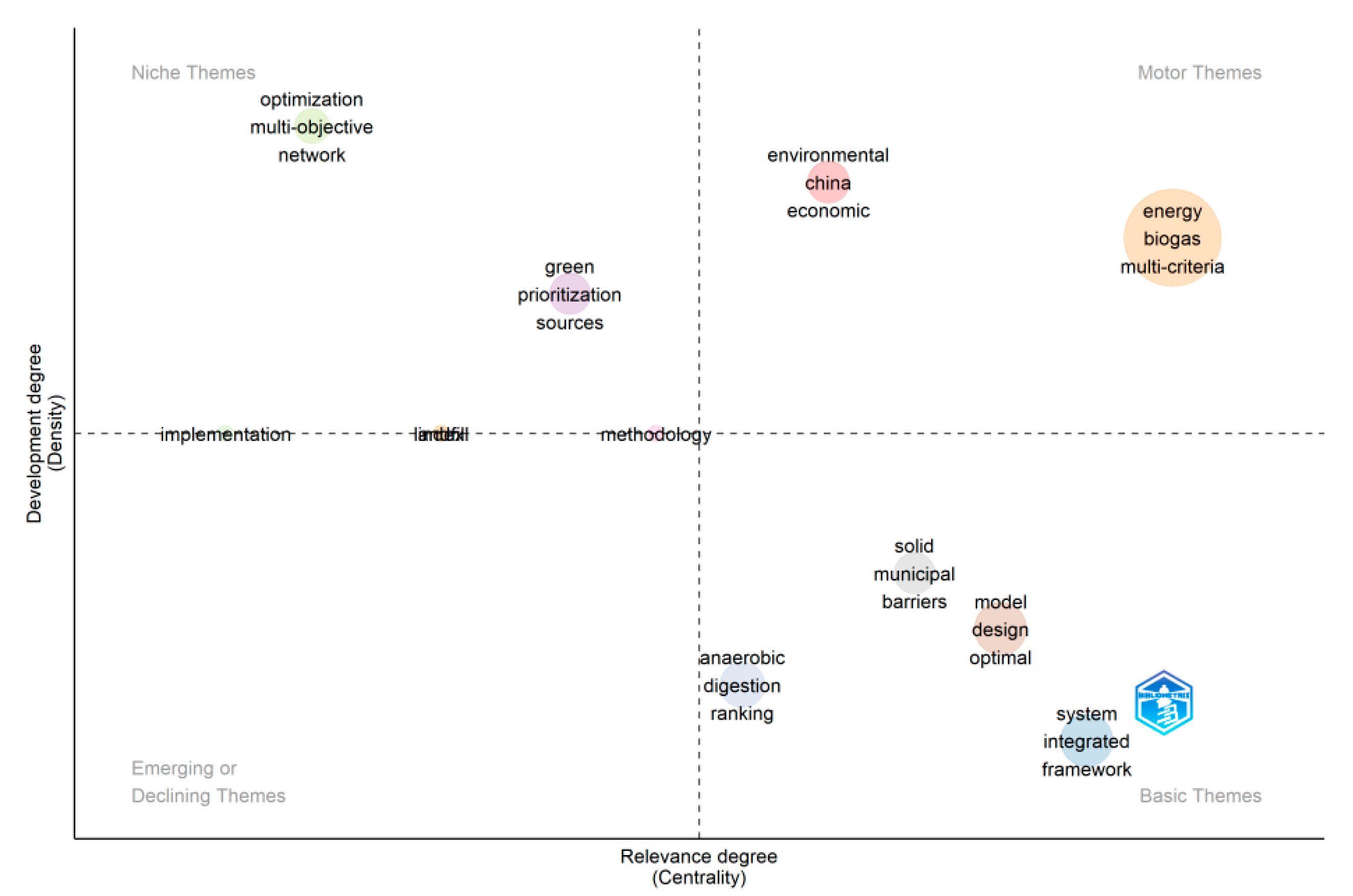

A bibliographic review was conducted with 145 articles from the Scopus and Web of Science databases. Through the analysis of these articles using Bibliometrix software version 4.3.0 and Biblioshiny function, a thematic map was generated based on the article titles. A research gap was identified related to biogas, energy generation, and the application of multicriteria decision-making methods as core themes in the field. Additionally, basic themes to be further developed were identified, including municipal solid barriers, ideal design models, and integrated system structures (

Figure 1).

With the identified research gap, the study aimed to determine the key parameters for decision making in biogas production projects. Yamaji et al. [

24] conducted a systematic analysis of scientific articles addressing decision making and biogas, compiling 58 analyzed articles that identified 499 distinct sub-criteria. These sub-criteria were subsequently grouped and classified, resulting in 39 sub-criteria covering four dimensions, which in this paper are referred to as decision-making criteria: environmental, economic, social, and technical.

For this study, five sub-criteria were selected for each main criterion, totaling 20 sub-criteria for analysis. These sub-criteria were chosen based on the results of the project model proposed by Yamaji et al. [

24], as presented in

Table 1.

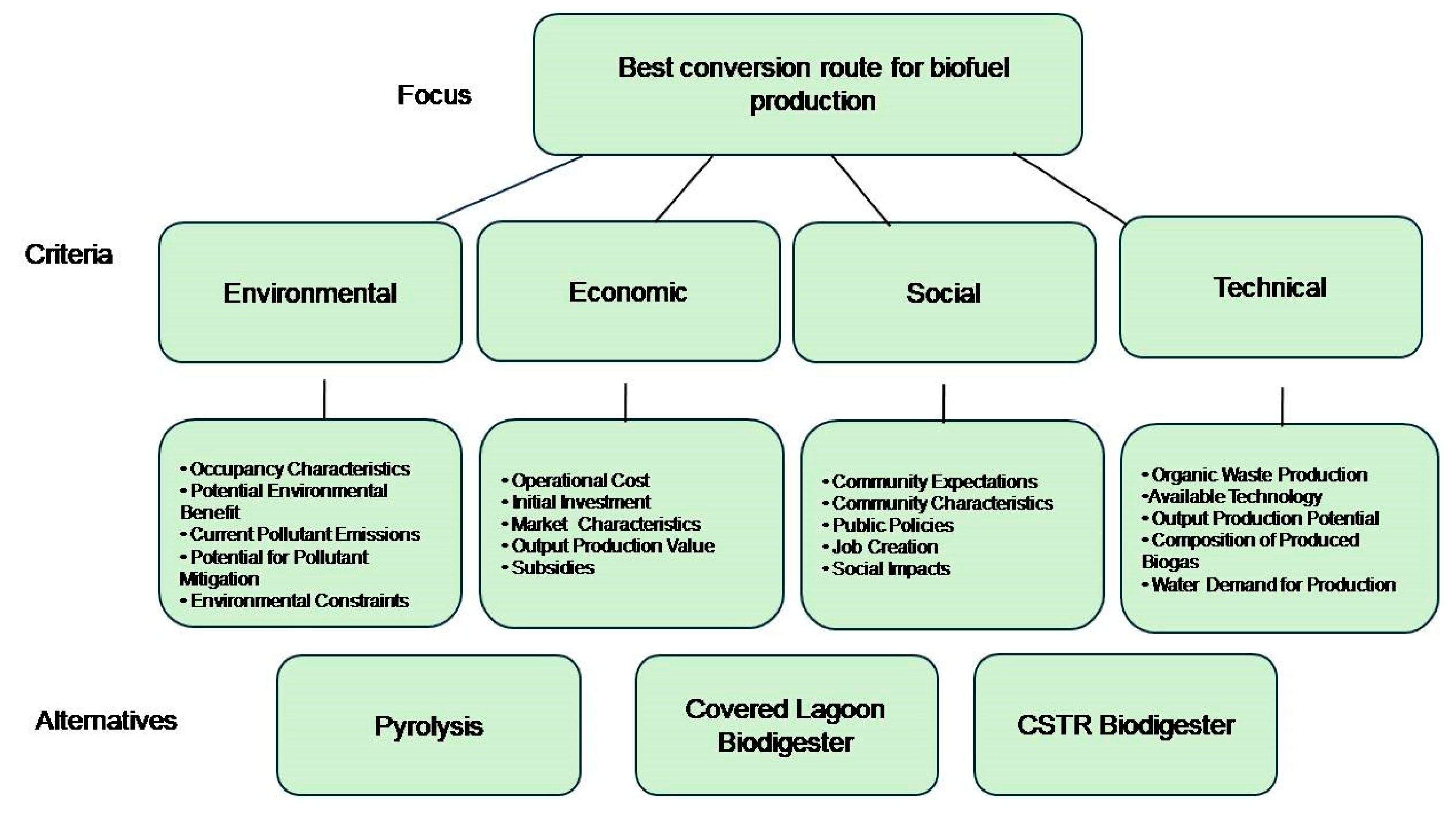

After defining the criteria, the weight allocation was carried out by a biogas specialist using the Analytic Hierarchy Process (AHP) and a fundamental scale that reflects the relative strength of preferences and perceptions. In the decision hierarchy (

Figure 2), the focus is set as the “best conversion route for biofuel production”, based on the following criteria: environmental, economic, social, and technical, along with the 20 sub-criteria for selecting among the alternatives of pyrolysis, covered lagoon biodigester, and CSTR biodigester. To model subjective decision-making processes based on multiple criteria within a hierarchical system, the structure must be based on three principles: (a) decision hierarchy, (b) pairwise comparative judgment of alternatives and criteria, and (c) consistency assessment of the results [

25].

After calculating the weights of each criterion using the AHP method, a questionnaire was created via Google Forms for public managers and biogas researchers to evaluate each sub-criterion related to each alternative on a scale from 0 to 10, where 0 represents highly disadvantageous and 10 represents highly advantageous. Following the evaluations, the TOPSIS method was applied, which is a technique for ordering preferences by similarity to the ideal solution (

Figure 3).

The TOPSIS method consists of selecting the alternative that is closest to the positive ideal solution and farthest from the negative ideal solution, where the highest-ranking alternative is considered the best choice [

26].

The objective of applying this methodology is to determine the best conversion route alternative for biofuel production among pyrolysis, covered lagoon biodigester, and CSTR biodigester. The TOPSIS method procedures can be described as follows: a set of alternatives (

A), a set of criteria (

C), where (

X) denotes the set of ratings, and (

W) represents the information set that denotes the performance ratings (

Table 2).

After constructing the TOPSIS information table, the normalized and weighted decision matrix (Nij) is calculated, as shown in Equation (1).

Equation (1): Normalized and Weighted Decision Matrix

Nij.

Source: Tzeng; Huang, 2011 [

26].

Next, the Positive Ideal Point (PIP) and Negative Ideal Point (NIP) of the ideal solution are calculated according to Equation (2).

Equation (2): Calculation of the Positive Ideal Point and Negative Ideal Point.

Source: Tzeng; Huang, 2011 [

26].

After calculating the NIP and PIP, the distance between the elements of the decision matrix and the ideal solutions is measured, as shown in Equation (3).

Equation (3): Distance between the elements of the decision matrix and the ideal solutions

Source: Tzeng; Huang, 2011 [

26].

As the final step, the closeness coefficient (CCj) is calculated for each alternative, as shown in Equation (4).

Equation (4): Closeness Coefficient (CCj) for each alternative

Source: Tzeng; Huang, 2011 [

26].

3. Results

This section presents the results of this study, including the matrices generated by the pairwise comparisons of the AHP methodand the tables produced by the TOPSIS method.

The calculation of weights for criteria and sub-criteria in the AHP reveals that the classical approach does not impose restrictions on the multiplication of the pairwise comparison matrix of criteria by the pairwise matrices of sub-criteria. As a result, information tends to spread across all base matrices used for computing the respective weights. However, the residuals from these multiplications introduce biases in the final weights, reflecting inter-criterion influences. In the context of the problem addressed in this study, each alternative (plant) has sufficiently distinct applications across the adopted criteria (dimensions), namely, environmental, economic, social, and technical aspects. Therefore, one of the specific objectives of the proposed methodology is to generate criterion-specific (dimension-specific) weights that are linearly independent. This enables the selection of an alternative (plant) to be evaluated in terms of the importance of each individual criterion, without the results being affected by inter-criterion influence. Achieving this configuration requires an appropriately adjusted mathematical modeling, as detailed below.

The selected evaluation criteria were environmental, economic, social, and technical. A total of 20 sub-criteria were assessed, including occupancy characteristics, potential environmental benefit, current pollutant emissions, potential for pollutant mitigation, environmental constraints, operational cost, initial investment, market characteristics, output production value, subsidies, community expectations, community characteristics, public policies, job creation, social impacts, organic waste production, available technology, output production potential, composition of produced biogas, and water demand for production.

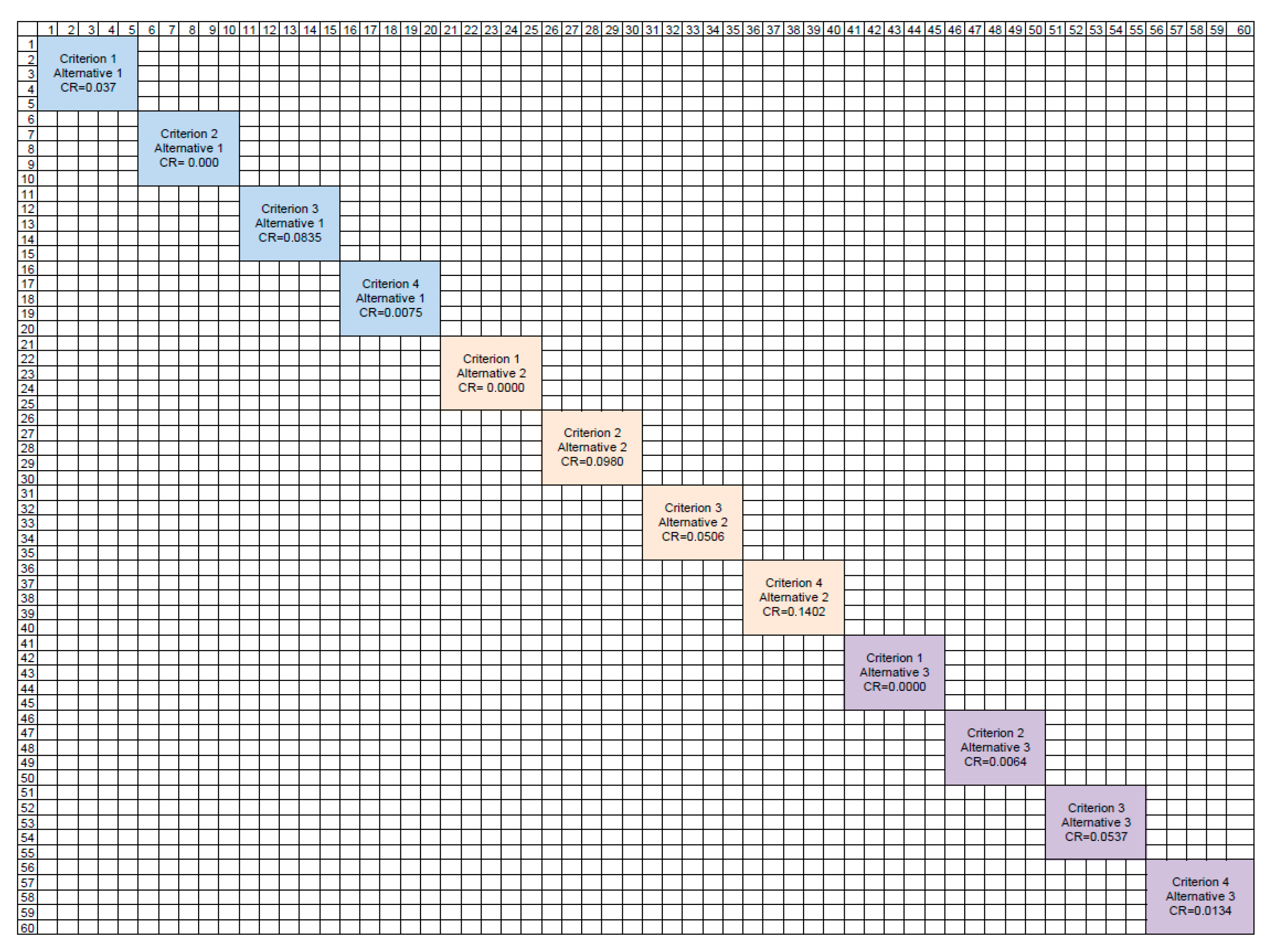

According to the hierarchical model proposed in this study, there are three plants evaluated based on four criteria, each composed of five sub-criteria. These sub-criteria must be compared relative to each other by an expert and also evaluated by decision-makers. This results in a total of 60 sub-criteria to be compared, applying a 1 to 9 scale to assess their relative importance.

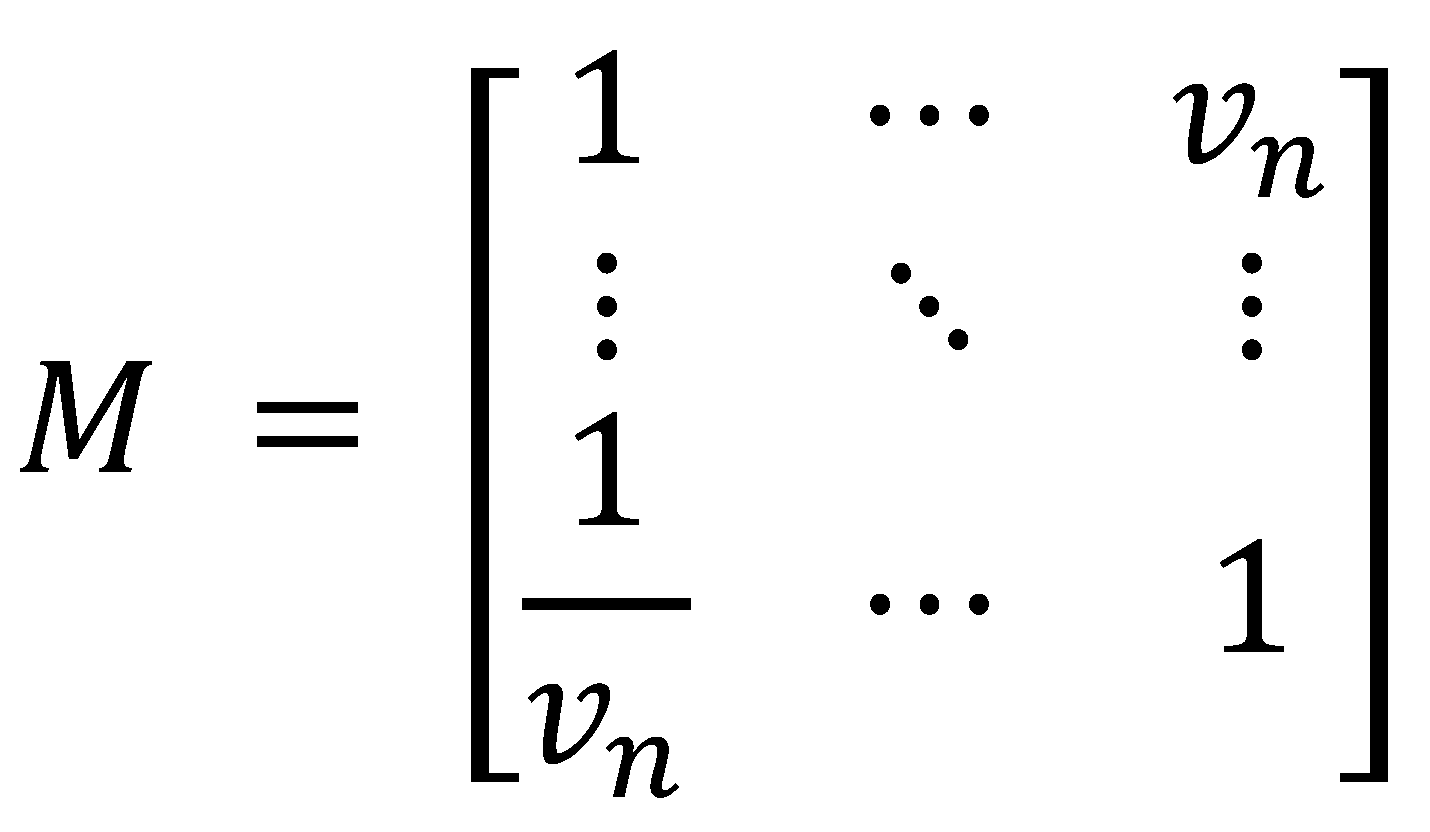

In this scenario, we have a matrix M (

Figure 4) with dimensions 60 × 60, totaling 3600 comparisons to be calculated by the volunteer expert. Considering that AHP defines the cells opposite the main diagonal of this matrix as the inverse of the value (1/vi), the number of required comparisons is reduced to 1200.

At this point, it is important to highlight the characteristics of the sub-criteria adopted from Yamaji et al. [

24], which follow the hierarchical structure illustrated in

Table 1. The concept introduced by Saaty [

22] implies that comparisons are made only among sub-criteria within the same criterion and belonging to the same plant.

This approach creates a filtering effect on the data, meaning that only a series of 12 sub-matrices with dimensions of 5 × 5, aligned along the main diagonal of the original matrix M, are actually subject to the pairwise comparison process by the expert. As a result, the workload is reduced to 402 direct comparisons, as shown in

Figure 5.

Each of these 12 sub-matrices with 5 × 5 dimensions represents the pairwise comparison of one criterion within a specific plant. The next step requires normalizing the internal values of these 12 sub-matrices (by dividing each value vi by the sum of the respective column of the sub-matrix).

Finally, by multiplying each original sub-matrix (row) by its normalized version (column), a sequence of 12 vectors (with 5 dimensions) is generated. These vectors are then organized into groups by criterion (across different plants), concluding with the calculation of an average vector for each criterion, which is also normalized to form the final weights of each sub-criterion (and its respective hierarchical criterion)

Table 3.

The next step involved the evaluation by municipal managers, consultants, project supervisors, and researchers in the biogas sector from a medium-sized municipality in the state of Paraná. They assessed the criteria and sub-criteria presented in

Table 1, rating each sub-criterion as either highly advantageous or highly disadvantageous for each conversion route alternative: pyrolysis, covered lagoon biodigester, and CSTR biodigester.

After collecting the participants’ ratings, the average score for each sub-criterion was calculated, defining whether it represented a cost or benefit function, and organizing the averages by conversion route (pyrolysis, covered lagoon biodigester, and CSTR biodigester). It is important to note that sub-criterion TEC11, which assesses water demand for production, is not applicable to the pyrolysis conversion route. To avoid errors in the model’s calculations, a value of 0.01 was assigned to this cell (

Table 4).

The next step was to calculate the normalized and weighted decision matrix (

Nij), as presented in Equation (1). The values of

rij,

vij, and

Nij were computed for the matrix calculation, as shown in

Table 5.

After completing these calculations, Equation (2) was used to calculate the Positive Ideal Solution (PIS) and Negative Ideal Solution (NIS), and Equation (3) was applied to measure the distance between the elements of the decision matrix and the ideal solutions (

Table 6 and

Table 7).

After calculating the positive and negative ideal points, the distance between the elements of the decision matrix and the ideal solutions was computed, as presented in Equation (3). The values obtained from this calculation are shown below:

To classify and rank the most advantageous conversion route, the closeness coefficient (CC) was calculated for each alternative according to Equation (4). The most advantageous alternative ranked (

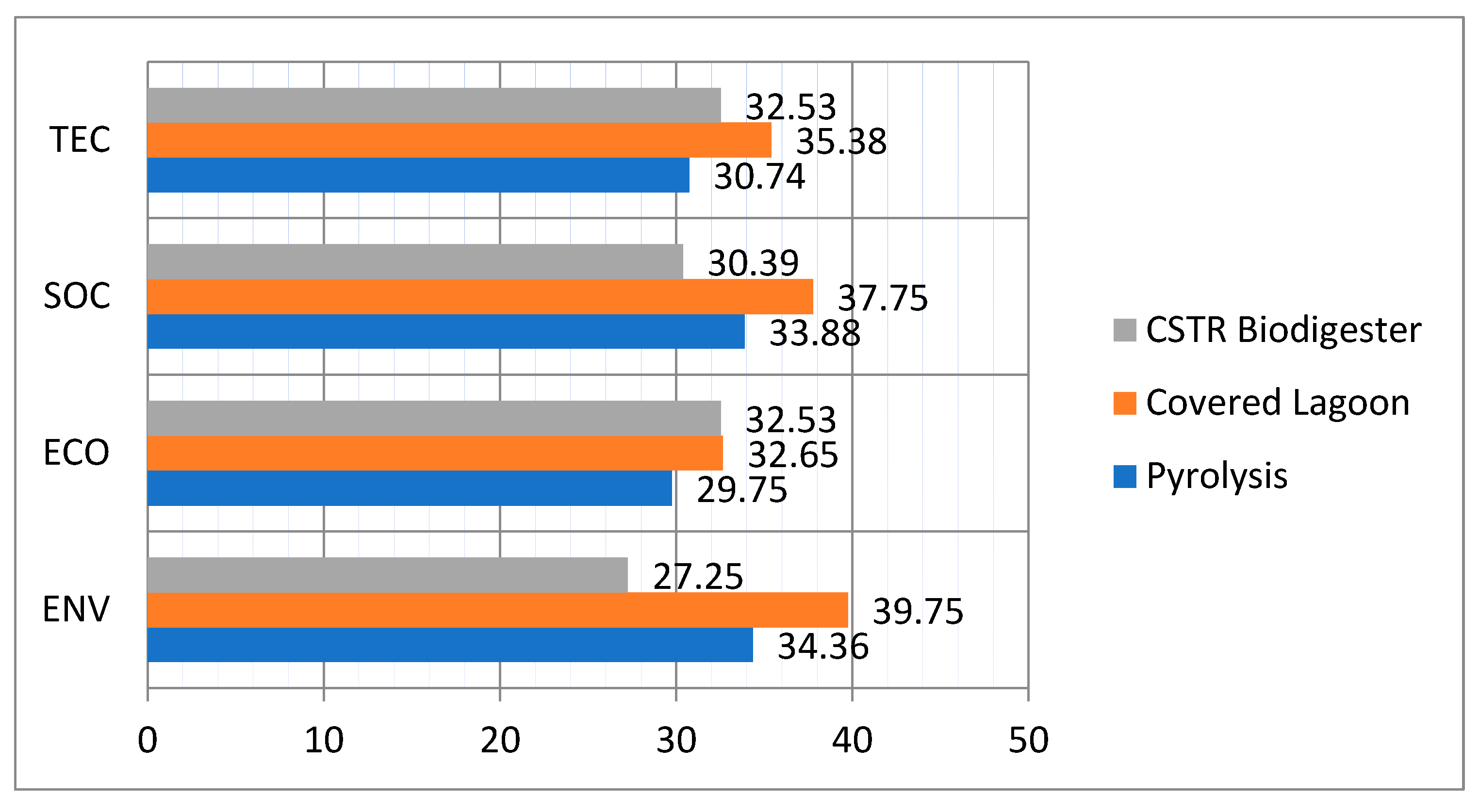

Table 8) first is the covered lagoon biodigester, followed by pyrolysis in second place, and the CSTR biodigester in third place.

Among the evaluated criteria, the environmental criterion received the highest score of 100.35, followed by the social criterion with 100.33. The technical criterion ranked third with 97.04, and the economic criterion ranked last with a total of 91.28.

The ranking of the criteria based on the decision-makers’ evaluation is presented in

Figure 6:

Covered Lagoon Biodigester: environmental, social, technical, and economic.

Pyrolysis: environmental, social, technical, and economic.

CSTR Biodigester: technical, economic, social and environmental.

By evaluating the criteria and sub-criteria individually and analyzing the scores given by each decision-maker, it is noted that in the ranking of criteria, the environmental and social dimensions received very similar scores, followed by the technical criterion, with the economic criterion ranking last. For the covered lagoon alternative, the environmental and technical criteria stood out.

By evaluating each sub-criterion individually and aggregating the scores provided by each decision-maker,

Table 9 was generated.

Among the five highest-rated sub-criteria, we have:

SOC05—Social Impacts: expected impacts on the community, such as improvements in public health, quality of life, decent work, and the promotion of the local economy;

ECO09—Subsidies: tax or credit incentives granted by the government for the project;

TEC04—Output Production Potential: estimated quantity of output production;

ENV02—Potential Environmental Benefits: environmental benefits anticipated by the project, such as increased use of biofertilizers, waste reinserted into the economic chain, and impact on global warming;

ENV04—Potential for Pollutant Emission Mitigation: the amount of pollutant emissions avoided through the implementation of the project.

These analyses can support public managers during the research and implementation phases of a biogas and biofuel plant, providing guidance on the most relevant criteria and sub-criteria to consider during the initial stages of planning, construction, and site selection.

4. Discussion

The promotion of renewable energy will assist Brazil in meeting its established targets for reducing greenhouse gas emissions—up to 37% by 2025 and 43% by 2030—thus contributing to the national goals under the Paris Agreement. The sustainable development of the biogas value chain requires the support of key stakeholders and decision-makers in the energy sector to identify growth opportunities, technological improvements, and policy measures aimed at stabilizing the sector and addressing the various bottlenecks highlighted in this study. These include the need for the approval of specific policies and regulations, broader dissemination of data on biogas production potential, the presence of qualified companies in the sector, greater clarity on financing mechanisms, increased development of R&D projects, and the creation of viable business models for the segment, among others.

Opportunities already identified should be seized, such as the expansion of vocational training programs, stronger collaboration between universities and companies in the sanitation sector, the development of intermunicipal consortia, the decentralization of municipal energy supply, and increased competitiveness in the sanitation sector. The results of this study aim to support public managers in implementing new biofuel conversion projects by guiding them on the most relevant criteria for selecting among the available routes, namely: pyrolysis, covered lagoon biodigester, and CSTR biodigester.

Among the proposed alternatives for biogas and biofuel conversion, the covered lagoon biodigester was identified as the most advantageous option, followed by pyrolysis, and lastly, the CSTR biodigester. This outcome may be attributed to the fact that this type of biodigester is the most commonly used for biogas production in Brazil and involves less technical complexity compared to the CSTR model.

The covered lagoon biodigester model is the most commonly used system. It features a low technological level and is easy to construct and operate. Due to its simplicity, it is widely employed in rural properties and agro-industrial facilities, and it can process a variety of substrates, such as waste from animal slaughterhouses, starch production, and swine farming [

27]. This type of biodigester is characterized by a masonry base, a gas holder made of flexible PVC membrane, and a plastic tarp lining in its fermentation chamber, which, due to its larger surface area exposed to the sun, increases biogas generation on hot days. The model can be applied in both small and large-scale properties, as well as agro-industrial projects. It is the most widespread model in Brazil. Its horizontal construction and suitability for shallow soils reduce the risk of groundwater contamination. This model has a medium level of construction complexity and is easy to operate. It is economically viable, with low initial investment, maintenance costs, and payback period compared to other models [

28].

Based on the criteria established and the feedback from respondents regarding the conversion routes that come closest to the ideal solution, the environmental criterion was ranked as the most important, followed by social, technical, and, finally, economic. This reveals that when considering biogas and biofuel generation, many decision-makers initially focus on the environmental and social benefits of the project. Although the implementation of biogas and biofuel plants typically begins with technical and economic assessments, this analysis indicates that environmental and social criteria should take precedence in the decision-making process.

5. Conclusions

This study aimed to apply a multicriteria decision-making model in a medium-sized city in the state of Paraná, with the objective of assisting public decision-makers in choosing among the conversion routes pyrolysis, covered lagoon biodigester, and CSTR biodigester for the production of biogas and biofuels, based on an analysis of environmental, social, economic, and technical criteria. These criteria and alternatives were evaluated using the multicriteria methods AHP and TOPSIS.

The contribution of this study lies in guiding and supporting municipal public managers in selecting the covered lagoon biodigester as the most advantageous conversion route in a scenario similar to the one analyzed (a medium-sized municipality). Regarding the evaluated criteria, it was observed that environmental and social criteria received higher scores than the technical and economic ones. Concerning the sub-criteria, the authors ranked the scores individually assigned by decision-makers, which can assist in determining which sub-criteria should be prioritized in public management analyses.

In light of the theoretical foundation, this study presented the AHP (Analytic Hierarchy Process) calculations, including the decision hierarchy, pairwise sub-matrices, and normalized weights by criterion. With the TOPSIS (Technique for Order Preference by Similarity to Ideal Solution) method, average scores from decision-makers for each conversion route were used to calculate sub-criteria weights, cost and benefit functions, the normalized and weighted decision matrix, positive and negative ideal points, distances between matrix elements and ideal solutions, and the closeness coefficient. Based on the multicriteria decision-making calculations, the most advantageous alternative was biogas and biofuel generation using the covered lagoon biodigester, followed by pyrolysis in second place and the CSTR biodigester in third.

This study presents some limitations. One is the adjustment required for criterion TEC11, which addresses water demand for production; since the pyrolysis route does not use water, a placeholder value of 0.01 was assigned to enable model calculations. Another limitation is that if any criteria or sub-criteria suggested in this study are modified, it is necessary to recalculate the AHP weights and rerun the TOPSIS method to determine the most advantageous conversion route.

For future research, conducting a comparative analysis of other MCDA methods is recommended, such as the application of AHP throughout the entire process, and comparisons among methods, such as Fuzzy ARAS, CODAS, COPRAS, EDAS, and OCRA. Further investigation should include sensitivity and stability analyses of the proposed approach in different applications and with larger datasets. This model can also serve as a guideline for the implementation of biogas and biofuel plants by carefully measuring and analyzing each criterion and sub-criterion using the covered lagoon biodigester as the conversion route, and assessing the universality and adaptability of this conversion route in diverse contexts. In a second phase, a comparative analysis among the three conversion routes can be conducted, evaluating indicators and limitations, provided they are located in the same region and use the same biomass inputs.