Assessment of Greenhouse Gas Reduction and Sustainability Index in Waste-to-Energy Conversion Scenarios Using System Dynamics Modeling

Abstract

1. Introduction

2. Materials and Methods

2.1. Model Structure

2.2. Model Validation and Sensitivity Analysis Overview

2.3. Electrical Energy Production and Consumption

2.4. GHG Emissions

2.5. Economic Profit

2.6. Environmental Outcomes

2.7. Sustainability Index

3. Results

3.1. Projected Waste Generation and Landfill Disposal

3.2. Waste Composition Prediction

3.3. Electricity Balance of Waste Management Scenarios

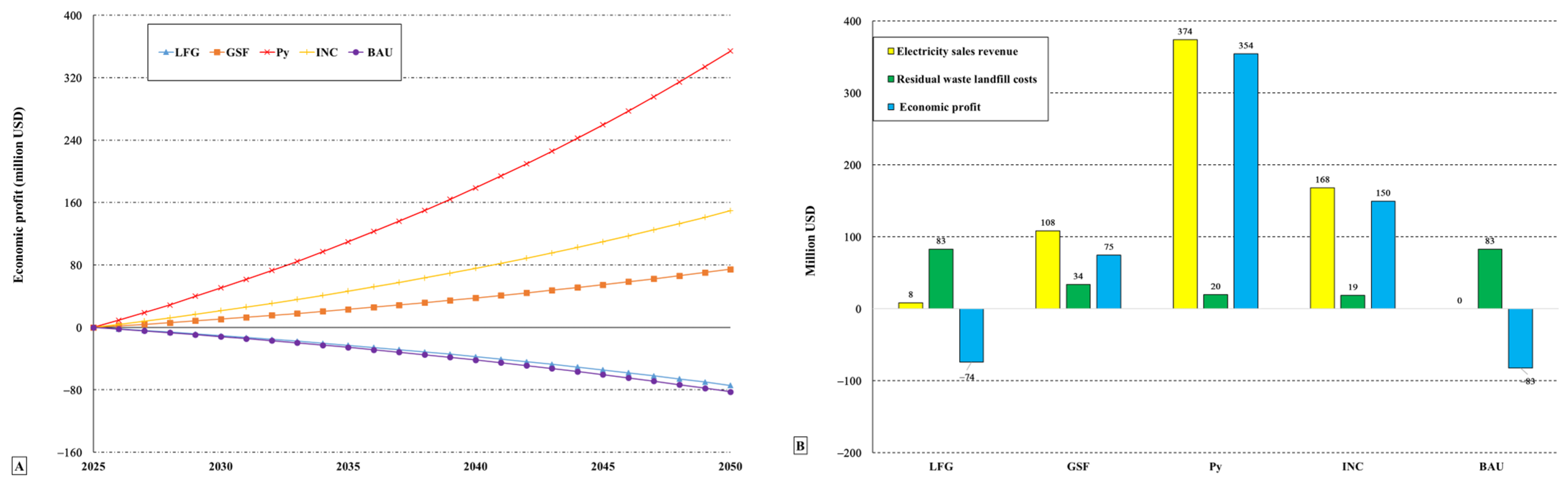

3.4. Net Economic Profit of Waste Management Scenarios

3.5. GHG Emissions in Waste Management Scenarios

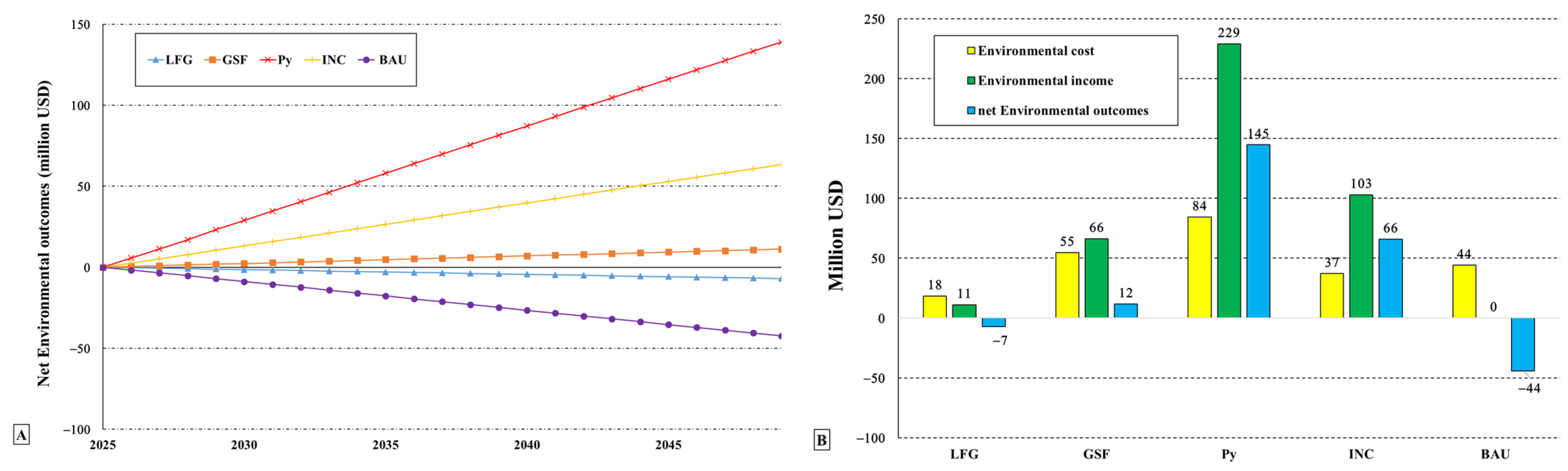

3.6. Net Environmental Outcomes in Waste Management Scenarios

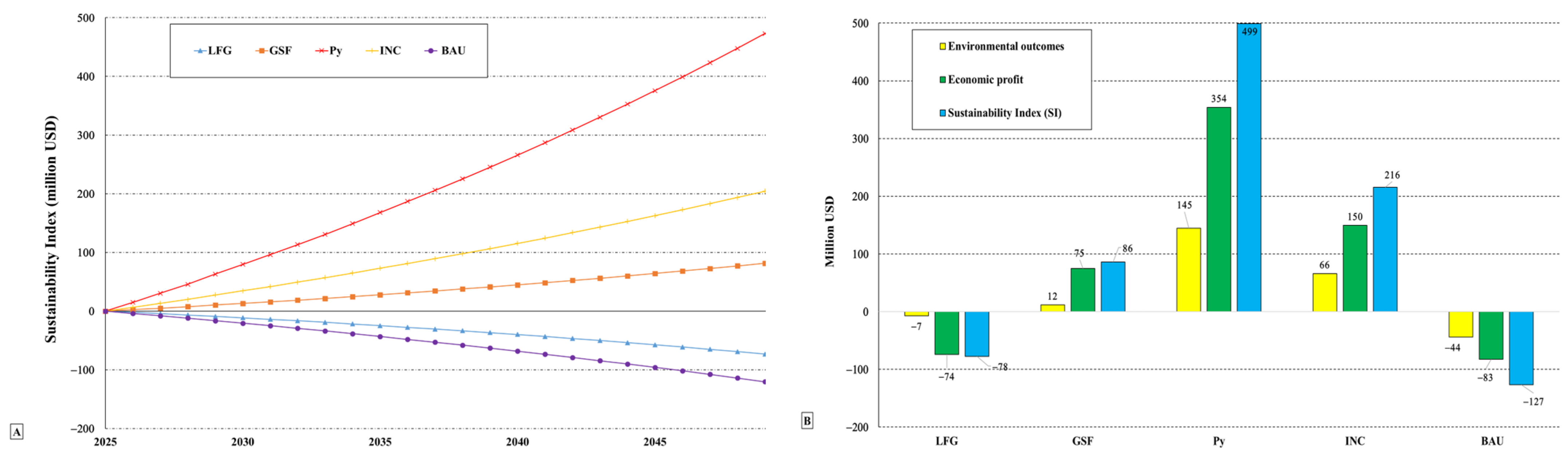

3.7. Sustainability Index in Waste Management Scenarios

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Nomenclature | |||

| Indexes | |||

| Different technologies (LFE, LF, INC, GSF) | Types of emissions (DEM, IEM, AV, IAV) | ||

| Landfill with gas recovery | GHG emissions from input material | ||

| Conventional landfill without gas recovery | Avoided GHGs from using tech | ||

| Incineration | Avoided GHGs from input material savings | ||

| Gasification | Direct emission of GHGs from tech | ||

| Py | Pyrolysis | Million tons | |

| Dry waste | Types of GHGs (CO2, CH4, N2O) | ||

| Global warming potential | Fuel | ||

| Parameters | |||

| Carbon credit (USD/ton) | Heat value of waste type K (MJ/ton) | ||

| Mechanical treatment efficiency for Py, GSF, and INC (%) | Heat value of methane (MJ/M3) | ||

| Efficiency of technologies (%) | The efficiency of methane to electricity (%) | ||

| Expected landfill diversion (%) | Methane generation rate (1/year) | ||

| The fraction of fossil carbon in waste | Methane potential generation capacity (M3/ton) | ||

| The ratio of carbon in household waste | Electricity consumption coefficient by different technologies (kWh/ton) | ||

| The combustion efficiency of the waste incinerator | The conversion factor of heat ratio (MJ to kWh) | ||

| The coefficient of CO2 emission from electricity consumption in tech | The molecular weight proportion of CO2/C | ||

| The coefficient of CO2 emission from fuel consumption in tech | Waste disposal costs (USD/ton) | ||

| Price of produced energy (USD/kWh) | The volume of waste to landfill (ton) | ||

| The estimated factor of X emission by different technologies | The volume of dry waste type K used in tech (ton) | ||

| The estimated X emission factor by different technologies | The savings in fuel from using different tech | ||

| The fuel consumption by different tech | |||

| Calculated variables | |||

| Produced energy by different technologies (kWh) | Produced waste in technologies (ton) | ||

| Electricity consumption by different technologies (USD/year) | Environmental income by different technologies (USD/year) | ||

| Economic income by different technologies (USD/year) | The savings in fuel by different technologies | ||

| Economic cost by different technologies (USD/year) | Environmental cost by different technologies (USD/year) | ||

| Economic profit by different technologies (USD/year) | Net electricity output by different technologies (kWh) | ||

| The GHG emissions of Y in tech | Environmental outcomes by different technologies (USD/year) | ||

| The net GHG emissions Y in tech | Sustainability index by different technologies (USD/year) | ||

References

- UNEP. Global Waste Management Outlook 2024: Beyond an Age of Waste, Turning Rubbish into a Resource. 2024. Available online: https://www.unep.org/resources/global-waste-management-outlook-2024 (accessed on 1 May 2024).

- Siddiqua, A.; Hahladakis, J.N.; Al-Attiya, W.A.K.A. An overview of the environmental pollution and health effects associated with waste landfilling and open dumping. Environ. Sci. Pollut. Res. 2022, 29, 58514–58536. [Google Scholar] [CrossRef]

- Gupta, J.; Ghosh, P.; Kumari, M.; Thakur, I.S.; Swati. Chapter 14—Solid waste landfill sites for the mitigation of greenhouse gases. In Biomass, Biofuels, Biochemicals; Thakur, I.S., Pandey, A., Ngo, H.H., Soccol, C.R., Larroche, C., Eds.; Elsevier: Rio de Janeiro, Brazil, 2022; pp. 315–340. [Google Scholar]

- Pegg, K.; Wilson, G.; Al-Duri, B. Exploring Trigeneration in MSW Gasification: An Energy Recovery Potential Study Using Monte Carlo Simulation. Energies 2025, 18, 1034. [Google Scholar] [CrossRef]

- Stark, B.M.; Tian, K.; Krause, M.J. Investigation of U.S. landfill GHG reporting program methane emission models. Waste Manag. 2024, 186, 86–93. [Google Scholar] [CrossRef] [PubMed]

- Keskin, T.; Yilmaz, E.; Kasap, T.; Sari, M.; Cao, S. Toward Viable Industrial Solid Residual Waste Recycling: A Review of Its Innovative Applications and Future Perspectives. Minerals 2024, 14, 943. [Google Scholar] [CrossRef]

- Agboola, S.O.; Inetabor, G.M.; Bello, O.O.; Bello, O.S. Waste Pollution and Management: Current Challenges and Future Perspectives. In Smart Waste and Wastewater Management by Biotechnological Approaches; Springer: Berlin/Heidelberg, Germany, 2025; pp. 3–20. [Google Scholar]

- Abubakar, I.R.; Maniruzzaman, K.M.; Dano, U.L.; AlShihri, F.S.; AlShammari, M.S.; Ahmed, S.M.S.; Al-Gehlani, W.A.G.; Alrawaf, T.I. Environmental Sustainability Impacts of Solid Waste Management Practices in the Global South. Int. J. Environ. Res. Public Health 2022, 19, 12717. [Google Scholar] [CrossRef]

- Marciniuk-Kluska, A.; Kluska, M. Energy Recovery from Municipal Biodegradable Waste in a Circular Economy. Energies 2025, 18, 2210. [Google Scholar] [CrossRef]

- Sharma, H.B.; Vanapalli, K.R.; Samal, B.; Cheela, V.R.S.; Dubey, B.K.; Bhattacharya, J. Circular economy approach in solid waste management system to achieve UN-SDGs: Solutions for post-COVID recovery. Sci. Total Environ. 2021, 800, 149605. [Google Scholar] [CrossRef]

- Jiang, T.; He, X.; Su, B.; Havea, P.H.; Wei, K.; Kundzewicz, Z.W.; Liu, D. COP 28: Challenge of coping with climate crisis. Innovation 2024, 5, 100559. [Google Scholar] [CrossRef]

- Molitor, M.R. The United Nations climate change agreements. In The Global Environment; Routledge: Oxfordshire, UK, 2023; pp. 210–235. [Google Scholar]

- Haraguchi, M.; Siddiqi, A.; Narayanamurti, V. Stochastic cost-benefit analysis of urban waste-to-energy systems. J. Clean. Prod. 2019, 224, 751–765. [Google Scholar] [CrossRef]

- Siddiqi, A.; Haraguchi, M.; Narayanamurti, V. Urban waste to energy recovery assessment simulations for developing countries. World Dev. 2020, 131, 104949. [Google Scholar] [CrossRef]

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank Publications: Washington, DC, USA, 2018. [Google Scholar]

- Neuwahl, F.; Cusano, G.; GÓMEZ, B.J.; Holbrook, S.; Roudier, S. Best available techniques (BAT) reference document for waste incineration: Industrial emissions directive 2010/75/EU (Integrated Pollution Prevention and Control). 2019. Available online: https://eippcb.jrc.ec.europa.eu/sites/default/files/2020-01/JRC118637_WI_Bref_2019_published_0.pdf (accessed on 7 January 2020).

- Khan, S.; Anjum, R.; Raza, S.T.; Ahmed Bazai, N.; Ihtisham, M. Technologies for municipal solid waste management: Current status, challenges, and future perspectives. Chemosphere 2022, 288, 132403. [Google Scholar] [CrossRef] [PubMed]

- Elmnifi, M.; Habeeb, L.J.; Majdi, H.S.; Oleksandr, T. Chapter 24—Energy recovery from municipal solid waste incineration: Case study—Libya. In Advances in Energy from Waste; Vambol, V., Vambol, S., Khan, N.A., Mozaffari, N., Mozaffari, N., Eds.; Woodhead Publishing: Cambridgeshire, UK, 2024; pp. 773–809. [Google Scholar]

- EU. Directive (EU) 2023/1791 of the European Parliament and of the Council of 13 September 2023 on Energy Efficiency and Amending Regulation (EU) 2023/955 (Recast). 2023. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32023L1791 (accessed on 17 February 2024).

- Samarasinghe, K.; Wijayatunga, P.D.C. Techno-economic feasibility and environmental sustainability of waste-to-energy in a circular economy: Sri Lanka case study. Energy Sustain. Dev. 2022, 68, 308–317. [Google Scholar] [CrossRef]

- Chen, Y.; Pinegar, L.; Immonen, J.; Powell, K.M. Conversion of food waste to renewable energy: A techno-economic and environmental assessment. J. Clean. Prod. 2023, 385, 135741. [Google Scholar] [CrossRef]

- Oliveira, J.P.; Pessoa, F.L.P.; Mehl, A.; Alves, F.C.; Secchi, A.R. Sustainability Indicators to MSW Treatment Assessment: The Rio de Janeiro Case Study. Sustainability 2024, 16, 7445. [Google Scholar] [CrossRef]

- Dastjerdi, B.H.; Strezov, V.; Kumar, R.; Behnia, M. Economic Feasibility and Sustainability Assessment of Residual Municipal Solid Waste Management Scenarios in NSW, Australia. Sustainability 2021, 13, 8972. [Google Scholar] [CrossRef]

- Eslami, S.; Kabir, G.; Ng, K.T.W. Waste Generation Modeling Using System Dynamics with Seasonal and Educational Considerations. Sustainability 2023, 15, 9995. [Google Scholar] [CrossRef]

- Rafew, S.M.; Rafizul, I.M. Application of system dynamics for municipal solid waste to electric energy generation potential of Khulna city in Bangladesh. Energy Rep. 2023, 9, 4085–4110. [Google Scholar] [CrossRef]

- Shahbazi, A.; Moeinaddini, M.; Abdoli, M.A.; Hosseinzadeh, M.; Jaafarzadeh, N.; Sinha, R. Environmental Damage of Different Waste Treatment Scenarios by Considering Avoided Emissions Based on System Dynamics Modeling. Sustainability 2023, 15, 16158. [Google Scholar] [CrossRef]

- Sterman, J. System Dynamics: Systems Thinking and Modeling for a Complex World; Massachusetts Institute of Technology: Cambridge, MA, USA, 2002. [Google Scholar]

- Wang, W.-J.; You, X.-Y. Benefits analysis of classification of municipal solid waste based on system dynamics. J. Clean. Prod. 2021, 279, 123686. [Google Scholar] [CrossRef]

- Dianati, K.; Schäfer, L.; Milner, J.; Gómez-Sanabria, A.; Gitau, H.; Hale, J.; Langmaack, H.; Kiesewetter, G.; Muindi, K.; Mberu, B.; et al. A system dynamics-based scenario analysis of residential solid waste management in Kisumu, Kenya. Sci. Total Environ. 2021, 777, 146200. [Google Scholar] [CrossRef]

- Xiao, S.; Dong, H.; Geng, Y.; Tian, X. Low carbon potential of urban symbiosis under different municipal solid waste sorting modes based on a system dynamic method. Resour. Conserv. Recycl. 2022, 179, 106108. [Google Scholar] [CrossRef]

- Hosseinalizadeh, R.; Shakouri, G.H.; Izadbakhsh, H. Planning for energy production from municipal solid waste: An optimal technology mix via a hybrid closed-loop system dynamics-optimization approach. Expert Syst. Appl. 2022, 199, 116929. [Google Scholar] [CrossRef]

- Di Nola, M.F.; Escapa, M.; Ansah, J.P. Modelling solid waste management solutions: The case of Campania, Italy. Waste Manag. 2018, 78, 717–729. [Google Scholar] [CrossRef]

- Hosseinalizadeh, R.; Izadbakhsh, H.; Shakouri, G.H. A planning model for using municipal solid waste management technologies- considering Energy, Economic, and Environmental Impacts in Tehran-Iran. Sustain. Cities Soc. 2021, 65, 102566. [Google Scholar] [CrossRef]

- van der Hulst, M.K.; Ottenbros, A.B.; van der Drift, B.; Ferjan, Š.; van Harmelen, T.; Schwarz, A.E.; Worrell, E.; van Zelm, R.; Huijbregts, M.A.J.; Hauck, M. Greenhouse gas benefits from direct chemical recycling of mixed plastic waste. Resour. Conserv. Recycl. 2022, 186, 106582. [Google Scholar] [CrossRef]

- Xayachak, T.; Haque, N.; Lau, D.; Parthasarathy, R.; Pramanik, B.K. Assessing the environmental footprint of plastic pyrolysis and gasification: A life cycle inventory study. Process Saf. Environ. Prot. 2023, 173, 592–603. [Google Scholar] [CrossRef]

- Damgaard, A.; Riber, C.; Fruergaard, T.; Hulgaard, T.; Christensen, T.H. Life-cycle-assessment of the historical development of air pollution control and energy recovery in waste incineration. Waste Manag. 2010, 30, 1244–1250. [Google Scholar] [CrossRef]

- Hong, J.; Li, X.; Zhaojie, C. Life cycle assessment of four municipal solid waste management scenarios in China. Waste Manag. 2010, 30, 2362–2369. [Google Scholar] [CrossRef]

- Shahbazi, A.L.I.; Moeinaddini, M.; Abdoli, M.; Hosseinzadeh, M.; Jaafarzadeh Haghighi Fard, N. Application of system dynamics modeling and life cycle impact assessment method based on endpoint in examining different waste management scenarios. J. Nat. Environ. 2025, 78, 153–167. [Google Scholar] [CrossRef]

- McDougall, F.R.; White, P.R.; Franke, M.; Hindle, P. Integrated Solid Waste Management: A Life Cycle Inventory; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Haight, M. Integrated Solid Waste Management Model; Technical Report; University of Waterloo, School of Planning: Waterloo, ON, Canada, 2004. [Google Scholar]

- Rashid, M.I.; Shahzad, K. Food waste recycling for compost production and its economic and environmental assessment as circular economy indicators of solid waste management. J. Clean. Prod. 2021, 317, 128467. [Google Scholar] [CrossRef]

- Yang, Q.; Han, F.; Chen, Y.; Yang, H.; Chen, H. Greenhouse gas emissions of a biomass-based pyrolysis plant in China. Renew. Sustain. Energy Rev. 2016, 53, 1580–1590. [Google Scholar] [CrossRef]

- Samer, M. Pyrolysis; IntechOpen: London, UK, 2017; p. 350. [Google Scholar]

- Dong, J.; Tang, Y.; Nzihou, A.; Chi, Y.; Weiss-Hortala, E.; Ni, M. Life cycle assessment of pyrolysis, gasification and incineration waste-to-energy technologies: Theoretical analysis and case study of commercial plants. Sci. Total Environ. 2018, 626, 744–753. [Google Scholar] [CrossRef] [PubMed]

- Faisal, F.; Rasul, M.G.; Jahirul, M.I.; Schaller, D. Pyrolytic conversion of waste plastics to energy products: A review on yields, properties, and production costs. Sci Total Environ. 2023, 861, 160721. [Google Scholar] [CrossRef]

- Astrup, T.F.; Tonini, D.; Turconi, R.; Boldrin, A. Life cycle assessment of thermal Waste-to-Energy technologies: Review and recommendations. Waste Manag. 2015, 37, 104–115. [Google Scholar] [CrossRef] [PubMed]

- Arena, U. Process and technological aspects of municipal solid waste gasification. A review. Waste Manag. 2012, 32, 625–639. [Google Scholar] [CrossRef]

- Cherubini, F.; Bargigli, S.; Ulgiati, S. Life cycle assessment of urban waste management: Energy performances and environmental impacts. The case of Rome, Italy. Waste Manag. 2008, 28, 2552–2564. [Google Scholar] [CrossRef]

- Singh, R.; Prasad, V.; Vaish, B. Advances in Waste-to-Energy Technologies; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Milutinović, B.; Stefanović, G.; Đekić, P.S.; Mijailović, I.; Tomić, M. Environmental assessment of waste management scenarios with energy recovery using life cycle assessment and multi-criteria analysis. Energy 2017, 137, 917–926. [Google Scholar] [CrossRef]

- Oliveira Neto, G.C.d.; Chaves, L.E.C.; Pinto, L.F.R.; Santana, J.C.C.; Amorim, M.P.C.; Rodrigues, M.J.F. Economic, Environmental and Social Benefits of Adoption of Pyrolysis Process of Tires: A Feasible and Ecofriendly Mode to Reduce the Impacts of Scrap Tires in Brazil. Sustainability 2019, 11, 2076. [Google Scholar] [CrossRef]

- Fernández-González, J.M.; Grindlay, A.L.; Serrano-Bernardo, F.; Rodríguez-Rojas, M.I.; Zamorano, M. Economic and environmental review of Waste-to-Energy systems for municipal solid waste management in medium and small municipalities. Waste Manag. 2017, 67, 360–374. [Google Scholar] [CrossRef]

- Lin, Y.; Wang, H.; Wang, Y.; Huo, R.; Huang, Z.; Liu, M.; Wei, G.; Zhao, Z.; Li, H.; Fang, Y. Review of Biomass Chemical Looping Gasification in China. Energy Fuels 2020, 34, 7847–7862. [Google Scholar] [CrossRef]

- Amini, E.; Nematollahi, H.; Moradi Banestani, N. Estimation and Modeling of Biogas Production in Rural Small Landfills (Case Study: Chaharmahaal and Bakhtiari and Yazd Rural Areas). Environ. Energy Econ. Res. 2017, 1, 383–392. [Google Scholar]

- Breukelman, H.; Krikke, H.; Löhr, A. Failing services on urban waste management in developing countries: A review on symptoms, diagnoses, and interventions. Sustainability 2019, 11, 6977. [Google Scholar] [CrossRef]

- Farooq, A.; Haputta, P.; Gheewala, S.H. Economic feasibility assessment of waste to energy technologies for the development of a sustainable municipal solid waste management system in Thailand. Renew. Energy 2024, 233, 121155. [Google Scholar] [CrossRef]

- Tan, S.T.; Ho, W.S.; Hashim, H.; Lee, C.T.; Taib, M.R.; Ho, C.S. Energy, economic and environmental (3E) analysis of waste-to-energy (WTE) strategies for municipal solid waste (MSW) management in Malaysia. Energy Convers. Manag. 2015, 102, 111–120. [Google Scholar] [CrossRef]

- Khwamman, S.; Chaiyat, N. Energy, economic, and environmental analysis of a waste-to-energy-to-zero system. Clean. Chem. Eng. 2025, 11, 100142. [Google Scholar] [CrossRef]

- Stewart, C.E.; Zheng, J.; Botte, J.; Cotrufo, M.F. Co-generated fast pyrolysis biochar mitigates green-house gas emissions and increases carbon sequestration in temperate soils. GCB Bioenergy 2013, 5, 153–164. [Google Scholar] [CrossRef]

- Eriksson, M.; Strid, I.; Hansson, P.-A. Carbon footprint of food waste management options in the waste hierarchy—A Swedish case study. J. Clean. Prod. 2015, 93, 115–125. [Google Scholar] [CrossRef]

- Yazaki, M.; Fushimi, C. Estimation of CO2 Reduction Potential and Cost of Solid Biomass Fuel Production Process Integrated with a Waste Gasification and Direct Melting System. Energy Fuels 2020, 34, 9632–9642. [Google Scholar] [CrossRef]

- Kumar, A.; Samadder, S.R. Assessment of energy recovery potential and analysis of environmental impacts of waste to energy options using life cycle assessment. J. Clean. Prod. 2022, 365, 132854. [Google Scholar] [CrossRef]

- Terwilliger, J. The new environmental economics: Sustainability and justice. Environ. Politics 2023, 32, 561–563. [Google Scholar] [CrossRef]

- Dong, J.; Tang, Y.; Nzihou, A.; Chi, Y. Key factors influencing the environmental performance of pyrolysis, gasification and incineration Waste-to-Energy technologies. Energy Convers. Manag. 2019, 196, 497–512. [Google Scholar] [CrossRef]

- Hoornweg, D.; Bhada-Tata, P. What a waste: A global review of solid waste management. Urban Dev. Ser. Knowl. Pap. 2012, 1, 68135. [Google Scholar]

- Palafox-Alcantar, P.G.; Hunt, D.V.L.; Rogers, C.D.F. The complementary use of game theory for the circular economy: A review of waste management decision-making methods in civil engineering. Waste Manag. 2020, 102, 598–612. [Google Scholar] [CrossRef] [PubMed]

- Hsu, H.-W.; Binyet, E.; Nugroho, R.A.A.; Wang, W.-C.; Srinophakun, P.; Chein, R.-Y.; Demafelis, R.; Chiarasumran, N.; Saputro, H.; Alhikami, A.F.; et al. Toward sustainability of Waste-to-Energy: An overview. Energy Convers. Manag. 2024, 321, 119063. [Google Scholar] [CrossRef]

- Chong, Y.T.; Teo, K.M.; Tang, L.C. A lifecycle-based sustainability indicator framework for waste-to-energy systems and a proposed metric of sustainability. Renew. Sustain. Energy Rev. 2016, 56, 797–809. [Google Scholar] [CrossRef]

- Stehlík, P. Contribution to advances in waste-to-energy technologies. J. Clean. Prod. 2009, 17, 919–931. [Google Scholar] [CrossRef]

- Luo, Y.; Ye, M.; Zhou, Y.; Su, R.; Huang, S.; Wang, H.; Dai, X. Assessing the Environmental Impact of Municipal Waste on Energy Incineration Technology for Power Generation Using Life Cycle Assessment Methodology. Toxics 2024, 12, 786. [Google Scholar] [CrossRef]

- Kasiński, S.; Dębowski, M. Municipal Solid Waste as a Renewable Energy Source: Advances in Thermochemical Conversion Technologies and Environmental Impacts. Energies 2024, 17, 4704. [Google Scholar] [CrossRef]

- Kędzia, G.; Ocicka, B.; Pluta-Zaremba, A.; Raźniewska, M.; Turek, J.; Wieteska-Rosiak, B. Social Innovations for Improving Compostable Packaging Waste Management in CE: A Multi-Solution Perspective. Energies 2022, 15, 9119. [Google Scholar] [CrossRef]

- Kasiński, S.; Dębowski, M.; Olkowska, M.; Rudnicki, M. Analysis of the Long-Term Mass Balance and Efficiency of Waste Recovery in a Municipal Waste Biodrying Plant. Energies 2021, 14, 7711. [Google Scholar] [CrossRef]

- Malinauskaite, J.; Jouhara, H.; Spencer, N. Waste prevention and technologies in the context of the EU Waste Framework Directive: Lost in translation? Eur. Energy Environ. Law Rev. 2017, 26, 66–80. [Google Scholar]

- Zorpas, A.A. Strategy development in the framework of waste management. Sci. Total Environ. 2020, 716, 137088. [Google Scholar] [CrossRef] [PubMed]

- Tahiru, A.-W.; Cobbina, S.J.; Asare, W. Public perceptions of waste-to-energy technology in developing countries: A case study of tamale, Ghana. Clean. Waste Syst. 2024, 9, 100192. [Google Scholar] [CrossRef]

| 2025 | 2050 | Cumulative Amount from 2025 to 2050 | Percent | |

|---|---|---|---|---|

| Total Waste | 720,337 | 726,198 | 18,720,336 | 100 |

| Organic waste | 509,926 | 514,076 | 13,252,126 | 71 |

| Dry waste | 210,410 | 212,123 | 5,468,209 | 29 |

| Waste-to-landfill: LFG | 166,670 | 165,919 | 4,255,938 | 78% dry waste |

| Waste-to-landfill: Py | 39,670 | 39,384 | 1,011,719 | 19% dry waste |

| Waste-to-landfill: GSF | 67,818 | 67,427 | 1,730,746 | 32% dry waste |

| Waste-to-landfill: INC | 37,536 | 37,257 | 957,190 | 18% dry waste |

| Waste-to-landfill: BAU | 166,670 | 165,919 | 4,255,938 | 78% dry waste |

| Year | 2020 | 2025 | 2030 | 2035 | 2040 | 2045 | 2050 | Percentage (%) |

|---|---|---|---|---|---|---|---|---|

| Organic Materials | 494,705 | 509,926 | 521,645 | 538,271 | 536,427 | 532,493 | 527,186 | 70.8 |

| Paper | 46,682 | 48,119 | 49,224 | 50,793 | 50,619 | 50,248 | 49,747 | 6.7 |

| Plastic | 84,839 | 87,449 | 89,459 | 92,310 | 91,994 | 91,319 | 90,409 | 12.1 |

| Metals | 7338 | 7564 | 7737 | 7984 | 7957 | 7898 | 7820 | 1.1 |

| Textiles | 14,606 | 15,055 | 15,401 | 15,892 | 15,837 | 15,721 | 15,565 | 2.1 |

| Wood | 2236 | 2305 | 2358 | 2433 | 2425 | 2407 | 2383 | 0.3 |

| Others | 48,429 | 49,919 | 51,067 | 52,694 | 52,514 | 52,129 | 51,609 | 6.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shahbazi, A.; Moeinaddini, M.; Sinha, R.; Abdoli, M.A.; Hosseinzadeh, M.; Jaafarzadeh Haghighi Fard, N.; Azizi, S. Assessment of Greenhouse Gas Reduction and Sustainability Index in Waste-to-Energy Conversion Scenarios Using System Dynamics Modeling. Energies 2025, 18, 2346. https://doi.org/10.3390/en18092346

Shahbazi A, Moeinaddini M, Sinha R, Abdoli MA, Hosseinzadeh M, Jaafarzadeh Haghighi Fard N, Azizi S. Assessment of Greenhouse Gas Reduction and Sustainability Index in Waste-to-Energy Conversion Scenarios Using System Dynamics Modeling. Energies. 2025; 18(9):2346. https://doi.org/10.3390/en18092346

Chicago/Turabian StyleShahbazi, Ali, Mazaher Moeinaddini, Rajib Sinha, Mohammad Ali Abdoli, Mahnaz Hosseinzadeh, Neamatollah Jaafarzadeh Haghighi Fard, and Shoaib Azizi. 2025. "Assessment of Greenhouse Gas Reduction and Sustainability Index in Waste-to-Energy Conversion Scenarios Using System Dynamics Modeling" Energies 18, no. 9: 2346. https://doi.org/10.3390/en18092346

APA StyleShahbazi, A., Moeinaddini, M., Sinha, R., Abdoli, M. A., Hosseinzadeh, M., Jaafarzadeh Haghighi Fard, N., & Azizi, S. (2025). Assessment of Greenhouse Gas Reduction and Sustainability Index in Waste-to-Energy Conversion Scenarios Using System Dynamics Modeling. Energies, 18(9), 2346. https://doi.org/10.3390/en18092346