Industry 5.0 and Human-Centered Energy System: A Comprehensive Review with Socio-Economic Viewpoints

Abstract

1. Introduction

- (1)

- How does Industry 5.0 enhance energy efficiency through digital technologies?

- (2)

- What role does the circular economy play in sustainable supply chain transformation?

- (3)

- How does AI-driven energy management facilitate a low-carbon transition?

- (4)

- How does Industry 5.0 lead to the human-centered energy system?

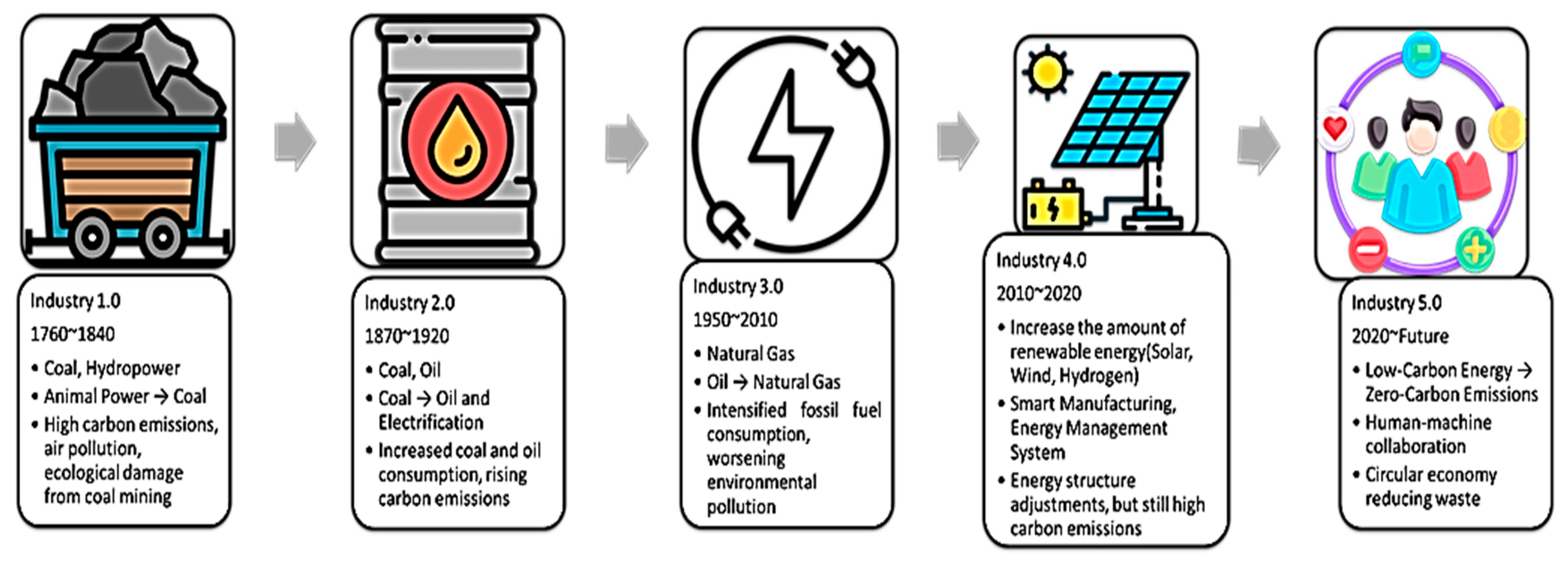

2. Evolution from Industry 1.0 to Industry 5.0

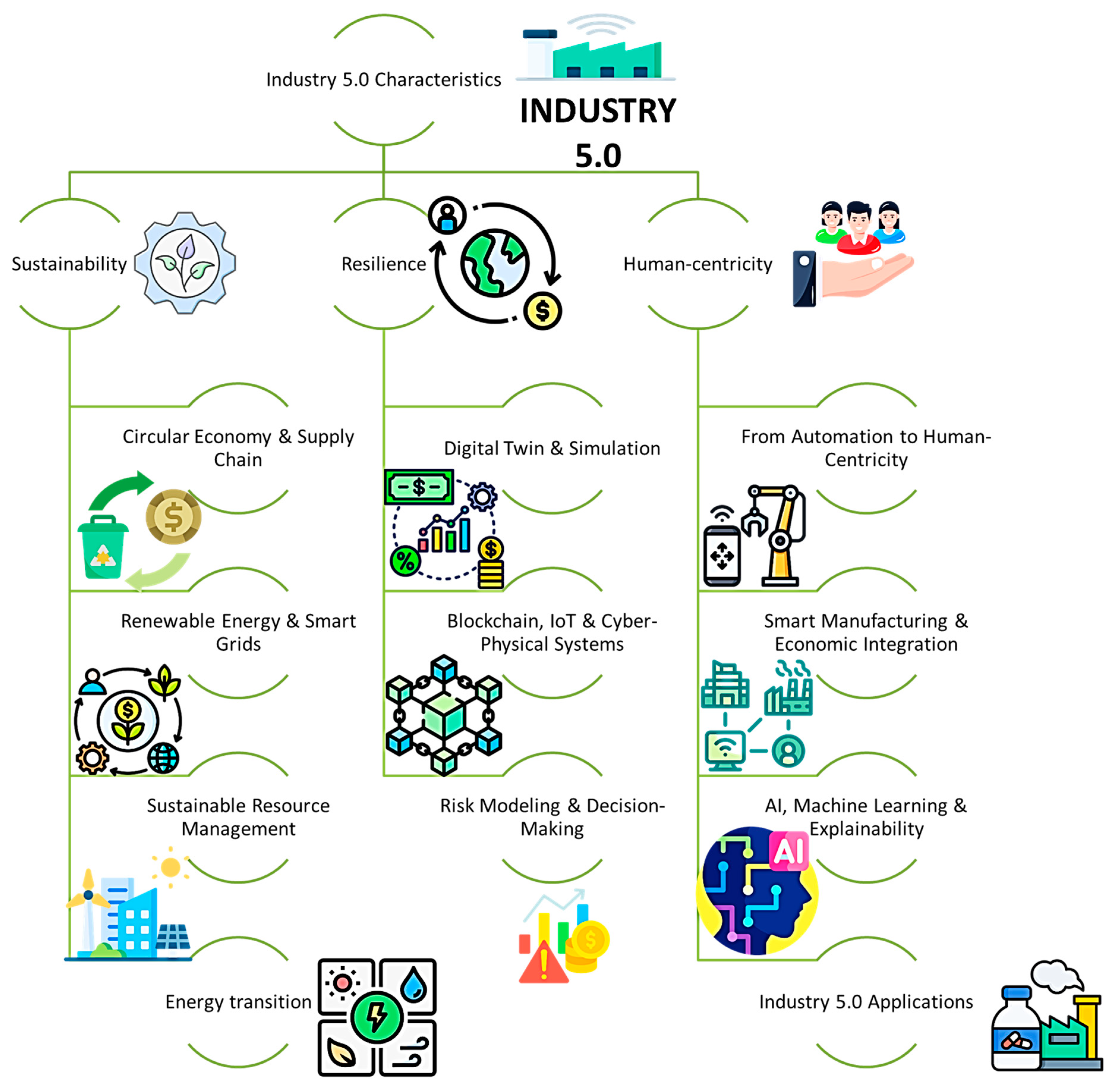

3. Sustainability

3.1. Circular Economy and Supply Chain Transformation

3.2. Energy Efficiency and Low-Carbon Transition Strategies

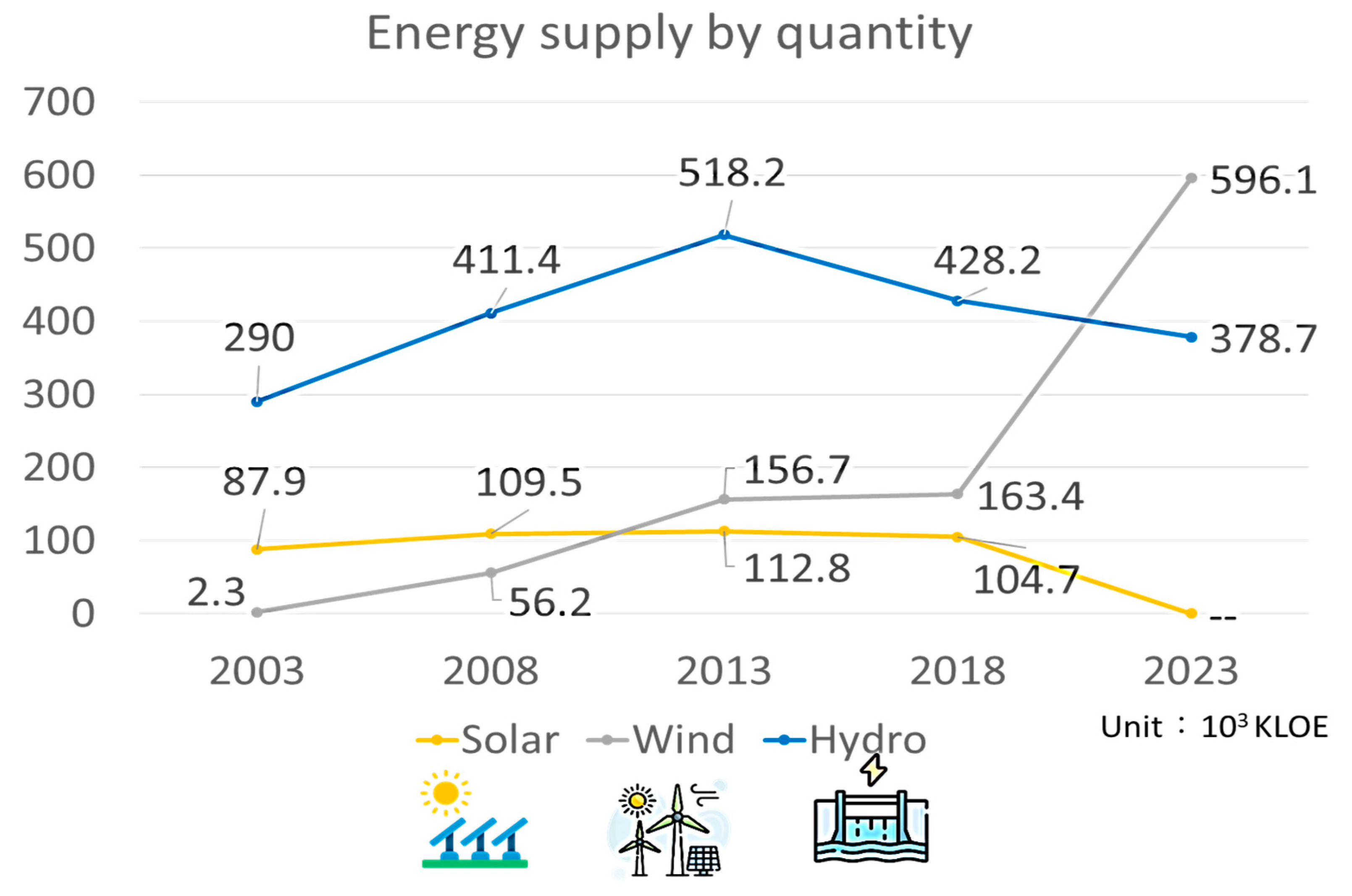

3.3. Integration of Renewable Energy and Smart Grids

4. Resilience

4.1. Digital Technologies, Smart Manufacturing, and the Integration of Economies

4.2. Artificial Intelligence, Machine Learning, and Human–Machine Collaboration

4.3. Digital Twin Technology and Simulation

4.4. Blockchain, IoT, and Cyber–Physical Systems

5. Human-Centricity

5.1. Shifting Paradigms: From Automation to Human-Centricity

5.2. Industry 5.0 in Sectoral Applications

5.3. Policy Initiatives and Governance

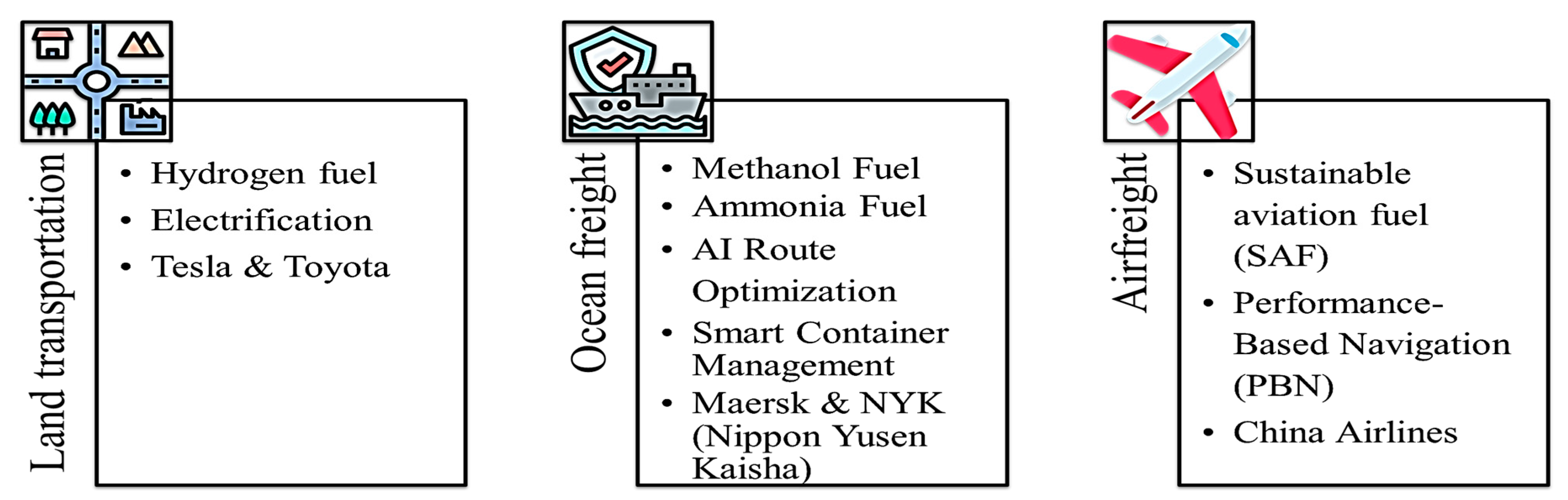

6. Discussion

6.1. Case Study: Land Transport—Tesla and Toyota

6.2. Case Study: China Airlines (TW)

6.3. Case Study: Maritime Transport—Maersk and Nippon Yusen Kaisha (NYK)

6.4. Integration and Interoperability Challenges

6.5. Human-Centered Energy Transition

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sheikh, R.A.; Ahmed, I.; Faqihi, A.Y.A.; Shehawy, Y.M. Global Perspectives on Navigating Industry 5.0 Knowledge: Achieving Resilience, Sustainability, and Human-Centric Innovation in Manufacturing. J. Knowl. Econ. 2024. [Google Scholar] [CrossRef]

- Reza, M.N.H.; Jayashree, S.; Malarvizhi, C.A.; Gunasekaran, A.; Mohiuddin, M. Towards sustainable sustainability: Exploring the impact of antecedents on industry 4.0 and sustainable performance of organizations—An empirical investigation. Ann. Oper. Res. 2024. [Google Scholar] [CrossRef]

- Okamoto, H.; Ohno, T.; Kobayashi, N.; Kataoka, T. The New Role of Electric Power Systems in Society 5.0: Harnessing the future of the human-centered industrial revolution through electrification of the globe. IEEE Electrif. Mag. 2024, 12, 95–103. [Google Scholar] [CrossRef]

- International Renewable Energy Agency (IRENA). World Energy Transitions Outlook 2023: 1.5 °C Pathway. IRENA. 2023. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2023/Jun/IRENA_World_energy_transitions_outlook_summary_2023.pdf (accessed on 26 December 2023).

- Daniel, R.; Yuqi, Z.; Richard, G.N.; Brian, C.P.; Aaron, B. Global Energy Outlook 2023: Sowing the Seeds of an Energy Transition; Resources for the Future: Washington, DC, USA, 2023. [Google Scholar]

- Vázquez-Canteli, J.R.; Nagy, Z. Reinforcement learning for demand response: A review of algorithms and modeling techniques. Appl. Energy 2019, 235, 1072–1089. [Google Scholar] [CrossRef]

- Jacobson, M.Z.; Delucchi, M.A. Providing all global energy with wind, water, and solar power, Part I: Technologies, energy resources, quantities and areas of infrastructure, and materials. Energy Policy 2011, 39, 1154–1169. [Google Scholar] [CrossRef]

- Creutzig, F.; Goldschmidt, J.C.; Lehmann, P.; Schmid, E.; von Blücher, F.; Breyer, C.; Fernandez, B.; Jakob, M.; Knopf, B.; Lohrey, S.; et al. Catching two European birds with one renewable stone: Mitigating climate change and Eurozone crisis by an energy transition. Renew. Sustain. Energy Rev. 2014, 38, 1015–1028. [Google Scholar] [CrossRef]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Akundi, A.; Euresti, D.; Luna, S.; Ankobiah, W.; Lopes, A.; Edinbarough, I. State of Industry 5.0—Analysis and identification of current research trends. Appl. Syst. Innov. 2022, 5, 27. [Google Scholar] [CrossRef]

- Abbas, T.; Fatima, A.; Shahzad, T.; Alharbi, M.; Khan, M.A.; Ahmed, A. Multidisciplinary cancer disease classification using adaptive FL in healthcare industry 5.0. Sci. Rep. 2024, 14, 18643. [Google Scholar] [CrossRef]

- Ahmed, R.; Khan, S.A.; Kumar, S. The Role of Industry 5.0 in Empowering Healthcare Through Technology and Value Creation. In Proceedings of the 2024 4th International Conference on Technological Advancements in Computational Sciences (ICTACS), Tashkent, Uzbekistan, 13–15 November 2024; pp. 1762–1767. [Google Scholar] [CrossRef]

- Abdelshafy, A.; Walther, G. Exploring the effects of energy transition on the industrial value chains and alternative resources: A case study from the German federal state of North Rhine-Westphalia (NRW). Resour. Conserv. Recycl. 2022, 177, 105992. [Google Scholar] [CrossRef]

- Alagoz, E.; Alghawi, Y. The Energy Transition: Navigating the Shift towards Renewables in the Oil and Gas Industry. J. Energy Nat. Resour. 2023, 12, 21–24. [Google Scholar] [CrossRef]

- Agrawal, S.; Agrawal, R.; Kumar, A.; Luthra, S.; Garza-Reyes, J.A. Can industry 5.0 technologies overcome supply chain disruptions?—A perspective study on pandemics, war, and climate change issues. Oper. Manag. Res. 2024, 17, 453–468. [Google Scholar] [CrossRef]

- Chatterjee, S.; Chaudhuri, R. Impacts of Industry 5.0 in Supply Chain Flow in Post COVID-19 Era: Moderating Role of Senior Leadership Support. Inf. Syst. Front. 2024. [Google Scholar] [CrossRef]

- Breque, M.; De Nul, L.; Petridis, A. Industry 5.0: Towards a Sustainable, Human-Centric and Resilient European Industry; European Commission, Directorate-General for Research and Innovation: Luxembourg, 2021; p. 46. [Google Scholar] [CrossRef]

- Costa, E. Industry 5.0 and SDG 9: A symbiotic dance towards sustainable transformation. Sustain. Earth Rev. 2024, 7, 4. [Google Scholar] [CrossRef]

- Carayannis, E.G.; Morawska, J. University and Education 5.0 for Emerging Trends, Policies and Practices in the Concept of Industry 5.0 and Society 5.0. In Industry 5.0: Creative and Innovative Organizations; Springer International Publishing: Cham, Switzerland, 2023; pp. 1–25. [Google Scholar] [CrossRef]

- Bautista Lazo, S. Sustainable Manufacturing: Turning Waste into Profitable Co-Products; University of Liverpool: Liverpool, UK, 2013. [Google Scholar] [CrossRef]

- Bakator, M.; Ćoćkalo, D.; Makitan, V.; Stanisavljev, S.; Nikolić, M. The three pillars of tomorrow: How Marketing 5.0 builds on Industry 5.0 and impacts Society 5.0? Heliyon 2024, 10. [Google Scholar] [CrossRef]

- Berkhout, F.; Marcotullio, P.; Hanaoka, T. Understanding energy transitions. Sustain. Sci. 2012, 7, 109–111. [Google Scholar] [CrossRef]

- Yin, Y.; Stecke, K.E.; Li, D. The evolution of production systems from Industry 2.0 through Industry 4.0. Int. J. Prod. Res. 2018, 56, 848–861. [Google Scholar] [CrossRef]

- Mathur, A.; Dabas, A.; Sharma, N. Evolution from industry 1.0 to industry 5.0. In Proceedings of the 2022 4th International Conference on Advances in Computing, Communication Control and Networking (ICAC3N), Greater Noida, India, 16–17 December 2022; pp. 1390–1394. [Google Scholar] [CrossRef]

- Romanova, O.; Kuzmin, E. From Industry 4.0 to Industry 5.0: Challenges and Opportunities of Evolutionary Transition in Russia. In The Future of Industry. Lecture Notes in Information Systems and Organisation; Appolloni, A., Kumar, V., Kuzmin, E., Akberdina, V., Eds.; Springer: Cham, Switzerland, 2024; Volume 70. [Google Scholar] [CrossRef]

- Davim, J.P. Perceptions of industry 5.0: Sustainability perspective. BioResources 2025, 20, 15–16. [Google Scholar] [CrossRef]

- Franco, A.; Miserocchi, L.; Testi, D. Energy indicators for enabling energy transition in industry. Energies 2023, 16, 581. [Google Scholar] [CrossRef]

- Carrasco, J.M. Power electronics for the integration of renewable energies into smart grids. In Proceedings of the 2011 International Conference on Power Engineering, Energy and Electrical Drives, Malaga, Spain, 11–13 May 2011; p. 1-1. [Google Scholar]

- Best, R. Switching towards coal or renewable energy? The effects of financial capital on energy transitions. Energy Econ. 2017, 63, 75–83. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy–A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Kulatunga, A.K.; Karunatilake, N.; Weerasinghe, N.; Ihalawatta, R.K. Sustainable manufacturing based decision support model for product design and development process. Procedia CIRP 2015, 26, 87–92. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M.; Morales, M.E.; Nilashi, M.; Amran, A. Actions and approaches for enabling Industry 5.0-driven sustainable industrial transformation: A strategy roadmap. Corp. Soc. Responsib. Environ. Manag. 2023, 30, 1473–1494. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, Y.; Zeeshan, M.; Han, F.; Song, K. Super-twisting sliding mode control of grid-side inverters for wind power generation systems with parameter perturbation. Int. J. Electr. Power 2025, 165, 110501. [Google Scholar] [CrossRef]

- Wu, H.; Liu, J.; Liang, B. AI-Driven Supply Chain Transformation in Industry 5.0: Enhancing Resilience and Sustainability. J. Knowl. Econ. 2024, 1–43. [Google Scholar] [CrossRef]

- Van Erp, T.; Carvalho, N.G.P.; Gerolamo, M.C.; Gonçalves, R.; Rytter, N.G.M.; Gladysz, B. Industry 5.0: A new strategy framework for sustainability management and beyond. J. Clean. Prod. 2024, 461, 142271. [Google Scholar] [CrossRef]

- Pandey, A.K.; Daultani, Y.; Pratap, S.; Ip, A.W.; Zhou, F. Analyzing Industry 4.0 Adoption Enablers for Supply Chain Flexibility: Impacts on Resilience and Sustainability. Glob. J. Flex. Syst. Manag. 2025, 26 (Suppl. 1), 1–24. [Google Scholar] [CrossRef]

- Shankar, R.; Gupta, L. Modelling risks in transition from Industry 4.0 to Industry 5.0. Ann. Oper. Res. 2024, 342, 1275–1320. [Google Scholar] [CrossRef]

- Demir, K.A.; Döven, G.; Sezen, B. Industry 5.0 and human-robot co-working. Procedia Comput. Sci. 2019, 158, 688–695. [Google Scholar] [CrossRef]

- Fantini, P.; Pinzone, M.; Taisch, M.; Altesa, J. Human-centric manufacturing workplaces: Aiming at increasing attractiveness and user experience. In Advances in Production Management Systems. Initiatives for a Sustainable World: IFIP WG 5.7 International Conference, APMS 2016, Iguassu Falls, Brazil, 3–7 September 2016; Revised Selected Papers; Springer International Publishing: New York City, NY, USA, 2016; pp. 363–370. [Google Scholar] [CrossRef]

- Kumar, R.; Gupta, P.; Singh, S.; Jain, D. Human Empowerment by Industry 5.0 in Digital Era: Analysis of Enablers. In Advances in Industrial and Production Engineering. Lecture Notes in Mechanical Engineering; Phanden, R.K., Mathiyazhagan, K., Kumar, R., Paulo Davim, J., Eds.; Springer: Singapore, 2021. [Google Scholar] [CrossRef]

- Carayannis, E.G.; Campbell, D.F.; Grigoroudis, E. Democracy and the environment: How political freedom is linked with environmental sustainability. Sustainability 2021, 13, 5522. [Google Scholar] [CrossRef]

- Roy, S.K.; Singh, G.; Gruner, R.L.; Dey, B.L.; Shabnam, S.; Muhammad, S.S.; Quaddus, M. Relationship quality in customer-service robot interactions in Industry 5.0: An analysis of value recipes. Inf. Syst. Front. 2023, 1–20. [Google Scholar] [CrossRef]

- Lovrenčić, S. The Role of Knowledge Management in Transition to Industry 5.0. In Proceedings of the 2023 46th MIPRO ICT and Electronics Convention (MIPRO), Opatija, Croatia, 22–26 May 2023; pp. 1076–1082. [Google Scholar] [CrossRef]

- Zaman, S.A.A.; Yushi, J.; Khan, S.; Jamil, S.; Zaman, S.I. Knowledge Creation in SMEs in the Era of Industry 4.0: A Comparative Study of Pakistan and China. J. Knowl. Econ. 2024, 1–27. [Google Scholar] [CrossRef]

- Zhang, H.; Leong, W.Y. Industry 5.0 and Education 5.0: Transforming Vocational Education through Intelligent Technology. Int. J. Innov. Technol. 2024, 2024. Available online: https://iuojs.intimal.edu.my/index.php/joit/article/view/540 (accessed on 28 April 2025).

- Sahoo, S.; Upadhyay, A. Improving triple bottom line (TBL) performance: Analyzing impacts of industry 4.0, lean six sigma and circular supply chain management. Ann. Oper. Res. 2024. [Google Scholar] [CrossRef]

- Zulkifli, A.; Wasesa, M. Industry 5.0 Research in the Sustainable Information Systems Sector: A Scoping Review Analysis. Int. J. Adv. Data Inf. Syst. 2024, 5, 136–156. [Google Scholar] [CrossRef]

- Kazancoglu, Y.; Mangla, S.K.; Berberoglu, Y.; Lafci, C.; Madaan, J. Towards industry 5.0 challenges for the textile and apparel supply chain for the smart, sustainable, and collaborative industry in emerging economies. Inf. Syst. Front. 2023, 26, 1857–1872. [Google Scholar] [CrossRef]

- Nayeri, S.; Sazvar, Z. Sustainable evaluation of the raw material providers based on industry 5.0 and circular economy aspects: A new stochastic method. Opsearch 2025. [Google Scholar] [CrossRef]

- Chowdhury, T.; Bhowmik, K.; Naidu, A.S.; Khan, S.A. Challenges in the Transition from Supply Chain 40 to Supply Chain 5.0. In Proceedings of the 2022 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Kuala Lumpur, Malaysia, 7–10 December 2022; pp. 837–842. [Google Scholar] [CrossRef]

- Sindhwani, R.; Behl, A.; Singh, R.; Kumari, S. Can Industry 5.0 Develop a Resilient Supply Chain? An Integrated Decision-Making Approach by Analyzing I5.0 CSFs. Inf. Syst. Front. 2024. [Google Scholar] [CrossRef]

- Modgil, S.; Singh, R.K.; Agrawal, S. Developing human capabilities for supply chains: An industry 5.0 perspective. Ann. Oper. Res. 2023. [Google Scholar] [CrossRef]

- Carayannis, E.G.; Morawska-Jancelewicz, J. The futures of Europe: Society 5.0 and Industry 5.0 as driving forces of future universities. J. Knowl. Econ. 2022, 13, 3445–3471. [Google Scholar] [CrossRef]

- Gillingham, K.; Rapson, D.; Wagner, G. The rebound effect and energy efficiency policy. Rev. Environ. Econ. Pol. 2016, 10, 68–88. [Google Scholar] [CrossRef]

- Sorrell, S. Reducing energy demand: A review of issues, challenges and approaches. Renew. Sustain. Energy Rev. 2015, 47, 74–82. [Google Scholar] [CrossRef]

- de Sépibus, J. The Integration of Electricity from Renewable Energy Sources in the European Union Electricity Market–The case for “Smart Grids”. 2013. Available online: https://boris.unibe.ch/49795/1/Smart_Grid__10_July_final.pdf (accessed on 28 April 2025).

- Holzinger, A.; Schweier, J.; Gollob, C.; Nothdurft, A.; Hasenauer, H.; Kirisits, T.; Häggström, C.; Visser, R.; Cavalli, R.; Spinelli, R.; et al. From industry 5.0 to forestry 5.0: Bridging the gap with human-centered artificial intelligence. Curr. For. Rep. 2024, 10, 442–455. [Google Scholar] [CrossRef] [PubMed]

- Doukas, H. Energy Transitions, Intelligence and Big data: Towards a prosumer concept with energy autonomy. In Proceedings of the 2022 13th International Conference on Information, Intelligence, Systems & Applications (IISA), Corfu, Greece, 18–20 July 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Kupzog, F.; Sauter, T.; Pollhammer, K. IT-enabled integration of renewables: A concept for the smart power grid. Eurasip J. Embed. Syst. 2011, 2011, 737543. [Google Scholar] [CrossRef]

- Gatto, A.; Drago, C. Measuring and modeling energy resilience. Ecol. Econ. 2020, 172, 106527. [Google Scholar] [CrossRef]

- Hu, J.L.; Chang, T.Y. Energy resilience: A cross-economy comparison. Energies 2023, 16, 2214. [Google Scholar] [CrossRef]

- Yao, X.; Ma, N.; Zhang, J.; Wang, K.; Yang, E.; Faccio, M. Enhancing wisdom manufacturing as industrial metaverse for industry and society 5.0. J. Intell. Manuf. 2024, 35, 235–255. [Google Scholar] [CrossRef]

- Oladeinde, A.H.; Ojo, O.O. Industry 5.0 and Production Planning and Control in Manufacturing Industries. In Proceedings of the 2024 International Conference on Science, Engineering and Business for Driving Sustainable Development Goals (SEB4SDG), Omu-Aran, Nigeria, 2–4 April 2024. [Google Scholar] [CrossRef]

- Alenezi, A.M.; Alsmairat, M.A.; Ljepava, N. Integrating the Triple Pillar: AI Marketing’s Pathway to Enhancing Industry 5.0 Through Sustainability, Resilience, and Customer Engagement. In Proceedings of the 2024 2nd International Conference on Cyber Resilience (ICCR), Dubai, United Arab Emirates, 26–28 February 2024; pp. 1–7. [Google Scholar] [CrossRef]

- Jiménez-Partearroyo, M.; Medina-López, A.; Juárez-Varón, D. Towards industry 5.0: Evolving the product-process matrix in the new paradigm. J. Technol. Transf. 2024, 49, 1496–1531. [Google Scholar] [CrossRef]

- Oyekunle, D.O.T.; Okwudili Matthew, U.; Bakare, K.M.; Fatai, L.O.; Asnui, O. Industry 5.0: A Paradigm Shift Towards Sustainability, Adaptability and Human-Centeredness. 2th IPMA Research Conference. J. Technol. Transf. 2024. [Google Scholar] [CrossRef]

- Ben Youssef, A.; Mejri, I. Linking digital technologies to sustainability through industry 5.0: A bibliometric analysis. Sustainability 2023, 15, 7465. [Google Scholar] [CrossRef]

- Chaikovska, I.; Hryhoruk, P.; Khrushch, N.; Grygoruk, S.; Tkach, T.; Chaikovskyi, M. Integration of Digital Economy, Knowledge Economy and Circular Economy in the Conditions of Industry 5.0. In Proceedings of the 2024 14th International Conference on Advanced Computer Information Technologies (ACIT), Ceske Budejovice, Czech Republic, 19–21 September 2024; pp. 250–253. [Google Scholar] [CrossRef]

- Mohammed, Z.K.; Zaidan, A.A.; Aris, H.B.; Alsattar, H.A.; Qahtan, S.; Deveci, M.; Delen, D. Bitcoin network-based anonymity and privacy model for metaverse implementation in Industry 5.0 using linear Diophantine fuzzy sets. Ann. Oper. Res. 2023, 342, 1193–1233. [Google Scholar] [CrossRef]

- Aheleroff, S.; Huang, H.; Xu, X.; Zhong, R.Y. Toward sustainability and resilience with Industry 4.0 and Industry 5.0. Front. Manuf. Technol. 2022, 2, 951643. [Google Scholar] [CrossRef]

- Yerram, S.R. Driving the Shift to Sustainable Industry 5.0 with Green Manufacturing Innovations. Asia Pac. J. Energy Environ. 2021, 8, 55–66. [Google Scholar] [CrossRef]

- Li, N.; Xie, G.; Zhang, X.; Shi, H.; Nie, X.; Wang, Y.; Wang, J.; Wang, J. Six-dimensional digital twin modeling and software platform design for complex industrial systems. J. Intell. Manuf. 2025. [Google Scholar] [CrossRef]

- Modad, O.A.A.; Ryska, J.; Chehade, A.; Ayoub, G. Revolutionizing sheet metal stamping through industry 5.0 digital twins: A comprehensive review. J. Intell. Manuf. 2024. [Google Scholar] [CrossRef]

- Redchuk, A.; Walas Mateo, F.; Pascal, G.; Tornillo, J.E. Adoption case of IIoT and machine learning to improve energy consumption at a process manufacturing firm, under Industry 5.0 model. Big Data Cogn. Comput. 2023, 7, 42. [Google Scholar] [CrossRef]

- Priyadarshini, J.; Singh, R.K.; Mishra, R.; He, Q.; Braganza, A. Implementation of additive manufacturing in the healthcare supply chain for circular economy goals: Paradoxical tensions and solutions from an Industry 5. 0 perspective. Inf. Syst. Front. 2024. [Google Scholar] [CrossRef]

- Bécue, A.; Gama, J.; Brito, P.Q. AI’s effect on innovation capacity in the context of industry 5.0: A scoping review. Artif. Intell. Rev. 2024, 57, 215. [Google Scholar] [CrossRef]

- Dey, A.K.; Gupta, G.P.; Sahu, S.P. BRL-ETDM: Bayesian reinforcement learning-based explainable threat detection model for industry 5.0 network. Clust. Comput. 2024, 27, 8243–8268. [Google Scholar] [CrossRef]

- Rane, N. ChatGPT and Similar Generative Artificial Intelligence (AI) for Smart Industry: Role, challenges and opportunities for industry 4.0, industry 5.0 and society 5.0. Chall. Oppor. Ind. 2024. [Google Scholar] [CrossRef]

- Martini, B.; Bellisario, D.; Coletti, P. Human-centered and sustainable artificial intelligence in industry 5.0: Challenges and perspectives. Sustainability 2024, 16, 5448. [Google Scholar] [CrossRef]

- Zhen, Z.; Yao, Y. The confluence of digital twin and blockchan technologies in Industry 5.0: Transforming supply chain management for innovation and sustainability. J. Knowl. Econ. 2024. [Google Scholar] [CrossRef]

- Fraga-Lamas, P.; Fernández-Caramés, T.M.; da Cruz, A.M.R.; Lopes, S.I. An overview of blockchain for Industry 5.0: Towards human-centric, sustainable and resilient applications. IEEE Access 2024, 12, 116162–116201. [Google Scholar] [CrossRef]

- Rehman Khan, S.A.; Yu, Z.; Sarwat, S.; Godil, D.I.; Amin, S.; Shujaat, S. The role of block chain technology in circular economy practices to improve organisational performance. Int. J. Logist. Res. Appl. 2022, 25, 1–18. [Google Scholar] [CrossRef]

- Rashid, S.; Nemati, A. Human-centered IoT-based health monitoring in the Healthcare 5.0 era: Literature descriptive analysis and future research guidelines. Discov Internet Things 2024, 4, 26. [Google Scholar] [CrossRef]

- Zeb, S.; Mahmood, A.; Khowaja, S.A.; Dev, K.; Hassan, S.A.; Qureshi, N.M.F.; Gidlund, M.; Bellavista, P. Industry 5.0 is coming: A survey on intelligent nextG wireless networks as technological enablers. arXiv 2024, arXiv:2205.09084. [Google Scholar] [CrossRef]

- Abdel-Basset, M.; Mohamed, R.; Chang, V. A Multi-criteria decision-making Framework to evaluate the impact of industry 5.0 technologies: Case Study, lessons learned, challenges and future directions. Inf. Syst. Front. 2024. [Google Scholar] [CrossRef]

- Dollija, E.; Gura, K. The Role of Humans as Key Enablers of Industry 5.0. In International Conference on Economic Scientific Research-Theoretical, Empirical and Practical Approaches; Springer Nature: Cham, Switzerland, 2022; pp. 39–55. [Google Scholar] [CrossRef]

- Barkalov, S.A.; Averina, T.A.; Avdeeva, E.A. Transformation of Organization Business Model in Conditions of Industry 5.0. In Proceedings of the 2023 5th International Conference on Control Systems, Mathematical Modeling, Automation and Energy Efficiency (SUMMA), Lipetsk, Russia, 8–10 November 2023; pp. 499–503. [Google Scholar] [CrossRef]

- Gooljar, V.; Issa, T.; Hardin-Ramanan, S.; Abu-Salih, B. Sentiment-based predictive models for online purchases in the era of marketing 5.0: A systematic review. J. Big Data 2024, 11, 107. [Google Scholar] [CrossRef]

- Kim, S.; Yoon, A. Analyzing active managers’ commitment to ESG: Evidence from United Nations principles for responsible investment. Manag. Sci. 2021. [Google Scholar] [CrossRef]

- European Commission: Directorate-General for Research and Innovation; Renda, A.; Schwaag Serger, S.; Tataj, D.; Morlet, A.; Darja, I.; Francisca, M.; Montserrat, M.R.; César, H.; Ailin, H.; et al. Industry 5.0, a Transformative Vision for Europe—Governing Systemic Transformations Towards a Sustainable Industry; Publications Office of the European Union: Luxembourg, 2021; Available online: https://data.europa.eu/doi/10.2777/17322 (accessed on 28 April 2025).

- European Commission: Directorate-General for Research and Innovation. ERA Industrial Technologies Roadmap on Human-Centric Research and Innovation for the Manufacturing Sector; Publications Office of the European Union: 2024. Available online: https://data.europa.eu/doi/10.2777/0266 (accessed on 28 April 2025).

- European Commission: Directorate-General for Research and Innovation. ERA Industrial Technology Roadmap for Low-Carbon Technologies in Energy-Intensive Industries—Annexes; Publications Office of the European Union:2022. Available online: https://data.europa.eu/doi/10.2777/969975 (accessed on 28 April 2025).

- Rodrigues, A.A. “Fit for 55”: The EU Plan for a Green Transition. In Sustainable Finances and the Law; Springer: Cham, Switzerland, 2024; Volume 16, pp. 333–344. [Google Scholar] [CrossRef]

- APEC. 2022 Leaders’ Declaration. 2022. Available online: https://www.apec.org/meeting-papers/listings/leaders-declarations (accessed on 19 November 2022).

- Asia-Pacific Economic Cooperation (APEC). APEC Leaders’ Declaration on Sustainable Development and Innovation; APEC Secretariat: Singapore, 2022; Available online: https://www.apec.org/meeting-papers/leaders-declarations/2022/2022-leaders-declaration (accessed on 18 November 2022).

- PRI. New and Former Signatories. 2022. Available online: https://www.unpri.org/annual-report-2022/signatories (accessed on 9 August 2023).

- Rame, R.; Purwanto, P.; Sudarno, S. Industry 5.0 and sustainability: An overview of emerging trends and challenges for a green future. Innov. Green Dev. 2024, 3, 100173. [Google Scholar] [CrossRef]

- FengTang, Z.; Leong, W.Y. Carbon Emission under Industry 5.0. J. Innov. Technol. 2024. Available online: https://iuojs.intimal.edu.my/index.php/joit/article/view/567 (accessed on 28 April 2025).

- Dhayal, K.S.; Giri, A.K.; Kumar, A.; Samadhiya, A.; Agrawal, S.; Agrawal, R. Can green finance facilitate Industry 5.0 transition to achieve sustainability? A systematic review with future research directions. Environ. Sci. Pollut. Res. 2023, 30, 102158–102180. [Google Scholar] [CrossRef]

- Bosovska, M.; Boiko, M.; Bovsh, L.; Okhrimenko, A. Models of the industrial revolution 5.0. In Proceedings of the 2022 IEEE 4th International Conference on Modern Electrical and Energy System (MEES), Kremenchuk, Ukraine, 20–23 October 2022; pp. 1–4. [Google Scholar] [CrossRef]

- International Air Transport Association (IATA). Sustainable Aviation Fuel (SAF) and its Role in Decarbonizing Aviation; IATA Publications: Quebec, QC, Canada, 2023; Available online: https://www.iata.org/en/programs/sustainability/sustainable-aviation-fuels/ (accessed on 28 April 2025).

- International Energy Agency (IEA). World Energy Outlook 2023; IEA Publications: Paris, France, 2023; Available online: https://www.iea.org/reports/world-energy-outlook-2023 (accessed on 28 April 2025).

- International Air Transport Association (IATA). Annual Review 2024 Maersk. Annual Report 2024: Sustainability. 2024. Available online: https://www.iata.org/en/publications/annual-review/ (accessed on 14 June 2024).

- Nippon Yusen Kaisha (NYK). Decarbonization efforts and zero-carbon shipping. NYK Reports. 2024. Available online: https://www.nyk.com/english/news/2024/__icsFiles/afieldfile/2024/11/28/NYK2024_E.pdf (accessed on 1 November 2024).

- Müller, J. Enabling Technologies for Industry 5.0. Results of a workshop with Europe’s Technology Leaders. 2020. [Google Scholar] [CrossRef]

- Carayannis, E.G.; Christodoulou, K.; Christodoulou, P.; Chatzichristofis, S.A.; Zinonos, Z. Known unknowns in an era of technological and viral disruptions—Implications for theory, policy, and practice. J. Knowl. Econ. 2021, 13, 587–610. [Google Scholar] [CrossRef]

- Hassoun, A.; Jagtap, S.; Trollman, H.; Garcia-Garcia, G.; Duong, L.N.; Saxena, P.; Bouzembrak, Y.; Treiblmaier, H.; Para-López, C.; Carmona-Torres, C.; et al. From Food Industry 4.0 to Food Industry 5.0: Identifying technological enablers and potential future applications in the food sector. Compr. Rev. Food Sci. Food Safety 2024, 23, e370040. [Google Scholar] [CrossRef] [PubMed]

- Supriya, Y.; Bhulakshmi, D.; Bhattacharya, S.; Gadekallu, T.R.; Vyas, P.; Kaluri, R.; Mahmud, M. Industry 5.0 in Smart Education: Concepts, Applications, Challenges, Opportunities, and Future Directions. IEEE Access 2024. [Google Scholar] [CrossRef]

- Jawor, J.K.; Matviienko, H. Digital Integration and Green Economy for the Transition to Industry 5.0. Rev. De La Univ. del Zulia 2023, 14, 239–257. [Google Scholar] [CrossRef]

- De Giovanni, P. Sustainability of the Metaverse: A transition to Industry 5.0. Sustainability 2023, 15, 6079. [Google Scholar] [CrossRef]

- Yadav, V.; Yadav, N. Beyond sustainability, toward resilience, and regeneration: An integrative framework for archetypes of regenerative innovation. Glob. J. Flex. Syst. Manag. 2024, 25, 849–879. [Google Scholar] [CrossRef]

- Binfield, L.; Nasir, V.; Dai, C. Bamboo industrialization in the era of Industry 5.0: An exploration of key concepts, synergies and gaps. In Environment, Development and Sustainability; Springer: Berlin/Heidelberg, Germany, 2024. [Google Scholar] [CrossRef]

- Santosh, I.; Shukla, P.; Sahoo, M.K.; Ramya, B. Industry 5.0—The Road to Sustainability-Review. In Anticipating Future Business Trends: Navigating Artificial Intelligence Innovations; Springer: Berlin/Heidelberg, Germany, 2024; pp. 241–250. [Google Scholar] [CrossRef]

- Buchinskaia, O. Industry 5.0: Quo Vadis? Challenges and Concerns for Future Development. In The Future of Industry: Human-Centric Approaches in Digital Transformation; Springer Nature: Cham, Switzerland, 2024; pp. 39–53. [Google Scholar] [CrossRef]

- Carayannis, E.G.; Dezi, L.; Gregori, G.; Calo, E. Smart environments and techno-centric and human-centric innovations for Industry and Society 5.0: A quintuple helix innovation system view towards smart, sustainable, and inclusive solutions. J. Knowl. Econ. 2022, 13, 926–955. [Google Scholar] [CrossRef]

- Carayannis, E.G.; Acikdilli, G.; Ziemnowicz, C. Creative destruction in international trade: Insights from the quadruple and quintuple innovation helix models. J. Knowl. Econ. 2020, 11, 1489–1508. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Mahdiraji, H.A.; Iranmanesh, M.; Jafari-Sadeghi, V. From Industry 4.0 digital manufacturing to Industry 5.0 digital society: A roadmap toward human-centric, sustainable, and resilient production. Inf. Syst. Front. 2024. [Google Scholar] [CrossRef]

- Mandal, S.; Kar, A.K.; Gupta, S.; Sivarajah, U. Achieving food supply chain resilience during natural disasters through industry 5.0 enablers—Empirical insights based on an FsQCA approach. Inf. Syst. Front. 2023. [Google Scholar] [CrossRef]

- Schröder, A.J.; Cuypers, M.; Götting, A. From Industry 4.0 to Industry 5.0: The Triple Transition Digital, Green and Social. In Industry 4.0 and the Road to Sustainable Steelmaking in Europe: Recasting the Future; Springer International Publishing: Cham, Switzerland, 2024; pp. 35–51. [Google Scholar] [CrossRef]

- Slavic, D. The main concepts of industry 5.0: A bibliometric analysis approach. In Proceedings of the 2023 22nd International Symposium Infoteh-Jahorina (INFOTEH), East Sarajevo, Bosnia and Herzegovina, 15–17 March 2023. [Google Scholar] [CrossRef]

- Szelągowski, M.; Berniak-Woźny, J.; Sliż, P.; Potoczek, N.; Napieraj, A.; Podobińska-Staniec, M.; Senkus, P. Exploring the diverse nature of business processes in organisations in Industry 4.0/5.0. Futur. Bus. J. 2024, 10, 118. [Google Scholar] [CrossRef]

- Sang, T.M.; Hung, N.T. Dynamic competitiveness, firm performance and the regulatory role of government policies in Industry 5.0. Discov. Sustain. 2024, 5, 1–21. [Google Scholar] [CrossRef]

- Carayannis, E.G.; Draper, J.; Bhaneja, B. Towards fusion energy in the Industry 5.0 and Society 5.0 context: Call for a global commission for urgent action on fusion energy. J. Knowl. Econ. 2021, 12, 1891–1904. [Google Scholar] [CrossRef]

- Sangode, P.B. Fusion of Blockchain and Industry 4.0: A Bibliometric Analysis and Detailed Review. In Operations Research Forum; Springer International Publishing: Cham, Switzerland, 2025; Volume 6, p. 22. [Google Scholar] [CrossRef]

- Narkhede, G.; Chinchanikar, S.; Narkhede, R.; Chaudhari, T. Role of Industry 5.0 for driving sustainability in the manufacturing sector: An emerging research agenda. J. Strategy Manag. 2024, ahead-of-print. [Google Scholar] [CrossRef]

- Narkhede, G.; Pasi, B.; Rajhans, N.; Kulkarni, A. Industry 5.0 and the future of sustainable manufacturing: A systematic literature review. Bus. Strategy Dev. 2023, 6, 704–723. [Google Scholar] [CrossRef]

- Gaughran, W.F.; Burke, S.; Phelan, P. Intelligent manufacturing and environmental sustainability. Comput.-Integr. Manuf. 2007, 23, 704–711. [Google Scholar] [CrossRef]

| Industrial Phase | Major Technologies | Societal Impact | Environmental Impact | Energy Transition Description |

|---|---|---|---|---|

| Industry 1.0 (Steam Engine Era) 1760–1840 | Steam engine innovation and application | Mechanized production replaced manual labor, boosting productivity and accelerating urbanization and environmental pollution. | High carbon emissions, air pollution, and ecological damage from coal mining | Steam engines (coal) transitioned to electricity and oil, improving energy efficiency but increasing environmental pollution. |

| Industry 2.0 (Electricity Revolution) 1870–1920 | Electricity adoption and internal combustion engine inventions | Enabled mass production, reduced costs, improved quality of life, but led to increased energy consumption | Increased coal and oil consumption, rising carbon emissions | Extensive use of oil, natural gas, and nuclear power increased energy demand and worsened pollution, but solar and wind energy emerged. |

| Industry 3.0 (Digital and Automation Era) 1960–2000 | Electronics, computing advancements, and automation in production | Increased automation, widespread IT adoption, globalization acceleration | Intensified fossil fuel consumption, worsening environmental pollution | Renewable energy (solar, wind) became widespread, with digital technologies (AI, IoT) optimizing energy management and efficiency. |

| Industry 4.0 (Smart Factory) 2000–2020 | IoT, AI, big data, and smart manufacturing | Interconnected production systems enabled innovative management, improving efficiency and resource utilization. | Energy structure adjustments, but still high carbon emissions | Shift to carbon neutrality and smart energy era, leveraging hydrogen, energy storage, blockchain energy trading, and smart grids. |

| Industry 5.0 (Human-Centric and Sustainable Industry) 2020-Future | Human–machine collaboration, human-centric design, and sustainability technologies | Focuses on human–machine synergy, environmental protection, and social welfare to achieve sustainable industrial development | Carbon neutrality targets and circular economy that reduces waste | Advanced sustainable energy systems integrate AI-driven optimization and decentralized energy networks. |

| Feature | Industry 4.0 | Industry 5.0 |

|---|---|---|

| Primary Driver | Technology-driven | Value-driven |

| Key Objectives | Network system, smart product, smart factory | Human–machine collaboration, sustainability, social responsibility |

| Impact on Workforce | Reduction in human labor, automation | Enhances human capabilities, promotes job security |

| Environmental Focus | Potential rise in energy consumption and waste | Promotes circular economy and carbon-neutral processes |

| Technical Challenges | Data silos, high energy consumption | High cost, cybersecurity risks |

| Application Cases | Tesla’s Success in Smart Factories | Siemens’ AI-driven energy optimization; Toyota’s use of hydrogen fuel cells |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, J.-L.; Li, Y.; Chew, J.-C. Industry 5.0 and Human-Centered Energy System: A Comprehensive Review with Socio-Economic Viewpoints. Energies 2025, 18, 2345. https://doi.org/10.3390/en18092345

Hu J-L, Li Y, Chew J-C. Industry 5.0 and Human-Centered Energy System: A Comprehensive Review with Socio-Economic Viewpoints. Energies. 2025; 18(9):2345. https://doi.org/10.3390/en18092345

Chicago/Turabian StyleHu, Jin-Li, Yang Li, and Jung-Chi Chew. 2025. "Industry 5.0 and Human-Centered Energy System: A Comprehensive Review with Socio-Economic Viewpoints" Energies 18, no. 9: 2345. https://doi.org/10.3390/en18092345

APA StyleHu, J.-L., Li, Y., & Chew, J.-C. (2025). Industry 5.0 and Human-Centered Energy System: A Comprehensive Review with Socio-Economic Viewpoints. Energies, 18(9), 2345. https://doi.org/10.3390/en18092345