Abstract

This study presents a methodology for assessing the technical and economic potential of electricity generation from biomass residues, using thermochemical conversion technologies. Applied in the state of Minas Gerais, Brazil, the analysis focuses on residues from corn, soybean, coffee, eucalyptus, and sugarcane. A multi-criteria decision-making (MCDM) approach, integrated with GIS, was used to identify the most viable biomass sources and most suitable conversion technologies, namely the Rankine cycle, organic Rankine cycle, and gasification with internal combustion engines, based on Technological Readiness Levels (TRLs). Eucalyptus emerged as the most suitable residue due to its high energy density, while sugarcane residues were the most abundant. The economic feasibility analysis indicates levelized costs ranging from USD 0.10 to USD 0.24 per kWh, with the conventional Rankine cycle emerging as the most cost-effective option for plants with a capacity exceeding 5 MWe. The proposed methodology supports strategic bioenergy planning by integrating geospatial, technological, and economic factors.

1. Introduction

The looming threats of climate change and air pollution underscore the urgent need for a global transition from fossil fuels. At COP28, a landmark decision committed humanity to phase out the use of fossil fuels “in energy systems in a fair, orderly and equitable manner within 25 years, accelerating the adoption of measures in this critical decade” [1,2]. Despite the consensus on the need for an energy transition, the pathways are not clearly stated, nor agreed upon. Key challenges include managing renewable energy variability, ensuring grid stability, developing energy storage solutions, and clarifying the role of nuclear energy [3]. In this context, biomass and bioenergy are pivotal within the energy–water–food nexus. Biomass, either in its natural state or converted into biofuels, can help mitigate the intermittency of wind and solar power, necessitating comprehensive assessments of land availability, water resources, geographic distribution, and biomass potential [4].

Bioenergy plays a fundamental role in the global energy matrix, currently accounting for around 10% of the primary energy supply, with an estimated production of 55.6 EJ. Projections indicate that its share of the primary energy supply could vary between 7.5% and 37% by 2050, depending on energy policies, technological advances, and the availability of land for growing biomass. Global bioenergy production could increase significantly, reaching between 64 EJ and 313 EJ, with the most optimistic scenarios suggesting an expansion of up to 21 times the current supply. This increase will be driven by the transition from traditional sources, such as firewood and agricultural waste, to high-yield energy crops and biological waste, converted using advanced technologies. Biomass can, thus, be consolidated as a viable alternative for the decarbonization of the energy sector, contributing to a more sustainable and diversified energy mix [5].

The growth of bioenergy on the global stage depends on several factors, including energy policies, technological advances, and the sustainable availability of biomass. Agricultural residues, forestry, and energy crops are becoming important sources for bioenergy production, and are helping to reduce fossil fuel dependence. However, challenges, such as competition for land use, its impact on biodiversity, and the need for more efficient technologies to convert biomass into energy, still limit its expansion. In order for bioenergy to play a central role in the global energy transition and reach the projection of producing up to 313 EJ in 2050, it is essential to invest in innovative solutions, such as advanced biofuels and integrated carbon capture and storage systems (CCUS). In addition, effective public policies and financial incentives can accelerate this transition, ensuring that bioenergy contributes to the decarbonization of the energy sector without compromising food and environmental security [6].

Recent publications from IRENA, UNIDO, and the ETC highlight biomass’s role in future sustainable energy systems [7,8,9]. Studies by Colla et al., Kabeyi and Olanrewaju and Tun et al. emphasize practical biomass applications and the synergies with low-carbon hydrogen [10,11,12]. Biomass sources include agricultural waste, forestry residues, industrial byproducts, MSW, sewage, wastewater, and energy crops, like eucalyptus and algae [13]. The longstanding food/bioenergy dilemma, prominent since the 1980s, still influences contemporary discussions on land use [14,15].

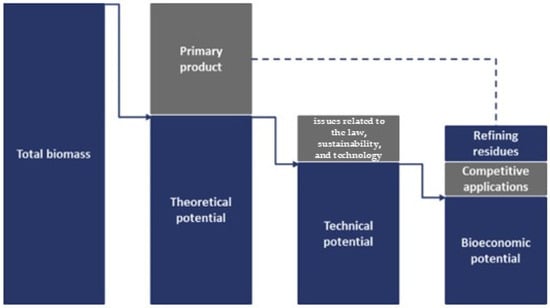

Studies by da Cunha Dias et al. [5] and Errera et al. [6] highlight factors like food habits, waste, and land degradation that impact bioenergy cultivation. These papers forecast the availability of land and the technical potential of bioelectricity and biofuels in various scenarios in 2050 [5,6]. Biomass residues offer a solution that avoids using dedicated land for energy crops and aligns with circular economy principles [16]. Evaluating biomass energy potential involves theoretical, technical, economic, and sustainability considerations (Figure 1). Theoretical potential (Tp) estimates the raw energy content, while technical potential (Tecp) considers conversion efficiencies and logistics. Economic potential (Ecomp) assesses financial viability, and sustainable potential (Sp) considers ecological and food security constraints [17].

Figure 1.

Stages in the assessment of biomass resource potential [18].

A holistic approach to the assessment of energy potential can unlock biomass’s transformative potential in regard to a sustainable energy future. For this task, utilizing Geographic Information Systems (GIS) is fundamental in order to gain better knowledge and more effectively allocate biomass resources and design biomass energy systems. GIS visualize the spatial distribution and availability of biomass residues, aiding the resource allocation process [19]. GIS can be used to determine optimal plant sizing, positioning, and supply chain configurations, enhancing the efficiency of biomass power generation. GIS, combined with a multi-criteria decision-making (MCDM) approach, helps in choosing the best technologies and strategies for biomass energy deployment [20,21,22]. This synergy subsidizes the determination of the energy potential of biomass in a sustainable and scalable way.

Several publications have developed biomass and waste utilization methodologies, addressing spatial and temporal availability, logistics, and technology selection. Notable examples include the study by Gomez et al. (2010) that focused on a case study in Spain, a similar study by Lozano-Garcia et al. (2020) in Mexico, and the studies by Ji et al. (2023), and Ukoba et al. (2023) in Nigeria [23,24,25,26]. However, these studies primarily focus on the theoretical and technical potential of biomass, often using a single conversion technology, typically the conventional steam cycle, while overlooking aspects including biomass technology compatibility, logistical constraints, and economic feasibility. Addressing these gaps is essential for advancing biomass energy assessments and supporting sustainable energy systems.

Therefore, this study proposes a logical and sequential methodology for assessing the theoretical, technical, and economic potential of electricity generated from agricultural residues. The main novelty of this research lies in its integrated approach, which combines a multi-Criteria decision-making (MCDM) approach, specifically the Analytic Hierarchy Process (AHP), with georeferencing, and a selection procedure involving multiple thermochemical conversion technologies. Unlike previous studies that analyze these aspects separately, our approach systematically evaluates the most suitable biomass residues, estimates the energy potential at different levels, and calculates the levelized cost of electricity (LCOE) for mature technologies.

This paper introduces several key innovations: (i) a structured methodology for assessing biomass residues for electricity generation, considering not only the theoretical, but also the technical and economic constraints; (ii) a comparative analysis of different thermochemical technologies is conducted, including the conventional Rankine cycle, organic Rankine cycle, and internal combustion engines coupled with gasifiers; (iii) the development of a method for determining the economic transportation radius of biomass residues; and (iv) the development of an integrated decision-support framework to optimize biomass energy planning in regions with a high level of agricultural activity.

This study provides strategic insights for optimizing agricultural waste management for electricity generation, by advancing biomass utilization planning through the use of a holistic, decision-oriented methodology. The application to Minas Gerais, an agriculturally dominant region with well-developed logistics infrastructure, further demonstrates its practical utility. This research supports the transition to cleaner, more resilient energy systems, aligning with global environmental and climate goals.

2. Materials and Methods

The primary objective of this study is to develop and apply a comprehensive methodology for assessing the technical and economic potential of electricity generation from diverse agricultural residues, incorporating the multi-criteria decision-making (MCDM) method, more specifically the Analytic Hierarchy Process (AHP), as well as georeferencing techniques, and the selection of the most suitable technology from among various thermochemical conversion technologies. The MCDM methodology is a set of methods used to evaluate and prioritize different alternatives based on multiple, often conflicting, criteria [27]. In this study, the AHP is applied as a structured technique that assigns relative weights to criteria through the use of pairwise comparisons, aiding in the selection of the most suitable biomass residues and conversion technologies [28]. Georeferencing is incorporated using Geographic Information Systems (GIS), which enables the spatial analysis of biomass availability and the assessment of logistical feasibility. Additionally, the levelized cost of electricity, LCOE, is used as a financial metric to compare the cost effectiveness of different biomass-based power generation systems [29].

The case study focusing on the state of Minas Gerais in Brazil is presented to illustrate the application of this approach. Key components of this methodology, as shown in the paper’s graphical abstract, include the following:

- Utilization of the MCDM/AHP method to decide on the most suitable biomass residues for electricity generation across different microregions, considering multiple criteria and preferences;

- Determination of the theoretical, technical, and economic potential of biomass;

- Determination of the levelized cost of electricity (LCOE) for different mature technologies, providing insights into the economic viability and competitiveness of biomass-based electricity generation.

2.1. Structure of the Proposed Methodology

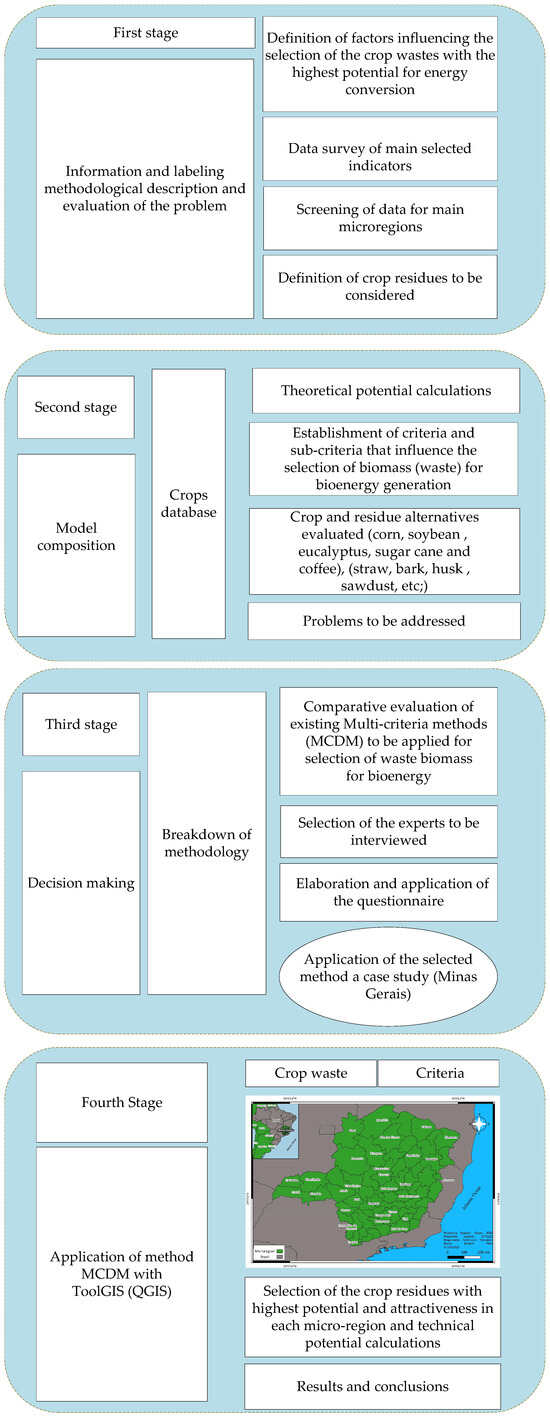

The utilization of the multi-criteria decision-making (MCDM) approach is essential in the context of this study for several compelling reasons. Firstly, the complexity inherent in evaluating diverse biomass agricultural residues for electricity generation requires a systematic and structured approach that can accommodate multiple criteria and preferences. MCDM provides a robust framework for the pairwise comparison of different criteria, such as technical feasibility, economic viability, environmental impact, and social acceptance, into a unified decision-making process [30]. By incorporating stakeholder preferences and expert judgments, MCDM enables a comprehensive and inclusive assessment that captures the multifaceted nature of energy planning and resource allocation. Moreover, MCDM facilitates the identification of trade-offs and synergies among competing alternatives, enabling decision makers to effectively consider complexities and uncertainties inherent to agricultural residue suitability utilization pathways [31]. In essence, the adoption of MCDM ensures transparency, rigor, and objectivity in decision making, thereby enhancing the efficacy and credibility of strategic energy planning efforts to promote sustainable biomass utilization for electricity generation. In this context, Figure 2 presents a flowchart of the proposed methodology, divided into four stages: data gathering, modeling, decision making, and application.

Figure 2.

A flowchart of the proposed methodology [32].

These steps provide a methodical assessment of biomass residues for electricity generation by incorporating data collection, decision-making techniques, and spatial analysis tools.

The first stage refers to the identification of relevant biomass sources. The study began by assessing the primary crops in the target region, based on production volume and residue availability. This step was crucial for selecting biomass sources that accurately reflect the agrarian landscape. In the case of Minas Gerais, Brazil, data were retrieved from SIDRA, the agricultural statistics database managed by the Brazilian Institute of Geography and Statistics (IBGE). To enhance data reliability, information from SIDRA was validated via expert consultations and supplementary literature, ensuring consistency with the agricultural conditions in the state.

The second stage refers to the definition of the analytical model. A review of multi-criteria decision-making (MCDM) methodologies applicable to energy planning was conducted, including AHP, ELECTRE, TOPSIS, VIKOR, MAUT, PROMETHEE, and MACBETH. The Analytic Hierarchy Process (AHP) was selected for use in this study, due to its effectiveness in handling complex decision scenarios and its successful use in previous biomass energy assessments. The theoretical and technical potential of biomass electricity generation were quantified, and the evaluation criteria and sub-criteria were established.

The third stage involves the implementation of the decision-making framework. The AHP methodology was structured to rank biomass residues based on key attributes, such as availability, energy potential, economic feasibility, and TRLs. A GIS was integrated into the decision-making framework to facilitate spatial analysis of the biomass distribution and identify the most suitable locations for energy generation.

The fourth stage concerns the application of the framework to the case study region. The developed methodology was applied to Minas Gerais, analyzing the theoretical, technical, and economic viability of biomass-based electricity generation. Suitable conversion technologies were selected, based on efficiency and feasibility criteria, including the Rankine cycle, organic Rankine cycle, and gasification with internal combustion engines. The final analysis mapped optimal agricultural residues-to-energy pathways, incorporating cost evaluations and logistical considerations to support decision making.

2.2. Multi-Criteria Methods

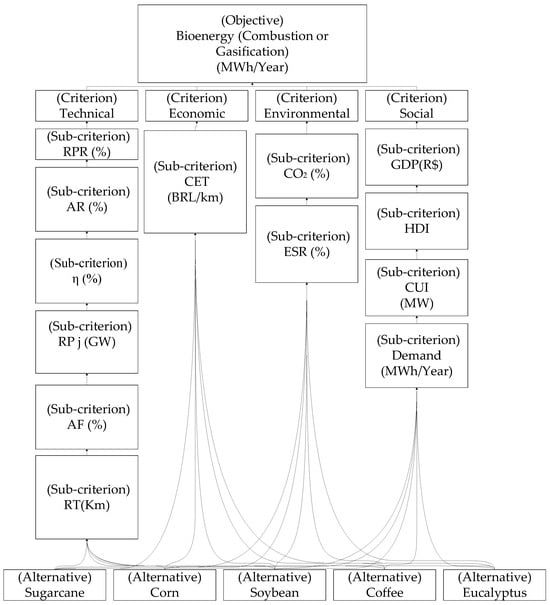

An Analytic Hierarchy Process assessment, coupled with a GIS, was conducted to identify and select the biomass residues from the primary crops with the highest electricity production potential in a specific region (Figure 3) Table 1 shows the description of the AHP criteria and sub-criteria.

Figure 3.

MCDM (AHP) method application flowchart, indicating criteria and sub-criteria [32].

Table 1.

Description of the AHP criteria and sub-criteria [32].

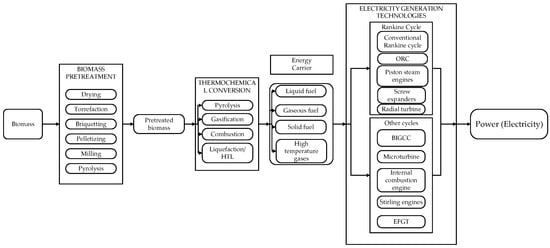

2.3. Conversion Technologies: Technological Maturity

The types of biomass electricity generation technologies considered, along with the alternatives for biomass pretreatment technologies, thermochemical conversion routes, and energy carriers linked to the selected generation technology and its capacity, are shown in Figure 4. Their maturity levels were determined via a worldwide survey and subsequent statistical analysis, using the widely known TRL thermometer methodology as a reference. A questionnaire was made available through a weblink, collecting the judgments of 31 experts from several locations. Most respondents were from Brazil and Italy, followed by Spain and Colombia. Regarding the respondents’ sector of work, the leading sector was universities, accounting for 86% of the total number of experts, followed by the industrial sector with 7%, and research institutions, also with 7%. The results from this survey were subjected to statistical consistency tests before their acceptance.

Figure 4.

Main biomass electricity generation technologies, showing pretreatment technologies, thermochemical conversion routes, and energy carriers [33].

The data and results provided in this research facilitated a logical approach to selecting the technology with the highest current technological maturity (TRL) for the preliminary design of biomass electricity generation systems. Among the technologies surveyed, it is evident that the conventional Rankine cycle (CRC) technology is the most widely explored, disseminated, and commercialized globally, with the highest maturity level (predominant TRL 9). However, technologies such as the organic Rankine cycle (ORC) are expected to soon reach the highest maturity level, due to the hundreds of new facilities installed or planned worldwide [34].

Determining the TRL for gasifier–internal combustion engine (G/ICE) technology proved to be a complex task, as reflected in the survey results. The weighted TRL is 6, with individual survey responses ranging from 5 to 7. This variation is due to the different maturity levels of existing operational units, which have varying operational characteristics and reliability, depending on the manufacturer.

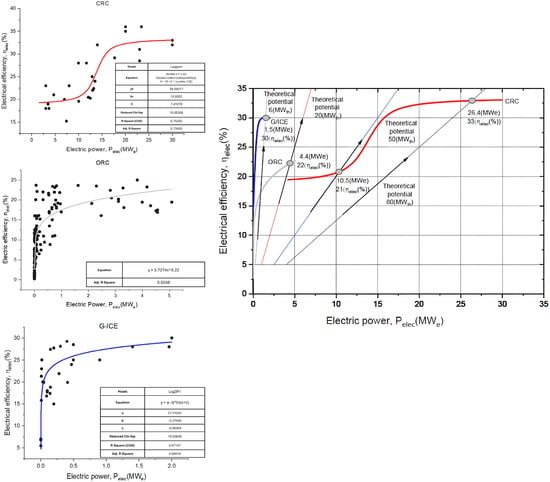

Finally, the technology for each evaluated case was selected among those with a TRL value corresponding to a high maturity level, specifically the conventional Rankine cycle (CRC), the organic Rankine cycle (ORC), and the gasifier/internal combustion engine system (G/ICE). The final technology selection for each microregion was based on efficiency vs. electric power curves, considering each evaluated technology’s most widespread power application power range (left column in Figure 5). By superimposing these curves onto a single graph (right side in Figure 5) and the intersection with a vertical line corresponding to the thermal power of biomass makes it possible power , through successive approximations, to select the appropriate technology and determine its capacity and efficiency for a particular use case [33].

Figure 5.

Fundamentals and visualization of the methodology for electricity generation technology selection, starting from biomass availability (adapted from Dovichi [34]).

The relationship between efficiency and installed power for different plants, based on CRC, ORC, and G-ICE technologies, was collected from scientific publications, resulting in the scatter plots shown on the left side of Figure 5. In general, efficiency increases with power, following a logarithmic regression curve. Otherwise, for CRC technology, the adjustment resulted in a Hill slope curve. In this case, three zones can be defined: the first with a power up to around 10 MWe, characterized by low steam parameters and efficiencies of around 20%; the second zone reaching about 20 MWe, where the steam parameters increase to 90–130 bar; and a third zone with efficiencies slightly above 30%, which includes modifications to the thermal scheme of the plant with the implementation of reheating and regenerative heating, in addition to parameters of up to 130 bar of pressure. Based on data on the availability of residual biomass for different case studies and its calorific value, it is possible to draw a straight line hypothetically showing the dependence between electrical capacity and efficiency for a given generation system. In Figure 5, three different lines were drawn as an example. The intersection of these lines with any of the efficiency vs. electric capacity curves allows us to define the bioelectricity technology to be used and to determine its power and efficiency; this approach is shown on the right side of Figure 5.

2.4. Logistics, Economic Radius, and Pretreatment

For the techno-economic modeling of the biomass residue supply chain, the study area is divided into microregions, and residue availability is considered. Each microregion was assumed to contain a single electricity generation plant located at its centroid, determined by the economical transportation radius for biomass residues.

In this model, each microregion was modelled to operate using a single biomass type, prioritizing the residue with the highest potential. The selected biomass is transported to the central generation unit, wherein it undergoes pretreatment and energy conversion, according to the adopted technology.

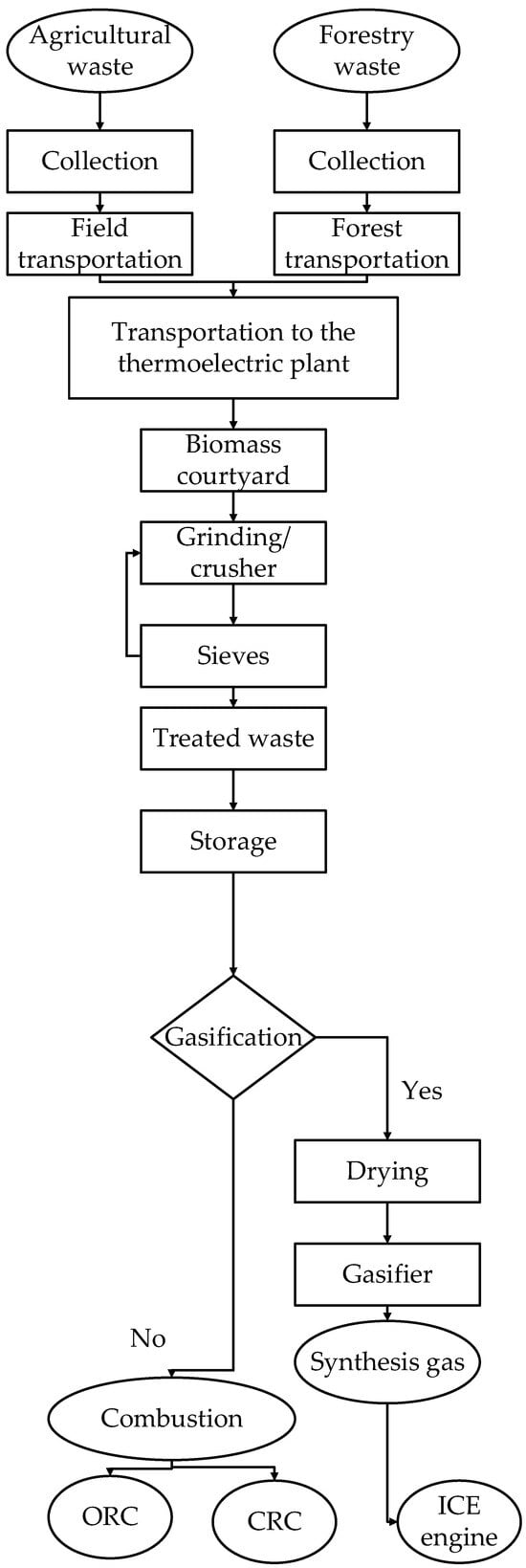

The bioenergy supply chain has four stages: (1) residue collection, (2) handling, and transportation, (3) pretreatment, and (4) energy conversion. Only drying and crushing were considered as pretreatment steps. Pelletization was excluded due to its higher costs and logistical complexity. The pretreatment model balanced the trade-off between natural drying with a larger storage capacity and forced drying with more robust equipment.

Regarding logistics, biomass handling and transportation were treated as a single step. Handling includes loading, unloading, and material movement inside the power plant, while transportation covers moving residues from collection sites to generation plants. Pretreatment occurs at the generation unit to avoid additional transportation costs or the need for multiple smaller pretreatment facilities at collection sites. The economic transportation radius guided this decision. Figure 6 illustrates the entire logistics process, from residue collection to energy conversion.

Figure 6.

Harvest, transport, and pretreatment logistics.

Dovichi et al. highlight the impact of logistics costs on the levelized cost of electricity (LCOE) for two microregions. Expenses related to harvesting, transportation, crushing, and drying represented 25% to 38% of the LCOE, emphasizing the need for careful planning [34].

The pretreatment processes of crushing and drying consider the requirements of each selected technology and the type of combustion or gasification reactor employed (fixed, bubbling, or circulating fluidized bed). These processes were adjusted based on the biomass moisture content and size distribution [34].

3. Results: The Case Study of the State of Minas Gerais in Brazil

Minas Gerais (MG) is located in Brazil’s southwest region (Figure 7). Its territorial area is 586,514 km2, with an estimated population of 21,411,923 inhabitants. It was chosen due to its vast agricultural lands, advanced farming techniques, variety of crops, and high production of biomass residues. Additionally, its well-developed transportation infrastructure facilitates the logistics of biomass collection and energy distribution, making it an ideal case study for evaluating biomass-to-electricity potential. This state is the second largest agricultural producer in the country, with a high level of participation in the production of corn, beans, and coffee, among others. In 2020, the state had a record level of production of about 15.4 million tons of grain (an increase of 5.8% compared to the previous harvest, with a 4.7% increase in productivity).

Figure 7.

Geographical location of the state of Minas Gerais.

According to the information available in the SIGA database (Information System for Generation of ANEEL, the regulatory agency for the electrical sector in Brazil), the state of Minas Gerais has 826 operational electricity generation plants, totaling 20.9 GW of installed capacity [35]. Most of this capacity comes from hydroelectric power plants, accounting for 64.6% of the state’s installed capacity. Minas Gerais hosts 442 thermal-based generation units (both fossil and biomass), comprising 2.9 GW of installed capacity, constituting 14% of the state’s total capacity. Explicitly focusing on biomass, there are 78 operational thermal power plants, with a total installed capacity of 1.96 GW. Additionally, the state has seven authorized projects, two already under construction, collectively adding 0.2 GW of installed capacity.

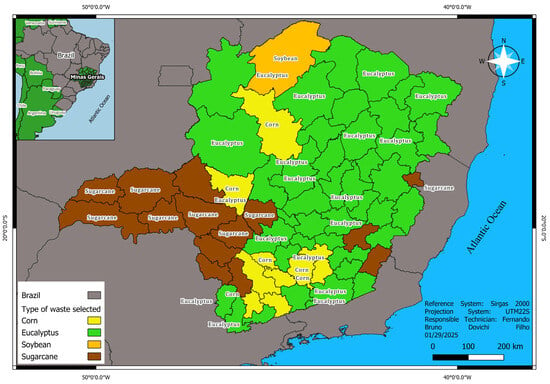

The most representative residues considered in this study come from eucalyptus, soybean, sugarcane, and coffee crops, as determined through the use of Pareto analysis and an MCDM study. The QGIS 3.34.3 software was used for georeferencing the obtained data, which was sourced from IBGE SIDRA [36]. The application of the AHP method identified eucalyptus residues as the most suitable and viable biomass for electricity generation in most microregions in Minas Gerais, followed by residues from sugarcane, corn, and soybean.

3.1. Theoretical Potential

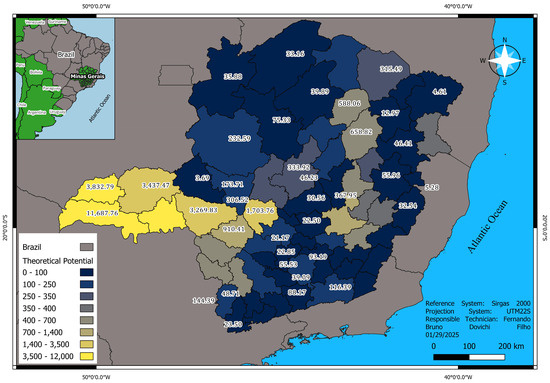

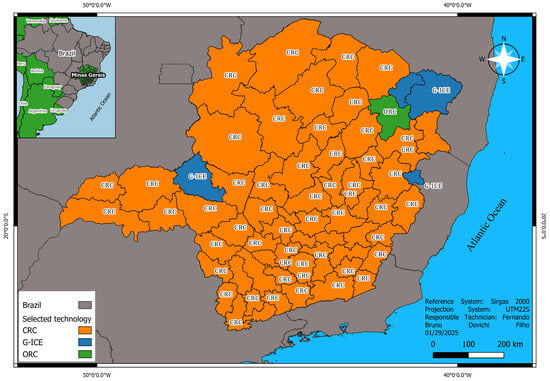

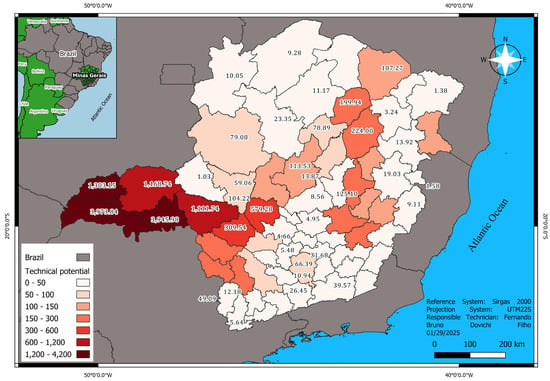

Once the biomass residue with the most significant potential and viability has been defined using the AHP method (Figure 8), its theoretical energy potential is determined, as shown in Figure 9. Selected power generation technologies and resulting technical potential by microregion are shown in Figure 10 and Figure 11 respectively.

Figure 8.

Biomass residues with the greatest potential and availability per microregion.

Figure 9.

Theoretical potential of selected residues by microregion, in MW.

Figure 10.

The results on the selection of feasible electricity generation technologies for each microregion.

Figure 11.

Technical potential of the selected residue by microregion, in MW.

3.2. Economic Potential

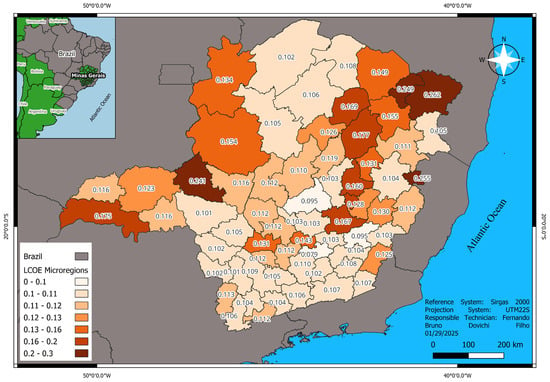

A techno-economic evaluation of the selected projects for electricity generation from biomass was carried out for each microregion, which resulted in power capacities ranging from 0.5 MW to 35 MW. The thermal efficiencies of these technologies ranged from 12% to 35%.

Table 2 presents the results of the economic feasibility study, using the following economic indicators: net present value (NPV), internal rate of return (IRR), levelized cost of electricity (LCOE), and payback time (PBT). These indicators allow us to determine whether a project is economically viable. Figure 12 displays data on the levelized cost of electricity for each microregion.

Table 2.

The results of the economic viability study of the bioenergy projects in each of the considered microregions.

Figure 12.

LCOE for the selected residue by microregion in the State of Minas Gerais, Brazil, in USD/kWh.

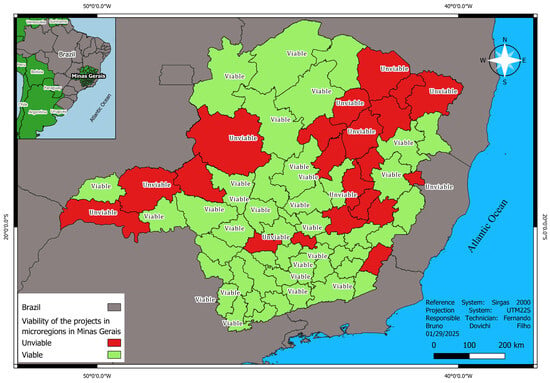

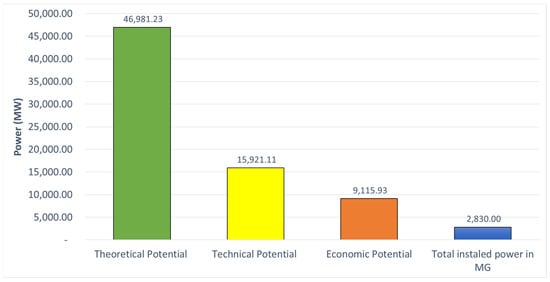

Data from Table 2 and Figure 12 allows one to identify which bioelectricity projects are economically viable (green cells) and unviable (red cells) in a given microregion, as shown in Figure 13. This analysis allowed for the calculation of the state’s economic potential, considering the data on bioelectricity projects that proved to be economically feasible. Figure 14 illustrates the total theoretical, technical, and economic potential of the state of Minas Gerais.

Figure 13.

Map showing the economic viability of bioelectricity projects in the different microregions in the state of Minas Gerais, Brazil (viable and unviable).

Figure 14.

Biomass potential of the microregions in the state of Minas Gerais, Brazil.

Additionally, it is important to acknowledge that market factors, such as fluctuations in biomass prices, changes in electricity market prices, and policy incentives, can significantly impact the economic feasibility of biomass energy projects. A sensitivity analysis considering these factors would provide a more robust assessment of the related investment risks and profitability. Future studies should explore the implications of these dynamics on biomass electricity generation in Minas Gerais, helping refine strategies for long-term energy planning.

As shown in Figure 14, the actual installed bioelectricity power amounts to only 31.0% of the calculated economic potential and 17.8% of the technical potential of the microregions. These data suggest considerable potential for expanding installed bioenergy capacity in Minas Gerais, which could further increase through the simultaneous utilization of various residual biomass sources in each microregion.

4. Conclusions

According to the Brazilian Institute of Geography and Statistics (IBGE), the state of Minas Gerais is divided into 66 microregions. The AHP multi-criteria evaluation identified the most suitable biomass residues and mapped their theoretical, technical, and economic electricity generation potential. Eucalyptus, corn, soybean, coffee, and sugarcane residues were biomass sources considered to be energy resources.

The results revealed that eucalyptus is the most suitable biomass for electricity generation in 41 out of 66 microregions (62%), sugarcane in 14 microregions (21%), corn in 10 microregions (15%), and soybean in only 1 microregion (2%). Coffee residues were not selected as the most suitable biomass in any microregion due to their low availability. The prevalence of eucalyptus as the preferred biomass source is attributed to its extensive cultivation across Minas Gerais. Regarding its theoretical potential, Minas Gerais could generate approximately 47 GW from biomass residues. Eucalyptus residues have a theoretical potential of 7.3 MW (15% of the total), while sugarcane contributes the most with 38.8 MW (83%). Corn and soybean residues have a potential of 915 kW (2% of the total) and 33 kW (irrelevant), respectively. The high contribution of sugarcane is due to the large volume of residues, including straw, tops, and bagasse.

This study developed and demonstrated a comprehensive multi-criteria/GIS methodology for assessing the technical and economic potential of biomass electricity generation. The methodology included a survey of existing residues, ranking their availability, the multi-criteria selection of the most suitable biomasses, a georeferenced theoretical potential calculation, technology selection based on efficiency/power curves, and an economic potential calculation. The Rankine cycle emerged as the most appropriate technology for 61 microregions. The gasification cycle integrated with an internal combustion engine was chosen in four microregions, and the organic Rankine cycle was recommended for only one microregion. Economically viable plants had levelized energy costs of between USD 0.1012/kWh and USD 0.2408/kWh, with eucalyptus and the conventional Rankine cycle generally having the lowest costs.

The proposed methodology’s main limitations are its consideration of only one type of biomass per microregion, that it ignores multi-residue conversion units, and the need for more detailed transportation logistics insights, including from GIS.

Integrating multiple biomass residues for energy generation offers potential benefits in regard to efficiency and resource utilization. However, practical challenges, such as varying physicochemical properties, logistical complexities, and the necessity for specific pretreatment processes, render multi-residue approaches intricate. While Brazil has made significant strides in biomass energy production, particularly with sugarcane bagasse and eucalyptus residues, large-scale projects utilizing multiple agricultural biomass residues are not yet prevalent. Future research should focus on the feasibility of mixed biomass utilization, evaluating its effects on power generation efficiency, cost structures, and environmental performance to optimize biomass energy strategies.

Author Contributions

Conceptualization: F.B.D.F., E.E.S.L. and J.C.E.P. Methodology: F.B.D.F., E.E.S.L. and J.C.E.P. Software: F.B.D.F. and L.V.M.d.S. Validation: F.B.D.F., D.M.Y.M. and O.J.V. Formal analysis: F.B.D.F., E.E.S.L. and M.R.E. Investigation: F.B.D.F., L.V.M.d.S., J.C.E.P., D.M.Y.M. and O.J.V. Resources: E.E.S.L. Data curation: E.E.S.L. Writing—original draft: F.B.D.F. Writing—review and editing: F.D.M. and M.R.E. Visualization: F.D.M. and M.R.E. Supervision: E.E.S.L. and J.C.E.P. Project administration: E.E.S.L. Funding acquisition: E.E.S.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Coordination for the Improvement of Higher Education Personnel (CAPES), the Minas Gerais State Agency for Research and Development (FAPEMIG APQ-02413-17); Project number RED-00090-21; and the National Council for Scientific and Technological Development (CNPq), Project numbers 406948/2021-6, 302860/2022-3, 317527/2021-5, and 311.022/2022-7 (MRE); (CAPES) and the BRICS project CNPQ/Finep/MCTIC/BRICS-STI No 03/2019, Process: 442318/2017-0; which provided scholarships for the researchers and graduate students.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding authors.

Acknowledgments

The authors wish to express their thanks to the Research Support Foundation of the state of Minas Gerais (FAPEMIG); the National Council for Scientific and Technological Development (CNPq); the Coordination for the Improvement of Higher-Level Personnel (CAPES) and the BRICS project CNPQ/Finep/MCTIC/BRICS-STI No 03/2019; and the Project “Green Hydrogen Center (CH2V)”, of the Federal University of Itajubá (UNIFEI).

Conflicts of Interest

The authors declare no conflict of interest.

Correction Statement

This article has been republished with a minor correction to the image quality of Figure 5. This change does not affect the scientific content of the article.

Abbreviations

| MCDM | Multi-criteria decision-making (Tomada de Decisão Multicritério) |

| TRLs | Technological Readiness Levels (Níveis de Prontidão Tecnológica) |

| GIS | Geographic Information Systems (Sistemas de Informação Geográfica) |

| MWe | Mega Watt elétrico |

| GIS-MCDM | Abordagem combinada de GIS e MCDM |

| LCOE | Levelized cost of electricity (Custo Nivelado de Eletricidade) |

| AHP | Analytic Hierarchy Process (Processo de Hierarquia Analítica) |

| NPV | Net Present Value (Valor Presente Líquido) |

| IRR | Internal Rate of Return (Taxa Interna de Retorno) |

| PBT | Payback Time (Tempo de Retorno do Investimento) |

| MSW | Municipal Solid Waste (Resíduos Sólidos Municipais) |

| ANEEL | Agência Nacional de Energia Elétrica (Brasil) |

| IBGE | Instituto Brasileiro de Geografia e Estatística |

| SIDRA | Sistema IBGE de Recuperação Automática |

| UNIDO | United Nations Industrial Development Organization (Organização das Nações Unidas para o Desenvolvimento Industrial) |

| IRENA | International Renewable Energy Agency (Agência Internacional de Energia Renovável) |

| ETC | Energy Transitions Commission (Comissão de Transições Energéticas) |

References

- Multilateral Consultation with Chairs of Negotiating Groups and Heads of Delegation on. Available online: https://unfccc.int/sites/default/files/resource/Co-Chairs_Summary_of_27_Feb_2025_HoDs.pdf (accessed on 24 April 2025).

- Hatab, E. Commentary on COP28: The “Beginning of The End” of The Fossil Fuel Era. Int. J. Comput. Audit. 2023, 5, 68–73. [Google Scholar] [CrossRef]

- Wyllie, M. Developments in the “LNG to Power” Market and the Growing Importance of Floating Facilities; Oxford Institute for Energy Studies: Oxford, UK, 2021; ISBN 9781784671815. [Google Scholar]

- Mandley, S.; Wicke, B.; Junginger, H.; Vuuren, D.; Daioglou, V. Integrated Assessment of the Role of Bioenergy within the EU Energy Transition Targets to 2050. GCB Bioenergy 2021, 14, 157–172. [Google Scholar] [CrossRef]

- Dias, T.A.d.C.; Lora, E.E.S.; Maya, D.M.Y.; del Olmo, O.A. Global Potential Assessment of Available Land for Bioenergy Projects in 2050 within Food Security Limits. Land Use Policy 2021, 105, 105346. [Google Scholar] [CrossRef]

- Errera, M.R.; Dias, T.A.d.C.; Maya, D.M.Y.; Lora, E.E.S. Global Bioenergy Potentials Projections for 2050. Biomass Bioenergy 2023, 170, 106721. [Google Scholar] [CrossRef]

- IRENA. Bioenergy for the Energy Transition Ensuring Sustainability and Overcoming Barriers; IRENA: Masdar City, Abu Dhabi, 2022. [Google Scholar]

- Lacrosse, L.; Englisch, M.; Danner, K.; Stokes, H. The Role of Bioenergy in the Clean Energy Transition and Sustainable Development Lessons from Developing Countries; UNIDO: Vienna, AT, USA, 2021. [Google Scholar]

- Energy Transition Commission. Bioresources within a Net-Zero Emissions Economy: Making a Sustainable Approach Possible The Making Mission Possible Series; Energy Transition Commission: London, UK, 2021. [Google Scholar]

- Colla, M.; Blondeau, J.; Jeanmart, H. Optimal Use of Lignocellulosic Biomass for the Energy Transition, Including the Non-Energy Demand: The Case of the Belgian Energy System. Front. Energy Res. 2022, 10, 802327. [Google Scholar] [CrossRef]

- Kabeyi, M.J.B.; Olanrewaju, O.A. Sustainable Energy Transition for Renewable and Low Carbon Grid Electricity Generation and Supply. Front. Energy Res. 2022, 9, 743114. [Google Scholar] [CrossRef]

- Tun, M.M.; Juchelkova, D.; Win, M.M.; Thu, A.M.; Puchor, T. Biomass Energy: An Overview of Biomass Sources, Energy Potential, and Management in Southeast Asian Countries. Resources 2019, 8, 81. [Google Scholar] [CrossRef]

- Yasseri, S.; Bahai, H. System Readiness Level Estimation of Oil and Gas Production Systems. Int. J. Coast. Offshore Environ. Eng. 2018, 2, 31–44. [Google Scholar] [CrossRef]

- Masi, M.; Oddo, E.; Rulli, M.C.; Seabra, J.E. Roadmap to 2050: The Land-Water-Energy Nexus of Biofuels. In Roadmap to 2050 The Land-Water-Energy Nexus of Biofuels. Sustainable Development Solutions Network and Fondazione Eni Enrico Mattei. 2021. Available online: https://roadmap2050.report/static/files/roadmap-to-2050-biofuels.pdf (accessed on 24 April 2025).

- Gamborg, C.; Millar, K.; Shortall, O.; Sandøe, P. Bioenergy and Land Use: Framing the Ethical Debate. J. Agric. Environ. Ethics 2011, 25, 909–925. [Google Scholar] [CrossRef]

- Alakangas, E. Biomass and Agricultural Residues for Energy Generation. In Fuel Flexible Energy Generation; Woodhead Publishing: Cambridge, UK, 2016; pp. 59–96. [Google Scholar] [CrossRef]

- Ladanai, S.; Vinterbäck, J. Global Potential of Sustainable Biomass for Energy. Rapport (Institutionen för Energi Och Teknik, SLU) 2009, 13. Available online: https://publications.slu.se/?file=publ/show&id=28604 (accessed on 24 April 2025).

- Thorenz, A.; Wietschel, L.; Stindt, D.; Tuma, A. Assessment of Agroforestry Residue Potentials for the Bioeconomy in the European Union. J. Clean. Prod. 2018, 176, 348–359. [Google Scholar] [CrossRef]

- Fiorese, G.; Guariso, G. A GIS-Based Approach to Evaluate Biomass Potential from Energy Crops at Regional Scale. Environ. Model. Softw. 2010, 25, 702–711. [Google Scholar] [CrossRef]

- Famoso, F.; Prestipino, M.; Brusca, S.; Galvagno, A. Designing Sustainable Bioenergy from Residual Biomass: Site Allocation Criteria and Energy/Exergy Performance Indicators. Appl. Energy 2020, 274, 115315. [Google Scholar] [CrossRef]

- Lovrak, A.; Pukšec, T.; Duić, N. A Geographical Information System (GIS) Based Approach for Assessing the Spatial Distribution and Seasonal Variation of Biogas Production Potential from Agricultural Residues and Municipal Biowaste. Appl. Energy 2020, 267, 115010. [Google Scholar] [CrossRef]

- Zhao, B.; Wang, H.; Huang, Z.; Sun, Q. Location Mapping for Constructing Biomass Power Plant Using Multi-Criteria Decision-Making Method. Sustain. Energy Technol. Assess. 2022, 49, 101707. [Google Scholar] [CrossRef]

- Gómez, A.; Rodrigues, M.; Montañés, C.; Dopazo, C.; Fueyo, N. The Potential for Electricity Generation from Crop and Forestry Residues in Spain. Biomass Bioenergy 2010, 34, 703–719. [Google Scholar] [CrossRef]

- Lozano-García, D.F.; Santibañez-Aguilar, J.E.; Lozano, F.J.; Flores-Tlacuahuac, A. GIS-Based Modeling of Residual Biomass Availability for Energy and Production in Mexico. Renew. Sustain. Energy Rev. 2019, 120, 109610. [Google Scholar] [CrossRef]

- Ji, L.; Zheng, Z.; Huang, Y.; Xie, Y.; Sun, L.; Huang, G. An Integrated Decision Support Method for Strategic Planning and Tactical Management of Regional Biomass Power Plants under Uncertainties. J. Clean. Prod. 2023, 388, 135968. [Google Scholar] [CrossRef]

- Ukoba, M.O.; Diemuodeke, E.O.; Briggs, T.A.; Imran, M.; Owebor, K.; Nwachukwu, C.O. Geographic Information Systems (GIS) Approach for Assessing the Biomass Energy Potential and Identification of Appropriate Biomass Conversion Technologies in Nigeria. Biomass Bioenergy 2023, 170, 106726. [Google Scholar] [CrossRef]

- Taherdoost, H.; Madanchian, M. Multi-Criteria Decision Making (MCDM) Methods and Concepts. Encyclopedia 2023, 3, 77–87. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision Making with the Analytic Hierarchy Process. Int. J. Serv. Sci. 2008, 1, 83–98. [Google Scholar] [CrossRef]

- Shen, W.; Chen, X.; Qiu, J.; Hayward, J.A.; Sayeef, S.; Osman, P.; Meng, K.; Dong, Z.Y. A Comprehensive Review of Variable Renewable Energy Levelized Cost of Electricity. Renew. Sustain. Energy Rev. 2020, 133, 110301. [Google Scholar] [CrossRef]

- Campos-Guzmán, V.; García-Cáscales, M.S.; Espinosa, N.; Urbina, A. Life Cycle Analysis with Multi-Criteria Decision Making: A Review of Approaches for the Sustainability Evaluation of Renewable Energy Technologies. Renew. Sustain. Energy Rev. 2019, 104, 343–366. [Google Scholar] [CrossRef]

- Kumar, A.; Sah, B.; Singh, A.R.; Deng, Y.; He, X.; Kumar, P.; Bansal, R.C. A Review of Multi Criteria Decision Making (MCDM) towards Sustainable Renewable Energy Development. Renew. Sustain. Energy Rev. 2017, 69, 596–609. [Google Scholar] [CrossRef]

- Dovichi Filho, F.B.; de Sousa, L.V.M.; Lora, E.E.S.; Palacio, J.C.E.; Borges, P.T.; Barros, R.M.; Jaen, R.L.; Errera, M.R.; Quintero, Q.R. A Methodology for the Feasibility Assessment of Using Crop Residues for Electricity Production Through GIS-MCD and Its Application in a Case Study. Agriculture 2025, 15, 334. [Google Scholar] [CrossRef]

- Dovichi Filho, F.B.; Castillo Santiago, Y.; Silva Lora, E.E.; Escobar Palacio, J.C.; Almazan del Olmo, O.A. Evaluation of the Maturity Level of Biomass Electricity Generation Technologies Using the Technology Readiness Level Criteria. J. Clean. Prod. 2021, 295, 126426. [Google Scholar] [CrossRef]

- Dovichi Filho, F.B.; Silva, E.; Escobar, C.; Venturini, O.J.; Jaén, R.L. An Approach to Technology Selection in Bioelectricity Technical Potential Assessment: A Brazilian Case Study. Energy 2023, 272, 126995. [Google Scholar] [CrossRef]

- Sistema de Informações de Geração da ANEEL. 2024. Available online: https://www.gov.br/aneel/pt-br/centrais-de-conteudos/relatorios-e-indicadores/geracao (accessed on 24 April 2025).

- IBGE. Sistema IBGE de Recuperação Automática SIDRA. 2023. Available online: https://sidra.ibge.gov.br/home/pms/brasil (accessed on 24 April 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).