Automatic and Versatile Test Bench for Data Collection on Battery Cells

Abstract

1. Introduction

2. Basics of Lithium-Ion Battery Degradation and Operation

3. Proposed Framework for Testing Lithium-Ion Batteries

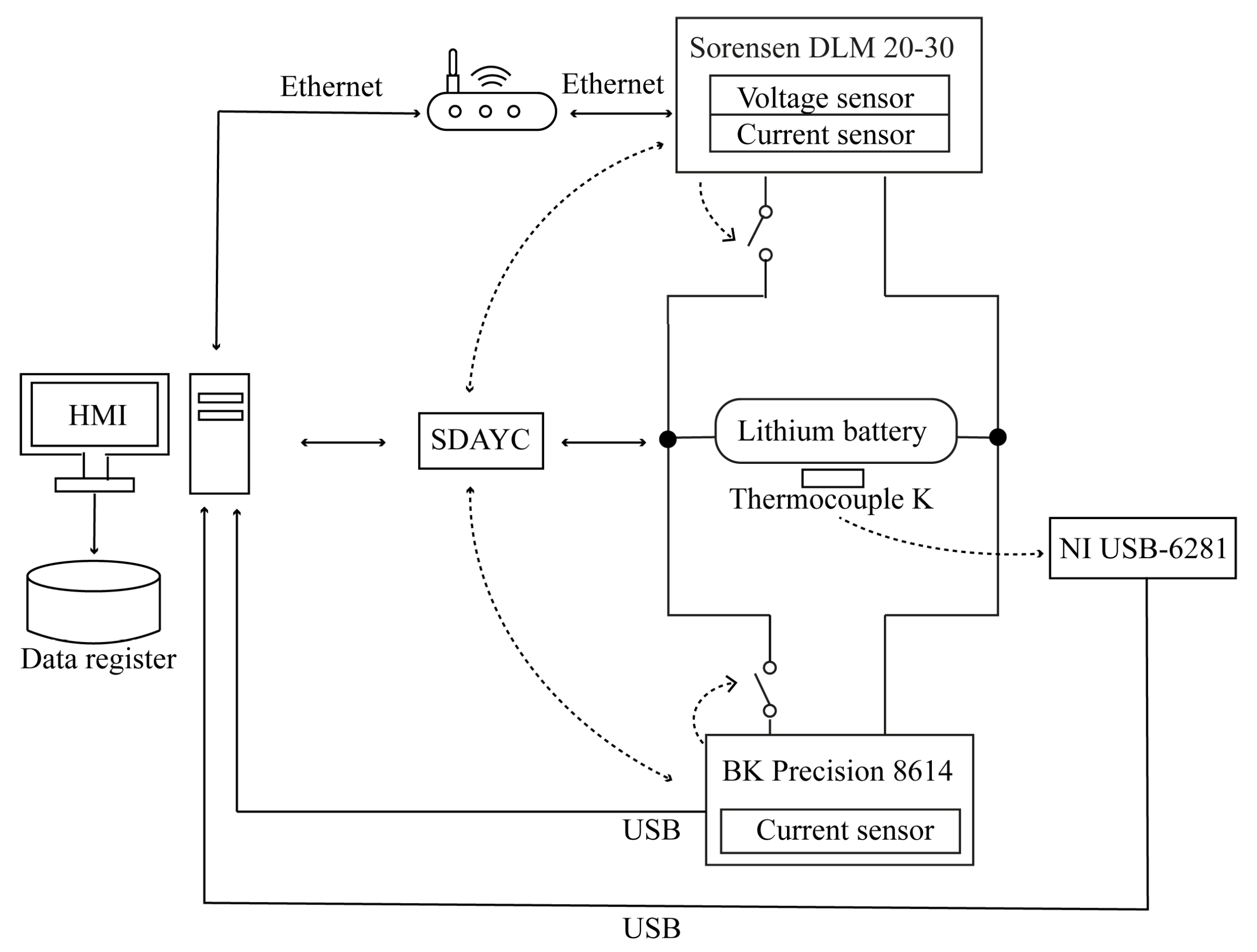

- Personal Computer: manages and controls the test bench.

- Power Supply: Sorensen DLM20-30, AMETEK, Inc., Berwyn, PA, USA (600 W), providing the necessary testing voltage. The system can handle the voltage and current required by the single battery pack (up to a maximum of 20 V and 30 A supplied by this electronic equipment). This is a major limitation of our system. Higher voltage or current testing values require another power supply.

- Router: D-Link D-300, D-Link Corporation, Taiwan, facilitating communication between devices.

- Electronic load: B&K Precision 8614, B&K Precision Corporation, Yorba Linda, CA, USA, designed to emulate battery charge and discharge conditions by dynamically adjusting voltage and current parameters. This allows accurate characterization of battery performance under various load scenarios.

- I/O Device: National Instruments USB-6281, Emerson Electric Co., St. Louis, MO, USA, serving as the test bench’s monitoring platform. It enables battery temperature measurement and allows system expansion by integrating additional relays and external monitoring devices.

- Thermocouple: K type, ensuring accurate thermal monitoring by measuring battery temperature during analysis.

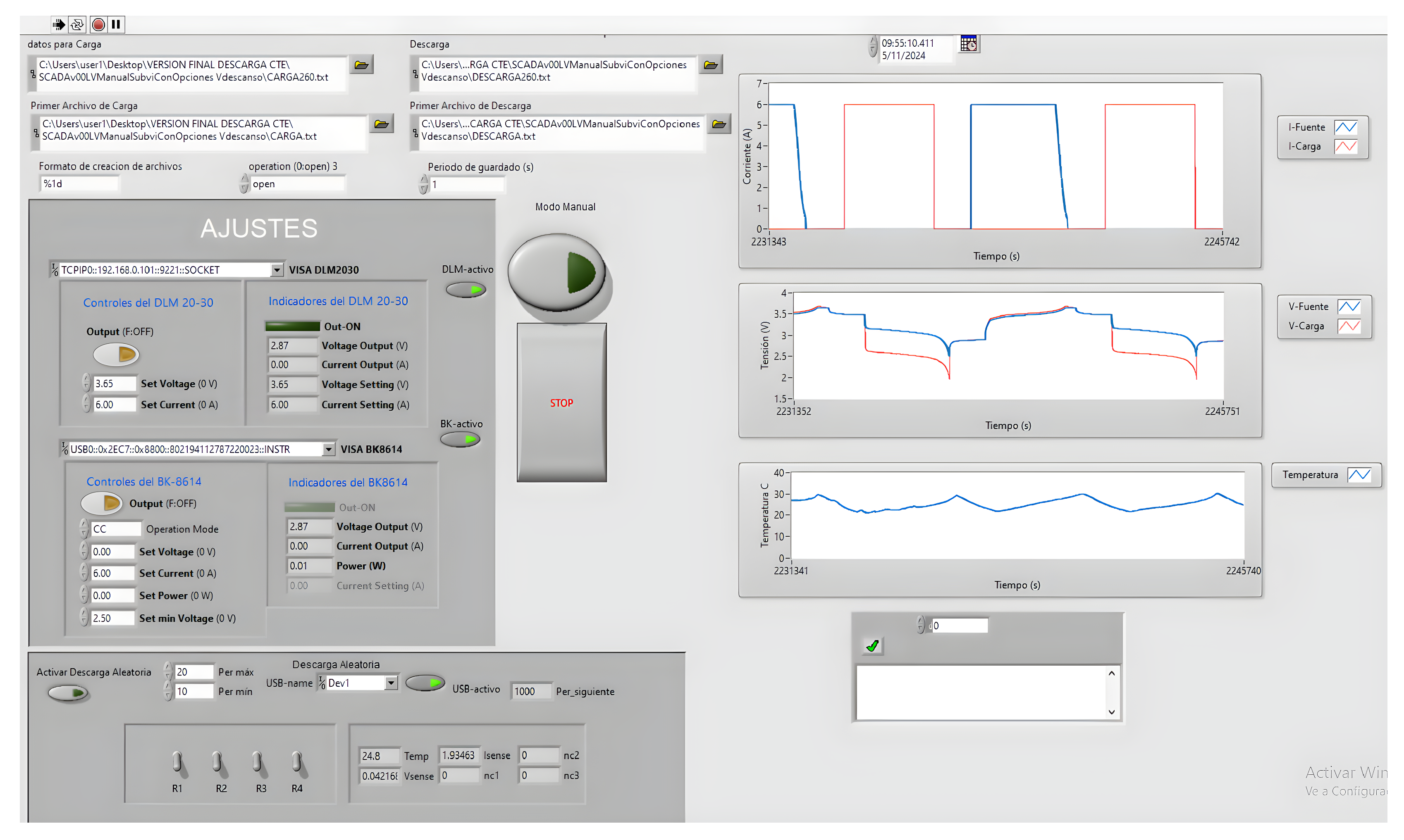

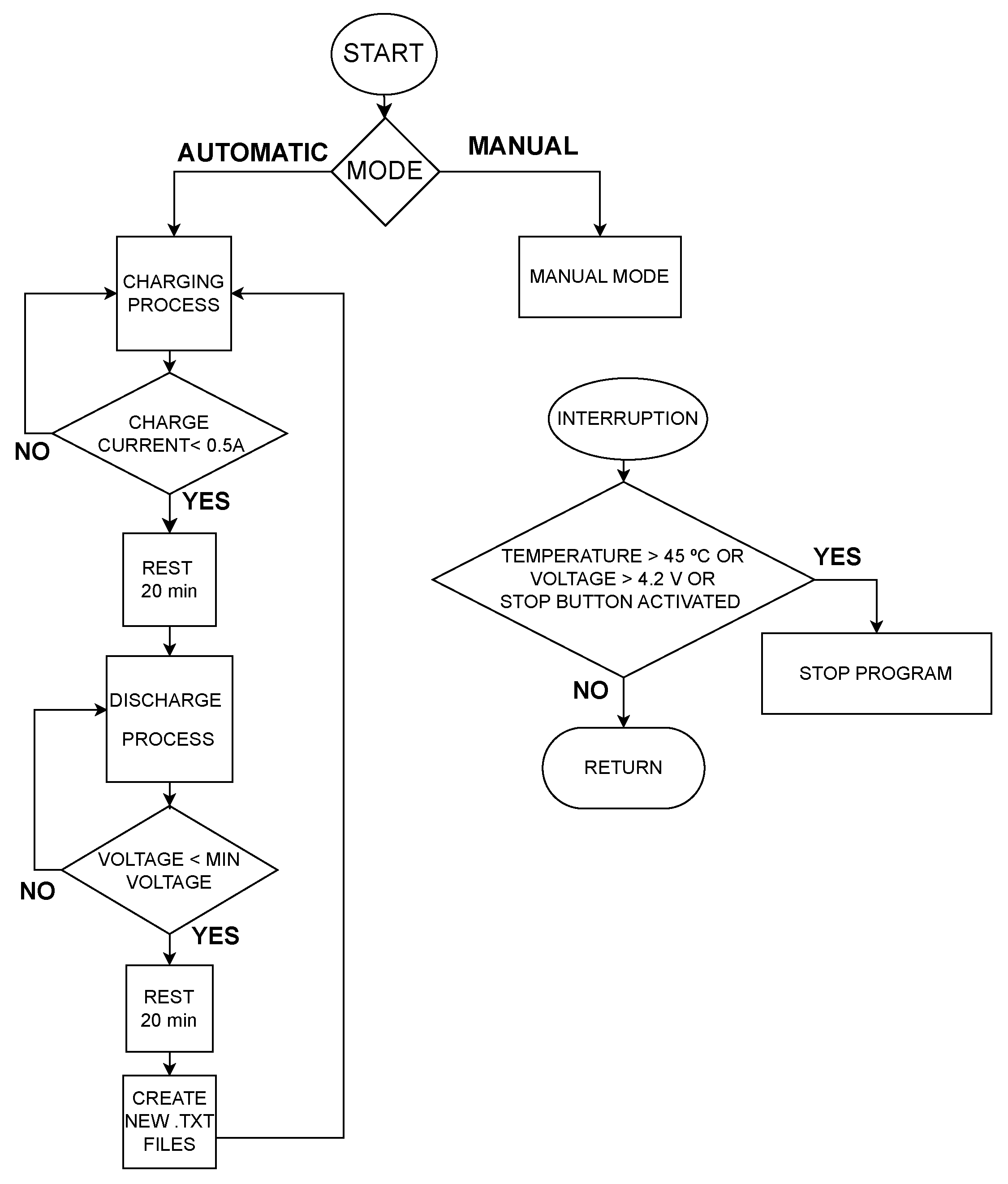

- It uses a LabVIEW environment to control and monitor the test bench. The developed software package allows the programming of charge and discharge cycles, real-time tracking of battery parameters, and data storage in plain text format for further analysis.

- Python (version 3.12.7) was used to develop a post-processing data tool and generate graphical representation of the results obtained.

4. Experimental Validation

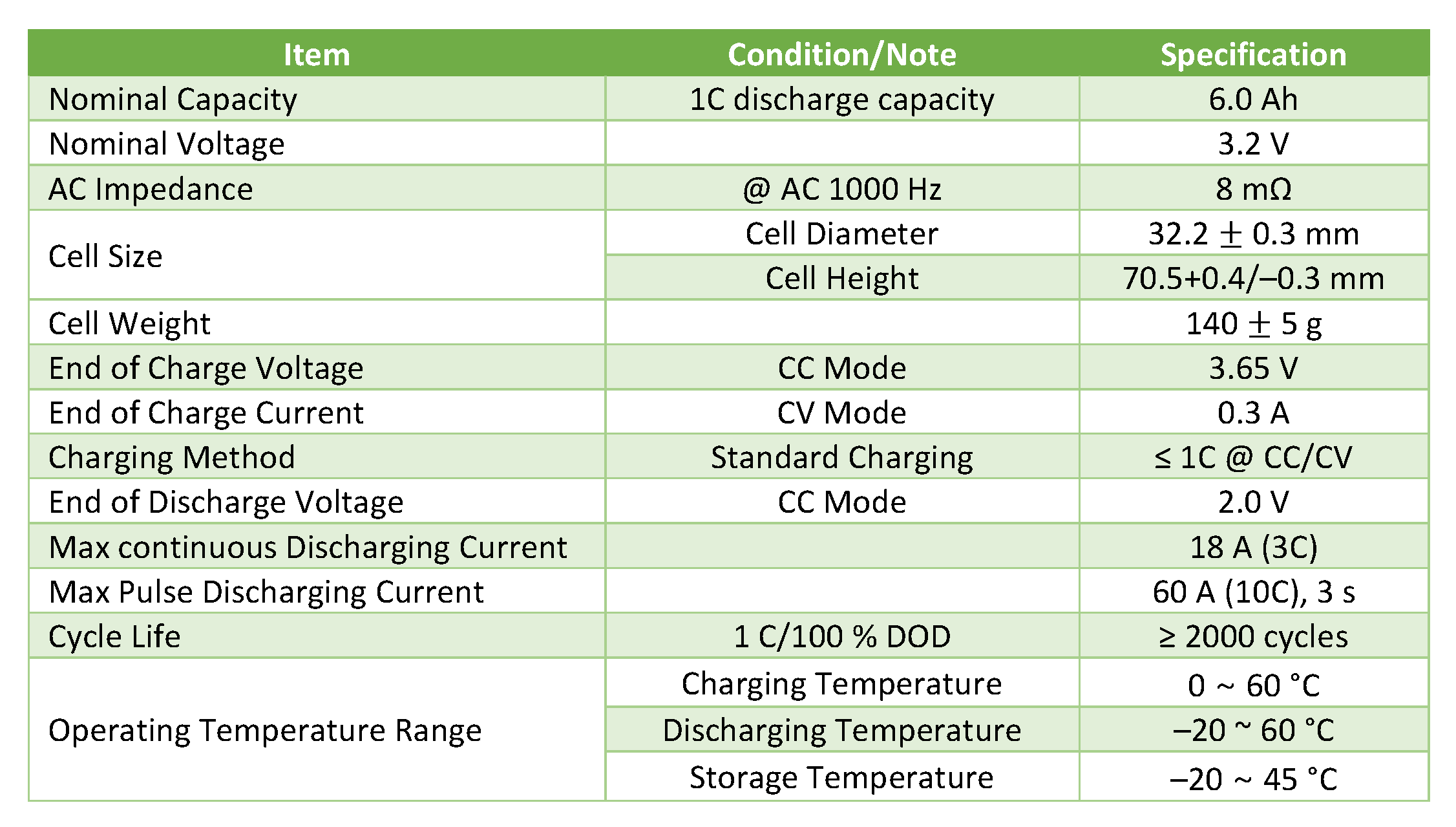

- The initial configurations are established, where the file names for the first charge and discharge cycles are defined as “Charge1.txt” and “Discharge1.txt”. The charging voltage is set at 3.65 V, the maximum charging and discharging current is set at 6 A, the minimum discharge voltage is set at 2.5 V, and a data sampling period of 1 s is established.

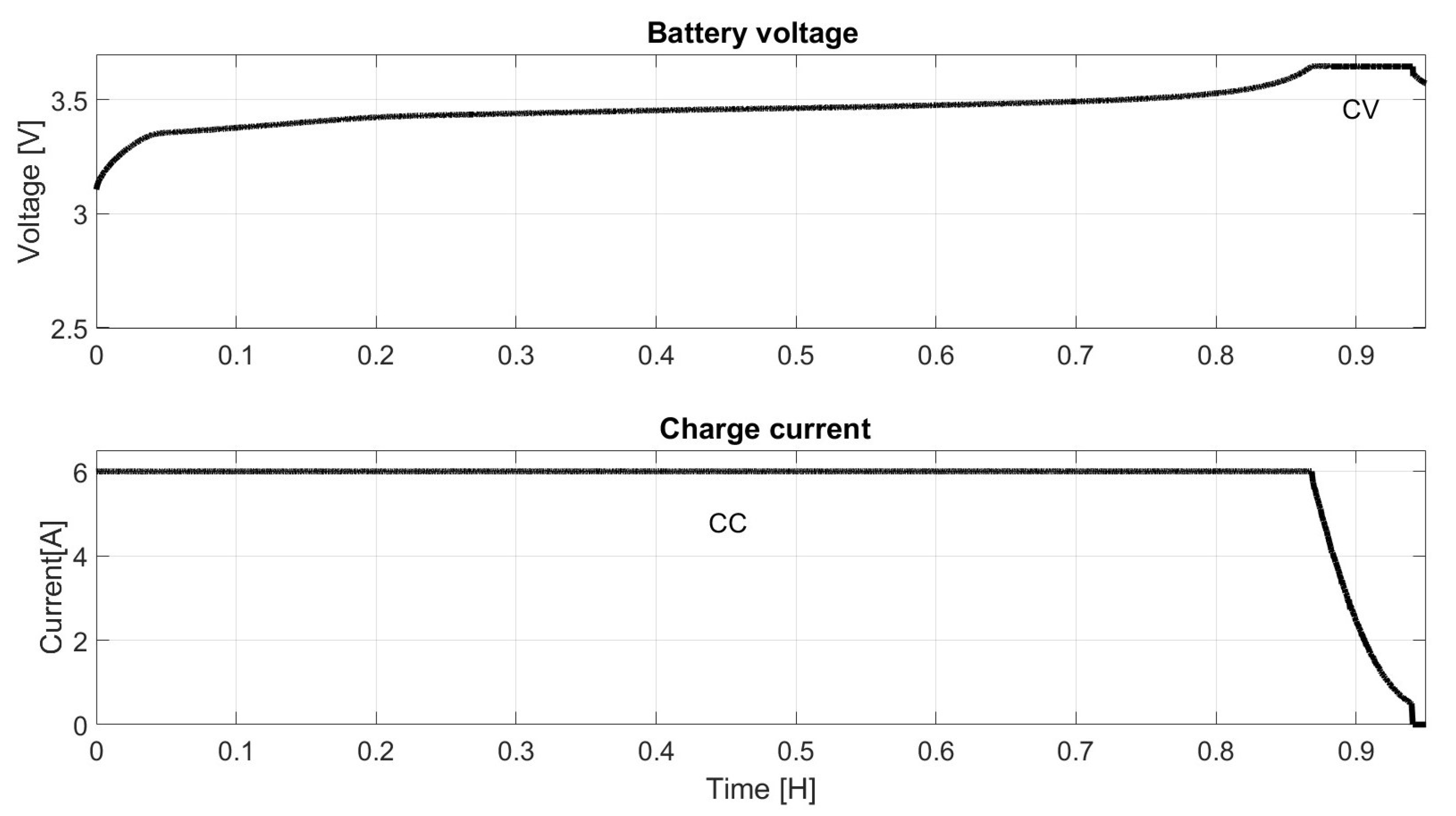

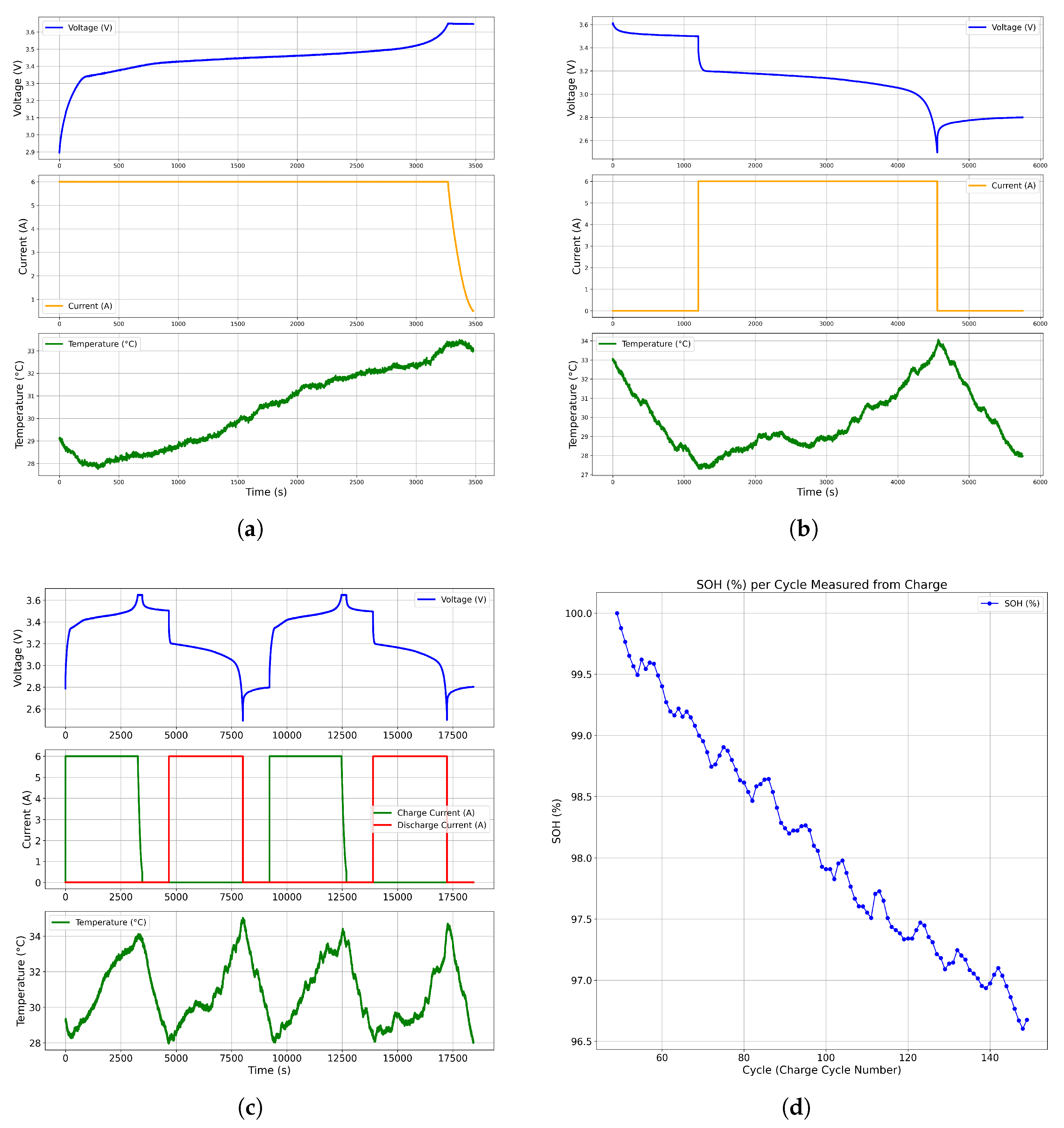

- The battery charging process begins with a CC-CV profile. Initially, charging begins with a CC at a rate of 1 C (6 A) until the battery reaches a voltage of 3.65 V (maximum charging voltage). Subsequently, a CV phase is applied at 3.65 V until the current decreases to a threshold of 0.5 A or less, at which point the software automatically terminates the charging process Figure 9a. During this process, the charging data is recorded in a charging text file. The data include the charging current measured by the power supply, the voltage provided by the power supply, the temperature measured by the thermocouple, and the time recorded in LabVIEW. These data are continuously logged and periodically exported.

- After a rest period of 20 min, the discharging process is initiated using a CC of 6 A, until the battery reaches a voltage of 2.5 V (minimum voltage). At this point, the discharging process is automatically stopped, see Figure 9b. During this process, discharge data are recorded in a discharge text file. These data include the discharging current measured by the programmable load, the voltage provided by the power supply, the temperature measured by the thermocouple, and the time recorded in LabVIEW. It is noteworthy that data during the resting periods are also stored in the discharging file, ensuring that all relevant information, including the intervals between charging and discharging cycles, is captured for further analysis Figure 9b.

- Subsequently, a 20-min rest period begins. Once this period ends, new text files are generated for the next charging and discharging processes, and the cycle restarts from Step 1.

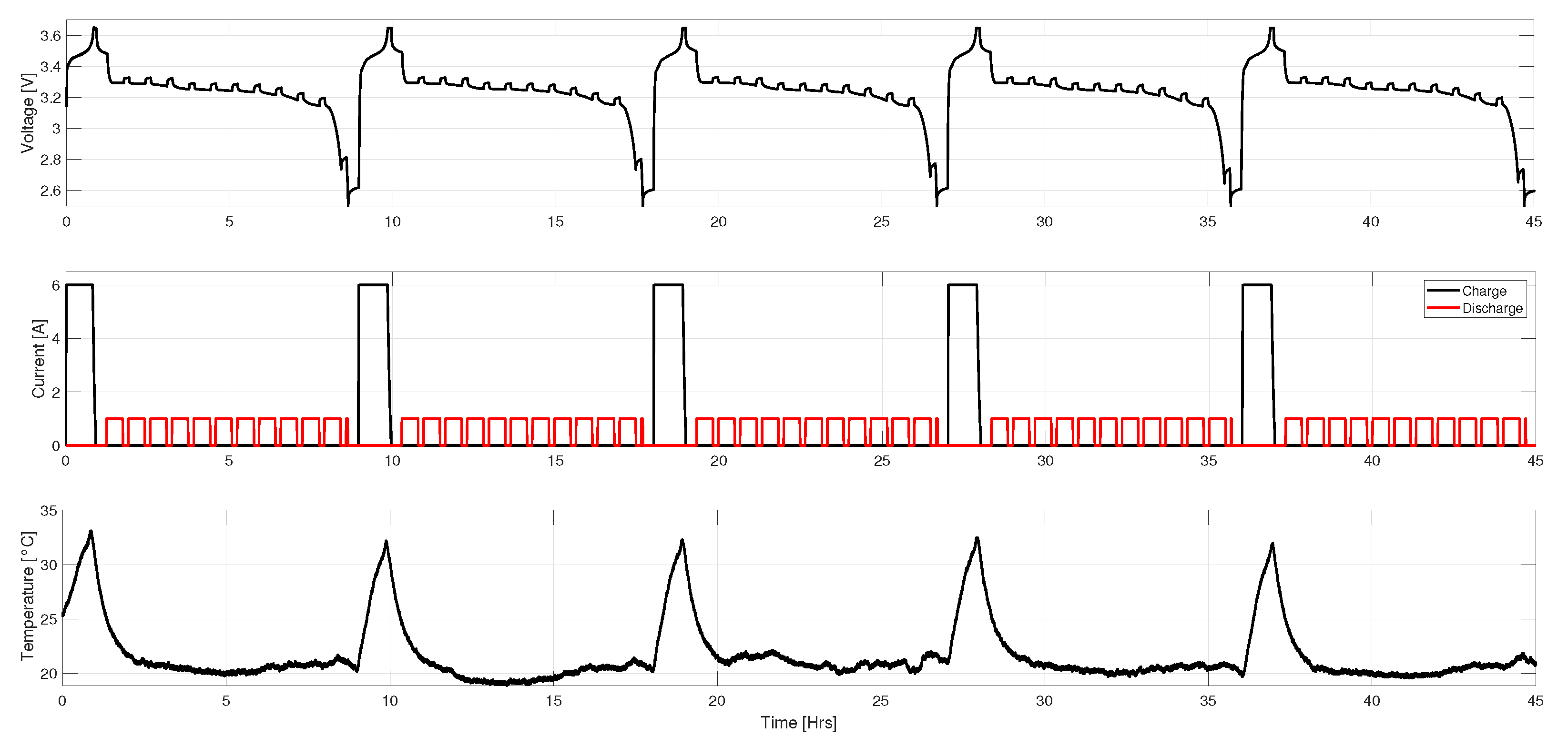

- Charging procedure: a CC-CV profile is followed. Initially, a constant current of 1 C (6 A) is applied until the battery voltage reaches 3.65 V. Then, the process switches to constant voltage mode at 3.65 V, maintaining this level until the current decreases to 0.5 A.

- Resting period: the battery is left to rest for 20 min once the charge is complete, allowing the voltage to relax.

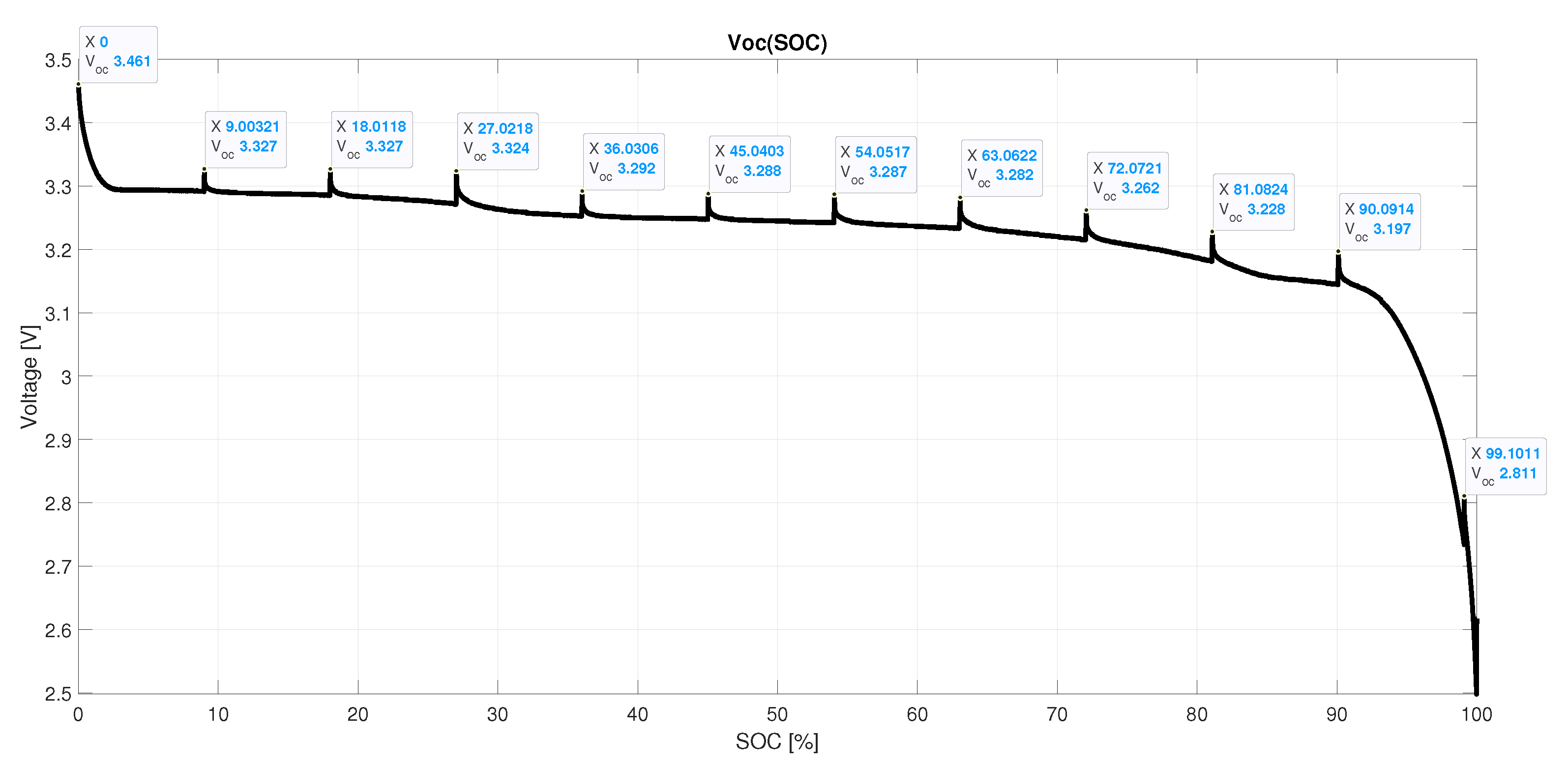

- Discharging process: the discharge process begins after the resting period, applying a constant current of 1 A. During discharge, the process is paused every 30 min for 10 min to record multiple open-circuit voltage points. The discharge continues until the battery voltage drops to 2.5 V, which is the discharge cut-off voltage and causes the cycle to stop completely.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Saw, L.H.; Poon, H.M.; Chong, W.T.; Wang, C.T.; Yew, M.C.; Yew, M.K.; Ng, T.C. Numerical Modeling of Hybrid Supercapacitor Battery Energy Storage System for Electric Vehicles. Energy Procedia 2019, 158, 2750–2755. [Google Scholar] [CrossRef]

- Nair, N.K.C.; Garimella, N. Battery Energy Storage Systems: Assessment for Small-Scale Renewable Energy Integration. Energy Build. 2010, 42, 2124–2130. [Google Scholar] [CrossRef]

- Zappettini, F.; Reyes-Chamorro, L.; Valencia, F.; Andrade, A.; Alarcón, M.; Lisoni, J. Design and Implementation of a Test Bench for Lithium-Ion Batteries. In Proceedings of the 2023 IEEE CHILEAN Conference on Electrical, Electronics Engineering, Information and Communication Technologies (CHILECON), Valdivia, Chile, 5–7 December 2023; pp. 1–5. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, T.; Chen, J.; Gao, B.; Yu, M.; Zhu, J. Advances in Safety of Lithium-Ion Batteries for Energy Storage: Hazard Characteristics and Active Suppression Techniques. Energy Rev. 2025, 4, 100117. [Google Scholar] [CrossRef]

- Menye, J.S.; Camara, M.B.; Dakyo, B. Lithium Battery Degradation and Failure Mechanisms: A State-of-the-Art Review. Energies 2025, 18, 342. [Google Scholar] [CrossRef]

- Júnior, C.A.R.; Sanseverino, E.R.; Gallo, P.; Amaral, M.M.; Koch, D.; Kotak, Y.; Diel, S.; Walter, G.; Schweiger, H.G.; Zanin, H. Unraveling the Degradation Mechanisms of Lithium-Ion Batteries. Energies 2024, 17, 3372. [Google Scholar] [CrossRef]

- Han, X.; Lu, L.; Zheng, Y.; Feng, X.; Li, Z.; Li, J.; Ouyang, M. A Review on the Key Issues of the Lithium Ion Battery Degradation among the Whole Life Cycle. eTransportation 2019, 1, 100005. [Google Scholar] [CrossRef]

- Aissa, B.; Lakhdar, L.; Med, B.B.; Yazid, B.E.; Amirat, M.A.; Bensikaddour, E.H. Lithium-Ion Battery Test Bench Development for Aerospace Applications. In Proceedings of the 2022 2nd International Conference on Advanced Electrical Engineering (ICAEE), Constantine, Algeria, 29–31 October 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Wei, P.; Abid, M.; Adun, H.; Awoh, D.K.; Cai, D.; Zaini, J.H.; Bamisile, O. Progress in Energy Storage Technologies and Methods for Renewable Energy Systems Application. Appl. Sci. 2023, 13, 5626. [Google Scholar] [CrossRef]

- Wang, L.; Jiang, S.; Mao, Y.; Li, Z.; Zhang, Y.; Li, M. Lithium-Ion Battery State of Health Estimation Method Based on Variational Quantum Algorithm Optimized Stacking Strategy. Energy Rep. 2024, 11, 2877–2891. [Google Scholar] [CrossRef]

- Ilies, A.I.; Pitica, D.; Chindris, G.; Fodor, A. Test Bench for Electrical and Performance Evaluation of Lithium-Ion Batteries. In Proceedings of the 2019 IEEE 25th International Symposium for Design and Technology in Electronic Packaging (SIITME), Cluj-Napoca, Romania, 23–26 October 2019; pp. 413–418. [Google Scholar] [CrossRef]

- Lipu, M.H.; Hannan, M.; Hussain, A.; Hoque, M.; Ker, P.J.; Saad, M.; Ayob, A. A Review of State of Health and Remaining Useful Life Estimation Methods for Lithium-Ion Battery in Electric Vehicles: Challenges and Recommendations. J. Clean. Prod. 2018, 205, 115–133. [Google Scholar] [CrossRef]

- Zhao, J.; Feng, X.; Tran, M.K.; Fowler, M.; Ouyang, M.; Burke, A.F. Battery Safety: Fault Diagnosis From Laboratory to Real World. J. Power Sources 2024, 598, 234111. [Google Scholar] [CrossRef]

- Khan, J. Challenges and Solutions for Hardware in the Loop Simulation - HILS Validation of Battery Management and Battery Monitoring System Modules. In Proceedings of the SAE 2016 World Congress and Exhibition, Detroit, MI, USA, 12–14 April 2016. [Google Scholar] [CrossRef]

- Fill, A.; Mader, T.; Schmidt, T.; Llorente, R.; Birke, K.P. Measuring Test Bench with Adjustable Thermal Connection of Cells to Their Neighbors and a New Model Approach for Parallel-Connected Cells. Batteries 2020, 6, 2. [Google Scholar] [CrossRef]

- Berg, P.; Soellner, J.; Jossen, A. Structural Dynamics of Lithium-Ion Cells—Part I: Method, Test Bench Validation and Investigation of Lithium-Ion Pouch Cells. J. Energy Storage 2019, 26, 100916. [Google Scholar] [CrossRef]

- Li, Q.; Song, R.; Wei, Y. A Review of State-of-Health Estimation for Lithium-Ion Battery Packs. J. Energy Storage 2025, 118, 116078. [Google Scholar] [CrossRef]

- Su, L.; Xu, Y.; Dong, Z. State-of-Health Estimation of Lithium-Ion Batteries: A Comprehensive Literature Review from Cell to Pack Levels. Energy Convers. Econ. 2024, 5, 224–242. [Google Scholar] [CrossRef]

- Wang, J.; Yang, H.; Wang, Z.; Zhou, Y.; Liu, P.; Hong, J. State of Health Analysis of Batteries at Different Stages Based on Real-World Vehicle Data and Machine Learning. J. Energy Storage 2024, 88, 111616. [Google Scholar] [CrossRef]

- Guerrero Cervera, T.; Vega-Leal, A.P.; Adame García, G.; Brey Sánchez, J. PEMFC Impedance Spectroscopy Using Synthetic Wide-Band Signals. Int. J. Hydrogen Energy 2014, 39, 4005–4008. [Google Scholar] [CrossRef]

- Gong, J.; Xu, B.; Chen, F.; Zhou, G. Predictive Modeling for Electric Vehicle Battery State of Health: A Comprehensive Literature Review. Energies 2025, 18, 337. [Google Scholar] [CrossRef]

- Zhang, J.; Li, K. State-of-Health Estimation for Lithium-Ion Batteries in Hybrid Electric Vehicles—A Review. Energies 2024, 17, 5753. [Google Scholar] [CrossRef]

- Lei, X.; Xie, F.; Wang, J.; Zhang, C. A Review of Lithium-Ion Battery State of Health and Remaining Useful Life Estimation Methods Based on Bibliometric Analysis. J. Traffic Transp. Eng. (English Ed.) 2024, 11, 1420–1446. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, H.; Yao, L.; Ding, J.; Chen, S.; Wang, Z. A Physics-Guided Approach for Accurate Battery SOH Estimation Using RCMHCRE and BatteryPINN. Adv. Eng. Inform. 2025, 65, 103211. [Google Scholar] [CrossRef]

- Zhao, X.; Hu, J.; Hu, G.; Qiu, H. A State of Health Estimation Framework Based on Real-World Electric Vehicles Operating Data. J. Energy Storage 2023, 63, 107031. [Google Scholar] [CrossRef]

- Sedlařík, M.; Vyroubal, P.; Capková, D.; Omerdic, E.; Rae, M.; Mačák, M.; Šedina, M.; Kazda, T. Advanced Machine Learning Techniques for State-of-Health Estimation in Lithium-Ion Batteries: A Comparative Study. Electrochim. Acta 2025, 524, 145988. [Google Scholar] [CrossRef]

- Soyoye, B.D.; Bhattacharya, I.; Dhason, M.V.A.; Banik, T. State of Charge and State of Health Estimation in Electric Vehicles: Challenges, Approaches and Future Directions. Batteries 2025, 11. [Google Scholar] [CrossRef]

- Lin, C.; Xu, J.; Jiang, D.; Hou, J.; Liang, Y.; Zou, Z.; Mei, X. Multi-Model Ensemble Learning for Battery State-of-Health Estimation: Recent Advances and Perspectives. J. Energy Chem. 2025, 100, 739–759. [Google Scholar] [CrossRef]

- Tao, J.; Wang, S.; Cao, W.; Takyi-Aninakwa, P.; Fernandez, C.; Guerrero, J.M. A Comprehensive Review of State-of-Charge and State-of-Health Estimation for Lithium-Ion Battery Energy Storage Systems. Ionics 2024, 30, 5903–5927. [Google Scholar] [CrossRef]

- Li, Q.; Xue, W. A Review of Feature Extraction toward Health State Estimation of Lithium-Ion Batteries. J. Energy Storage 2025, 112, 115453. [Google Scholar] [CrossRef]

- Hong, J.; Li, K.; Liang, F.; Yang, H.; Zhang, C.; Yang, Q.; Wang, J. A Novel State of Health Prediction Method for Battery System in Real-World Vehicles Based on Gated Recurrent Unit Neural Networks. Energy 2024, 289, 129918. [Google Scholar] [CrossRef]

- Wentao, M.; Shizhuo, R.; Peng, G. Review of State of Power Estimation for Li-Ion Batteries: Methods, Issues, and Prospects. J. Electrochem. Sci. Technol. 2025, 16, 15–36. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X.; Li, Z.; Li, X.; Liu, G.; Gao, W. Accurate and adaptive state of health estimation for lithium-ion battery based on patch learning framework. Measurement 2025, 250, 117083. [Google Scholar] [CrossRef]

- Chen, J.; Li, K.; Liu, W.; Yin, C.; Zhu, Q.; Tang, H. A Novel State of Charge Estimation Method for LiFePO4 Battery Based on Combined Modeling of Physical Model and Machine Learning Model. J. Energy Storage 2025, 115, 115888. [Google Scholar] [CrossRef]

- Chen, G.J.; Chung, W.H. Evaluation of Charging Methods for Lithium-Ion Batteries. Electronics 2023, 12, 4095. [Google Scholar] [CrossRef]

- Liu, H.; Naqvi, I.; Li, F.; Liu, C.; Shafiei, N.; Li, Y.; Pecht, M. An Analytical Model for the CC-CV Charge of Li-Ion Batteries with Application to Degradation Analysis. J. Energy Storage 2020, 29, 101342. [Google Scholar] [CrossRef]

- Maheswaran, V.D.; Carter, S.B.R.; Vijay, V.; Raj, S.V. Study and Implementation of Constant Current-Constant Voltage(CC-CV) Charger for Lithium-Ion(Li-Ion) Battery Using Machine Learning(ML). In Proceedings of the 2024 IEEE 4th International Conference on Sustainable Energy and Future Electric Transportation (SEFET), Hyderabad, India, 31 July–3 August 2024; pp. 1–5. [Google Scholar] [CrossRef]

- Shen, W.; Vo, T.T.; Kapoor, A. Charging Algorithms of Lithium-Ion Batteries: An Overview. In Proceedings of the 2012 7th IEEE Conference on Industrial Electronics and Applications (ICIEA), Singapore, 18–20 July 2012; pp. 1567–1572. [Google Scholar] [CrossRef]

- Singh, P.; Chen, C.; Tan, C.M.; Huang, S.C. Semi-Empirical Capacity Fading Model for SoH Estimation of Li-Ion Batteries. Appl. Sci. 2019, 9, 3012. [Google Scholar] [CrossRef]

- Theuerkauf, D.; Swan, L. Characteristics of Open Circuit Voltage Relaxation in Lithium-Ion Batteries for the Purpose of State of Charge and State of Health Analysis. Batteries 2022, 8, 77. [Google Scholar] [CrossRef]

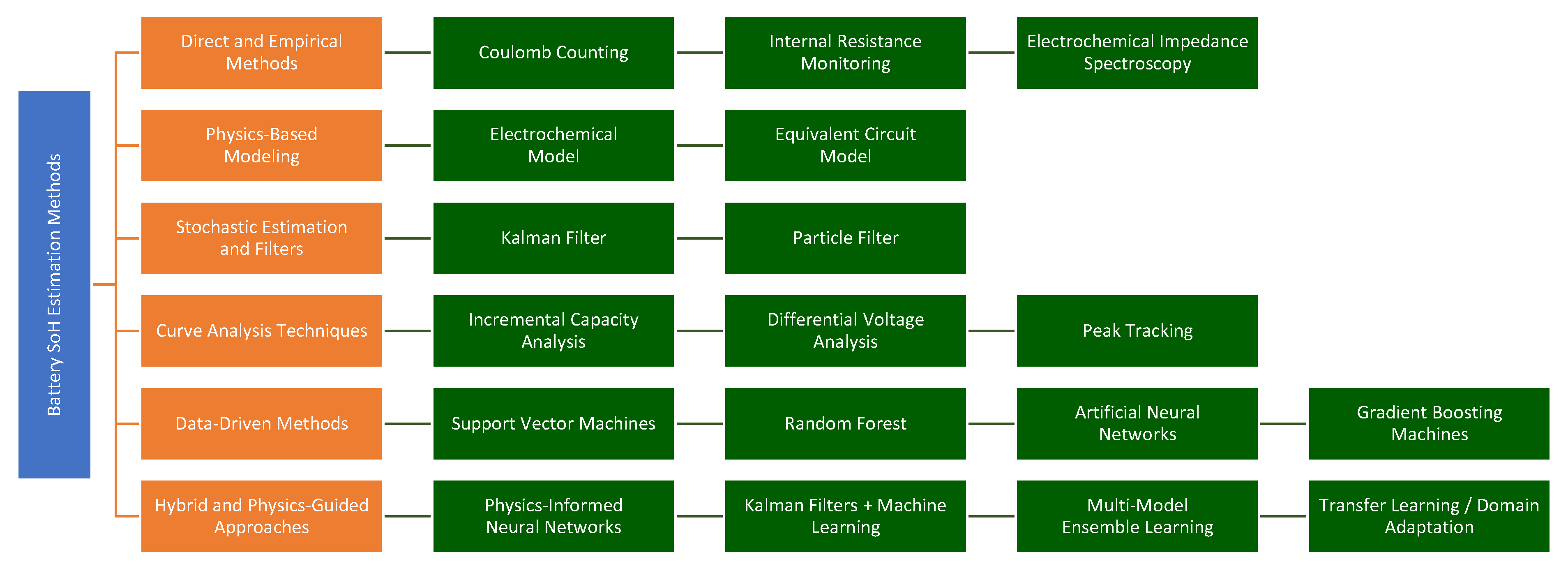

| Category | Representative Methods | Pros | Cons |

|---|---|---|---|

| Direct and empirical | Coulomb counting, internal resistance, electrochemical impedance spectroscopy | Simple implementation; Physically interpretable; High accuracy under lab conditions | Requires controlled environments; Poor performance for online estimation; Sensitive to noise and aging |

| Physics-based models | Electrochemical model, equivalent circuit model | Mechanistic insight; Captures degradation mechanisms; Enables predictive modeling | High computational cost; Difficult parameter identification |

| Stochastic filters | Kalman filter, particle filter | Real-time estimation; Handles noisy/incomplete data; Adaptable to system changes | Model-dependent; Computationally intensive; Sensitive to initialization |

| Curve Analysis Techniques | Incremental capacity analysis, differential voltage analysis, peak tracking | Non-invasive; Detects specific degradation modes; Useful for cell diagnostics | Requires high-resolution data; Sensitive to noise; Not suitable for real-time use |

| Machine Learning | Support vector machines, random forest, artificial neural networks, gradient boosting machines | Learns complex nonlinear patterns; Suitable for real-time applications; Can integrate into BMS | Needs large, labeled datasets; Risk of overfitting; Often lacks physical interpretability |

| Hybrid & Physics-Guided | Physics-informed neural networks, Kalman filters + Machine learning, multi-model ensemble learning, transfer learning/domain adaptation | Combines data and physics; High accuracy and generalization; Adaptive and robust | Complex to design and tune; Synchronization of models is challenging; Often still in research phase |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marsal, E.; Martínez, N.; Pérez Vega-Leal, A.; Barrero, F.; Hamdan, M.; Satué, M.G. Automatic and Versatile Test Bench for Data Collection on Battery Cells. Energies 2025, 18, 2304. https://doi.org/10.3390/en18092304

Marsal E, Martínez N, Pérez Vega-Leal A, Barrero F, Hamdan M, Satué MG. Automatic and Versatile Test Bench for Data Collection on Battery Cells. Energies. 2025; 18(9):2304. https://doi.org/10.3390/en18092304

Chicago/Turabian StyleMarsal, Esteban, Nicolás Martínez, Alfredo Pérez Vega-Leal, Federico Barrero, Mohamad Hamdan, and Manuel G. Satué. 2025. "Automatic and Versatile Test Bench for Data Collection on Battery Cells" Energies 18, no. 9: 2304. https://doi.org/10.3390/en18092304

APA StyleMarsal, E., Martínez, N., Pérez Vega-Leal, A., Barrero, F., Hamdan, M., & Satué, M. G. (2025). Automatic and Versatile Test Bench for Data Collection on Battery Cells. Energies, 18(9), 2304. https://doi.org/10.3390/en18092304