Impact of Ethanol–Diesel Blend on CI Engine Performance and Emissions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Test Stand

2.2. Fuel

2.3. ESC Test

3. Results

4. Discussion

- 1.

- Speed characteristics at full load:

- -

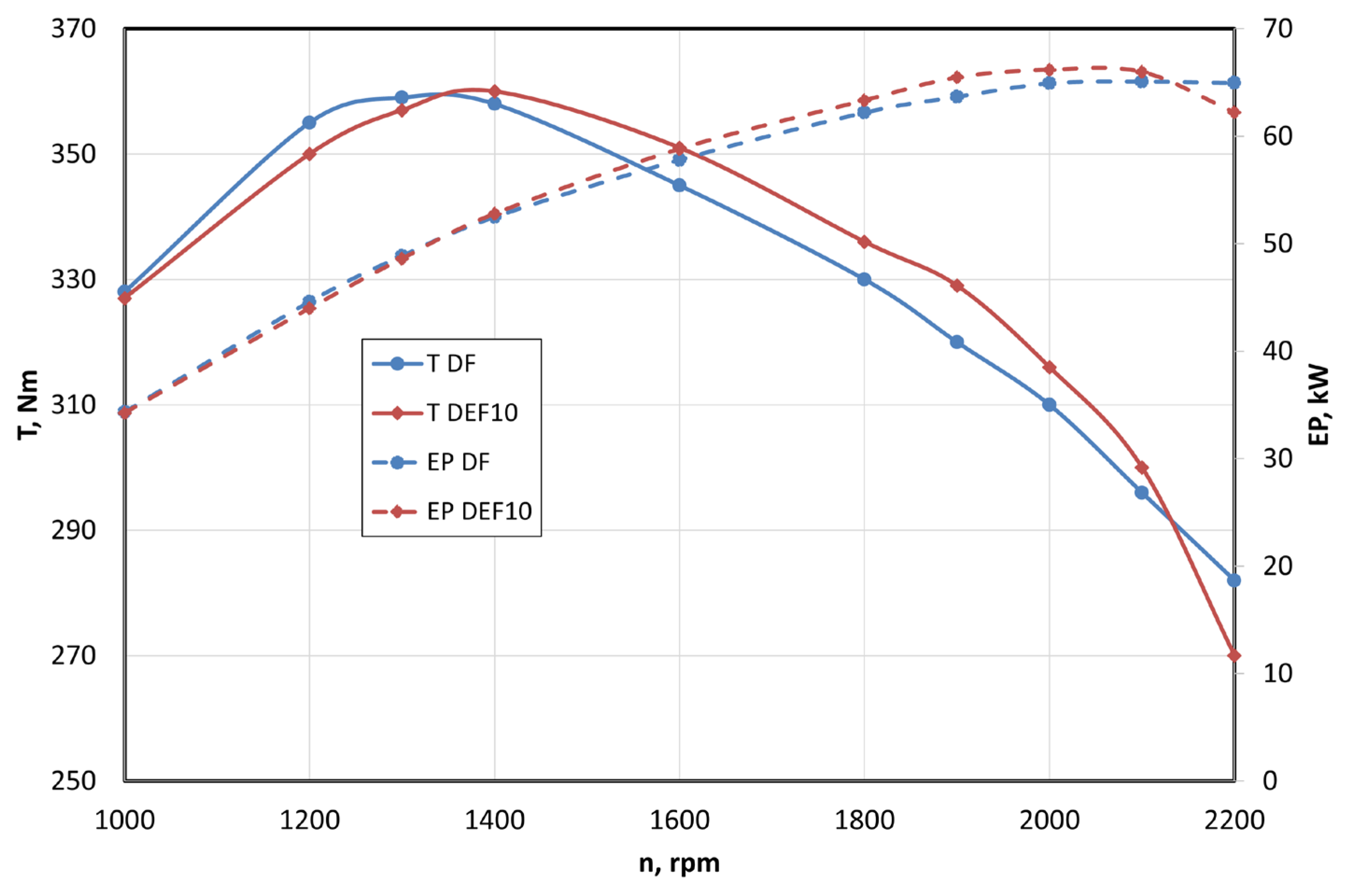

- Achieving higher torque (above 1400 rpm) and effective power (across the range) for DFE10 compared to DF (Figure 3). The maximum increase is 5%. It can be seen from the above that the addition of ethanol alters the combustion process, which increases torque, especially at higher engine crankshaft speeds. Despite the lower energy density of ethanol, its addition improves the thermal efficiency of the engine, leading to better utilization of the energy contained in the fuel. Ethanol has a higher boiling and evaporation temperature, which reduces heat loss. As a result, the DFE10 blend allows for a higher effective power output compared to pure diesel under the same engine-operating conditions.

- -

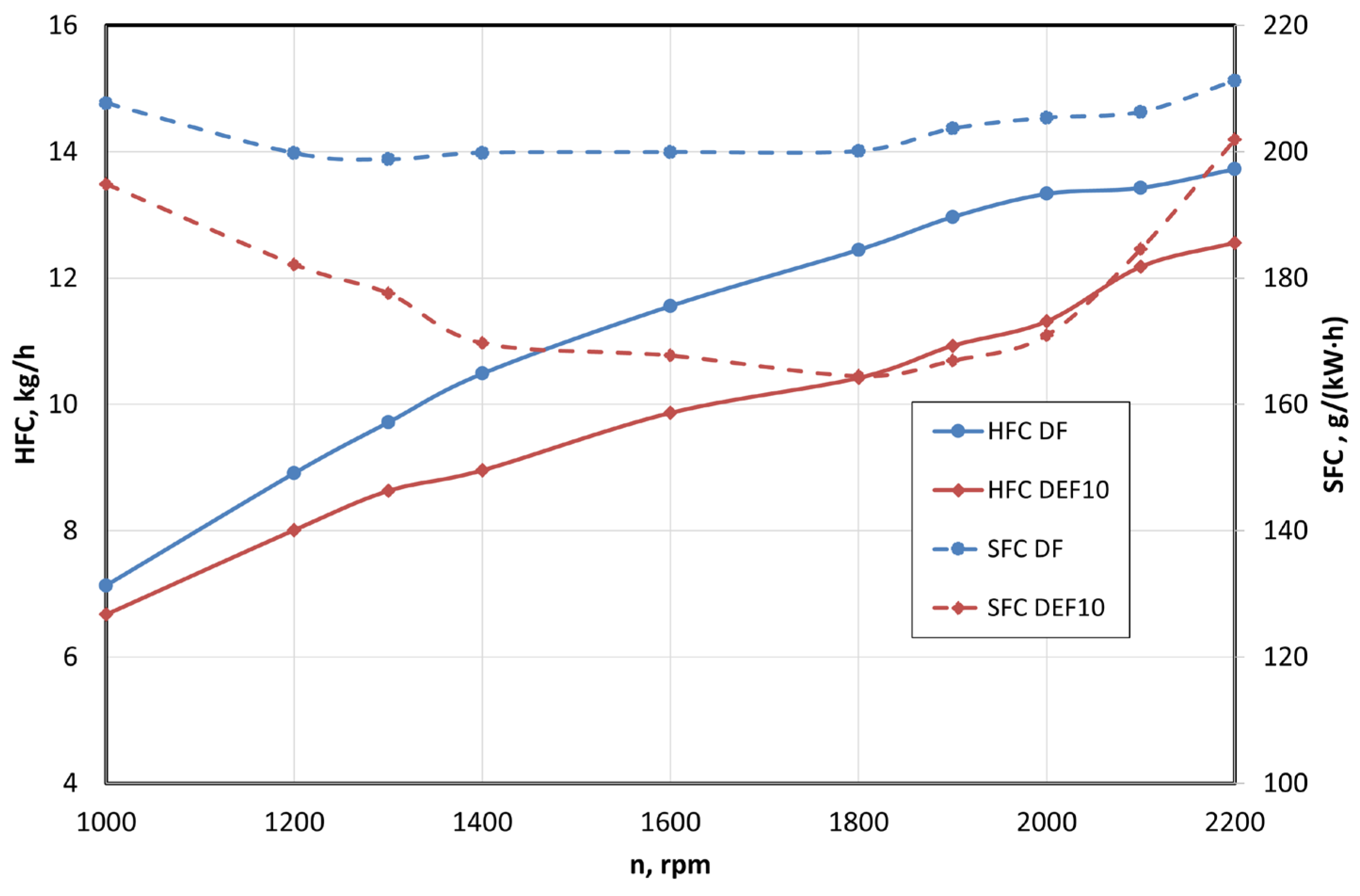

- Achieving lower specific and hourly fuel consumption (across the speed range) for DFE10, with a maximum reduction of 3% (Figure 4). The lower specific and hourly fuel consumption for the diesel blend with 10% ethanol (DFE10) compared to pure diesel is due to the different combustion process. The addition of ethanol to diesel, despite the lower energy density of such a blend, allows for a more optimal use of the energy contained in the fuel. In addition, ethanol has a higher evaporation coefficient, which affects the combustion process in the engine, reducing energy losses. The DFE10 blend can also reduce heat loss, leading to better temperature distribution in the running engine. As a result, an engine fueled with this blend uses less fuel, resulting in a reduction in overall fuel consumption compared to pure diesel.

- 2.

- Concentrations and emissions:

- -

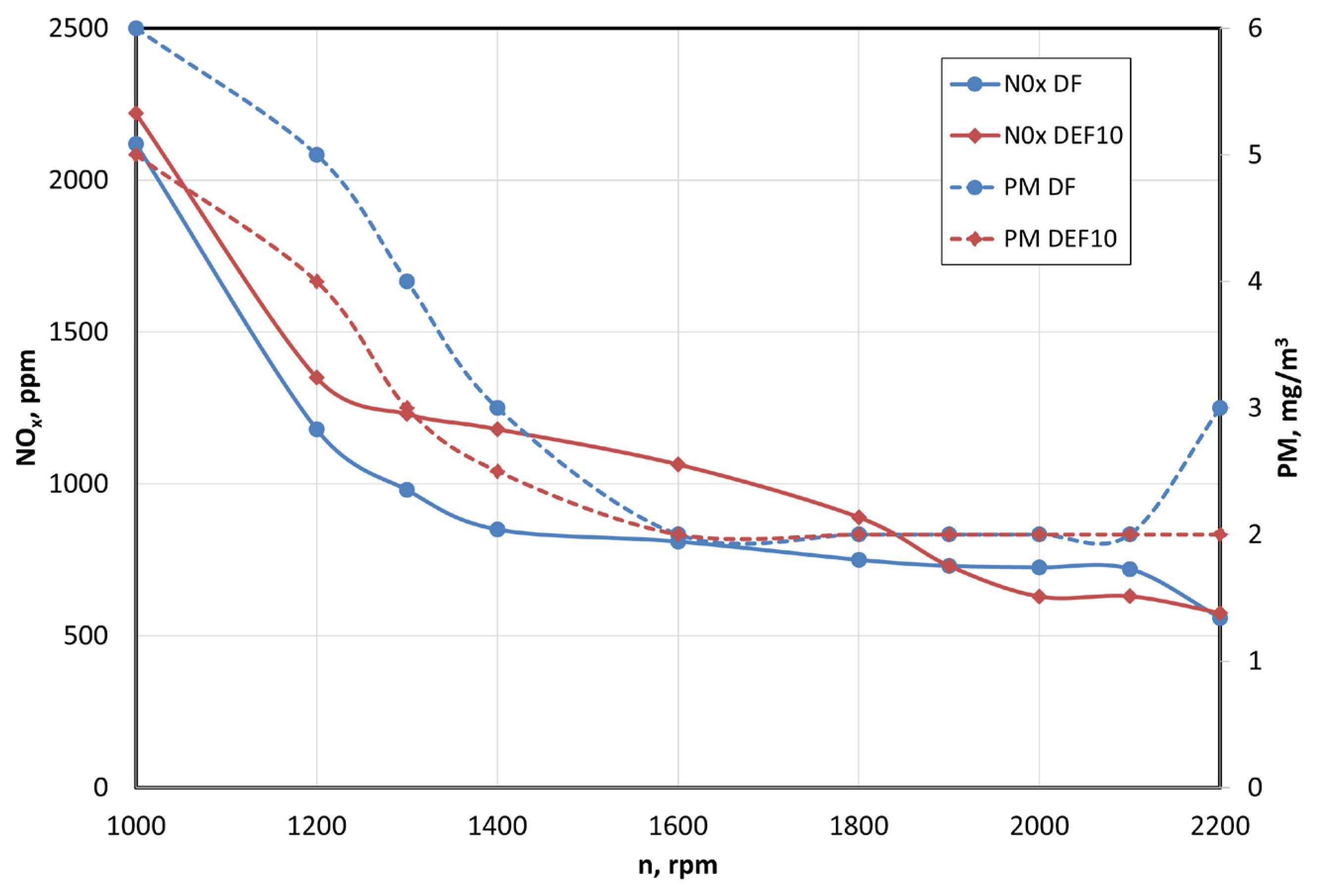

- Speed characteristics (Figure 5): The data show that NOx concentrations are higher with DFE10, with a maximum increase of 15%. However, particulate matter (PM) emissions are significantly lower, showing a reduction of 30% compared to diesel fuel (DF).

- -

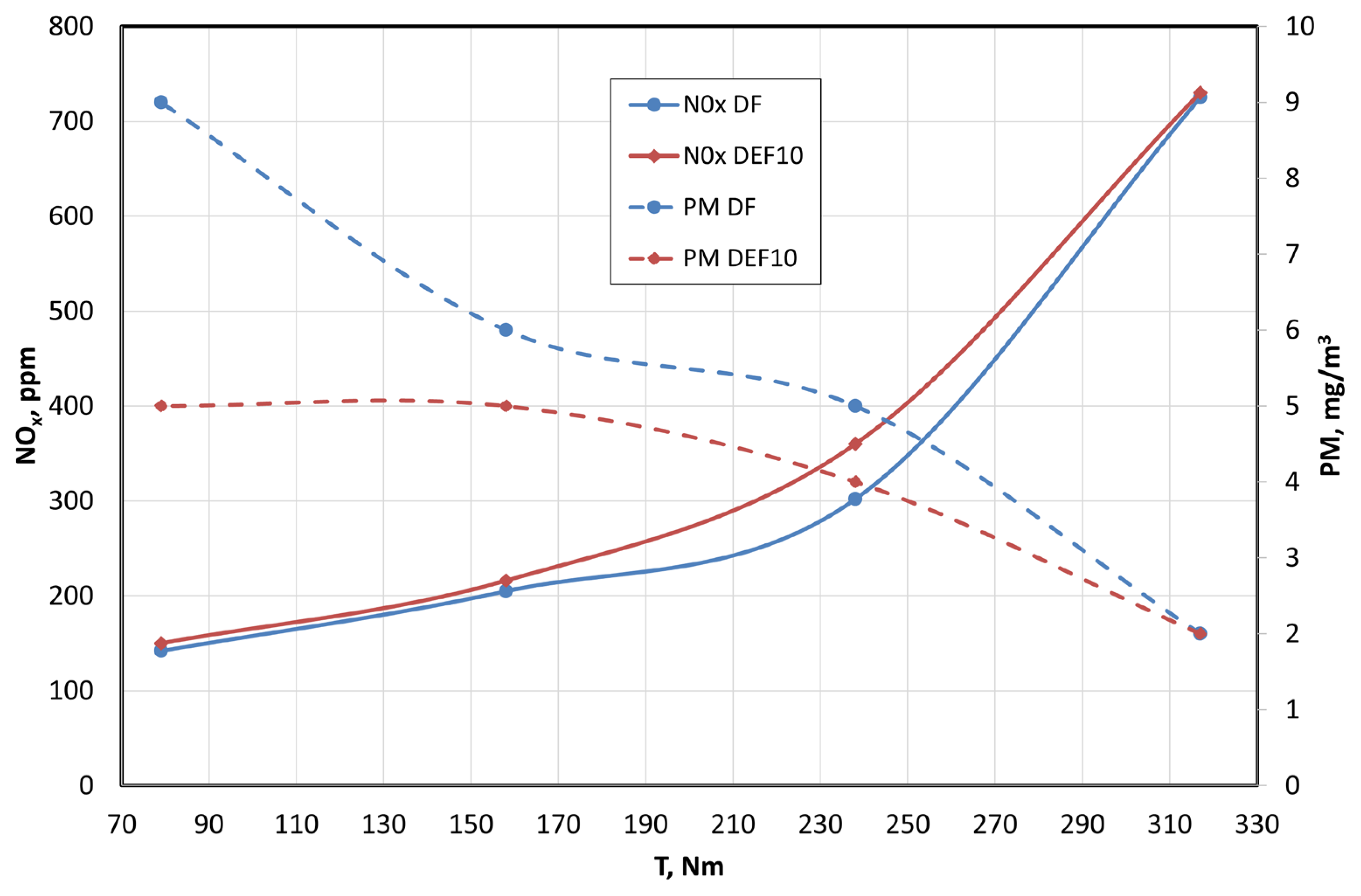

- Load characteristics at 1300 rpm (Figure 6): At this constant engine speed, NOx concentrations are higher for DFE10 throughout the load range, with a maximum increase of 20%. On the other hand, PM emissions for DFE10 are consistently lower, showing a reduction of up to 30% at higher engine loads.

- -

- Load characteristics at 1600 rpm (Figure 7): NOx concentrations are higher for DFE10, especially at high engine loads, with a maximum difference of 14%. However, particulate matter (PM) concentrations for DFE10 are 32% lower over the entire load range tested, especially at low engine loads.

- -

- Load characteristics at 1900 rpm (Figure 8): At higher loads, NOx concentrations are approximately 10% lower for DFE10. As the engine load decreases, the emissions of both fuels become more similar, with a maximum difference of only 4%. For DFE10, particulate emissions are significantly lower, showing a reduction of 48% over the entire load range tested, especially at low engine loads.

- 3.

- Specific NOx emissions determined by the ESC test for the Perkins 854E engine are 2.2% lower with DFE10 compared to DF. Additionally, specific particulate matter (PM) emissions are 44% lower for DFE10 compared to conventional diesel fuel (DF). This suggests that DFE10 offers a significant reduction in PM emissions, with a small reduction in NOx emissions, which may be beneficial from an environmental perspective.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DF | diesel fuel |

| DFE10 | 90% diesel fuel with 10% ethanol |

| EP | effective power |

| T | engine crankshaft torque |

| RS, n | engine crankshaft rotation speed |

| HFC | hourly fuel consumption |

| SFC | specific fuel consumption |

| NOx | nitrogen oxides |

| PM | particulate matter |

| ESC | European Stationary Cycle |

References

- Łagowski, P.; Wcisło, G.; Kurczyński, D. Study of Combustion Process Parameters in a Diesel Engine Powered by Biodiesel from Waste of Animal Origin. Energies 2024, 17, 5857. [Google Scholar] [CrossRef]

- Kesharvani, S.; Dwivedi, G.; Verma, T.N.; Verma, P. The Experimental Investigation of a Diesel Engine Using Ternary Blends of Algae Biodiesel, Ethanol and Diesel Fuels. Energies 2023, 16, 229. [Google Scholar] [CrossRef]

- Al-Esawi, N.; Al Qubeissi, M.; Kolodnytska, R. The Impact of Biodiesel Fuel on Ethanol/Diesel Blends. Energies 2019, 12, 1804. [Google Scholar] [CrossRef]

- Hamdi, F.; Yahya, I.; Gassoumi, M.; Boutar, Z.; Raja Ahsan Shah, R.M.; Al Qubeissi, M.; Ennetta, R.; Soyhan, H.S. Effects of Ethanol Addition to Diesel–Biodiesel Blends on the CI Engine Characteristics. Sci. Technol. Energy Transit. 2024, 79, 33. [Google Scholar] [CrossRef]

- Kim, H.Y.; Ge, J.C.; Choi, N.J. Effects of Ethanol–Diesel on the Combustion and Emissions from a Diesel Engine at a Low Idle Speed. Appl. Sci. 2020, 10, 4153. [Google Scholar] [CrossRef]

- Liu, J.; Guo, G.; Wei, M. Effects of Methanol Addition on the Combustion Process of the Methanol/Diesel Dual-Fuel Based on an Optical Engine. Energies 2023, 16, 7946. [Google Scholar] [CrossRef]

- Aydın, F.; Öğüt, H. Effects of Using Ethanol-Biodiesel-Diesel Fuel in Single Cylinder Diesel Engine to Engine Performance and Emissions. Renew. Energy 2017, 103, 688–694. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, J.; Zhang, Z.; Zhang, B.; Hu, J.; Zhong, W.; Ye, Y. A Comprehensive Review of Stability Enhancement Strategies for Metal Nanoparticle Additions to Diesel/Biodiesel and Their Methods of Reducing Pollutant. Process Saf. Environ. Prot. 2024, 183, 1258–1282. [Google Scholar] [CrossRef]

- Pandey, S. A Critical Review: Application of Methanol as a Fuel for Internal Combustion Engines and Effects of Blending Methanol with Diesel/Biodiesel/Ethanol on Performance, Emission, and Combustion Characteristics of Engines. Heat Transf. 2022, 51, 3334–3352. [Google Scholar] [CrossRef]

- Kruczyński, S.; Ślęzak, M. A Simulation and Experimental Verification of the Operation of the Oxidising Catalytic Converter in Diesel Engine. Eksploat. I Niezawodn.—Maint. Reliab. 2024, 26, 184090. [Google Scholar] [CrossRef]

- Sahu, T.K.; Shukla, P.C.; Belgiorno, G.; Maurya, R.K. Alcohols as Alternative Fuels in Compression Ignition Engines for Sustainable Transportation: A Review. Energy Sources Part A Recover. Util. Environ. Eff. 2022, 44, 8736–8759. [Google Scholar] [CrossRef]

- Lee, S. Alternative Fuels; Routledge: New York, NY, USA, 2023; pp. 1–485. [Google Scholar] [CrossRef]

- Verma, P.; Stevanovic, S.; Zare, A.; Dwivedi, G.; Van, T.C.; Davidson, M.; Rainey, T.; Brown, R.J.; Ristovski, Z.D. An Overview of the Influence of Biodiesel, Alcohols, and Various Oxygenated Additives on the Particulate Matter Emissions from Diesel Engines. Energies 2019, 12, 1987. [Google Scholar] [CrossRef]

- Tutak, W.; Jamrozik, A.; Pyrc, M.; Sobiepański, M. A Comparative Study of Co-Combustion Process of Diesel-Ethanol and Biodiesel-Ethanol Blends in the Direct Injection Diesel Engine. Appl. Therm. Eng. 2017, 117, 155–163. [Google Scholar] [CrossRef]

- Rezende, M.J.C.; de Lima, A.L.; Silva, B.V.; Mota, C.J.A.; Torres, E.A.; da Rocha, G.O.; Cardozo, I.M.M.; Costa, K.P.; Guarieiro, L.L.N.; Pereira, P.A.P.; et al. Biodiesel: An Overview II. J. Braz. Chem. Soc. 2021, 32, 1301–1344. [Google Scholar] [CrossRef]

- Antar, M.; Lyu, D.; Nazari, M.; Shah, A.; Zhou, X.; Smith, D.L. Biomass for a Sustainable Bioeconomy: An Overview of World Biomass Production and Utilization. Renew. Sustain. Energy Rev. 2021, 139, 110691. [Google Scholar] [CrossRef]

- Ning, L.; Duan, Q.; Chen, Z.; Kou, H.; Liu, B.; Yang, B.; Zeng, K. A Comparative Study on the Combustion and Emissions of a Non-Road Common Rail Diesel Engine Fueled with Primary Alcohol Fuels (Methanol, Ethanol, and n-Butanol)/Diesel Dual Fuel. Fuel 2020, 266, 117034. [Google Scholar] [CrossRef]

- Tanwar, M.D.; Tanwar, P.K.; Bhand, Y.; Bhand, S.; Jadhav, K.; Bhand, S. Biofuels: Production and Properties as Substitute Fuels. In Advanced Biodiesel—Technological Advances Challenges and Sustainability Considerations; IntechOpen: London, UK, 2023. [Google Scholar] [CrossRef]

- Tongroon, M.; Saisirirat, P.; Suebwong, A.; Aunchaisri, J.; Kananont, M.; Chollacoop, N. Combustion and Emission Characteristics Investigation of Diesel-Ethanol-Biodiesel Blended Fuels in a Compression-Ignition Engine and Benefit Analysis. Fuel 2019, 255, 115728. [Google Scholar] [CrossRef]

- Ayhan, V.; Çangal, Ç.; Cesur, İ.; Safa, A. Combined Influence of Supercharging, EGR, Biodiesel and Ethanol on Emissions of a Diesel Engine: Proposal of an Optimization Strategy. Energy 2020, 207, 118298. [Google Scholar] [CrossRef]

- Sikora, M.; Orliński, P.; Bednarski, M. Research of Nitrogen Oxides Concentrations in Exhaust Gas of Compression Ignition Engine Fuelled with Alternative Fuel. Adv. Sci. Technol. Res. J. 2021, 15, 75–83. [Google Scholar] [CrossRef]

- Razak, N.H.; Hashim, H.; Yunus, N.A.; Klemeš, J.J. Reducing Diesel Exhaust Emissions by Optimisation of Alcohol Oxygenates Blend with Diesel/Biodiesel. J. Clean. Prod. 2021, 316, 128090. [Google Scholar] [CrossRef]

- Dasore, A.; Rajak, U.; Panchal, M.; Reddy, V.N.; Verma, T.N.; Chaurasiya, P.K. Prediction of Overall Characteristics of a Dual Fuel CI Engine Working on Low-Density Ethanol and Diesel Blends at Varying Compression Ratios. Arab. J. Sci. Eng. 2022, 47, 15323–15330. [Google Scholar] [CrossRef]

- Shrivastava, K.; Thipse, S.S.; Patil, I.D. Optimization of Diesel Engine Performance and Emission Parameters of Karanja Biodiesel-Ethanol-Diesel Blends at Optimized Operating Conditions. Fuel 2021, 293, 120451. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Gupta, J.G.; Dhar, A. Potential and Challenges for Large-Scale Application of Biodiesel in Automotive Sector. Prog. Energy Combust. Sci. 2017, 61, 113–149. [Google Scholar] [CrossRef]

- Temizer, İ.; Eskici, B. Investigation on the Combustion Characteristics and Lubrication of Biodiesel and Diesel Fuel Used in a Diesel Engine. Fuel 2020, 278, 118363. [Google Scholar] [CrossRef]

- Yadav, J.; Deppenkemper, K.; Pischinger, S. Impact of Renewable Fuels on Heavy-Duty Engine Performance and Emissions. Energy Rep. 2023, 9, 1977–1989. [Google Scholar] [CrossRef]

- Sikora, M.; Orliński, P. Hydrotreated Vegetable Oil Fuel within the Fit for 55 Package. Combust. Engines 2024, 197, 3–8. [Google Scholar] [CrossRef]

- Zheng, F.; Cho, H. Combustion and Emission of Castor Biofuel Blends in a Single-Cylinder Diesel Engine. Energies 2023, 16, 5427. [Google Scholar] [CrossRef]

- Orliński, P.; Sikora, M.; Bednarski, M.; Gis, M. The Influence of Powering a Compression Ignition Engine with HVO Fuel on the Specific Emissions of Selected Toxic Exhaust Components. Appl. Sci. 2024, 14, 5893. [Google Scholar] [CrossRef]

- Operation and Maintenance Manuals|Perkins. Available online: https://www.perkins.com/en_GB/aftermarket/operation-maintenance-manuals.html (accessed on 6 February 2025).

- Lapuerta, M.; Rodríguez-Fernández, J.; Fernández-Rodríguez, D.; Patiño-Camino, R. Modeling Viscosity of Butanol and Ethanol Blends with Diesel and Biodiesel Fuels. Fuel 2017, 199, 332–338. [Google Scholar] [CrossRef]

- Bhurat, S.S.; Pandey, S.; Chintala, V.; Ranjit, P.S. Experimental Study on Performance and Emissions Characteristics of Single Cylinder Diesel Engine with Ethanol and Biodiesel Blended Fuels with Diesel. Mater. Today Proc. 2019, 17, 220–226. [Google Scholar] [CrossRef]

- Hamdi, F.; Gassoumi, M.; Boutar, Z.; Ennetta, R.; Soyhan, H.S. Experimental Study of Alcohol Blending Effects on the Operating Characteristics of a Diesel Engine. Int. J. Automot. Sci. Technol. 2022, 6, 49–53. [Google Scholar] [CrossRef]

- Natarajan, A.; Kandasamy, A.; Perumal Venkatesan, E.; Saleel, C.A. Experimental Investigation on the Effect of Graphene Oxide in Higher Alcohol Blends and Optimization of Injection Timing Using an ANN Method. ACS Omega 2023, 8, 41339–41355. [Google Scholar] [CrossRef] [PubMed]

- Zhan, C.; Feng, Z.; Ma, W.; Zhang, M.; Tang, C.; Huang, Z. Experimental Investigation on Effect of Ethanol and Di-Ethyl Ether Addition on the Spray Characteristics of Diesel/Biodiesel Blends under High Injection Pressure. Fuel 2018, 218, 1–11. [Google Scholar] [CrossRef]

- Nour, M.; Attia, A.M.A.; Nada, S.A. Combustion, Performance and Emission Analysis of Diesel Engine Fuelled by Higher Alcohols (Butanol, Octanol and Heptanol)/Diesel Blends. Energy Convers. Manag. 2019, 185, 313–329. [Google Scholar] [CrossRef]

- Ennetta, R.; Soyhan, H.S.; Koyunoğlu, C.; Demir, V.G. Current Technologies and Future Trends for Biodiesel Production: A Review. Arab. J. Sci. Eng. 2022, 47, 15133–15151. [Google Scholar] [CrossRef]

- Liang, J.; Zhang, Q.; Ma, Q.; Chen, Z.; Zheng, Z. Effect of Various Ethanol/Diesel Cosolvents Addition on Combustion and Emission Characteristics of a CRDI Heavy Diesel Engine. Energy Rep. 2022, 8, 735–748. [Google Scholar] [CrossRef]

- Khoobbakht, G.; Karimi, M.; Kheiralipour, K. Effects of Biodiesel-Ethanol-Diesel Blends on the Performance Indicators of a Diesel Engine: A Study by Response Surface Modeling. Appl. Therm. Eng. 2019, 148, 1385–1394. [Google Scholar] [CrossRef]

- Freitas, E.S.D.C.; Guarieiro, L.L.N.; Da Silva, M.V.I.; Amparo, K.K.D.S.; Machado, B.A.S.; Guerreiro, E.T.D.A.; De Jesus, J.F.C.; Torres, E.A. Emission and Performance Evaluation of a Diesel Engine Using Addition of Ethanol to Diesel/Biodiesel Fuel Blend. Energies 2022, 15, 2988. [Google Scholar] [CrossRef]

- Gowrishankar, S.; Krishnasamy, A. Emulsification—A Promising Approach to Improve Performance and Reduce Exhaust Emissions of a Biodiesel Fuelled Light-Duty Diesel Engine. Energy 2023, 263, 125782. [Google Scholar] [CrossRef]

- Wang, Z.; Li, L. Effects of Different Ethanol/Diesel Blending Ratios on Combustion and Emission Characteristics of a Medium-Speed Diesel Engine. Processes 2022, 10, 173. [Google Scholar] [CrossRef]

- Wai, P.; Kanokkhanarat, P.; Oh, B.S.; Wongpattharaworakul, V.; Depaiwa, N.; Po-Ngaen, W.; Chollacoop, N.; Srisurangkul, C.; Kosaka, H.; Yamakita, M.; et al. Experimental Investigation of the Influence of Ethanol and Biodiesel on Common Rail Direct Injection Diesel Engine’s Combustion and Emission Characteristics. Case Stud. Therm. Eng. 2022, 39, 102430. [Google Scholar] [CrossRef]

- Zuo, L.; Wang, J.; Mei, D.; Dai, S.; Adu-Mensah, D. Experimental Investigation on Combustion and (Regulated and Unregulated) Emissions Performance of a Common-Rail Diesel Engine Using Partially Hydrogenated Biodiesel-Ethanol-Diesel Ternary Blend. Renew. Energy 2022, 185, 1272–1283. [Google Scholar] [CrossRef]

- Chłopek, Z.; Biedrzycki, J.; Lasocki, J.; Wójcik, P.; Samson-Bręk, I. Modelling of Motor Vehicle Operation for the Evaluation of Pollutant Emission and Fuel Consumption. Combust. Engines 2017, 171, 156–163. [Google Scholar] [CrossRef]

- Samoilenko, D.; Cho, H.M. Improvement of Combustion Efficiency and Emission Characteristics of IC Diesel Engine Operating on ESC Cycle Applying Variable Geometry Turbocharger (VGT) with Vaneless Turbine Volute. Int. J. Automot. Technol. 2013, 14, 521–528. [Google Scholar] [CrossRef]

- Atelge, M.R.; Arslan, E.; Kahraman, N.; Ünalan, S. Evaluation of Hybrid Nanoparticles to Oxygenated Fuel with Ethanol and n- Butanol on Combustion Behavior. Fuel 2023, 344, 128048. [Google Scholar] [CrossRef]

- Chłopek, Z.; Lasocki, J.; Wójcik, P.; Badyda, A.J. Experimental Investigation and Comparison of Energy Consumption of Electric and Conventional Vehicles Due to the Driving Pattern. Int. J. Green Energy 2018, 15, 773–779. [Google Scholar] [CrossRef]

- Fil, H.E.; Akansu, S.O. Experimental Investigation of Diesel Ethanol Fuel Blends in a Compression Ignition Engine. Int. J. Energy Clean Environ. 2022, 23, 139–151. [Google Scholar] [CrossRef]

| Mode | Unit | Value/Feature |

|---|---|---|

| Cylinder arrangement | - | in-line |

| Engine displacement | dm3 | 3.4 |

| Number of cylinders | - | 4 |

| Maximum torque | Nm | 450 |

| Nominal power | kW | 86 |

| Speed at maximum torque | rpm | 1400 |

| Nominal power speed | rpm | 2200 |

| Compression ratio | - | 17 |

| Cylinder diameter | mm | 99 |

| Piston stroke | mm | 110 |

| Engine type | - | compression-ignition |

| Species | Range | Analyzer Error |

|---|---|---|

| NOx | High: 50–10,000 Low: 30–5000 | ±2 ppm ±1 ppm |

| Properties | Unit | Method | DF | DFE10 |

|---|---|---|---|---|

| Kinematic viscosity (at 40 °C) | ISO 8217 | 2.9 | 1.8 | |

| Density (at 15 °C) | ISO 12185 | 835 | 810 | |

| Dynamic viscosity (at 40 °C) | Pa∙s | ISO 3104 | ||

| Pour point | K | ISO 3016 | 237 | 226 |

| Flash point | K | ISO 2719 | 345 | 339 |

| Properties | Unit | Method | DF | DFE10 |

|---|---|---|---|---|

| Cetane number | - | ISO 5165 | 54.6 | 49.8 |

| Total aromatic | % v/v | EN 12916 | 23.1 | 19.8 |

| Lower Heating | PN-86/C-04062 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sikora, M.; Orliński, P.; Bednarski, M. Impact of Ethanol–Diesel Blend on CI Engine Performance and Emissions. Energies 2025, 18, 2277. https://doi.org/10.3390/en18092277

Sikora M, Orliński P, Bednarski M. Impact of Ethanol–Diesel Blend on CI Engine Performance and Emissions. Energies. 2025; 18(9):2277. https://doi.org/10.3390/en18092277

Chicago/Turabian StyleSikora, Mieczysław, Piotr Orliński, and Mateusz Bednarski. 2025. "Impact of Ethanol–Diesel Blend on CI Engine Performance and Emissions" Energies 18, no. 9: 2277. https://doi.org/10.3390/en18092277

APA StyleSikora, M., Orliński, P., & Bednarski, M. (2025). Impact of Ethanol–Diesel Blend on CI Engine Performance and Emissions. Energies, 18(9), 2277. https://doi.org/10.3390/en18092277