A Comprehensive Analysis of Thermal Heat Dissipation for Lithium-Ion Battery Packs

Abstract

1. Introduction

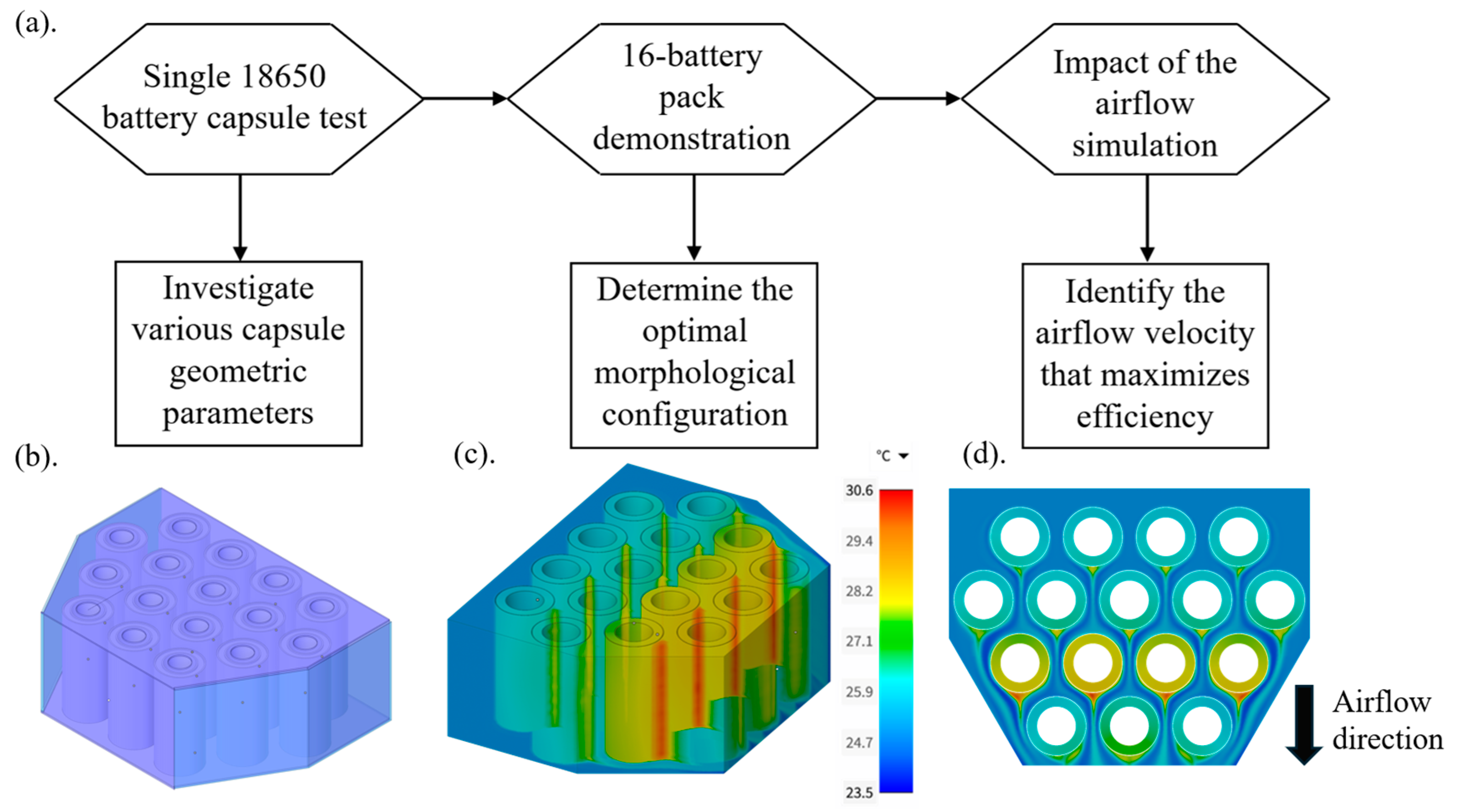

2. Design and Simulation

2.1. Base Parameters Setting

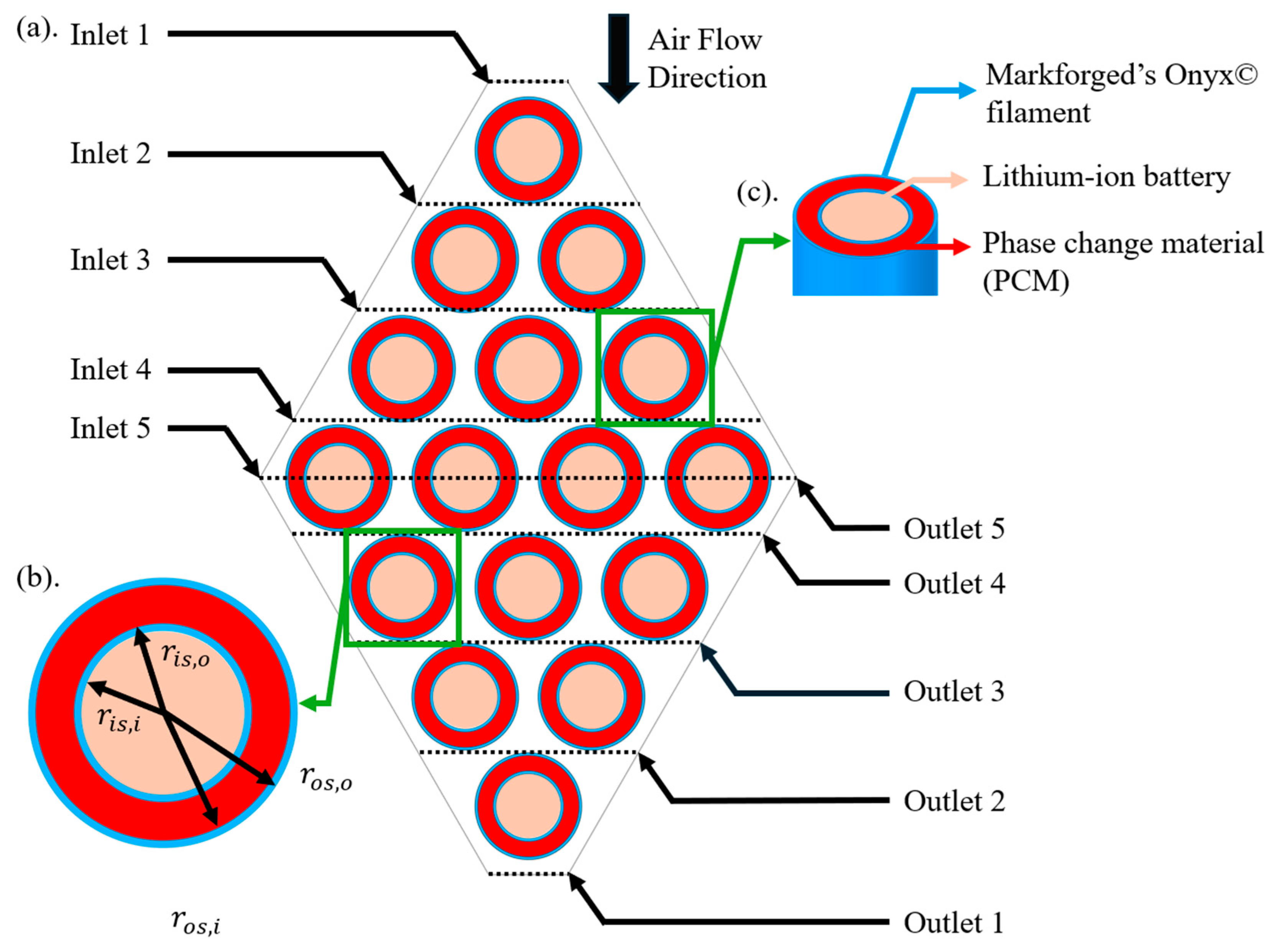

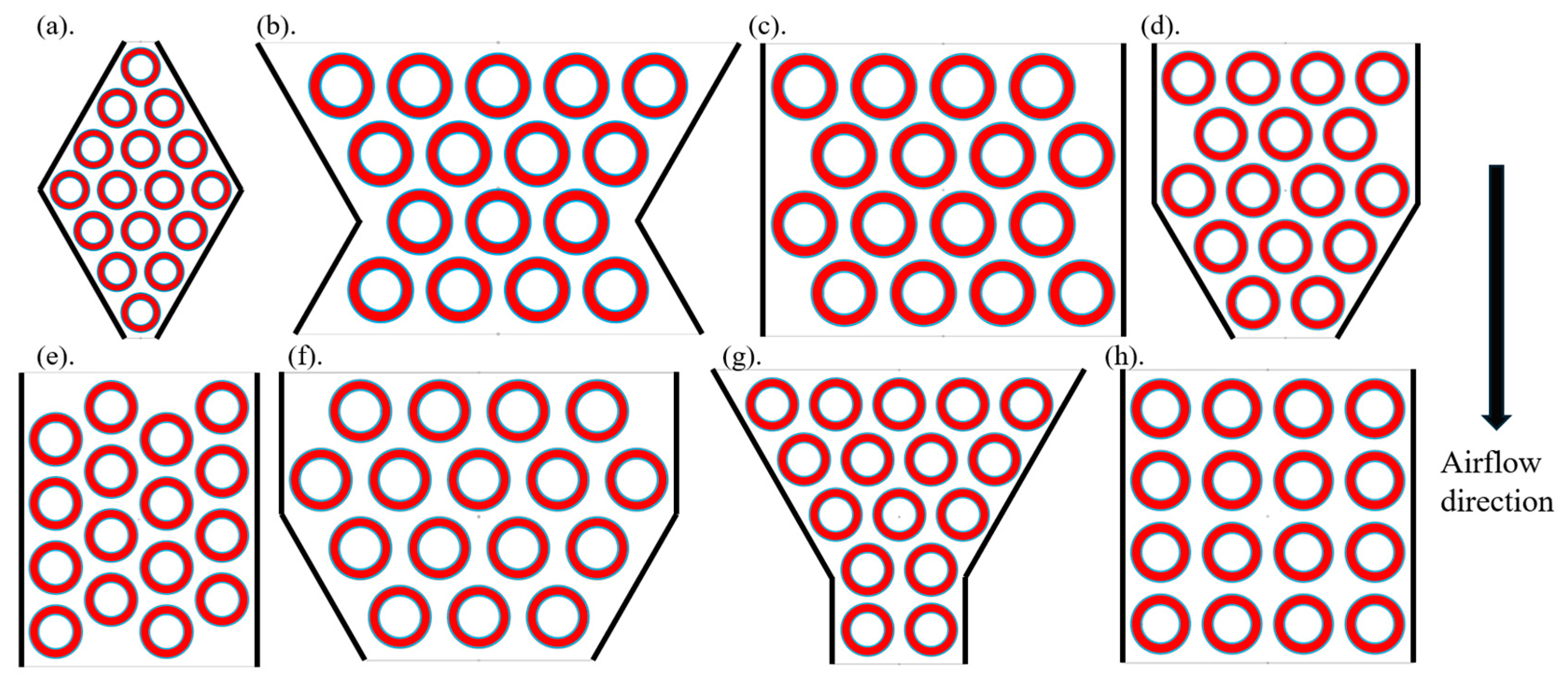

2.2. The 16-Battery Pack Configuration

2.3. Ansys Thermal Simulation Settings

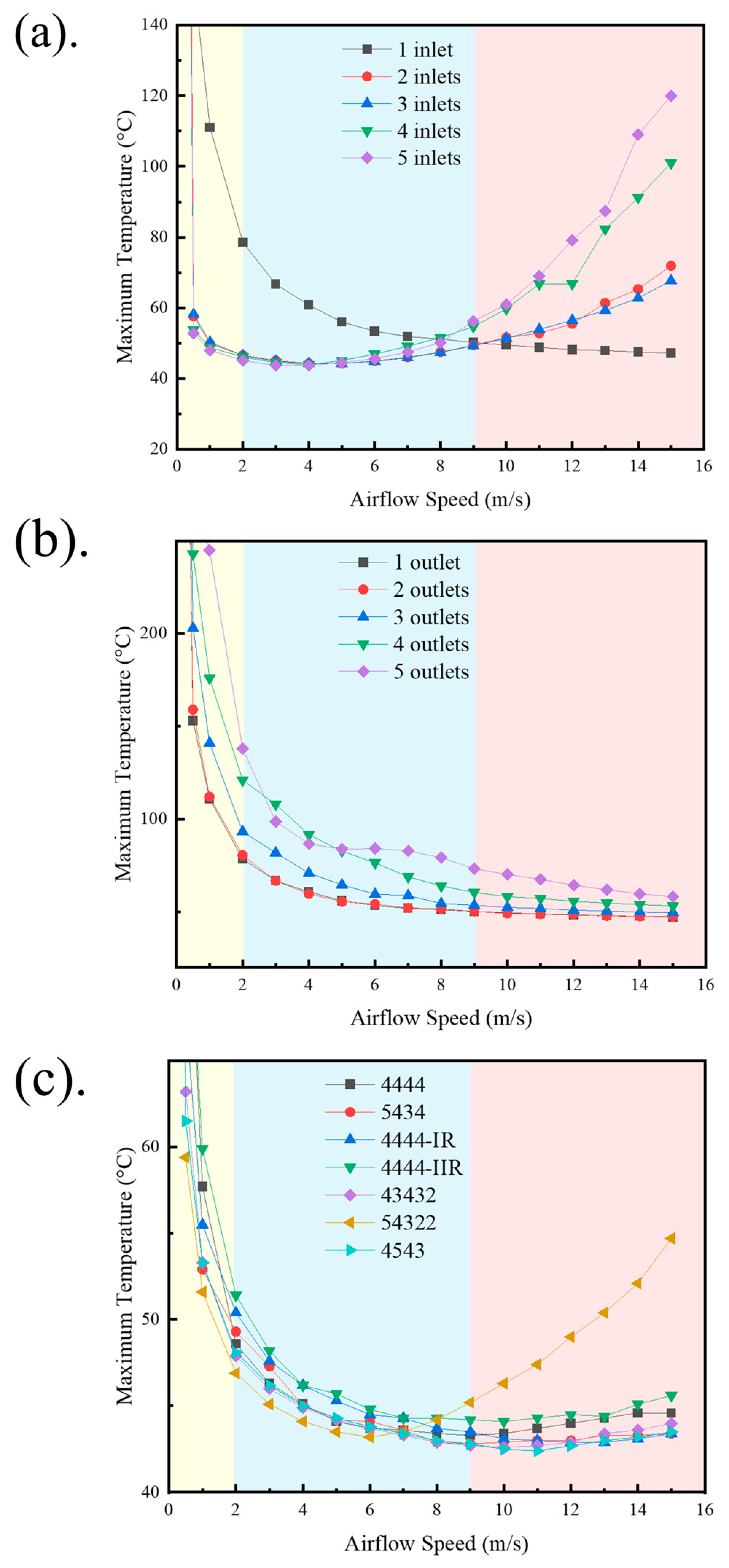

3. Simulation Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Amer, M.M.; Shouman, M.A.; Salem, M.S.; Kannan, A.M.; Hamed, A.M. Advances in thermal management systems for Li-Ion batteries: A review. Therm. Sci. Eng. Prog. 2024, 53, 102714. [Google Scholar] [CrossRef]

- Sorensen, A.; Urgikar, V.; Betz, J.E. A study of thermal runaway mechanisms in lithium-ion batteries and predictive numerical modeling techniques. Batteries 2024, 10, 116. [Google Scholar] [CrossRef]

- Ortiz, Y.; Paul Arévalo, E.; Peña, D.; Jurado, F. Recent advances in thermal management strategies for lithium-ion batteries: A comprehensive review. Batteries 2024, 10, 83. [Google Scholar] [CrossRef]

- E, J.; Yue, M.; Chen, J.; Zhu, H.; Deng, Y.; Zhu, Y.; Zhang, F.; Wen, M.; Zhang, B.; Kang, S. Effects of the different air cooling strategies on cooling performance of a lithium-ion battery module with baffle. Appl. Therm. Eng. 2018, 144, 231–241. [Google Scholar] [CrossRef]

- Shi, C.; Kim, S.H.; Warren, N.; Guo, N.; Zhang, X.; Wang, Y.; Willemsen, A.; López-Pernía, C.; Liu, P.; Kingon, A.I. Hierarchically micro- and nanostructured polymer via crystallinity alteration for sustainable environmental cooling. Langmuir 2024, 40, 20195–20203. [Google Scholar] [CrossRef]

- Li, X.; Sun, X.; Zhang, X.; Zheng, Y.; Minus, M.L. Ease-of-manufacture highly transparent thin polyvinyl alcohol aerogel. Sci. Rep. 2024, 14, 26276. [Google Scholar] [CrossRef]

- Wankhede, S.; Thorat, P.; Shisode, S.; Sonawane, S.; Wankhade, R. A study of different battery thermal management systems for battery pack cooling in electric vehicles. Heat Transf. 2022, 51, 7487–7539. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Y.; Halbig, M.; Singh, M.; Almansour, A.; Zheng, Y. Development and optimization of hybrid heat dissipation system for lithium-ion battery packs. Appl. Therm. Eng. 2024, 254, 123912. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, X.; Chen, F.; Tian, Y.; Mu, Y.; Minus, M.L.; Zheng, Y. Accelerated water transportation phenomenon through a hydrophilic metal roll. ACS Appl. Eng. Mater. 2023, 1, 2745–2751. [Google Scholar] [CrossRef]

- Geng, S.; Zhang, X.; Liang, H.; Zheng, Y. Photonic-metamaterial-based, near-field-enhanced biosensing approach for early detection of lung and ovarian cancer. Photonics 2024, 11, 1020. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, D.; Li, C.; Wang, J.; Zhang, J.; Cheng, Y.; Mei, W.; Cheng, S.; Qin, P.; Duan, Q. Numerical optimization for a phase change material based lithium-ion battery thermal management system. Appl. Therm. Eng. 2023, 225, 119839. [Google Scholar] [CrossRef]

- Zore, P.; Perera, N.; Lahr, J.; Hason, R. A novel thermal management system for cylindrical lithium-ion batteries using internal-external fin-enhanced phase change material. Appl. Therm. Eng. 2024, 238, 121985. [Google Scholar] [CrossRef]

- Kim, G.H.; Pesaran, A.; Spotnitz, R. A three-dimensional thermal abuse model for lithium-ion cells. J. Power Sources 2007, 170, 476–489. [Google Scholar] [CrossRef]

- Wang, T.; Tseng, K.J.; Zhao, J.; Wei, Z. Thermal investigation of lithium-ion battery module with different cell arrangement structures and forced air-cooling strategies. Appl. Energy 2014, 134, 229–238. [Google Scholar] [CrossRef]

- Karthik, C.A.; Kalita, P.; Cui, X.; Peng, X. Thermal management for prevention of failures of lithium ion battery packs in electric vehicles: A review and critical future aspects. Energy Storage 2020, 2, e137. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, X.; Negnevitsky, M.; Zhang, H. A review of air-cooling battery thermal management systems for electric and hybrid electric vehicles. J. Power Sources 2021, 501, 230001. [Google Scholar] [CrossRef]

- Hamisi, C.M.; Gerutu, G.B.; Greyson, K.A.; Chombo, P.V. Thermal behavior of lithium-ion battery under variation of convective heat transfer coefficients, surrounding temperatures, and charging currents. J. Loss Prev. Process Ind. 2022, 80, 104922. [Google Scholar] [CrossRef]

- El Idi, M.M.; Karkri, M.; Tankari, M.A. A passive thermal management system of Li-ion batteries using PCM composites: Experimental and numerical investigations. Int. J. Heat Mass Transf. 2021, 169, 120894. [Google Scholar] [CrossRef]

- Zhang, S.B.; He, X.; Long, N.C.; Shen, Y.J.; Gao, Q. Improving the air-cooling performance for lithium-ion battery packs by changing the air flow pattern. Appl. Therm. Eng. 2023, 221, 119825. [Google Scholar] [CrossRef]

- Nazar, M.W.; Iqbal, N.; Ali, M.; Nazir, H.; Amjad, M.Z.B. Thermal management of Li-ion battery by using active and passive cooling method. J. Energy Storage 2023, 61, 106800. [Google Scholar] [CrossRef]

- Li, X.; Zhao, J.; Yuan, J.; Duan, J.; Liang, C. Simulation and analysis of air cooling configurations for a lithium-ion battery pack. J. Energy Storage 2021, 35, 102270. [Google Scholar] [CrossRef]

- Li, Y.; Du, Y.; Xu, T.; Wu, H.; Zhou, X.; Ling, Z.; Zhang, Z. Optimization of thermal management system for Li-ion batteries using phase change material. Appl. Therm. Eng. 2018, 131, 766–778. [Google Scholar] [CrossRef]

- Dubey, D.; Mishra, A.; Ghosh, S.; Reddy, M.V.; Pandey, R. Geometry-influenced cooling performance of lithium-ion battery. Appl. Therm. Eng. 2023, 230, 120723. [Google Scholar] [CrossRef]

- Fayaz, H.; Afzal, A.; Mohammed Samee, A.D.; Elahi, M.; Soudagar, M.; Akram, N.; Mujtaba, M.A.; Jilte, R.D.; Islam, M.T.; Ağbulut, Ü.; et al. Optimization of thermal and structural design in lithium-ion batteries to obtain energy efficient battery thermal management system (BTMS): A critical review. Arch. Comput. Methods Eng. 2022, 29, 129–194. [Google Scholar] [CrossRef]

- Mastan Vali, P.S.N.; Murali, G. Battery thermal management system on trapezoidal battery pack with liquid cooling system utilizing phase change material. J. Heat Mass Transf. 2024, 146, 011003. [Google Scholar] [CrossRef]

- Xu, C.; Zhang, H.; Fang, G. Review on thermal conductivity improvement of phase change materials with enhanced additives for thermal energy storage. J. Energy Storage 2022, 51, 104568. [Google Scholar] [CrossRef]

- Wang, H.; Guo, Y.; Ren, Y.; Yeboah, S.; Wang, J.; Long, F.; Zhang, Z.; Jiang, R. Investigation of the thermal management potential of phase change material for lithium-ion battery. Appl. Therm. Eng. 2024, 236, 121590. [Google Scholar] [CrossRef]

- Labat, M.; Virgone, J.; David, D.; Kuznik, F. Experimental assessment of a PCM to air heat exchanger storage system for building ventilation application. Appl. Therm. Eng. 2014, 66, 375–382. [Google Scholar] [CrossRef]

- Bianco, N.; Fragnito, A.; Iasiello, M.; Mauro, G.M. Multiscale analysis of a seasonal latent thermal energy storage with solar collectors for a single-family building. Therm. Sci. Eng. Prog. 2024, 50, 102538. [Google Scholar] [CrossRef]

- Ansys, Inc. Ansys Discovery 2024 R1 and Ansys Workbench 2024 R1: Multiphysics Simulation Software; Ansys: Canonsburg, PA, USA, 2024; Available online: https://www.ansys.com (accessed on 1 September 2024).

| Parameters | Value | Units |

|---|---|---|

| Battery operating temperature range | 10–55 | °C |

| Optimal operating temperature | 45 | °C |

| Surface heat flux | 1322.88 | |

| Initial temperature | 25 | °C |

| Inlet velocity | 0–15 | |

| PCM melting temperature | 40 | °C |

| PCM latent heat | 173,400 | |

| PCM specific heat | 2890 | |

| PCM density | 800 | |

| PCM thermal conductivity | 16.6 | |

| Sheath thermal conductivity | 0.13 | |

| Sheath density | 1380 | |

| Sheath specific heat | 1420 | |

| Inner sheath inside radius | 9 | |

| Inner sheath outside radius | 9.9 | |

| Outer sheath inside radius | 14 | |

| Outer sheath outside radius | 14.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Zhang, H.; Almansour, A.; Singh, M.; Kiser, J.D.; Zhu, H.; Halbig, M.C.; Zheng, Y. A Comprehensive Analysis of Thermal Heat Dissipation for Lithium-Ion Battery Packs. Energies 2025, 18, 2234. https://doi.org/10.3390/en18092234

Zhang X, Zhang H, Almansour A, Singh M, Kiser JD, Zhu H, Halbig MC, Zheng Y. A Comprehensive Analysis of Thermal Heat Dissipation for Lithium-Ion Battery Packs. Energies. 2025; 18(9):2234. https://doi.org/10.3390/en18092234

Chicago/Turabian StyleZhang, Xuguang, Hexiang Zhang, Amjad Almansour, Mrityunjay Singh, James D. Kiser, Hengling Zhu, Michael C. Halbig, and Yi Zheng. 2025. "A Comprehensive Analysis of Thermal Heat Dissipation for Lithium-Ion Battery Packs" Energies 18, no. 9: 2234. https://doi.org/10.3390/en18092234

APA StyleZhang, X., Zhang, H., Almansour, A., Singh, M., Kiser, J. D., Zhu, H., Halbig, M. C., & Zheng, Y. (2025). A Comprehensive Analysis of Thermal Heat Dissipation for Lithium-Ion Battery Packs. Energies, 18(9), 2234. https://doi.org/10.3390/en18092234