Hydrothermal Liquefaction for Biofuel Synthesis: Assessment of VFA (Volatile Fatty Acid) and FAME (Fatty Acid Methyl Ester) Profiles from Spent Coffee Grounds

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Process

2.2. Methods of Analysis

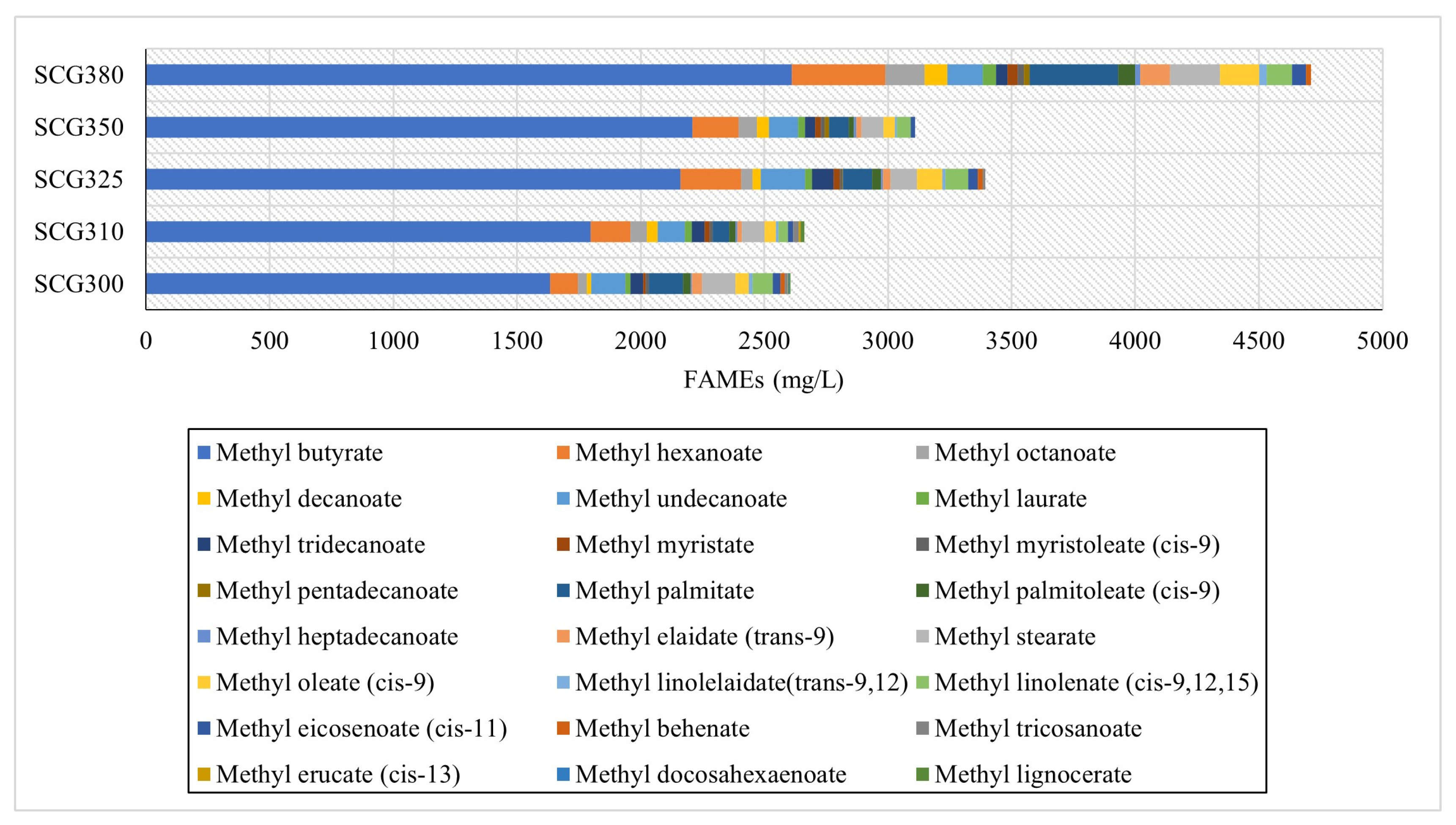

3. Results

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| COD | Chemical Oxygen Demand |

| °C | Degrees of Celsius |

| FAMEs | Fatty Acid Methyl Esters |

| HHV | High Heating Value |

| HtL | Hydrothermal Liquefaction |

| MJ/kg | Megajoule per kilogram |

| mg/L | Milligram per liter |

| % | Percentage |

| SCGs | Spent Coffee Grounds |

| TS | Total Solids |

| VFAs | Volatile Fatty Acids |

| VS | Volatile Solids |

References

- Kovalcik, A.; Obruca, S.; Marova, I. Valorization of spent coffee grounds: A review. Food Bioprod. Process. 2018, 110, 104–119. [Google Scholar] [CrossRef]

- Forcina, A.; Petrillo, A.; Travaglioni, M.; di Chiara, S.; De Felice, F. A comparative life cycle assessment of different spent coffee ground reuse strategies and a sensitivity analysis for verifying the environmental convenience based on the location of sites. J. Clean. Prod. 2023, 385, 135727. [Google Scholar] [CrossRef]

- McNutt, J.; He, Q.S. Spent Coffee Grounds: A Review on Current Utilization. J. Ind. Eng. Chem. 2019, 71, 78–88. [Google Scholar] [CrossRef]

- Yang, L.; Nazari, L.; Yuan, Z.; Corscadden, K.; Xu, C.C. Hydrothermal liquefaction of spent coffee grounds in water medium for bio-oil production. Biomass Bioenergy 2016, 86, 191–198. [Google Scholar] [CrossRef]

- Saberian, M.; Li, J.; Donnoli, A.; Bonderenko, E.; Oliva, P.; Gill, B.; Lockrey, S.; Siddique, R. Recycling of spent coffee grounds in construction materials: A review. J. Clean. Prod. 2021, 289, 125837. [Google Scholar] [CrossRef]

- Battista, F.; Barampouti, E.M.; Mai, S.; Bolzonella, D.; Malamis, D.; Moustakas, K.; Loizidou, M. Added-value molecules recovery and biofuels production from spent coffee grounds. Renew. Sustain. Energy Rev. 2020, 131, 110007. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, J.; Wang, S.; Rupasinghe, H.V. Experimental exploration of processes for deriving multiple products from spent coffee grounds. Food Bioprod. Process. 2021, 128, 21–29. [Google Scholar] [CrossRef]

- Kim, J.; Kim, H.; Baek, G.; Lee, C. Anaerobic co-digestion of spent coffee grounds with different waste feedstocks for biogas production. Waste Manag. 2017, 60, 322–328. [Google Scholar] [CrossRef]

- Kang, S.B.; Oh, H.Y.; Kim, J.J.; Choi, K.S. Characteristics of spent coffee ground as a fuel and combustion test in a small boiler (6.5 kW). Renew. Energy 2017, 113, 1208–1214. [Google Scholar] [CrossRef]

- Marx, S.; Venter, R.; Karmee, S.K.; Louw, J.; Truter, C. Biofuels from spent coffee grounds: Comparison of processing routes. Biofuels 2022, 13, 537–543. [Google Scholar] [CrossRef]

- Kim, H.J.; Oh, S.C. Hydrothermal carbonization of spent coffee grounds. Appl. Sci. 2021, 11, 6542. [Google Scholar] [CrossRef]

- Vakalis, S.; Moustakas, K.; Benedetti, V.; Cordioli, E.; Patuzzi, F.; Loizidou, M.; Baratieri, M. The “COFFEE BIN” concept: Centralized collection and torrefaction of spent coffee grounds. Environ. Sci. Pollut. Res. 2019, 26, 35473–35481. [Google Scholar] [CrossRef]

- Afolabi, O.O.; Sohail, M.; Cheng, Y.L. Optimisation and characterization of hydrochar production from spent coffee grounds by hydrothermal carbonisation. Renew. Energy 2020, 147, 1380–1391. [Google Scholar] [CrossRef]

- Hu, Y.; Gallant, R.; Salaudeen, S.; Farooque, A.A.; He, S. Hydrothermal carbonization of spent coffee grounds for producing solid fuel. Sustainability 2022, 14, 8818. [Google Scholar] [CrossRef]

- Bodur, F.G.; Güngören-Madenoğlu, T.; Özdemir, G.; Ballice, L.; Kabay, N. Biochemical and biohythane production from anaerobically digested water plant by hydrothermal liquefaction/gasification. Int. J. Hydrogen Energy 2024, 52, 183–201. [Google Scholar] [CrossRef]

- Thomsen, L.B.S.; Anastasakis, K.; Biller, P. Hydrothermal liquefaction potential of wastewater treatment sludges: Effect of wastewater treatment plant and sludge nature on products distribution. Fuel 2024, 355, 129525. [Google Scholar] [CrossRef]

- Wei, C.; Xu, Y.; Li, Y.; Wei, W.; Feng, Y.; Li, Z.; Xu, L. Life-cycle assessment of microalgae liquid biofuel production in biofilm cultivation system via conversion technologies of transesterification, hydrothermal liquefaction and pyrolysis. J. Clean. Prod. 2024, 436, 140559. [Google Scholar] [CrossRef]

- Ni, J.; Qian, L.; Wang, Y.; Zhang, B.; Gu, H.; Hu, Y.; Wang, Q. A review on fast hydrothermal liquefaction of biomass. Fuel 2022, 327, 125135. [Google Scholar] [CrossRef]

- Liu, G.; Chen, F.; Cao, K.; Jin, B.; Rao, L.; Jin, X.; He, F.; Huang, Q. Fe-catalyzed low-temperature hydrothermal liquefaction of coffee shells: Influence of operating parameters on bio-oil yield, distribution of bio-oil products. J. Energy Inst. 2024, 113, 101525. [Google Scholar] [CrossRef]

- Atabani, A.E.; Ali, I.; Naqvi, S.R.; Badruddin, I.A.; Aslam, M.; Mahmoud, E.; Almomani, F.; Juchelková, D.; Atelge, M.R.; Khan, T.M.Y. A state-of-the-art review on spent coffee ground (SCG) pyrolysis for future biorefinery. Chemosphere 2022, 286, 131730. [Google Scholar] [CrossRef]

- Sklavos, S.; Gatidou, G.; Stasinakis, A.S.; Haralambopoulos, D. Use of solar distillation for olive mill wastewater drying and recovery of polyphenolic compounds. J. Environ. Manag. 2015, 162, 46–52. [Google Scholar] [CrossRef] [PubMed]

- APHA. Standard Methods for the Examination of Water and Wastewater, 20th ed.; American Public Health Association, Port City Press: Baltimore, MD, USA, 1998. [Google Scholar]

- Osorio-Arias, J.; Delgado-Arias, S.; Cano, L.; Zapata, S.; Quintero, M.; Nuñez, H.; Ramírez, C.; Simpson, R.; Vega-Castro, O. Sustainable management and valorization of spent coffee grounds through the optimization of thin layer hot air-drying process. Waste Biomass Valorization 2020, 11, 5015–5026. [Google Scholar] [CrossRef]

- Yang, J.; Niu, H.; Corscadden, K.; He, Q.; Zhou, N. MW-assisted hydrothermal liquefaction of spent coffee grounds. Can. J. Chem. Eng. 2022, 100, 1729–1738. [Google Scholar] [CrossRef]

- Yang, L.; Havard, P.; Corscadden, K.; Xu, C.C.; Wang, X. Co-liquefaction of spent coffee grounds and lignocellulosic feedstocks. Bioresour. Technol. 2017, 237, 108–121. [Google Scholar] [CrossRef]

- Muller, L.C.; Pearson, J.; Louw, J.; Marx, S.; Kumar Karmee, S. Hydrothermal liquefaction of spent coffee grounds followed by biocatalytic upgradation to produce biofuel: A circular economy approach. Biofuels 2022, 13, 779–788. [Google Scholar] [CrossRef]

- Vakalis, S.; Georgiou, A.; Moustakas, K.; Fountoulakis, M. Assessing the effect of hydrothermal treatment on the volatile solids content and the biomethane potential of common reed (Phragmites australis). Bioresour. Technol. Rep. 2022, 17, 100923. [Google Scholar] [CrossRef]

- Basar, I.A.; Liu, H.; Eskicioglu, C. Incorporating hydrothermal liquefaction into wastewater treatment–Part III: Aqueous phase characterization and evaluation of on-site treatment. Chem. Eng. J. 2023, 467, 143422. [Google Scholar] [CrossRef]

- Liu, H.; Basar, I.A.; Eskicioglu, C. Hydrothermal liquefaction for sludge-to-energy conversion: An evaluation of biocrude production and management of waste streams. Energy 2023, 281, 128268. [Google Scholar] [CrossRef]

- Alimoradi, S.; Stohr, H.; Stagg-Williams, S.; Sturm, B. Effect of temperature on toxicity and biodegradability of dissolved organic nitrogen formed during hydrothermal liquefaction of biomass. Chemosphere 2020, 238, 124573. [Google Scholar] [CrossRef]

- Li, X.; Liang, J.; Zhang, L.; Zhang, S.; Xu, L.; Wang, Y.; Hu, X. Coke Formation in the Co-production of Hydrogen and Phenols from Pyrolysis-Reforming of Lignin. Int. J. Hydrogen Energy 2022, 47, 32835–32848. [Google Scholar] [CrossRef]

- Caetano, N.S.; Silva, V.F.; Melo, A.C.; Martins, A.A.; Mata, T.M. Spent coffee grounds for biodiesel production and other applications. Clean Technol. Environ. Policy 2014, 16, 1423–1430. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Q.; Wang, B.; Yang, G.; Lucia, L.A.; Chen, J. Hydrothermal carbonization of corncob residues for hydrochar production. Energy Fuels 2015, 29, 872–876. [Google Scholar] [CrossRef]

- Duman, G.; Balmuk, G.; Cay, H.; Kantarli, I.C.; Yanik, J. Comparative evaluation of torrefaction and hydrothermal carbonization: Effect on fuel properties and combustion behavior of agricultural wastes. Energy Fuels 2020, 34, 11175–11185. [Google Scholar] [CrossRef]

- Saqib, N.U.; Baroutian, S.; Sarmah, A.K. Physicochemical, structural and combustion characterization of food waste hydrochar obtained by hydrothermal carbonization. Bioresour. Technol. 2018, 266, 357–363. [Google Scholar] [CrossRef] [PubMed]

- Liakos, D.; Altiparmaki, G.; Moustakas, K.; Malamis, S.; Stergios Vakalis, S. The fate of Volatile Fatty Acids (VFAs) during the thermodynamic transition from hydrothermal carbonization to hydrothermal liquefaction: HtC-to-HtL. Sustain. Chem. Pharm. 2024, 41, 101683. [Google Scholar] [CrossRef]

- Saengsuriwong, R.; Onsree, T.; Phromphithak, S.; Tippayawong, N. Biocrude oil production via hydrothermal liquefaction of food waste in a simplified high-throughput reactor. Bioresour. Technol. 2021, 341, 125750. [Google Scholar] [CrossRef]

- Shah, A.A.; Toor, S.S.; Conti, F.; Nielsen, A.H.; Rosendahl, L.A. Hydrothermal liquefaction of high ash containing sewage sludge at sub and supercritical conditions. Biomass Bioenergy 2020, 135, 105504. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, C.; Rao, Y.; Jing, Y.; Luo, G.; Zhang, S. Methane potentials of wastewater generated from hydrothermal liquefaction of rice straw: Focusing on the wastewater characteristics and microbial community compositions. Biotechnol. Biofuels 2017, 10, 140. [Google Scholar] [CrossRef]

- Lachos-Perez, D.; Torres-Mayanga, P.C.; Abaide, E.R.; Zabot, G.L.; De Castilhos, F. Hydrothermal carbonization and liquefaction: Differences, progress, challenges, and opportunities. Bioresour. Technol. 2022, 343, 126084. [Google Scholar] [CrossRef]

- Song, H.; Yang, T.; Li, B.; Tong, Y.; Li, R. Hydrothermal liquefaction of sewage sludge into biocrude: Effect of aqueous phase recycling on energy recovery and pollution mitigation. Water Res. 2022, 226, 119278. [Google Scholar] [CrossRef]

- Bi, Z.; Zhang, J.; Peterson, E.; Zhu, Z.; Xia, C.; Liang, Y.; Wiltowski, T. Biocrude from pretreated sorghum bagasse through catalytic hydrothermal liquefaction. Fuel 2017, 188, 112–120. [Google Scholar] [CrossRef]

- Tang, S.; Shi, Z.; Tang, X.; Yang, X. Hydrotreatment of biocrudes derived from hydrothermal liquefaction and lipid extraction of the high-lipid Scenedesmus. Green Chem. 2019, 21, 3413–3423. [Google Scholar] [CrossRef]

- Leow, Y.; Yew, P.Y.M.; Chee, P.L.; Loh, X.J.; Kai, D. Recycling of Spent Coffee Grounds for Useful Extracts and Green Composites. RSC Adv. 2021, 11, 2682–2692. [Google Scholar] [CrossRef]

- Islam, M.T.; Sultana, A.I.; Chambers, C.; Saha, S.; Saha, N.; Kirtania, K.; Reza, M.T. Recent Progress on Emerging Applications of Hydrochar. Energies 2022, 15, 9340. [Google Scholar] [CrossRef]

- Ighalo, J.O.; Akaeme, F.C.; Georgin, J.; de Oliveira, J.S.; Franco, D.S.P. Biomass Hydrochar: A Critical Review of Process Chemistry, Synthesis Methodology, and Applications. Sustainability 2025, 17, 1660. [Google Scholar] [CrossRef]

- Masoumi, S.; Borugadda, V.B.; Nanda, S.; Dalai, A.K. Hydrochar: A Review on Its Production Technologies and Applications. Catalysts 2021, 11, 939. [Google Scholar] [CrossRef]

- Fang, J.; Zhan, L.; Ok, Y.S.; Gao, B. Minireview of Potential Applications of Hydrochar Derived from Hydrothermal Carbonization of Biomass. J. Ind. Eng. Chem. 2018, 57, 15–21. [Google Scholar] [CrossRef]

- Kim, N.-J.; Lim, S.-J.; Chang, H.N. Volatile Fatty Acid Platform: Concept and Application. In Emerging Areas in Bioengineering, 1st ed.; Chang, H.N., Ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2018; pp. 172–191. [Google Scholar]

- Rezaei Motlagh, S.; Harun, R.; Radiah Awang Biak, D.; Hussain, S.A.; A. Elgharbawy, A.; Khezri, R.; Wilfred, C.D. Prediction of Potential Ionic Liquids (ILs) for the Solid–Liquid Extraction of Docosahexaenoic Acid (DHA) from Microalgae Using COSMO-RS Screening Model. Biomolecules 2020, 10, 1149. [Google Scholar] [CrossRef]

- Islam, M.A.; Rainey, T.J.; Ristovski, Z.; Brown, R.J. Performance and Exhaust Emissions of Diesel Engines Using Microalgae FAME and the Prospects for Microalgae HTL Biocrude. Renew. Sustain. Energy Rev. 2018, 82, 4269–4278. [Google Scholar] [CrossRef]

| Samples | Temperature (°C) | Pressure (bar) | Resident Time (min) |

|---|---|---|---|

| SCGs300 | 300 | 84.3 | 30 |

| SCGs310 | 310 | 97.4 | 30 |

| SCGs325 | 325 | 118.8 | 30 |

| SCGs350 | 350 | 163.5 | 30 |

| SCGs380 | 380 | 89.8 | 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liakos, D.; Altiparmaki, G.; Malamis, S.; Vakalis, S. Hydrothermal Liquefaction for Biofuel Synthesis: Assessment of VFA (Volatile Fatty Acid) and FAME (Fatty Acid Methyl Ester) Profiles from Spent Coffee Grounds. Energies 2025, 18, 2094. https://doi.org/10.3390/en18082094

Liakos D, Altiparmaki G, Malamis S, Vakalis S. Hydrothermal Liquefaction for Biofuel Synthesis: Assessment of VFA (Volatile Fatty Acid) and FAME (Fatty Acid Methyl Ester) Profiles from Spent Coffee Grounds. Energies. 2025; 18(8):2094. https://doi.org/10.3390/en18082094

Chicago/Turabian StyleLiakos, Dimitrios, Georgia Altiparmaki, Simos Malamis, and Stergios Vakalis. 2025. "Hydrothermal Liquefaction for Biofuel Synthesis: Assessment of VFA (Volatile Fatty Acid) and FAME (Fatty Acid Methyl Ester) Profiles from Spent Coffee Grounds" Energies 18, no. 8: 2094. https://doi.org/10.3390/en18082094

APA StyleLiakos, D., Altiparmaki, G., Malamis, S., & Vakalis, S. (2025). Hydrothermal Liquefaction for Biofuel Synthesis: Assessment of VFA (Volatile Fatty Acid) and FAME (Fatty Acid Methyl Ester) Profiles from Spent Coffee Grounds. Energies, 18(8), 2094. https://doi.org/10.3390/en18082094