Enhancing Performance of PEM Fuel Cell Powering SRM System Using Metaheuristic Optimization

Abstract

1. Introduction

- Three objectives are evaluated to mitigate ripples in the PEMFC system, identifying the one with the most significant impact.

- These objectives are minimized both individually and concurrently under operating conditions with varying load torques and SRM speeds.

- The system’s performance is assessed, including a detailed analysis of its effects on PEMFC current and voltage ripples.

2. System Architecture and Dynamic Modeling

2.1. PEMFC

2.2. Supercapacitors

2.3. Battery

2.4. SRM

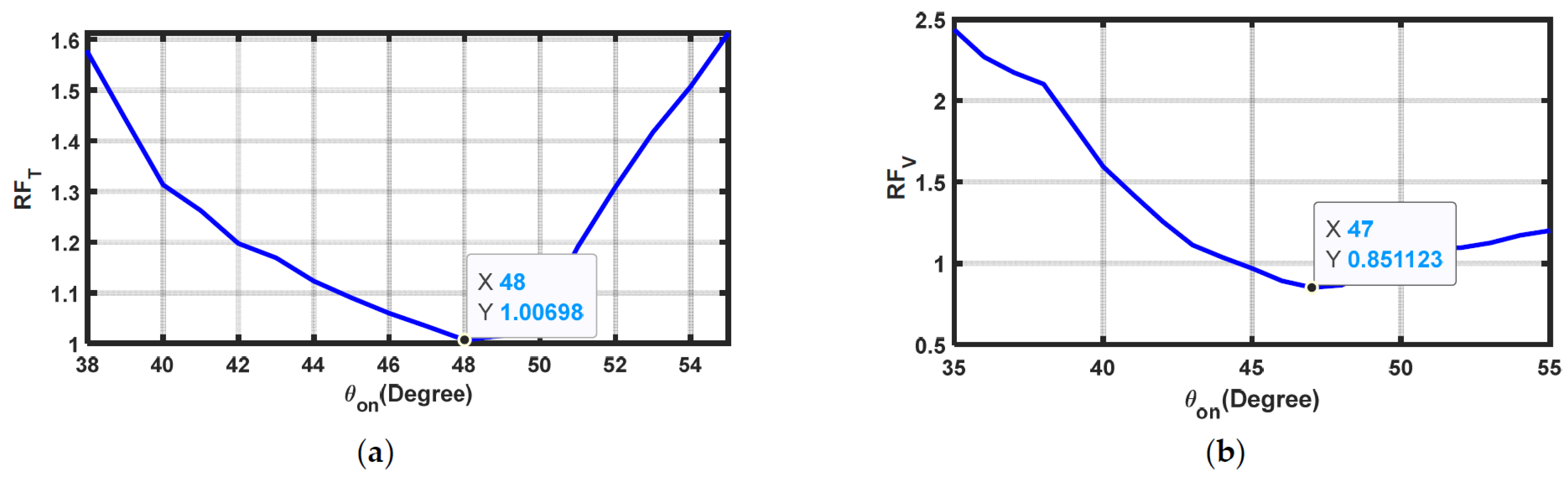

3. SRM Ripples with Varying Turn-On/Off Angles

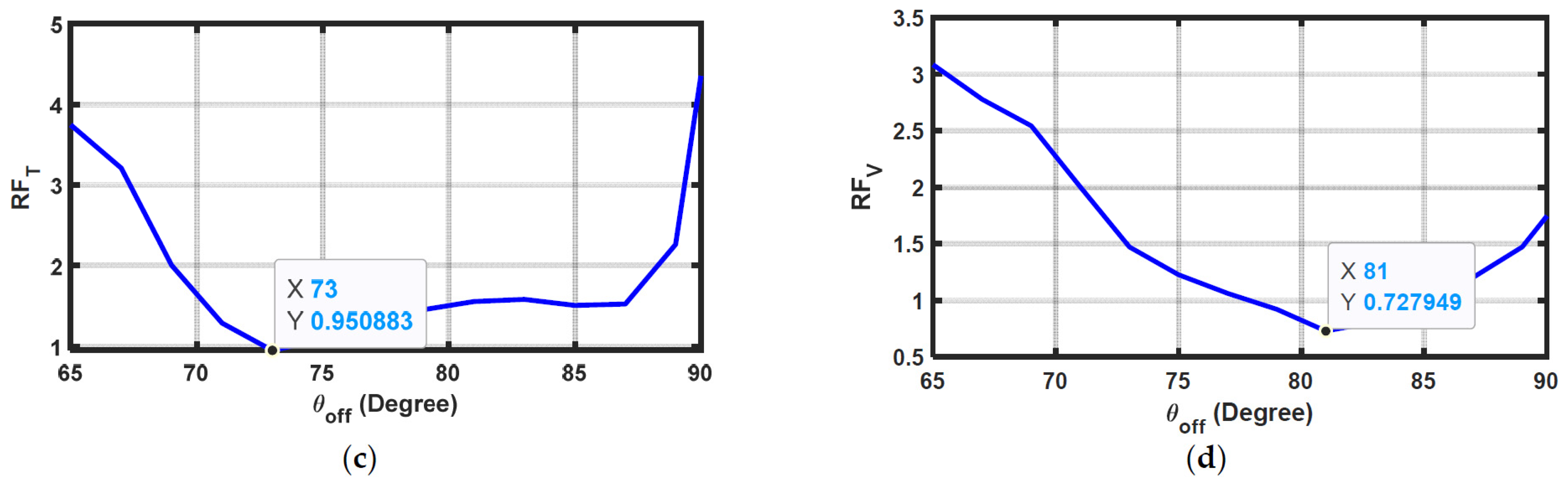

4. Overview of Lichtenberg Optimization Algorithms

- i-

- Its fractal nature allows the method to efficiently explore a vast search space and identify global optima in complex problems with many variables.

- ii-

- The algorithm effectively balances exploitation (refining solutions near optimal ones) and exploration (searching new regions), fostering the pursuit of a global optimum while minimizing the risk of premature convergence to local optima.

- iii-

- The fractal-like structure of the search space allows for the possibility of multiple solutions.

5. Simulations and Discussions

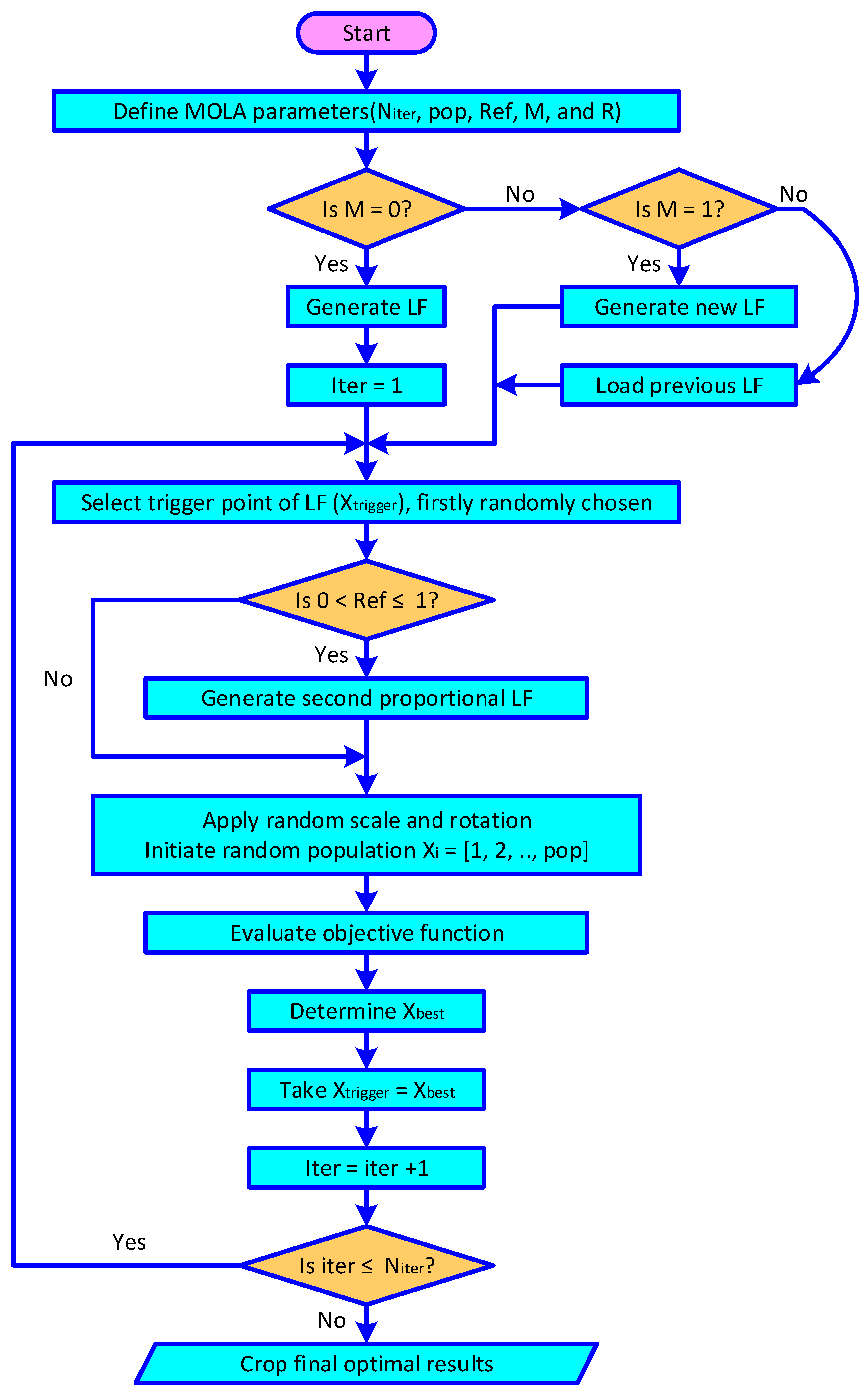

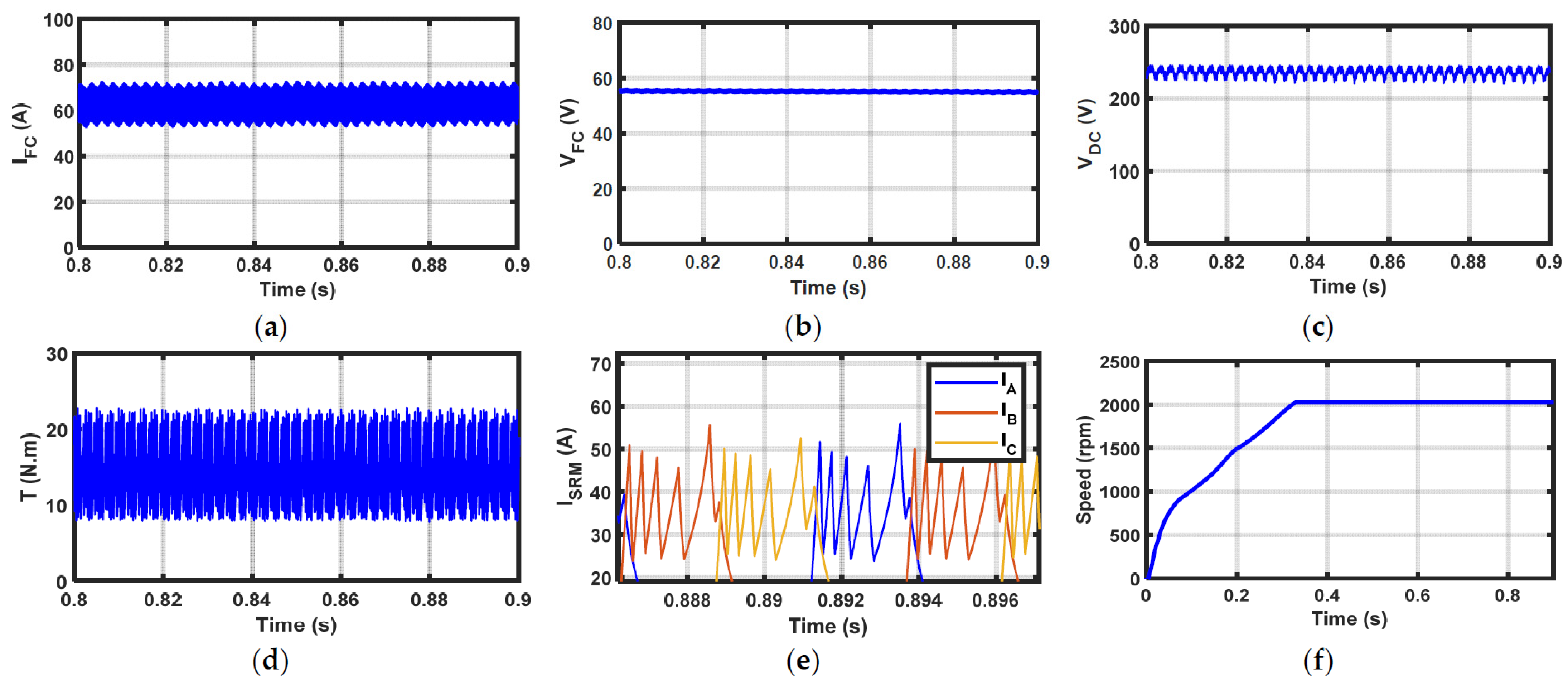

5.1. Single-Objective Scenario

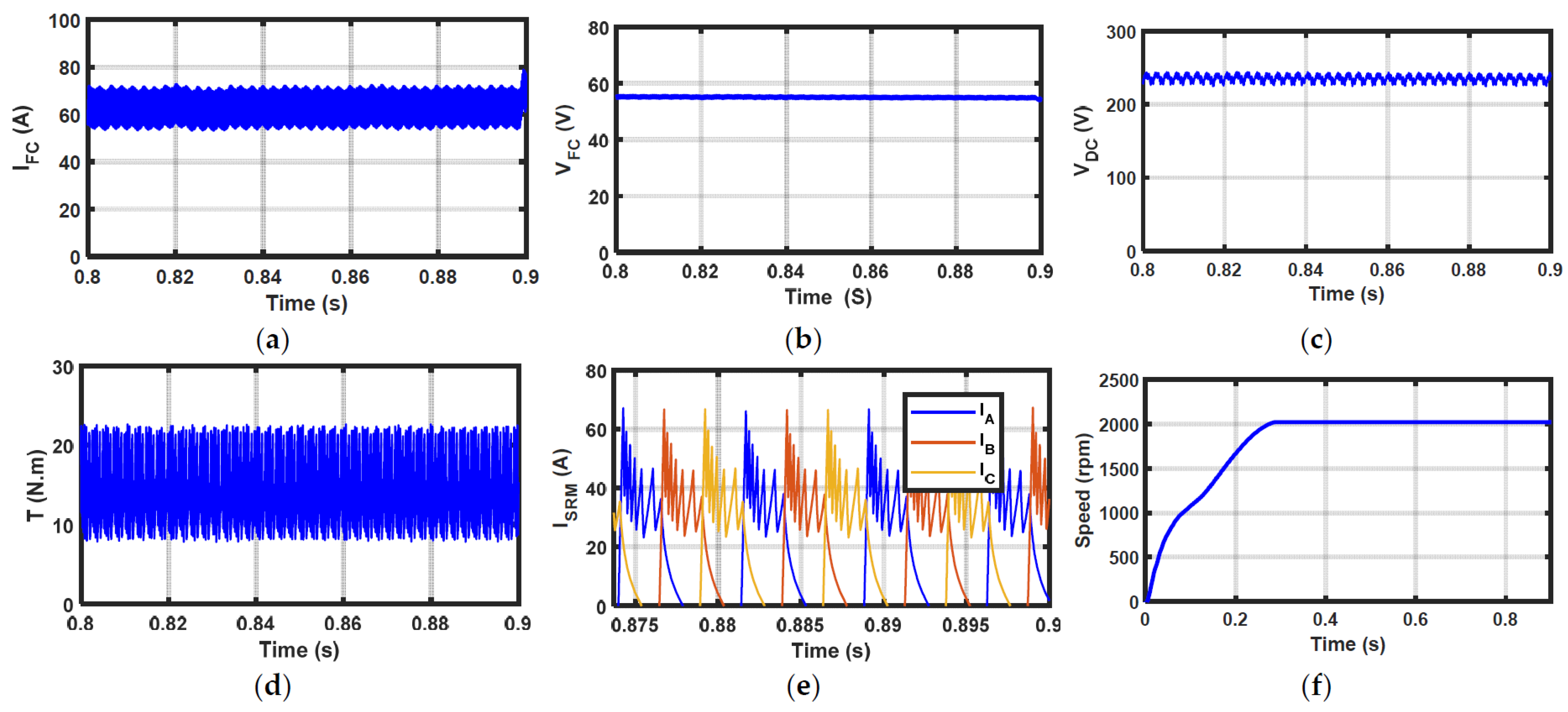

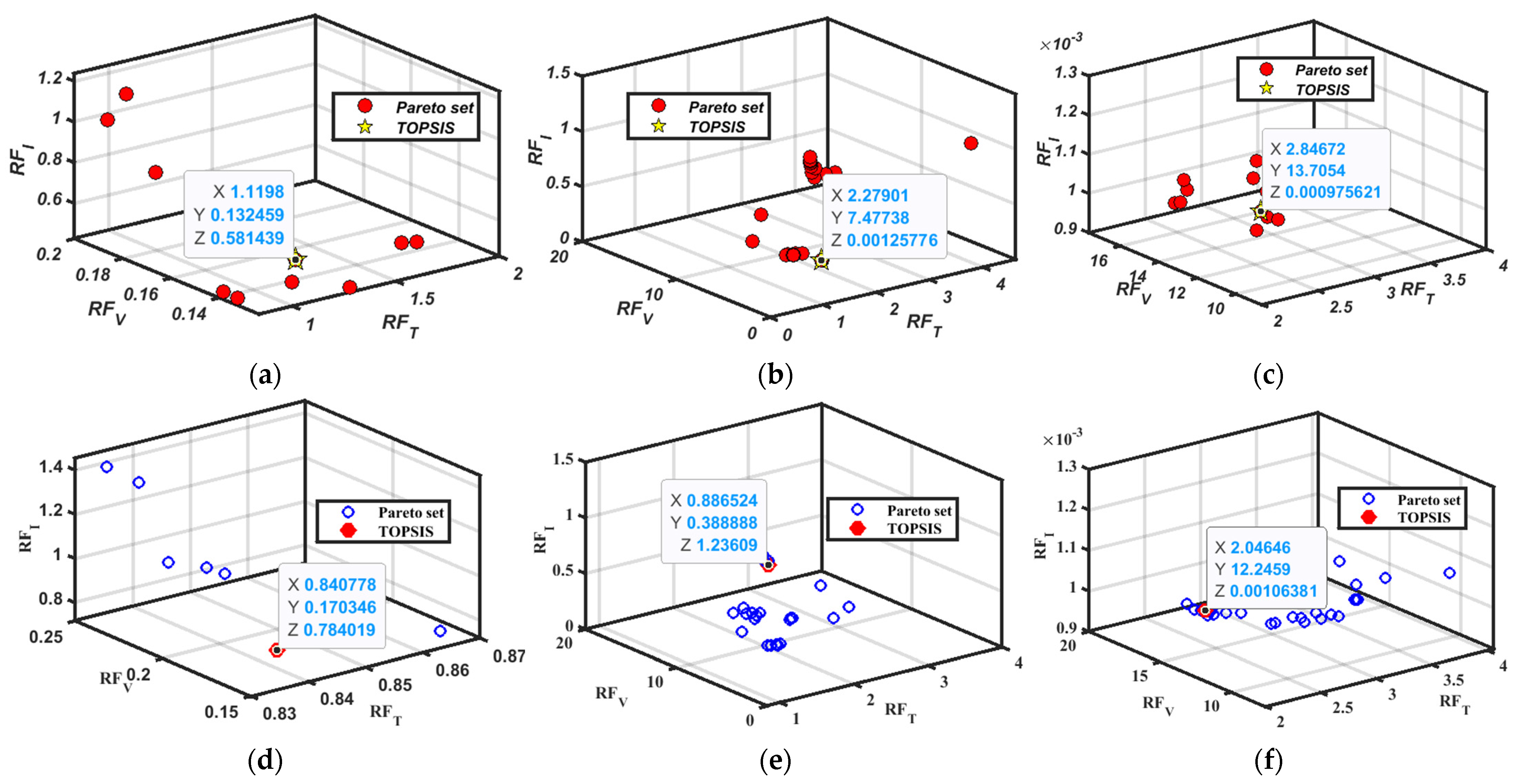

5.2. Multi-Objective Scenario

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

- The following abbreviations are used in this manuscript:

| ANN | Artificial neural network |

| AST | Average starting torque |

| BS | Boost converter |

| DTC | Direct torque control |

| IGBT | Integrated gate bipolar transistor |

| LA | Lichtenberg algorithm |

| LFs | Lichtenberg figures |

| MODF | Multi-objective Dragonfly |

| MOLA | Multi-objective Lichtenberg algorithm |

| PEMFC | Proton exchange membrane fuel cell |

| PSO | Particle swarm optimization |

| SC | Supercapacitor |

| SFS | Stochastic fractional search |

| SRM | Switched reluctance motor |

| TAR | Torque/ampere ratio |

| TSF | Torque smoothness factor |

| UPS | Uninterruptible power supply |

References

- Rahman, K.M.; Fahimi, B.; Suresh, G.; Rajarathnam, A.; Ehsani, M. Advantages of Switched Reluctance Motor Applications to EV and HEV: Design and Control Issues. IEEE Trans. Ind. Appl. 2000, 36, 111–121. [Google Scholar] [CrossRef]

- Ramya, K.C.; Ramani, J.G.; Sridevi, A.; Rai, R.S.; Shirley, D.R.A. Analysis of the Different Types of Electric Motors Used in Electric Vehicles. In E-Mobility; Kathiresh, M., Kanagachidambaresan, G.R., Williamson, S.S., Eds.; EAI/Springer Innovations in Communication and Computing; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Valdez-Resendiz, J.E.; Rosas-Caro, J.C.; Sanchez, V.M.; Lopez-Nunez, A.R. Experimental study of a fuel cell stack performance operating with a power electronics converter with high-frequency current ripple. Int. J. Hydrogen Energy 2025, 108, 66–75. [Google Scholar] [CrossRef]

- Parache, F.; Schneider, H.; Turpin, C.; Richet, N.; Debellemanière, O.; Bru, É.; Thieu, A.T.; Bertail, C.; Marot, C. Impact of Power Converter Current Ripple on the Degradation of PEM Electrolyzer Performances. Membranes 2022, 12, 109. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Lee, I.; Tak, Y.; Cho, B.H. Impedance-based diagnosis of polymer electrolyte membrane fuel cell failures associated with a low frequency ripple current. Renew. Energy 2013, 51, 302–309. [Google Scholar] [CrossRef]

- Gürlek, Y.; Joos, O.; Lang, C.; Ackerl, M.; Dold, R.; Basler, T.; Neuburger, M. Analysis on the Impact of Current Ripples in Fuel Cell Electric Heavy-Duty Trucks. In Proceedings of the 2023 25th European Conference on Power Electronics and Applications (EPE’23 ECCE Europe), Aalborg, Denmark, 4–8 September 2023. [Google Scholar] [CrossRef]

- Zhan, Y.; Guo, Y.; Zhu, J.; Liang, B.; Yang, B. Comprehensive influences measurement and analysis of power converter low frequency current ripple on PEM fuel cell. Int. J. Hydrogen Energy 2019, 44, 31352–31359. [Google Scholar] [CrossRef]

- Yildiz, E.; Vural, B.; Akar, F. Current ripple minimization of a PEM fuel cell via an interleaved converter to prolong the stack life. In Proceedings of the 19th International Symposium on Electrical Apparatus and Technologies (SIELA), Bourgas, Bulgaria, 29 May–1 June 2016; pp. 1–4. [Google Scholar] [CrossRef]

- Zhan, Y.; Guo, Y.; Zhu, J.; Li, L. Performance comparison of input current ripple reduction methods in UPS applications with hybrid PEM fuel cell/supercapacitor power sources. Int. J. Electr. Power Energy Syst. 2015, 64, 96–103. [Google Scholar] [CrossRef]

- Fasdi, N.; Abd-Rahim, N.; Rohani, S.; Al-Turki, Y. Parallel Inductor Multilevel Current Source Inverter for Input Ripple Current Reduction in PEM Fuel Cell Applications. IETE J. Res. 2018, 66, 505–517. [Google Scholar] [CrossRef]

- Li, S.; Zhang, S.; Habetler, T.G.; Harley, R.G. Modeling, design optimization, and applications of switched reluctance machines—A review. EEE Trans. Ind. Appl. 2019, 55, 2660–2681. [Google Scholar] [CrossRef]

- Mohanraj, D.; Gopalakrishnan, J.; Chokkalingam, B.; Mihet-Popa, L. Critical aspects of electric motor drive controllers and mitigation of torque ripple—Review. IEEE Access 2022, 10, 73635–73674. [Google Scholar] [CrossRef]

- Deng, X.; Mecrow, B.; Wu, H.; Martin, R. Design and Development of Low Torque Ripple Variable-Speed Drive System with Six-Phase Switched Reluctance Motors. IEEE Trans. Energy Convers. 2018, 33, 420–429. [Google Scholar] [CrossRef]

- Deng, X.; Mecrow, B.; Wu, H.; Martin, R.; Gai, Y. Cost-Effective and High-Efficiency Variable-Speed Switched Reluctance Drives with Ring-Connected Winding Configuration. IEEE Trans. Energy Convers. 2019, 34, 120–129. [Google Scholar] [CrossRef]

- Röth, C.; Milde, F.; Trebbels, D.; Schmidt, J.; Doppelbauer, M. A Stator with Offset Segments and a Double Stator Design for the Reduction of Torque Ripple of a Switched Reluctance Motor. IEEE Trans. Energy Convers. 2022, 37, 1233–1240. [Google Scholar] [CrossRef]

- Davarpanah, G.; Faiz, J. A Novel Structure of Switched Reluctance Machine with Higher Mean Torque and Lower Torque Ripple. IEEE Trans. Energy Convers. 2020, 35, 1859–1867. [Google Scholar] [CrossRef]

- Mehta, S.; Kabir, M.A.; Pramod, P.; Husain, I. Segmented Rotor Mutually Coupled Switched Reluctance Machine for Low Torque Ripple Applications. EEE Trans. Ind. Appl. 2021, 57, 3582–3594. [Google Scholar] [CrossRef]

- Mohammadi, S.E.M.; Chen, P.; Moallem, M.; Fahimi, B.; Kiani, M. An Alternate Rotor Geometry for Switched Reluctance Machine with Reduced Torque Ripple. IEEE Trans. Energy Convers. 2023, 38, 939–947. [Google Scholar] [CrossRef]

- Mohanraj, D.; Gopalakrishnan, J.; Chokkalingam, B.; Ojo, J.O. An Enhanced Model Predictive Direct Torque Control of SRM Drive Based on a Novel Modified Switching Strategy for Low Torque Ripple. IEEE J. Emerg. Sel. Top. Power Electron. 2024, 12, 2203–2213. [Google Scholar] [CrossRef]

- Li, H.; Bilgin, B.; Emadi, A. An Improved Torque Sharing Function for Torque Ripple Reduction in Switched Reluctance Machines. IEEE Trans. Power Electron. 2019, 34, 1635–1644. [Google Scholar] [CrossRef]

- Sun, X.; Wu, J.; Lei, G.; Guo, Y.; Zhu, J. Torque Ripple Reduction of SRM Drive Using Improved Direct Torque Control with Sliding Mode Controller and Observer. IEEE Trans. Ind. Electron. 2021, 68, 9334–9345. [Google Scholar] [CrossRef]

- Deng, X.; Mecrow, B. A Direct Energy Control Technique for Torque Ripple and DC-link Voltage Ripple Reduction in Switched Reluctance Drive Systems. In Proceedings of the International Conference on Electrical Machines (ICEM), Gothenburg, Sweden, 23–26 August 2020. [Google Scholar] [CrossRef]

- Du, L.; Gu, B.; Lai, J.-S.J.; Swint, E. Control of pseudo-sinusoidal switched reluctance motor with zero torque ripple and reduced input current ripple. In Proceedings of the 2013 IEEE Energy Conversion Congress and Exposition, Denver, CO, USA, 15–19 September 2013. [Google Scholar] [CrossRef]

- Ge, L.; Zhong, J.; Cheng, Q.; Fan, Z.; Song, S.; De Doncker, R.W. Model Predictive Control of Switched Reluctance Machines for Suppressing Torque and Source Current Ripples Under Bus Voltage Fluctuation. IEEE Trans. Ind. Electron. 2023, 70, 11013–11021. [Google Scholar] [CrossRef]

- Haque, M.E.; Chowdhury, A.; Chowdhury, S.M.; Harasis, S.; Das, S.; Sozer, Y.; Gundogmus, O.; Vadamodala, L.; Venegas, F.; Colavincenzo, D.; et al. DC-Link Current Ripple Reduction in Switched Reluctance Machine Drives. IEEE Trans. Ind. Appl. 2021, 57, 1429–1439. [Google Scholar] [CrossRef]

- Kimpara, M.L.M.; Reis, R.R.C.; Da Silva, L.E.B.; Pinto, J.O.P.; Fahimi, B. A Two-Step Control Approach for Torque Ripple and Vibration Reduction in Switched Reluctance Motor Drives. IEEE Access 2022, 10, 82106–82118. [Google Scholar] [CrossRef]

- Saha, N.; Panda, S.; Sahoo, D.K. Modified Whale Optimisation Technique for Combined Objective of Torque Ripple Minimization & Speed Control of SRM Drive. In Proceedings of the 2020 3rd International Conference on Energy, Power and Environment: Towards Clean Energy Technologies, Shillong, Meghalaya, India, 5–7 March 2021. [Google Scholar] [CrossRef]

- Jing, B.; Dang, X.; Liu, Z.; Long, S. Torque ripple suppression of switched reluctance motor based on fuzzy indirect instant torque control. IEEE Access 2022, 10, 75472–75481. [Google Scholar] [CrossRef]

- Elhay, E.A.; Elkholy, M.M. Optimal dynamic and steady-state performance of switched reluctance motor using water cycle algorithm. IEEJ Trans. Electr. Electron. Eng. 2018, 13, 882–890. [Google Scholar] [CrossRef]

- Pereira, J.L.J.; Oliver, G.A.; Francisco, M.B.; Cunha, S.S., Jr.; Gomes, G.F. Multi-objective Lichtenberg Algorithm: A Hybrid Physics-based Meta-heuristic for solving Engineering Problems. Expert Syst. Appl. 2022, 187, 115939. [Google Scholar] [CrossRef]

- Pereira, J.L.J.; Francisco, M.B.; Diniz, C.A.; Oliver, G.A.; Cunha, S.S.; Gomes, G.F. Lichtenberg algorithm: A novel hybrid PHYSICS-based metaheuristic for global optimization. Expert Syst. Appl. 2021, 170, 114522. [Google Scholar] [CrossRef]

- Pereira, J.L.J.; Chuman, M.; Cunha, S.S., Jr.; Gomes, G.F. Lichtenberg optimization algorithm applied to crack tip identification in thin platelike structures. Eng. Comput. 2021, 38, 151–166. [Google Scholar] [CrossRef]

- Pereira, J.; Francisco, M.B.; Cunha, S.S., Jr.; Gomes, G.F. A powerful Lichtenberg optimization algorithm: A damage identification case study. Eng. Appl. Artif. Intell. 2021, 97, 104055. [Google Scholar] [CrossRef]

- Francisco, M.B.; Junqueira, D.M.; Oliver, G.A.; Pereira, J.L.J.; da Cunha, S.S., Jr.; Gomes, G.F. Design optimizations of carbon fibre reinforced polymer isogrid lower limb prosthesis using particle swarm optimization and Lichtenberg algorithm. Eng. Optim. 2021, 53, 1922–1945. [Google Scholar] [CrossRef]

- Allaou, B.; Asnoune, K.; Mebarki, B. Energy management of PEM fuel cell/supercapacitor hybrid power sources for an electric vehicle. Int. J. Hydrogen Energy 2017, 42, 21158–21166. [Google Scholar] [CrossRef]

- El-Hay, E.A.; El-Hameed, M.A.; El-Fergany, A.A. Performance enhancement of autonomous system comprising proton exchange membrane fuel cells and switched reluctance motor. Energy 2018, 163, 699–711. [Google Scholar] [CrossRef]

- Fathabadi, H. Novel fuel cell/battery/supercapacitor hybrid power source for fuel cell hybrid electric vehicles. Energy 2018, 143, 467–477. [Google Scholar] [CrossRef]

- Odeim, F.; Roes, J.; Heinzel, A. Power Management Optimization of a Fuel Cell/Battery/Supercapacitor Hybrid System for Transit Bus Applications. IEEE Trans. Veh. Technol. 2016, 65, 5783–5788. [Google Scholar] [CrossRef]

- El-Hay, E.A.; El-Hameed, M.A.; El-Fergany, A.A. Improved performance of PEM fuel cells stack feeding switched reluctance motor using multi-objective dragonfly optimizer. Neural Comput. Appl. 2019, 31, 6909–6924. [Google Scholar] [CrossRef]

- Oldham, K.B. A Gouy-Chapman-Stern model of the double layer at a (metal)/(ionic liquid) interface. J. Electroanal. Chem. 2008, 613, 131–138. [Google Scholar] [CrossRef]

- Xu, N.; Riley, J. Nonlinear analysis of a classical system: The double-layer capacitor. Electrochem. Commun. 2011, 13, 1077–1081. [Google Scholar] [CrossRef]

- Omar, N.; Monem, M.A.; Firouz, Y.; Salminen, J.; Smekens, J.; Hegazy, O.; Gaulous, H.; Mulder, G.; Van Den Bossche, P.; Coosemans, T.; et al. Lithium iron phosphate based battery—Assessment of the aging parameters and development of cycle life model. Appl. Energy 2014, 113, 1575–1585. [Google Scholar] [CrossRef]

- Saw, L.H.; Somasundaram, K.; Ye, Y.; Tay, A.A.O. Electro-thermal analysis of Lithium Iron Phosphate battery for electric vehicles. J. Power Sources 2014, 249, 231–238. [Google Scholar] [CrossRef]

- Tremblay, O.; Dessaint, L.A. Experimental Validation of a Battery Dynamic Model for EV Applications. World Electr. Veh. J. 2009, 3, 289–298. [Google Scholar] [CrossRef]

- Zhu, C.; Li, X.; Song, L.; Xiang, L. Development of a theoretically based thermal model for lithium-ion battery pack. J. Power Sources 2013, 223, 155–164. [Google Scholar] [CrossRef]

- Witten, T.A.; Sander, L.M. Diffusion-limited aggregation: A kinetic critical phenomenon. Phys. Rev. Lett. 1981, 47, 1400–1403. [Google Scholar] [CrossRef]

- Witten, T.A.; Sander, L.M. Diffusion-limited aggregation. Phys. Rev. Lett. 1983, 27, 5686–5697. [Google Scholar] [CrossRef]

- Huang, C.L.; Yoon, K. Multi Attribute Decision Making: Methods and Applications; Springer: New York, NY, USA, 1981. [Google Scholar]

- Kaya, T.; Kahraman, C. Multicriteria decision making in energy planning using a modified fuzzy TOPSIS methodology. Expert Syst. Appl. 2011, 38, 6577–6585. [Google Scholar] [CrossRef]

- Cristobal, S.; Ramon, J. Multi-Criteria Analysis in the Renewable Energy Industry, Green Energy and Technology; Springer: London, UK, 2012. [Google Scholar]

- Kennedy, J.; Eberhart, R. Particle Swarm Optimization. In Proceedings of the IEEE International Conference on Neural Networks IV, Perth, WA, Australia, 27 November–1 December 1995; pp. 1942–1948. [Google Scholar] [CrossRef]

- Salimi, H. Stochastic fractal search: A powerful metaheuristic algorithm. Knowl.-Based Syst. 2015, 75, 1–18. [Google Scholar] [CrossRef]

- Mirjalili, S. Dragonfly Algorithm: A New Meta-heuristic Optimization Technique for Solving Single-objective, Discrete, and Multi-objective Problems. Neural Comput. Appl. 2015, 27, 1053–1073. [Google Scholar] [CrossRef]

| Torque (Nm) | 10 | 15 | 20 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Speed (rpm) | 1000 | 1500 | 2000 | 1000 | 1500 | 2000 | 1000 | 1500 | 2000 | |

| (Degree) | PSO | 48.1794 | 44.0915 | 50.2228 | 43.9880 | 46.3924 | 45.9370 | 47.0776 | 43.6093 | 49.7966 |

| SFS | 48.4703 | 44.0165 | 47.9042 | 49.2470 | 43.3923 | 48.9389 | 48.2005 | 44.2624 | 49.7966 | |

| (Degree) | PSO | 78.2242 | 82.5960 | 82.7097 | 82.9534 | 77.6847 | 76.8664 | 77.4199 | 79.9288 | 79.7495 |

| SFS | 78.8795 | 77.3748 | 79.1520 | 79.8030 | 76.5849 | 78.9234 | 78.6596 | 78.8998 | 84.3889 | |

| PSO | 0.4666 | 0.2180 | 0.3092 | 0.1984 | 0.0000 | 0.4073 | 0.0000 | 0.1170 | 0.2954 | |

| SFS | 0.0148 | 0.2278 | 0.2679 | 0.1118 | 0.1696 | 0.2330 | 0.2373 | 0.3616 | 0.1482 | |

| PSO | 579.5989 | 445.6444 | 349.2389 | 419.5363 | 440.9503 | 536.6692 | 573.3328 | 464.2013 | 563.5176 | |

| SFS | 568.2403 | 464.2483 | 373.9740 | 517.7874 | 369.5236 | 494.6761 | 381.6491 | 440.2 | 491.1486 | |

| PSO | 1.2223 | 1.1527 | 1.0563 | 0.9974 | 0.9168 | 2.5242 | 0.8352 | 0.8504 | 2.2950 | |

| SFS | 1.4693 | 1.1432 | 1.0402 | 0.9889 | 0.9255 | 2.4133 | 0.83402 | 0.84622 | 2.3742 | |

| Torque (Nm) | 10 | 15 | 20 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Speed (rpm) | 1000 | 1500 | 2000 | 1000 | 1500 | 2000 | 1000 | 1500 | 2000 | |

| (Degree) | PSO | 46.5105 | 44.7474 | 47.6361 | 44.3281 | 44.0866 | 46.3099 | 45.8386 | 47.6287 | 47.0839 |

| SFS | 46.3317 | 47.5369 | 49.1804 | 45.4132 | 45.5096 | 47.4479 | 46.6104 | 48.1237 | 46.2041 | |

| (Degree) | PSO | 82.6337 | 75.4941 | 78.6817 | 84.9404 | 75.0000 | 80.9261 | 76.0351 | 82.5000 | 76.5700 |

| SFS | 81.2462 | 75.1389 | 79.5597 | 75.9803 | 75.6942 | 79.2000 | 76.9706 | 78.7294 | 84.8362 | |

| PSO | 0.3871 | 0.4876 | 0.3732 | 0.0061 | 0.0084 | 0.5000 | 0.4023 | 0.5000 | 0.0531 | |

| SFS | 0.3844 | 0.4602 | 0.2238 | 0.1769 | 0.1717 | 0.2524 | 0.3910 | 0.0987 | 0.2533 | |

| PSO | 323.6789 | 446.7317 | 404.2172 | 312.5365 | 396.2236 | 313.2306 | 306.3635 | 300.1970 | 348.7012 | |

| SFS | 357.483 | 394.3156 | 347.3662 | 325.8527 | 362.9984 | 303.8323 | 383.3297 | 309.6486 | 691.3157 | |

| PSO | 0.2148 | 0.2444 | 0.0851 | 0.2700 | 0.0968 | 0.5155 | 0.1583 | 0.5176 | 9.5034 | |

| SFS | 0.24242 | 0.23738 | 0.0847 | 0.2383 | 0.0977 | 0.4896 | 0.1708 | 0.5041 | 7.9081 | |

| Torque (Nm) | 10 | 15 | 20 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Speed (rpm) | 1000 | 1500 | 2000 | 1000 | 1500 | 2000 | 1000 | 1500 | 2000 | |

| (Degree) | PSO | 44.0974 | 42.8785 | 44.5896 | 40.1379 | 46.7143 | 46.0109 | 38.7612 | 48.7787 | 48.4775 |

| SFS | 40.8703 | 48.8952 | 42.6167 | 42.2230 | 46.3249 | 48.5282 | 50.7953 | 49.5963 | 49.8022 | |

| (Degree) | PSO | 86.9698 | 84.6344 | 81.9696 | 78.9839 | 83.1027 | 81.4362 | 75.5156 | 85.4630 | 87.1308 |

| SFS | 76.3039 | 87.2697 | 79.1404 | 76.9762 | 75.6533 | 79.8604 | 76.0858 | 79.9741 | 83.3693 | |

| PSO | 0.0511 | 0.0220 | 0.4049 | 0.1993 | 0.1248 | 0.2529 | 0.2835 | 0.1247 | 0.0000 | |

| SFS | 0.1929 | 0.3093 | 0.1480 | 0.2945 | 0.1419 | 0.1823 | 0.3686 | 0.2858 | 0.1263 | |

| PSO | 333.0230 | 440.0060 | 654.9691 | 517.9592 | 350.0524 | 485.9360 | 601.6650 | 598.2038 | 319.5331 | |

| SFS | 328.7698 | 369.4885 | 602.4511 | 323.3124 | 374.8419 | 616.4534 | 336.7534 | 470.3064 | 379.4838 | |

| PSO | 2.2592 | 1.7257 | 0.0006 | 1.8556 | 0.3528 | 0.0010 | 0.8150 | 0.0010 | 0.0010 | |

| SFS | 2.2568 | 1.6606 | 0.0006 | 1.7955 | 0.32622 | 0.0010 | 0.7620 | 0.0011 | 0.0010 | |

| Item | Present Paper | Ref. [36] | Ref. [39] | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Objectives |

|

|

| ||||||

| Decision variables |

|

|

| ||||||

| 1000 rpm | RFT | RFV | RFI | TAR | TSF | ηstack % | TAR | TSF | AST |

| 1.2223 | 0.2715 | 2.4549 | 1.5 | 0.25 | 78.14 | 0.6258 | 0.2630 | 46.4432 | |

| 1.3729 | 0.2148 | 2.3886 | 0.95 | 1.22 | 77.25 | 0.5596 | 1.7848 | 61.1050 | |

| 1.2376 | 0.2310 | 2.2592 | 1.33 | 0.36 | 79.92 | Not mentioned | |||

| 1500 rpm | 1.1527 | 0.2763 | 1.8499 | 1.54 | 0.21 | 77.29 | 0.6339 | 0.4138 | 38.8810 |

| 1.1635 | 0.2444 | 1.7904 | 0.99 | 1.29 | 77.13 | 0.5570 | 1.8152 | 63.6280 | |

| 1.2517 | 0.2677 | 1.7257 | 1.56 | 0.24 | 79.33 | Not mentioned | |||

| 2000 rpm | 1.0563 | 0.1083 | 0.3208 | 1.63 | 0.3 | 50.02 | 0.6968 | 0.3456 | 34.2097 |

| 1.0464 | 0.0851 | 0.4116 | 1.05 | 1.4 | 76.07 | 0.6033 | 1.8508 | 45.2680 | |

| 2.5360 | 0.6002 | 0.0006 | 1.57 | 0.32 | 79.12 | Not mentioned | |||

| Torque (Nm) | 10 | 15 | 20 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Speed (rpm) | 1000 | 1500 | 2000 | 1000 | 1500 | 2000 | 1000 | 1500 | 2000 | |

| (Degree) | MOLA | 50.2129 | 43.6179 | 47.7404 | 45.5964 | 46.2022 | 46.2093 | 47.8512 | 46.0233 | 51.4311 |

| MODF | 45.8152 | 45.7067 | 49.6368 | 44.5407 | 46.4487 | 47.6000 | 51.5000 | 42.4000 | 47.6000 | |

| (Degree) | MOLA | 81.4281 | 75.3121 | 77.9918 | 75.9503 | 75.4744 | 83.3829 | 77.2934 | 80.6653 | 85.7743 |

| MODF | 76.0297 | 76.6507 | 87.8713 | 75.6301 | 76.9075 | 84.7944 | 82.5602 | 79.6086 | 83.6344 | |

| MOLA | 0.5000 | 0.1955 | 0.0312 | 0.0556 | 0.3521 | 0.000 | 0.3091 | 0.4038 | 0.5000 | |

| MODF | 0.0167 | 0.0106 | 0.0200 | 0.0000 | 0.0200 | 0.0200 | 0.0000 | 0.0000 | 0.0131 | |

| MOLA | 300.0000 | 300.0000 | 347.2399 | 456.2041 | 300.0000 | 596.3592 | 316.6290 | 566.9783 | 402.0087 | |

| MODF | 523.4516 | 465.9377 | 491.9917 | 514.0998 | 490.3249 | 524.7088 | 499.0793 | 475.2724 | 520.7434 | |

| MOLA | 1.4404 | 1.1833 | 1.1670 | 1.0503 | 1.1680 | 2.2522 | 1.1198 | 2.2790 | 2.8467 | |

| MODF | 1.2459 | 1.1282 | 2.6111 | 1.0621 | 0.9643 | 2.2927 | 0.8408 | 0.8865 | 2.0465 | |

| MOLA | 0.2123 | 0.2206 | 0.0934 | 0.2835 | 0.1019 | 9.2342 | 0.1325 | 7.4774 | 13.7054 | |

| MODF | 0.2453 | 0.0934 | 8.7782 | 0.1631 | 0.4460 | 8.9843 | 0.1703 | 0.3889 | 12.2459 | |

| MOLA | 2.2665 | 1.5870 | 0.3055 | 1.9157 | 0.3243 | 0.0011 | 0.5814 | 0.0013 | 0.0010 | |

| MODF | 2.0530 | 0.4525 | 0.0011 | 1.1679 | 1.9105 | 0.0011 | 0.7840 | 1.2361 | 0.0011 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El-Hameed, M.A.; Saeed, M.; Kabbani, A.; El-Hay, E.A. Enhancing Performance of PEM Fuel Cell Powering SRM System Using Metaheuristic Optimization. Energies 2025, 18, 2004. https://doi.org/10.3390/en18082004

El-Hameed MA, Saeed M, Kabbani A, El-Hay EA. Enhancing Performance of PEM Fuel Cell Powering SRM System Using Metaheuristic Optimization. Energies. 2025; 18(8):2004. https://doi.org/10.3390/en18082004

Chicago/Turabian StyleEl-Hameed, Mohamed A., Mahfouz Saeed, Adnan Kabbani, and Enas Abd El-Hay. 2025. "Enhancing Performance of PEM Fuel Cell Powering SRM System Using Metaheuristic Optimization" Energies 18, no. 8: 2004. https://doi.org/10.3390/en18082004

APA StyleEl-Hameed, M. A., Saeed, M., Kabbani, A., & El-Hay, E. A. (2025). Enhancing Performance of PEM Fuel Cell Powering SRM System Using Metaheuristic Optimization. Energies, 18(8), 2004. https://doi.org/10.3390/en18082004