Solar Panel Waste Management: Challenges, Opportunities, and the Path to a Circular Economy

Abstract

1. Introduction

2. Methodology

3. Results

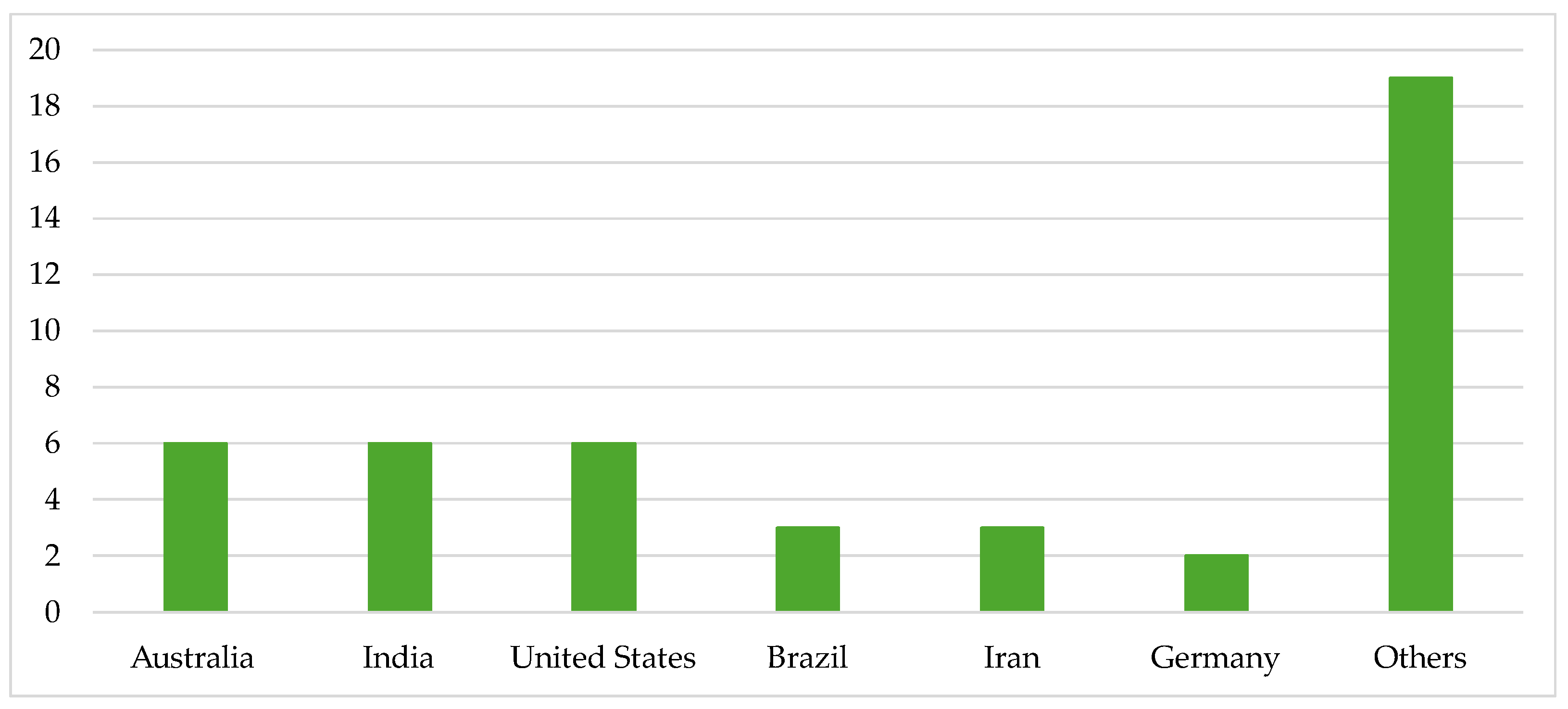

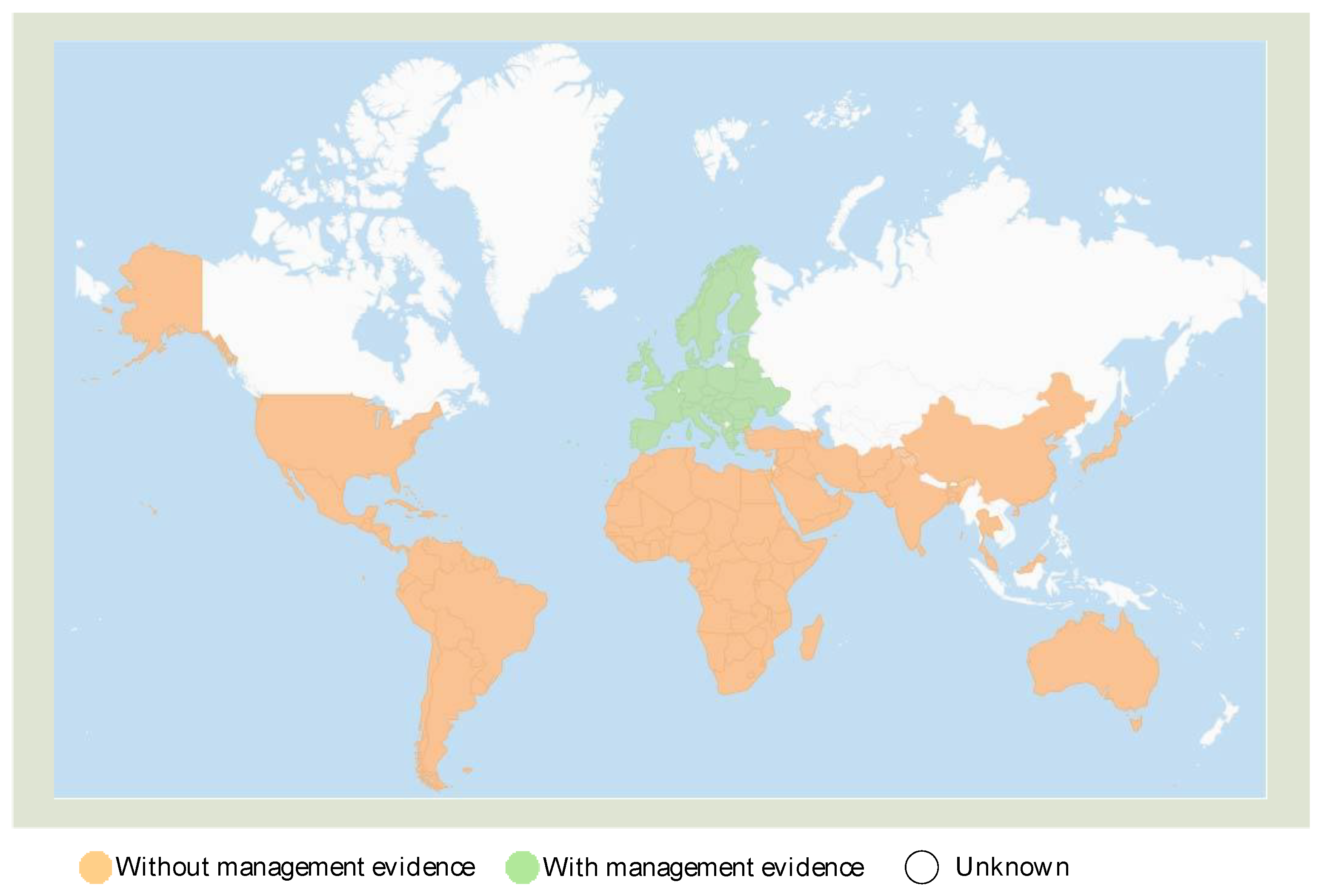

3.1. Descriptive Analysis of Selected Publications

3.2. Results of the Literature Review

What Is the Solar Panel Supply Chain?

| Link | Activities | References |

|---|---|---|

| Upstream | Silica extraction | [23,24,26] |

| Solar grade silicon production | [23,24,25,26] | |

| Silicon ingots | ||

| Silicon wafers | ||

| Production of steel, aluminum, glass, encapsulant film, and others | [23,24,26] | |

| Cell production | [26,27,28,29] | |

| Module production | ||

| Balance of system production | [27,28] | |

| Research and development | [28] | |

| Photovoltaic system installation |

| Link | Activities | References |

|---|---|---|

| Midstream Core | Cell production | [23,24] |

| Manufacture of cables, frames, sealants, junction box | ||

| Module production | ||

| Balance of system production | [23,25,26] | |

| Project development | [25] | |

| Photovoltaic system installation | [25,26] | |

| Operation and maintenance | ||

| System deactivation | [26] | |

| Business model operation | [28] |

| Link | Activities | References |

|---|---|---|

| Downstream | Project development | [23,27,29] |

| Photovoltaic system installation | [23,24,27] | |

| Operation and maintenance | [6] | |

| System deactivation | [25,28,29] | |

| Research and development | [27] |

| Link | Activities | References |

|---|---|---|

| Auxiliary | Project development | [28] |

| Marketing and sales | [19,20,28] | |

| Customer service | ||

| Financing and insurance | ||

| Government support | [19,20] | |

| Assistance from associations and interest organizations | ||

| Legal assistance | ||

| Research and development | ||

| Human resources | ||

| Transportation and logistics | ||

| Commissioning services |

3.3. What Waste Is Produced in the Solar Panel Supply Chain and How Is It Managed?

3.3.1. Types of Waste in the Solar Panel Supply Chain

3.3.2. Types of Waste Management in the Solar Panel Supply Chain

3.3.3. Trends in Research and Waste Management in the Solar Panel Supply Chain

3.3.4. What Opportunities Are There in the Waste Management of the Solar Panel Supply Chain?

Recycle

Recover

Reuse

Reduce

Repair

Refine

4. Discussion

5. Conclusions

6. Future Potential Research Directions

- Enhancing High-Value Recycling Technologies: Examining efficient and economical techniques for the extraction and reprocessing of valuable materials from retired solar panels.

- Policy and Regulatory Frameworks: Assessing the efficacy of current policies across various locations and recommending standardized international regulations for the management of solar panel trash.

- Innovative Commercial Models: Investigating circular economy-oriented commercial ideas, including solar panel leasing, buyback initiatives, and second-life applications for utilized photovoltaic modules.

- Technological Advancements in Eco-Design: Promoting the creation of modular and recyclable panel designs that enable simpler disassembly and material retrieval.

- Lifecycle Assessments: Performing thorough environmental impact evaluations to compare various waste management scenarios and determine the most sustainable alternatives.

- Socioeconomic Implications: Evaluating the employment generation potential and economic advantages of a robust solar waste treatment sector, especially in developing economies.

- Economic Impacts: determining the costs of recycling, how they impact energy production, and the costs of the supply chain.

- By focusing on these aspects, researchers and industry leaders may advance the establishment of a genuinely sustainable solar energy sector, guaranteeing that the advantages of photovoltaics are not undermined by their enduring waste issues. The shift to a circular economy model in solar energy will diminish environmental impacts and generate new economic opportunities, enhancing the industry’s resilience and sustainability in the future.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Motamedisedeh, O.; Omrani, S.; Karim, A.; Drogemuller, R.; Walker, G. A Comprehensive Review of Optimum Integration of Photovoltaic-Based Energy Systems. Renew. Sustain. Energy Rev. 2024, 207, 114935. [Google Scholar] [CrossRef]

- International Energy Agency—IEA. Renewables 2023—Analysis and Forecast to 2028; International Energy Agency: Paris, France, 2024. [Google Scholar]

- Izam, N.S.M.N.; Itam, Z.; Sing, W.L.; Syamsir, A. Sustainable Development Perspectives of Solar Energy Technologies with Focus on Solar Photovoltaic—A Review. Energies 2022, 15, 2790. [Google Scholar] [CrossRef]

- Diwania, S.; Agrawal, S.; Siddiqui, A.S.; Singh, S. Photovoltaic–Thermal (PV/T) Technology: A Comprehensive Review on Applications and Its Advancement. Int. J. Energy Environ. Eng. 2020, 11, 33–54. [Google Scholar] [CrossRef]

- International Renewable Energy Agency (IRENA). Renewable Capacity Statistics 2023 Statistiques de Capacité Renouvelable 2023 Estadísticas de Capacidad Renovable 2023 About Irena; International Renewable Energy Agency: Masdar City, United Arab Emirates, 2023; ISBN 978-92-9260-525-4. [Google Scholar]

- Ukoba, K.; Yoro, K.O.; Eterigho-Ikelegbe, O.; Ibegbulam, C.; Jen, T.C. Adaptation of Solar Energy in the Global South: Prospects, Challenges and Opportunities. Heliyon 2024, 10, e28009. [Google Scholar]

- Sequeira, T.N.; Santos, M.S. Renewable Energy and Politics: A Systematic Review and New Evidence. J. Clean. Prod. 2018, 192, 553–568. [Google Scholar] [CrossRef]

- Rabaia, M.K.H.; Shehata, N.; Olabi, V.; Abdelkareem, M.A.; Semeraro, C.; Chae, K.J.; Sayed, E.T. Enabling the Circular Economy of Solar PV through the 10Rs of Sustainability: Critical Review, Conceptualization, Barriers, and Role in Achieving SDGs. Sustain. Horiz. 2024, 11, 100106. [Google Scholar]

- Amrollahi Biyouki, Z.; Zaman, A.; Marinova, D.; Minunno, R.; Askari Shayegan, M. Solar Photovoltaics Value Chain and End-of-Life Management Practices: A Systematic Literature Review. Sustainability 2024, 16, 7038. [Google Scholar] [CrossRef]

- Song, G.; Lu, Y.; Liu, B.; Duan, H.; Feng, H.; Liu, G. Photovoltaic Panel Waste Assessment and Embodied Material Flows in China, 2000–2050. J. Environ. Manag. 2023, 338, 117675. [Google Scholar] [CrossRef]

- Rahman, M.M.; Chowdhury, F.N. Recycling of Solar PV Panels in Bangladesh along with South and South East Asia. Curr. Opin. Green Sustain. Chem. 2023, 44, 100862. [Google Scholar]

- Aşkın, A.; Kılkış, S.; Akınoğlu, B.G. Recycling Photovoltaic Modules within a Circular Economy Approach and a Snapshot for Türkiye. Renew. Energy 2023, 208, 583–596. [Google Scholar] [CrossRef]

- Yang, H.L.; Liu, I.T.; Liu, C.E.; Hsu, H.P.; Lan, C.W. Recycling and Reuse of Kerf-Loss Silicon from Diamond Wire Sawing for Photovoltaic Industry. Waste Manag. 2019, 84, 204–210. [Google Scholar] [CrossRef] [PubMed]

- Mathur, D.; Gregory, R.; Hogan, E. Do Solar Energy Systems Have a Mid-Life Crisis? Valorising Renewables and Ignoring Waste in Regional Towns in Australia’s Northern Territory. Energy Res. Soc. Sci. 2021, 76, 101934. [Google Scholar] [CrossRef]

- IEA. Special Report on Solar PV Global Supply Chains; IEA: Paris, France, 2022. [Google Scholar]

- Gan, P.Y.; Li, Z.D. Quantitative Study on Long Term Global Solar Photovoltaic Market. Renew. Sustain. Energy Rev. 2015, 46, 88–99. [Google Scholar] [CrossRef]

- Ndzibah, E.; Pinilla-De La Cruz, G.A.; Shamsuzzoha, A. Collaboration towards Value Creation for End-of-Life Solar Photovoltaic Panel in Ghana. J. Clean. Prod. 2022, 333, 129969. [Google Scholar] [CrossRef]

- Wardal, W.J.; Mazur, K.; Barwicki, J.; Tseyko, M. Fundamental Barriers to Green Energy Production in Selected EU Countries. Energies 2024, 17, 3664. [Google Scholar] [CrossRef]

- Guerin, T.F. Evaluating Treatment Pathways for Managing Packaging Materials from Construction of a Solar Photovoltaic Power Station. Waste Manag. Res. 2020, 38, 1345–1357. [Google Scholar] [CrossRef]

- Singh, S.; Powar, S.; Dhar, A. End of Life Management of Crystalline Silicon and Cadmium Telluride Photovoltaic Modules Utilising Life Cycle Assessment. Resour. Conserv. Recycl. 2023, 197, 107097. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, J.; Baskaran, S.; Imhoff, C.H.; Holladay, J.D. Enabling Renewable Energy—And the Future Grid—With Advanced Electricity Storage. JOM 2010, 62, 14–23. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, n71. [Google Scholar]

- Bisognin Garlet, T.; Duarte Ribeiro, J.L.; de Souza Savian, F.; Mairesse Siluk, J.C. Competitiveness of the Value Chain of Distributed Generation of Photovoltaic Energy in Brazil. Energy Sustain. Dev. 2022, 71, 447–461. [Google Scholar] [CrossRef]

- Garlet, T.B.; Ribeiro, J.L.D.; de Souza Savian, F.; Siluk, J.C.M. Value Chain in Distributed Generation of Photovoltaic Energy and Factors for Competitiveness: A Systematic Review. Sol. Energy 2020, 211, 396–411. [Google Scholar]

- Davy, E.; Hansen, U.E.; Nygaard, I. Localizing the Solar Value Chain in Kenya? Innov. Dev. 2022, 14, 217–240. [Google Scholar]

- Nyffenegger, R.; Boukhatmi, Ä.; Radavičius, T.; Tvaronavičienė, M. How Circular Is the European Photovoltaic Industry? Practical Insights on Current Circular Economy Barriers, Enablers, and Goals. J. Clean. Prod. 2024, 448, 141376. [Google Scholar] [CrossRef]

- Almarshoud, A.F.; Adam, E. A Transition toward Localizing the Value Chain of Photovoltaic Energy in Saudi Arabia. Clean Technol. Environ. Policy 2021, 23, 2049–2059. [Google Scholar]

- Franco, M.A.; Groesser, S.N. A Systematic Literature Review of the Solar Photovoltaic Value Chain for a Circular Economy. Sustainability 2021, 13, 9615. [Google Scholar] [CrossRef]

- Birlain-Escalante, M.O.; Islas-Samperio, J.M.; de la Vega-Navarro, Á.; Morales-Acevedo, A. Development and Upstream Integration of the Photovoltaic Industry Value Chain in Mexico. Energies 2023, 16, 2072. [Google Scholar] [CrossRef]

- Udayakumar, M.D.; Anushree, G.; Sathyaraj, J.; Manjunathan, A. The Impact of Advanced Technological Developments on Solar PV Value Chain. Mater. Today Proc. 2021, 45, 2053–2058. [Google Scholar] [CrossRef]

- Sandor, D.; Fulton, S.; Engel-Cox, J.; Peck, C.; Peterson, S. System Dynamics of Polysilicon for Solar Photovoltaics: A Framework for Investigating the Energy Security of Renewable Energy Supply Chains. Sustainability 2018, 10, 160. [Google Scholar] [CrossRef]

- Kousha, A.; Rahmani, D.; Dehghani, E. Designing a Competitive Photovoltaic Supply Chain Under Uncertainty: An Efficient L-Shape Algorithm. J. Clean. Prod. 2024, 434, 140113. [Google Scholar] [CrossRef]

- IEA. Pvp Snapshot of Global PV Markets 2020; IEA: Paris, France, 2020; pp. 1–16. Available online: https://iea-pvps.org/ (accessed on 1 January 2020).

- Zeng, B.; Fahad, S.; Bai, D.; Zhang, J.; Işık, C. Assessing the Sustainability of Natural Resources Using the Five Forces and Value Chain Combined Models: The Influence of Solar Energy Development. Resour. Policy 2023, 86, 104079. [Google Scholar] [CrossRef]

- Gan, Y.; Elgowainy, A.; Lu, Z.; Kelly, J.C.; Wang, M.; Boardman, R.D.; Marcinkoski, J. Greenhouse Gas Emissions Embodied in the U.S. Solar Photovoltaic Supply Chain. Environ. Res. Lett. 2023, 18, 104012. [Google Scholar] [CrossRef]

- Chang, N.L.; Dehghanimadvar, M.; Egan, R. The Cost of Risk Mitigation—Diversifying the Global Solar PV Supply Chain. Joule 2022, 6, 2686–2688. [Google Scholar]

- Gautam, A.; Shankar, R.; Vrat, P. Managing End-of-Life Solar Photovoltaic e-Waste in India: A Circular Economy Approach. J. Bus. Res. 2022, 142, 287–300. [Google Scholar] [CrossRef]

- Tembo, P.M.; Subramanian, V. Current Trends in Silicon-Based Photovoltaic Recycling: A Technology, Assessment, and Policy Review. Sol. Energy 2023, 259, 137–150. [Google Scholar]

- Maybury, L.; Corcoran, P.; Cipcigan, L. Mathematical Modelling of Electric Vehicle Adoption: A Systematic Literature Review. Transp. Res. D Transp. Environ. 2022, 107, 103278. [Google Scholar] [CrossRef]

- IRENA. End of Life Management Solar Photovoltaic Panels. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2016/IRENA_IEAPVPS_End-of-Life_Solar_PV_Panels_2016.pdf (accessed on 24 March 2025).

- Sovacool, B.K.; Agostino, A.L.D.; Bambawale, M.J. The Socio-Technical Barriers to Solar Home Systems (SHS) in Papua New Guinea: “Choosing Pigs, Prostitutes, and Poker Chips over Panels”. Energy Policy 2011, 39, 1532–1542. [Google Scholar] [CrossRef]

- Bartie, N.J.; Cobos-Becerra, Y.L.; Fröhling, M.; Schlatmann, R.; Reuter, M.A. The Resources, Exergetic and Environmental Footprint of the Silicon Photovoltaic Circular Economy: Assessment and Opportunities. Resour. Conserv. Recycl. 2021, 169, 105516. [Google Scholar] [CrossRef]

- Xiong, Y.; Yang, X. Government Subsidies for the Chinese Photovoltaic Industry. Energy Policy 2016, 99, 111–119. [Google Scholar] [CrossRef]

- Irena. Irena Cost and Competitiveness Indicators Rooftop Solar PV; Irena: Masdar City, United Arab Emirates, 2017. [Google Scholar]

- Mathur, N.; Singh, S.; Sutherland, J.W. Promoting a Circular Economy in the Solar Photovoltaic Industry Using Life Cycle Symbiosis. Resour. Conserv. Recycl. 2020, 155, 104649. [Google Scholar] [CrossRef]

- De Sousa, N.M.; Oliveira, C.B.; Cunha, D. Photovoltaic Electronic Waste in Brazil: Circular Economy Challenges, Potential and Obstacles. Social. Sci. Humanit. Open 2023, 7, 100456. [Google Scholar]

- Brandt, A.R.; Plevin, R.J.; Farrell, A.E. Dynamics of the Oil Transition: Modeling Capacity, Depletion, and Emissions. Energy 2010, 35, 2852–2860. [Google Scholar] [CrossRef]

- Nili, M.; Seyedhosseini, S.M.; Jabalameli, M.S.; Dehghani, E. A Multi-Objective Optimization Model to Sustainable Closed-Loop Solar Photovoltaic Supply Chain Network Design: A Case Study in Iran. Renew. Sustain. Energy Rev. 2021, 150, 111428. [Google Scholar] [CrossRef]

- IRENA. Renewable Energy Statistics 2024 Statistiques D’énergie Renouvelable 2024 Estadísticas de Energía Renovable 2024; IRENA: Masdar City, United Arab Emirates, 2024; ISBN 9789292606145. [Google Scholar]

- Shahsavari, A.; Akbari, M. Potential of Solar Energy in Developing Countries for Reducing Energy-Related Emissions. Renew. Sustain. Energy Rev. 2018, 90, 275–291. [Google Scholar] [CrossRef]

- IEA. Annual Energy Outlook 2024; IEA: Paris, France, 2024; Available online: https://www.iea.org/reports/world-energy-outlook-2024 (accessed on 6 July 2024).

- Shahbazbegian, V.; Hosseini-Motlagh, S.M.; Haeri, A. Integrated Forward/Reverse Logistics Thin-Film Photovoltaic Power Plant Supply Chain Network Design with Uncertain Data. Appl. Energy 2020, 277, 115538. [Google Scholar] [CrossRef]

- Al-Aqqad, A.O.G.; Menyhart, J. Solar Panels Problem After End-of-Life and Waste Management (SWOT Analysis for the Global Directives of PV’s Waste Management). Int. Rev. Appl. Sci. Eng. 2023, 14, 220–229. [Google Scholar] [CrossRef]

- Sheoran, M.; Kumar, P.; Sharma, S.; Bukya, M. Current Situation Analysis of Solar PV Waste Management in India. Mater. Today Proc. 2022, 58, 773–782. [Google Scholar]

- Schumacher, K.; Yang, Z. The Determinants of Wind Energy Growth in the United States: Drivers and Barriers to State-Level Development. Renew. Sustain. Energy Rev. 2018, 97, 1–13. [Google Scholar] [CrossRef]

- Khawaja, M.K.; Ghaith, M.; Alkhalidi, A. Public-Private Partnership Versus Extended Producer Responsibility for End-of-Life of Photovoltaic Modules Management Policy. Sol. Energy 2021, 222, 193–201. [Google Scholar] [CrossRef]

- Das, P.; Mathuria, P.; Bhakar, R.; Mathur, J.; Kanudia, A.; Singh, A. Flexibility Requirement for Large-Scale Renewable Energy Integration in Indian Power System: Technology, Policy and Modeling Options. Energy Strategy Rev. 2020, 29, 100482. [Google Scholar] [CrossRef]

- Jain, S.; Sharma, T.; Gupta, A.K. End-of-Life Management of Solar PV Waste in India: Situation Analysis and Proposed Policy Framework. Renew. Sustain. Energy Rev. 2022, 153, 111774. [Google Scholar] [CrossRef]

- Farrell, C.C.; Osman, A.I.; Doherty, R.; Saad, M.; Zhang, X.; Murphy, A.; Harrison, J.; Vennard, A.S.M.; Kumaravel, V.; Al-Muhtaseb, A.H.; et al. Technical Challenges and Opportunities in Realising a Circular Economy for Waste Photovoltaic Modules. Renew. Sustain. Energy Rev. 2020, 128, 109911. [Google Scholar]

- Oteng, D.; Zuo, J.; Sharifi, E. An Expert-Based Evaluation on End-of-Life Solar Photovoltaic Management: An Application of Fuzzy Delphi Technique. Sustain. Horiz. 2022, 4, 100036. [Google Scholar] [CrossRef]

- IEA. Trends 2015 in Photovoltaic Applications; IEA: Paris, France, 2015. [Google Scholar]

- D’Adamo, I.; Ferella, F.; Gastaldi, M.; Ippolito, N.M.; Rosa, P. Circular Solar: Evaluating the Profitability of a Photovoltaic Panel Recycling Plant. Waste Manag. Res. 2023, 41, 1144–1154. [Google Scholar] [PubMed]

- Karmellos, M.; Kosmadakis, V.; Dimas, P.; Tsakanikas, A.; Fylaktos, N.; Taliotis, C.; Zachariadis, T. A Decomposition and Decoupling Analysis of Carbon Dioxide Emissions from Electricity Generation: Evidence from the EU-27 and the UK. Energy 2021, 231, 120861. [Google Scholar] [CrossRef]

- Mahmoudi, S.; Huda, N.; Behnia, M. Critical Assessment of Renewable Energy Waste Generation in OECD Countries: Decommissioned PV Panels. Resour. Conserv. Recycl. 2021, 164, 105145. [Google Scholar] [CrossRef]

- Rahmandad, H.; Sterman, J. Heterogeneity and Network Structure in the Dynamics of Diffusion: Comparing Agent-Based and Differential Equation Models. Manag. Sci. 2008, 54, 998–1014. [Google Scholar]

- Hong, S.; Yang, T.; Chang, H.J.; Hong, S. The Effect of Switching Renewable Energy Support Systems on Grid Parity for Photovoltaics: Analysis Using a Learning Curve Model. Energy Policy 2020, 138, 111233. [Google Scholar] [CrossRef]

- Hedman, Å.; Sepponen, M.; Virtanen, M. Energy Efficiency Rating of Districts, Case Finland. Energy Policy 2014, 65, 408–418. [Google Scholar] [CrossRef]

- IEA. IEA Atlas of Energy. Available online: https://www.iea.org/events/atlas-of-energy-efficiency-brazil-2020-main-findings (accessed on 6 July 2018).

- Kim, S.; Jeong, B. Closed-Loop Supply Chain Planning Model for a Photovoltaic System Manufacturer with Internal and External Recycling. Sustainability 2016, 8, 596. [Google Scholar] [CrossRef]

- Van Opstal, W.; Smeets, A. Circular Economy Strategies as Enablers for Solar PV Adoption in Organizational Market Segments. Sustain. Prod. Consum. 2023, 35, 40–54. [Google Scholar] [CrossRef]

- Mulvaney, D.; Bazilian, M. Price Volatility, Human Rights, and Decarbonization Challenges in Global Solar Supply Chains. Energy Res. Soc. Sci. 2023, 102, 103167. [Google Scholar]

- Li, D.; Zouma, A.; Liao, J.T.; Yang, H.T. An Energy Management Strategy with Renewable Energy and Energy Storage System for a Large Electric Vehicle Charging Station. eTransportation 2020, 6, 100076. [Google Scholar] [CrossRef]

- IRENA. Global Renewable Generation Continues Its Strong Growth, New IRENA Capacity Data Shows. Available online: https://www.irena.org/News/pressreleases/2018/Apr/Global-Renewable-Generation-Continues-its-Strong-Growth-New-IRENA-Capacity-Data-Shows (accessed on 6 July 2024).

- Buchanan. Stacy EERE Technical Report. Template. 2022. Available online: https://www.nrel.gov/docs/fy18osti/71500.pdf (accessed on 6 July 2024).

- Yu, H.F.; Hasanuzzaman, M.; Rahim, N.A. Recycling End-of-Life Photovoltaic Modules in Malaysia: Challenges and Potential Solutions. IOP Conf. Ser. Earth Environ. Sci. 2023, 1261, 012017. [Google Scholar]

- Singh, M.; Ahmed, S. IoT Based Smart Water Management Systems: A Systematic Review. Mater. Today Proc. 2021, 46, 5211–5218. [Google Scholar] [CrossRef]

| Question | Keywords |

|---|---|

| 1 | Supply chain, value chain, manufacturing chain |

| 2, 3 | Waste, management, control, organization, reuse, recycle, reject, repair, reduce, renew, recovery, sustainable, circular |

| 1, 2, 3 | Panel, cell, photovoltaic, solar |

| Classification | No. | Criteria |

|---|---|---|

| Inclusion | C1 | Title, abstract, and/or keywords contain the keywords from Table 2. |

| C2 | Publications in English. | |

| C3 | The abstract and superficial review of the article allow for answering one of the three research questions either directly or indirectly. | |

| Exclusion | C4 | Title, abstract, and/or keywords contain terms related to other energy sources such as hydrogen or wind. |

| C5 | Duplicate publications. | |

| C6 | Restricted access publications. |

| Document Type | Amount | Proportion |

|---|---|---|

| Article | 30 | 66.7% |

| Conference paper | 2 | 4.4% |

| Review | 8 | 17.8% |

| Report | 3 | 6.7% |

| Note | 1 | 2.2% |

| Survey | 1 | 2.2% |

| Name of the Journal/Institution | Amount | Name of the Journal/Institution | Amount |

|---|---|---|---|

| Resources, Conservation and Recycling | 5 | Innovation and Development | 1 |

| Journal of Cleaner Production | 3 | International Energy Agency—IEA | 1 |

| Renewable and Sustainable Energy Reviews | 3 | International Renewable Energy Agency—IRENA | 1 |

| Solar Energy | 3 | International Review of Applied Sciences and Engineering | 1 |

| Sustainability | 3 | IOP Conference Series: Earth and Environmental Science | 1 |

| Energy Research and Social Science | 2 | Joule | 1 |

| Materials Today: Proceedings | 2 | Journal of Business Research | 1 |

| Waste Management and Research | 2 | Microsystem Technologies | 1 |

| Applied Energy | 1 | Office of Scientific and Technical Information—OSTI | 1 |

| Clean Technologies and Environmental Policy | 1 | Renewable Energy | 1 |

| Current Opinion in Green and Sustainable Chemistry | 1 | Resources Policy | 1 |

| Energies | 1 | Social Sciences & Humanities Open | 1 |

| Energy for Sustainable Development | 1 | Sustainable Horizons | 1 |

| Energy Technology | 1 | Sustainable Production and Consumption | 1 |

| Environmental Research Letters | 1 | Waste Management | 1 |

| Journal | Citations | Publication | Authors | Year |

|---|---|---|---|---|

| Renewable and Sustainable Energy Reviews | 124 | “Technical challenges and opportunities in realising a circular economy for waste photovoltaic modules” | 11 | 2020 |

| Resources | 116 | “End-of-life photovoltaic modules: A systematic quantitative literature review” | 5 | 2019 |

| Waste Management | 78 | “Recycling and reuse of kerf-loss silicon from diamond wire sawing for photovoltaic industry” | 5 | 2019 |

| Resources, Conservation and Recycling | 50 | “Promoting a circular economy in the solar photovoltaic industry using life cycle symbiosis” | 3 | 2020 |

| Resources, Conservation and Recycling | 49 | “Critical assessment of renewable energy waste generation in OECD countries: Decommissioned PV panels” | 3 | 2021 |

| Type of Waste | Description | References |

|---|---|---|

| Solid | Glass, metals, packaging, etc. | [26,38,41,42,46,48,53,54,55,56] |

| WEEE | Inverters, cables, batteries, etc. | [33,45,46,48,49] |

| Environmental | Manufacturing, transportation, or decommissioning waste that generates leaching, GHG emissions, etc. | [16,17,26,38,45,52,54,57] |

| Hazardous | Metals that threaten human health. | [45,46,50,52,53,54,56] |

| Management Type | Description | References |

|---|---|---|

| Dumping | Widely practiced worldwide. | [27,49,56,58,59,66] |

| Recycling | Only 10% of panels are recycled worldwide. | [12,17,19,26,37,42,46,49,53] |

| Reuse | Export of panels and second-hand market. | [12,17,19,37,45,53,54,56,58,63] |

| Incineration | Common practice without emission control. | [33,49,59] |

| Research Trend | Description | References | Percentage |

|---|---|---|---|

| Upstream | Research focused on waste in the manufacturing stage. | [19,42,43,59] | 11.10% |

| Downstream | Research focused on waste at the end of the life cycle of panels. | [17,26,33,46,53,54,56,58,59,60,63,64] | 48.90% |

| R | Upstream | Dowstream | Auxiliary |

|---|---|---|---|

| R1: Recycle [17,26,37,38,53,58,60,62,64,69,70] | Recycling of silicon wafer cutting. | High-value recycling centers for valuable materials. | NA |

| Recycling technology services. | |||

| Disassembly, logistics, transportation, and recycling services. | |||

| WEEE recycling plant. | |||

| R2: Recover [26,45,48,50,59,64,71] | NA | Use of waste materials as raw material for other industries. | NA |

| Recovery of high-value materials. | |||

| Recovery of BOS components for reintegration. | |||

| R3: Reuse [17,19,26,49,70,72] | Reuse of silicon cuttings in other industries. | Second-life panel market, resale, and installation. | NA |

| Reuse of packaging products in soil treatment. | |||

| R4: Reduce [26,73]) | NA | Maintenance services to extend the lifespan. | More efficient solar panel designs. |

| R5: Repair [17,49,70] | NA | Repair and control services. | Insurance companies for panel repair. |

| R6: Refine [26] | NA | NA | Services for handling logistical deficiencies. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piedrahita, A.; Cárdenas, L.M.; Zapata, S. Solar Panel Waste Management: Challenges, Opportunities, and the Path to a Circular Economy. Energies 2025, 18, 1844. https://doi.org/10.3390/en18071844

Piedrahita A, Cárdenas LM, Zapata S. Solar Panel Waste Management: Challenges, Opportunities, and the Path to a Circular Economy. Energies. 2025; 18(7):1844. https://doi.org/10.3390/en18071844

Chicago/Turabian StylePiedrahita, Allison, Laura M. Cárdenas, and Sebastian Zapata. 2025. "Solar Panel Waste Management: Challenges, Opportunities, and the Path to a Circular Economy" Energies 18, no. 7: 1844. https://doi.org/10.3390/en18071844

APA StylePiedrahita, A., Cárdenas, L. M., & Zapata, S. (2025). Solar Panel Waste Management: Challenges, Opportunities, and the Path to a Circular Economy. Energies, 18(7), 1844. https://doi.org/10.3390/en18071844