Mud Loss Analysis Through Predictive Modeling of Pore Pressure and Fracture Gradients in Tin Fouye Tabankort Field, Western Illizi Basin, Algeria

Abstract

1. Introduction

2. Materials and Methods

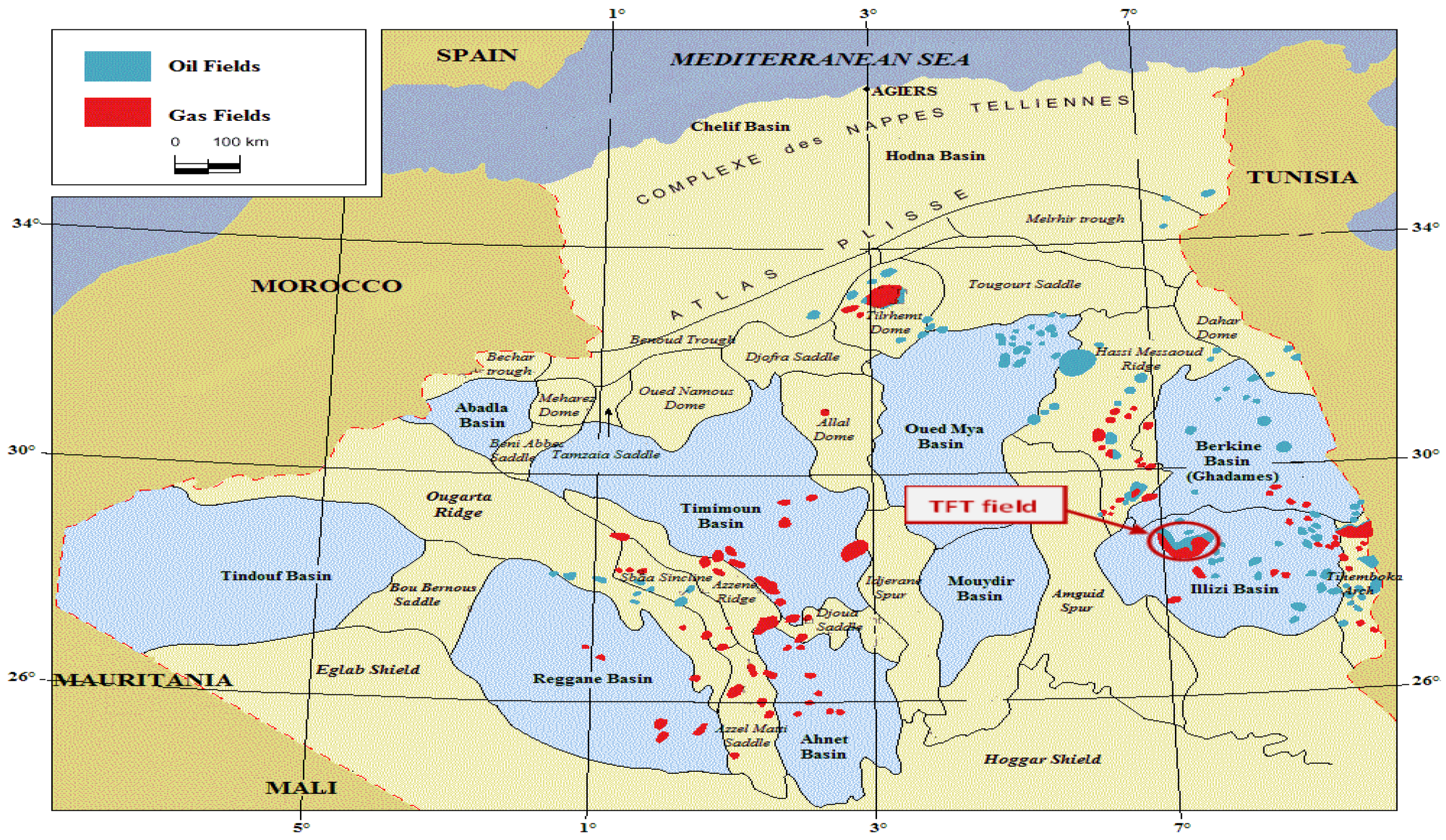

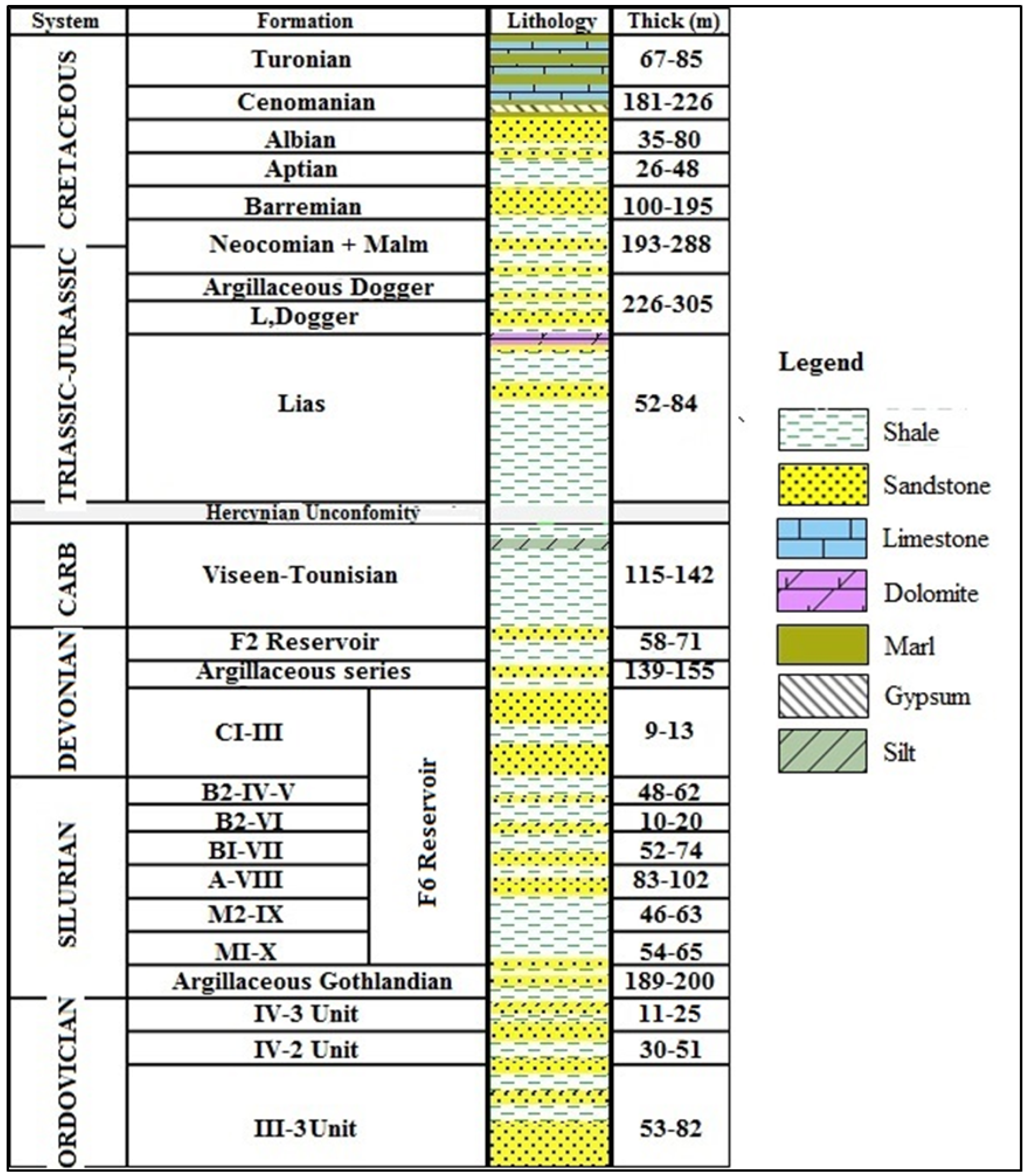

2.1. Description of Study Area

2.2. Data Source

2.3. Procedure

2.3.1. Estimation of Poisson’s Ratio

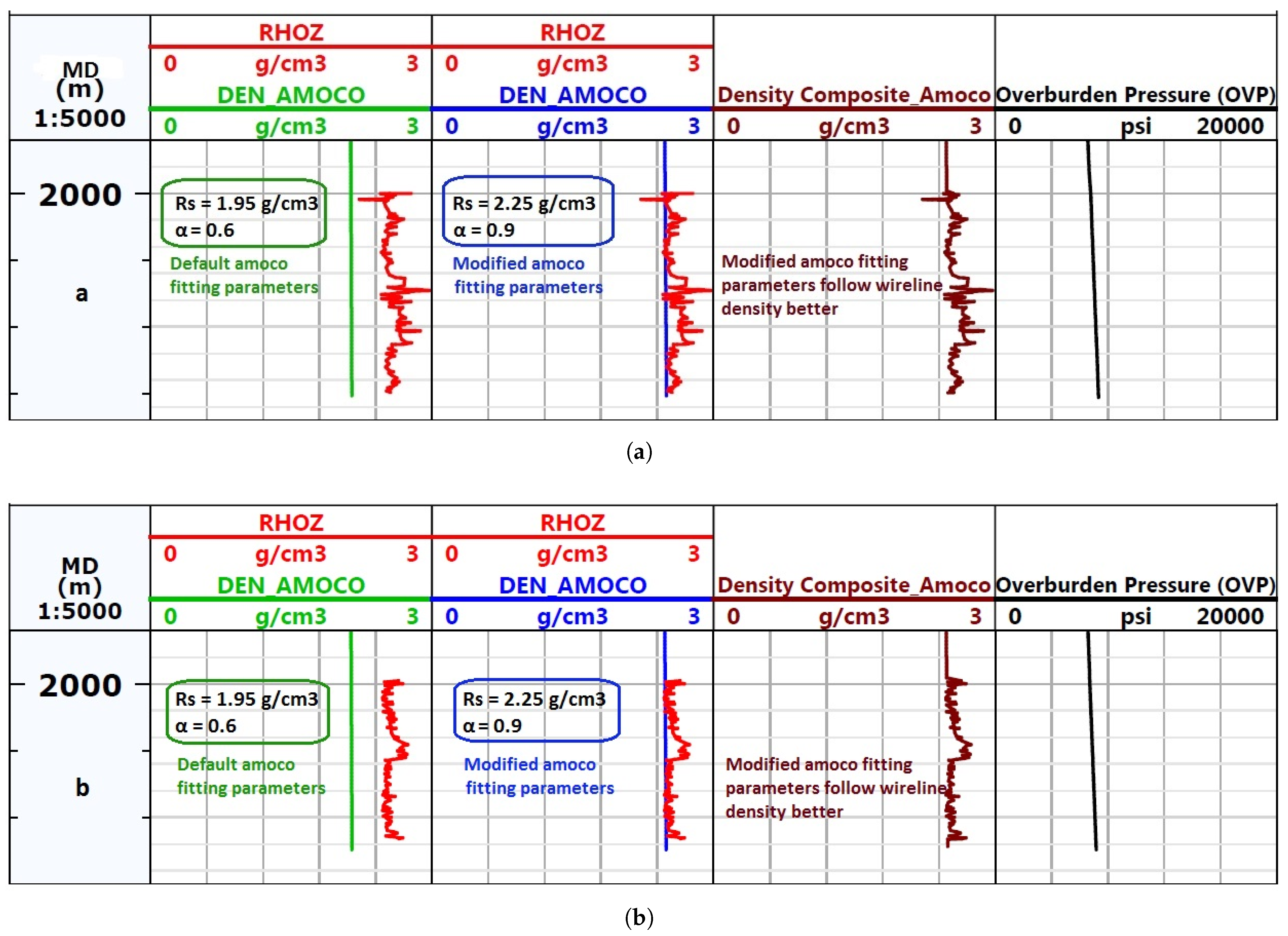

2.3.2. Estimation of OVP

2.3.3. Estimation of PP

2.3.4. Estimation of FG

3. Results

3.1. Poisson’s Ratio and OVP

3.2. PP and FG Modeling

3.2.1. Well TF1

3.2.2. Well TF2

3.2.3. Well TF3

3.2.4. Well TF4

3.2.5. Well TF5

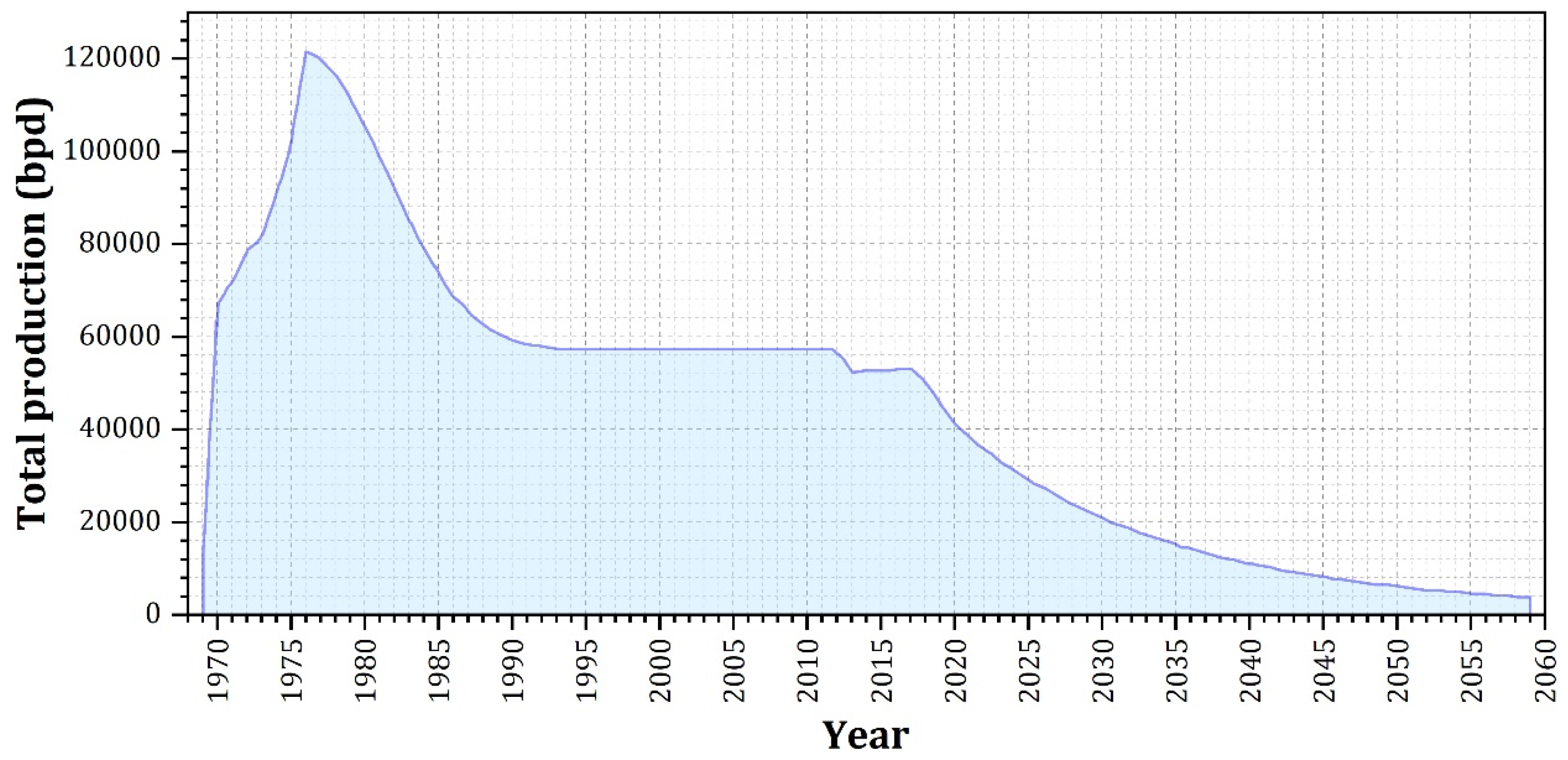

4. Discussion

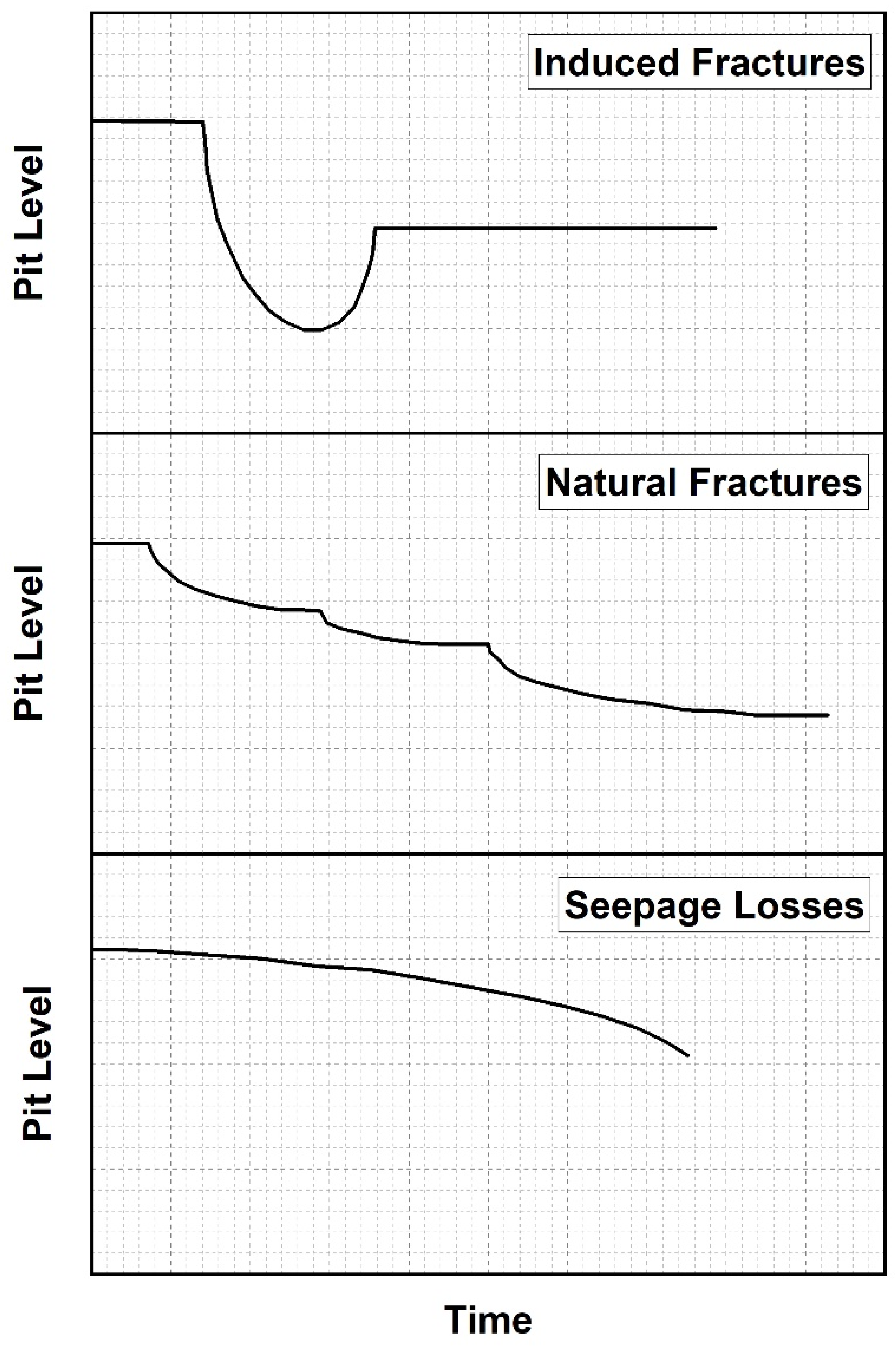

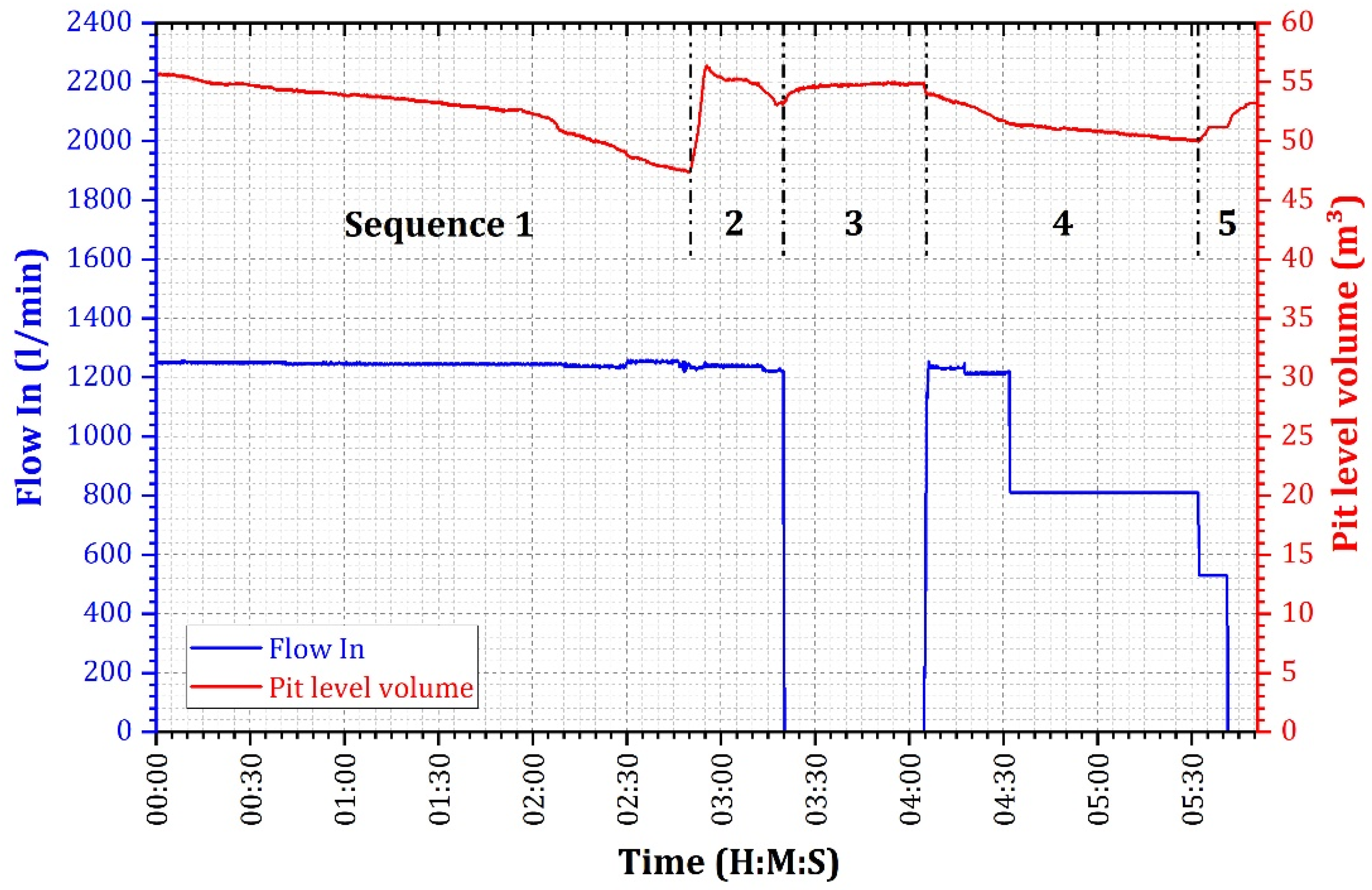

Mud Losses Monitoring While Drilling

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ECD | Equivalent circulating density |

| FG | Fracture gradient |

| LCM | Lost circulation material |

| LOT | Leak-Off Test |

| LWD | Logging While Drilling |

| NCT | Normal compaction trends |

| NPT | Non-productive time |

| OBG | Overburden gradient |

| OBM | Oil-based mud |

| OVP | Overburden pressure |

| PP | Pore pressure |

| PPFG | Pore pressure fracture gradient model |

| RFT | Repeat Formation Test |

| Sv | Vertical stress |

| TFT | Tin Fouye Tabankort |

| TVD | True vertical depth |

References

- Zhao, L.; Yuan, C.; Shan, K.; Gao, M.; Long, X.; Xu, M.; Ao, T.; Yang, Y. Expandable profile liner technology for mitigating lost circulation and wellbore instability in geothermal drilling. Renew. Sustain. Energy Rev. 2025, 209, 115109. [Google Scholar] [CrossRef]

- Elrayah, A.A.I. Enhancing drilling operations: Prioritizing wellbore integrity, formation preservation, and effective mud waste control (case study). J. Eng. Appl. Sci. 2024, 71, 86. [Google Scholar] [CrossRef]

- Ounegh, A.; Hasan-Zadeh, A.; Khanaposhtani, M.M.; Kazaemzadeh, Y. Wellbore stability analysis based on the combination of geomechanical and petrophysical studies. Results Eng. 2024, 24, 103016. [Google Scholar] [CrossRef]

- Gholilou, A.; Vialle, S.; Madadi, M. Determination of safe mud window considering time-dependent variations of temperature and pore pressure: Analytical and numerical approaches. J. Rock Mech. Geotech. Eng. 2017, 9, 900–911. [Google Scholar] [CrossRef]

- Alawami, M.; Al-Yami, A.; Gharbi, S.; Al-Rubaii, M. A Real Time Geomechanics Drilling Mud Window to Enhance Drilling Efficiency. In Proceedings of the SPE EOR Conference at Oman Petroleum & Energy Show, Muscat, Oman, 21 March 2022. SPE-200033-MS. [Google Scholar] [CrossRef]

- Dodson, J.; Dodson, T.; Schmidt, V. Gulf of Mexico ’trouble time’ creates major drilling expenses: Use of cost-effective technologies needed. Offshore 2004, 64, 46–48. [Google Scholar]

- AEhsan, M.; Manzoor, U.; Chen, R.; Hussain, M.; Abdelrahman, K.; Radwan, A.E.; Ullah, J.; Iftikhar, M.K.; Arshad, F. Pore pressure prediction based on conventional well logs and seismic data using an advanced machine learning approach. J. Rock Mech. Geotech. Eng. 2024; in press. [Google Scholar]

- Khoshnaw, F.; Jaf, P.; Farkha, S. Pore, abnormal formation and fracture pressure prediction. WIT Trans. Ecol. Environ. 2014, 186, 579–593. [Google Scholar] [CrossRef]

- Eaton, B.A. Fracture gradient prediction and its application in oilfield operations. J. Pet. Technol. 1969, 21, 1353–1360. [Google Scholar] [CrossRef]

- Mouchet, J.P.; Mitchell, A. Abnormal Pressures While Drilling: Origins, Prediction, Detection, Evaluation, 2nd ed.; Manuals Techniques; Elf Aquitaine: Boussens, France, 1989. [Google Scholar]

- Teufel, L.W.; Rhett, D.W.; Farrell, H.E. Effect of reservoir depletion and pore pressure drawdown on in situ stress and deformation in the Ekofisk field, North Sea. In Proceedings of the 32nd U.S. Symposium on Rock Mechanics (USRMS), Norman, OK, USA, 10–12 July 1991. ARMA-91-063. [Google Scholar]

- Kassem, A.A.; Sen, S.; Radwan, A.E.; Abdelghany, W.K.; Abioui, M. Effect of depletion and fluid injection in the Mesozoic and Paleozoic sandstone reservoirs of the October Oil Field, Central Gulf of Suez Basin: Implications on drilling, production and reservoir stability. Nat. Resour. Res. 2021, 30, 2587–2606. [Google Scholar] [CrossRef]

- Ghosal, D.; Daungkaew, S.; Karpfinger, F.; Chansiriwilaikul, N.; Han, S.E.; Cavalleri, C.; Kumar, V.; Hademi, N. Creating a Blueprint for Successful CCS in Southeast Asia: Roadmap to a Sustainable Future. In Proceedings of the International Petroleum Technology Conference, Kuala Lumpur, Malaysia, 18–20 February 2025. [Google Scholar] [CrossRef]

- Hashemi, S.S.; Kovscek, A. Numerical Simulation of CO2 Storage in the Soft Sediments of Depleted Reservoirs in the Gulf of Mexico. In Proceedings of the SPE Western Regional Meeting, Palo Alto, CA, USA, 16–18 April 2024. [Google Scholar] [CrossRef]

- Kuakool, S.; Rahmati, H.; Al-Ismaeeli, O.; Awae, H.; Suk-iam, S.; Kulananpakdee, K. Pre-Drill 1D Geomechanical Earth Models for Optimizing Drilling Programs in the Phitsanulok Basin, Thailand. In Proceedings of the SPWLA Asia-Pacific Regional Conference, Bangkok, Thailand, 6–9 October 2024. [Google Scholar]

- Melikov, R.; Krasnikov, A.; Tatur, O.; Stishenko, S.; Lobashov, V.; Chaschin, S.; Anh, N.L.; Chung, H.N.; Sustavov, V.; Âu, P.V. Implementing Innovative Technology to Provide Pore Pressure Prediction During Drilling Operations: A Case Study of the ‘White Tiger’ Offshore Oilfield. In Proceedings of the International Geomechanics Conference, Kuala Lumpur, Malaysia, 18–20 November 2024. [Google Scholar] [CrossRef]

- Askri, H.; Belmecheri, A.; Benrabah, B.; Boudjema, A.; Boumendjel, K.; Daoudi, M.; Drid, M.; Ghalem, T.; Docca, A.M.; Ghandriche, H.; et al. Geology of Algeria. In Well Evaluation Conference Algeria (WEC); Schlumberger: Houston, TX, USA, 1995; pp. 1–93. [Google Scholar]

- Wendt, J.; Kaufmann, B.; Belka, Z. Devonian stratigraphy and depositional environments in the southern Illizi Basin (Algerian Sahara). J. Afr. Earth Sci. 2009, 54, 85–96. [Google Scholar] [CrossRef]

- Baouche, R.; Sen, S.; Ganguli, S.S. Pore pressure and in-situ stress magnitudes in the Bhiret Hammou hydrocarbon field, Berkine Basin, Algeria. J. Afr. Earth Sci. 2020, 171, 103945. [Google Scholar] [CrossRef]

- Daniels, R.; Emme, J.J. Petroleum system model, eastern Algeria, from source rock to accumulation: When, where and how. In Proceedings of the Seminar on Source Rocks and Hydrocarbon Habitat in Tunisia, Tunis, Tunisia, 15–18 November 1995; Entreprise Tunisienne d’Activités Petrolieres Memoir: Tunis, Tunisia; pp. 101–124. [Google Scholar]

- Echikh, K. Geology and hydrocarbon occurrences in the Ghadames basin, Algeria, Tunisia, Libya. Geol. Soc. London, Spec. Publ. 1998, 132, 109–129. [Google Scholar] [CrossRef]

- Khamehchi, E.; Khaleghi, M.R.; Abbasi, A.; Mahdavi Kalatehno, J. Estimating the Formation Fracture Pressure Through Geomechanical Modeling. In Applied Matrix Acidizing of Carbonate Reservoir; Petroleum Engineering; Springer Nature: Cham, Switzerland, 2024; pp. 45–73. [Google Scholar] [CrossRef]

- Alneasan, M.; Behnia, M.; Bagherpour, R. The effect of Poisson’s ratio on the creation of tensile branches around dynamic faults. J. Struct. Geol. 2020, 131, 103950. [Google Scholar] [CrossRef]

- Abdollahipour, A.; Soltanian, H.; Pourmazaheri, Y.; Kazemzadeh, E.; Fatehi-Marji, M. Sensitivity analysis of geomechanical parameters affecting a wellbore stability. J. Cent. South Univ. 2019, 26, 768–778. [Google Scholar] [CrossRef]

- Fjaer, E.; Holt, R.M.; Horsrud, P.; Raaen, A.M.; Risnes, R. Petroleum Related Rock Mechanics, 2nd ed.; Elsevier Science Publishers B.V.: Amsterdam, The Netherland, 2008; pp. 1–53. [Google Scholar] [CrossRef]

- Cui, L.; Cheng, A.H.; Abousleiman, Y. Poroelastic Solution for an Inclined Borehole. J. Appl. Mech. 1997, 64, 32–38. [Google Scholar] [CrossRef]

- Han, Y.; Liu, C.; Phan, D.; AlRuwaili, K.; Abousleiman, Y. Advanced wellbore stability analysis for drilling naturally fractured rocks. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 18–21 March 2019. SPE-195021-MS, D032S077R002. [Google Scholar] [CrossRef]

- Eaton, B.A.; Eaton, T.L. Fracture gradient prediction for the new generation. World Oil 1997, 218, 93–100. [Google Scholar]

- Wang, H. Theory of Linear Poroelasticity with Applications to Geomechanics and Hydrogeology, 1st ed.; Princeton University Press: Princeton, NJ, USA, 2000. [Google Scholar]

- English, J.M.; Finkbeiner, T.; English, K.L.; Cherif, R.Y. State of stress in exhumed basins and implications for fluid flow: Insights from the Illizi Basin, Algeria. Geol. Soc. Lond. Spec. Publ. 2017, 458, 89–112. [Google Scholar] [CrossRef]

- Plumb, R.A.; Evans, K.F.; Engelder, T. Geophysical log responses and their correlation with bed-to-bed stress contrasts in Paleozoic rocks, Appalachian Plateau, New York. J. Geophys. Res. 1991, 96, 14509–145280. [Google Scholar] [CrossRef]

- Sen, S.; Corless, J.; Dasgupta, S.; Maxwell, C.; Kumar, M. Issues faced while calculating overburden gradient and picking shale zones to predict pore pressure. In Proceedings of the First EAGE Workshop on Pore Pressure Prediction, Pau, France, 19–21 March 2017. [Google Scholar] [CrossRef]

- Radwan, A.E.; Abudeif, A.M.; Attia, M.M.; Mohammed, M.A. Pore and fracture pressure modeling using direct and indirect methods in Badri Field, Gulf of Suez, Egypt. J. Afr. Earth Sci. 2019, 156, 133–143. [Google Scholar] [CrossRef]

- Aadnoy, B.S.; Looyeh, R. Petroleum Rock Mechanics: Drilling Operations and Well Design, 2nd ed.; Gulf Professional Publishing: Cambridge, MA, USA, 2019. [Google Scholar]

- Vega, M.P.; de Moraes Oliveira, G.F.; Fernandes, L.D.; Martins, A.L. Monitoring and control strategies to manage pressure fluctuations during oil well drilling. J. Pet. Sci. Eng. 2018, 166, 337–349. [Google Scholar] [CrossRef]

- Eaton, B.A. The equation for geopressure prediction from well logs. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 28 September–1 October 1975. [Google Scholar] [CrossRef]

- Sen, S.; Ganguli, S.S. Estimation of pore pressure and fracture gradient in Volve field, Norwegian North Sea. In Proceedings of the SPE Oil and Gas India Conference and Exhibition, Mumbai, India, 9–11 April 2019. [Google Scholar] [CrossRef]

- Fang, Z.; Zamikhan, N.; Tarang, R.T.; On, C.K.; Huver, P.H. An Integrated Geomechanical Approach to Accurately Predicting the Fracture Gradient for Mitigating Drilling Losses of Challenging Wellbores. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, The Hague, The Netherlands, 5–7 March 2019. [Google Scholar] [CrossRef]

- Jamshidian, M.; Mansuri Zadeh, M.; Mohammadzadeh, O.; Abdideh, M. Developing a geomechanical model to predict breakdown pressure in a vertical borehole using failure analysis: A case study. Geomech. Geophys. Geo-Energ. Geo-Resour. 2024, 10, 179. [Google Scholar] [CrossRef]

- Udo, K.I.; George, N.J.; Akankpo, A.O.; Azuoko, G.B.; Aka, M.U. Determining fracture pressure gradients from well logs. Int. J. Adv. Geosci. 2020, 81, 5–9. [Google Scholar] [CrossRef]

- Zhang, J.; Wieseneck, J. Challenges and surprises of abnormal pore pressures in shale gas formations. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 30 October–2 November 2011. [Google Scholar] [CrossRef]

- Matthews, W.R. How to predict formation pressure and fracture gradient from electric and sonic logs. Oil and Gas 1967, 20, 92–106. [Google Scholar]

- Banerjee, A.; Chatterjee, R. Pore pressure modeling and in situ stress determination in Raniganj basin, India. Bull. Eng. Geol. Environ. 2022, 81, 49. [Google Scholar] [CrossRef]

- Zhang, J. Pore pressure prediction from well logs: Methods, modifications, and new approaches. Earth-Sci. Rev. 2011, 108, 50–63. [Google Scholar] [CrossRef]

- Baylocq, P.; Sahnoune, A.; Martin, A.; Sims, M. Tin Fouye Tabankort gas field-how understanding of abnormal fracture propagation and reservoir uncertainties led to successful hydraulic fracturing operations. In Proceedings of the SPE Europec featured at EAGE Conference and Exhibition, The Hague, The Netherlands, 20–22 October 1998. [Google Scholar] [CrossRef]

- Alem, N.; Assassi, S.; Benhebouche, S.; Kadi, B. Controls on hydrocarbon occurrence and productivity in the F6 reservoir, Tin Fouyé-Tabankort area, NW Illizi Basin. Geol. Soc. Lond. Spec. Publ. 1998, 132, 175–186. [Google Scholar] [CrossRef]

- Beda, G.; Carugo, C. Use of mud microloss analysis while drilling to improve the formation evaluation in fractured reservoir. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September–3 October 2001. [Google Scholar] [CrossRef]

- Majidi, R.; Edwards, S.; Zhang, J.; Sant, R.; Last, N. Drilling depleted sands: Geomechanics, challenges and mitigations. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 28–30 September 2015. [Google Scholar] [CrossRef]

- Dyke, C.G.; Wu, B.; Milton-Tayler, D. Advances in characterizing natural-fracture permeability from mud-log data. SPE Form. Eval. 1995, 10, 160–166. [Google Scholar] [CrossRef]

- Majidi, R.; Miska, S.Z.; Zhang, J. Fingerprint of Mud Losses into Natural or Induced Fractures. In Proceedings of the SPE European Formation Damage Conference, Noordwijk, The Netherlands, 7–10 June 2011. [Google Scholar] [CrossRef]

- Bratton, T.R.; Rezmer-Cooper, I.M.; Desroches, J.; Gille, Y.E.; Li, Q.; McFayden, M. How to diagnose drilling induced fractures in wells drilled with oil-based muds with real-time resistivity and pressure measurements. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, Amsterdam, The Netherlands, 27 February–1 March 2001. [Google Scholar] [CrossRef]

| Wells | ||||||

|---|---|---|---|---|---|---|

| Ordovician Unit | TF1 | TF2 | TF3 | TF4 | TF5 | |

| Top (m) | IV-3 Unit | 2001 | 2057 | 2003 | 2000 | 1979 |

| IV-2 Unit | 2014 | 2073 | 2014 | 2025 | 2000 | |

| III-3 Unit | 2066 | - | 2070 | 2056 | - | |

| TD | 2130 | 2128 | 2150 | 2120 | 2120 |

| Poisson’s Ratio | ||||||

|---|---|---|---|---|---|---|

| Formation | Lithology | Well | ||||

| TF1 | TF2 | TF3 | TF4 | TF5 | ||

| IV-3 | Sandstone | 0.10–0.13 | 0.06–0.14 | 0.05–0.19 | 0.04–0.15 | 0.06–0.18 |

| Shale | 0.14–0.20 | / | / | / | / | |

| IV-2 | Sandstone | 0.12–0.14 | 0.06–0.18 | / | 0.08–0.19 | 0.09–0.18 |

| Shale | 0.18–0.29 | 0.15–0.23 | 0.14–0.27 | 0.18–0.29 | 0.17–0.28 | |

| III-3 | Shale | 0.16–0.29 | / | 0.18–0.28 | 0.19–0.26 | / |

| Well | Formation | Pore Pressure (PP) | Fracture Gradient (FG) | Drilling Mud Weight | ||

|---|---|---|---|---|---|---|

| psi/ft | ppg | psi/ft | ppg | ppg | ||

| TF1 | IV-3 | 0.422 | 8.11 | 0.531–0.60 | 10.32–11.53 | 8.178–8.512 |

| IV-2 | 0.453 | 8.71 | 0.53–0.68 | 10.19–13.07 | ||

| III-3 | 0.451 | 8.67 | 0.56–0.69 | 10.76–13.26 | ||

| TF2 | IV-3 | 0.303 | 5.81 | 0.385–0.430 | 7.40–8.27 | 7.598–7.765 |

| IV-2 | 0.31–0.44 | 5.96–8.46 | 0.400–0.610 | 7.69–11.73 | ||

| TF3 | IV-3 | 0.325 | 6.24 | 0.393–0.456 | 7.56–8.78 | 7.431–7.765 |

| IV-2 | 0.38 | 7.30 | 0.430–0.630 | 8.27–12.11 | ||

| III-3 | 0.38 | 7.30 | 0.450–0.700 | 8.65–3.46 | ||

| TF4 | IV-3 | 0.315 | 6.06 | 0.398–0.475 | 7.67–9.14 | 7.431–7.765 |

| IV-2 | 0.425 | 8.17 | 0.480–0.680 | 9.23–13.07 | ||

| III-3 | 0.40 | 7.69 | 0.520–0.590 | 10.00–11.34 | ||

| TF5 | IV-3 | 0.292 | 5.61 | 0.387–0.439 | 7.45–8.44 | 7.348–7.515 |

| IV-2 | 0.41–0.44 | 7.88–8.46 | 0.45–0.67 | 8.65–12.88 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Laouini, R.; Hacini, M.; Merabti, H.; Medjani, F.; Mahmoud, O. Mud Loss Analysis Through Predictive Modeling of Pore Pressure and Fracture Gradients in Tin Fouye Tabankort Field, Western Illizi Basin, Algeria. Energies 2025, 18, 1836. https://doi.org/10.3390/en18071836

Laouini R, Hacini M, Merabti H, Medjani F, Mahmoud O. Mud Loss Analysis Through Predictive Modeling of Pore Pressure and Fracture Gradients in Tin Fouye Tabankort Field, Western Illizi Basin, Algeria. Energies. 2025; 18(7):1836. https://doi.org/10.3390/en18071836

Chicago/Turabian StyleLaouini, Reda, Messaoud Hacini, Hocine Merabti, Fethi Medjani, and Omar Mahmoud. 2025. "Mud Loss Analysis Through Predictive Modeling of Pore Pressure and Fracture Gradients in Tin Fouye Tabankort Field, Western Illizi Basin, Algeria" Energies 18, no. 7: 1836. https://doi.org/10.3390/en18071836

APA StyleLaouini, R., Hacini, M., Merabti, H., Medjani, F., & Mahmoud, O. (2025). Mud Loss Analysis Through Predictive Modeling of Pore Pressure and Fracture Gradients in Tin Fouye Tabankort Field, Western Illizi Basin, Algeria. Energies, 18(7), 1836. https://doi.org/10.3390/en18071836