4.2. HRV Applicability Analysis

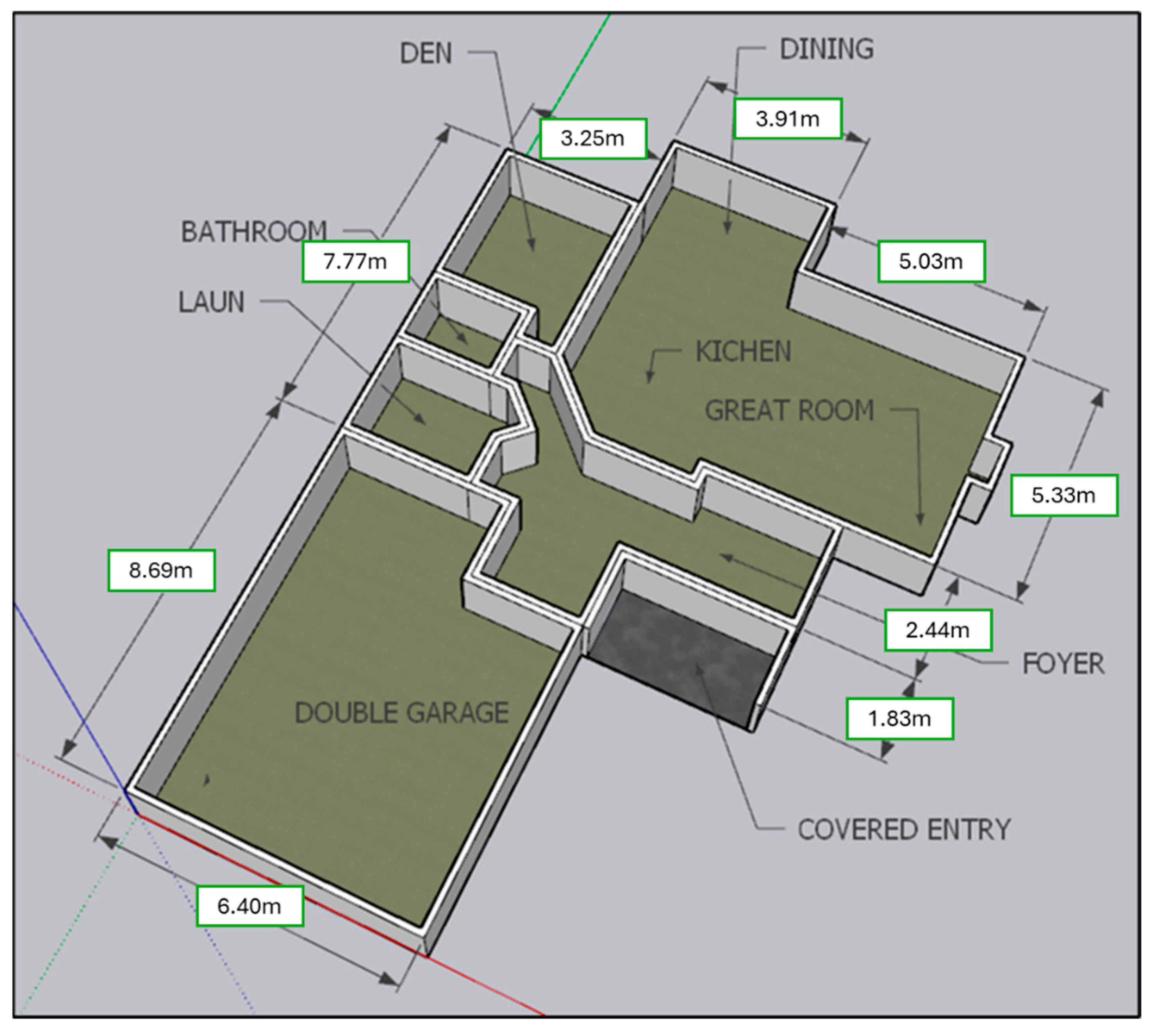

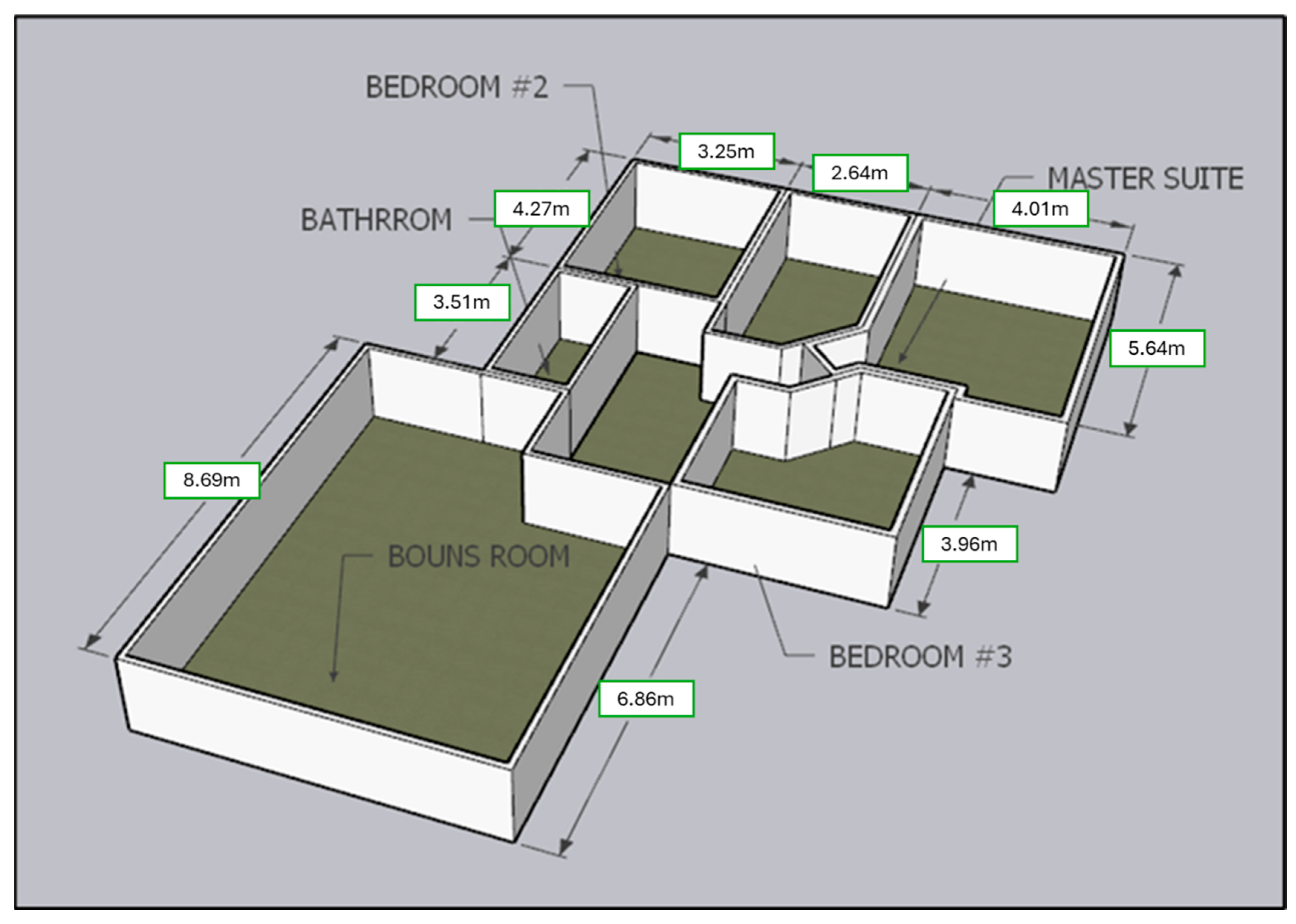

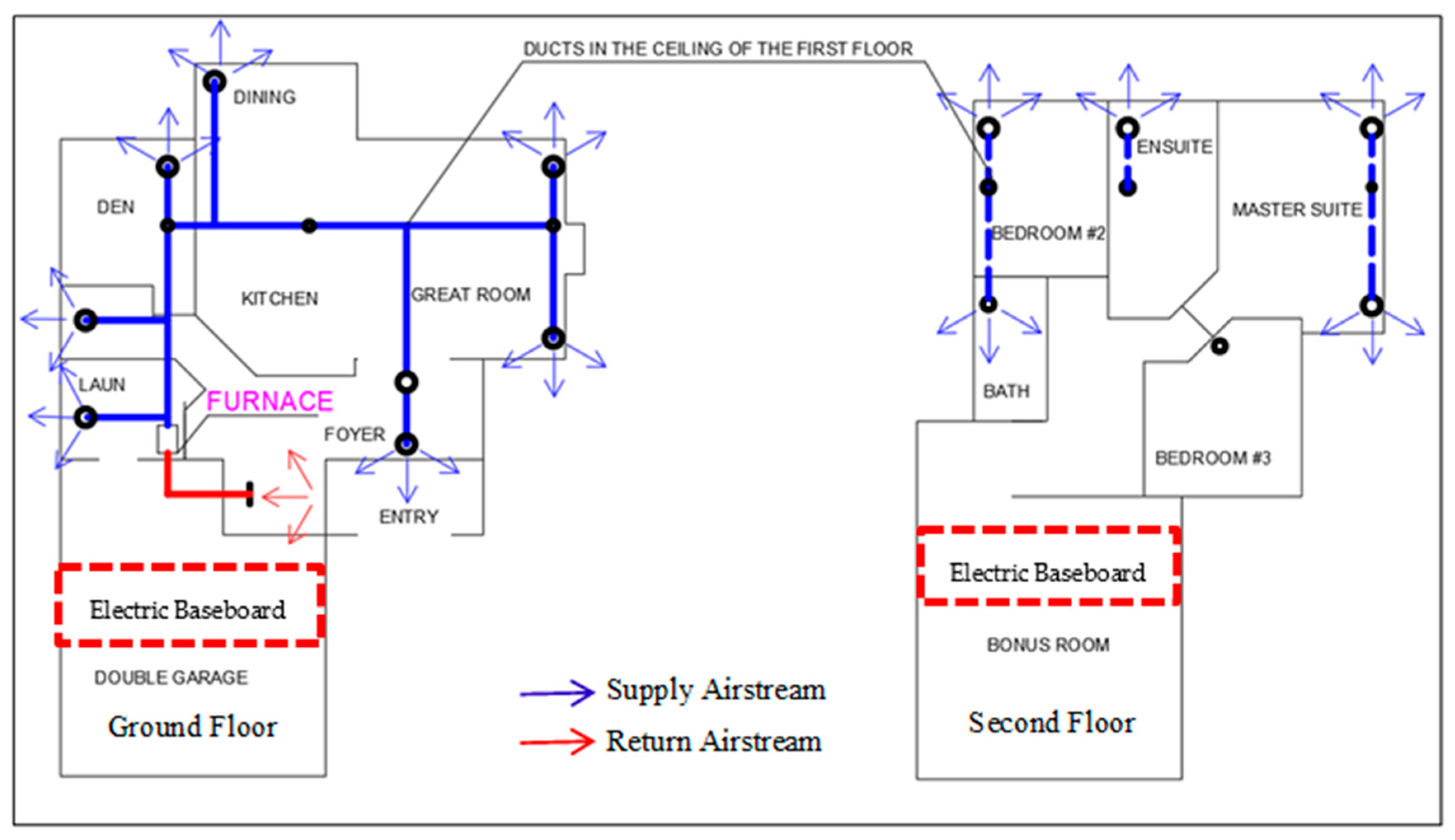

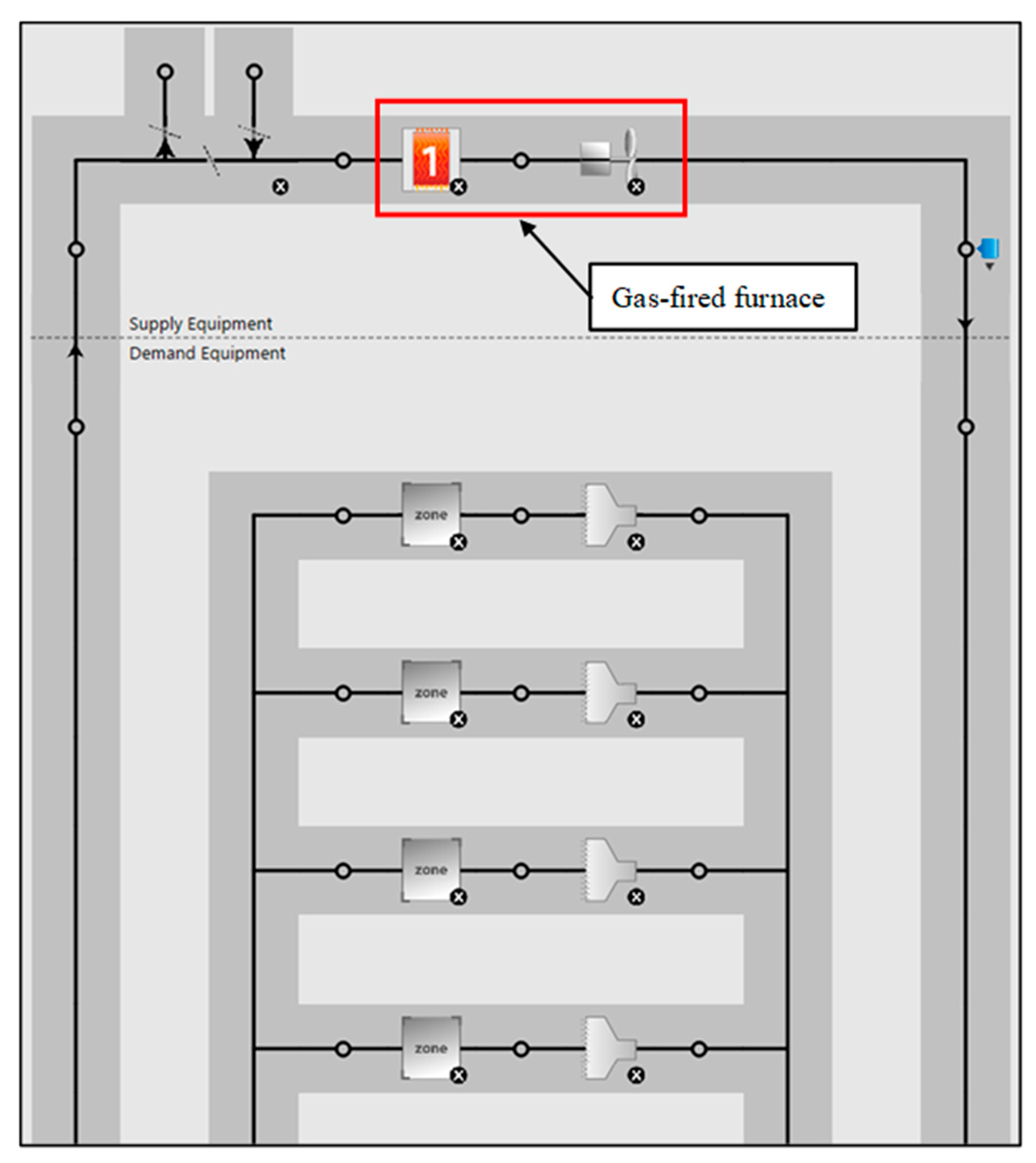

The impact of implementing an HRV into the existing gas-fired furnace heating system serving the main residence was evaluated by comparing the space heating energy consumption in scenarios with and without HRV.

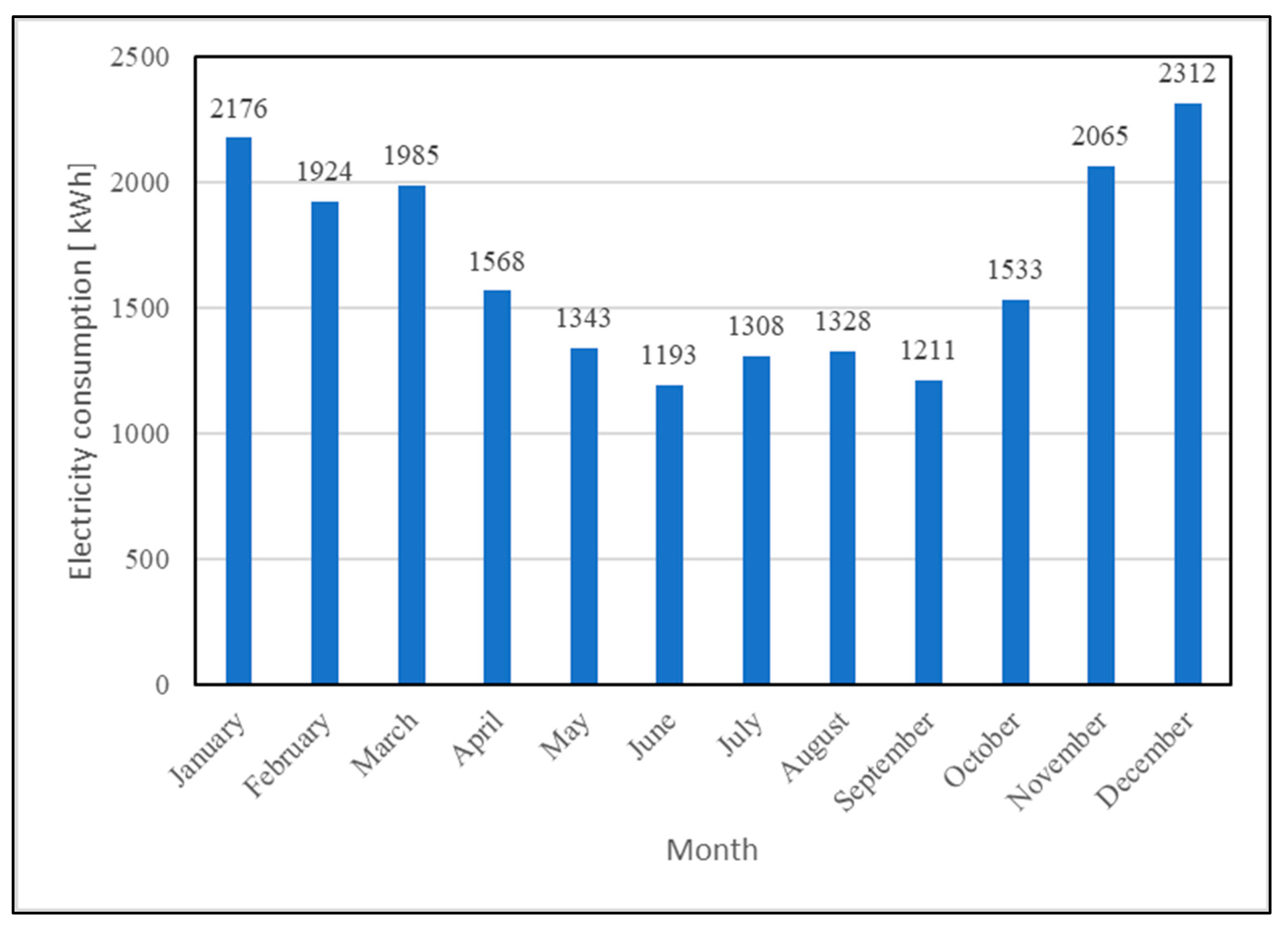

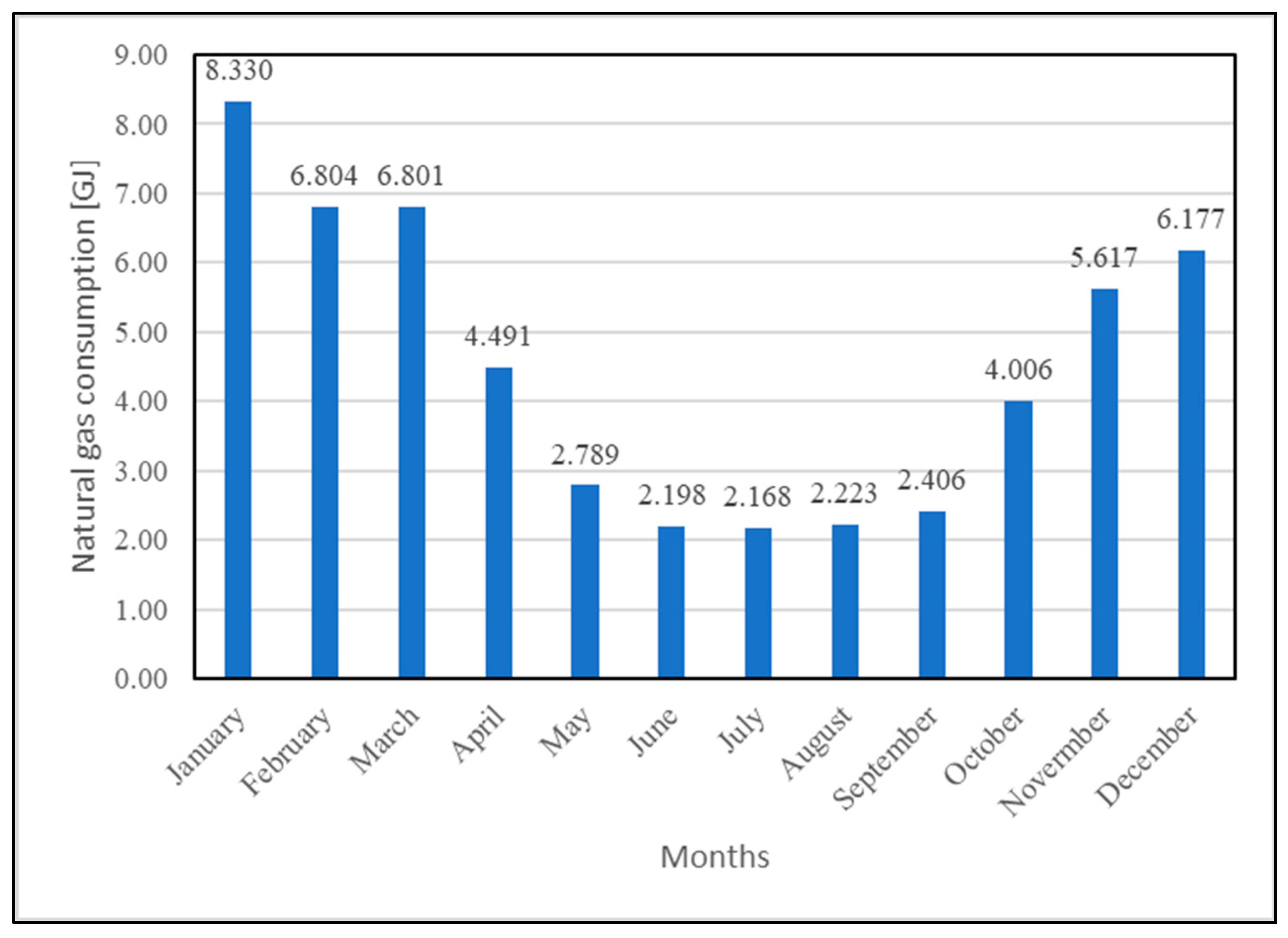

Table 4 and

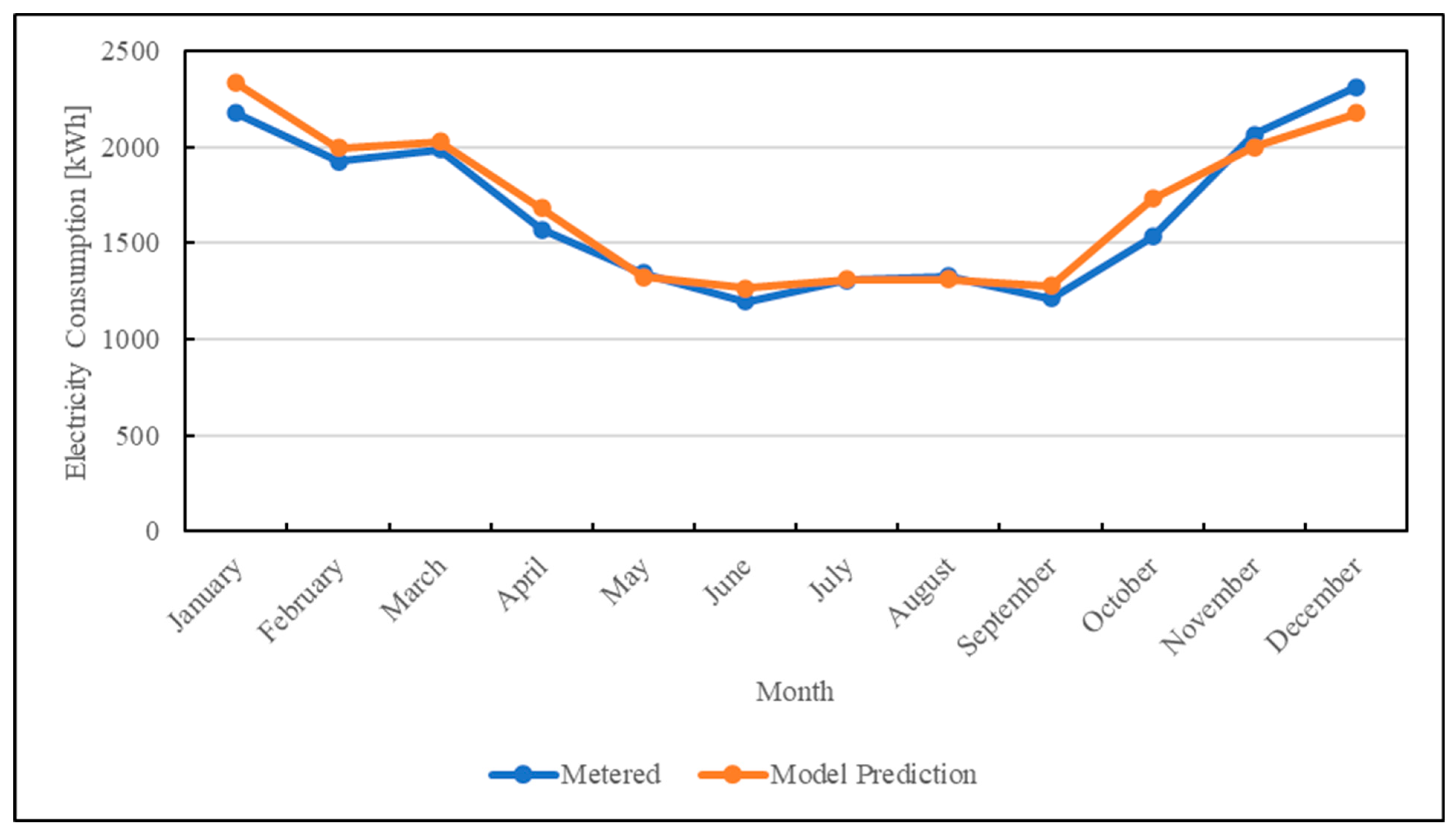

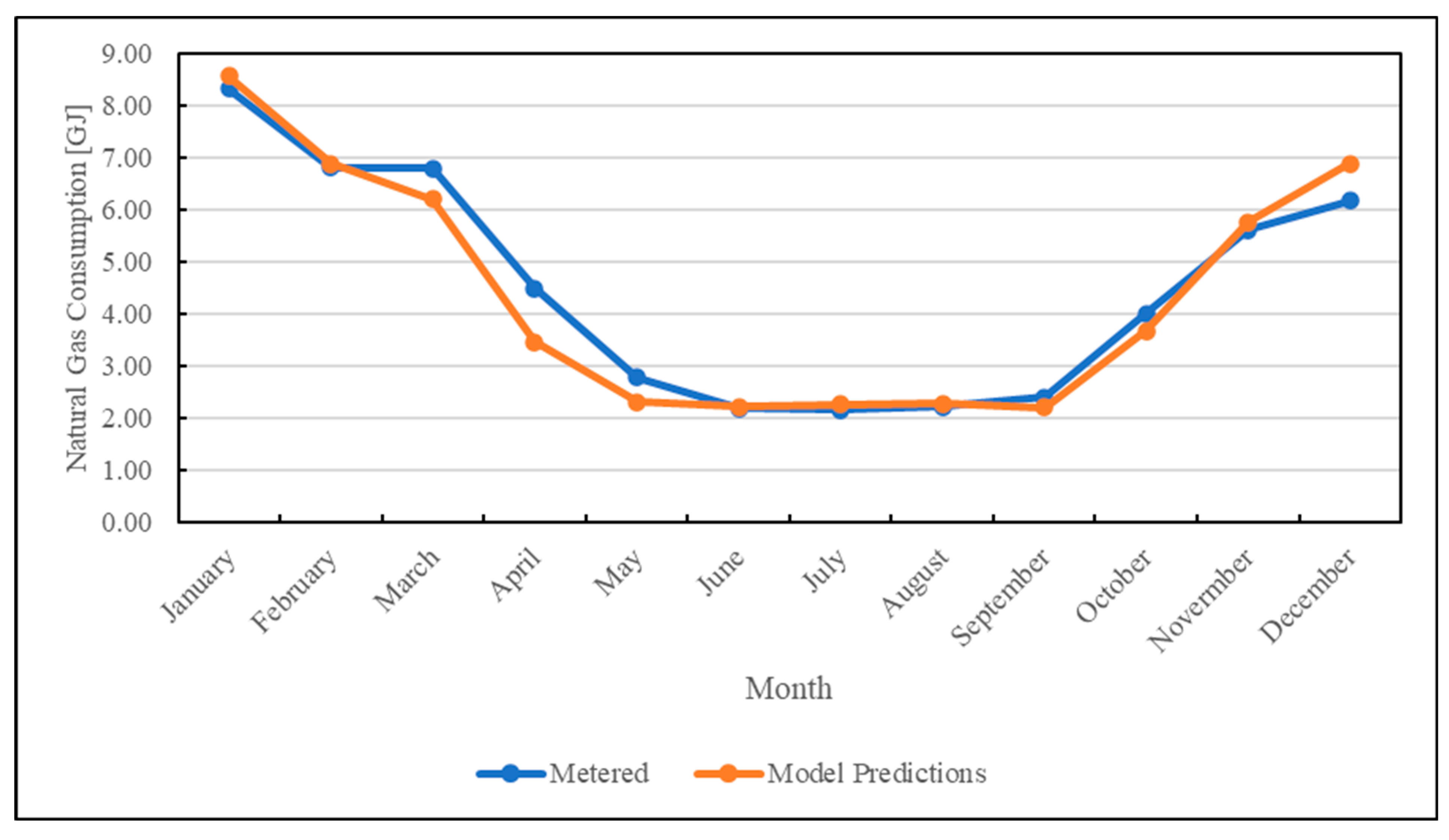

Table 5 present the simulated annual electricity and natural gas consumptions for the building’s main energy end-uses under both scenarios. The results indicate that the introduction of the HRV results in an annual electricity consumption of 75.49 GJ and natural gas consumption of 56.70 GJ. In contrast, without the HRV, the consumptions are 73.64 GJ for electricity and 52.70 GJ for natural gas. The increased electricity usage in the HRV scenario is primarily attributed to the operation of the HRV’s exhaust and supply air fans, which facilitates continuous ventilation by introducing fresh air into the space and exhausting indoor stale air outside the building.

Figure 15 illustrates the comparison of natural gas consumption across main energy end-use between the two scenarios. As seen in the figure, the additional natural gas usage in the HRV scenario is predominantly attributed to the space heating end-use.

The increased natural gas consumption in the HRV scenario is primarily due to the additional heat loss associated with the mechanically ventilated air introduced by the HRV system. In the scenario without the HRV, the building is passively ventilated by intermittently running washroom exhaust fans, with windows assumed to remain closed during simulations. Consequently, infiltration is the sole source of outside air-induced heat loss of the building in this scenario. The infiltration-air-induced heat loss in the existing building,

, can be calculated using the following equation:

where

= infiltration-air-induced space heat loss in existing house,

= mass flowrate of infiltrated air in existing building, ;

= specific heat capacity of air, ;

= indoor heating setpoint temperature,

= outdoor dry bulb temperature, .

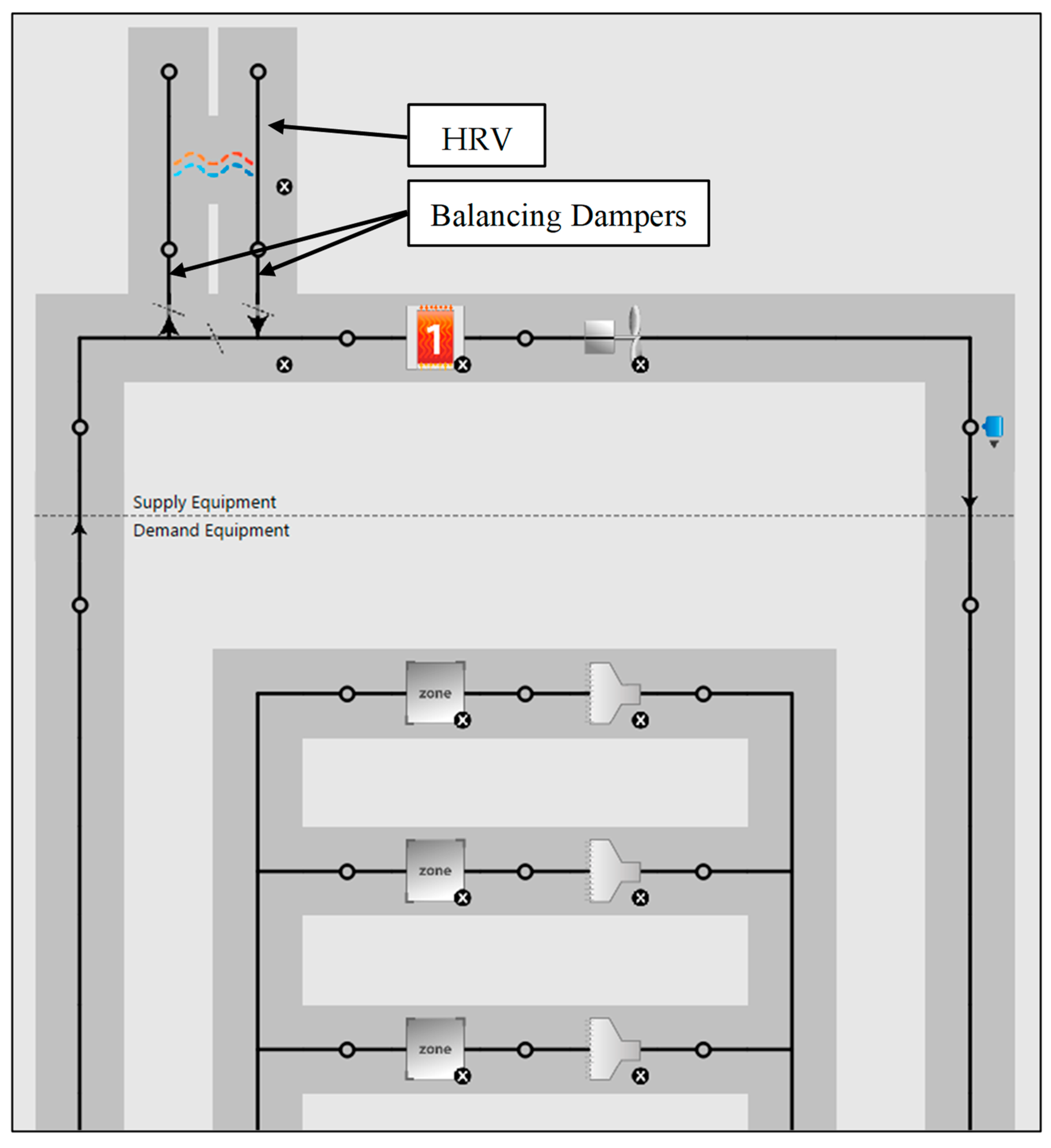

In contrast, the scenario with the HRV assumes a balanced ventilation system is added to the existing HVAC system to accommodate the deployment of the HRV. Thus, the HRV introduces outside air at a certain flowrate into the space, partially heating this air by harvesting waste the waste heat from the exhaust air stream passing through the HRV, depending on the HRV’s heat exchange effectiveness. Therefore, in the scenario with the HRV, both infiltration and mechanically ventilated air contribute the outside-air-induced building heat loss,

, which can be calculated as:

where

= total outside-air-induced space heat loss after the HRV is applied,

= rated mass flowrate of the HRV supply/exhaust fan, ;

= HRV heat exchange effectiveness,

= mass flowrate of the infiltrated air in the with-HRV scenario, ;

= specific heat capacity of air, ;

= indoor heating setpoint temperature,

= outdoor dry bulb temperature, .

In this study, the mass flowrate of infiltrated air remains the same (i.e., vs. ) in both scenarios. Equations (4) and (5) imply the outside air-induced heat loss in the with-HRV scenario must be greater than that in the without-HRV scenario since the heat exchange effectiveness of the HRV, , is always less than unity (i.e., 100% efficiency). As a result, the space heating system in the with-HRV scenario consumes more natural gas than in the without-HRV scenario.

In order to balance the additional heat loss induced by the mechanically ventilated air passing through the HRV, the total outside air-induced space heat loss after HRV is applied,

, must be equal to or less than the infiltration air-induced space heat loss in the existing house,

. Thus, by dividing the terms,

in both equations, we have:

Equation (6) implies that if the envelope air tightness after the deployment of the HRV can be improved to a level such that

then the total outside air-induced space heat loss in the with-HRV scenario will be smaller than that in the without-HRV scenario, resulting in reductions in building space heating energy consumption. This suggests that for an existing building without an active or balanced mechanical ventilation system in place, implementing an HRV should always be accompanied by the retrofit of building envelope systems to improve airtightness. In this study, the infiltration rate in the without-HRV scenario was modeled as 0.367

(i.e.,

), while the ventilation air and the heat exchange effectiveness of the HRV in the with-HRV scenario were modeled as 0.367

(i.e.,

) and 75.9% (i.e.,

, respectively. Thus, the infiltration rate of the building envelope after the HRV retrofit,

, needs to be equal to or less than 0.281

, according to Equation (7), so that the implementation of the HRV will not lead to additional space heating energy use.

In the practice, if calculations indicate that achieving the required infiltration rate (i.e., ) after the HRV implementation is unrealistically low or non-existent (i.e., ), that suggests that adding an HRV to the existing building heating system may result in increased space heating energy consumption. This scenario typically occurs in existing buildings with a relatively low infiltration rate; hence, it is essential to assess whether the building is under-ventilated by comparing the current infiltration airflow rate to the minimum ventilation airflow rate requirements specified by relevant codes and standards, such as AHRAE 62.2.

If the building does not meet these ventilation standards, the implementation of an HRV in existing HVAC system becomes essential to improve the indoor air quality. In such scenarios, when comparing space heating energy consumption between scenarios with and without an HRV, it is crucial to account for the improved indoor air quality conditions provided by the HRV. However, to avoid unnecessary over-ventilation, which can lead to increased space heating energy consumption, the HRV’s ventilation capacity should be carefully determined. Ideally, the HRV should only supply the additional outdoor airflow necessary to meet the minimum code required ventilation rate, compensating for any shortfall in the building’s natural infiltration. This approach ensures compliance with the ventilation standards while minimizing the outdoor air-induced energy usage.

If the building already meets the required ventilation standards through natural infiltration, the implementation of an HRV in existing building solely to improve the indoor air quality may not be necessary. In such cases, the building relies on passive ventilation, which is neither controllable nor preheated, potentially leading to increased space heating energy consumption. To address this, enhancing the building envelope airtightness is recommended before any retrofit with an HRV system. This approach minimizes the uncontrolled infiltration and allows the HRV to be sized appropriately to compensate for the reduced infiltration, while maintaining the desired indoor air quality levels.

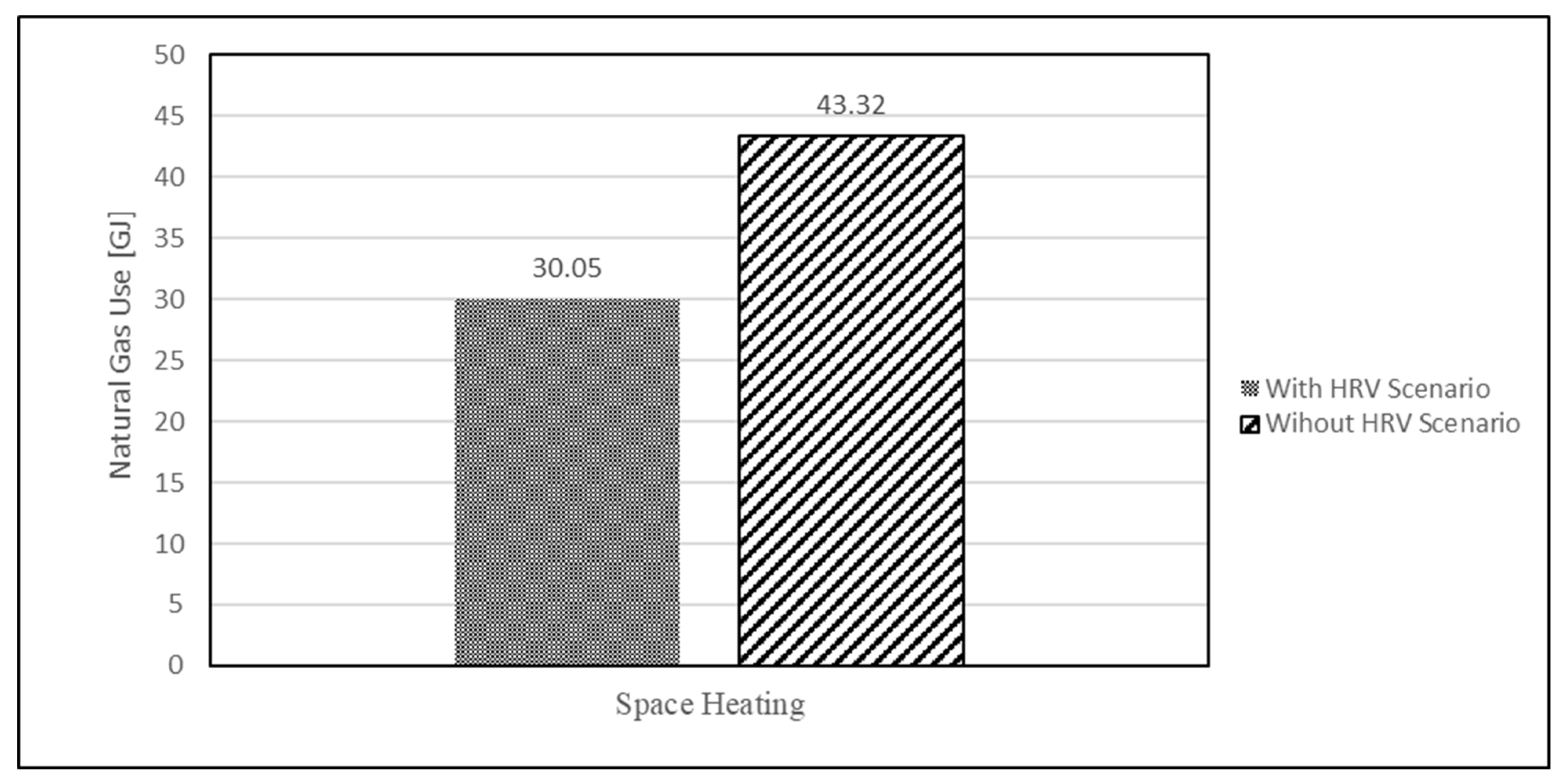

Figure 16 illustrates the comparison of the natural gas consumed by space heating systems coupled with and without the HRV under identical ventilation conditions. In this scenario, both the HRV’s ventilation air flow rate and infiltration air rate are set equally across both systems. As seen in the figure, the building space heating system equipped with an HRV consumes 30.05 GJ of natural gas, while the same system without implementing the HRV consumes 43.32 GJ. This suggests that for existing buildings with active or balanced mechanical ventilation systems in place, employing an HRV can significantly reduce space heating energy consumption.