A CFD Model for the Direct Coupling of the Combustion Process and Glass Melting Flow Simulation in Glass Furnaces

Abstract

:1. Introduction

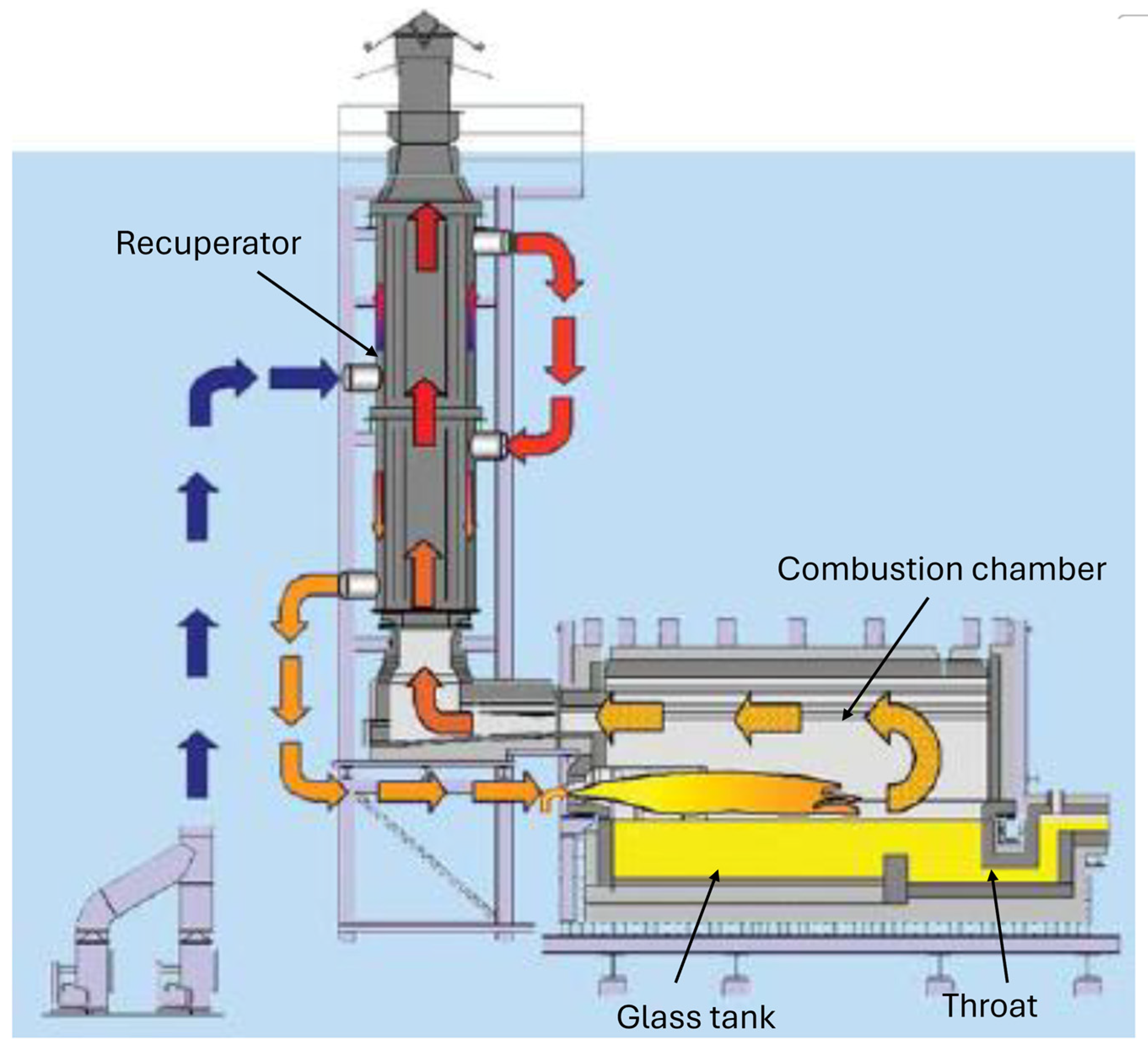

2. Furnace

3. Mathematical Model

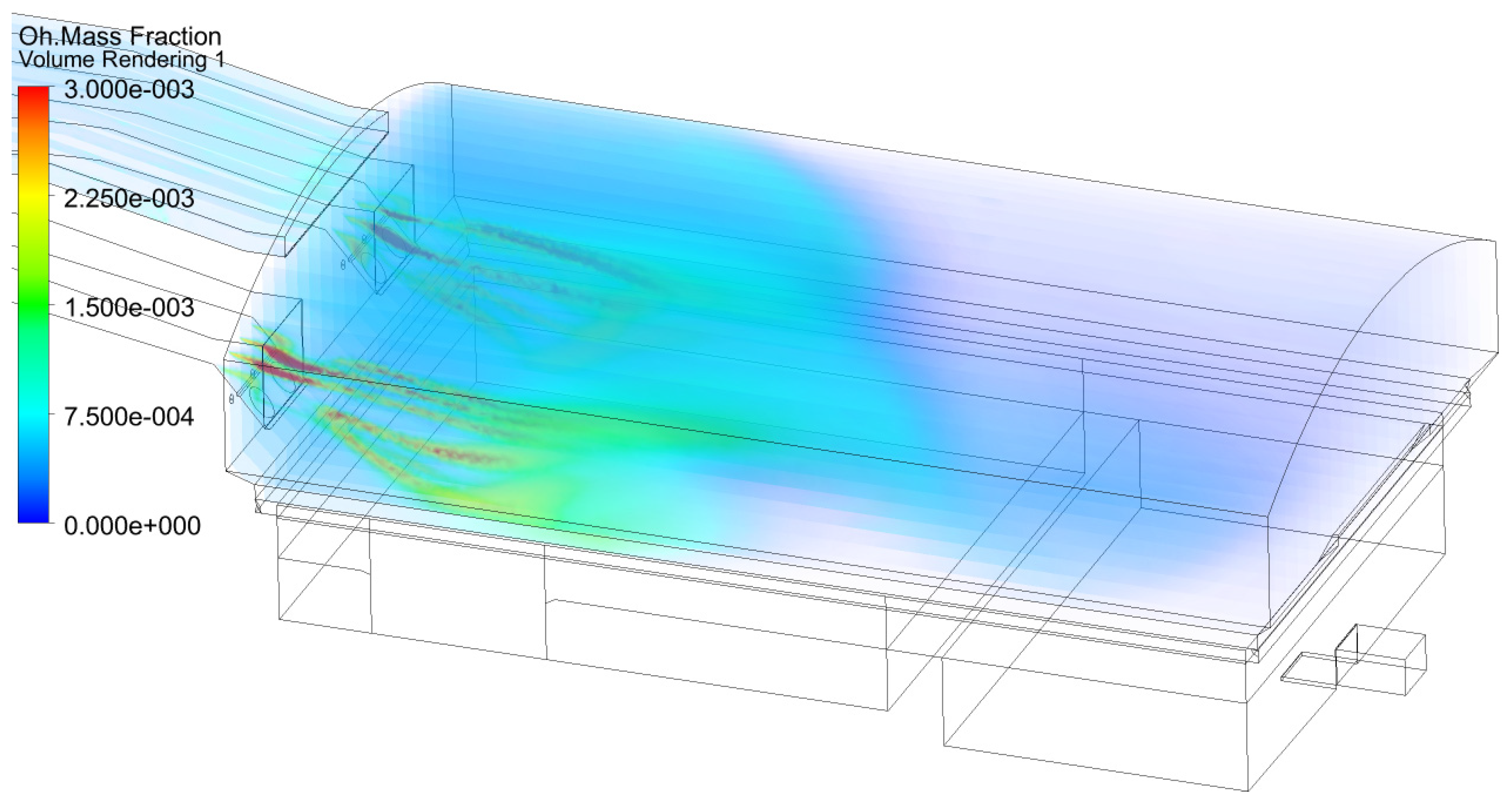

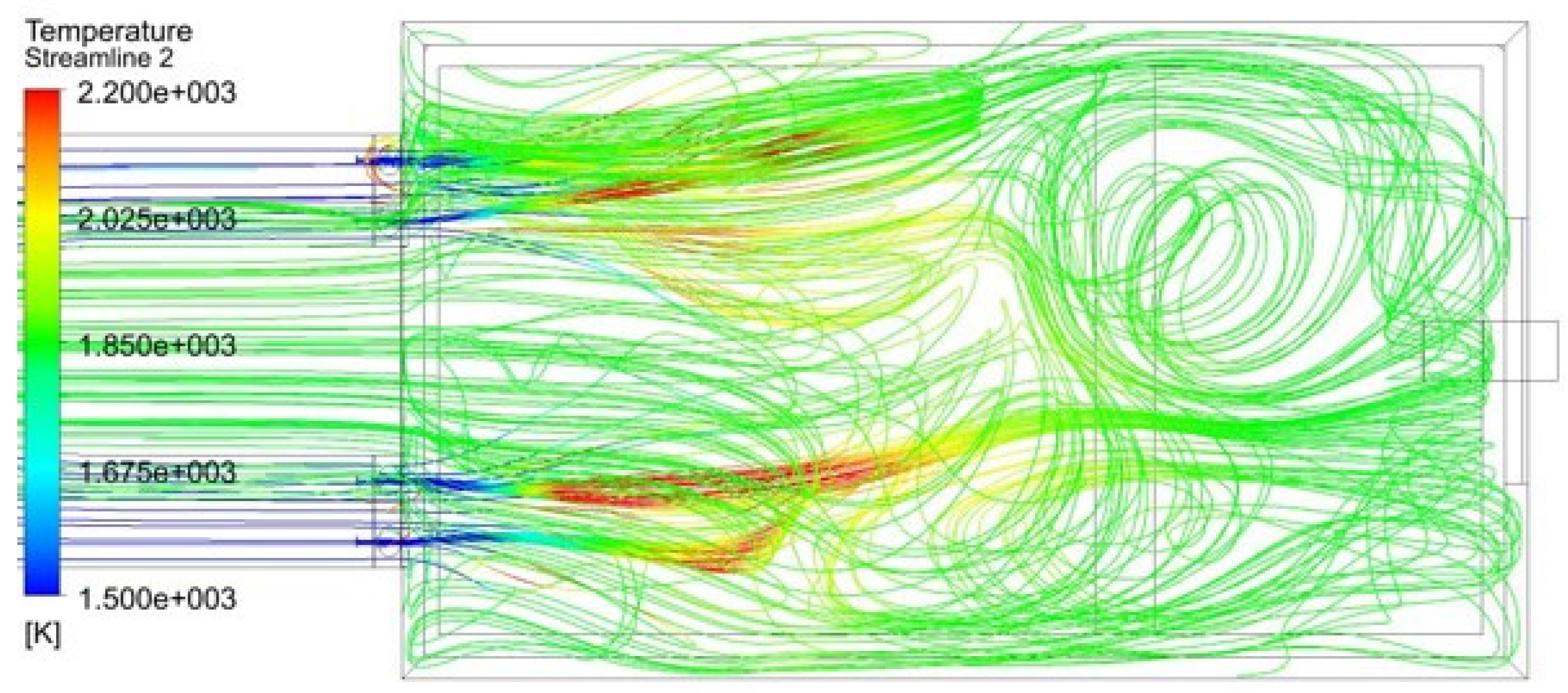

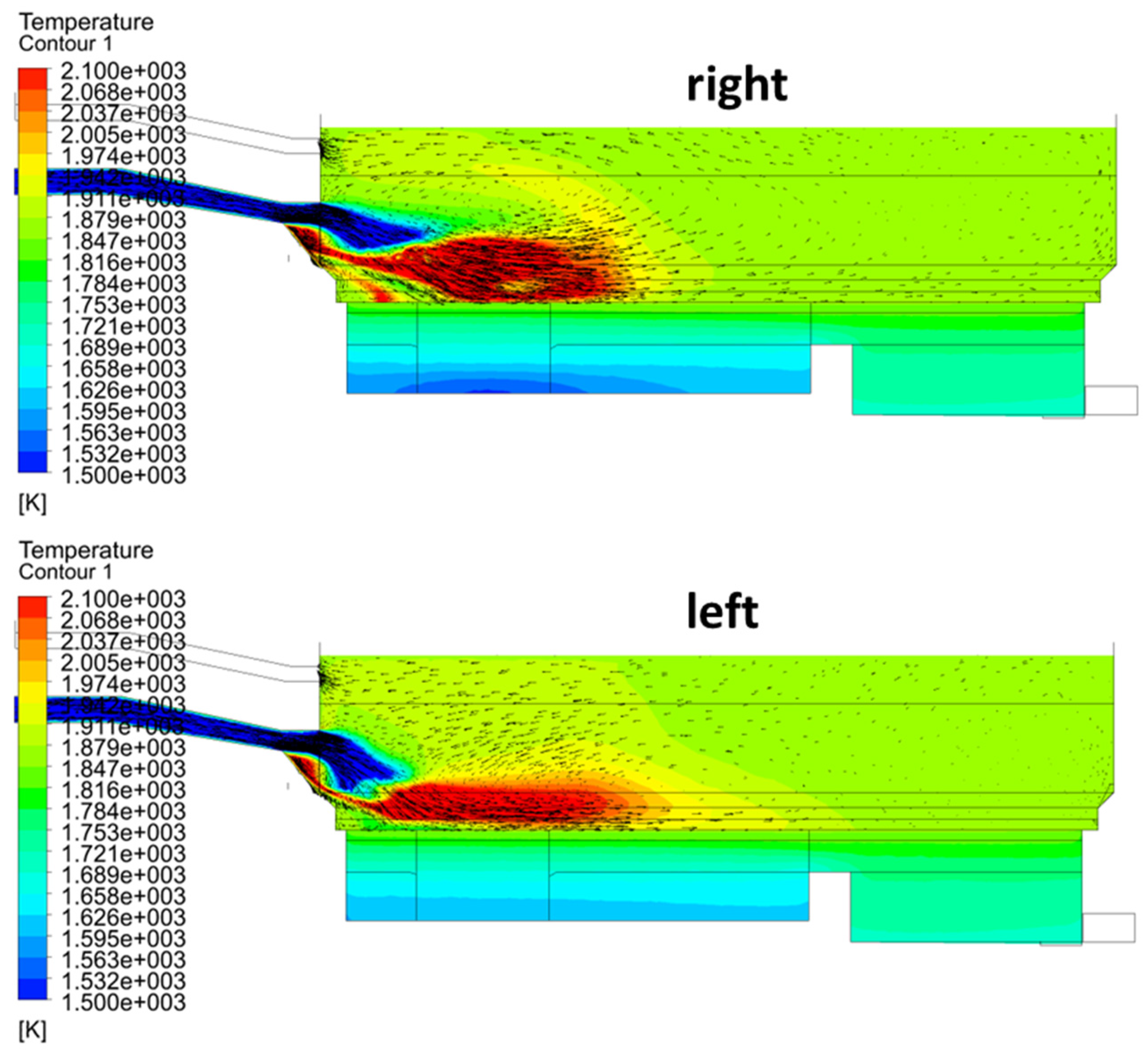

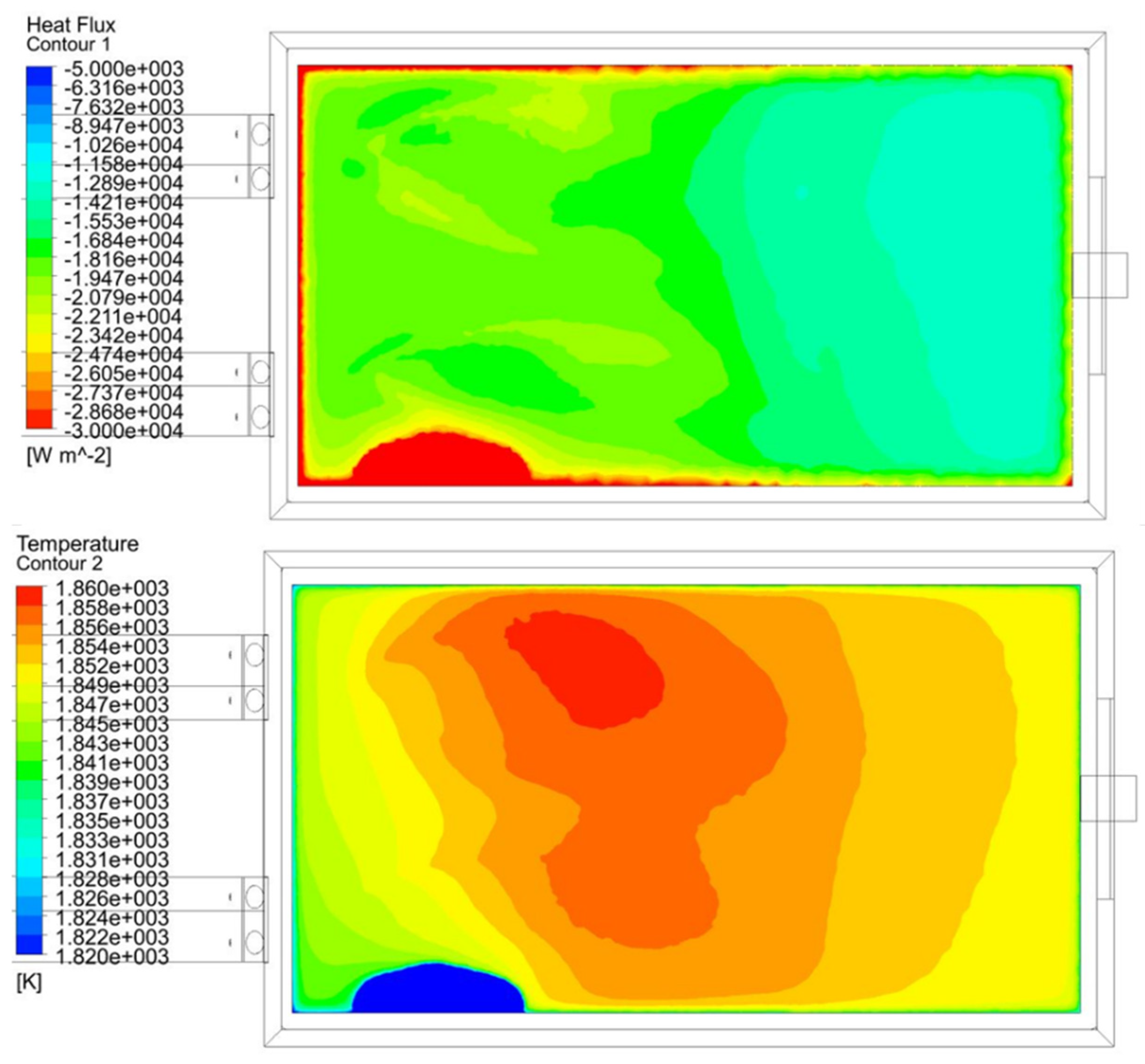

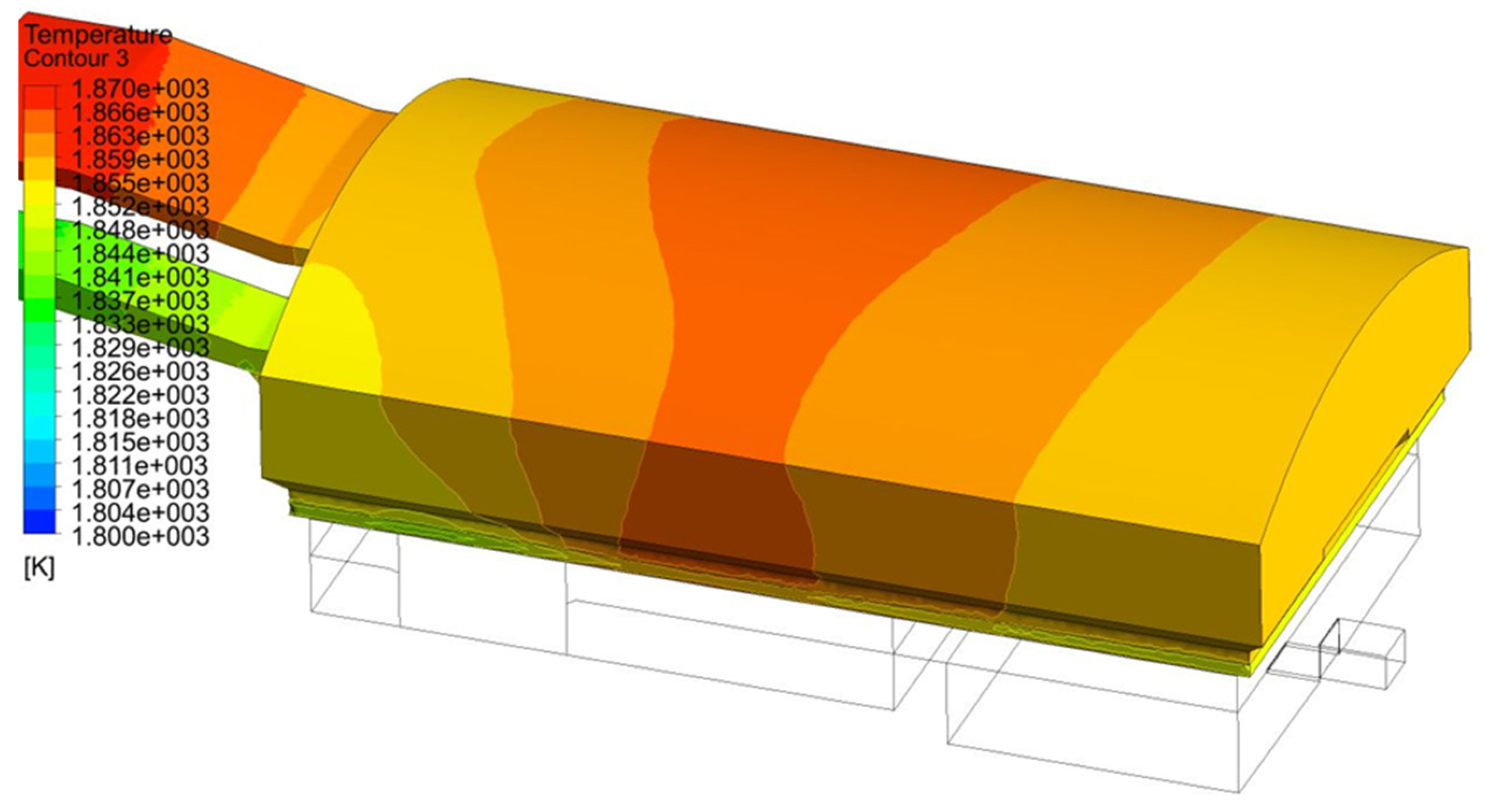

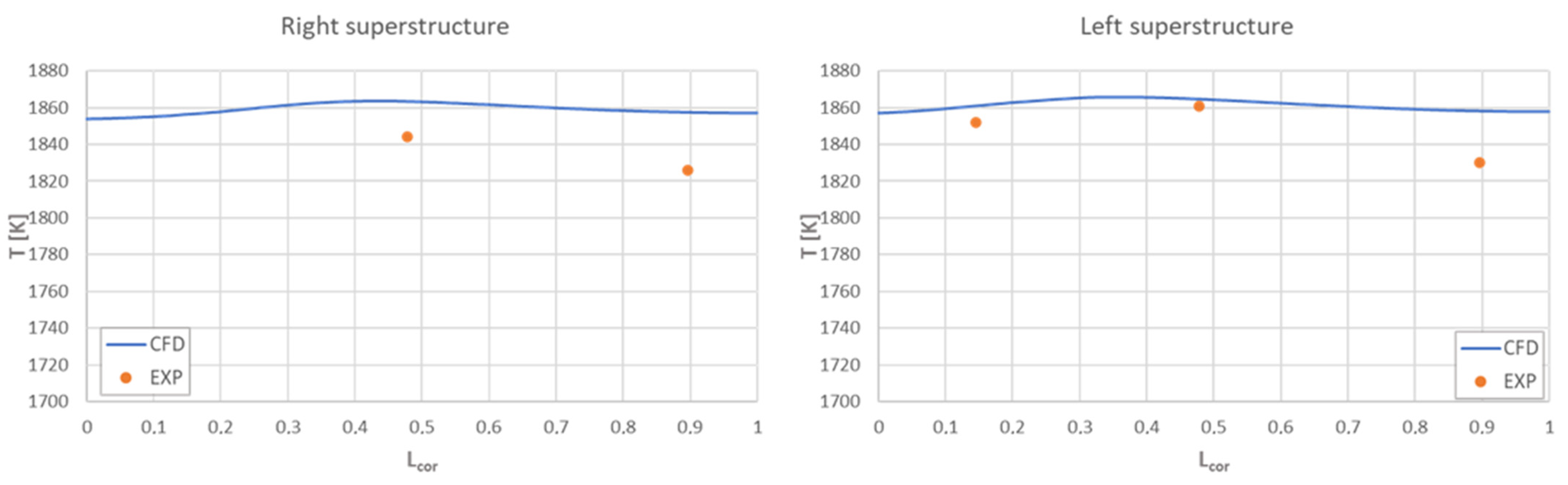

3.1. Combustion Space

3.1.1. Fluid Dynamics Governing Equations

3.1.2. Turbulence Model

3.1.3. Radiation Model

3.1.4. Combustion Model

3.1.5. Combustion Space Boundary Conditions

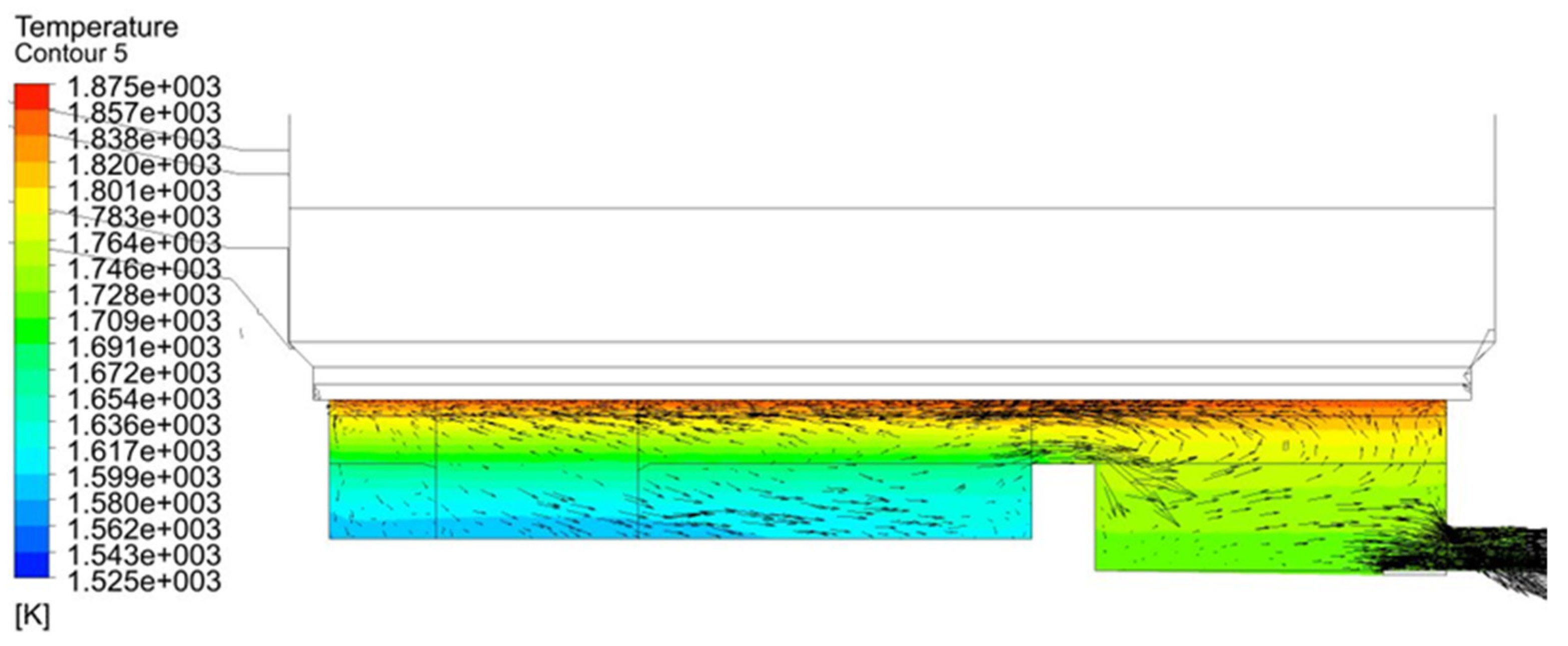

3.2. Glass Tank

3.2.1. Glass Tank Model and Properties

3.2.2. Glass Tank Boundary Conditions

4. Method of Solution

Coupling of Combustion Space to Glass Tank Model

5. Results

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Cp | Specific heat capacity at constant pressure |

| Dm,n | Molecular diffusion coefficient of species n |

| Dt | Turbulent diffusion coefficient |

| e | Internal energy |

| hf | Fluid side heat transfer coefficient based on the local flow field conditions |

| hn | Sensible enthalpy of species n |

| I | Turbulence intensity |

| Jn | Diffusion flux of species n |

| k | Molecular conductivity |

| kt | Turbulent thermal conductivity |

| K | Turbulent kinetic energy |

| L | Length |

| ṁ | Mass flow rate |

| n | Local coordinate normal to the wall |

| p | Pressure |

| Prt | Prandtl number |

| q | Heat flow |

| Q | Power |

| Rn | Net rate of production of species n |

| S | Surface |

| Sh | Source term |

| Sct | Schmidt number |

| t | Time |

| tij | Viscous stress tensor |

| T | Temperature |

| Tf | Local fluid temperature |

| u | Velocity |

| x | Cartesian coordinate |

| Yn | Mass fraction of species n |

| γ* | Length scale |

| ε | Rate of dissipation of turbulent kinetic energy |

| εv | Thermal emissivity |

| µ | Dynamic viscosity |

| µt | Turbulent viscosity |

| ν | Kinematic viscosity |

| ρ | Density |

| ξ | Length fraction |

| τ∗ | Mean residence time |

| Subscript | |

| atm | Atmospheric |

| cc | Combustion chamber |

| CFD | Computational fluid dynamics |

| cor | Corrected |

| EXP | Experimental |

| gt | Glass tank |

| in | Inlet |

| ou | Outlet |

| rad | Radiation |

| w | Wall |

References

- Schmitz, A.; Kaminski, J.; Scalet, B.M.; Soria, A. Energy consumption and CO2 emissions of the European glass industry. Energy Policy 2011, 39, 142–155. [Google Scholar]

- Koshelnik, A.V. Modelling operation of system of recuperative heat exchangers for aero engine with combined use of porosity model and thermos-mechanical model. Glass Ceram. 2008, 65, 9–10, 301–304. [Google Scholar]

- Selvaray, J.; Varun, V.S.; Vishwam, V. Waste heat recovery from metal casting and scrap preheating using recovered heat. Procedia Eng. 2014, 97, 267–276. [Google Scholar]

- Fathi, M.; Saray, R.K.; Checkel, M.D. The influence of Exhaust Gas Recirculation (EGR) on combustion and emissions of n-heptane/natural gas fueled Homogeneous Charge Compression Ignition (HCCI) engines. Appl. Energy 2011, 88, 4719–4724. [Google Scholar]

- Spliethoff, H.; Greul, U.; Rüdiger, H.; Hein, K.R. Basic effects on NOx emissions in air staging and reburning at a bench-scale test facility. Fuel 1996, 75, 560–564. [Google Scholar]

- Staiger, B.; Unterberger, S.; Berger, R.; Hein, K.R. Development of an air staging technology to reduce NOx emissions in grate fired boilers. Energy 2005, 30, 1429–1438. [Google Scholar]

- Guillen, D.P. Bubbling behavior in a waste glass melter. WIT Trans. Eng. Sci 2016, 105, 75–85. [Google Scholar]

- Kuzyak, V.A. Electric boosting of glass heating in flame tank furnaces. Glass Ceram. 1958, 15, 586–591. [Google Scholar]

- Fiehl, M.; Leicher, J.; Giese, A.; Görner, K.; Fleischmann, B.; Spielmann, S. Biogas as a co-firing fuel in thermal processing industries: Implementation in a glass melting furnace. Energy Procedia 2017, 120, 302–308. [Google Scholar]

- Gallagher, M.J.; Vinod, A.; Roger, A. Blue and Green Hydrogen Production, Distribution, and Supply for the Glass Industry and the Potential Impact of Hydrogen Fuel Blending in Glass Furnaces. In 83rd Conference on Glass Problems: Ceramic Transactions; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2023; Volume 271, pp. 127–135. [Google Scholar]

- McConnell, R.R.; Goodson, R.E. Modeling of glass furnace design for improved energy efficiency. Glass Technol. 1979, 20, 100–106. [Google Scholar]

- Mase, H.; Oda, K. Mathematical model of glass tank furnace with batch melting process. J. Non-Cryst. Solids 1980, 38–39, 807–812. [Google Scholar]

- Carvalho, M.G. Computer Simulation of a Glass Furnace. Ph.D. Thesis, London University, London, UK, 1983. [Google Scholar]

- Carvalho, M.G.; Lockwood, F.C. Mathematical simulation of an end-port regenerative glass furnace. Proc. Inst. Mech. Eng. C 1985, 199, 113–120. [Google Scholar]

- Carvalho, M.G.; Oliveira, P.; Semiao, V. A three-dimensional modelling of an industrial glass furnace. J. Inst. Energy 1988, 61, 143–156. [Google Scholar]

- Carvalho, M.G.; Nogueira, M. Modelling fluid flow and heat transfer in an industrial glass furnace. In Proceedings of the Annual ESPRIT Conference, Dordrecht, The Netherlands, 12–15 November 1990; pp. 530–543. [Google Scholar]

- Carvalho, M.G.; Nogueira, M. Modelling of glass melting industrial process. J. Phys. IV 1993, 3, C7-1357–C7-1366. [Google Scholar]

- Carvalho, M.G.; Nogueira, M.; Wang, J. Mathematical modeling of glass melting industrial process. In Proceedings of the 17th International Congress on Glass, Beijing, China, 9–14 October 1995; Volume 6, pp. 69–74. [Google Scholar]

- Chmelar, J.; Schill, P.; Franek, A. Mathematical models of glass melting furnaces. In Proceedings of the 4th International Conference on Advances in Fusion and Processing of Glass, Wurzburg, Germany, 22–24 May 1995; pp. 63–66. [Google Scholar]

- Hoke, B.C.; Marchiando, R.D. Using combustion modeling to improve glass melt model results. In Proceedings of the 4th International Seminar on Mathematical Simulation in the Glass Melting, Horni Becva, Czech Republic, 16–17 June 1997; pp. 87–95. [Google Scholar]

- Golchert, B.; Zhou, C.Q.; Chang, S.L.; Petrick, M. Investigation of spectral radiation heat transfer and NOx emission in a glass furnace. In Proceedings of the International Mechanical Congress and Exposition, Orlando, FL, USA, 5–10 November 2000. [Google Scholar]

- Chang, S.L.; Zhou, C.Q.; Golchert, B. Eulerian approach for multiphase flow simulation in a glass melter. Appl. Therm. Eng. 2005, 25, 3083–3103. [Google Scholar]

- Wang, J.; Brewster, B.S.; Mcquay, M.Q.; Webb, B.W. Validation of Advanced Models for Glass Melting Furnaces. In Proceedings of the 60th Conference on Glass Problems, Urbana, IL, USA, 19–20 October 2000. [Google Scholar]

- Choudhary, M.K.; Huff, N.T. Mathematical Modeling in the Glass Industry: An Overview of Status and Needs. Glastech. Ber. 1997, 70, 363–370. [Google Scholar]

- Viskanta, R. Review of Three-Dimensional Mathematical Modeling of Glass Melting. J. Non. Cryst. Solids 1994, 177, 347–362. [Google Scholar]

- Choudhary, M.K. Mathematical Modeling of Transport Phenomena in Glass Furnaces: An Overview of Status and Needs. In Proceedings of the International Commission on Glass Annual Meeting, Amsterdam, The Netherlands, 15–17 May 2000. [Google Scholar]

- Choudhary, M.K. Recent Advances in Mathematical Modeling of Flow and Heat Transfer Phenomena in Glass Furnaces. J. Am. Ceram. Soc. 2002, 85, 1030–1036. [Google Scholar]

- Beerkens, R.G. Modeling of the Melting Process in Industrial Glass Furnaces (Chapter 2.1). In Mathematical Simulation in Glass Technology; Krause, D., Loch, H., Eds.; Springer: Berlin/Heidelberg, Germany, 2002. [Google Scholar]

- Choudhary, M.K.; Venuturumilli, R.; Hyre, M.R. Mathematical Modeling of Flow and Heat Transfer Phenomena in Glass Melting, Delivery, and Forming Processes. Int. J. Appl. Glass Sci. 2010, 1, 188–214. [Google Scholar]

- Abbassi, A.; Khoshmanesh, K. Numerical simulation and experimental analysis of an industrial glass melting furnace. Appl. Therm. Eng. 2008, 28, 450–459. [Google Scholar]

- Li, L.; Lin, H.J.; Han, J.; Ruan, J.; Xie, J.; Zhao, X. Three-dimensional glass furnace model of combustion space and glass tank with electric boosting. Mater. Trans. 2019, 60, 1034–1043. [Google Scholar]

- Raič, J.; Gaber, C.; Wachter, P.; Demuth, M.; Gerhardter, H.; Knoll, M.; Prieler, R.; Hochenauer, C. Validation of a coupled 3D CFD simulation model for an oxy-fuel cross-fired glass melting furnace with electric boosting. Appl. Therm. Eng. 2021, 195, 117166. [Google Scholar]

- Daurer, G.; Raič, J.; Demuth, M.; Gaber, C.; Hochenauer, C. Detailed comparison of physical fining methods in an industrial glass melting furnace using coupled CFD simulations. Appl. Therm. Eng. 2023, 232, 121022. [Google Scholar]

- Cravero, C.; Marsano, D. Numerical simulation of regenerative chambers for glass production plants with a non-equilibrium heat transfer model. WSEAS Trans. Heat Mass Transf. 2017, 12, 21–29. [Google Scholar]

- Cravero, C.; Marsano, D.; Spoladore, A. Numerical strategies for fluid-dynamic and heat transfer simulation for regenerative chambers in glass production plants. NAUN Int. J. Math. Model. Methods Appl. Sci. 2017, 11, 82–87. [Google Scholar]

- Cravero, C.; De Domenico, D.; Leutcha, P.J.; Marsano, D. Strategies for the numerical modelling of regenerative pre-heating systems for recycled glass raw material. Math. Model. Eng. Probl. 2019, 6, 324–332. [Google Scholar]

- Cogliandro, S.; Cravero, C.; Marini, M.; Spoladore, A. Simulation strategies for regenerative chambers in glass production plants with strategic exhaust gas recirculation system. Int. J. Heat Technol. 2017, 35, S449–S455. [Google Scholar]

- Cravero, C.; De Domenico, D. The Use of CFD for the Design and Development of Innovative Configurations in Regenerative Glass Production Furnaces. Energies 2019, 12, 2455. [Google Scholar] [CrossRef]

- Cravero, C.; De Domenico, D.; Marsano, D. The Use of Uncertainty Quantification and Numerical Optimization to Support the Design and Operation Management of Air-Staging Gas Recirculation Strategies in Glass Furnaces. Fluids 2023, 8, 76. [Google Scholar] [CrossRef]

- Cravero, C.; Marsano, D. Numerical Simulation of Melted Glass Flow Structures inside a Glass Furnace with Different Heat Release Profiles from Combustion. Energies 2023, 16, 4187. [Google Scholar] [CrossRef]

- Cravero, C.; Lamberti, A.; Poggio, L. CFD Prediction of a Double Impulse Burner for Glass Furnaces. Energies 2023, 16, 4275. [Google Scholar] [CrossRef]

- Cravero, C.; Lamberti, A.; Marsano, D.; Milanese, G. Numerical investigation of turbulent fuel jet diffusion and its influence on the auto-igniting diffusive flame development. J. Phys. Conf. Ser. 2024, 2893, 012032. [Google Scholar] [CrossRef]

- Sommariva, B. Development of a CFD Reactive Model for Combustion Simulation in Glass Furnace. Master’s Thesis, University of Genoa, Genoa, Italy, 2024. [Google Scholar]

- Launder, B.E.; Spalding, D.B. Mathematical Models of Turbulence; Academic Press: London, UK, 1972. [Google Scholar]

- Rodi, W. Turbulence Models and Their Application in Hydraulics: A State-of-the-Art Review, 3rd ed.; IAHR Monograph Series; A.A. Balkema: Rotterdam, The Netherlands, 2017. [Google Scholar]

- Gran, I.R.; Magnussen, B.F. A numerical study of a bluff-body stabilized diffusion flame. Part 2. Influence of combustion modeling and finite-rate chemistry. Combust. Sci. Technol. 1996, 119, 191–217. [Google Scholar] [CrossRef]

- Launder, B.E.; Spalding, D.B. The numerical computation of turbulent flows. Comput. Methods Appl. Mech. Eng. 1974, 3, 269–289. [Google Scholar] [CrossRef]

- Thangam, S. Analysis of Two-Equation Turbulence Models for Recirculating Flows; NASA/CR-1991-187607. Available online: https://ntrs.nasa.gov/citations/19910021161 (accessed on 31 March 2025).

- Magnussen, B. On the structure of turbulence and a generalized eddy dissipation concept for chemical reaction in turbulent flow. In Proceedings of the 19th Aerospace Sciences Meeting, Aerospace Sciences Meetings, American Institute of Aeronautics and Astronautics, St. Louis, MO, USA, 12–15 January 1981. [Google Scholar]

- Modest, M. Radiative Heat Transfer, 2nd ed.; Academic Press: Cambridge, MA, USA, 2003. [Google Scholar]

- Peters, N. Laminar diffusion flamelet models in non-premixed turbulent combustion. Prog. Energy Combust. Sci. 1984, 10, 319–339. [Google Scholar] [CrossRef]

- Available online: http://combustion.berkeley.edu/gri_mech/ (accessed on 31 March 2025).

- ANSYS Inc. Ansys Fluent Theory Guide v.17; ANSYS Inc.: Canonsburg, PA, USA, 2017. [Google Scholar]

- Davoudzadeh, F.; Liu, N.S.; Moder, J.P. Investigation of swirling air flows generated by axial swirlers in a flame tube. Turbo Expo Power Land Sea Air 2006, 42363, 891–902. [Google Scholar]

- Rahman, T.M.R. An investigation of RANS simulations for swirl-stabilized isothermal turbulent flow in a gas turbine burner. CFD Lett. 2019, 11, 14–31. [Google Scholar]

- Xu, S.; Zhao, J.; Wu, H.; Zhang, S.; Müller, J.-D.; Huang, H.; Rahmati, M.; Wang, D. A Review of Solution Stabilization Techniques for RANS CFD Solvers. Aerospace 2023, 10, 230. [Google Scholar] [CrossRef]

| Equation | Inlet | Outlet | Wall |

|---|---|---|---|

| Momentum | Standard wall functions | ||

| Energy | - | Standard wall functions | |

| Transport species | - | - | |

| Turbulent kinetic energy | = 5% | - | |

| Turbulent dissipation rate | - | ||

| Thermal radiation |

| Contribution | Value [%] |

|---|---|

| Qexhaust | −89.0 |

| Qair | 22.7 |

| Qwall,cc | −7.5 |

| Qto-glass | 27.7 |

| Qglass,out | −19.2 |

| Qwall,gt | −5.3 |

| Species | Value |

|---|---|

| O2 [%] | 0.4 |

| CO [ppm] | 2457 |

| H2O [%] | 18.8 |

| CO2 [%] | 9.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cravero, C.; Marsano, D.; Milanese, G. A CFD Model for the Direct Coupling of the Combustion Process and Glass Melting Flow Simulation in Glass Furnaces. Energies 2025, 18, 1792. https://doi.org/10.3390/en18071792

Cravero C, Marsano D, Milanese G. A CFD Model for the Direct Coupling of the Combustion Process and Glass Melting Flow Simulation in Glass Furnaces. Energies. 2025; 18(7):1792. https://doi.org/10.3390/en18071792

Chicago/Turabian StyleCravero, Carlo, Davide Marsano, and Gabriele Milanese. 2025. "A CFD Model for the Direct Coupling of the Combustion Process and Glass Melting Flow Simulation in Glass Furnaces" Energies 18, no. 7: 1792. https://doi.org/10.3390/en18071792

APA StyleCravero, C., Marsano, D., & Milanese, G. (2025). A CFD Model for the Direct Coupling of the Combustion Process and Glass Melting Flow Simulation in Glass Furnaces. Energies, 18(7), 1792. https://doi.org/10.3390/en18071792