Adaptability Evaluation of High-Density Kill Fluid for Ultra-Deep and Ultra-High Temperature Well Testing in Tarim Oilfield

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Sample

2.2. Basic Performance Testing of Kill Fluids

2.2.1. Particle Size Testing

2.2.2. Electron Microscope Scan

2.2.3. Infrared Spectroscopic Testing

2.2.4. Zeta Potential Test

2.3. Rheology Test

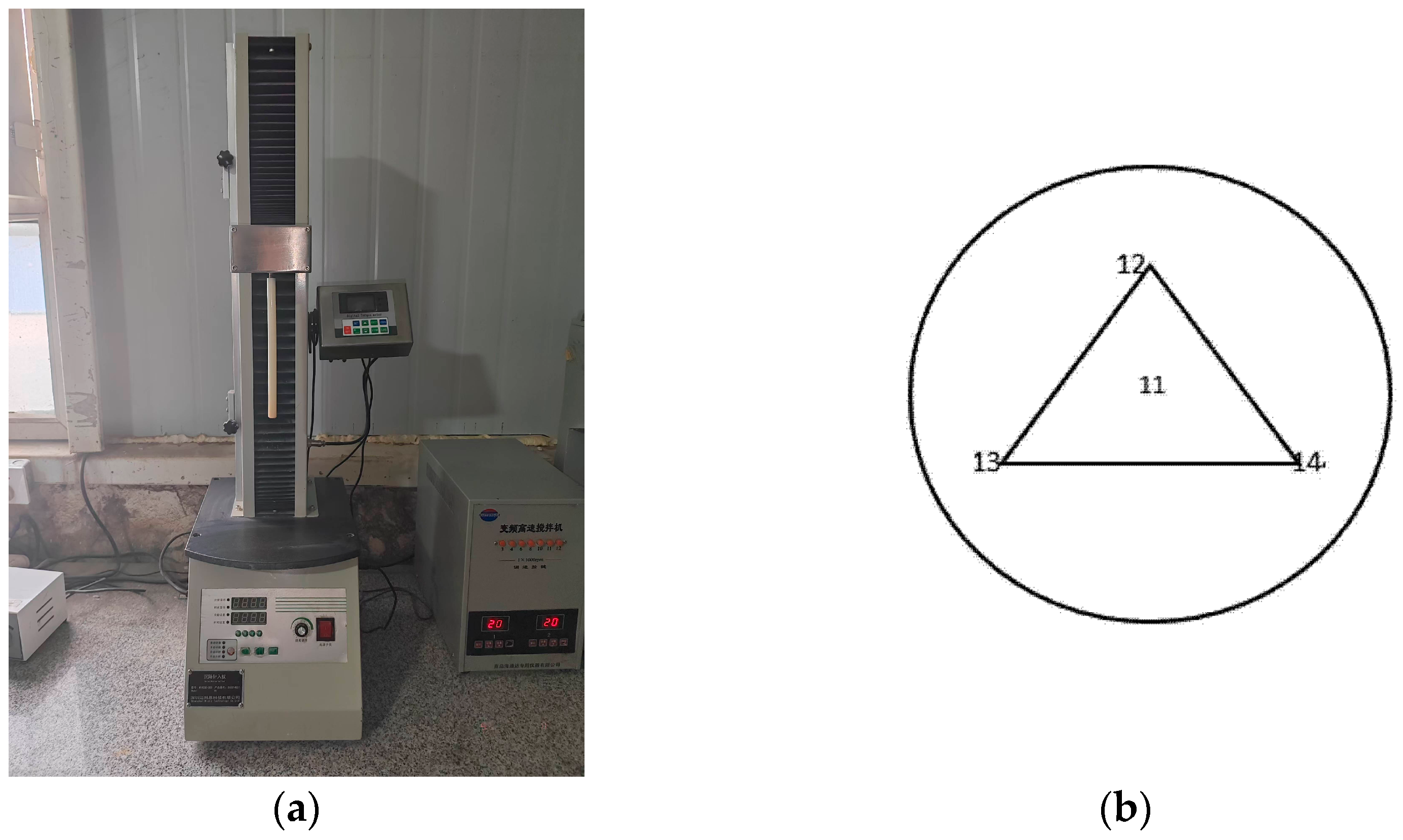

2.4. Settling Stability Test

2.4.1. Establishment of Settling Stability Evaluation Method

2.4.2. Settling Stability Test

3. Results and Discussion

3.1. Ultrafine Barite-Weighted Kill Fluid Basic Performance Results

3.1.1. Ultrafine Barite-Weighted Kill Fluid Particle Size Test Results

Comparison of Particle Size Before and After High-Temperature Aging for Different Densities of Ultrafine Barite-Weighted Kill Fluid

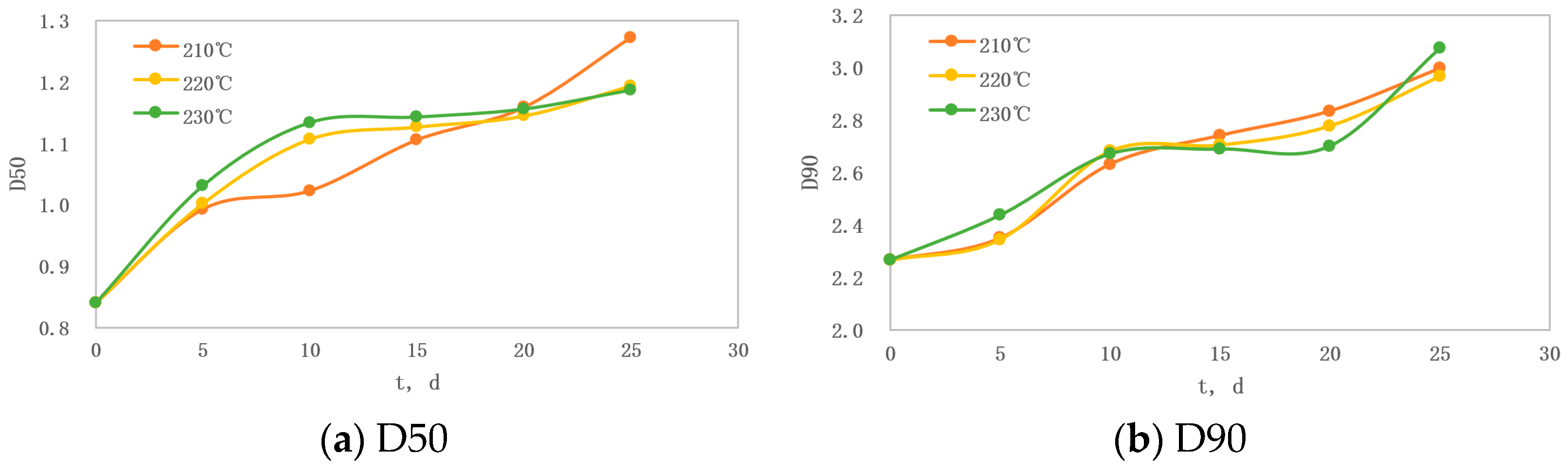

Comparison of Particle Size Before and After Aging of Ultrafine Barite-Weighted Kill Fluid at Different Temperatures

Comparison of Sediment and System Particle Size After Aging of Ultrafine Barite-Weighted Kill Fluid

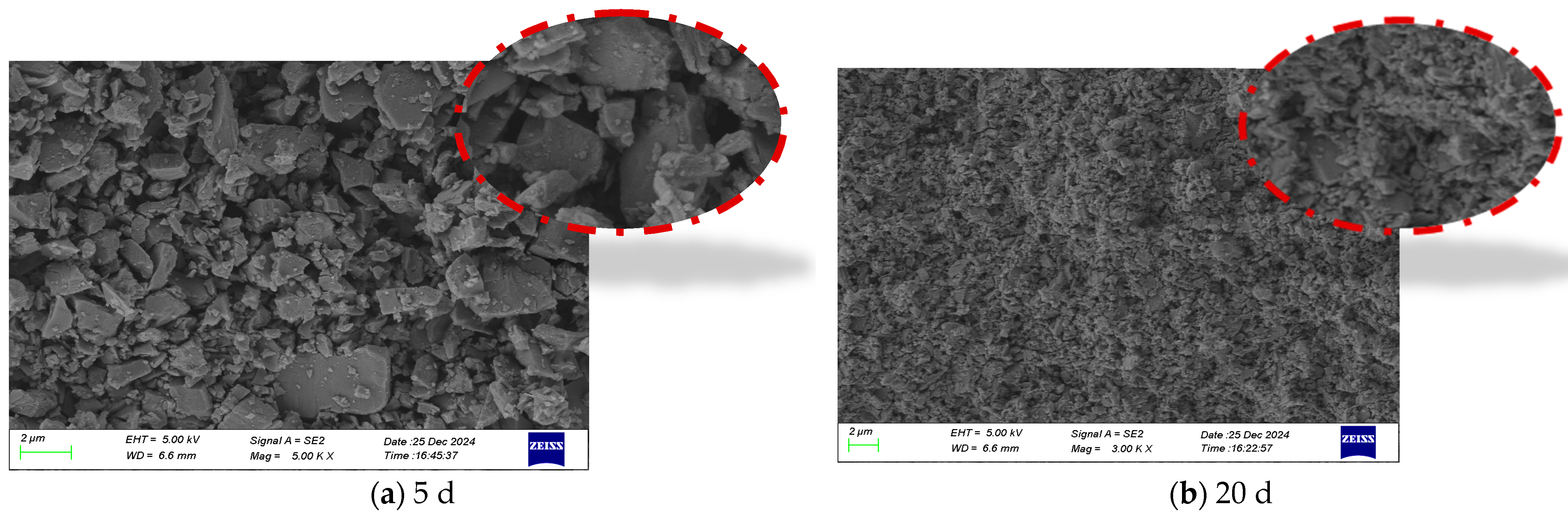

3.1.2. Electron Microscope Scanning

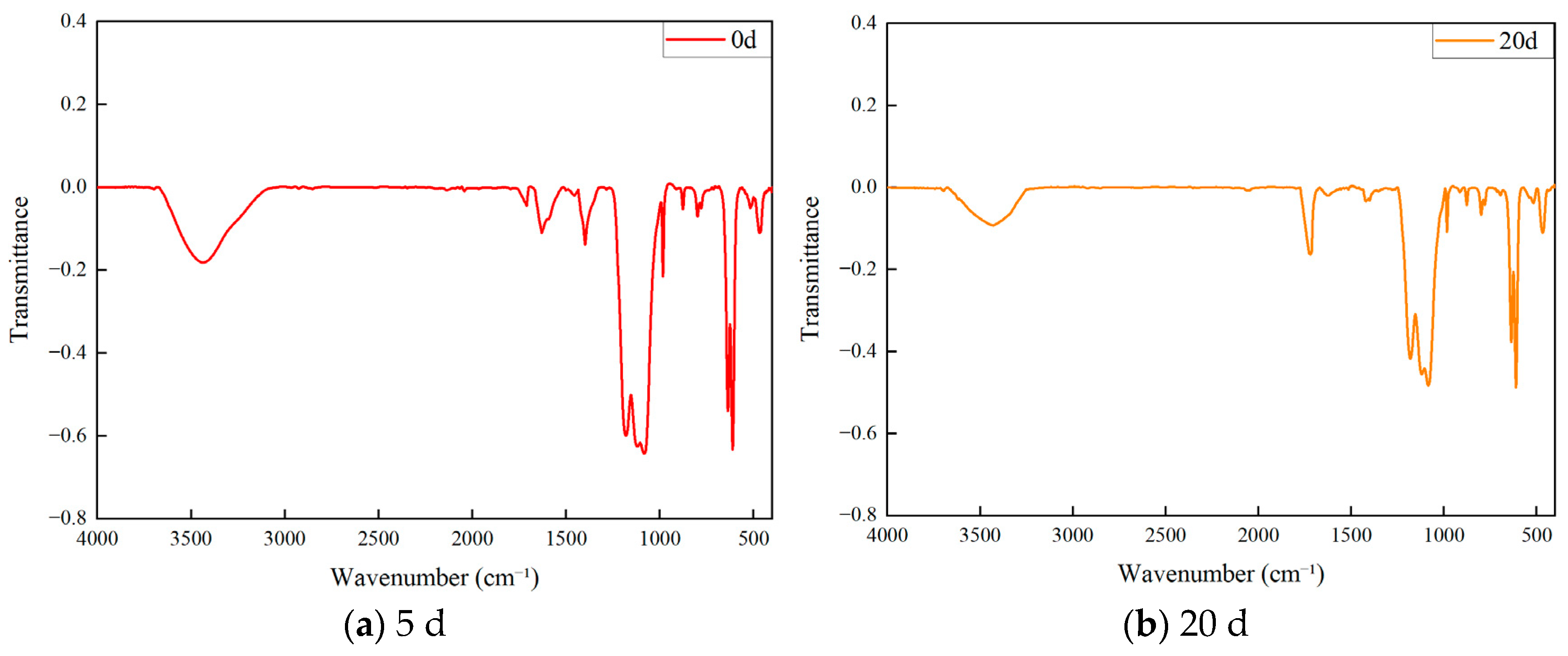

3.1.3. Infrared Analysis

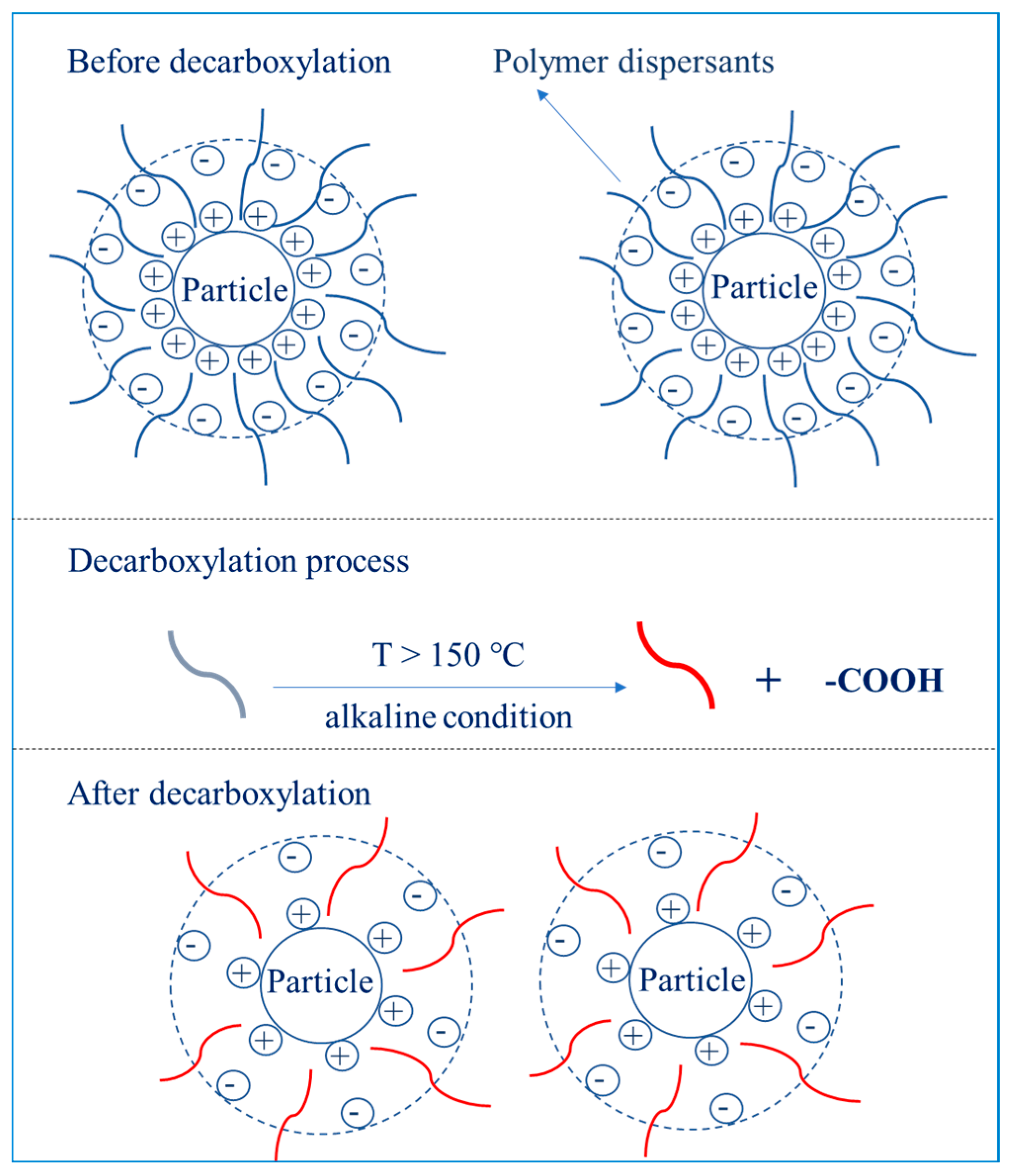

3.1.4. Zeta Potential Analysis

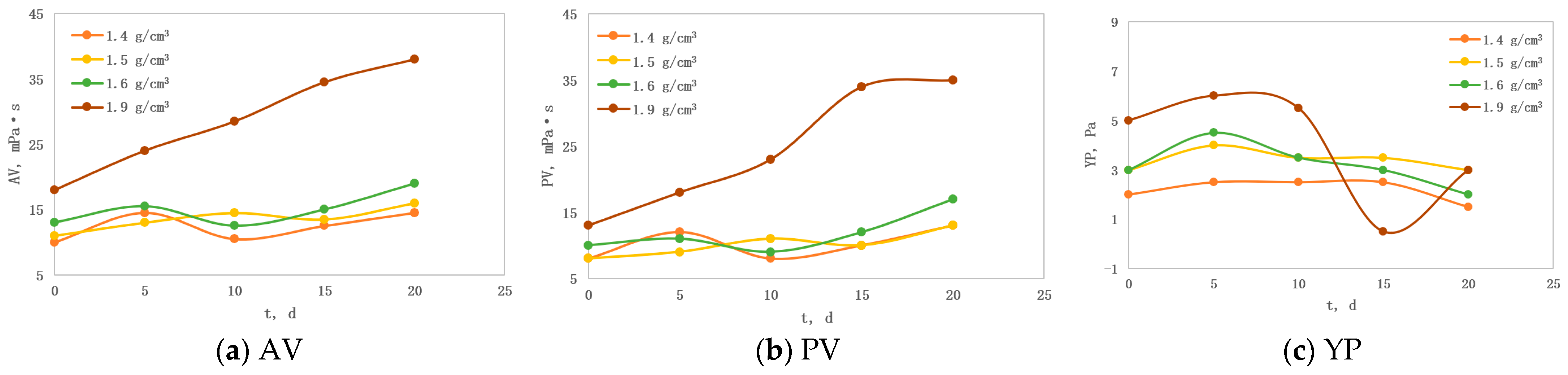

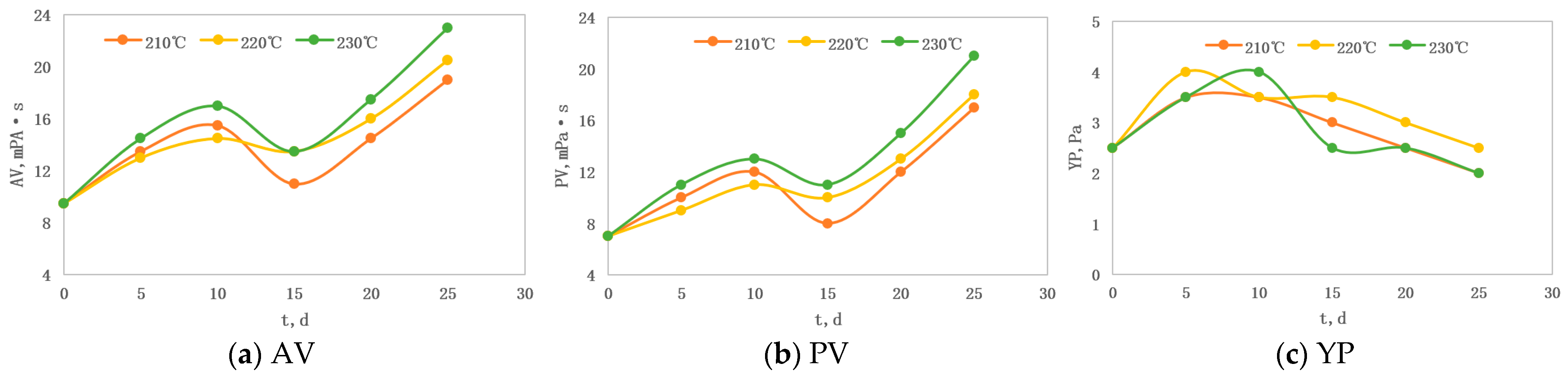

3.2. Ultrafine Barite-Weighted Kill Fluid Rheology Test Results

3.3. Results of Settling Stability Tests of Ultrafine Barite-Weighted Kill Fluid

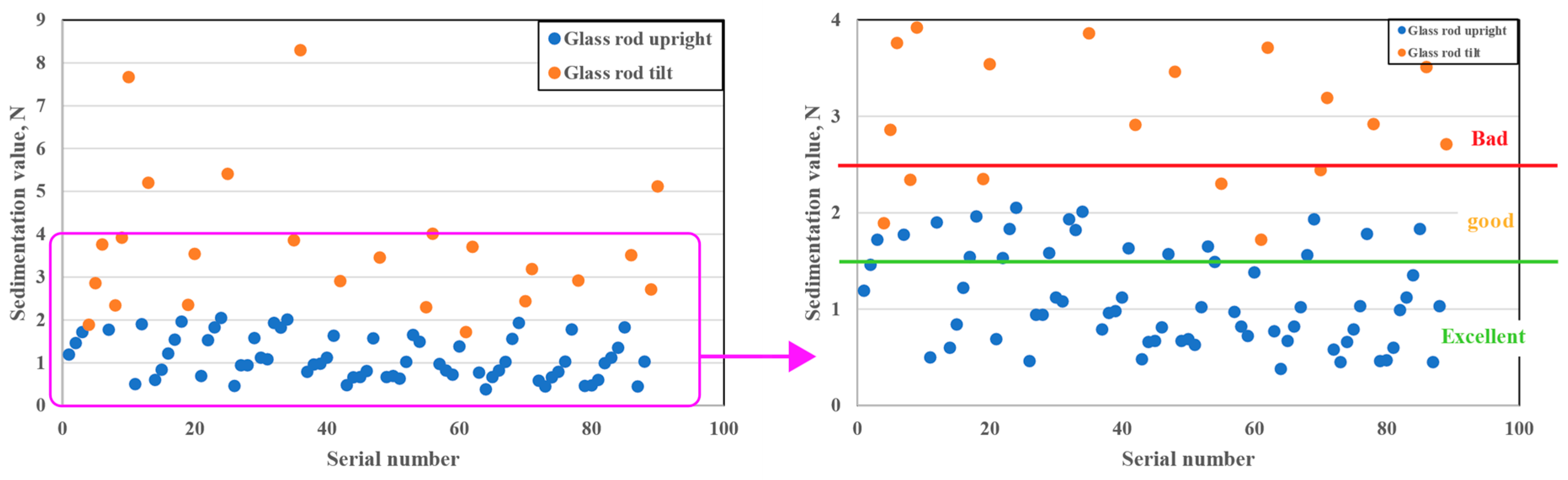

3.3.1. Method Creation

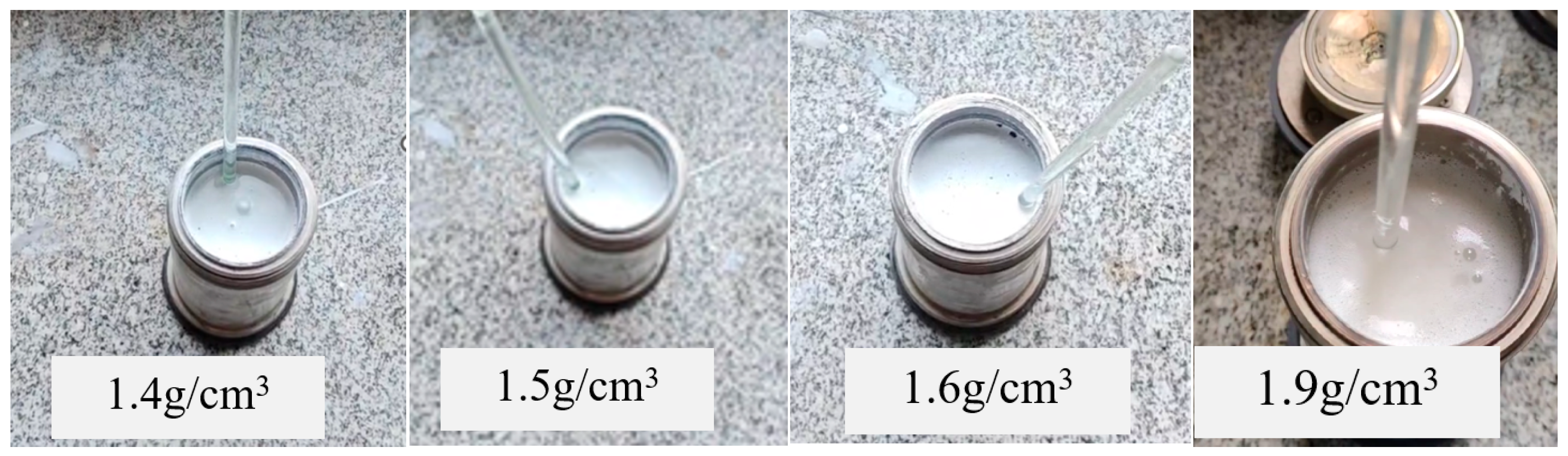

3.3.2. Settling Stability Test

3.3.3. Mechanisms of Settling Stability

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Su, Y.; Lu, B.; Liu, Y.; Zhou, Y.; Liu, X.; Liu, W.; Zang, Y. Status and Research Suggestions on the Drilling and Completion Technologies for Onshore Deep and Ultra Deep Wells in China. Oil Drill. Prod. Technol. 2020, 42, 527–542. [Google Scholar] [CrossRef]

- Sun, J.; Yang, J.; Bai, R.; Lv, K.; Liu, F. Research progress and development of deep and ultra-deep drilling fluid technology. Pet. Explor. Dev. 2024, 51, 889–898. [Google Scholar]

- Liu, L. Study on Settling Stability of High Temperature and High Density Water-Based Completion Fluid. Master’s Thesis, Southwest Petroleum University, Chengdu, China, 2018. [Google Scholar]

- Song, Z.; Li, Z.; Xue, Y.; Yang, Q. Drilling Fluid Technology for Horizontal Section of Ultra-Deep Well Yuanba 103H. Oil Drill. Prod. Technol. 2012, 34, 28–32. [Google Scholar] [CrossRef]

- Zhao, J.; Zhao, J.; Xue, Y.; Li, G.; Lan, Q. Drilling and Completion Fluids with Reservoir Protection of Horizontal Wells in Shengli Oilfield. Oil Drill. Prod. Technol. 2009, 31, 64–69. [Google Scholar]

- Sun, J.; Liu, W.; Wang, Q.; Huang, H.; Ji, G. Challenges and Development Prospects of Oil and Gas Drilling and Completionin Myriametric Deep Formation in China. Drill. Prod. Technol. 2024, 47, 1–9. [Google Scholar] [CrossRef]

- Liu, X.; Ding, P. Application and Research Progress of High Temperature and High Density Completion Fluids. Chem. Eng. 2022, 36, 71–74+70. [Google Scholar] [CrossRef]

- Budiman, H. Composition of Specifically Formulated Phosphate Salts, Used for Increasing Density of Completion Fluids, and as a Hi-Temperature and Easy to Use Completion Fluids in the Oil and Gas Industry. US20110124531A1, 6 May 2011. [Google Scholar]

- Collins, N.; Thaemlitz, C. Method for Drilling Using a Drilling and Completion Fluid Comprising a Phosphate Based Blend. US8901048B2, 2 December 2014. [Google Scholar]

- Champeau, M.; Wei, X.; Jackson, P.; Sui, C.; Zhang, J.; Okhrimenko, A. Alternative High Density Brines. In Proceedings of the SPE Offshore Europe Conference and Exhibition, Aberdeen, UK, 3–6 September 2019; OnePetro: Richardson, TX, USA, 2019. [Google Scholar]

- Hu, W.; Pan, L.; Huang, Z.; Du, C.; Wang, S.; Li, D.; Long, W.; Zhai, K.; Xu, Y.; Li, L. Low-Solid-Phase High-Temperature-Resistant Formate Drilling and Completion Fluid and Its Preparation Method. CN110105927A, 9 August 2019. [Google Scholar]

- Yue, C. Study on High Temperature and High Density Complex Brine Completion Fluid in Low Permeability Reservoir. Master’s Thesis, Southwest Petroleum University, Chengdu, China, 2018. [Google Scholar]

- Jiang, J. Progress of Research and Application of High-Density Drilling Fluid. Shandong Chem. Ind. 2021, 50, 76–77. [Google Scholar] [CrossRef]

- Yan, J. Drilling Fluid Processes; Revised Edition; China University of Petroleum Press: Beijing, China, 2013; ISBN 978-7-5636-3795-9. [Google Scholar]

- Xie, J.; Zhang, L.; Yang, X.; Lu, X.; Liao, R.; Zhang, G. High Temperature Settlement Stability Technology for Oil-Based Completion Fluid in PiedmontBlock of the Tarim Oilfield. Autom. Aoolication 2023, 64, 241–244. [Google Scholar]

- Al-Yami, A.S.; Nasr-El-Din, H.A.; Al-Majed, A.A.; Menouar, H. An Innovative Manganese Tetra-Oxide/KCl Water-Based Drill-in Fluids for HT/HP Wells; OnePetro: Richardson, TX, USA, 2007. [Google Scholar]

- Al-Saeedi, M.J.; Al-Khayyat, B.; Al-Enezi, D.; Aslan, A.; Luzardo, J.; Carrera, C. Successful HPHT Application of Potassium Formate/Manganese Tetra-Oxide Fluid Helps Improve Drilling Characteristics and Imaging Log Quality; OnePetro: Richardson, TX, USA, 2010. [Google Scholar]

- Zhang, T.; Ren, S.; Mei, M.; Kang, W. Application of Low Solid and H Igh Density Com Pletion Fluid in Dongfang B Gas Field. Sci. Technol. Innov. 2022, 6, 188–191. [Google Scholar]

- Gao, Z.; Zhu, L.; Zhou, M.; Liu, X.; Li, L. Application of High Density Ultra-Micro Barite Completion Fluid in Ultra-Deep Wells in Tarim Oilfield. Drill. Fluid Complet. Fluid 2013, 30, 50–52+98–99. [Google Scholar]

- Yan, L.; Ni, X.; Zhang, J.; Wang, J.; Shi, H.; Gao, S. Nanoparticles Improved the Sedimentation Stability of High-Density Oil-Based Drilling & Completion Fluids. Appl. Chem. Ind. 2023, 52, 53–57. [Google Scholar] [CrossRef]

- Nie, Q.; Chou, H.; Xu, X.; Wang, P.; Yang, L.; Zhang, T.; Cheng, X. Regression Analysis of Static Settling Stability of Water-Based Completion Fluid. Guangzhou Chem. Ind. 2024, 52, 123–125. [Google Scholar]

- Liang, Y.; Yang, L.; Nie, Q.; Zhou, H.; Ma, G.; Xiao, F.; Qi, M. A Method for Quantitatively Evaluating the Static Stability of Water-Based Completion Fluids in Different Density Sections; CNPC Chuanqing Drilling Engineering Company Limited: Chuanqing, China; China National Petroleum Corporation: Beijing, China, 2020. [Google Scholar]

- Zeng, W.; Mario Bouguetta, A. Comparative Assessment of Barite SAG Evaluation Methods. In Proceedings of the SPE Deepwater Drilling and Completions Conference, Galveston, TX, USA, 14–15 September 2016; SPE: Dallas, TX, USA, 2016. [Google Scholar]

- Bern, P.A.; van Oort, E.; Neusstadt, B.; Ebeltoft, H.; Zurdo, C.; Zamora, M.; Slater, K. Barite Sag: Measurement, Modelling and Management. SPE Drill. Complet. 2000, 15, 25–30. [Google Scholar] [CrossRef]

- Hanson, P.M.; Trigg, T.K.; Rachal, G.; Zamora, M. Investigation of Barite “Sag” in Weighted Drilling Fluids in Highly Deviated Wells. In Proceedings of the Society of Petroleum Engineers Annual Technical Conference and Exhibition, New Orleans, LA, USA, 23–26 September 1990; Society of Petroleum Engineers: Dallas, TX, USA, 1990. [Google Scholar]

- Ye, Y. An Ultra-High Temperature High-Density Oil Test Completion Fluid and Its Preparation Method and Application. CN110028938A, 19 July 2019. [Google Scholar]

- Ye, Y.; Yin, D.; Liu, C.; Lu, H.; Wang, Y.; Li, L. A Kind of High-Density Test Oil Working Fluid Settlement Stability Test Device. CN202814944U, 20 March 2013. [Google Scholar]

| Blocs | Temperature | Density | Underground Operating Hours |

|---|---|---|---|

| BOZI | 112.85~160.15 | 1.45~2.08 | 12~43 |

| KESHEN | 143~190 | 1.3~1.9 | 11~40 |

| DABEI | 85.11~149.74 | 1.48~2.32 | 14~27 |

| Others | 101.84~171.00 | 1.55~1.98 | 7~22 |

| Serial Number | Density (g/cm3) | Temperature (°C) | Aging Time (d) |

|---|---|---|---|

| 1 | 1.4 | 220 | 0, 5, 10, 15, 20 |

| 2 | 1.5 | 210 | 0, 5, 10, 15, 20 |

| 3 | 220 | 0, 5, 10, 15, 20 | |

| 4 | 230 | 0, 5, 10, 15, 20 | |

| 5 | 1.6 | 220 | 0, 5, 10, 15, 20 |

| 6 | 1.9 | 220 | 0, 5, 10, 15, 20 |

| 7 | 1.53 | 180 | 0, 10, 20, 30, 40 |

| 8 | 1.77 | 180 | 0, 10, 20, 30, 40 |

| 9 | 1.85 | 170 | 0, 5, 15, 20, 30 |

| 10 | 1.91 | 180 | 0, 10, 20, 30 |

| Experimental Condition | 1.4 g/cm3 | 1.5 g/cm3 | 1.6 g/cm3 | 1.9 g/cm3 | ||||

|---|---|---|---|---|---|---|---|---|

| D50 | D90 | D50 | D90 | D50 | D90 | D50 | D90 | |

| 0 d | 0.98 | 2.357 | 0.84 | 2.267 | 1.037 | 2.344 | 1.125 | 2.641 |

| 5 d | 1.101 | 2.431 | 1.002 | 2.345 | 1.115 | 2.463 | 1.205 | 2.753 |

| 10 d | 1.042 | 2.561 | 1.107 | 2.682 | 1.173 | 2.649 | 1.348 | 3.105 |

| 15 d | 1.113 | 2.597 | 1.127 | 2.705 | 1.206 | 2.776 | 1.382 | 3.326 |

| 20 d | 1.116 | 2.683 | 1.145 | 2.778 | 1.264 | 2.874 | 1.421 | 3.562 |

| Average Value | 1.0704 | 2.5258 | 1.0442 | 2.5554 | 1.159 | 2.6212 | 1.2962 | 3.0774 |

| Standard Deviation | 0.0588 | 0.1309 | 0.1269 | 0.2320 | 0.0869 | 0.2182 | 0.1257 | 0.3856 |

| t/d | 210 °C | 220 °C | 230 °C | |||

|---|---|---|---|---|---|---|

| D50 | D90 | D50 | D90 | D50 | D90 | |

| 0 | 0.840 | 2.267 | 0.84 | 2.267 | 0.84 | 2.267 |

| 5 | 0.993 | 2.291 | 1.002 | 2.345 | 1.031 | 2.438 |

| 10 | 1.023 | 2.532 | 1.107 | 2.682 | 1.134 | 2.671 |

| 15 | 1.106 | 2.741 | 1.127 | 2.705 | 1.143 | 2.689 |

| 20 | 1.139 | 2.834 | 1.145 | 2.778 | 1.156 | 2.895 |

| 25 | 1.173 | 2.996 | 1.194 | 2.967 | 1.237 | 3.073 |

| Average Value | 1.0457 | 2.6102 | 1.0692 | 2.624 | 1.0902 | 2.6722 |

| Standard Deviation | 0.1218 | 0.2973 | 0.1289 | 0.2671 | 0.1391 | 0.2931 |

| t (d) | Zeta Potential (mV) |

|---|---|

| 0 | −40.3 |

| 20 | −26.4 |

| 25 | −22.7 |

| Density (g/cm3) | Temperature (°C) | t (d) | Sedimentation Value (N) | Drop Shot |

|---|---|---|---|---|

| 1.53 | 180 | 10 | 0.67 | The glass rod falls freely to the bottom and rebounds against the wall. |

| 20 | 1.12 | The glass rod falls freely for 17 cm and is gently inserted into the bottom. | ||

| 30 | 1.93 | The glass rod tilted, softly sunk 2 cm, and gently inserted into the bottom. | ||

| 40 | 2.44 | The glass rod is tilted, softly sunk 5 cm, and gently inserted into the bottom. | ||

| 1.77 | 180 | 10 | 0.69 | The glass rod falls freely to the bottom and rebounds against the wall. |

| 20 | 1.02 | The glass rod falls freely to the bottom and rebounds against the wall. | ||

| 30 | 1.49 | The glass rod falls freely for 15 cm and is gently plunged to the bottom. | ||

| 40 | 4.01 | The glass rod is upright, soft sinking 9 cm, and forced to the bottom. | ||

| 1.85 | 170 | 5 | 1.77 | The glass rod is tilted, softly sinking 1 cm, and gently inserted into the bottom. |

| 15 | 2.34 | The glass rod is tilted, softly sinking 3 cm, and gently inserted into the bottom. | ||

| 20 | 3.92 | The glass rod is upright, softly sinking 7 cm, and forced to the bottom. | ||

| 30 | 7.67 | The glass rod is upright, hard sinking 2 cm, not forced to the bottom, and the glass rod is suctioned. | ||

| 1.91 | 180 | 10 | 0.96 | The glass rod falls freely to the bottom and rebounds against the wall. |

| 20 | 1.63 | The glass rod is tilted, softly sinking 4 cm, and gently inserted into the bottom. | ||

| 30 | 2.91 | The glass rod is upright, soft sinking 6 cm, and forced to the bottom. |

| Gradings | Sedimentation Value/N | Drop Shot |

|---|---|---|

| excellent | 0~1 | The glass rod falls freely to the bottom and rebounds against the wall. |

| 1~1.5 | The glass rod falls freely 15~18 cm and is gently inserted to the bottom. | |

| good | 1.5~2.5 | The glass rod is tilted, soft sinking 2~5 cm, and is gently inserted into the bottom. |

| poor | 2.5~5 | The glass rod is upright, soft sinking ≥ 6 cm, and forced to the bottom. |

| 5 or more | The glass rod is upright, hard sinking ≥ 2 cm, not forced to the bottom, and the glass rod is suctioned. |

| Density (g·cm−3) | t (d) | Sedimentation Value (N) | Drop Shot | Gradings |

|---|---|---|---|---|

| 1.4 | 5 | 0.31 | The glass rod falls freely to the bottom and rebounds against the wall. | excellent |

| 10 | 0.42 | The glass rod falls freely to the bottom and rebounds against the wall. | ||

| 15 | 0.76 | The glass rod falls freely to the bottom and rebounds against the wall. | ||

| 20 | 0.83 | The glass rod falls freely to the bottom and rebounds against the wall. | ||

| 1.5 | 5 | 0.44 | The glass rod falls freely to the bottom and rebounds against the wall. | excellent |

| 10 | 0.53 | The glass rod falls freely to the bottom and rebounds against the wall. | ||

| 15 | 0.79 | The glass rod falls freely to the bottom and rebounds against the wall. | ||

| 20 | 0.89 | The glass rod falls freely to the bottom and rebounds against the wall. | ||

| 1.6 | 5 | 0.52 | The glass rod falls freely to the bottom and rebounds against the wall. | excellent |

| 10 | 0.63 | The glass rod falls freely to the bottom and rebounds against the wall. | ||

| 15 | 0.89 | The glass rod falls freely to the bottom and rebounds against the wall. | ||

| 20 | 1.23 | The glass rod falls freely for 17 cm and is gently inserted into the bottom. | ||

| 1.9 | 5 | 0.9 | The glass rod falls freely to the bottom and rebounds against the wall. | excellent |

| 10 | 1.45 | The glass rod falls freely for 15 cm and is gently plunged to the bottom. | ||

| 15 | 2.22 | The glass rod is tilted, softly sinking 4 cm, and gently inserted into the bottom. | good | |

| 20 | 3.38 | The glass rod is upright, softly sinking 7 cm, and forced to the bottom. | poor |

| Temperature (°C) | t (d) | Sedimentation Value (N) | Drop Shot | Gradings |

|---|---|---|---|---|

| 210 | 5 | 0.25 | The glass rod falls freely to the bottom and rebounds against the wall. | excellent |

| 10 | 0.34 | The glass rod falls freely to the bottom and rebounds against the wall. | ||

| 15 | 0.54 | The glass rod falls freely to the bottom and rebounds against the wall. | ||

| 20 | 0.69 | The glass rod falls freely to the bottom and rebounds against the wall. | ||

| 25 | 1.25 | The glass rod falls freely for 17 cm and is gently inserted into the bottom. | ||

| 220 | 5 | 0.44 | The glass rod falls freely to the bottom and rebounds against the wall. | excellent |

| 10 | 0.53 | The glass rod falls freely to the bottom and rebounds against the wall. | ||

| 15 | 0.79 | The glass rod falls freely to the bottom and rebounds against the wall. | ||

| 20 | 0.89 | The glass rod falls freely to the bottom and rebounds against the wall. | ||

| 25 | 1.73 | The glass rod falls freely to the bottom and rebounds against the wall. | ||

| 230 | 5 | 0.36 | The glass rod falls freely to the bottom and rebounds against the wall. | excellent |

| 10 | 0.46 | The glass rod falls freely to the bottom and rebounds against the wall. | ||

| 15 | 0.73 | The glass rod falls freely to the bottom and rebounds against the wall. | ||

| 20 | 0.93 | The glass rod falls freely to the bottom and rebounds against the wall. | ||

| 25 | 1.96 | The glass rod is tilted, softly sinking 3 cm, and is gently inserted into the bottom. | good |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Li, L.; Liu, S.; Ye, Y.; Cheng, S.; Wang, K.; Wang, L.; Wu, Z.; Wu, J. Adaptability Evaluation of High-Density Kill Fluid for Ultra-Deep and Ultra-High Temperature Well Testing in Tarim Oilfield. Energies 2025, 18, 1779. https://doi.org/10.3390/en18071779

Liu J, Li L, Liu S, Ye Y, Cheng S, Wang K, Wang L, Wu Z, Wu J. Adaptability Evaluation of High-Density Kill Fluid for Ultra-Deep and Ultra-High Temperature Well Testing in Tarim Oilfield. Energies. 2025; 18(7):1779. https://doi.org/10.3390/en18071779

Chicago/Turabian StyleLiu, Junyan, Lili Li, Shuang Liu, Yan Ye, Sihan Cheng, Kun Wang, Lang Wang, Zhenjiang Wu, and Jun Wu. 2025. "Adaptability Evaluation of High-Density Kill Fluid for Ultra-Deep and Ultra-High Temperature Well Testing in Tarim Oilfield" Energies 18, no. 7: 1779. https://doi.org/10.3390/en18071779

APA StyleLiu, J., Li, L., Liu, S., Ye, Y., Cheng, S., Wang, K., Wang, L., Wu, Z., & Wu, J. (2025). Adaptability Evaluation of High-Density Kill Fluid for Ultra-Deep and Ultra-High Temperature Well Testing in Tarim Oilfield. Energies, 18(7), 1779. https://doi.org/10.3390/en18071779