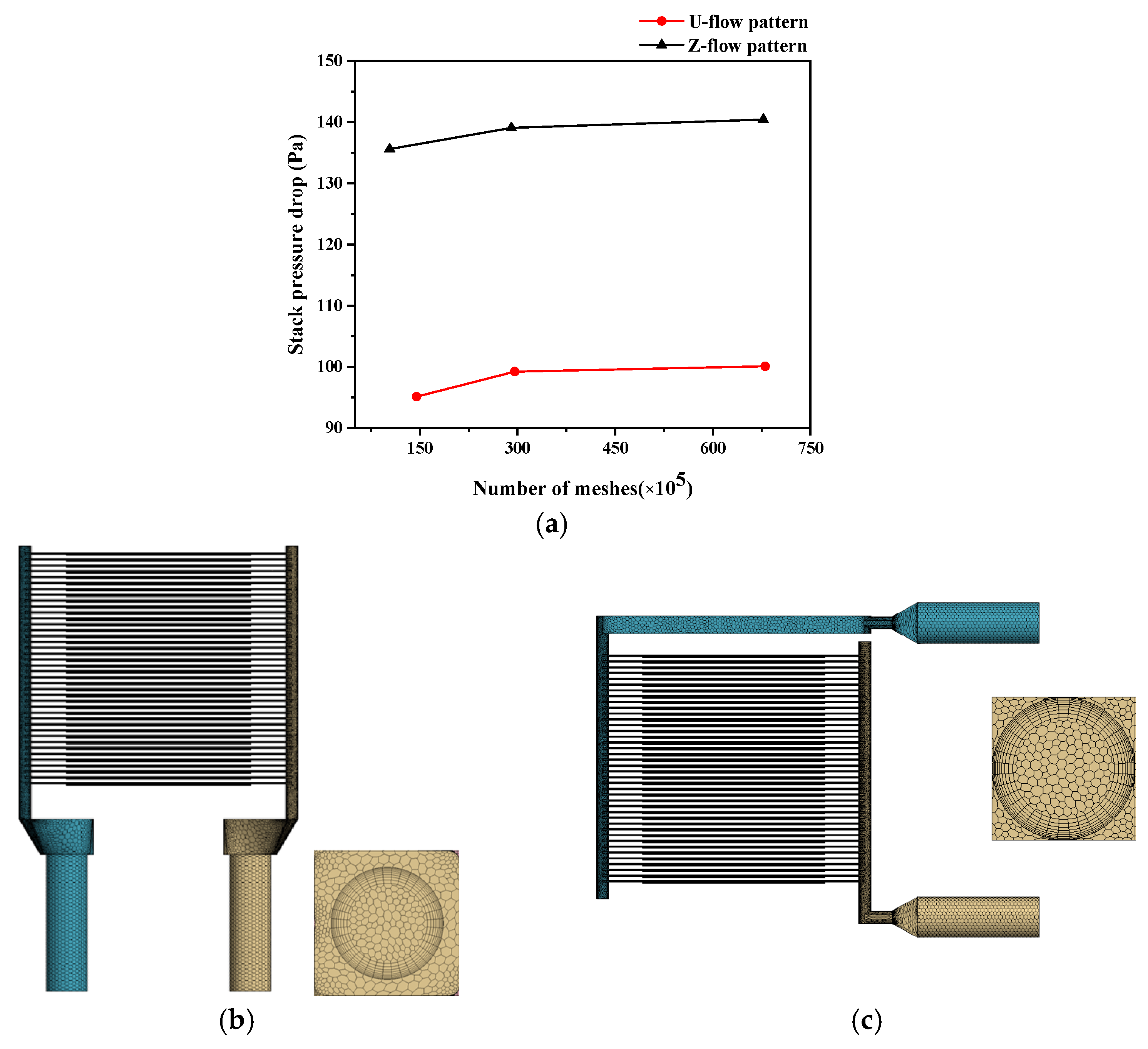

Based on the aforementioned three-dimensional models and selected flow calculation models, CFD simulations were conducted. This chapter provides a detailed discussion of the flow characteristics and differences between the U-flow and Z-flow pattern designs. Additionally, the flow uniformity of gases is compared under varying stack capacities and reactant utilization conditions. In all subsequent simulations, hydrogen and air are used as the working gases for the anode and cathode fluid regions, respectively.

3.1. Variation of Pressure Drop Within the Stack

It is well known that pressure drop is the driving force of fluid flow. Therefore, it is necessary to first perform a detailed comparison and analysis of the pressure distribution before analyzing the flow characteristics of the gases.

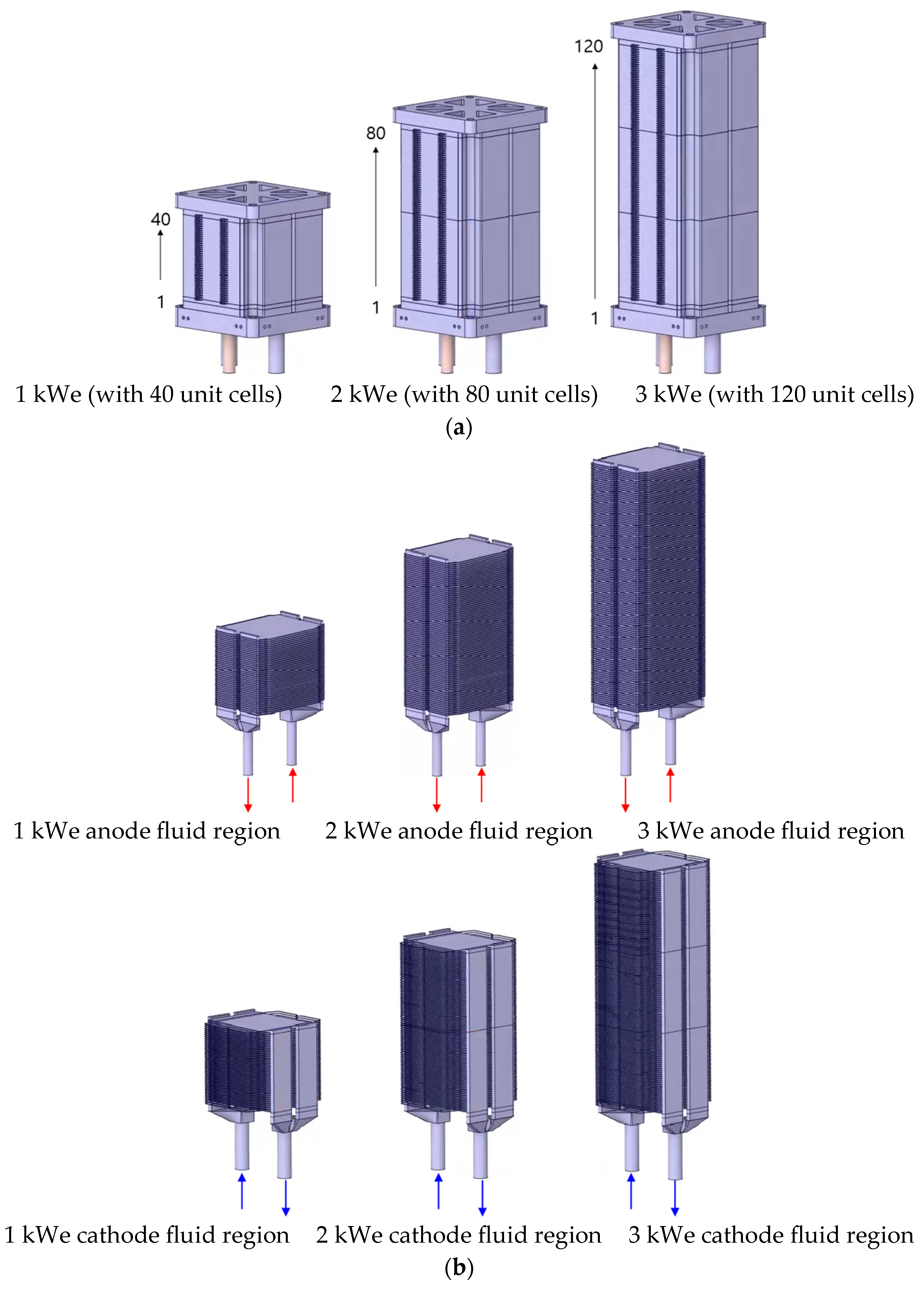

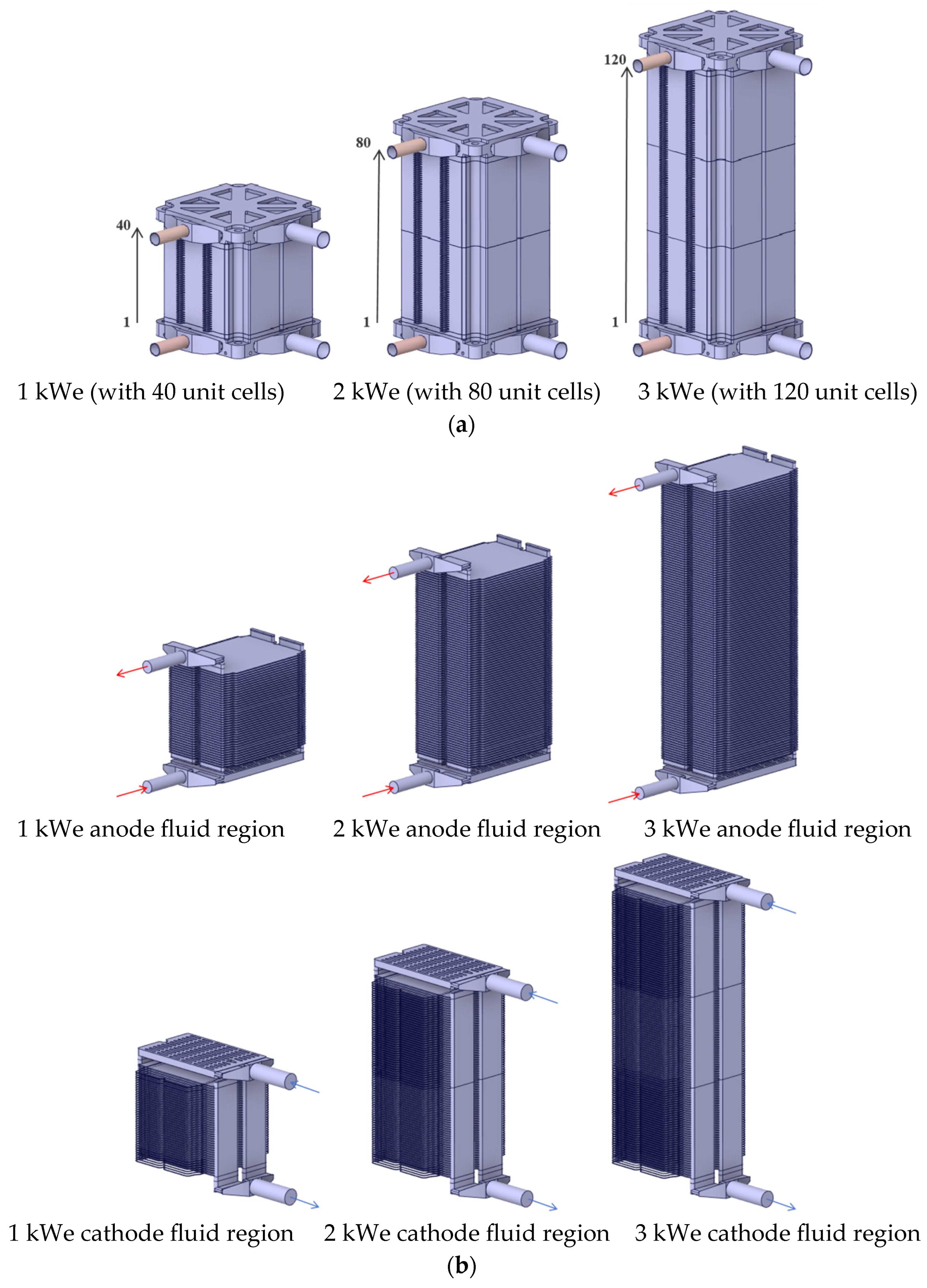

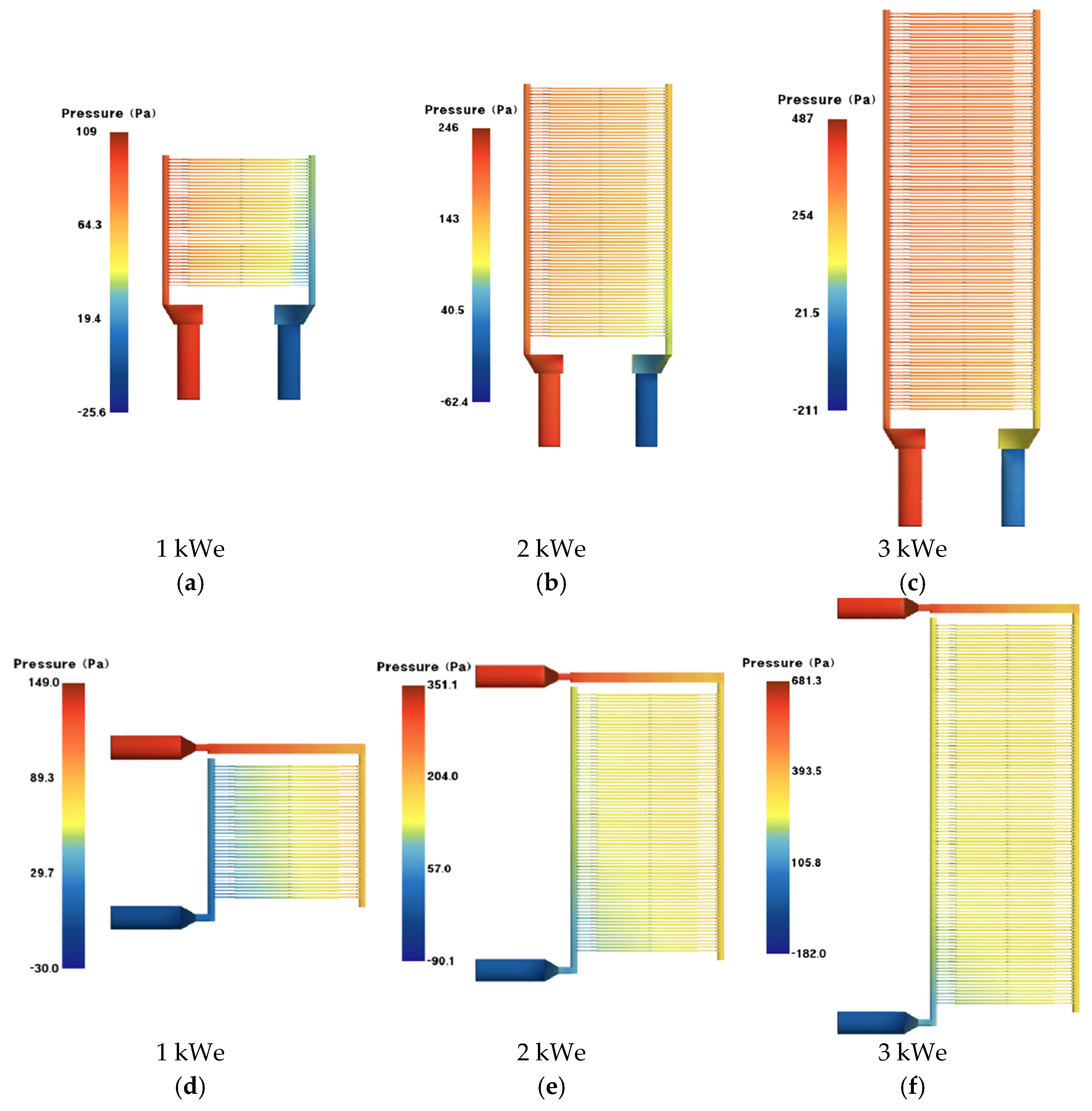

Figure 6 shows the pressure distribution of the U-flow and Z-flow patterns in the anode fluid region under hydrogen utilization of 75% and stack capacities of 1–3 kWe. It can be observed that the total pressure drop in the anode fluid region is relatively small, with the maximum pressure occurring at the hydrogen inlet and gradually decreasing along the flow path until reaching 0 Pa at the outlet.

Figure 7 presents the pressure distribution in the cathode fluid region. Compared to the anode fluid region, the pressure drop in the cathode fluid region is significantly larger. The maximum pressure is also observed at the inlet, and the pressure decreases along the flow path. However, the minimum pressure values are negative. Since the outlet boundary condition is set to atmospheric pressure (0 Pa), the presence of negative pressure values indicates the occurrence of vortices in the outlet manifold. This further confirms that the flow state in the cathode fluid region is turbulent.

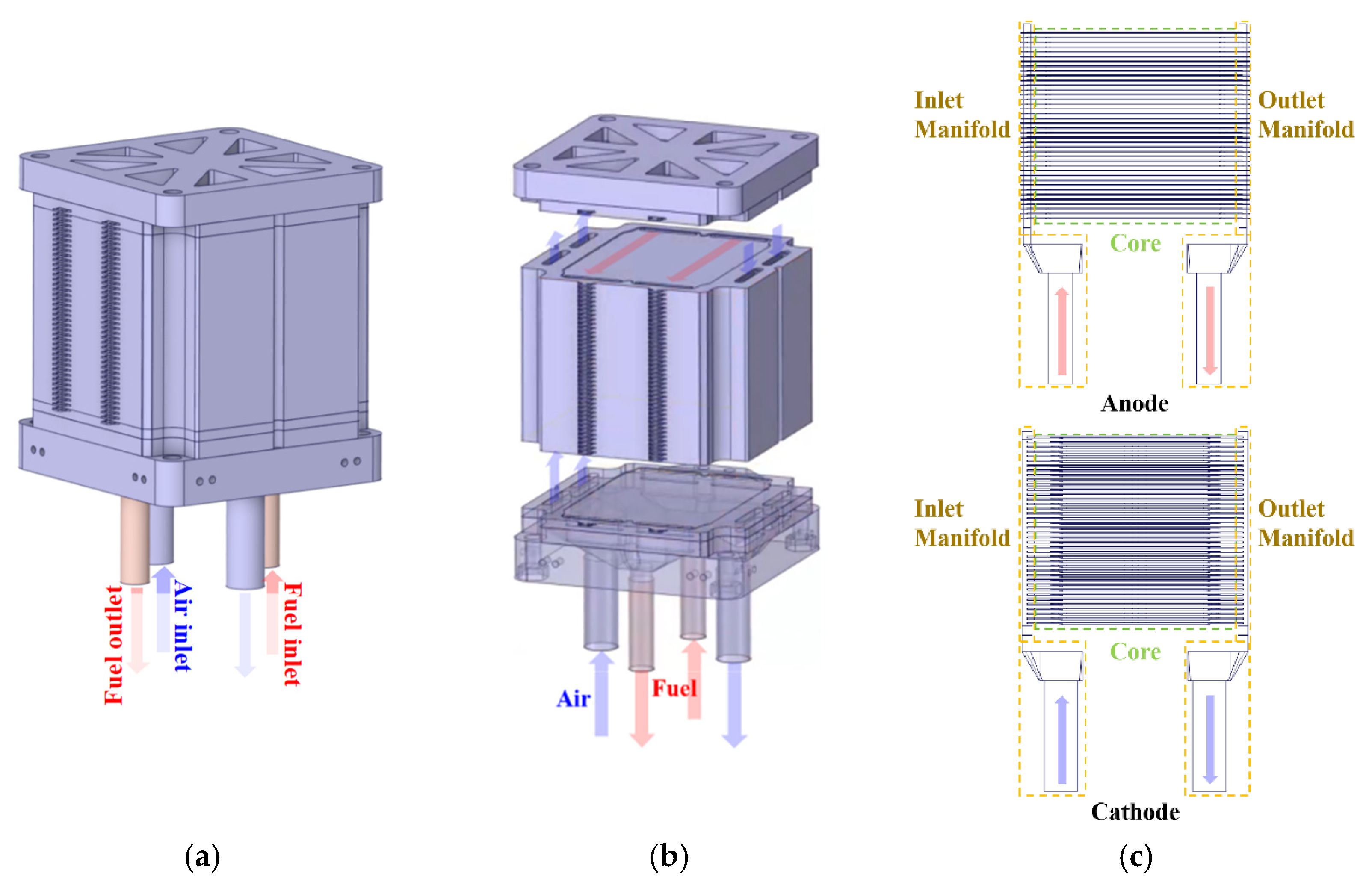

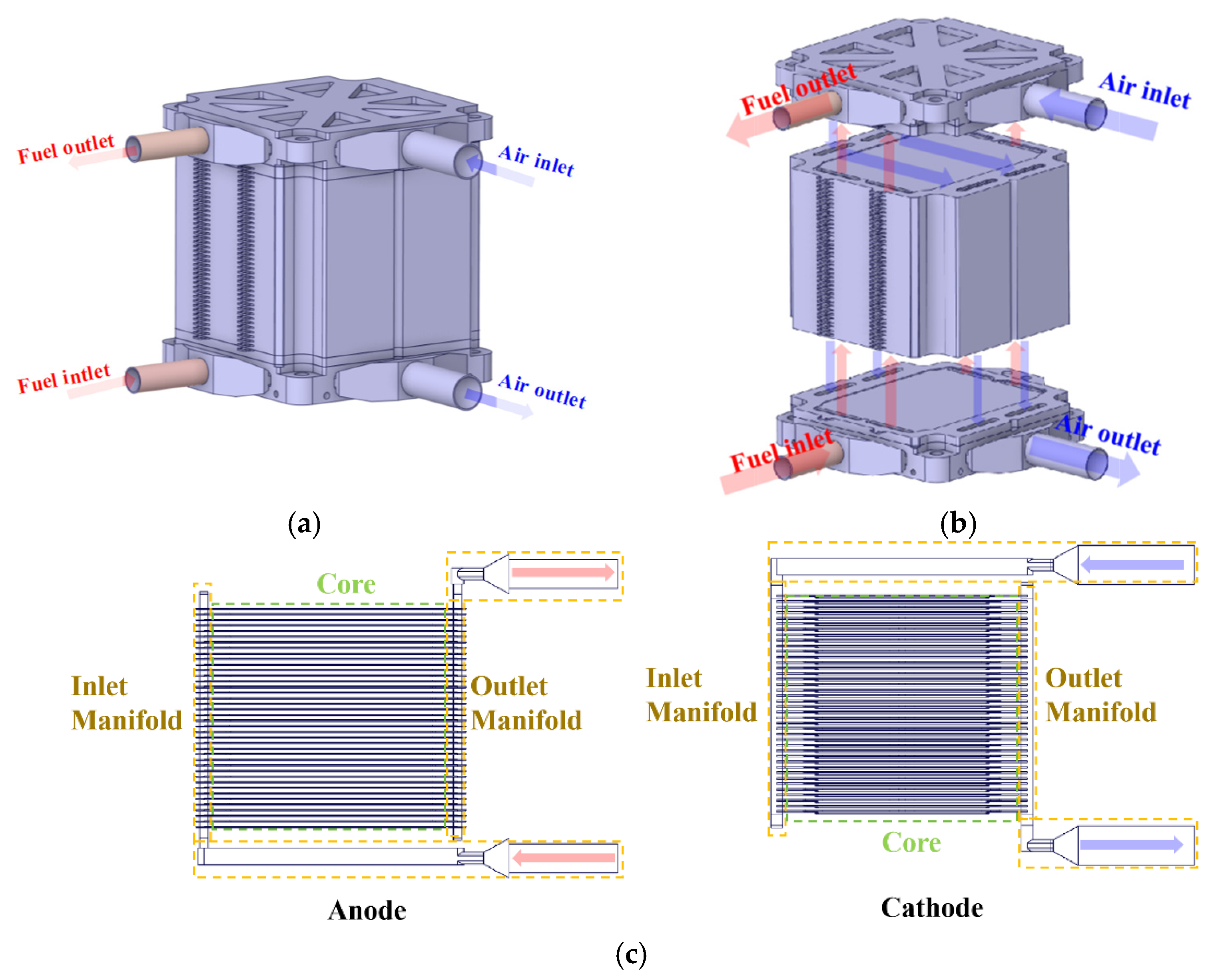

To further analyze the pressure drop in each component of the fluid region, the region was divided into three sections—the inlet manifold, core, and outlet manifold—as described in

Section 2.1. The corresponding pressure drop values were calculated and are presented in

Table 4 and

Table 5, which show the results for the anode and cathode fluid regions, respectively. From the results, it can be observed that under the same number of unit cells and reaction gas utilization rates, the total pressure drop of the U-flow pattern is smaller than that of the Z-flow pattern. This phenomenon can be attributed to the Z-flow pattern’s channel structure, which includes more bends, leading to higher kinetic energy losses. According to Bernoulli’s principle, the kinetic energy lost by the fluid is converted into pressure potential energy, which explains why the total pressure drop in the Z-flow pattern is greater than that of the U-flow pattern. Examining the results of the U-flow pattern reveals that the pressure drops in the inlet and outlet manifolds are nearly identical due to their symmetrical design. However, in the Z-flow pattern, the pressure drop in the inlet manifold is approximately twice that of the outlet manifold. Focusing on the average pressure drop in the core of the anode and cathode fluid regions under the same reaction gas utilization rates, the values are found to be very similar (Note: The core pressure drop mentioned here refers to the anode and cathode fluid region core pressure drops, respectively). For example, in the anode fluid region, under a fuel utilization rate of 50%, the average core pressure drops for the U-flow pattern are 3.05 Pa (1 kWe), 3.15 Pa (2 kWe), and 3.44 Pa (3 kWe), while those for the Z-flow pattern are 3.04 Pa (1 kWe), 3.05 Pa (2 kWe), and 3.08 Pa (3 kWe). A similar trend is also observed in the cathode fluid region. To further explore the main factors affecting core pressure drop variation, 3D bar charts were created to illustrate the ratio of core pressure drop to total stack pressure drop under different stack capacities and reaction gas utilization rates. As shown in

Figure 8,

Figure 8a,b presents the core pressure drop ratios for the U-flow and Z-flow patterns in the anode fluid region under various conditions, while

Figure 8c,d shows the corresponding ratios for the cathode fluid region. The overall trend indicates that increasing stack capacity significantly reduces the core pressure drop ratio. In the anode fluid region, the core pressure drop ratio shows a slight upward trend with increasing hydrogen utilization rates. In contrast, in the cathode fluid region, the core pressure drop ratio increases more significantly with rising air utilization rates. This suggests that the core pressure drop ratio in the cathode fluid region is more sensitive to changes in reactant utilization rates. In summary, the core pressure drop ratio in both the anode and cathode fluid regions decreases with increasing stack capacity but rises with increasing reactant utilization rates.

3.2. Analysis of Flow Characteristics Within a 1 kWe Stack

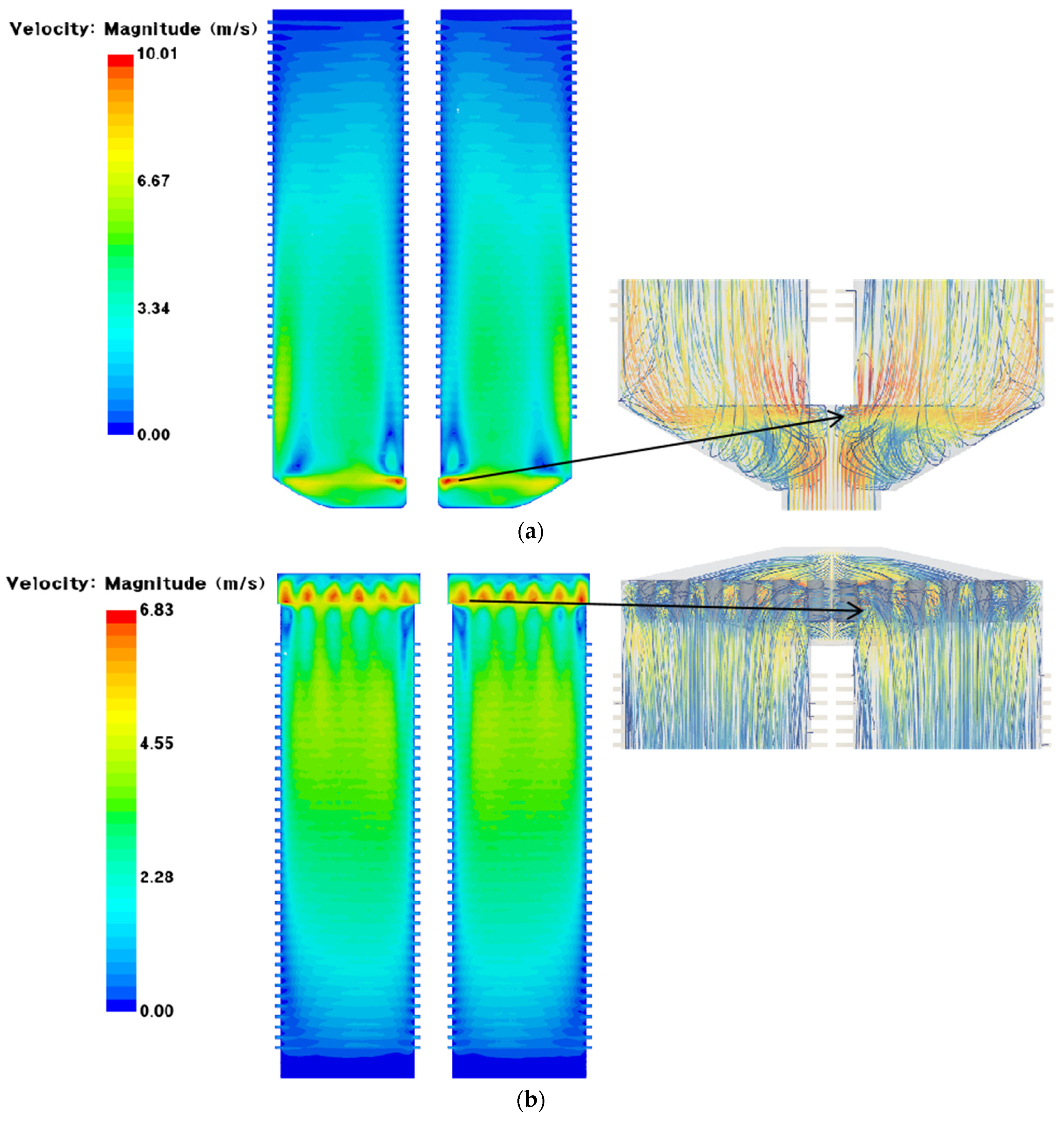

In the previous section, the pressure drop distribution across three local regions of the stack’s overall flow region was discussed, with a particular focus on the concept of the core pressure drop ratio and the factors influencing it. The formation of the core pressure drop cannot be separated from the influence of the inlet manifold, which is a critical component for supplying reactant gases to the unit cells. In this section, the cathode fluid region of a 1 kWe stack is taken as an example to analyze the velocity variation within the inlet manifold and the flow behavior in the unit cells in detail. First, a cross-section of the inlet manifold, located 1 mm upstream of the unit cell inlets, was selected, and the velocity distribution at this cross-section under an air utilization rate of 30% was plotted as a contour map (

Figure 9). It is evident from

Figure 9 that significant velocity gradients are present across the inlet manifold cross-section for both U-flow and Z-flow patterns. The maximum velocity is observed near the inlet of the manifold, and the velocity gradually decreases along the flow path. However, the velocity gradient near the region of maximum velocity is uneven. To investigate further, a streamline plot at this region was generated. The streamline plot reveals that turbulent streamlines occur near the unit cell inlets, indicating the presence of vortices in this region. This phenomenon arises because, after entering the inlet manifold, the airflow changes direction near the unit cell inlets, leading to significant variations in velocity due to the inherent geometry of the flow channel. Therefore, it can be judged that the presence of vortices in the inlet manifold creates velocity gradients along the flow path, with larger velocity fluctuations occurring near regions where the airflow direction changes.

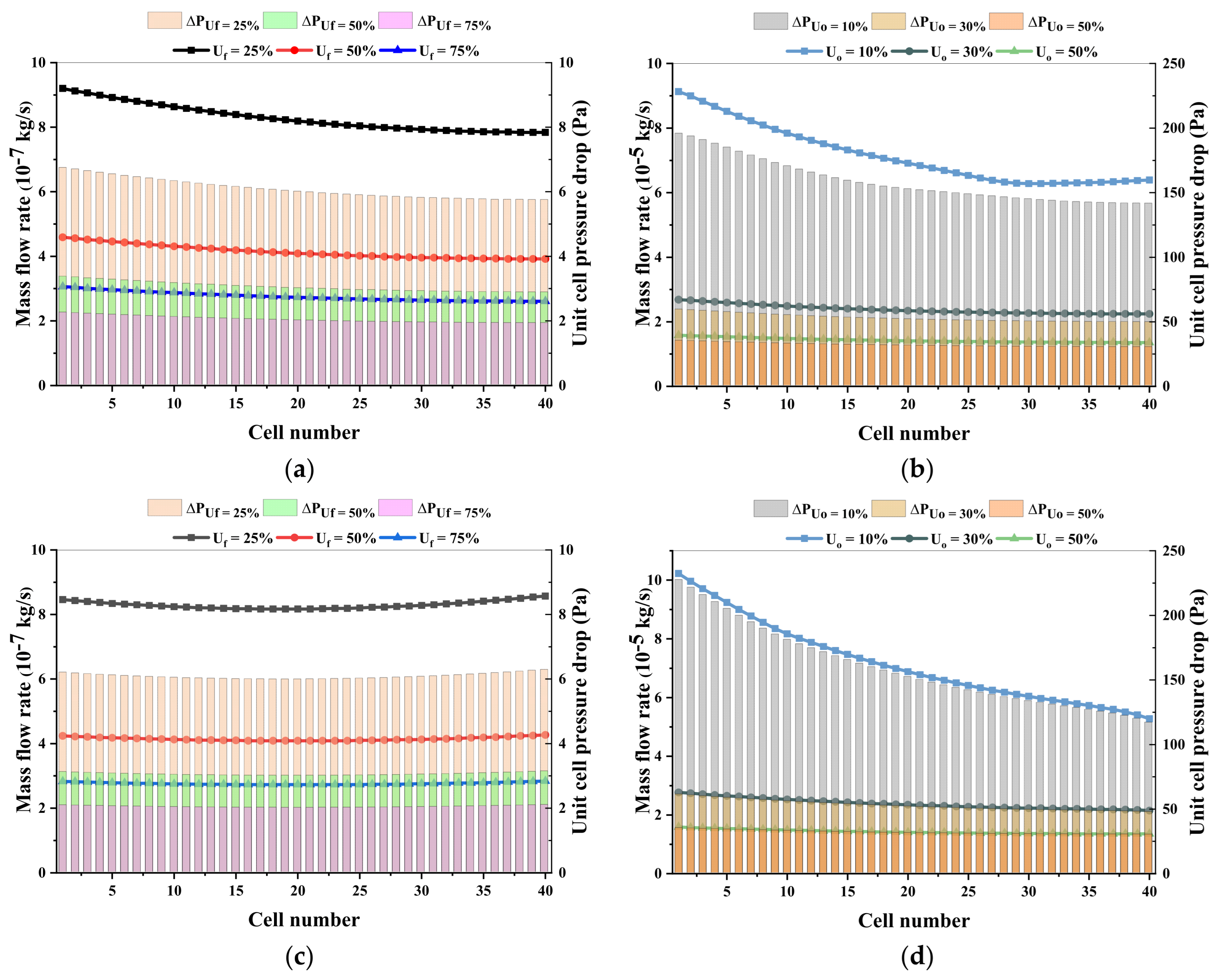

This phenomenon impacts the uniformity of gas distribution from the inlet manifold to each unit cell. To explore the mass flow rate supplied to each unit cell and the corresponding pressure drop trends, a plot of the mass flow rate and pressure drop at the unit cell inlets was generated, as shown in

Figure 10. The bar chart illustrates the pressure drop trend, and the line plot shows the mass flow rate trend. The figure also includes results calculated under different reaction gas utilization conditions. From the trend plots, it can be observed that the pressure drop trend closely aligns with the mass flow rate trend. As the reaction gas utilization decreases, the mass flow rate and pressure drop for the corresponding unit cells increase. The variations in mass flow rate and pressure drop in the anode fluid region are significantly smaller compared to those in the cathode fluid region. Notably, under an air utilization rate of 10%, both the mass flow rate and pressure drop for the unit cells exhibit a steep decline along the stack height. This result further demonstrates that at lower air utilization rates, the flow situation in the cathode fluid region becomes more complex, and the flow uniformity deteriorates significantly.

3.3. Analysis of Flow Uniformity in Unit Cells

Based on the evaluation of the flow conditions within the 1 kWe stack, the mass flow rate distribution across the unit cells exhibits different trends under varying reaction gas utilization rates, with poorer flow distribution observed in the cathode fluid region. Therefore, this section provides a detailed discussion on the uniformity of mass flow rate distribution in unit cells under different reaction gas utilization rates and stack capacities. Firstly, a dimensionless mass flow rate equation is introduced to calculate and quantify the mass flow rate distribution trends under various conditions. The dimensionless mass flow rate equation is presented as follows:

Here,

represents the dimensionless mass flow rate,

denotes the mass flow rate of the nth cell, and

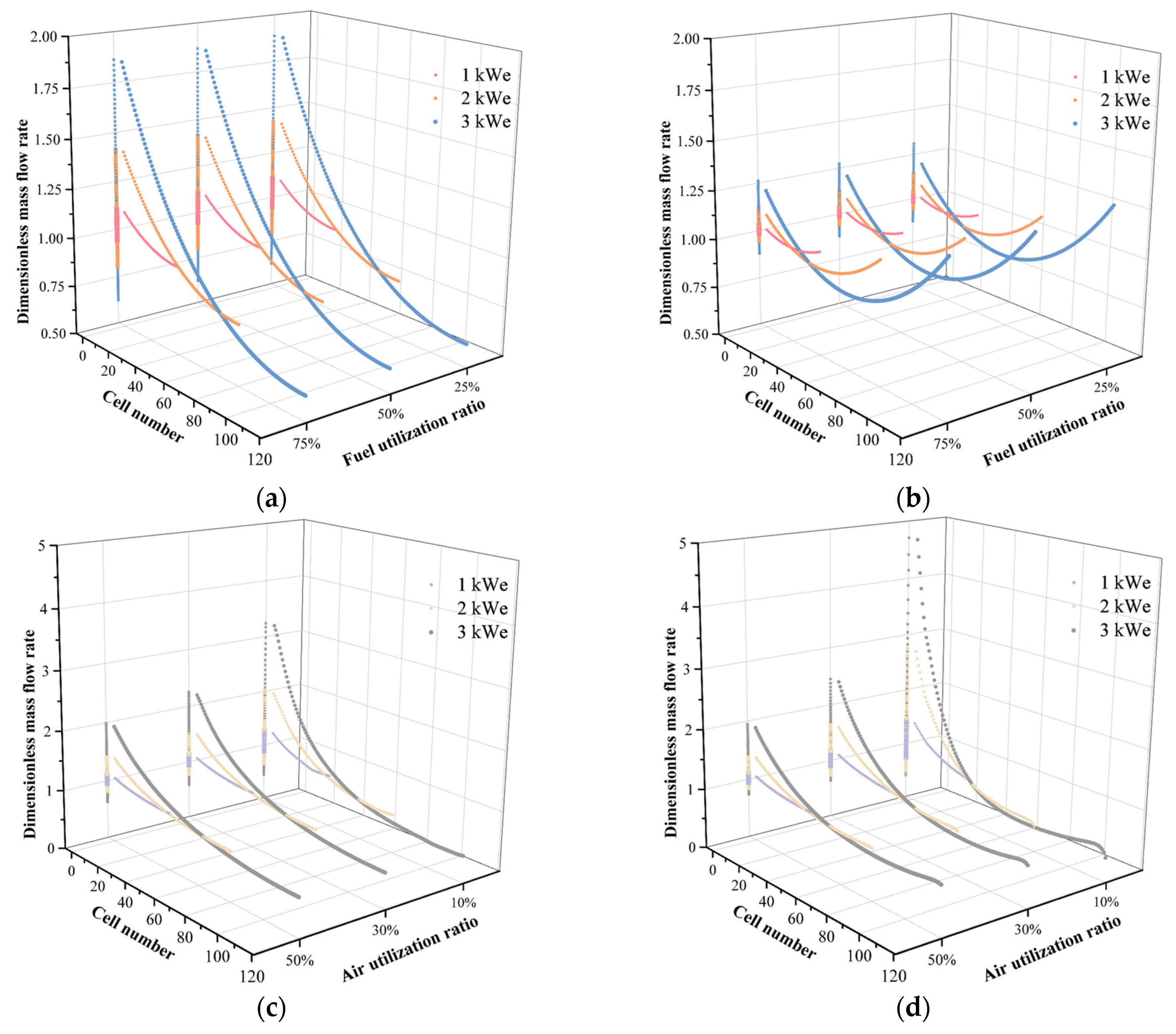

refers to the average mass flow rate of the unit cell. The closer the calculated result of this equation is to “1”, the smaller the mass flow rate deviation among the unit cells, indicating a more uniform flow distribution. All calculated results are plotted as a 3D scatter plot in

Figure 11.

Figure 11 effectively compares the deviation of the dimensionless mass flow rate under different stack capacities and reaction gas utilization rates for the two designs.

Figure 11a,b shows the dimensionless mass flow rate values calculated for each unit cell in the anode fluid region of the U-flow and Z-flow patterns under different conditions, respectively. For the anode fluid region of the U-flow pattern, the results indicate that the maximum dimensionless mass flow rate consistently appears in the first unit cell under all operating conditions and gradually decreases with an increasing number of unit cells. However, in the Z-flow pattern results shown in

Figure 11b, the trend differs: the dimensionless mass flow rate first decreases and then increases with the number of unit cells, with the minimum value observed in unit cells located near the center of the stack. The deviation in the dimensionless mass flow rate is most pronounced under the 3 kWe condition for the anode fluid region. However, changes in fuel utilization have little effect on the magnitude of the deviation under the same stack capacity. Comparing the two designs, the Z-flow pattern exhibits smaller deviations in the dimensionless mass flow rate in the anode fluid region than the U-flow pattern.

In the cathode fluid region, the deviation in the dimensionless mass flow rate also increases with stack capacity. Under the same stack capacity, the deviation increases as air utilization decreases. Notably, when the air utilization is 10%, the Z-flow pattern exhibits significantly higher deviations in the dimensionless mass flow rate compared to other conditions.

In summary, the deviation in the dimensionless mass flow rate increases with stack capacity and decreases with higher reaction gas utilization rates. However, in the anode fluid region, the deviation is less influenced by changes in fuel utilization. To further quantify the deviation in dimensionless mass flow rate and facilitate comparisons of flow uniformity, a uniformity factor, α, is introduced to evaluate and compare the flow uniformity under different conditions. The equation for calculating the uniformity factor is as follows:

Similar to the dimensionless mass flow rate, the closer the value of α is to 1, the better the flow uniformity under the given condition.

Table 6 presents the calculated α values for each condition, where α1 and α2 represent the results for the U-flow pattern and Z-flow pattern, respectively.

From the overall results in the table, it appears that the outcomes for the anode fluid region of the 1 kWe stack are closer to “1”. The values of α1 and α2 decrease to varying degrees with increasing stack capacity and changes in reaction gas utilization rates. To visualize the results in

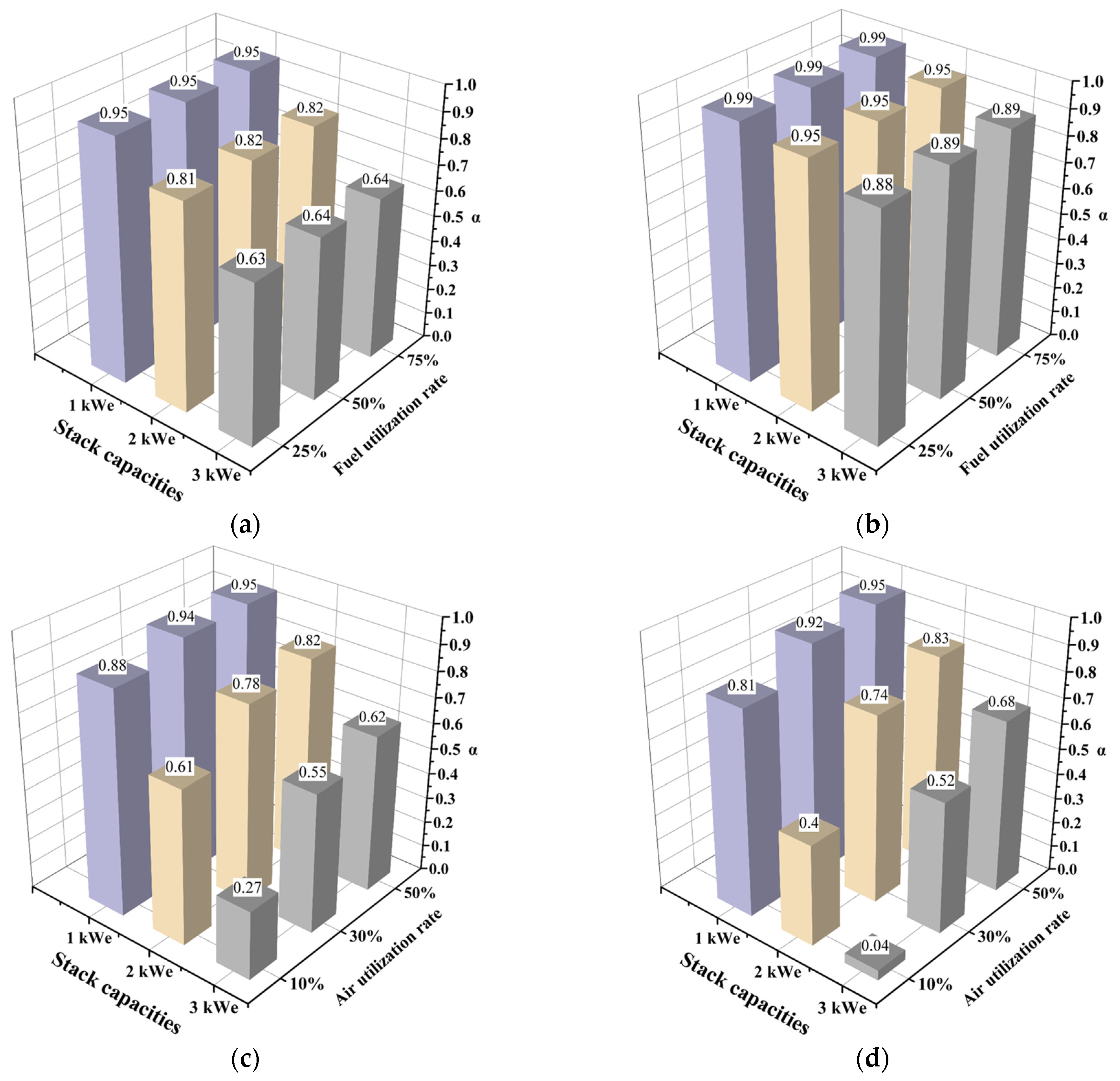

Table 6 and facilitate better comparisons, a 3D bar chart of the uniformity factor α was created, as shown in

Figure 12. In

Figure 12, it can be observed that the globally optimal uniformity is achieved in the anode fluid region of the 1 kWe Z-flow pattern, with an α value of 0.99. This is followed by the 2 kWe Z-flow pattern and the 1 kWe U-flow pattern in the anode fluid region, both with α values of 0.95. In the U-flow pattern, the minimum α value is 0.63, corresponding to the condition of 3 kWe and a fuel utilization rate of 25%. Under the same condition, the Z-flow pattern also exhibits the minimum α value, but at 0.88. These results indicate that in the anode fluid region, the Z-flow pattern exhibits better uniformity than the U-flow pattern. Additionally, under the same stack capacity, changes in fuel utilization have little effect on the calculated α values, which is consistent with the trends observed in

Figure 11.

Comparing the results for the cathode fluid region, the maximum α values are consistently observed under the condition of 1 kWe with an air utilization rate of 50%. The minimum α values occur under the condition of 3 kWe with an air utilization rate of 10%. Notably, under this condition, the α value for the Z-flow pattern is only 0.04. Additionally, the uniformity of the cathode fluid region is particularly sensitive to changes in any condition. By comparing

Figure 12 with

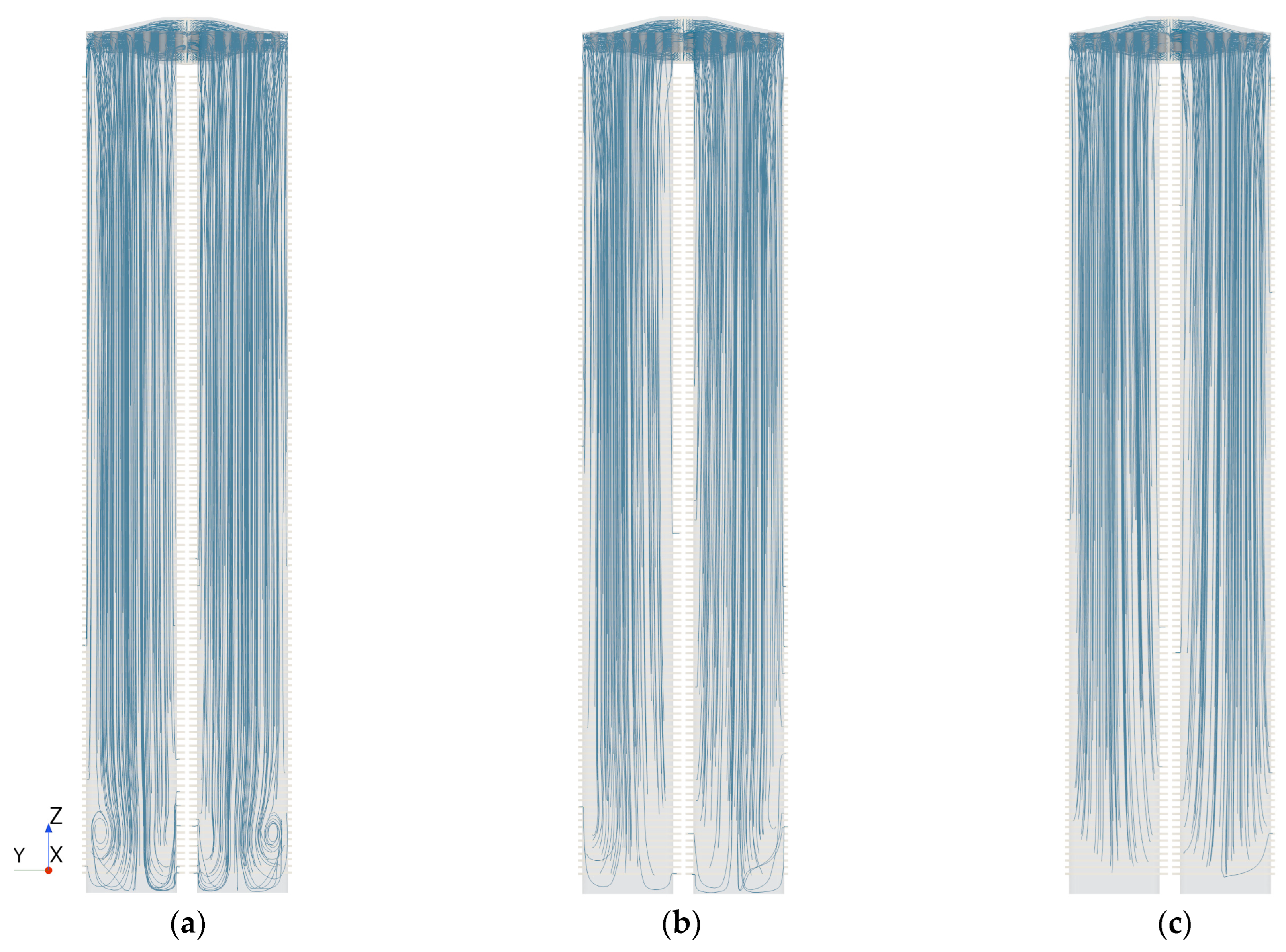

Figure 8, it can be observed that the distribution pattern of the uniformity factor α aligns closely with the distribution pattern of the core pressure drop ratio. Specifically, conditions with higher or lower core pressure drop ratios correspond to conditions with higher or lower α values. This indicates that a higher core pressure drop ratio significantly improves flow uniformity, whereas a lower core pressure drop ratio results in a marked decrease in flow uniformity. The key factor influencing the core pressure drop ratio lies in the pressure drop control within the manifolds. Therefore, optimizing the flow path design within the manifolds to make it smoother can effectively improve the flow uniformity of the stack, thereby enhancing its overall performance. To investigate the cause of the sudden deterioration in uniformity of the Z-flow pattern at 10% air utilization, we visualized the streamline plots in the air inlet manifold (

Figure 13). The results clearly demonstrate that under 10% air utilization conditions, noticeable vortices form at the bottom of the manifold, resulting in disturbed flow characteristics in this region. These vortices induce uneven mass flow distribution among the bottom unit cells of the stack, consequently affecting the overall flow uniformity evaluation results (as shown in

Figure 12). This phenomenon also reasonably explains the significant deviation in the dimensionless mass flow rate among unit cells in the 3 kWe stack at an air utilization rate of 10%, as illustrated in

Figure 11d.

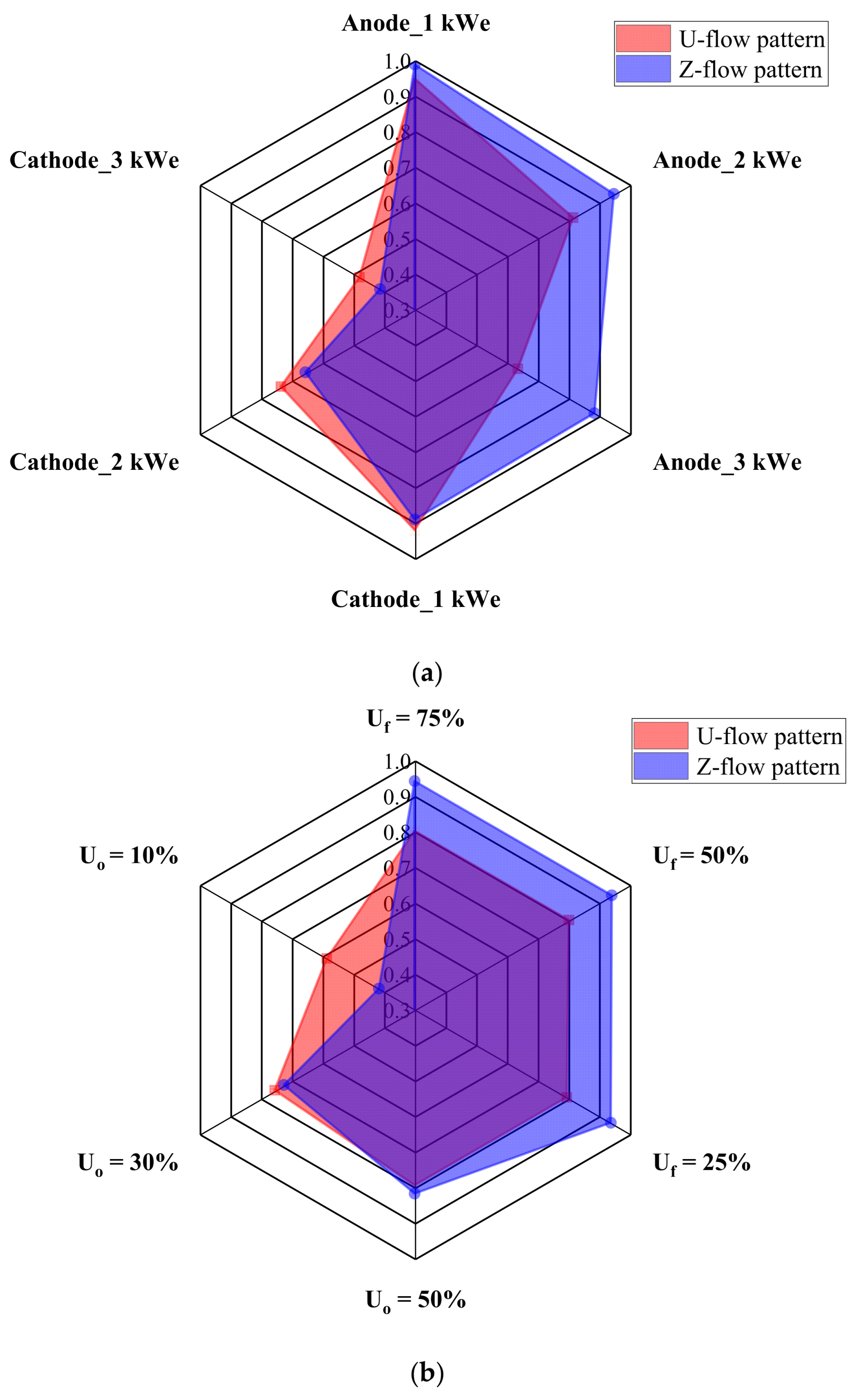

To better illustrate the differences in flow uniformity performance between the U-flow and Z-flow pattern designs, radar charts were created, as shown in

Figure 14. These charts evaluate the flow uniformity of the U-flow and Z-flow patterns from two perspectives. First, the evaluation method used in

Figure 14a involves comparing the average values of the three uniformity factors α calculated in

Table 6 under the same stack capacity. For example, in the 1 kWe cathode fluid region of the U-flow pattern, the calculated α values under air utilization rates of 10%, 30%, and 50% are 0.88, 0.94, and 0.95, respectively. The average α value is thus 0.923. Similarly, the average α values for other conditions can be calculated. The evaluation method used in

Figure 14b compares the average α values under the same reaction gas utilization rate but across different stack capacities. For instance, in the Z-flow pattern at an air utilization rate of 50%, the α values for 1 kWe, 2 kWe, and 3 kWe are 0.95, 0.83, and 0.68, respectively, resulting in an average α value of 0.82. The same approach is applied to calculate the average α values for other conditions. The radar charts created using these two evaluation methods effectively reveal the differences in flow uniformity performance between the two designs. In

Figure 14a, it can be observed that for the anode fluid region, the Z-flow pattern outperforms the U-flow pattern across all capacities, particularly under the 3 kWe condition. For the cathode fluid region, the U-flow pattern has only a slight advantage over the Z-flow pattern. Under fixed fuel utilization conditions, the Z-flow pattern consistently outperforms the U-flow pattern. However, under an air utilization rate of 10%, the U-flow pattern surpasses the Z-flow pattern in performance. In summary, under various fuel utilization rates and stack capacities, the flow uniformity in the anode fluid region of the Z-flow pattern is superior to that of the U-flow pattern. Only when the air utilization rate is 10% does the performance of the Z-flow pattern lag significantly behind the U-flow pattern. Considering that the practical efficiency of fuel cells is the product of reversible thermodynamic efficiency, voltage efficiency, and fuel utilization efficiency, the performance of the anode fluid region is particularly critical. If a stack can achieve good flow uniformity under both high fuel utilization and large capacity conditions, it will significantly enhance the overall performance of the stack. The Z-flow pattern design is undoubtedly the better choice for stacks with large capacity requirements.

Equations (2) and (3) can be used to calculate the mass flow rate at the stack inlet based on the reaction gas utilization rates specified in the boundary conditions. From the simulations, it is observed that the mass flow rates distributed to individual unit cells within the stack are not uniform. Therefore, Equations (2) and (3) can also be used to calculate the corresponding reaction gas utilization rates for each unit cell. The minimum mass flow rate values under different conditions were selected, and the corresponding reaction gas utilization rates were calculated. The results are presented in

Table 7. The results show that the reaction gas utilization rate corresponding to the minimum mass flow rate is higher than the reaction gas utilization rate specified in the boundary conditions, but the overall difference is small. However, it is noteworthy that in the anode fluid region of the U-flow pattern, when the stack capacity is 3 kWe and the fuel utilization rate is 75%, the fuel utilization rate corresponding to the minimum mass flow rate exceeds 100%. This unit cell is located at the top of the U-flow pattern stack. Although the fuel utilization rate of the unit cell calculated by the equation may differ from the fuel utilization rate of the unit cell derived from the actual operating condition of the stack, the result can also reflect the insufficient supply of fuel to the unit cell located at the top of the U-flow pattern stack and may be at risk of fuel starvation.